Movable mobile phase control system with double gradient adjustment function and treatment method and application of control system

A technology of control system and processing method, which is applied in the direction of using material absorption and weighing, using sonic/ultrasonic/infrasonic waves to analyze fluids, and using sonic/ultrasonic/infrasonic waves for material analysis, etc. Slow development and other problems, to achieve the effect of meeting the requirements of the connection interface, easy maintenance, and high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

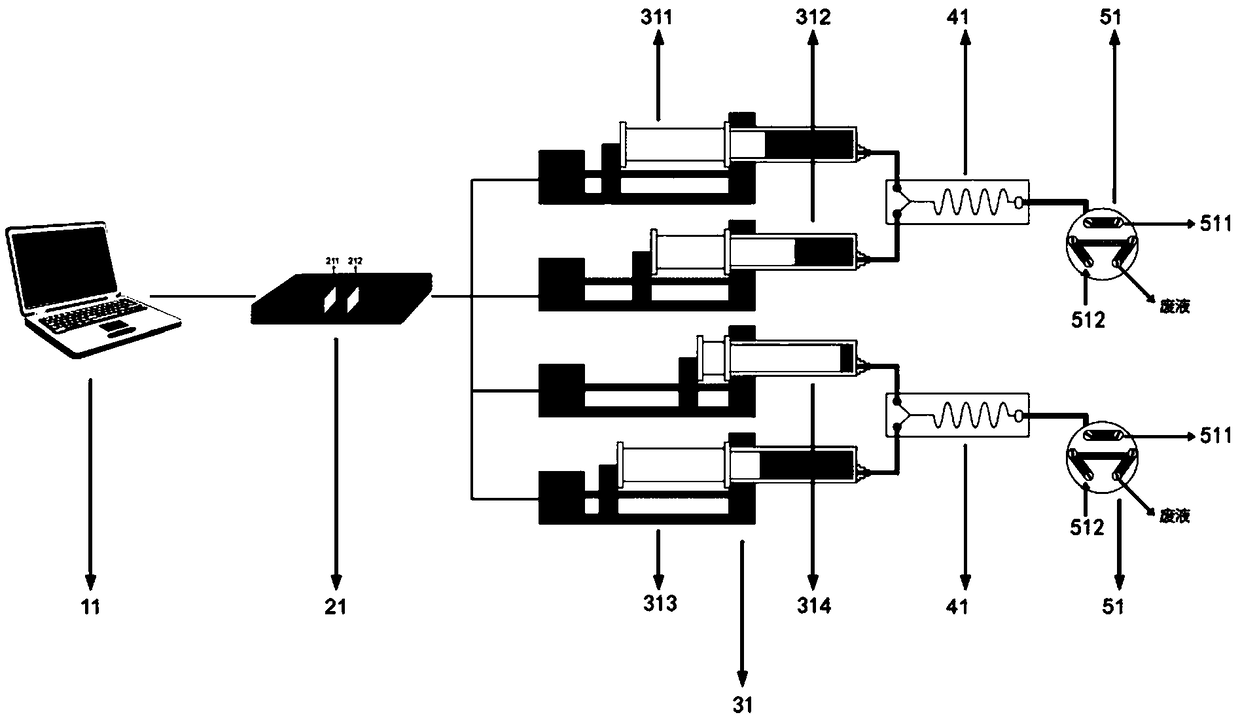

[0055] This embodiment provides a mobile phase control system with dual gradient adjustment function and its processing method, the system is as figure 1 As shown, it includes a control assembly, a syringe pump group 31 , a gradient mixer 41 and a sampling valve 51 connected in sequence.

[0056] Wherein, the control assembly includes a control device 11 and a main controller 21 connected in sequence, the control device 11 and the main controller 21 are connected by a network cable, the control assembly and the injection pump group 31 are connected by an electronic circuit, and the injection pump group 31. The gradient mixer 41 and the sampling valve 51 are sequentially connected through a liquid connecting pipe.

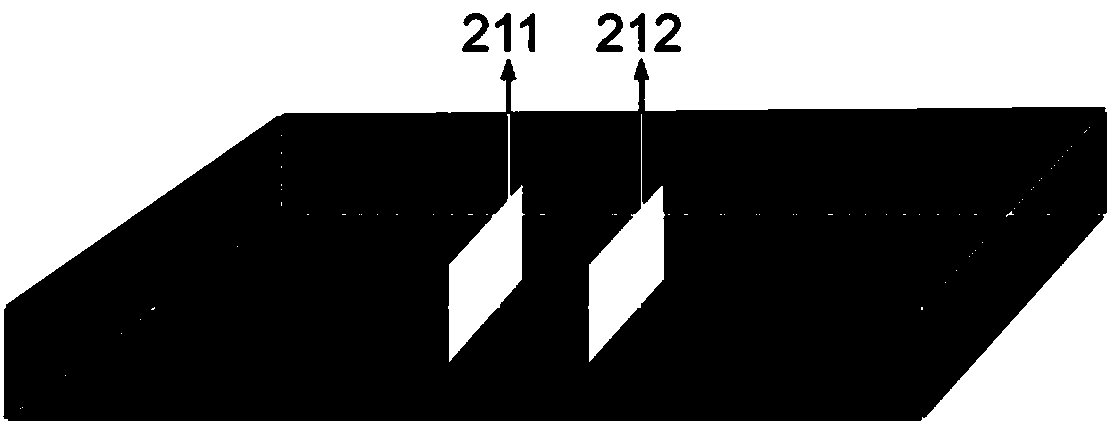

[0057] Described control device 11 selects computer for use, and main controller 21 is made up of core control board 211 and IO board 212, as figure 2 As shown, the core control board 211 and the IO board 212 are integrated together, wherein the core control board...

Embodiment 2

[0068] This embodiment provides a mobile phase control system with dual-gradient adjustment functions and its processing method. The structure and processing method of the system refer to Embodiment 1, the difference is that the single-channel syringe pump is a split type syringe pump, The volume of the syringe is 0.5 mL.

Embodiment 3

[0070] This embodiment provides a mobile phase control system with dual gradient adjustment functions and its processing method. The structure and processing method of the system refer to Embodiment 1, except that the volume of the syringe is 200 mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com