Patents

Literature

41results about How to "Mix evenly and stably" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

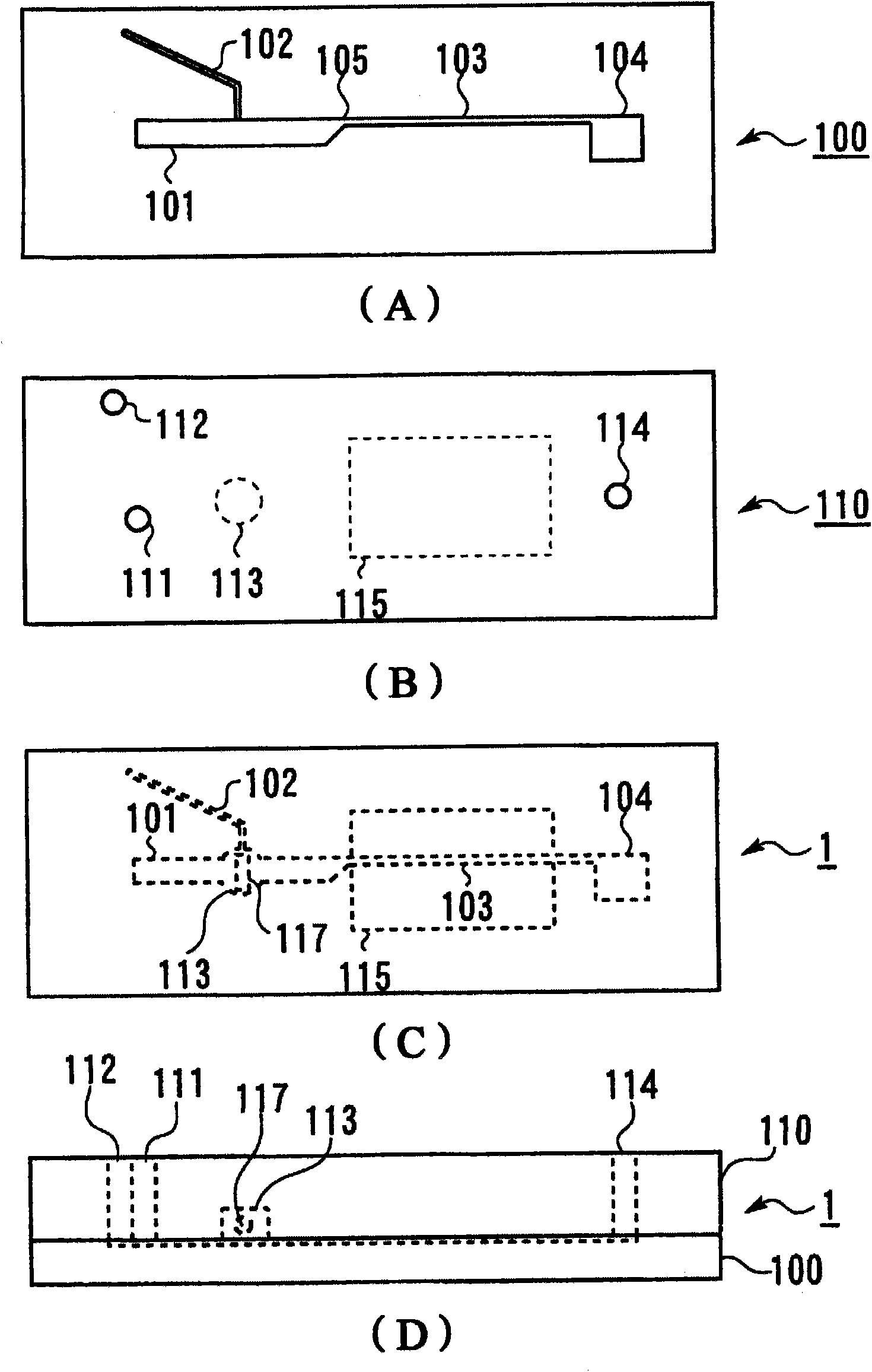

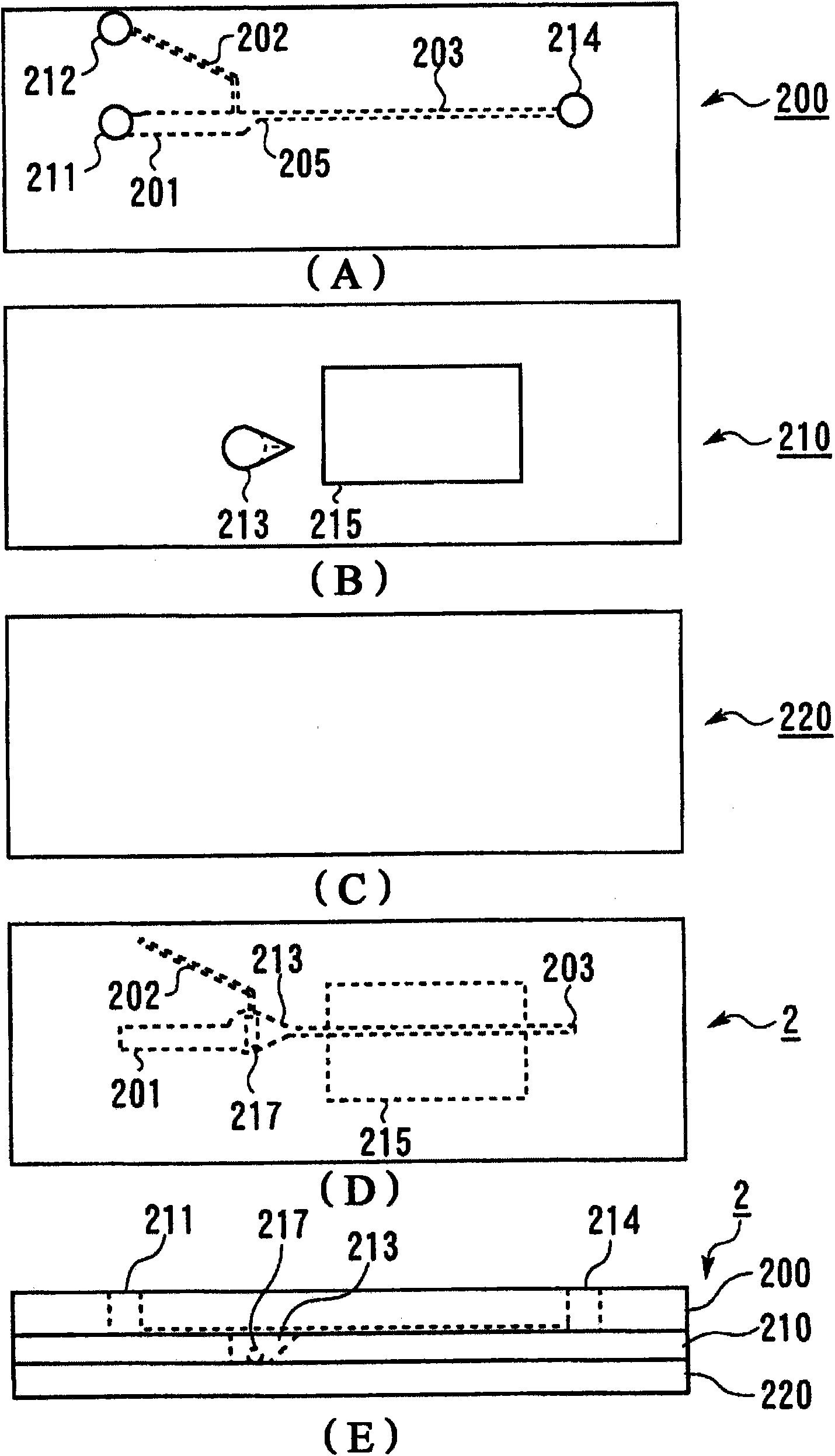

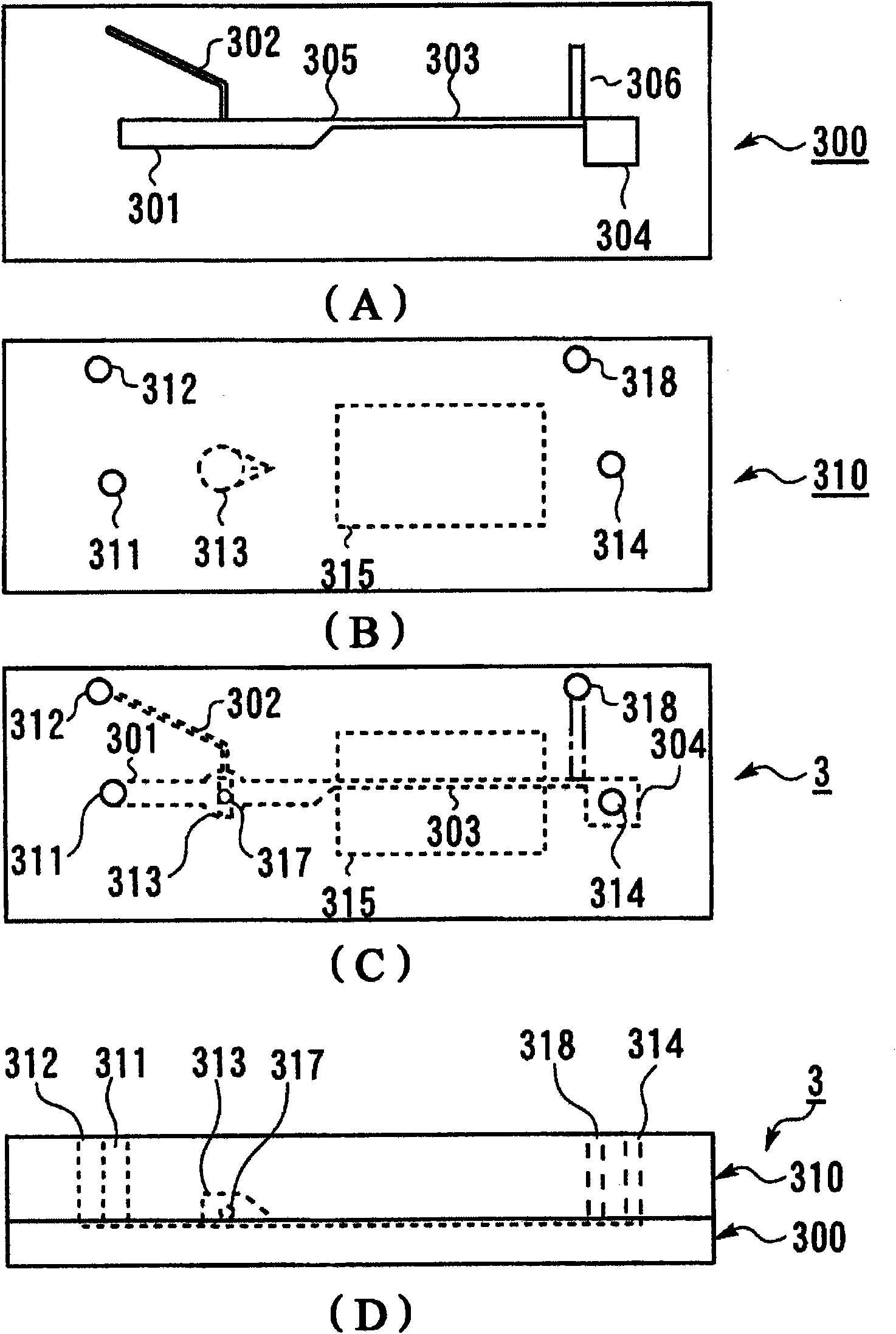

Microchip and blood monitoring device

ActiveCN101874208AGenerate efficientlyEfficient determinationFlow mixersTransportation and packagingMedicineBlood plasma

A microchip which comprises therein a first channel for the inflow of a first liquid selected from among whole blood, platelet-rich plasma or a liquid prepared by treating the same with a chemical, a second channel connected to the first channel for the inflow of a second liquid containing a chemical capable of reacting with the first liquid as described above, and a confluence channel extended from the connection section of the first channel with the second channel, characterized in that a stirring section provided with a stirrer for mixing the above-described first liquid with the above-described second liquid is provided in the confluence channel as described above, and a blood monitoring device using the microchip.

Owner:FUJIMORI KOGYO CO LTD

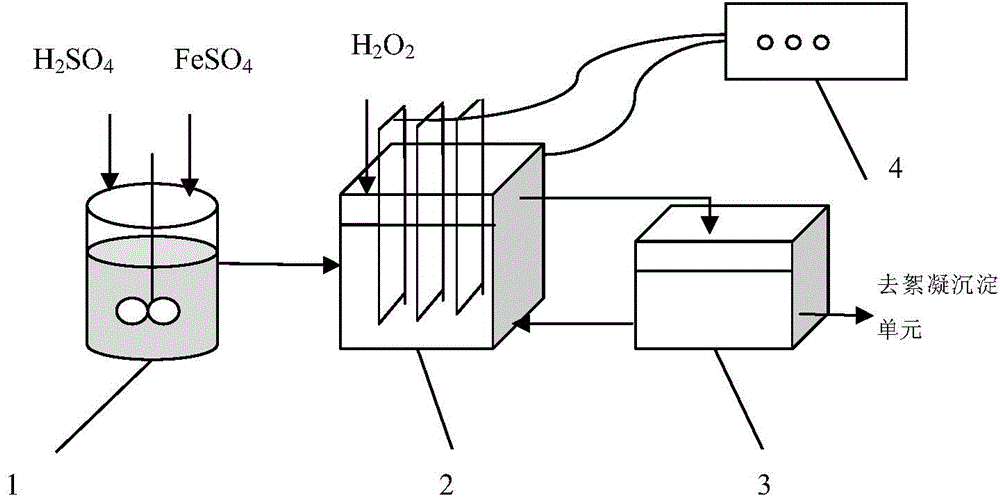

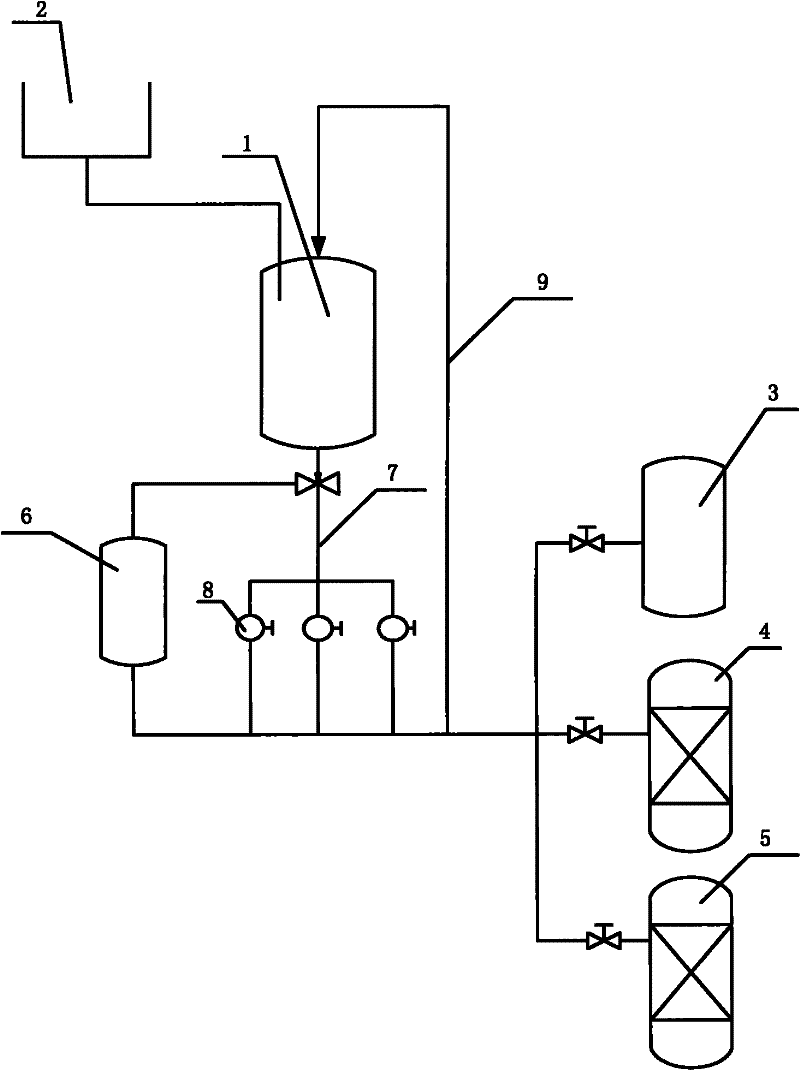

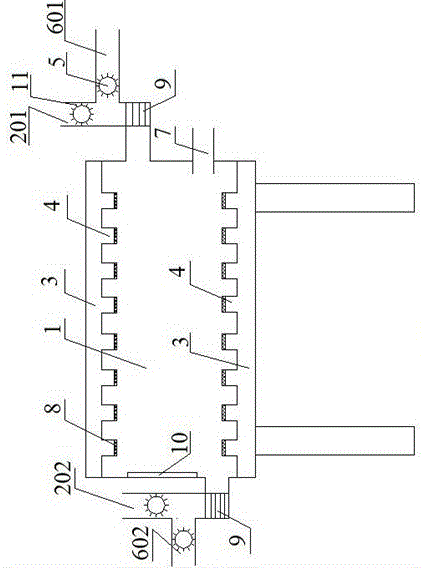

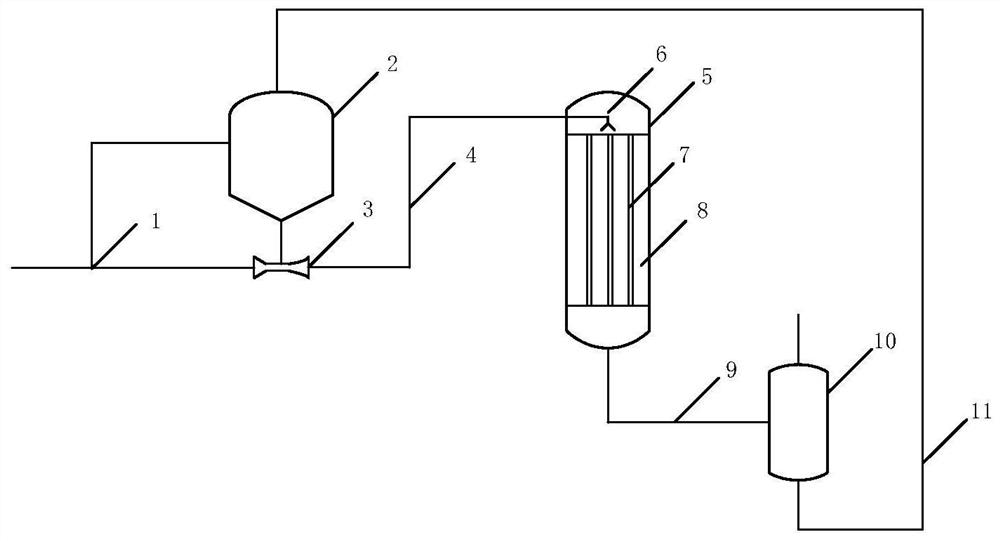

Pretreatment method of nonionic surfactant wastewater

InactiveCN104310665AMix evenly and stablyLow running costWater contaminantsMultistage water/sewage treatmentPretreatment methodElectrolysis

The invention relates to a pretreatment method of nonionic surfactant wastewater. The invention aims to provide a method which has the characteristics of high treatment efficiency, capability of full automation operation of the treatment system and lower operating cost. The technical scheme is as follows: the method sequentially comprises the following steps: a. regulating the pH value of wastewater in a wastewater regulating tank to 2.0-4.0 with sulfuric acid, and meanwhile, adding a catalyst FeSO4; b. sending the wastewater treated by the step a into an electrolytic reaction tank filled with an oxidizer to perform electrolytic treatment, sending into a catalytic oxidation reaction tank to perform sufficient oxidation reaction, and meanwhile, enabling the wastewater output after the reaction of the catalytic oxidation reaction tank to flow to the electrolytic reaction tank according to a certain internal circulation proportion; and c. sending the wastewater output by the catalytic oxidation reaction tank in the step b into a flocculating settling unit to perform settling treatment, sending the supernate into a subsequent treatment technique, and treating the waste residues according to the specifications.

Owner:ZHEJIANG ZONE KING ENVIRONMENTAL SCI&TECH CO LTD

Method for preparing material special for polybutylene terephthalate (PBT) optical fiber loose tubes

ActiveCN102675608AQuality improvementAchieve high speedFibre mechanical structuresPolyethylene terephthalateReaction temperature

The invention provides a method for preparing a material special for polybutylene terephthalate (PBT) optical fiber loose tubes. The method comprises the following steps of: uniformly mixing a solid additive required by the production of the PBT optical fiber loose tubes and 1,4-butanediol, conveying and metering by using a gear pump, adding into a slurry preparation tank in a proportion, allowing the obtained slurry and slurry which is prepared from 1,4-butanediol and terephthalic acid to enter an esterification reaction kettle, and thus obtaining a PBT base material for optical fiber loose tubes by a direct esterification and continuous condensation production technology; and ensuring that the PBT base material continuously enters a solid-phase system through metering, preheating and crystallizing, entering a solid-phase reactor for tackification at the temperature of 170 to 210 DEG C for 15 to 20 hours, cooling a product obtained after tackification, dedusting, conveying, and packaging to obtain the material special for the PBT optical fiber loose tubes. By the method, a color value of the product can be effectively controlled, the special additive is uniformly mixed in the product, the PBT product for the optical fiber loose tubes has relatively stable quality, and the high-speed development tendency of the machining process of the loose tubes is met.

