Patents

Literature

80 results about "Interface analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Interface analysis. (testing) A software test which checks the interfaces between program elements for consistency and adherence to predefined rules or axioms.

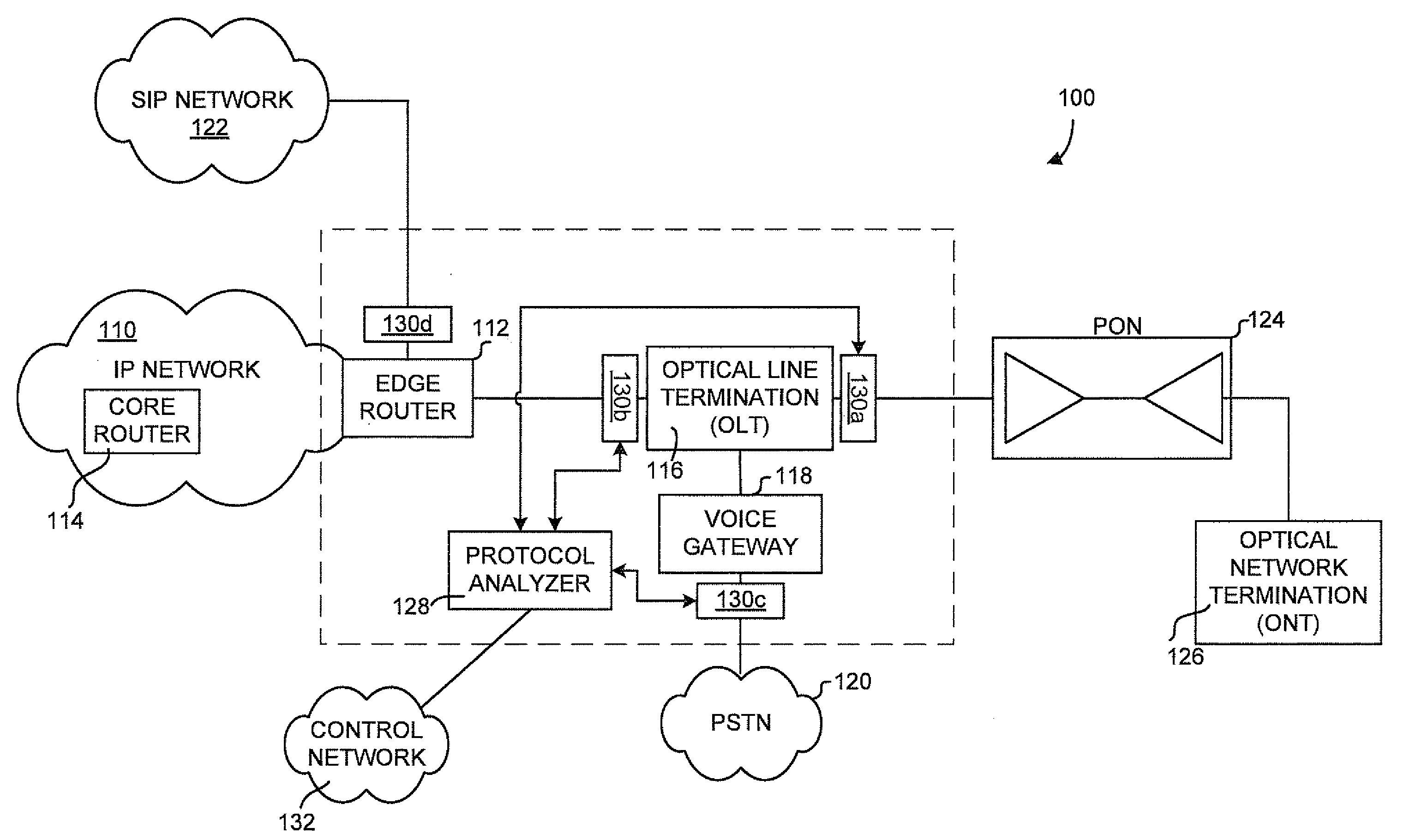

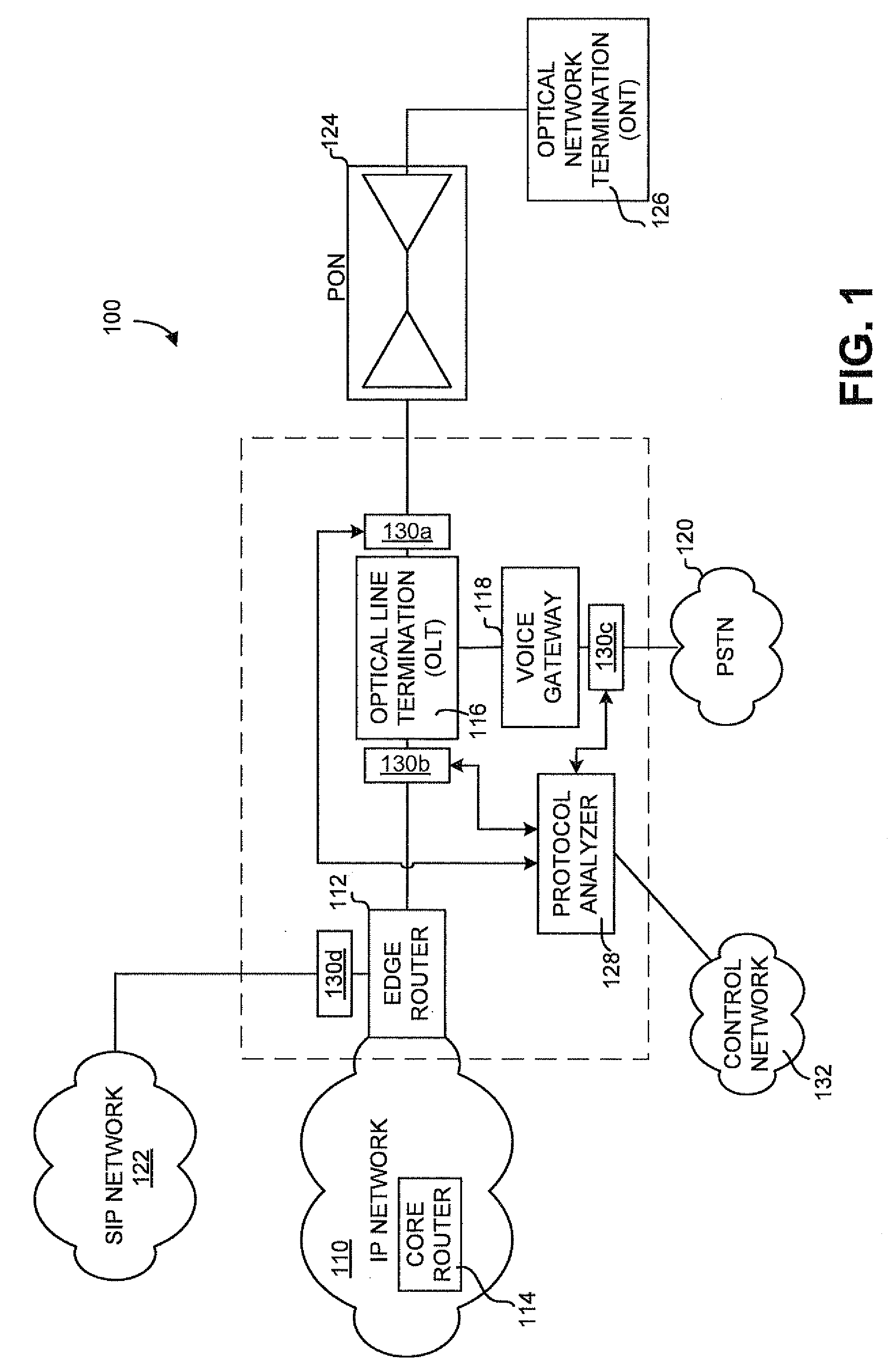

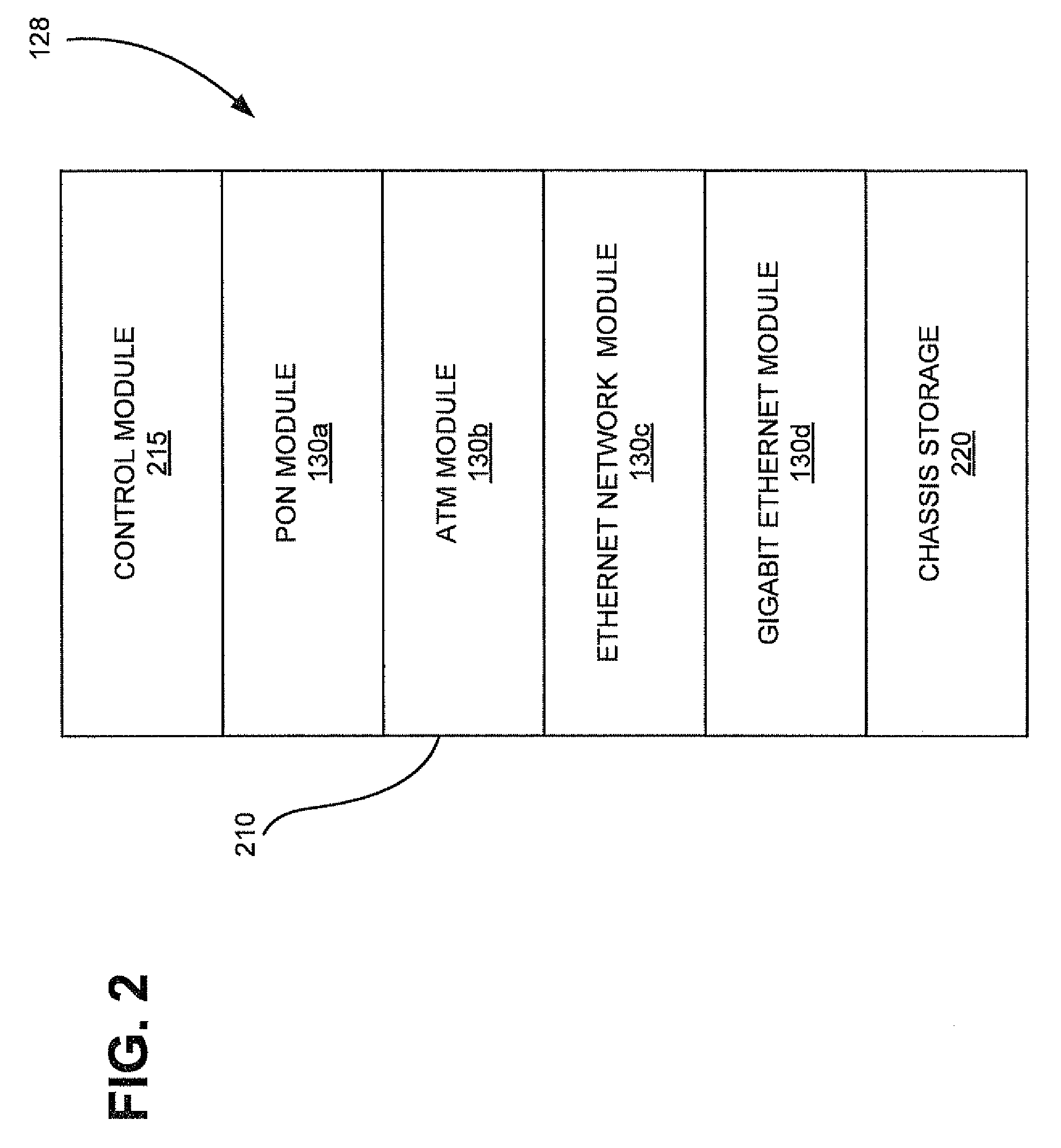

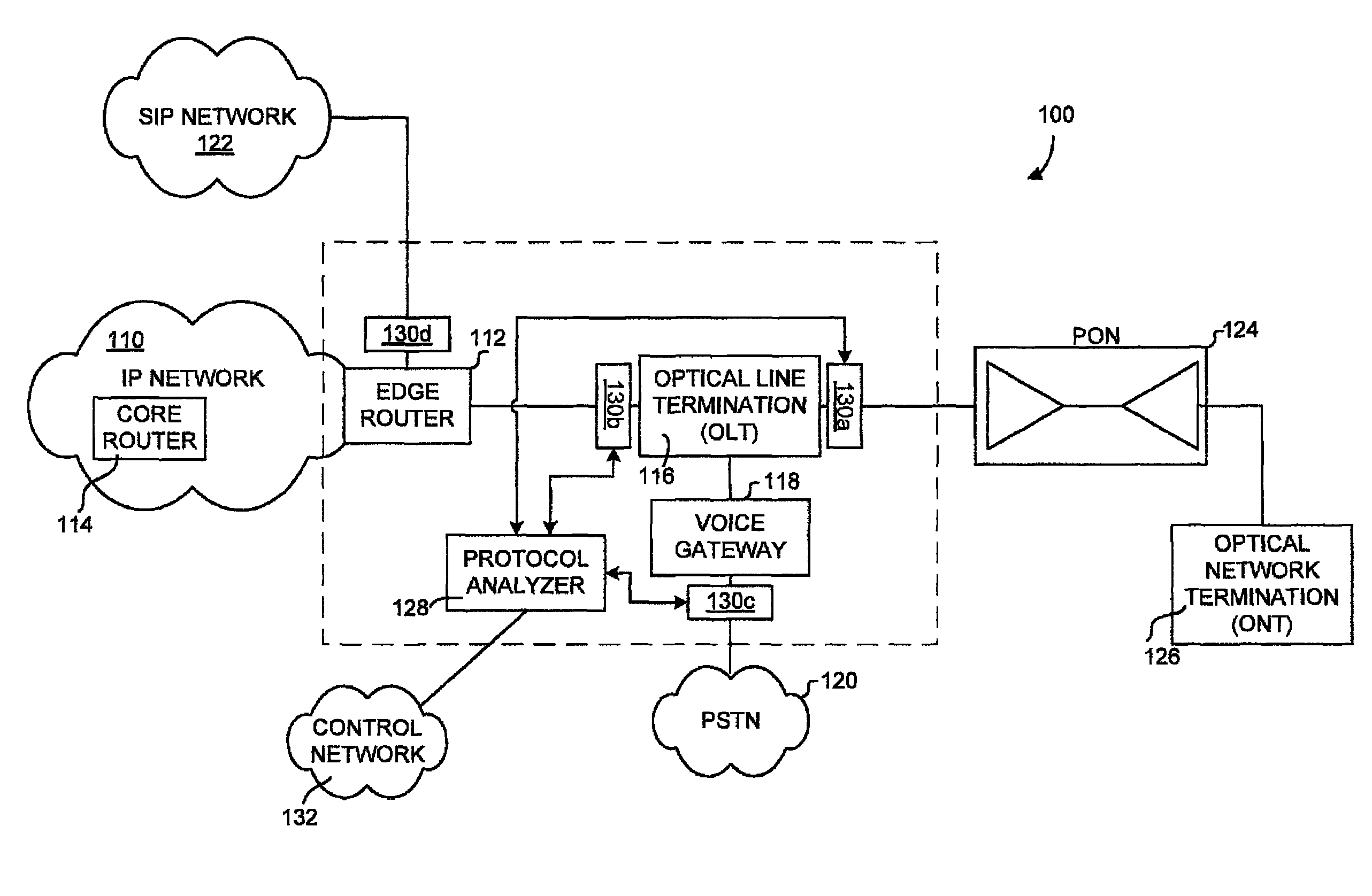

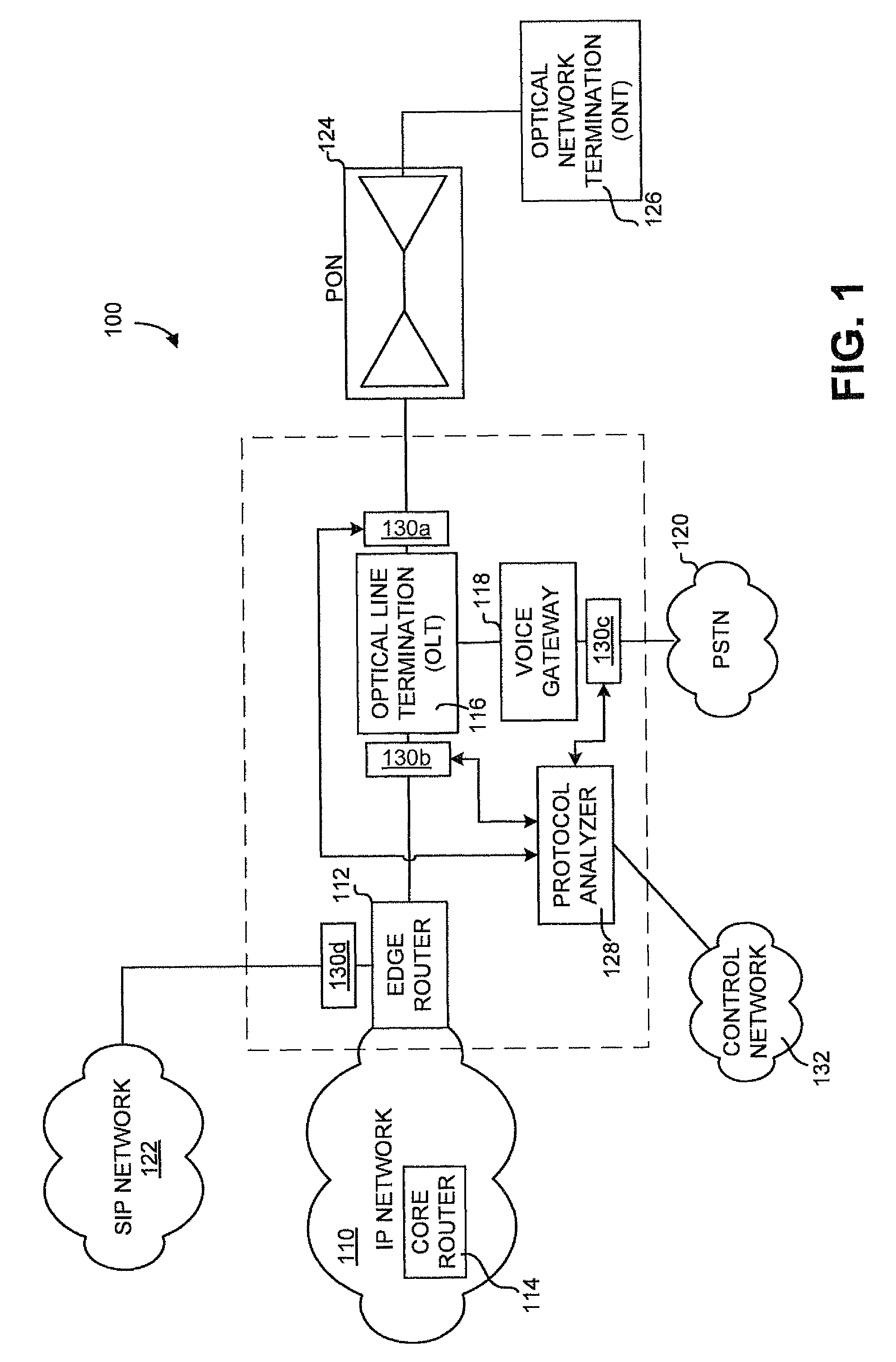

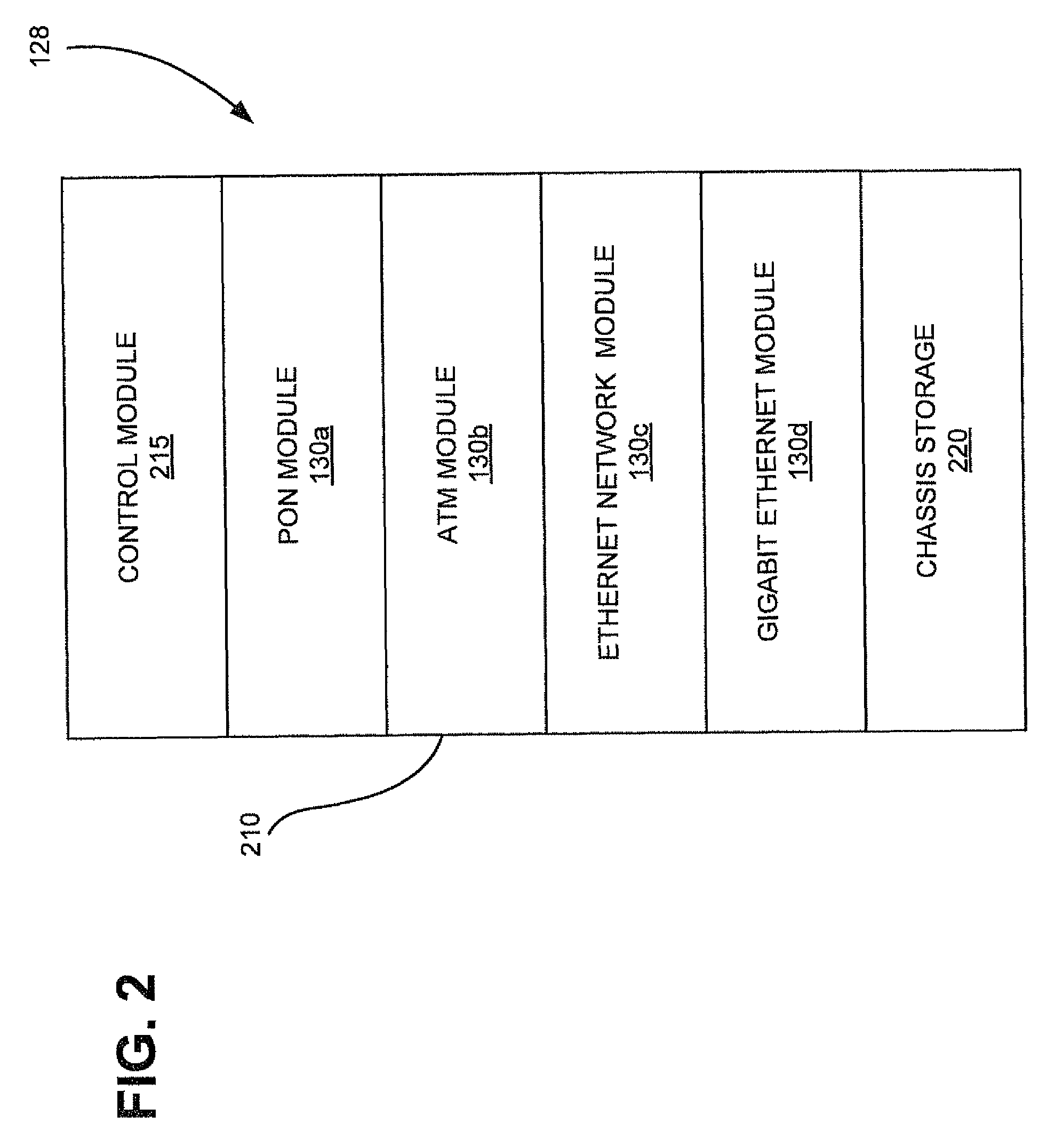

Multi-interface protocol analysis system

A device may include a first network module to capture network data at a first location in a network and a second network module to capture network data at a second location in the network different from the first location in the network. The device may include a control module to receive control commands relating to the first network module and the second network module. The control module may forwarded the control commands to the first network module and the second network module. The control module may receive the captured network data from the first network module and the second network module.