Owner:CHINA PETROCHEMICAL CORP

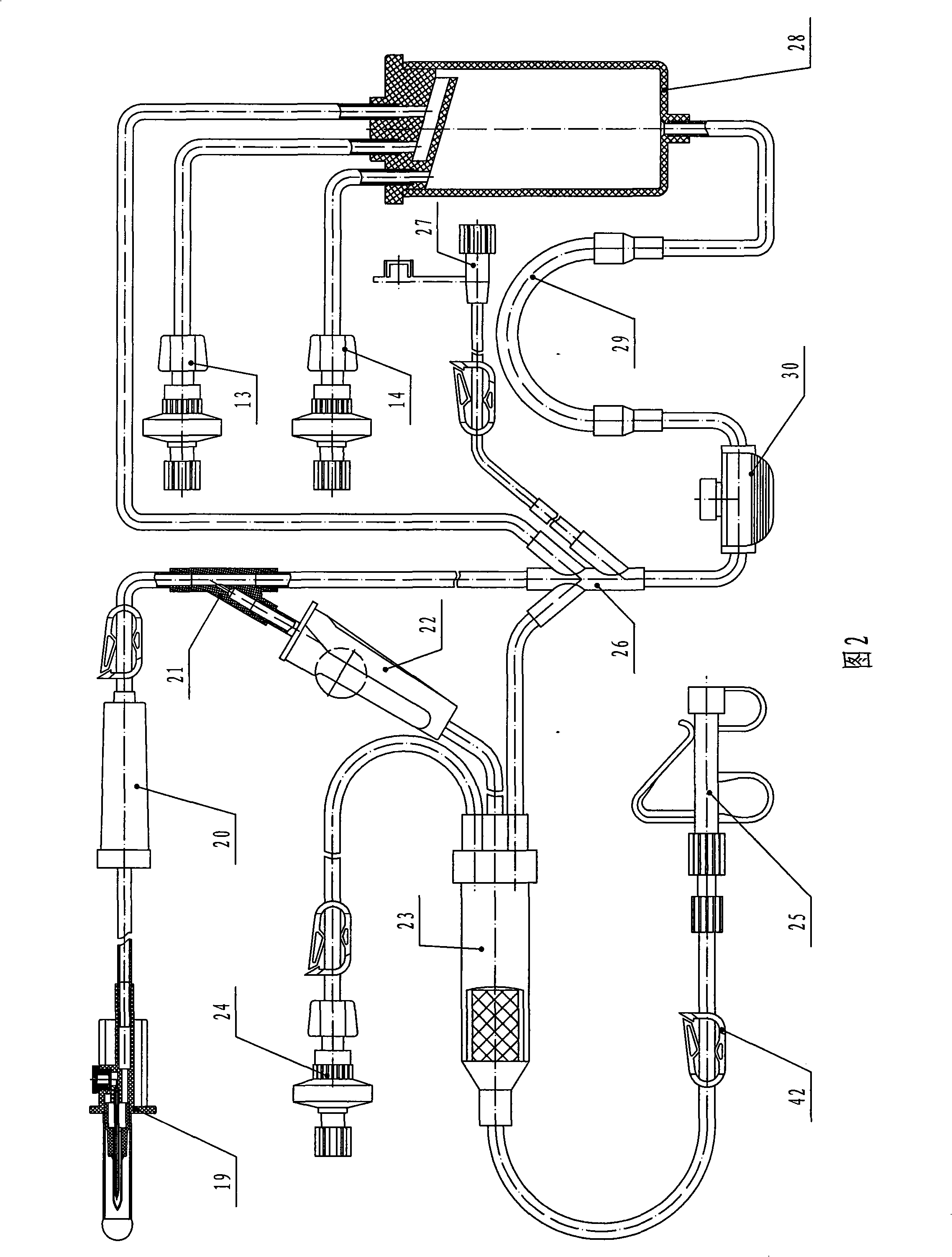

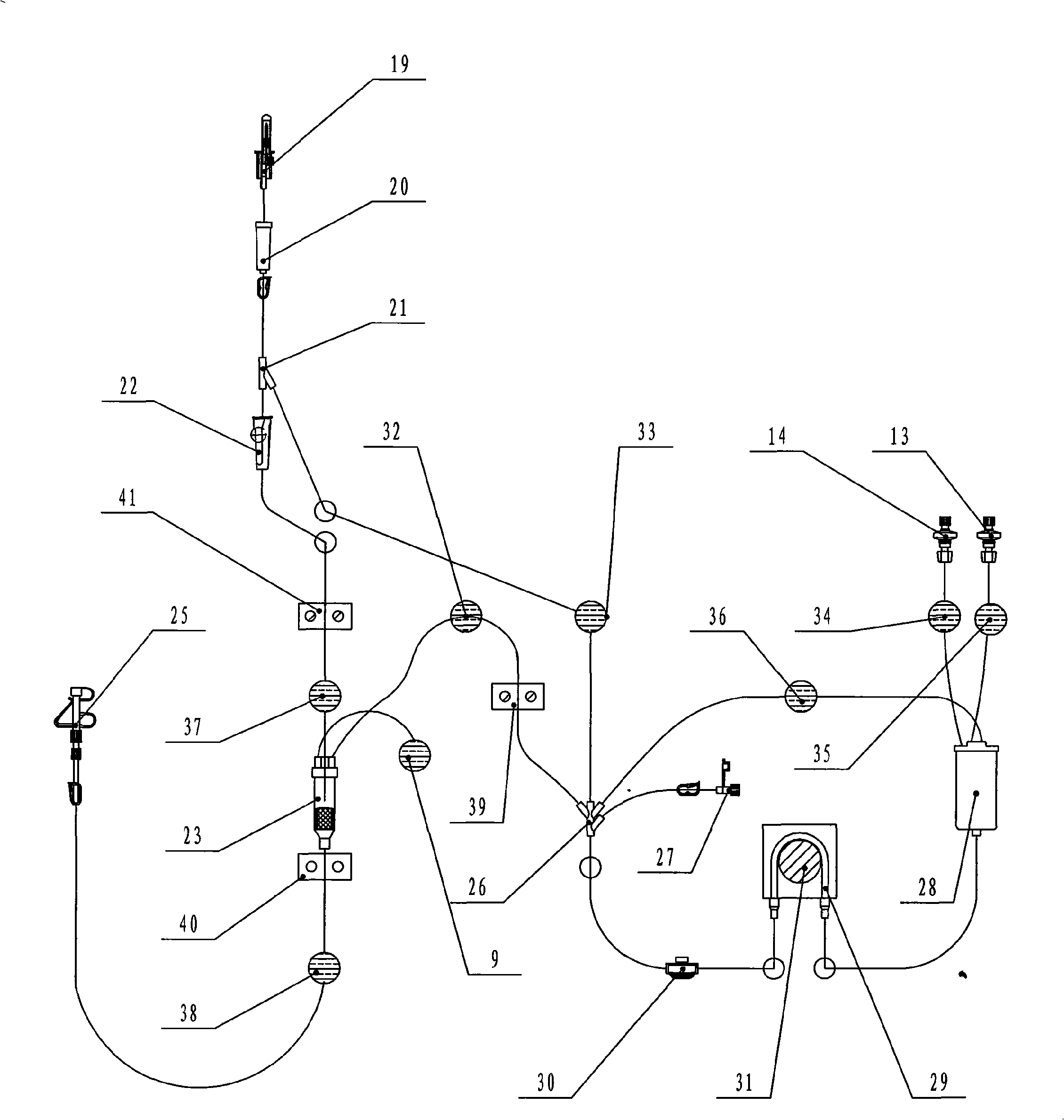

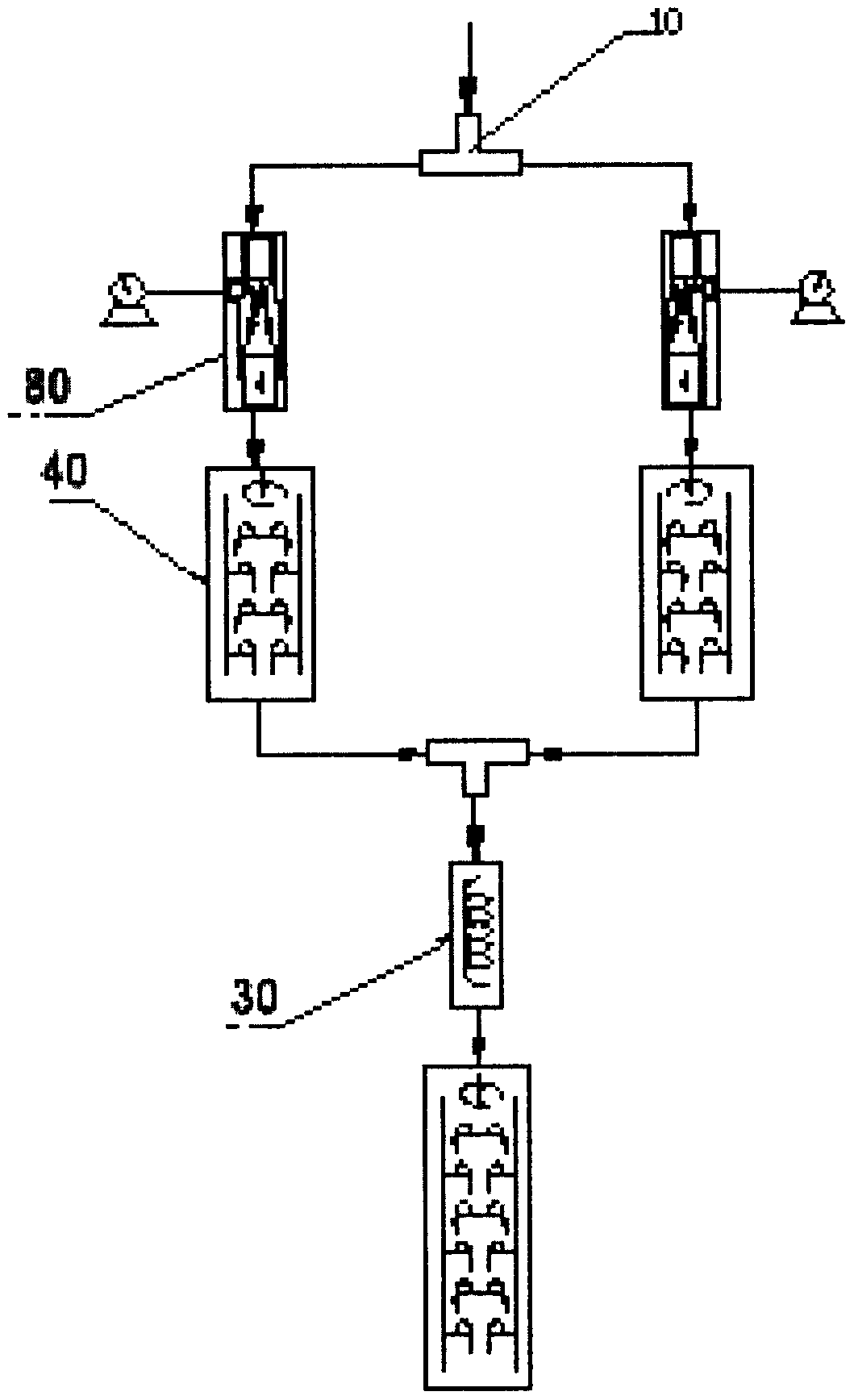

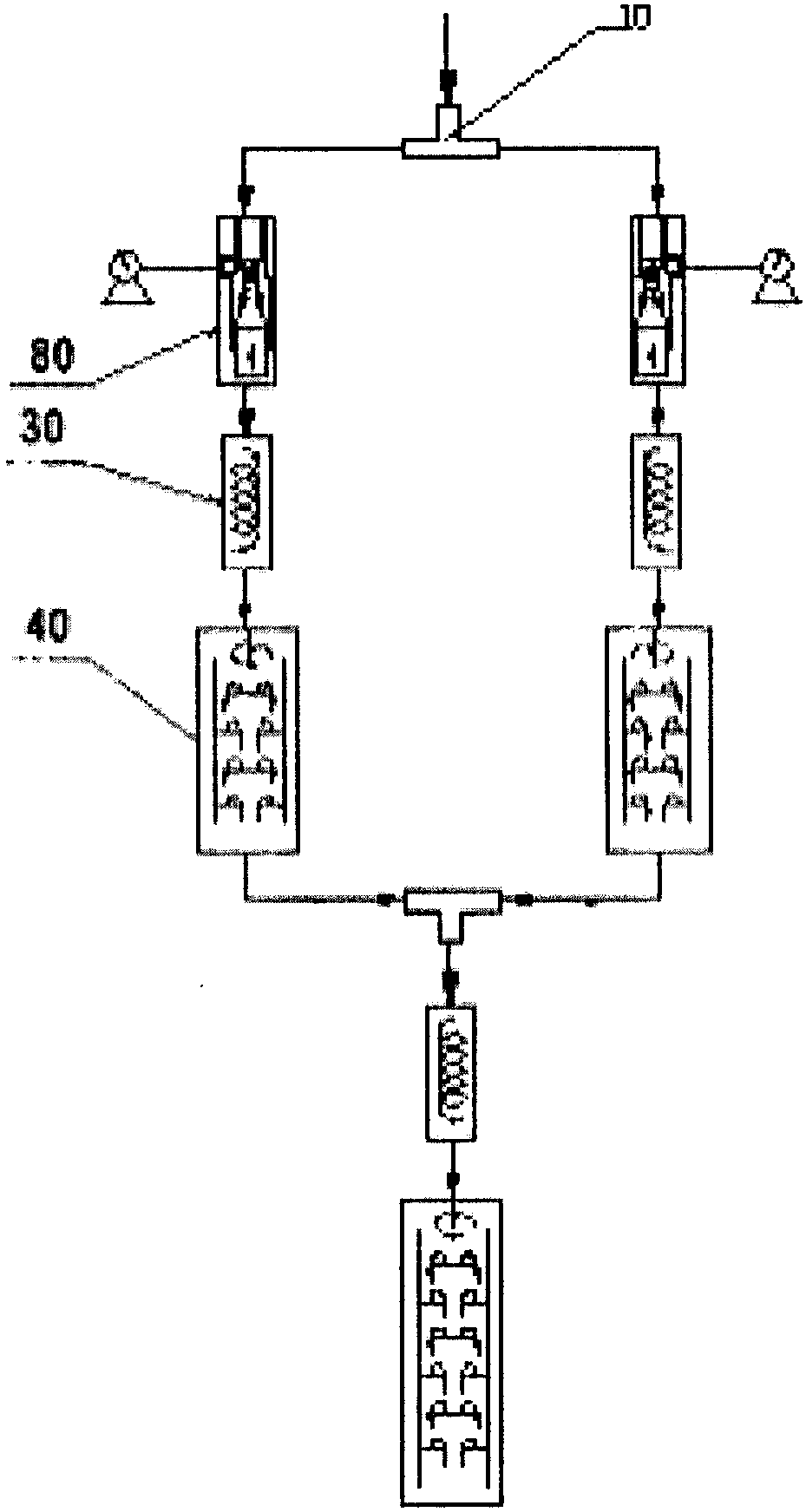

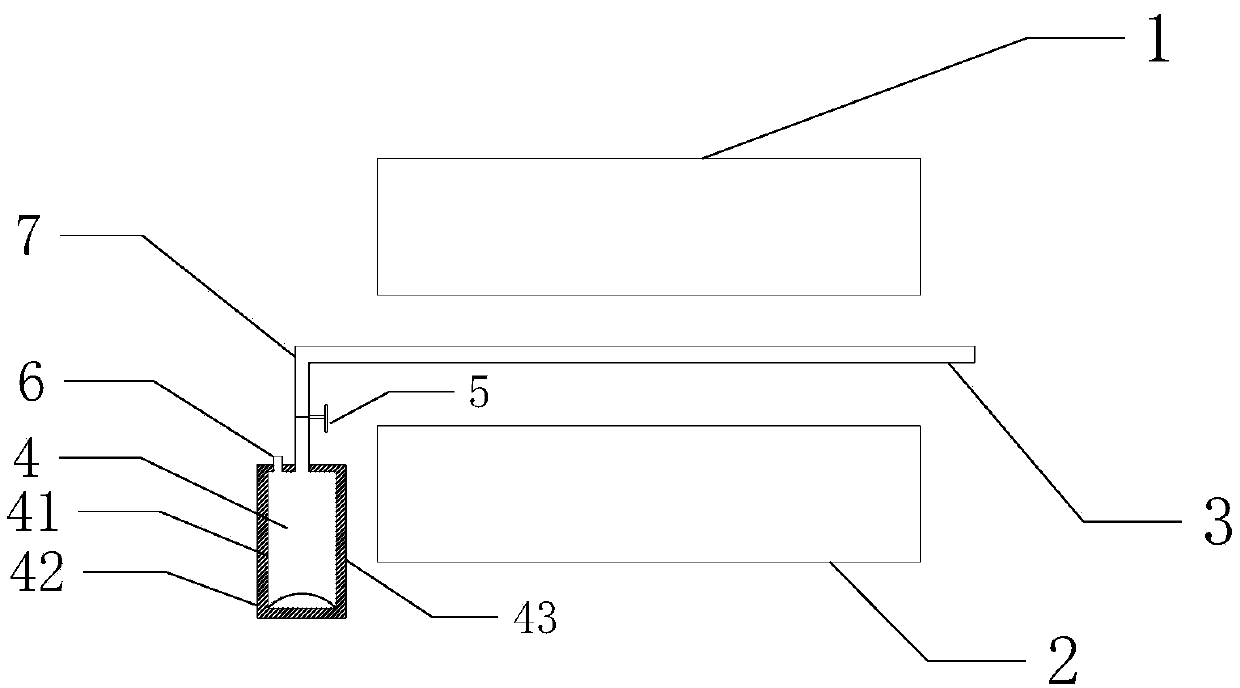

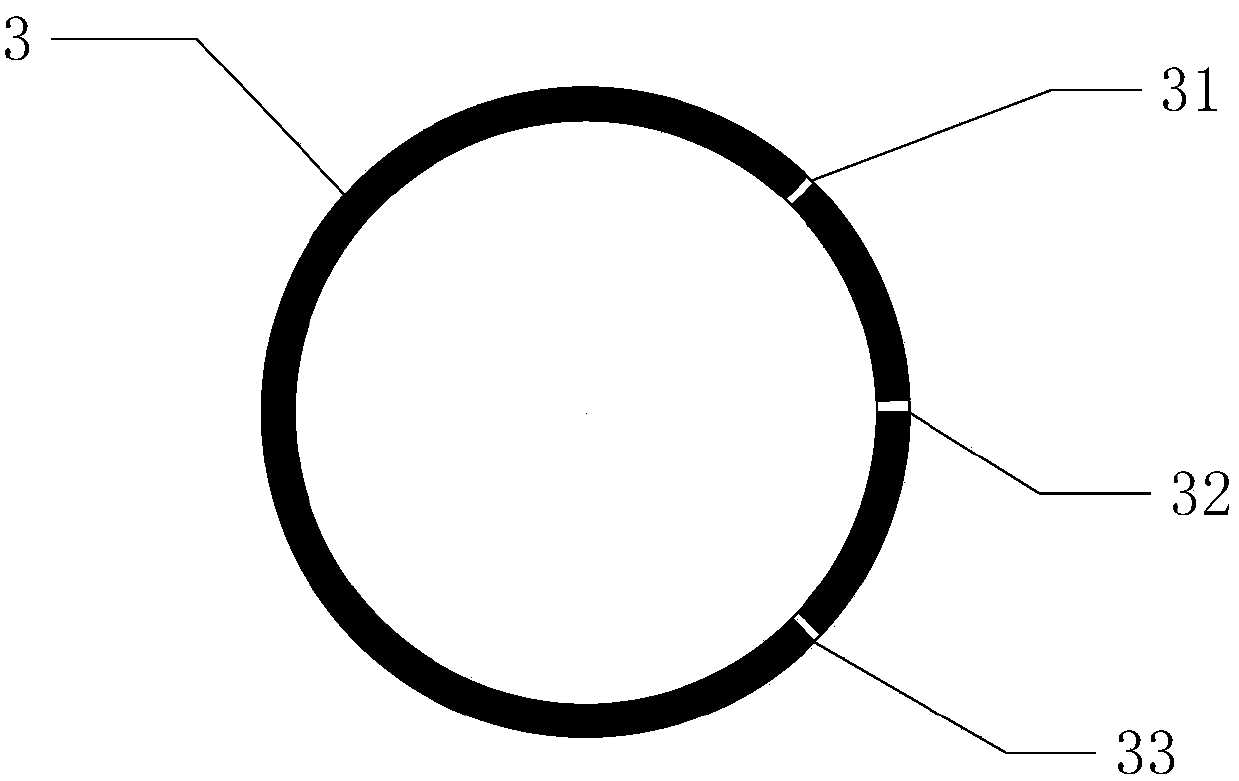

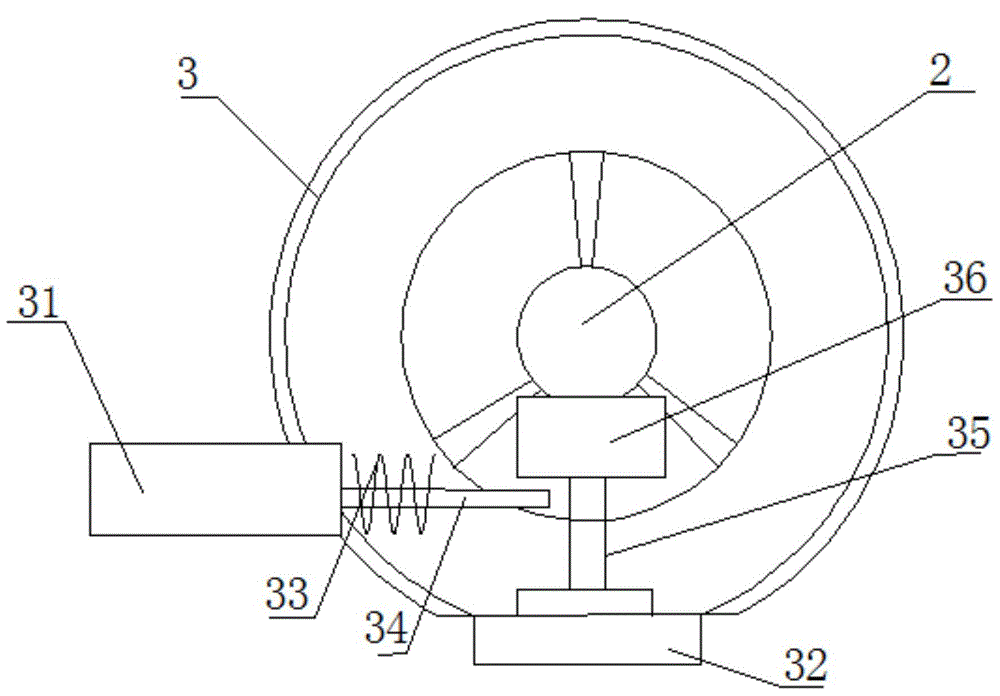

Ozone immunoregulation equipment

The invention discloses an ozone immunity regulating device, comprising a case, an ozone generating device and a disposable in vitro qi and blood mixing pipe installation; the ozone generating device is arranged in the case; the ozone generating device is connected with the disposable in vitro qi and blood mixing pipe installation; the case is provided with an electric control device; the case panel is provided with an electromagnetic valve assembly that is used for controlling conduction or non-conduction of the disposable in vitro qi and blood mixing pipe installation; the ozone generating device and the electromagnetic valve assembly are both electrically connected with the electric control device. The device not only avoids cross infection caused by blood leakage in therapeutic process and foam generation when qi and blood are mixed, but also has convenient operation, thus greatly reducing the labor intensity of medical staff.