Owner:VERIZON PATENT & LICENSING INC

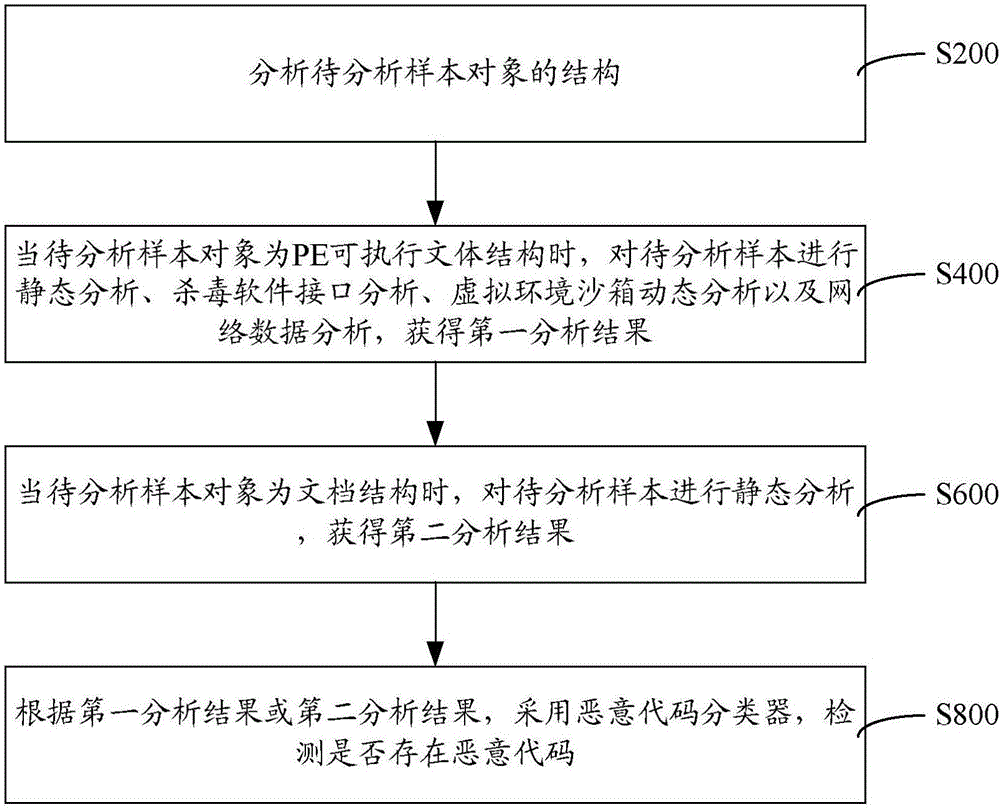

Malicious code detection method and system

InactiveCN106778268AReliable analysis and identification abilityPlatform integrity maintainanceStatic timing analysisData profiling