Owner:宁波天益医疗器械股份有限公司

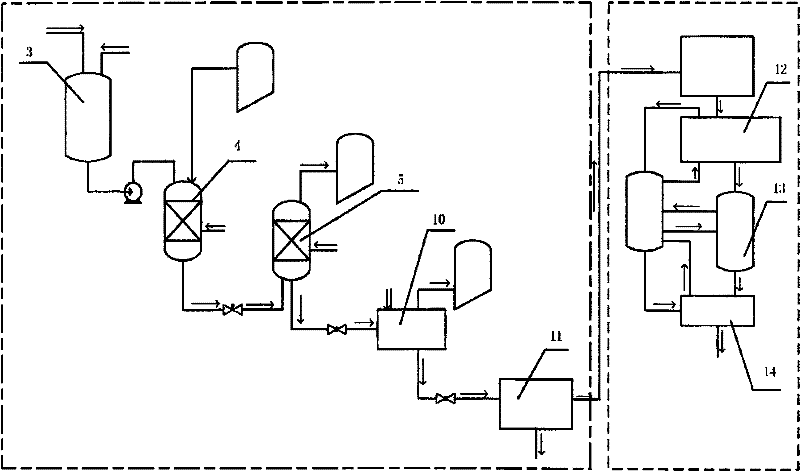

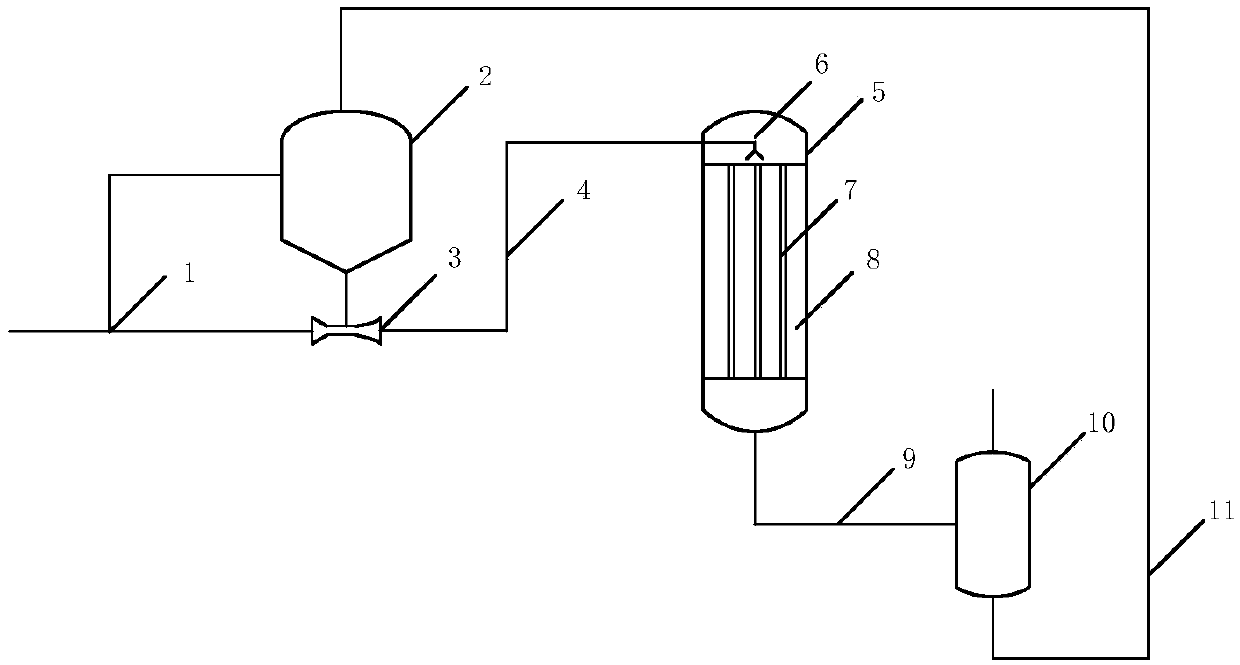

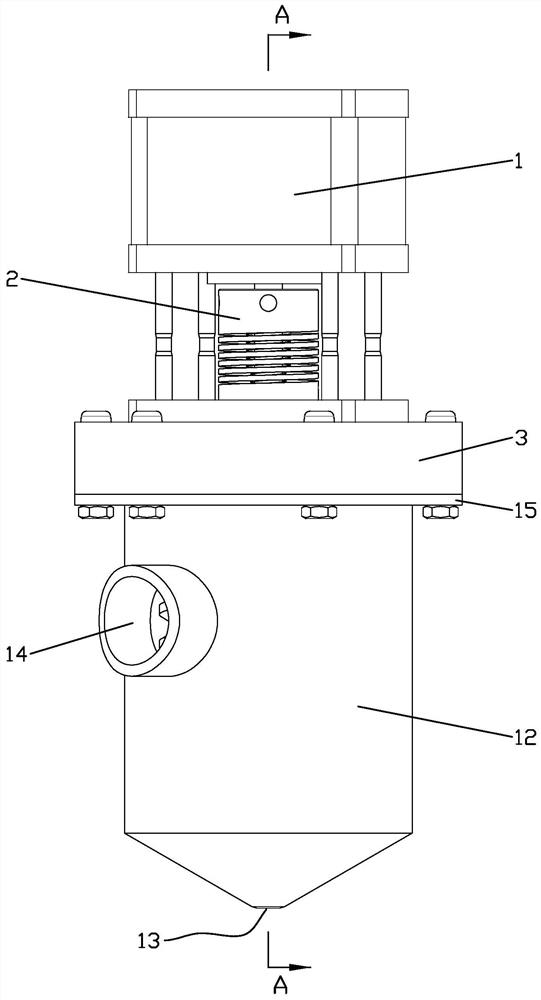

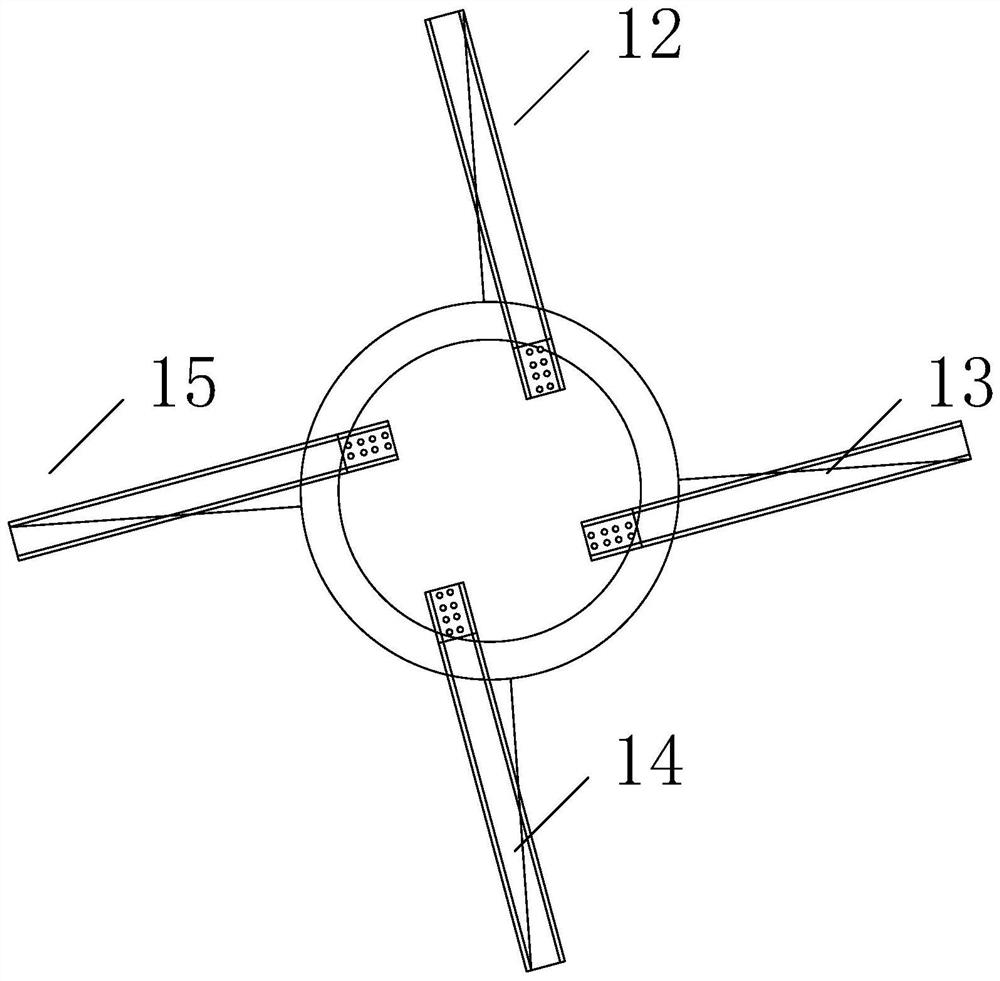

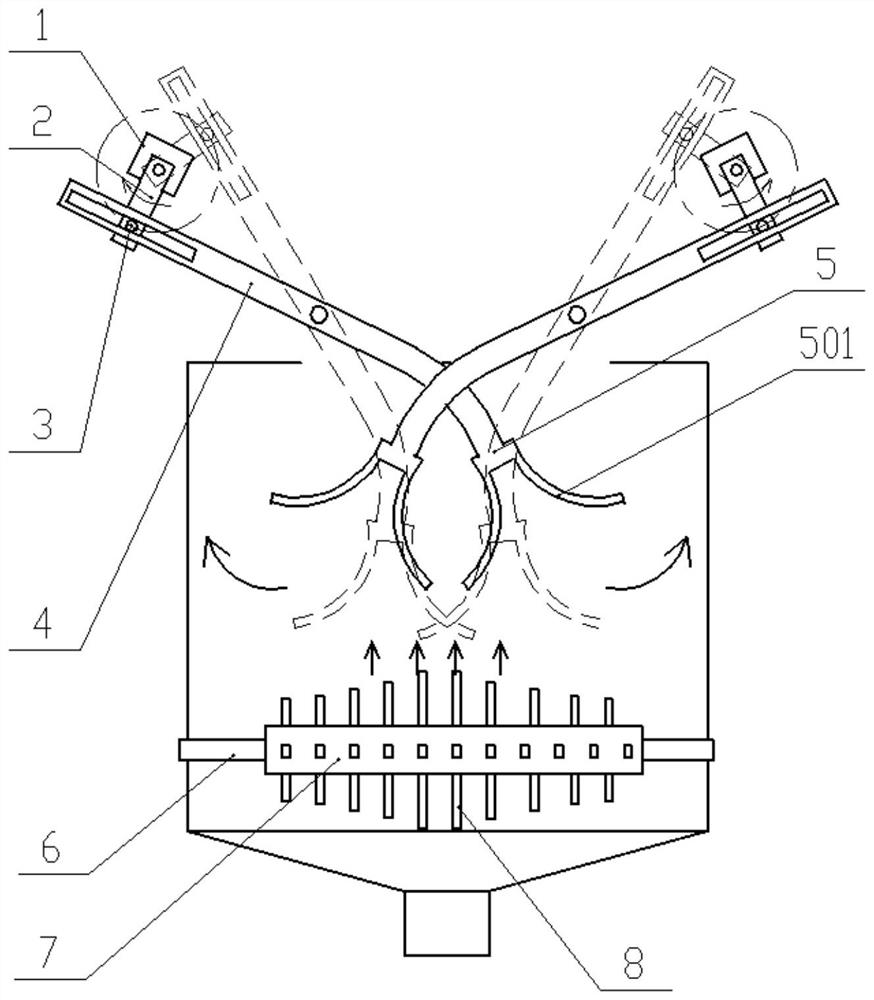

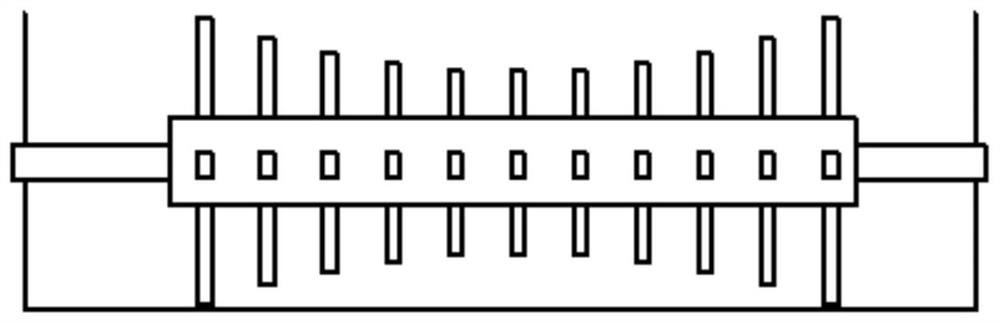

Opposed type solid particle spraying distributor online coke cleaning device

ActiveCN109696079AEnhance gas-solid mixing effectFully diffusedNon-rotary device cleaningSpray nozzleEngineering

The invention relates to an opposed type solid particle spraying distributor online coke cleaning device. The device main solves the problem in the prior art of the hard removing of coke accumulated in gas cooler tubes. The device includes a solid particle storage tank, an ammonia oxidation reaction gas cooler, a solid particle unloading device, a solid particle spraying distributor and gas-solidseparators; the ammonia oxidation reaction gas cooler includes a hollow upper head and a heat exchange section distributed with the tubes; the upper part of the heat exchange section is provided witha protection plate; the solid particle spraying distributor is placed in the upper head along an axial direction; a solid particle distributor is arranged in an opposed manner at least by more than two nozzles which are in opposed arrangement or inclined at a certain angle; the inlet of inert gas communicates with the solid particle spraying distributor after being parallel with the outlet of thesolid particle storage tank; and the outlet of the cooler is provided with at least one gas-solid separator to recycle solid particles. Thus, the problem can be well solved, so that the device can beused for online coke removing industrial devices.

Owner:CHINA PETROLEUM & CHEM CORP +1

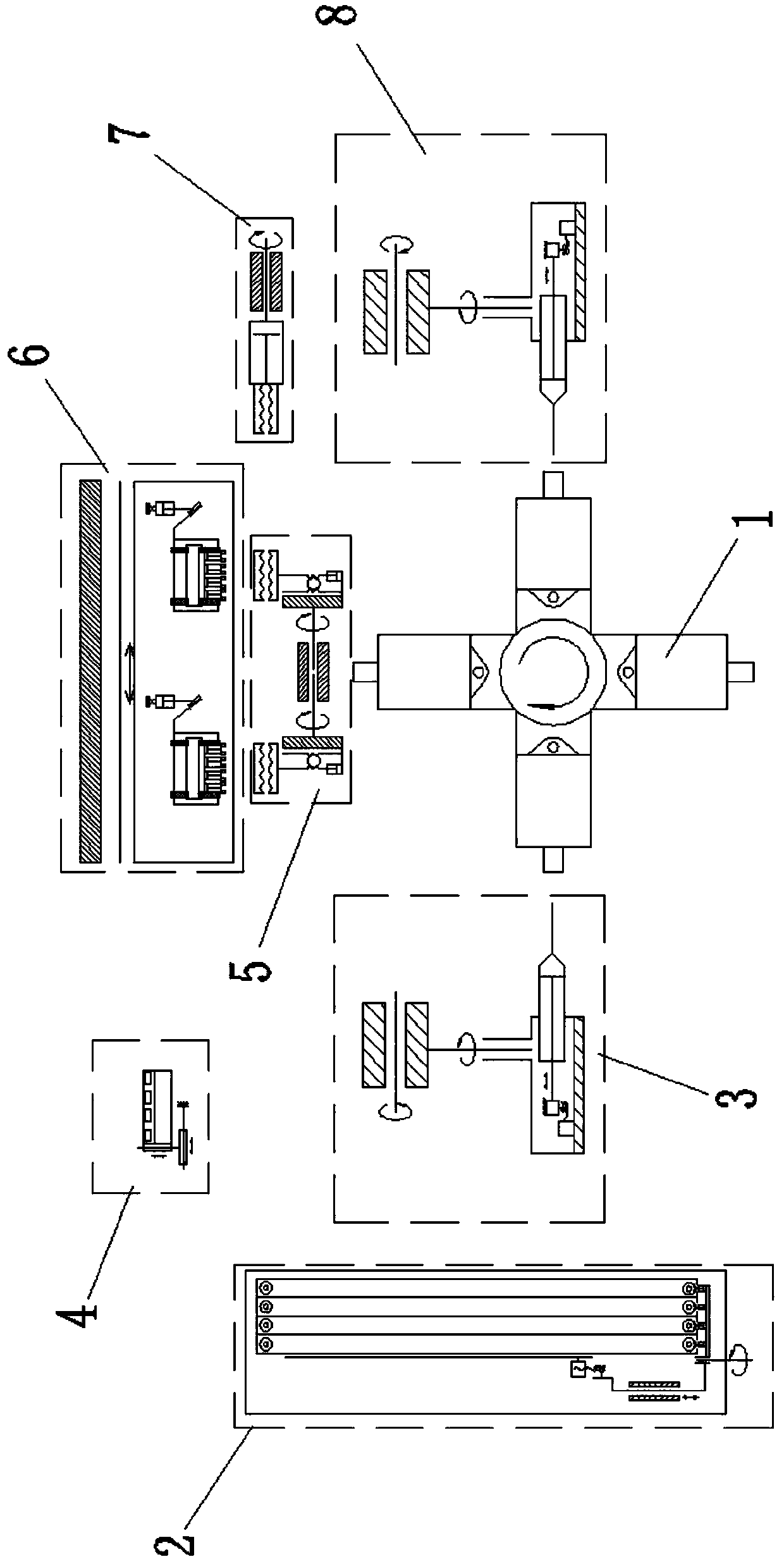

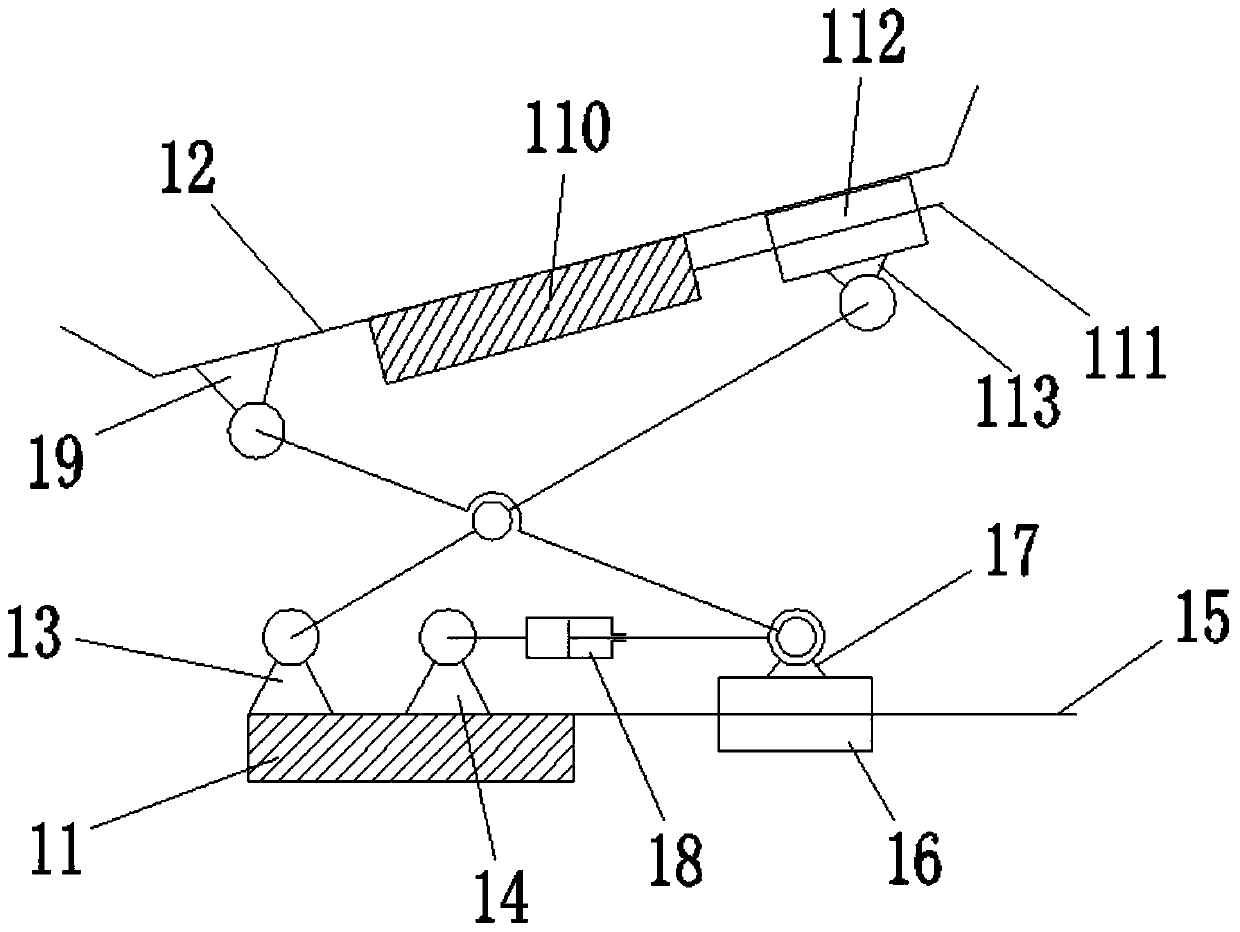

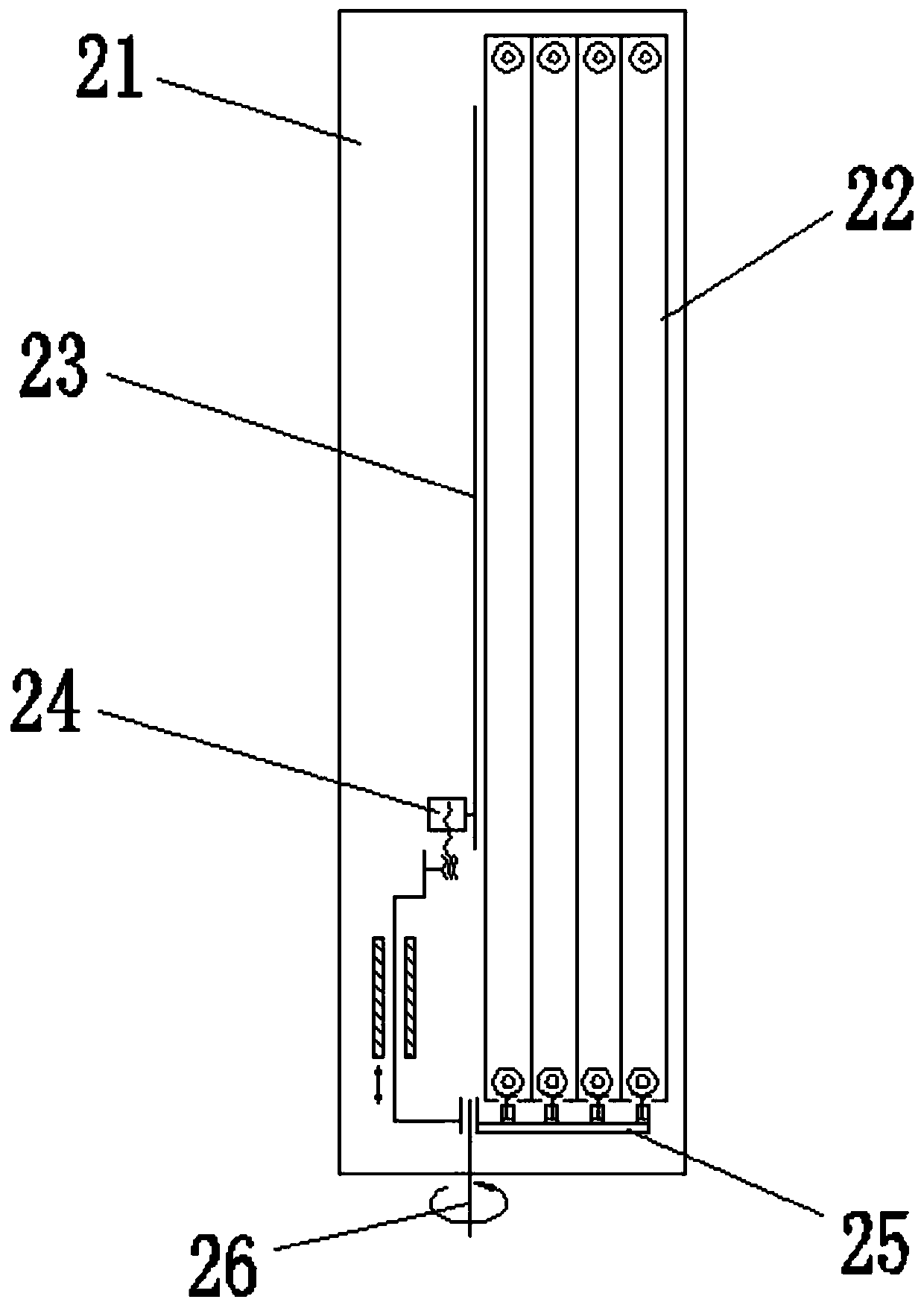

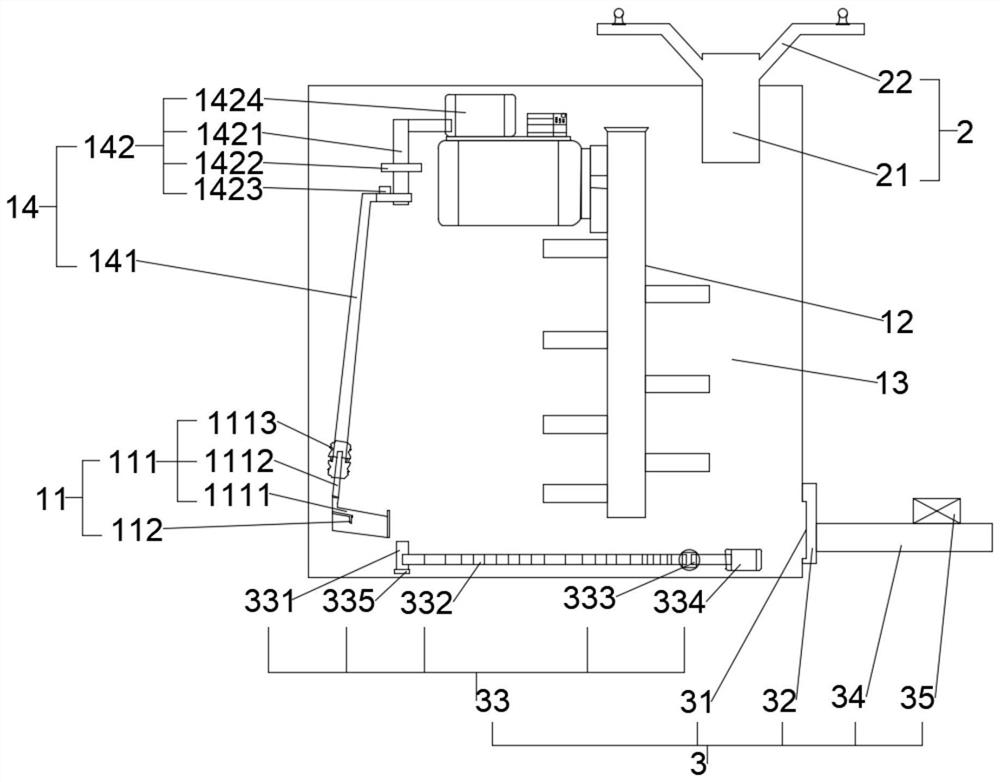

Robotic assembly line for powder dispensing

PendingCN110448459AAvoid pollutionAvoid harmShaking/oscillating/vibrating mixersPharmaceutical containersRoboticsDrug Contamination

The invention provides a robotic assembly line for powder dispensing. The robotic assembly line for powder dispensing comprises a rotary platform used for holding a mother liquid bag, a powder bottleloading device used for pushing and arranging a powder bottle, a manipulator suction device used for taking medical liquid from the mother liquid bag and injecting the medical liquid into the powder bottle, a solution bottle flow steering device used for grabbing the powder bottle and cooperatively completing the injection of the medical liquid, a solution bottle swing mixing device used for receiving an original solution bottle and completing the mixing of powder and the medical liquid, a solution bottle transfer device used for grabbing and transporting the solution bottle after mixing, a solution bottle turning device used for receiving and turning over the solution bottle after mixing, and a manipulator injection device for pumping a solution from the solution bottle after mixing and injecting the solution into the mother liquid bag. The robotic assembly line for powder dispensing provided can realize automatic dispensing, allow manual operation without contacting drugs, prevent drug contamination and avoid harm to operators, the prepared solution is evenly mixed and stable, and the multi-dose dispensing efficiency is high.