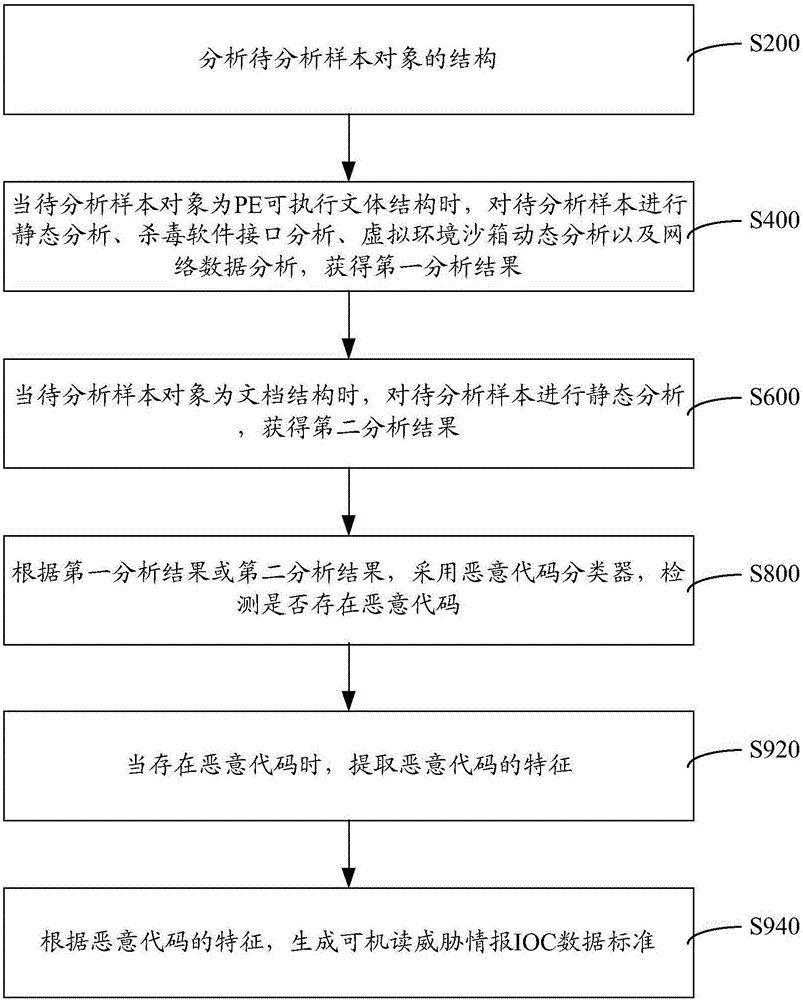

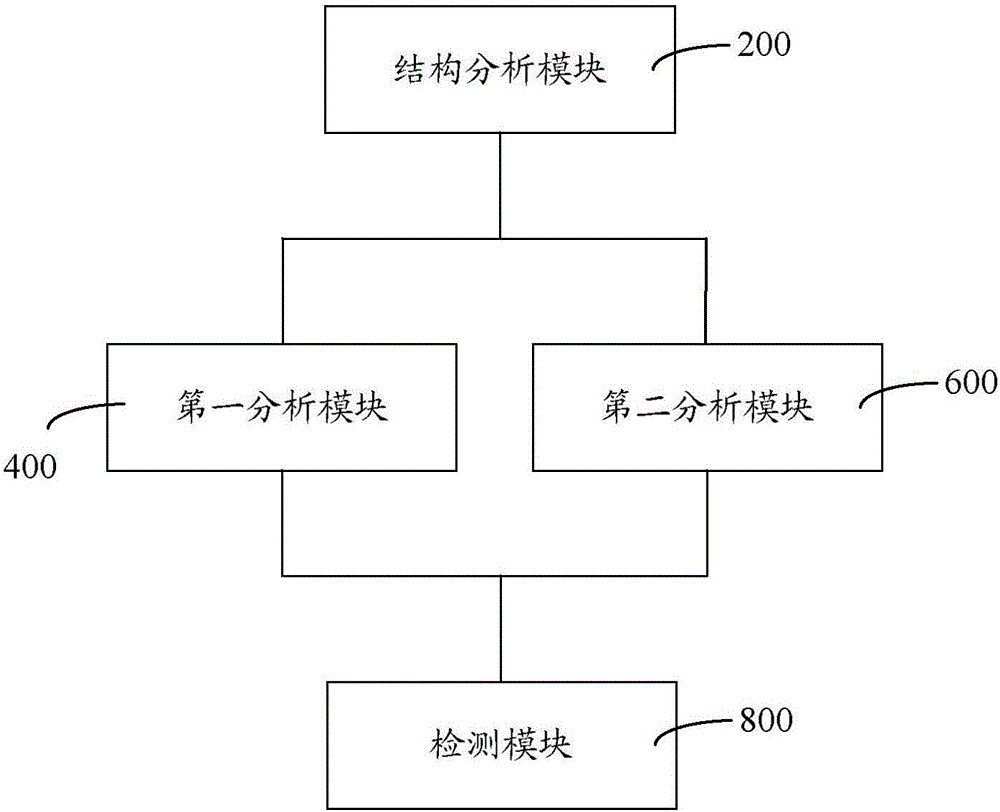

The invention provides a malicious code detection method and system. The malicious code detection method comprises the following steps: analyzing a structure of a to-be-analyzed sample object; when the to-be-analyzed sample object is of a PE executable stylistic structure, performing static analysis, antivirus software interface analysis, dynamic virtual environment sandbox analysis and network data analysis on the to-be-analyzed sample object and obtaining a first analysis result; when the to-be-analyzed sample object is of a text structure, performing static analysis on the to-be-analyzed sample object and obtaining a second analysis result; detecting whether a malicious code exists or not by adopting a malicious code classifier according to the first analysis result or the second analysis result. In the whole process, data structures of different sample object types are analyzed; static analysis, antivirus software interface analysis, dynamic virtual environment sandbox analysis and network data analysis are adopted; the analysis and identification abilities are reliable, and a source of a network attack incident can be traced.

Owner:广东省信息安全测评中心 +1

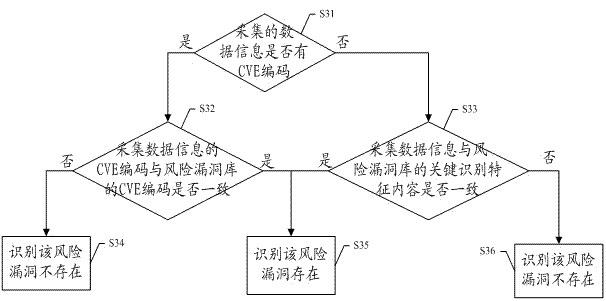

Method and system for automated information security evaluation

ActiveCN102354310AObjective analysisAutomation and intelligenceSpecial data processing applicationsRisk levelEvaluation system