Owner:WUXI ANZHIZHUO MEDICAL ROBOT CO LTD

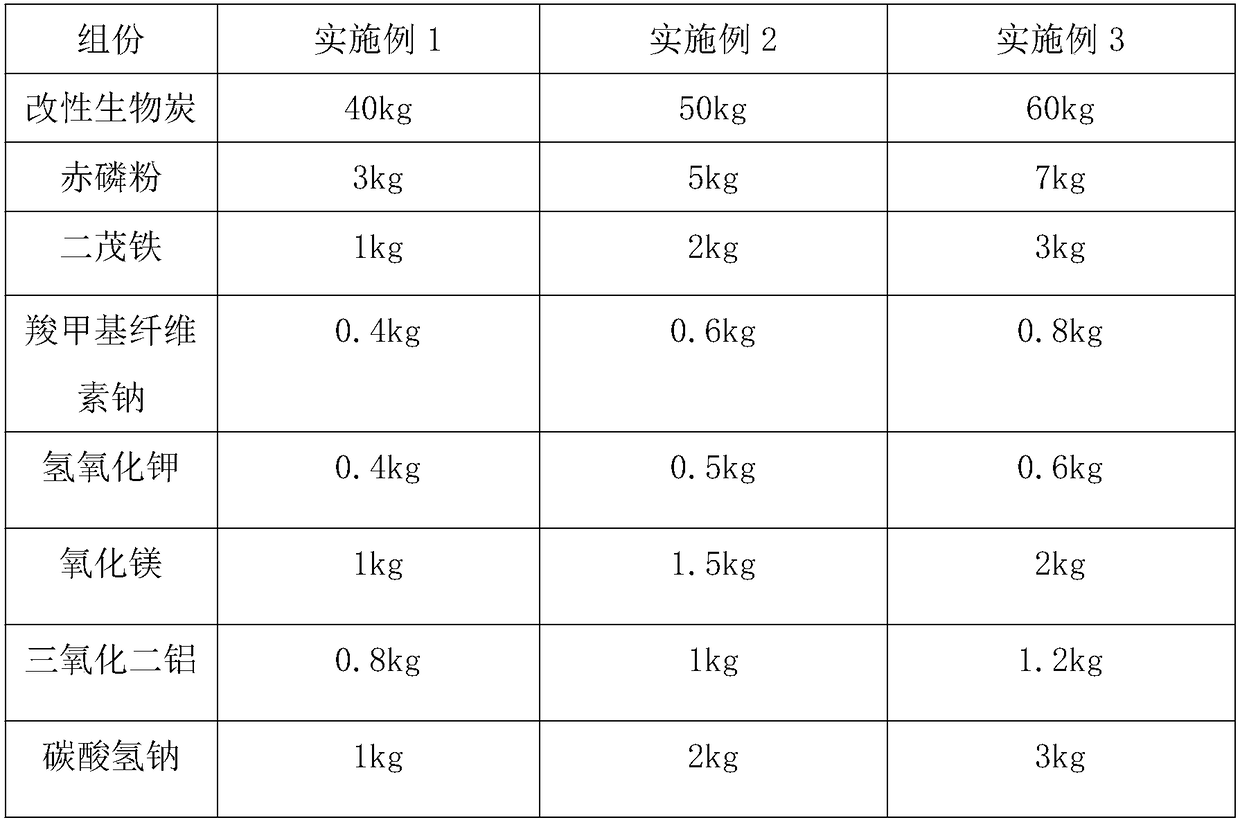

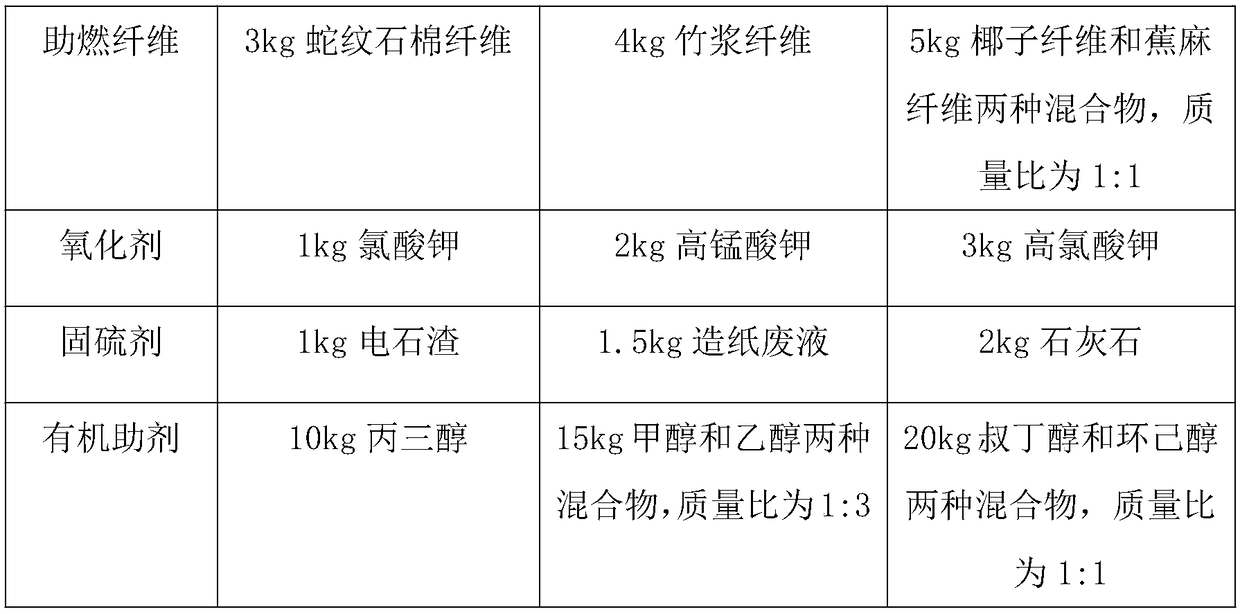

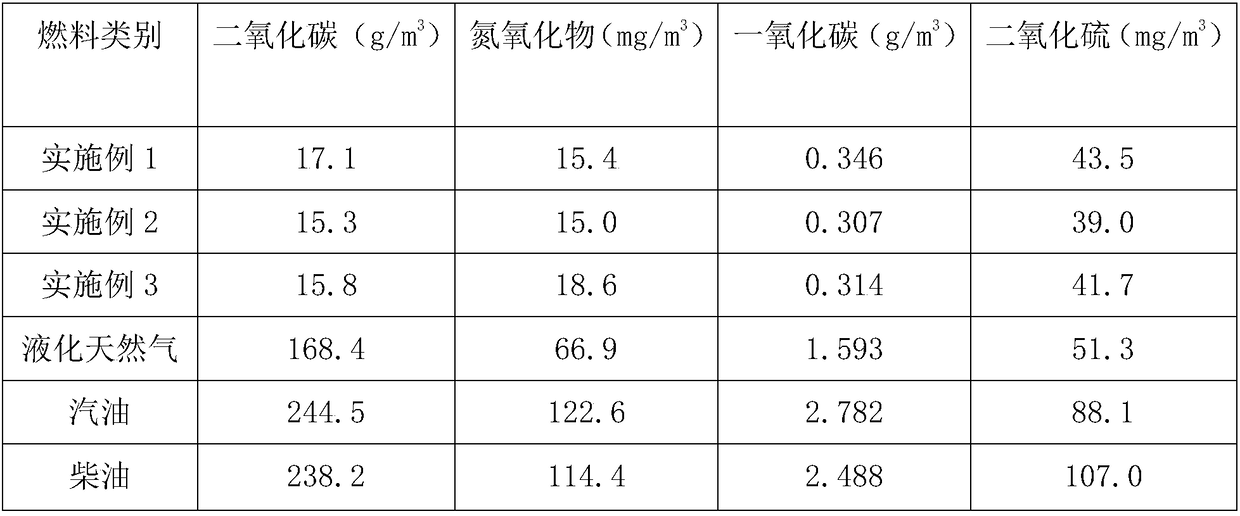

Novel biomass pellet fuel and preparation method thereof

The invention discloses a novel biomass pellet fuel and a preparation method thereof, which belong to the technical field of a solid fuel. The fuel comprises the following raw materials: modified charcoal, red phosphorus powder, ferrocene, carboxymethylcellulose sodium, potassium hydroxide, magnesium oxide, alumina, sodium bicarbonate, combustion-supporting fiber, an oxidizing agent, a sulfur fixing agent, and an organic auxiliary agent. The preparation method is characterized by mixing the raw materials. The biomass pellet fuel preparation has the advantages of simple process, low cost, environmental protection, convenient carrying and transporting, large calorific value generated by combustion, and high combustion efficiency.

Owner:HEBEI JIASHICHENG ENERGY TECH CO LTD

Polyvinyl chloride color masterbatch suitable for high-speed production of automobile wires and cables and preparation method of polyvinyl chloride color masterbatch

InactiveCN109096652AMix evenly and stablyHigh degree of polymerizationPolyvinyl chlorideColoring problem

The invention relates to polyvinyl chloride color masterbatch suitable for high-speed production of automobile wires and cables and a preparation method of the polyvinyl chloride color masterbatch. The active components of the polyvinyl chloride color masterbatch consist of the following raw materials in parts by weight: 45-55 parts of polyvinyl chloride, 5-12 parts of titanium dioxide, 4-8 partsof a brightening agent, 3-6 parts of a calcium zinc stabilizer, 1-3 parts of oxidized polyethlene wax, 1-3 parts of a surface treating agent, 1-3 parts of zinc stearate, 1-3 parts of a coupling agentand 25-35 parts of pigment. The polyvinyl chloride and the oxidized polyethlene wax are pre-stirred, so that substrate materials are stable and uniform when being mixed, the polymerizing degree is higher, when the temperature of masterbatch substrates is lower than that of squeezed materials, diverging and coloring of masterbatch are facilitated, the fusion degree of the masterbatch substrate materials and the squeezed materials is increased, and high-speed squeezing is facilitated; and through measures of added materials and a production technology, the masterbatch materials are more suitablefor high-speed squeezing of automobile wires and cables, the production efficiency is greatly improved, and unnecessary losses caused by color problems are reduced.

Owner:山东寰宇线缆有限公司

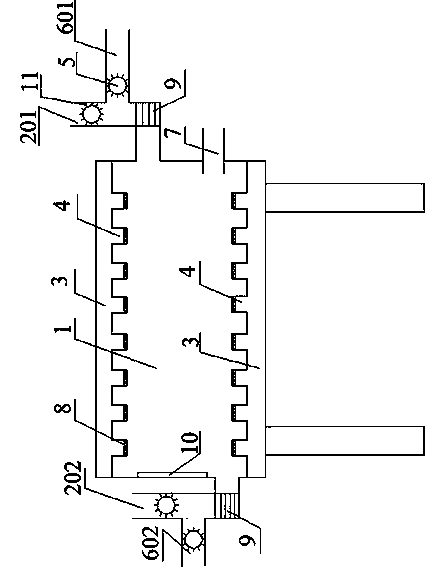

Cotton mixing machine

The invention relates to machines in the textile industry, in particular to a cotton mixing machine. The cotton mixing machine comprises a cotton mixing chamber, cotton inlets and a cotton outlet, wherein the cotton inlets and the cotton outlet are formed in the cotton mixing chamber. The top and the bottom of the cotton mixing chamber are respectively provided with an air jetting groove, and each air jetting groove is provided with an air jetting hole. The cotton inlets comprise the upper cotton inlet and the lower cotton inlet, wherein the upper cotton inlet is close to the top of the cotton mixing chamber, the lower cotton inlet is close to the bottom of the cotton mixing chamber, and an air suction fan is connected between each cotton inlet and the cotton mixing chamber. After the structure is adopted, cotton products of different densities can be evenly mixed, production efficiency is improved, and production quality is guaranteed.

Owner:南通雅日纺织品有限公司

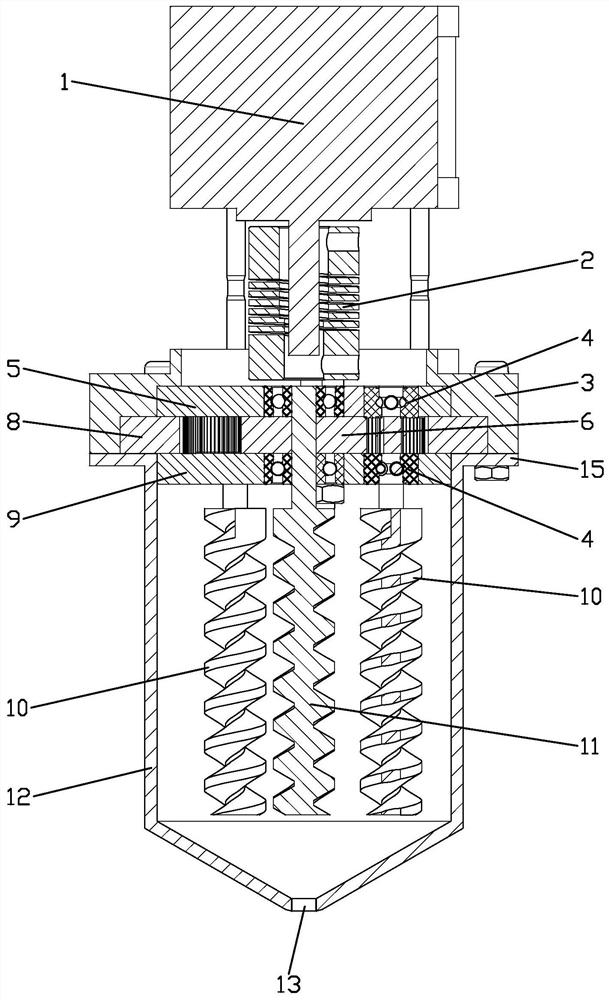

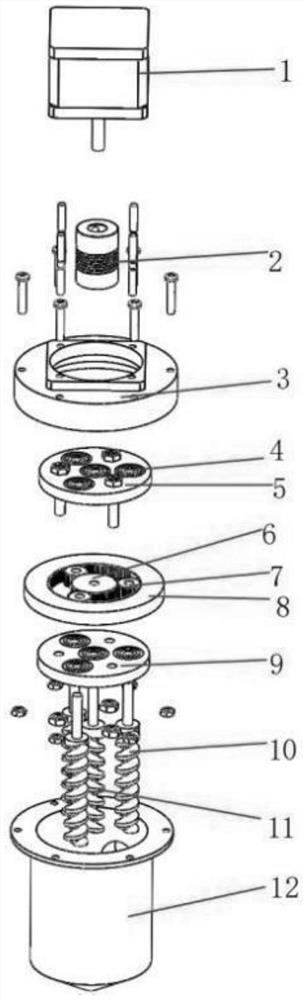

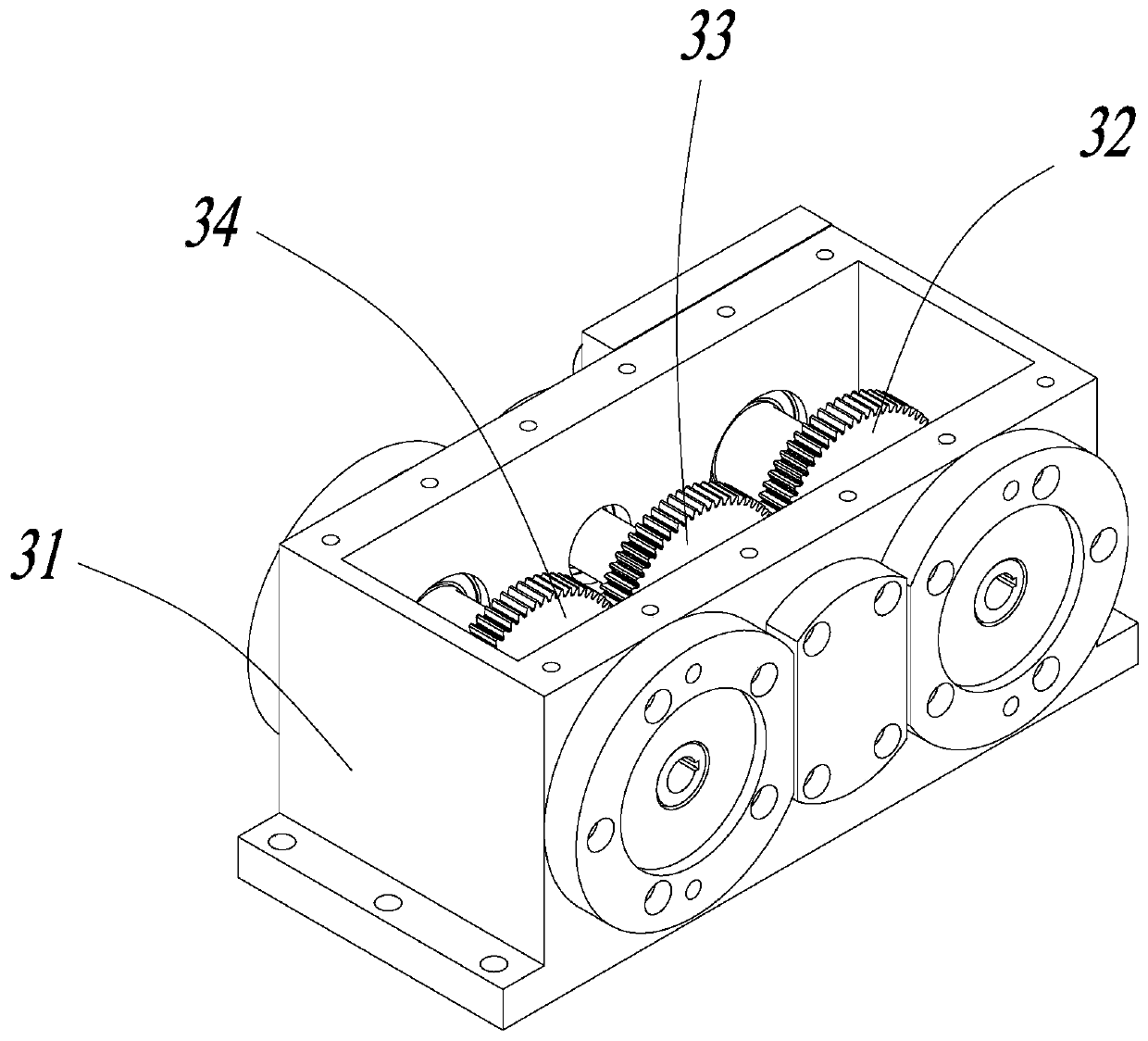

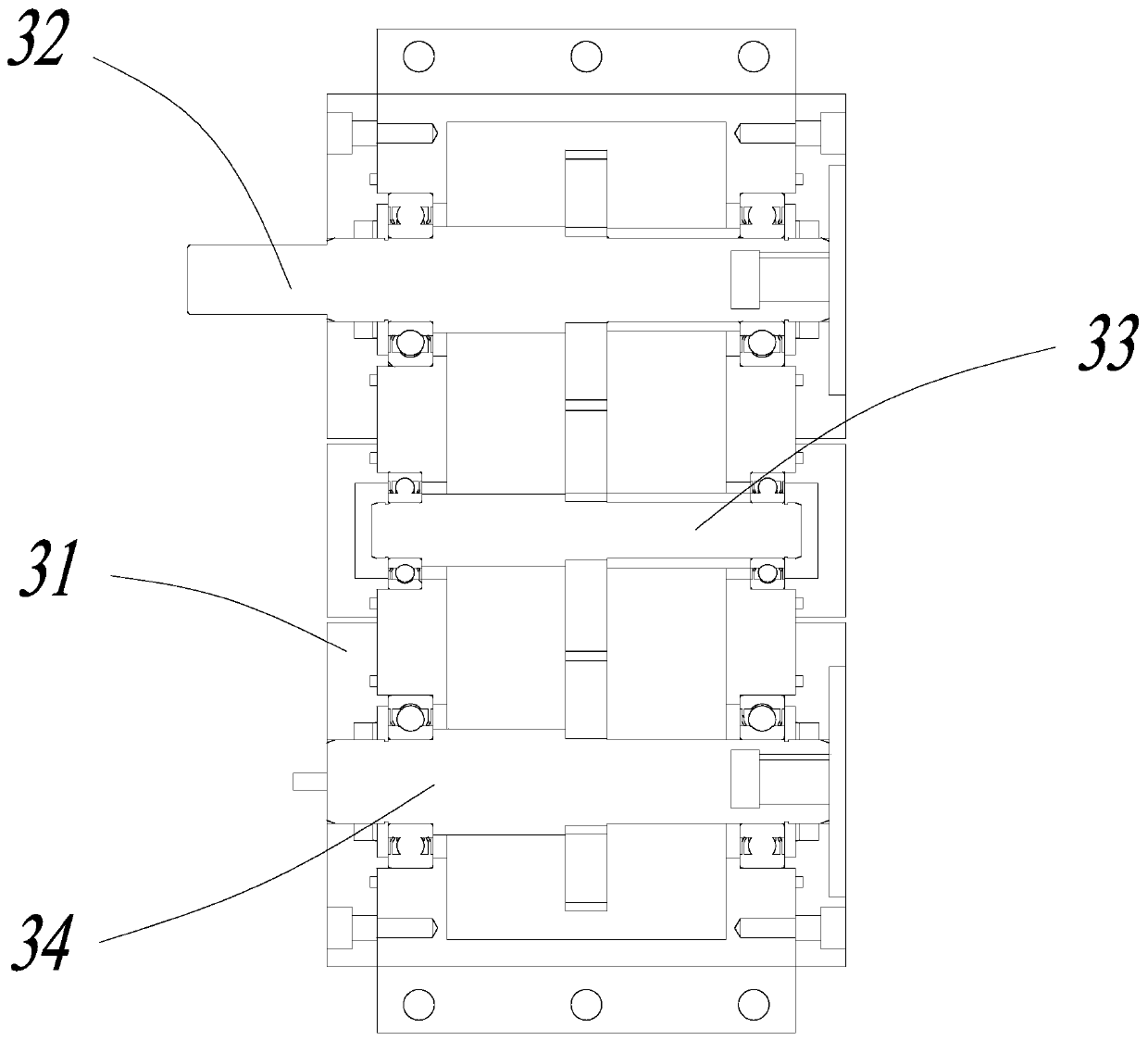

Planetary mixed extrusion molding device

PendingCN112677283AMix evenly and stablyExtrude evenlyAdditive manufacturing apparatusCeramic shaping apparatusPhysicsEngineering

The invention discloses a planetary mixed extrusion molding device. The planetary mixed extrusion molding device comprises a stirring cylinder, a driving mechanism, a sun screw rod arranged in the stirring cylinder and a plurality of planetary screw rods, wherein a nozzle is arranged at the lower end of the stirring cylinder, and a feeding opening is formed in the outer side wall of the stirring cylinder; the sun screw rod is arranged in the middle portion of the stirring cylinder, and all the planetary screw rods and the sun screw rod are arranged in parallel; and the driving mechanism drives the sun screw rod to rotate around the axis of the sun screw rod, and the driving mechanism further drives all the planetary screw rods to revolve around the axis of the sun screw rod and rotate around the rotating axis of the planetary screw rods. The planetary mixed extrusion molding device adopts a planetary gear set, and stirring and extruding are carried out at the same time, so that it is guaranteed that slurry is evenly and stably mixed inside the stirring cylinder.

Owner:ZHONGSHAN AISHANGZHITONG INFORMATION TECH CO LTD

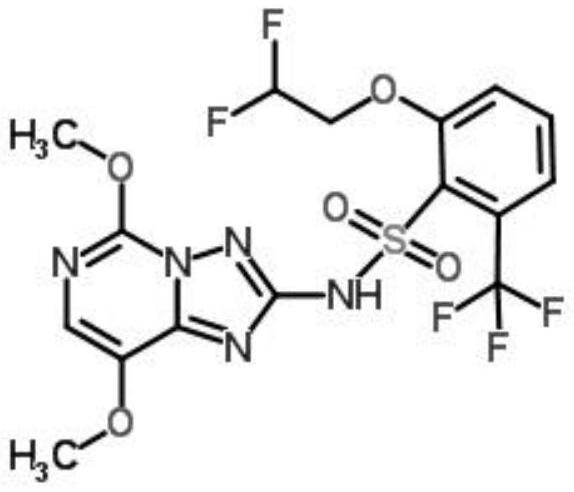

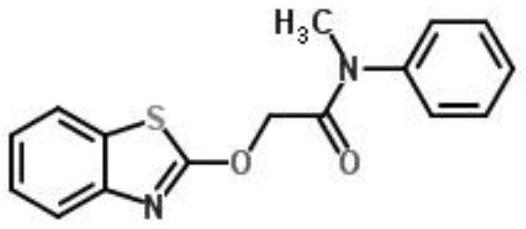

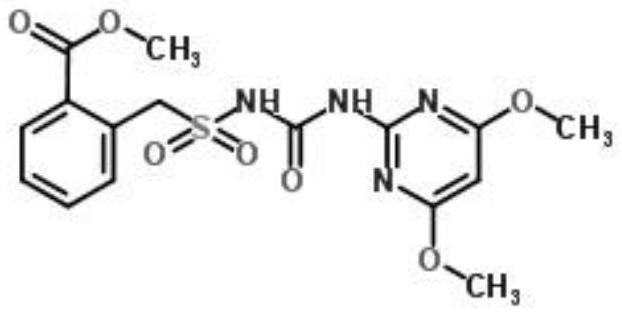

Paddy field weeding granule containing penoxsulam, mefenacet and bensulfuron methyl as well as preparation method and application thereof

PendingCN112155014AEffective controlImprove the effect of prevention and controlBiocideAnimal repellantsBensulfuron methylActive ingredient

The invention relates to a paddy field weeding granule containing penoxsulam, mefenacet and bensulfuron methyl as well as a preparation method and application of the paddy field weeding granule. The granule comprises a A-phase component, a B-phase component and a C-phase component, wherein the A-phase component comprises 70%-95% of a granule carrier, the B-phase component comprises 0.1%-30% of functional mother powder containing three active ingredients, namely penoxsulam, mefenacet and bensulfuron methyl, and the C-phase component contains 1%-40% of a coalescing agent; and the coalescing agent comprises a binder, an inducer and a warning color. The paddy field weeding granule containing penoxsulam, mefenacet and bensulfuron methyl is scientific and reasonable in design, is prepared by a coating film forming method, is good in film forming, glossy, good in wear resistance, free of caking, falling and dust, high in safety, capable of being separately spread, capable of being mixed witha fertilizer to be spread, convenient, rapid, easy to operate and capable of reducing labor.

Owner:TIANJIN HIGHPOINT PLANT PROTECTION

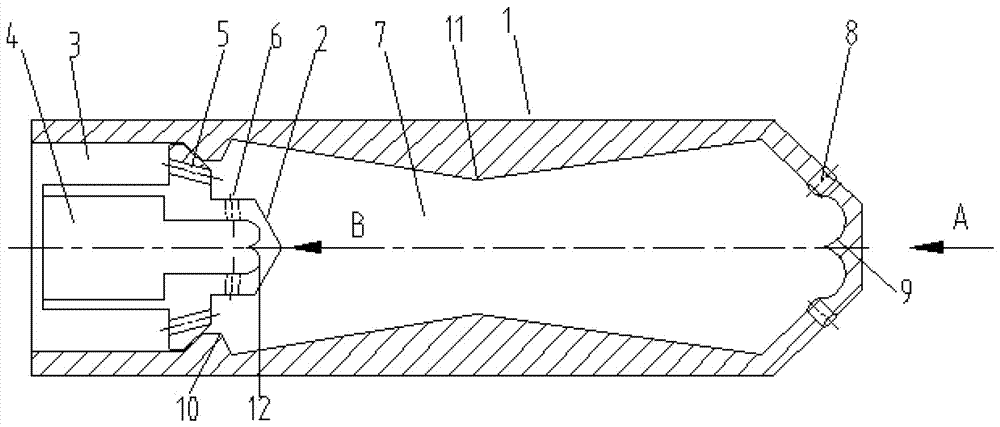

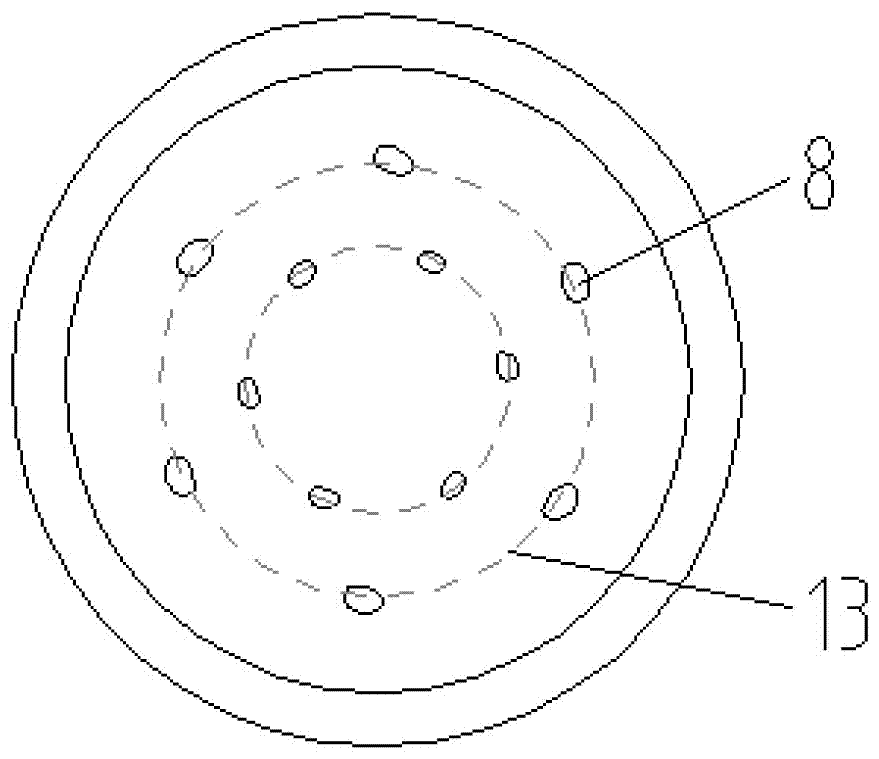

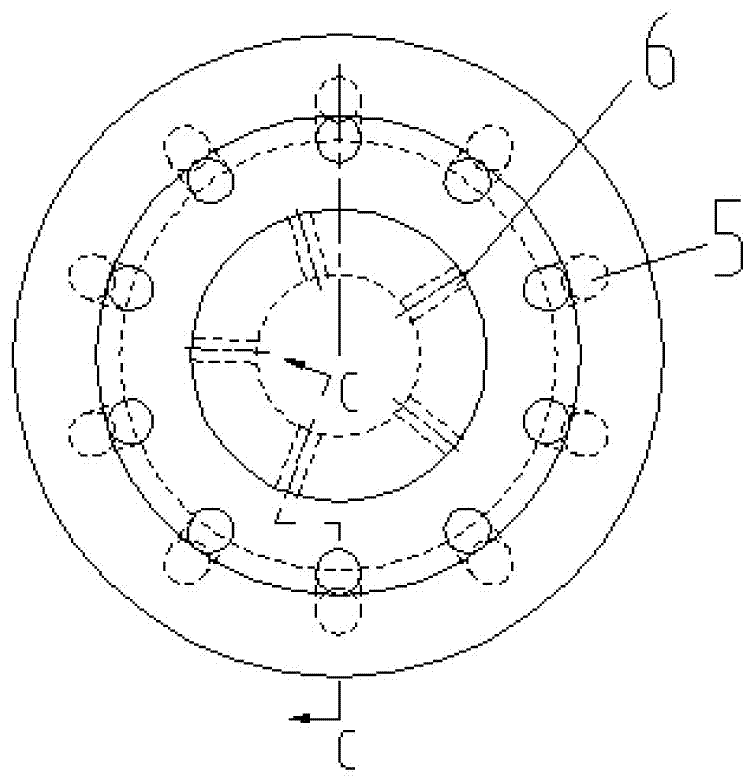

Low-resistance internal mixing type gas nucleus atomization oil gun

PendingCN107218598AEnhance and ensure the atomization effectOvercome stickinessBurnersCombustionEngineering

The invention discloses a low-resistance internal mixing type gas nucleus atomization oil gun aims at achieving the technical purposes that oil mist mixing is uniform and combustion is complete, and belongs to the technical field of fuel oil atomization. The atomization oil gun comprises an oil gun shell and a mixing core arranged on the inner side of the tail of the oil gun shell. A fuel oil channel is arranged on the inner side of a center barrel at the tail end of the mixing core. An automation medium channel is arranged between the outer side of the center barrel and the inner side face of the oil gun shell. The front end of the fuel oil channel is provided with a blind hole. The wall of the blind hole is provided with multiple radial oil spraying holes. The inner side face on the top of the blind hole is provided with a first conical flow guide device. Multiple automation medium spraying holes are formed in the outward-convex face of the shoulder of the mixing core and located at the front end of the atomization medium channel. An oil-gas mixing chamber in the middle of an inner cavity of the oil gun shell is of a Venturi structure, the top of the front end of the oil-gas mixing chamber is provided with a second conical flow guide device, and the inclined face of a cone frustum of the front end of the oil gun shell is provided with secondary atomization spraying holes. The low-resistance internal mixing type gas nucleus atomization oil gun has the advantages that the mixing core and the oil-gas mixing chamber are provided with flow guide parts correspondingly, oil mist mixing is uniform and combustion is complete under the rectification effect of a Venturi pipe of the oil-gas mixing chamber, and the low-resistance internal mixing type gas nucleus atomization oil gun is suitable for combusting various kinds of oil.

Owner:SHANGHAI WISEBOND TECH

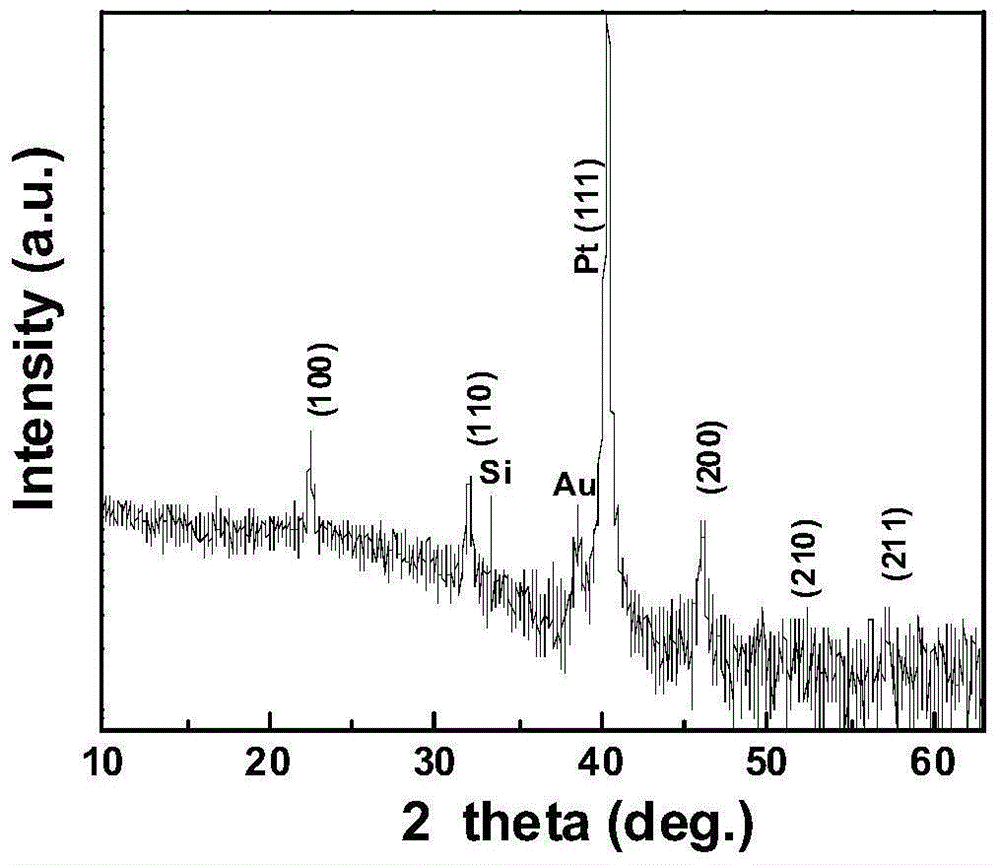

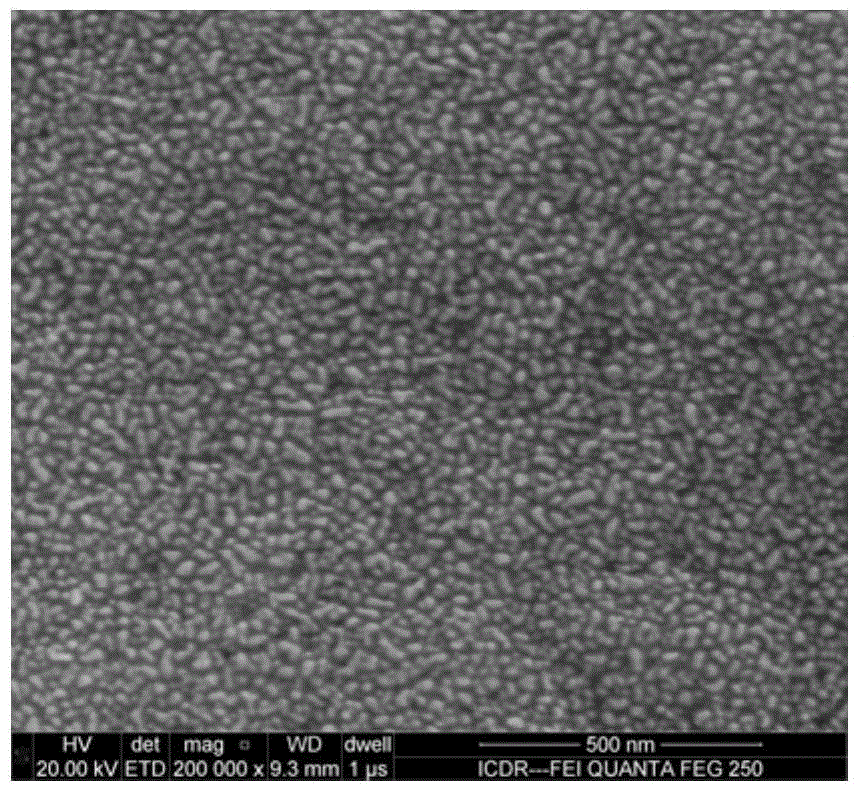

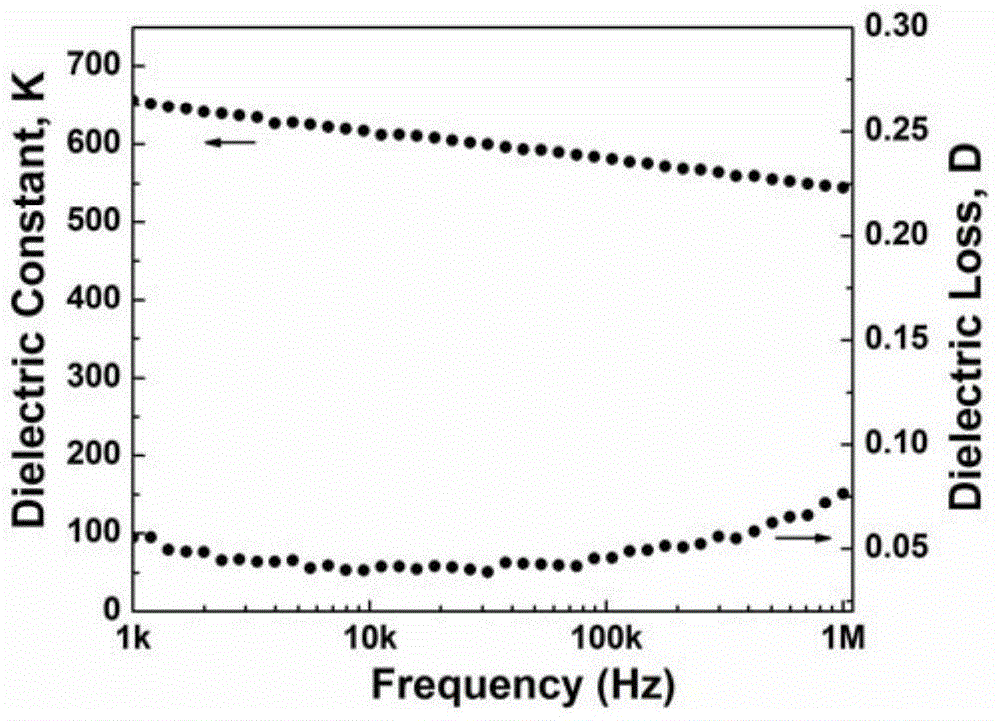

Preparation method of potassium-sodium niobate-barium zirconate-sodium bismuth titanate lead-free piezoelectric film with vertical phase boundary

InactiveCN105200405ANo crackGood electrical propertiesSolid/suspension decomposition chemical coatingSodium bismuth titanateMono layer

The invention provides a preparation method of a potassium-sodium niobate-barium zirconate-sodium bismuth titanate lead-free piezoelectric film with a vertical phase boundary. A chemical solution deposition technique is adopted; a KNN-BZ-BNT precursor solution is spin-coated and deposited on a substrate; a compact and crack-free single layer crystal film is obtained by heat treatment. A KNN-BZ-BNT film with the thickness of 0.4 to 2 mu. m is obtained after a spin-coating-heat treatment technique is repeated for multiple times. Through modification of a polymer polyethylene pyrrolidone and / or Mn(2+) and Co(2+) or Fe(2+) and the like, the electrical properties, especially ferroelectric and piezoelectric properties, of the KNN-BZ-BNT film are improved.

Owner:XI AN JIAOTONG UNIV

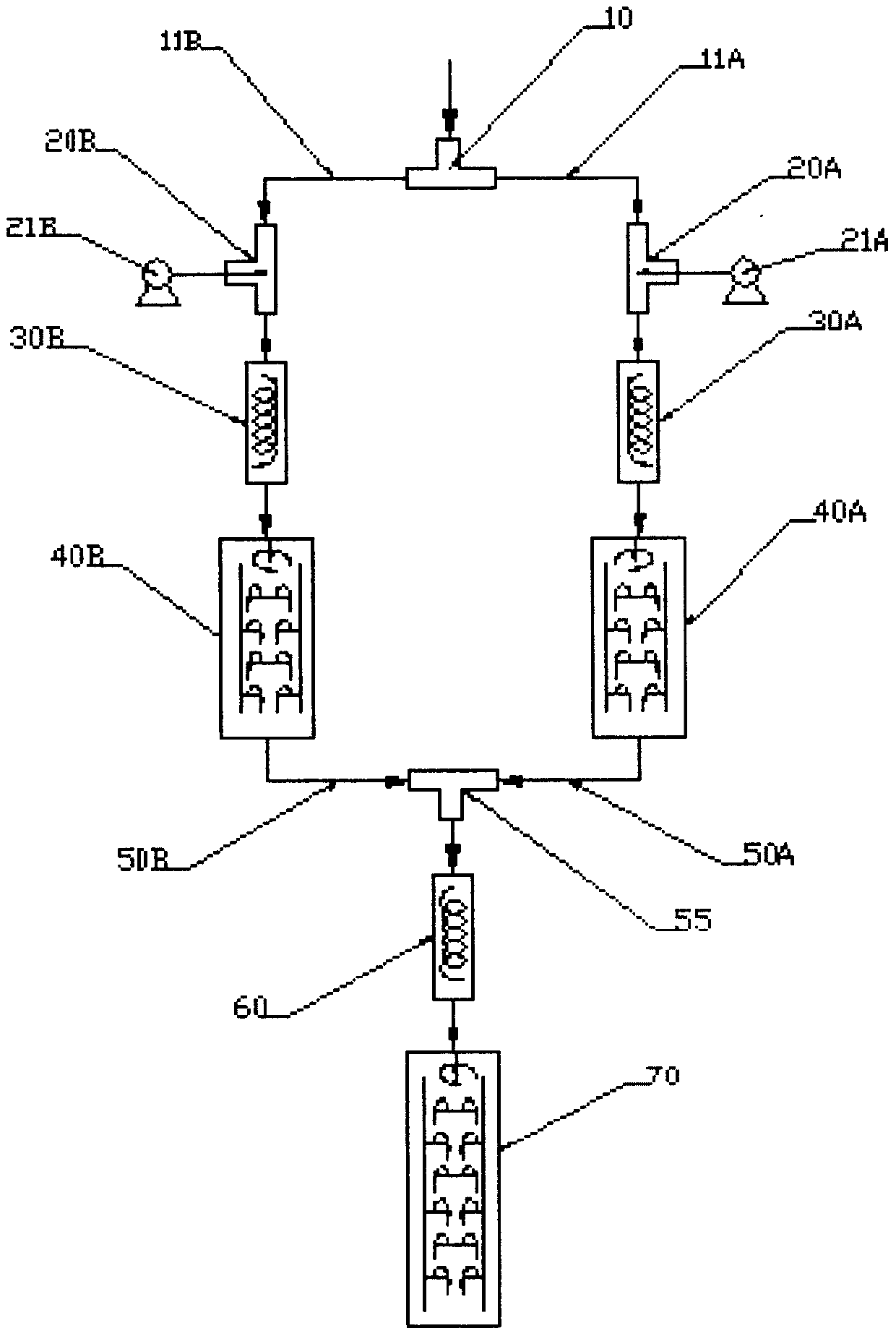

Weakly acidic hypochlorous acid disinfectant generator capable of achieving stable concentrations and stable pH values

The present invention relates to a weakly acidic hypochlorous acid disinfectant generator capable of achieving stable concentrations and stable pH values. The weakly acidic hypochlorous acid disinfectant generator comprises a diversion pipe and mixer sets, wherein the mixer sets comprise two or more than two sets selected from a spiral mixer set, a venturi mixer set and an impact type mixer set. According to the present invention, through the operation of the single mixer set or the combination of the multiple mixer sets, the purpose of the rapid, uniform and stable mixing can be achieved; andthe three mixers are easy to process, can be subjected to batch processing through injection mold, have characteristics of compact structure and convenient assembly, can be completely assembled intothe standard pipe members so as to occupy the small space, and are suitable for use in the weakly acidic hypochlorous acid disinfectant generator.

Owner:宁波净雅德环保科技股份有限公司

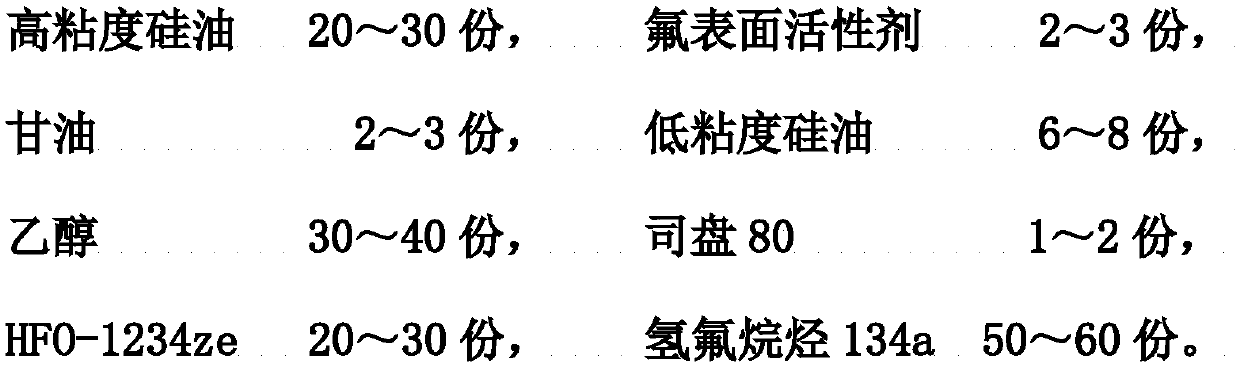

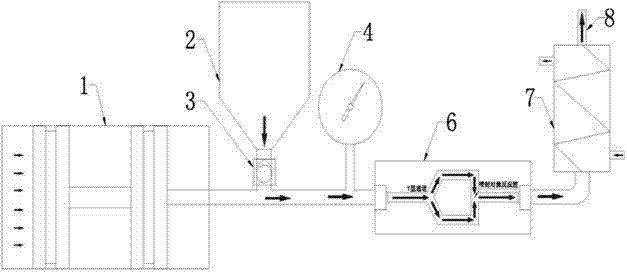

Aerosol type rubber conveyer belt releasing agent, preparation method thereof and spraying system thereof

PendingCN109092597AReduce dosageGood chemical stabilitySpraying apparatusAdditivesAlkaneVulcanization

The invention relates to an aerosol type rubber conveyer belt releasing agent, a preparation method thereof and a spraying system thereof. The aerosol type rubber conveyer belt releasing agent is prepared from the raw materials including, by weight part, 20-30 parts of high-viscosity silicone oil, 2-3 parts of fluorinated surfactant, 2-3 parts of glycerin, 6-8 parts of low-viscosity silicone oil,20-40 parts of ethyl alcohol, 1-2 parts of Span-80, 20-30 parts of HFO-1234ze and 50-60 parts of hydrofluoroalkane 134a. The aerosol type rubber conveyer belt releasing agent has the advantages of being low in consumption, good in chemical stability, high in lubricating property and the like, thereby being applicable to rubber conveyer belt production. Correspondingly the invention also provides the preparation method of the aerosol type rubber conveyer belt releasing agent. Besides, the invention also provides the aerosol type rubber conveyer belt releasing agent spraying system for sprayingthe aerosol type rubber conveyer belt releasing agent onto the upper and lower curing plates on a curing press.

Owner:ZHEJIANG FENFEI RUBBER & PLASTIC PROD CO LTD

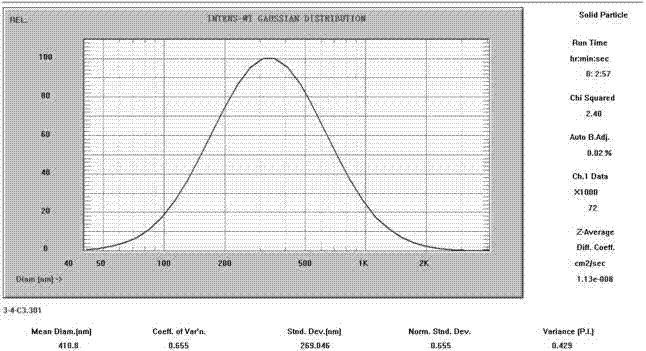

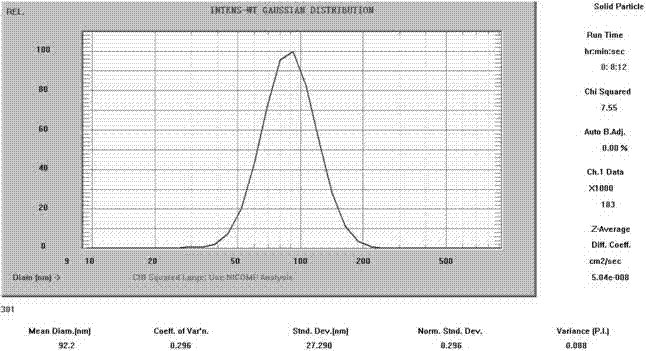

Emulsifying cavity device for high-pressure homogenizing emulsification equipment and method for emulsifying cavity device

InactiveCN102806038ASmall particle sizeMix evenly and stablyFlow mixersMixing methodsEngineeringHigh pressure

The invention relates to the technical field of high-pressure homogenizing emulsification equipment, in particular to an emulsifying cavity device for the high-pressure homogenizing emulsification equipment and a method for the emulsifying cavity device. The emulsifying cavity device comprises a hydraulic plunger pump, a feed cup, a check valve, a pressure gauge, a heat exchanger and a discharge hole, and is characterized in that the hydraulic plunger pump is connected with a main pipeline of the equipment; one end of a tap of the main pipeline is connected with a funnel discharging hole of the funnel-shaped feed cup by the check valve, and the other end of the main pipeline is connected with a feeding hole of a Y-shaped spray cavity structure; the pressure gauge is arranged at one end of the tap of the main pipeline between the Y-shaped spray cavity structure and the check valve; a discharge hole of the Y-shaped spray cavity structure is connected with a feed opening of the heat exchanger by a pipeline; a discharge hole is formed at the other end of the heat exchanger; and a water inlet and a water outlet for a heat supply exchange medium are formed on the heat exchanger. The emulsifying cavity device is novel in structure, and two liquid flows of materials collide with each other at an intersection by utilizing the specific Y-shaped spray cavity structure, so that the grain diameters of the materials are reduced, and the materials are mixed uniformly and stably.

Owner:诺泽流体科技(上海)有限公司

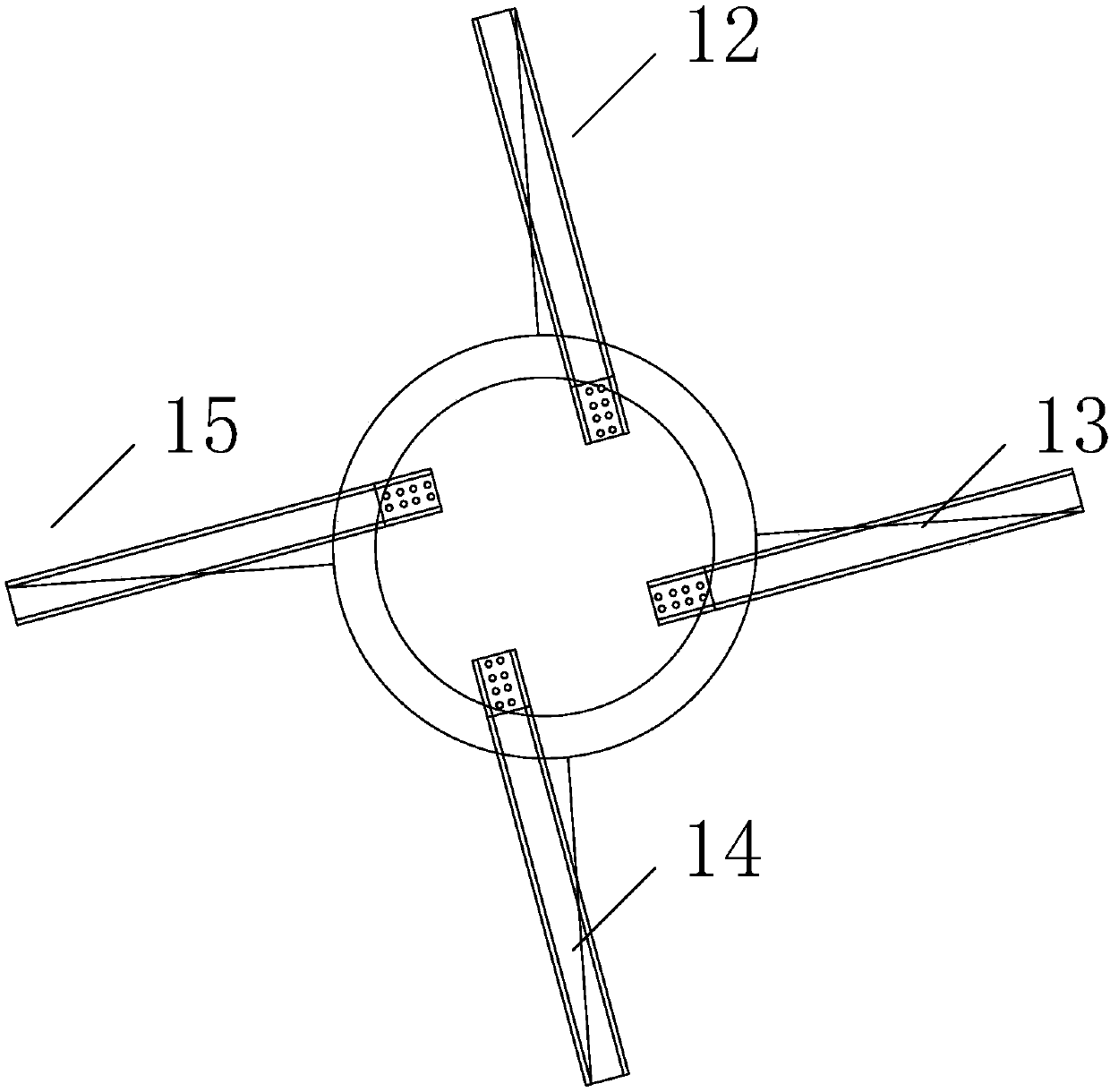

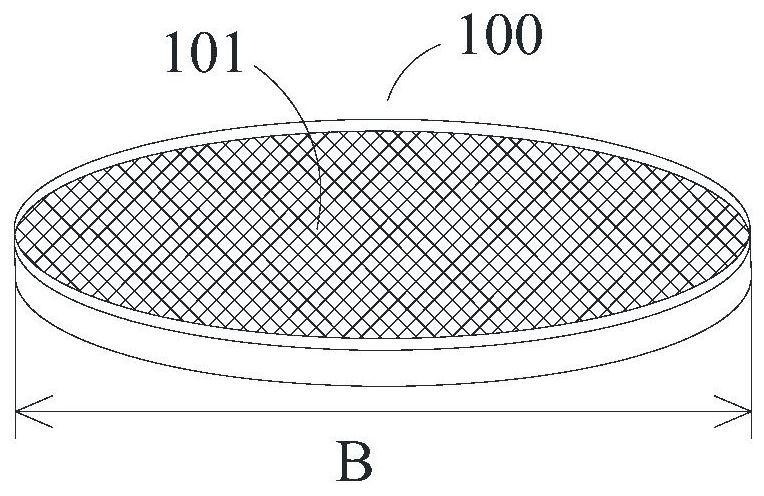

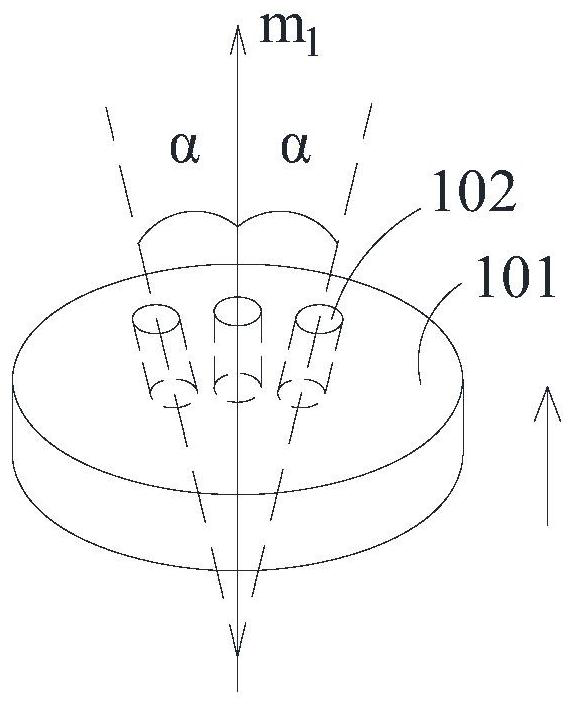

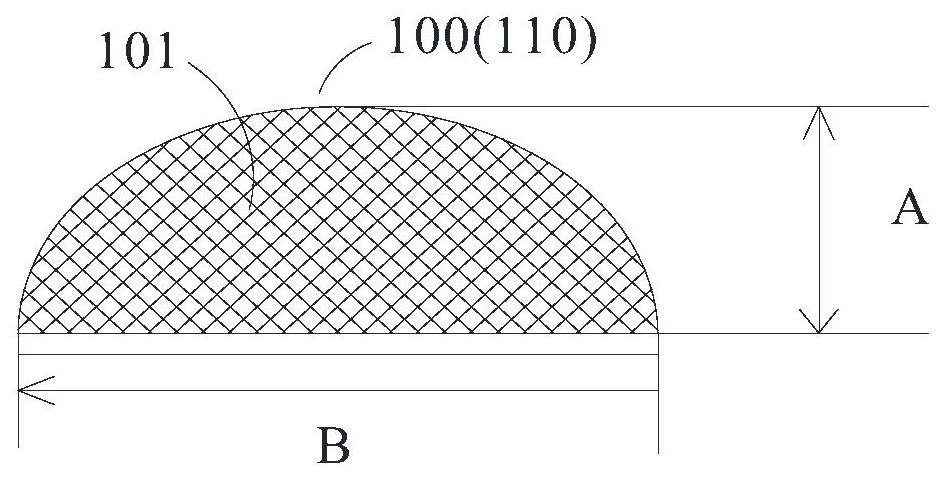

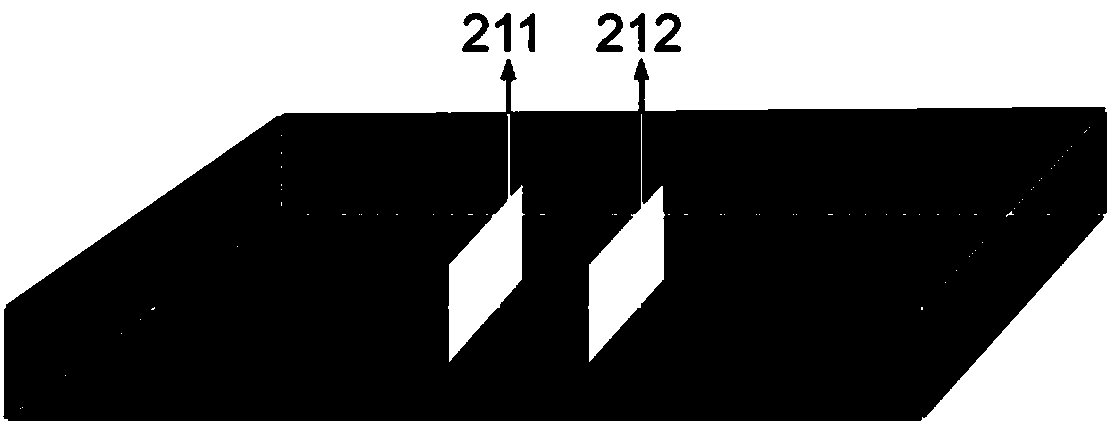

Flow dividing element and fluid distributor

PendingCN113007929ASimple structureEasy to processFluid circulation arrangementMixed flowEngineering

The invention relates to the technical field of fluid distribution, and discloses a flow dividing element which comprises an element body. A plurality of flow dividing through holes are distributed on the element body; the porosity of the element body is 60 percent to 78 percent; and the included angle between the axis of each flow dividing through hole and the normal of the plane where the flow dividing through hole is located is 0 degree to 15 degrees. By controlling the porosity of the flow dividing through holes and setting the forming directions of the flow dividing through holes, a better flow mixing effect can be achieved on fluid, and the fluid flowing through the flow dividing through holes can be evenly and stably mixed; the fluid distributor comprising the flow dividing element is uniform in liquid distribution, so that good uniformity and stability are achieved, and the uniformity and the stability of the fluid distributor can be even superior to the uniformity and the stability of an existing venturi distributor; and furthermore, a heat exchanger adopting the fluid distributor is uniform in flow distribution, and the energy efficiency is improved. Meanwhile, the flow dividing element provided by the embodiment of the invention is simple in structure, easy to machine and form and low in machining cost. The invention further discloses the fluid distributor.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

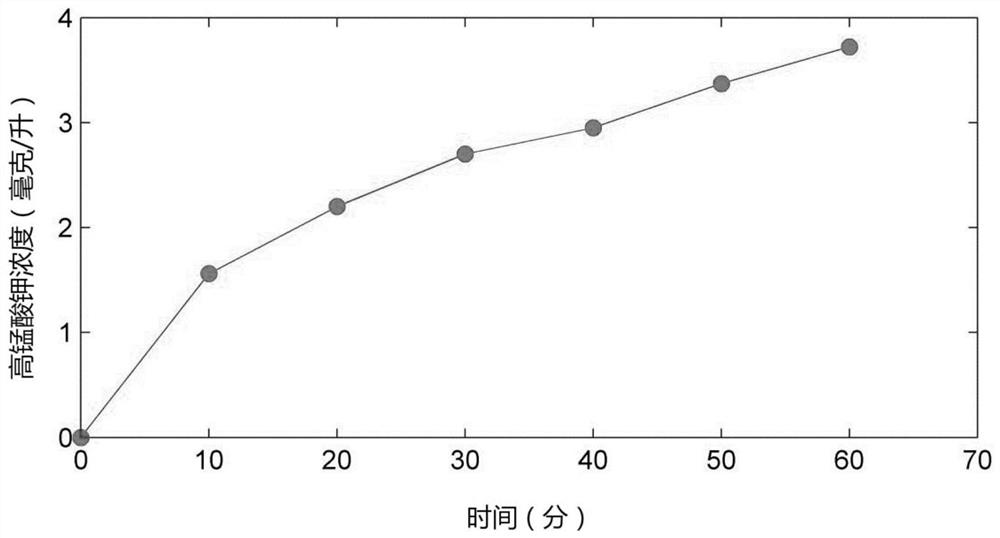

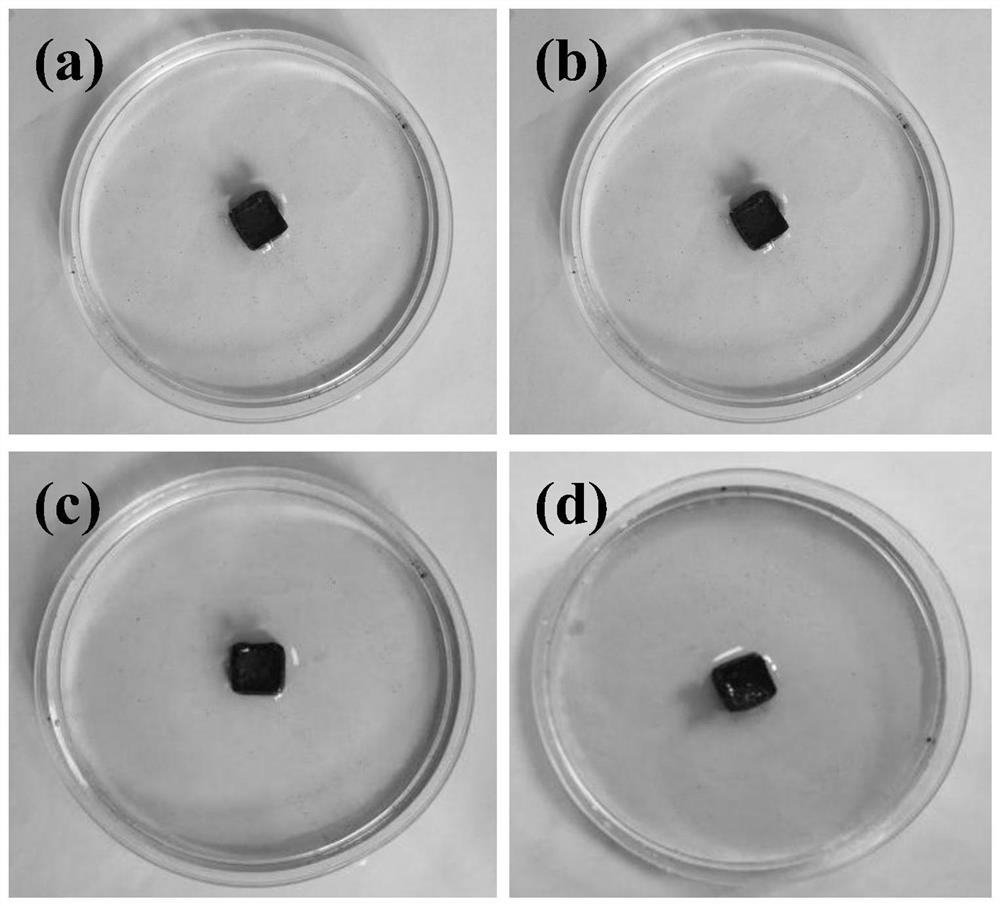

A kind of potassium permanganate sustained-release agent and its preparation method and application

ActiveCN110387242BImprove permeabilityImprove adsorption capacityContaminated soil reclamationOrganic fertilisersActivated charcoal powderActivated carbon

The invention discloses a potassium permanganate sustained-release agent. The potassium permanganate sustained-release agent comprises the following raw materials by mass: 30% to 50% of paraffin, 30%to 50% of quartz sand, 5% to 20% of activated carbon and 5% to 10% of potassium permanganate, summing to 100%. The invention also discloses a preparation method for the potassium permanganate sustained-release agent. The preparation method comprises the following steps of: (1) adding the paraffin into a mixture of absolute ethanol and polyethylene glycol, carrying out heating to 60-80 DEG C, and performing stirring until the paraffin is completely melted; (2) adding a surfactant, the quartz sand, activated carbon powder and potassium permanganate into a solution obtained in the step (1) understirring; and (3) cooling a molten material obtained in the step (2) so as to obtain the potassium permanganate sustained-release agent. The invention also discloses the application of the potassium permanganate sustained-release agent to repairing soil and groundwater contaminated by volatile organic pollutants. The potassium permanganate sustained-release agent has good coating effect, low release rate, good permeability and adsorption performance, and the characteristic of mixed adsorption.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

a blending machine

ActiveCN103526340BMix evenly and stablyHybrid Efficient ImplementationFibre mixingVolumetric Mass DensityEngineering

The invention relates to a textile industry machine, in particular to a cotton blending machine, comprising a cotton blending bin, a cotton inlet and a cotton outlet arranged on the blending bin; the top and bottom of the blending bin are provided with air jet grooves , the air jet groove is provided with an air jet hole; the cotton inlet is divided into an upper cotton inlet and a lower cotton inlet, the upper cotton inlet is located near the top of the cotton mixing warehouse, and the lower cotton inlet is located near the top of the cotton mixing chamber. The position at the bottom of the cotton mixing chamber is described, and an exhaust fan is connected between the cotton inlet and the cotton mixing chamber. After adopting the above structure, cotton products with different densities can be evenly mixed, which improves production efficiency and ensures production quality.

Owner:南通雅日纺织品有限公司

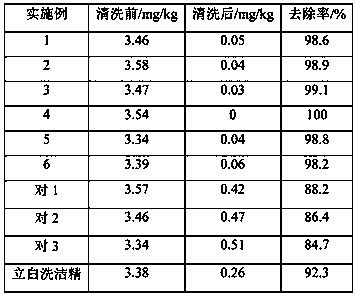

Fruit and vegetable cleaning agent and preparation method thereof

InactiveCN109576083AGood antibacterial effectStrong degreasing abilityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsBetaineClearance rate

The invention discloses a fruit and vegetable cleaning agent and a preparation method thereof. The fruit and vegetable cleaning agent is prepared from, by weight, 15-25 parts of orange peel extract liquid, 5-10 parts of white mulberry bark extract liquid, 1-6 parts of tea polyphenol, 5-10 parts of coconut oil fatty acid diacetyl amide, 10-20 parts of sodium secondary alkyl sulfonate, 6-12 parts ofcocoamidopropyl betaine, 10-20 parts of bamboo carbon powder, 2-5 parts of hydroxyethyl cellulose and 60-80 parts of water. The fruit and vegetable cleaning agent can effectively remove pesticide residues on surfaces of fruits and vegetables by a clearance rate of more than 99.1%, can keep surface freshness of the fruits and the vegetables and can effectively sterilize the surfaces of the fruitsand the vegetables, non-toxic or no harm is caused to human body, cleaning wastewater is pollution-free to the environment, and the fruit and vegetable cleaning agent can be stably preserved for morethan 12 months.

Owner:陈泠伊

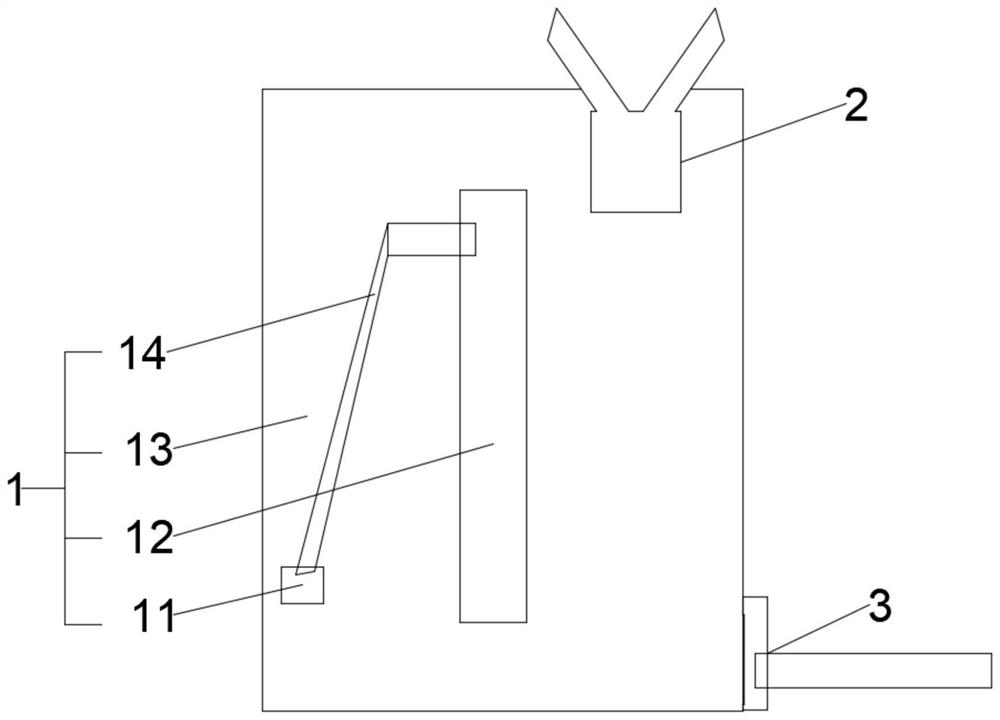

High-polymer uniform and stable air charging device

The embodiment of the invention discloses a high-polymer uniform and stable air charging device. The high-polymer uniform and stable air charging device comprises a first pump, a second pump, a synchronous driving device, a feed pipe, an air inlet pipe and a discharge pipe, and is characterized in that the working volume of the first pump is less than that of the second pump; the synchronous driving device is connected with rotary shafts of the first pump and the second pump correspondingly; the feed pipe communicates with an inlet of the first pump, and an outlet of the first pump communicates with an inlet of the second pump; the air inlet pipe communicates with an inlet of the second pump; and the discharge pipe communicates with an outlet of the second pump. Compared with the prior art, the high-polymer uniform and stable air charging device has the following beneficial effects that the working volume of the first pump is less than that of the second pump; the rotating speeds of the rotary shafts of the first pump and the second pump remain consistent through the synchronous driving device, so that the constant negative pressure is formed in the second pump during operation, and the volume of the air sucked into the device through the air inlet pipe remains stable; and accordingly, bubbles and a matrix are evenly mixed.

Owner:鄂州市德标机械有限公司

Mixing cavity system of wet material system of gypsum board production line

ActiveCN113522076APre-mix wellMix evenly and stablyRotary stirring mixersMixer accessoriesProduction linePhysical chemistry

The invention discloses a mixing cavity system of a wet material system of a gypsum board production line. The system comprises a wet material mixing device connected to a mixing machine and a feeding mechanism connected to the wet material mixing device, and the wet material mixing device is connected with the mixing machine through a discharging mechanism; and the feeding mechanism is used for weighing wet material components and then conveying the weighed wet material components into the wet material mixing device, the wet material mixing device is used for uniformly mixing the wet material components, and the discharging mechanism is used for guiding wet mixed materials which are uniformly mixed by the wet material mixing device into the mixing machine. By arranging the wet material mixing device, wet materials are uniformly pre-stirred and then conveyed into the mixing machine to be mixed with other materials, so that uniformly and stably mixed slurry is obtained, and the product quality is improved.

Owner:北新建材(苏州)有限公司

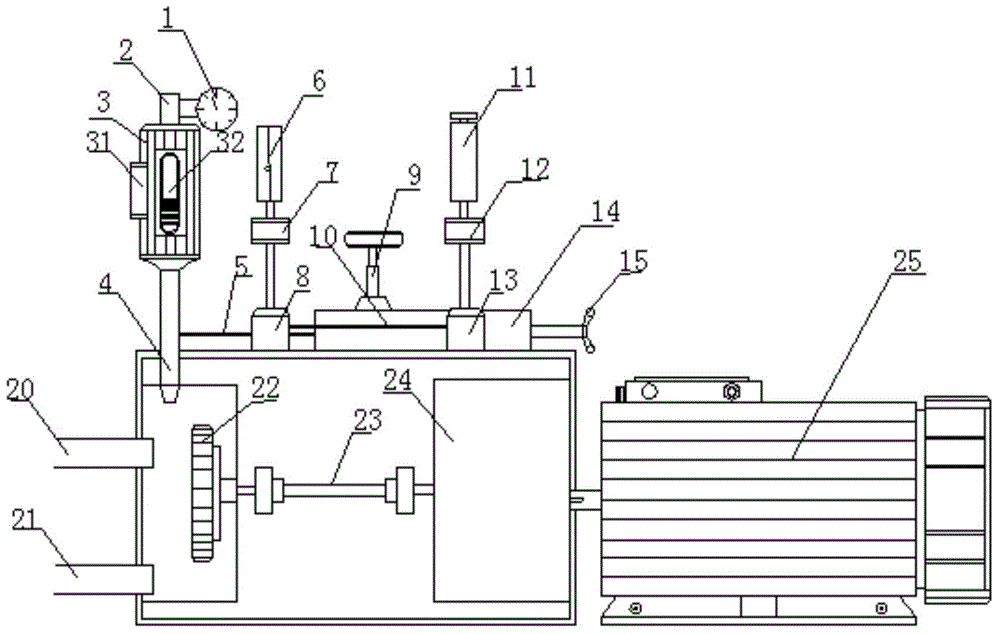

Gas-liquid mixing pump

InactiveCN105435663AWell mixedMix evenly and stablyFlow mixersMixing methodsAutomatic controlTransducer

The invention provides a gas-liquid mixing pump. The gas-liquid mixing pump comprises a pressure gauge, an air intake duct, an automatic control mechanism, an air intake, a connecting pipe, an air chamber, a first pressure measuring port, a pressure meter, a second pressure measuring port, a pressure transducer, a liquid inlet, a liquid outlet, a stirring wheel, a bearing, a gearbox and a motor; the pressure gauge is arranged on the air intake duct and the air intake duct is connected to the automatic control mechanism; the air intake is arranged below the automatic control mechanism, and the automatic control mechanism is connected to the first pressure measuring port and the second pressure measuring port in order by the connecting pipe; the pressure meter is arranged above the first pressure measuring port with connection, and a connecting base is arranged below the first pressure measuring port with connection; the pressure transducer is arranged above the second pressure measuring port with connection, and a connecting base is arranged below the second pressure measuring port with connection; the motor is connected to the gearbox, the bearing and the stirring wheel in order; the liquid inlet and the liquid outlet are arranged at the left side of a pump case. The gas-liquid mixing pump has the beneficial effects that air input can be accurately controlled according requirements of different mixed liquors and self-adjustment of air pressure in the operation process is realized, the air pressure is constant, so that fully mixing of gas and liquid is realized and scrubbing effect is improved.

Owner:WEIHAI CREDITFAN VENTILATOR

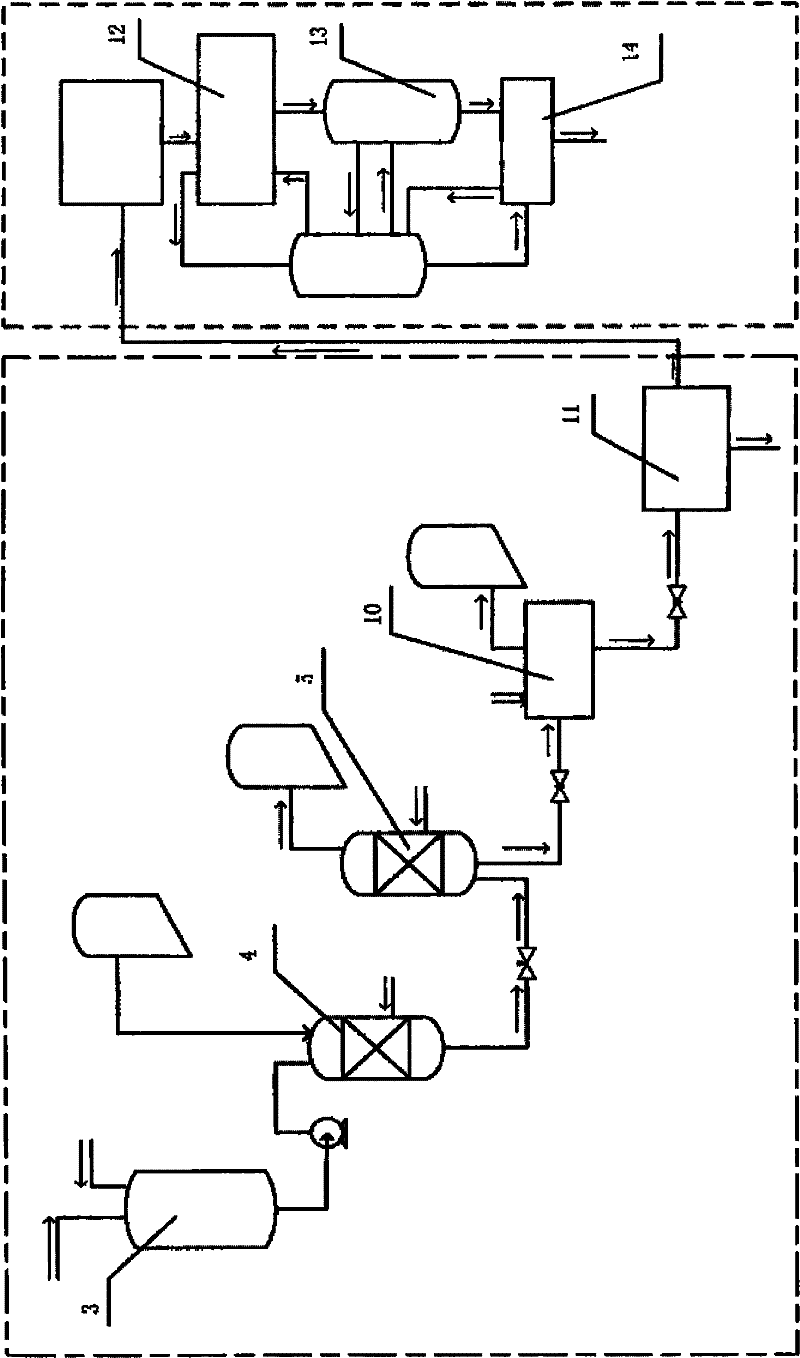

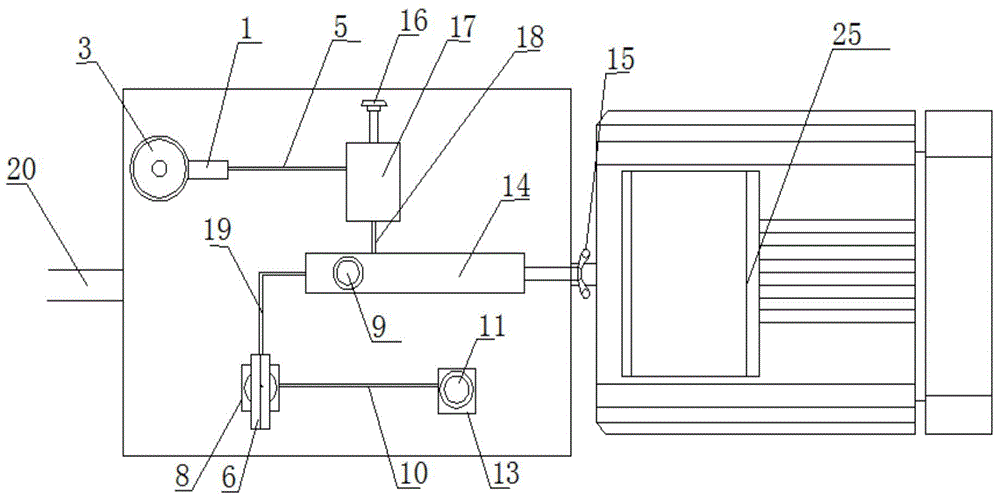

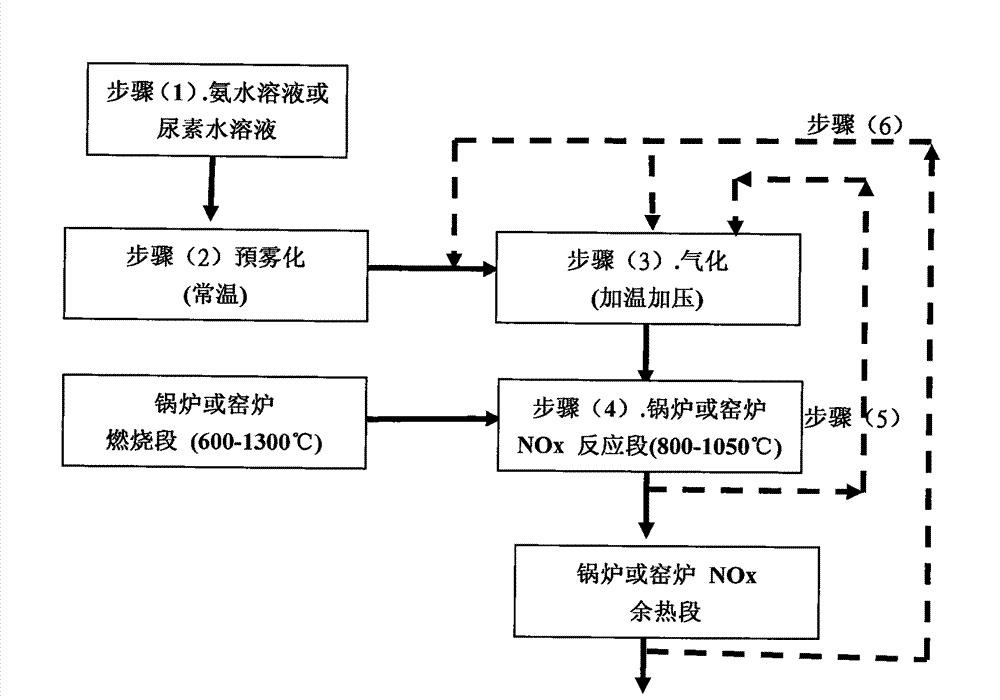

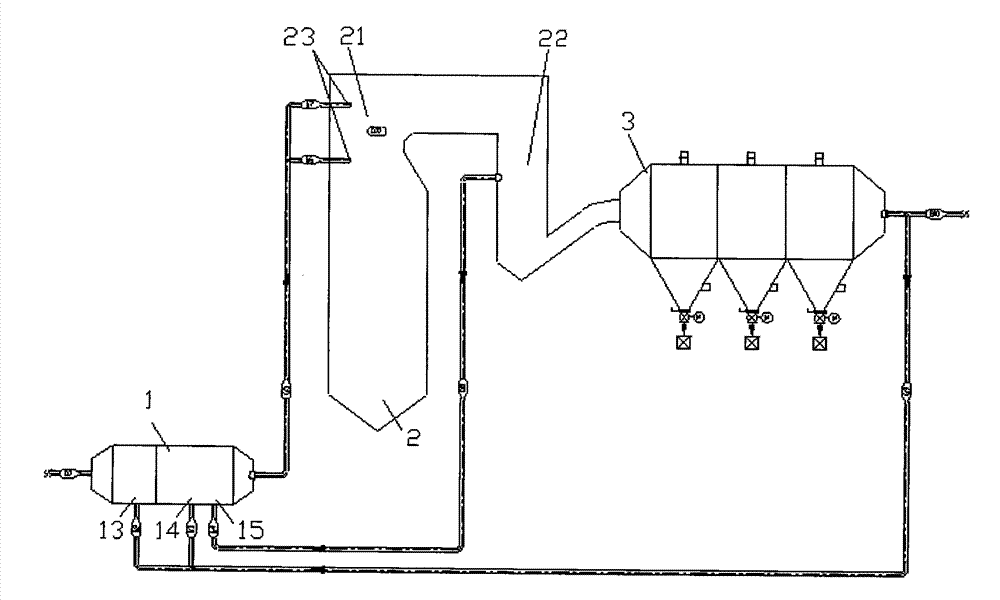

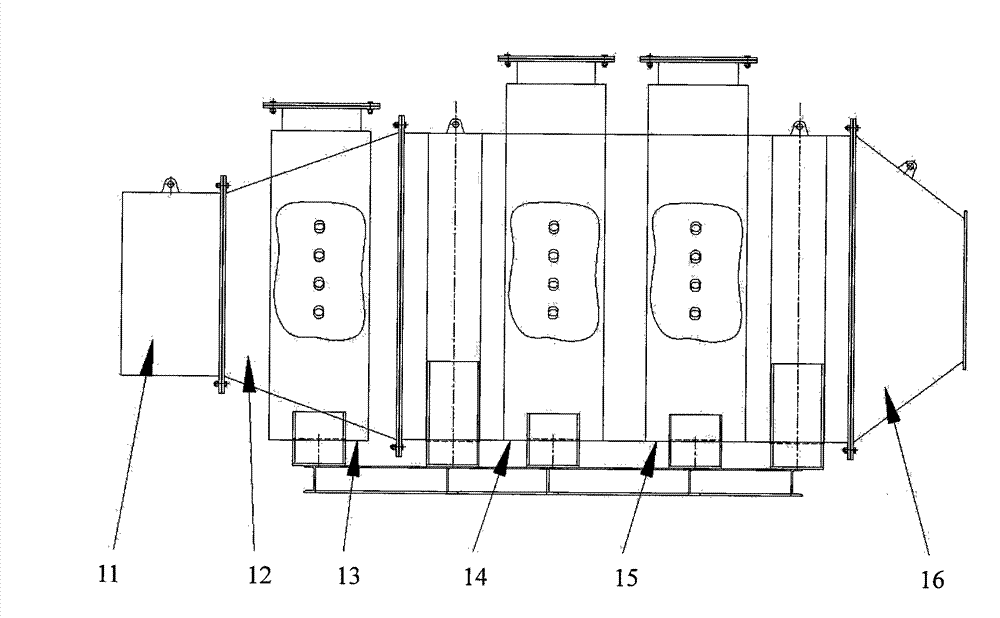

High-efficiency ammonia-method denitration process and device thereof

InactiveCN101890279BMix evenly and stablyExpand the effective reaction temperatureDispersed particle separationReaction temperatureWater content

The invention discloses a high-efficiency ammonia-method denitration process and a high-efficiency ammonia-method denitration device. The process comprises the following steps of: first atomizing in advance the aqueous solution of ammonia or urea solution at the normal temperature, then performing high-temperature gasification and pressurization on the atomized aqueous solution of ammonia or urea solution, spraying the treated aqueous solution of ammonia or urea solution into a denitration reaction area of a smoke generation source, allowing the sprayed aqueous solution of ammonia or urea solution to be fully mixed, contact and react with smoke by using an ammonia temperature-increasing and pressurizing mixer. According to the invention, the atomization and gasification of the aqueous solution of ammonia or urea solution are performed in advance and high-temperature ammonia is introduced into the reaction area of the smoke generation source only after being fully and stably mixed, which improves the denitration effect by about 70 percent, maximally by 85 percent, and raises the effective reaction temperature of conventional selective non-catalytic reduction (SNCR) to 800 to 1,100 DEG C; therefore, the device can be called high-efficiency high-temperature ammonia-method denitration (HE-SNCR) system. Moreover, due to the adoption of ammonia-method selective non-catalytic reduction reaction, the process also can achieve the denitration effect under the condition of high dust thickness, and the denitration effect is better than that of selective catalytic reduction (SCR) or other post-treatment sections (low-dust thickness and low-water content).

Owner:东莞兆能环境科技有限公司 +1

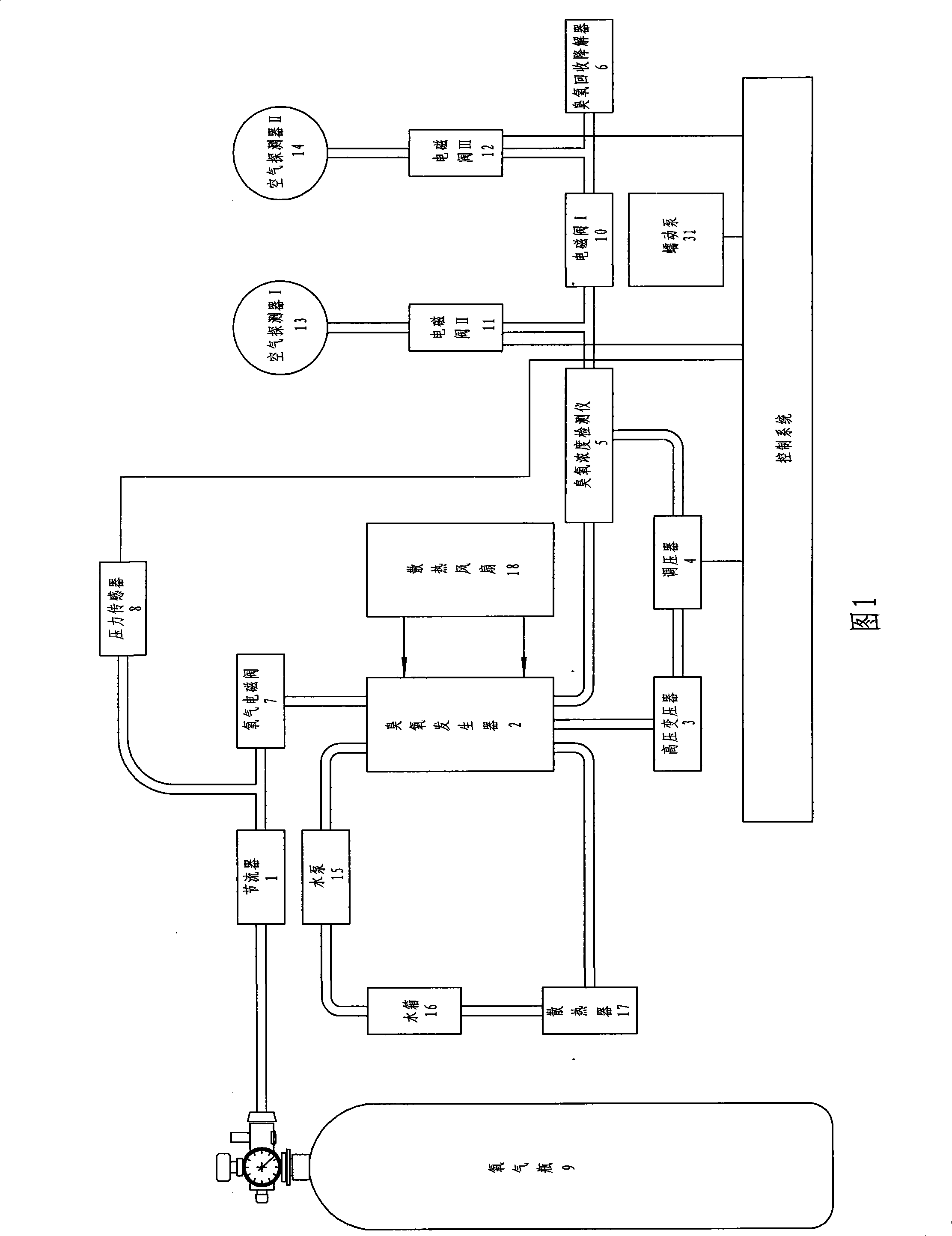

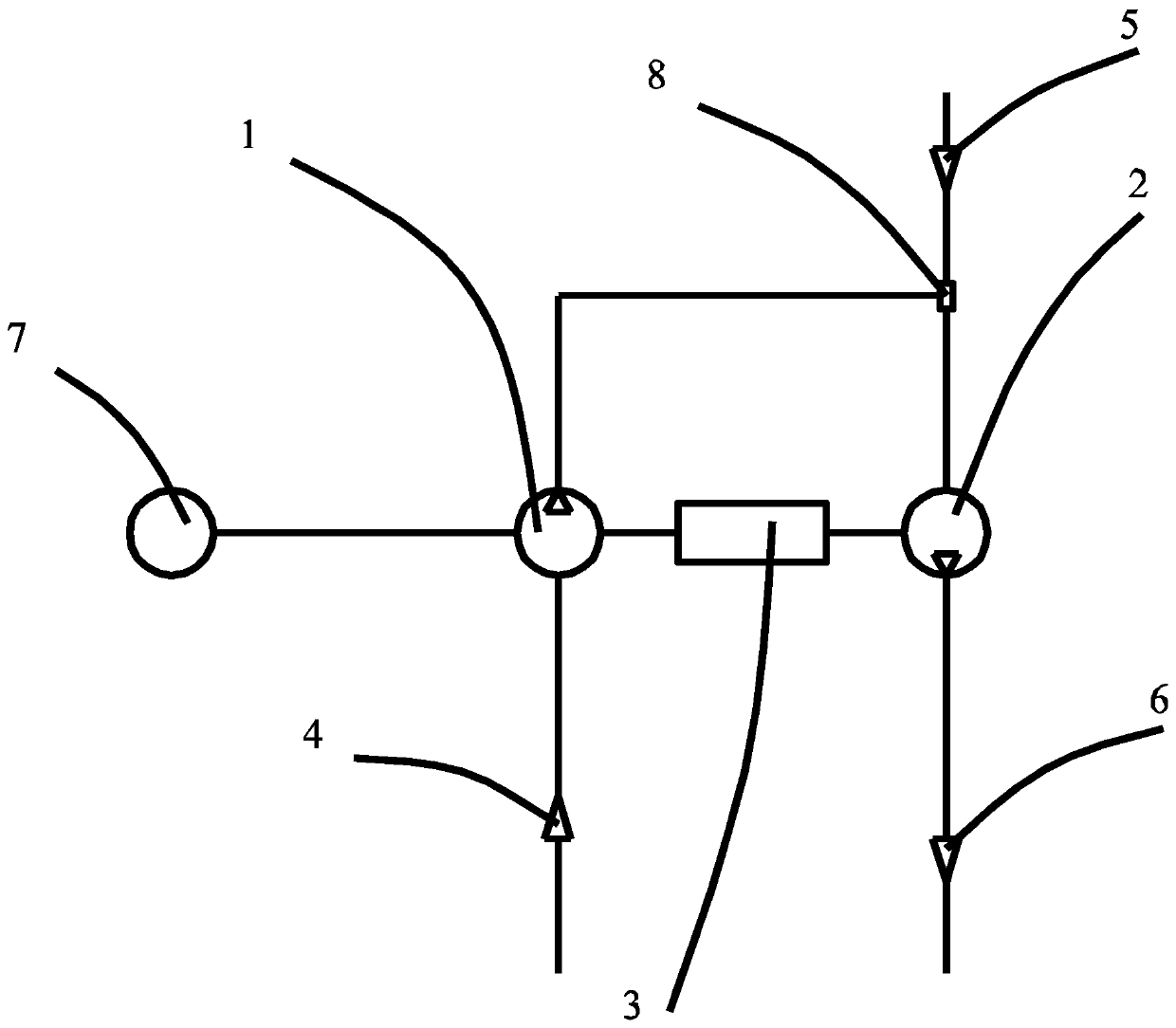

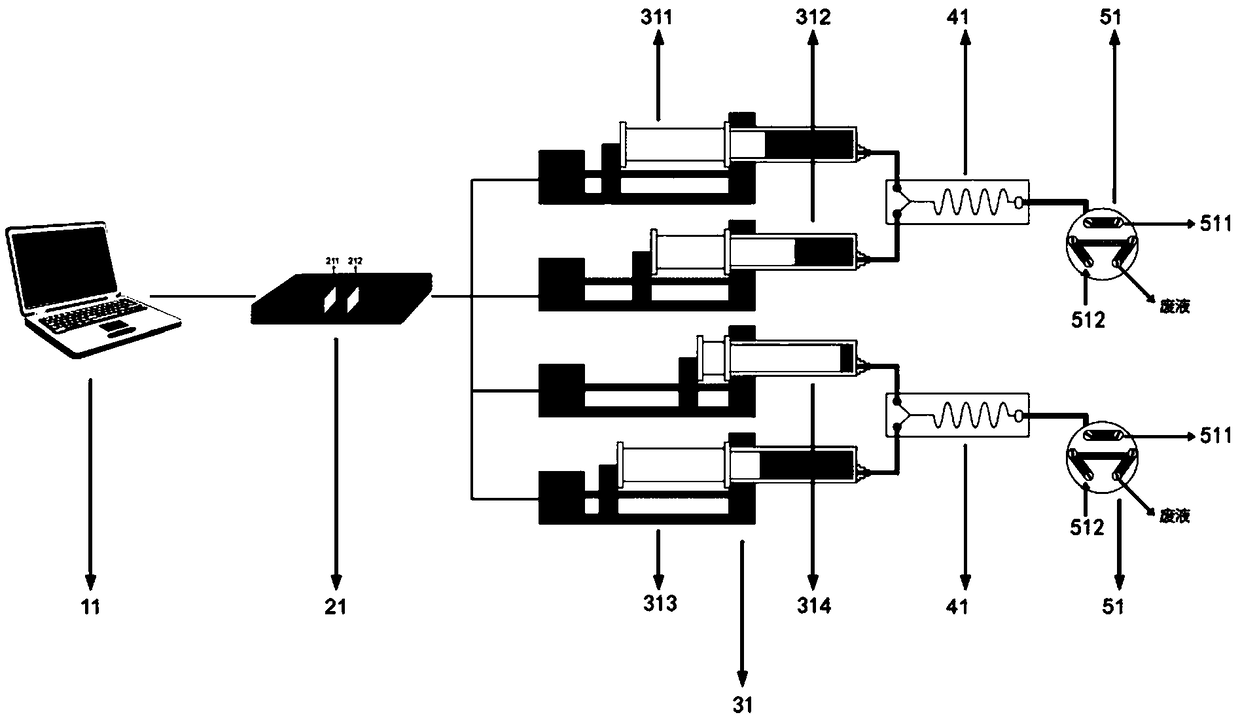

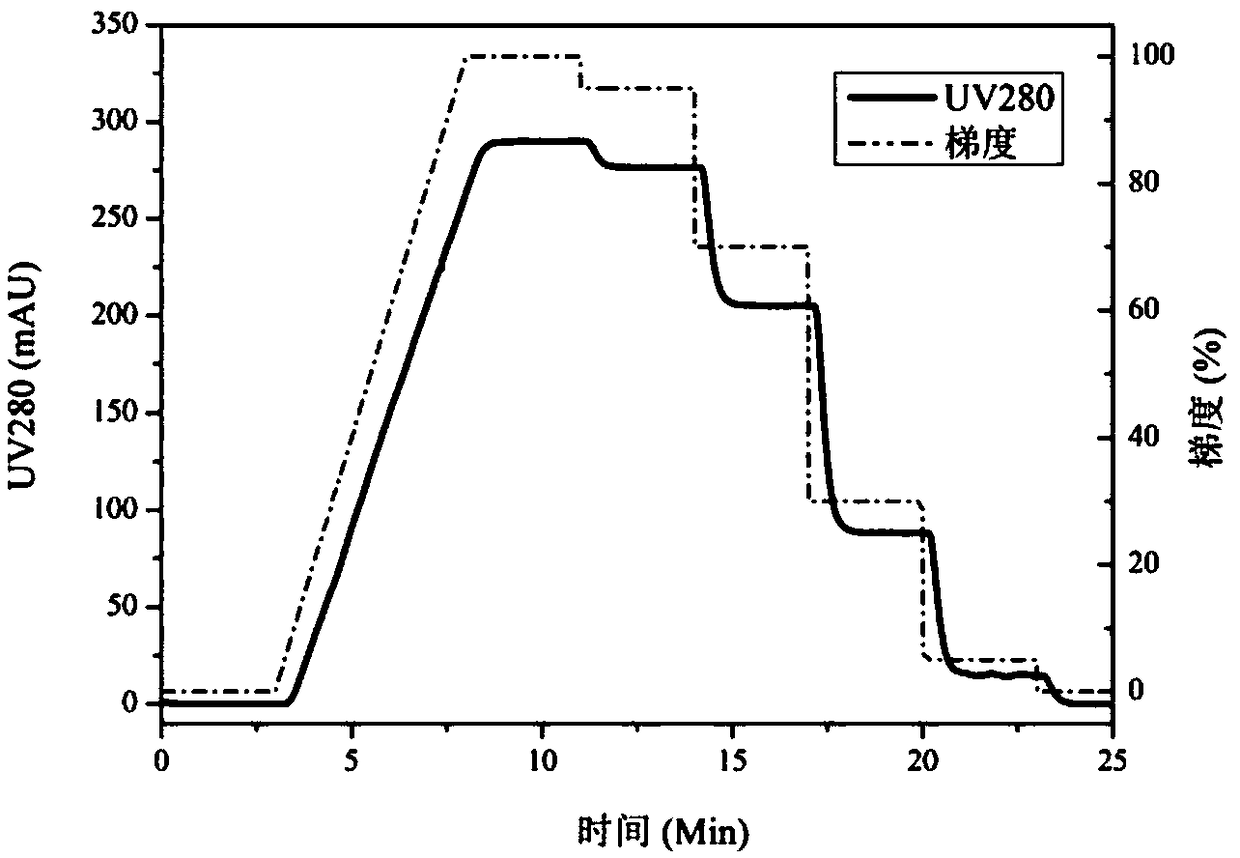

Movable mobile phase control system with double gradient adjustment function and treatment method and application of control system

PendingCN108614033ASatisfy precise injectionMix evenly and stablyAnalysing fluids using sonic/ultrasonic/infrasonic wavesWeighing by absorbing componentControl systemAgricultural engineering

The invention provides a movable mobile phase control system with a double gradient adjustment function, and a treatment method and an application of the control system. The system comprises a controlcomponent, an injection pump group, gradient mixers and introduction valves. The mobile phase control system is suitable as a mobile phase system of an analysis and characterization instrument in a biological material study to simulate a complicated solid-liquid interface environment and is applied to the field of interface analysis, characterization and detection.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Opposite solid particle jet distributor online coke cleaning device

The invention relates to an opposed type solid particle spraying distributor online coke cleaning device. The device main solves the problem in the prior art of the hard removing of coke accumulated in gas cooler tubes. The device includes a solid particle storage tank, an ammonia oxidation reaction gas cooler, a solid particle unloading device, a solid particle spraying distributor and gas-solidseparators; the ammonia oxidation reaction gas cooler includes a hollow upper head and a heat exchange section distributed with the tubes; the upper part of the heat exchange section is provided witha protection plate; the solid particle spraying distributor is placed in the upper head along an axial direction; a solid particle distributor is arranged in an opposed manner at least by more than two nozzles which are in opposed arrangement or inclined at a certain angle; the inlet of inert gas communicates with the solid particle spraying distributor after being parallel with the outlet of thesolid particle storage tank; and the outlet of the cooler is provided with at least one gas-solid separator to recycle solid particles. Thus, the problem can be well solved, so that the device can beused for online coke removing industrial devices.

Owner:CHINA PETROLEUM & CHEM CORP +1

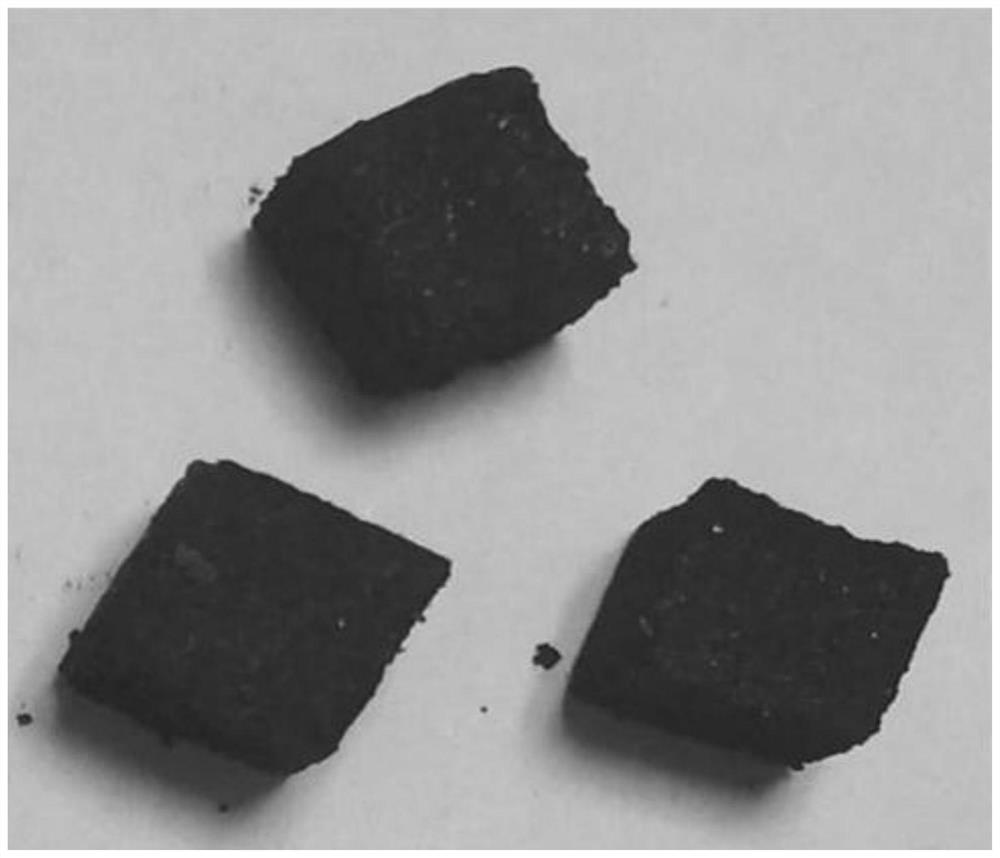

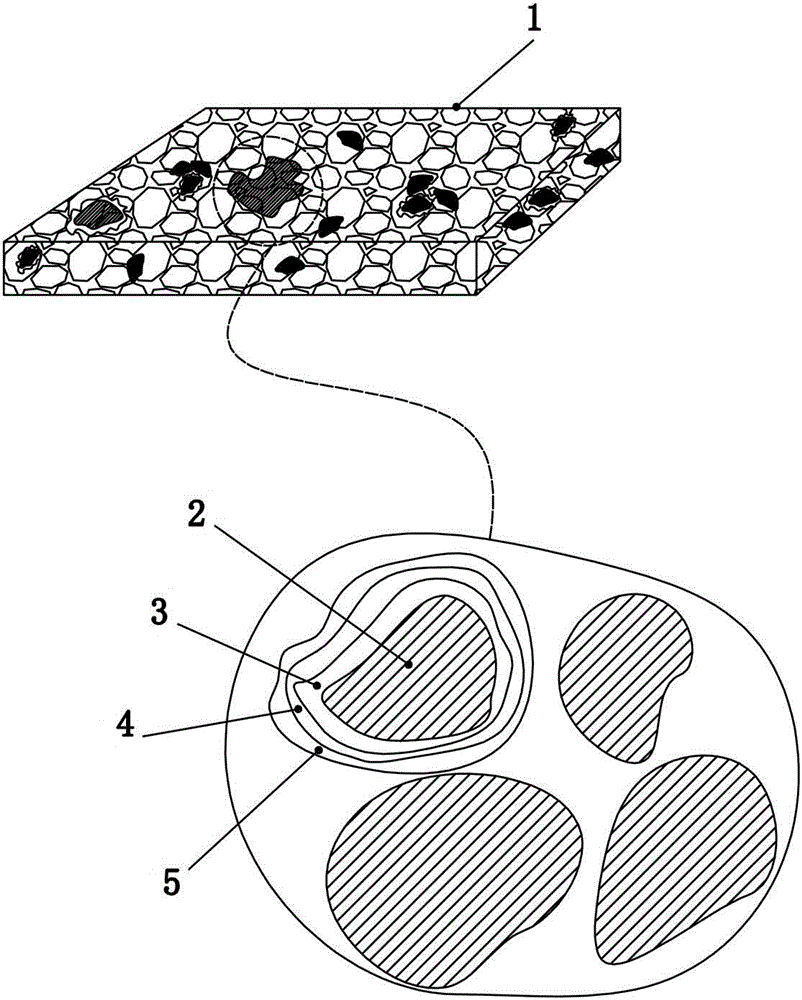

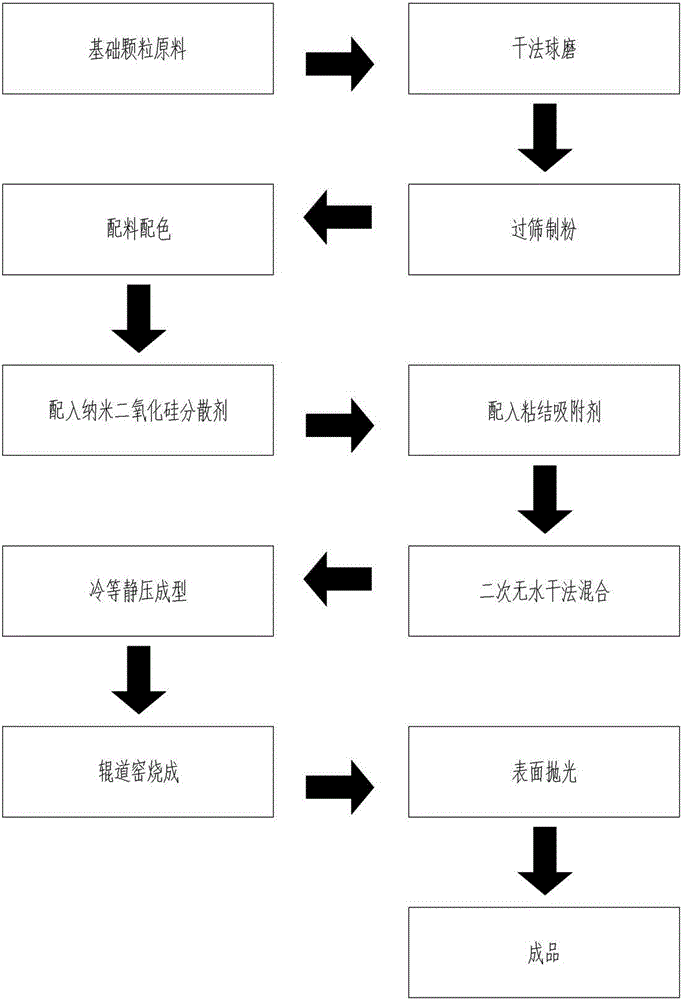

A kind of dry mix tile and production method

ActiveCN103936357BReduce energy consumptionEliminate the need for spray drying powder making processPigmentKiln

The invention relates to a dry-mixed ceramic tile and a production method thereof. A nano dispersing agent material has the properties of small particle size, large specific area, strong surface adsorption force, good dispersing performance and specific thermal resistance and electrical resistance and can be applied to anhydrous dry process mixing technique of ceramic raw materials and pigment, a powder three-dimensional mixing machine is adopted for uniformly mixing powder particles, dry process mixing is carried out on ceramic basis powder particles, pigment, decorative points and other materials, a cold isostatic press is used for moulding green bodies, and the green bodies are fired into the ceramic tile products in a kiln. The production method of the dry-mixed ceramic tile is energy-saving, environmental-friendly and simple and easy to operate, the problems of irregular colours, colour spots and colour blocks of the product are solved, and the product has clear granular sensation and layering effect.

Owner:FOSHAN SANSHUI NEW PEARL CONSTR CERAMICS IND +1

Concrete mixing device for water conservancy engineering

InactiveCN109719847BAchieving stirringThree-dimensional motion trackCement mixing apparatusVertical mixingElectric machinery

Owner:湖南佳伦建筑工程有限公司

Hydraulic engineering ecological slope protection brick and preparation method thereof

PendingCN114086510AImprove cementing performanceAchieve the effect of usingSolid waste managementCoastlines protectionEnvironmental resource managementBrick

Owner:HOHAI UNIV

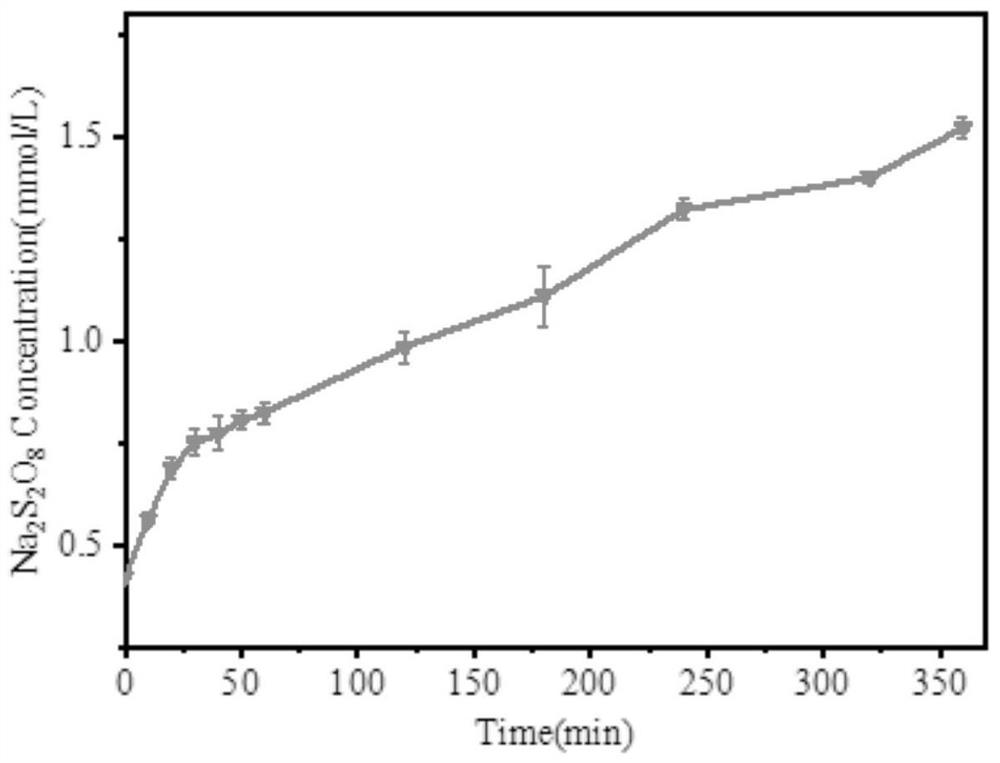

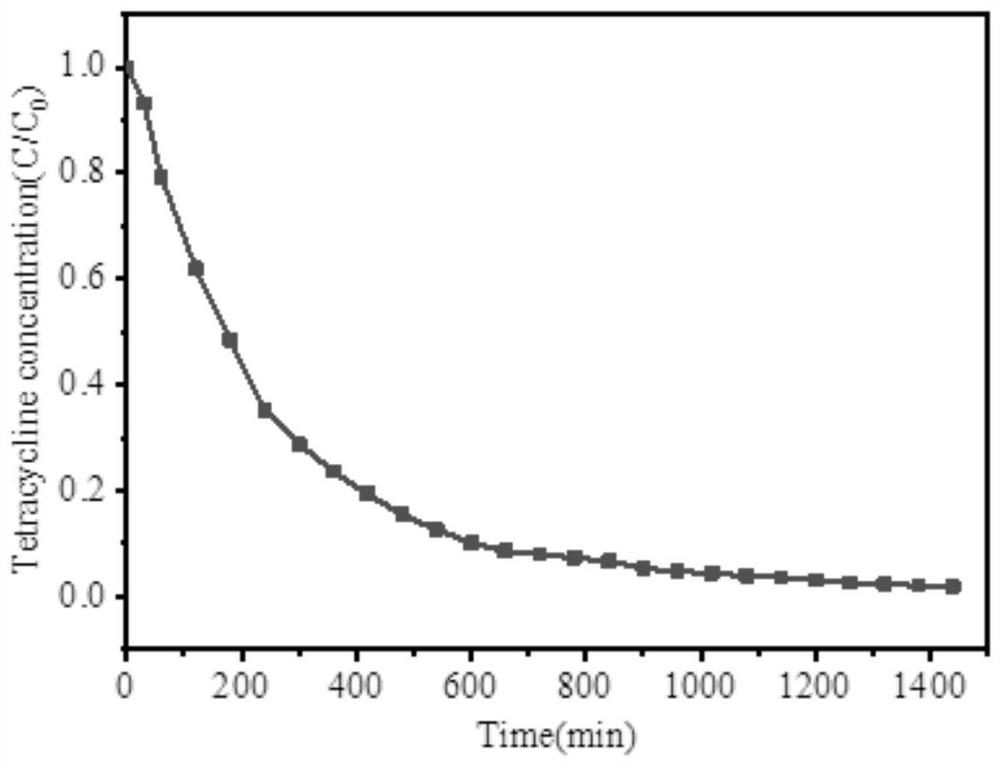

Sodium persulfate sustained-release agent suitable for catalytic oxidation degradation of antibiotics and its preparation and application

ActiveCN113044949BImprove permeabilityImprove adsorption capacityPhysical/chemical process catalystsWater contaminantsActive agentCatalytic oxidation

The invention discloses a sodium persulfate slow-release agent suitable for catalyzing oxidation and degrading antibiotics, its preparation and application in repairing soil and groundwater polluted by antibiotics. The sodium persulfate slow-release agent is based on the total mass of raw materials as 100%. The raw material composition includes: paraffin wax 30%-50%, quartz sand 30%-50%, ordered mesoporous manganese oxide 1%-4%, sodium persulfate 10% % to 20%; the ordered mesoporous manganese oxide is prepared by the hard template method, and the template agent is SBA-15. The preparation method comprises steps: (1) adding paraffin into absolute ethanol, heating to 60-80° C., after the paraffin is completely melted, adding surfactant, quartz sand, ordered mesoporous manganese oxide and Sodium persulfate; (2) cooling the molten state material that step (1) obtains promptly gets sodium persulfate sustained-release agent. The sodium persulfate slow-release agent has good coating effect, low release rate, good permeability and adsorption, and good oxidative degradation characteristics.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com