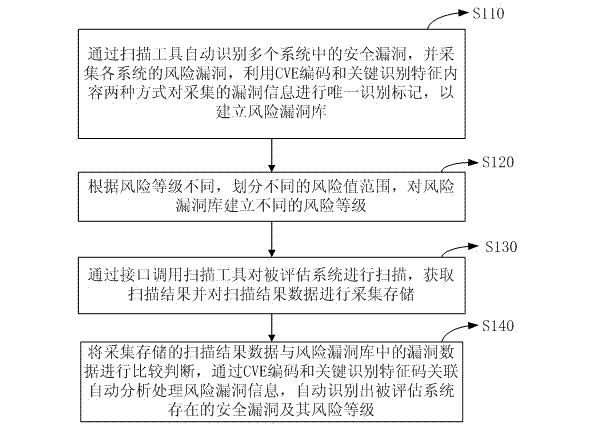

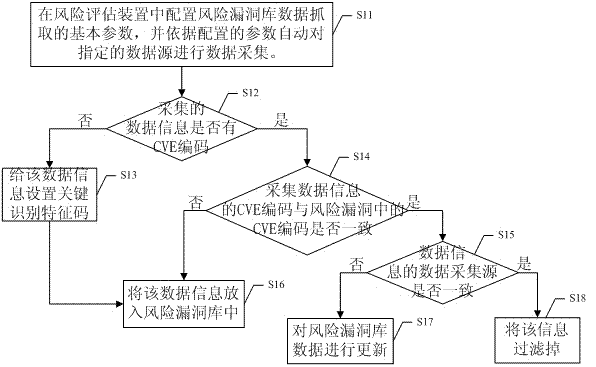

The invention discloses a method and a system for automated information security evaluation. The method includes the following steps: creating a risky leak library; creating the risk levels of the risky leak library; utilizing an interface call-scanning tool to scan an evaluated system, and acquiring and storing scanning result data; comparing the acquired scanning result data with the leak data in the risky leak library for judgement, and identifying security leaks and risk levels thereof existing in the evaluated system. Since the method and the system for automated information security evaluation provided by the invention adopt the scanning tool to directly carry out interface analysis and read the scanning result data of the scanning tool, the invention can carry out complete, objective and intelligent data analysis on scanning results by means of a security mapping identification mechanism of the evaluation system, thus guaranteeing accuracy, increasing the working efficiency andreducing the manpower cost.

Owner:GUANGDONG POWER GRID CO LTD INFORMATION CENT

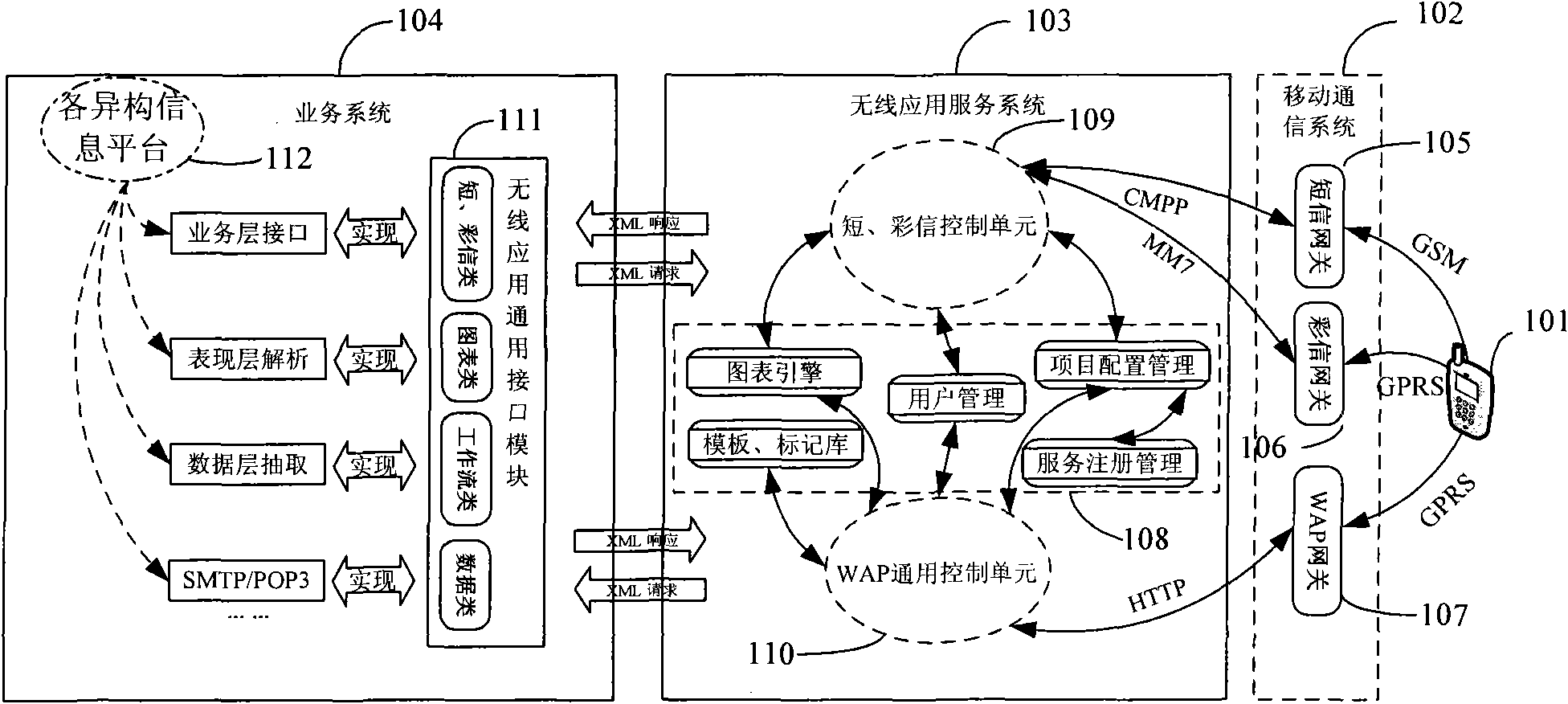

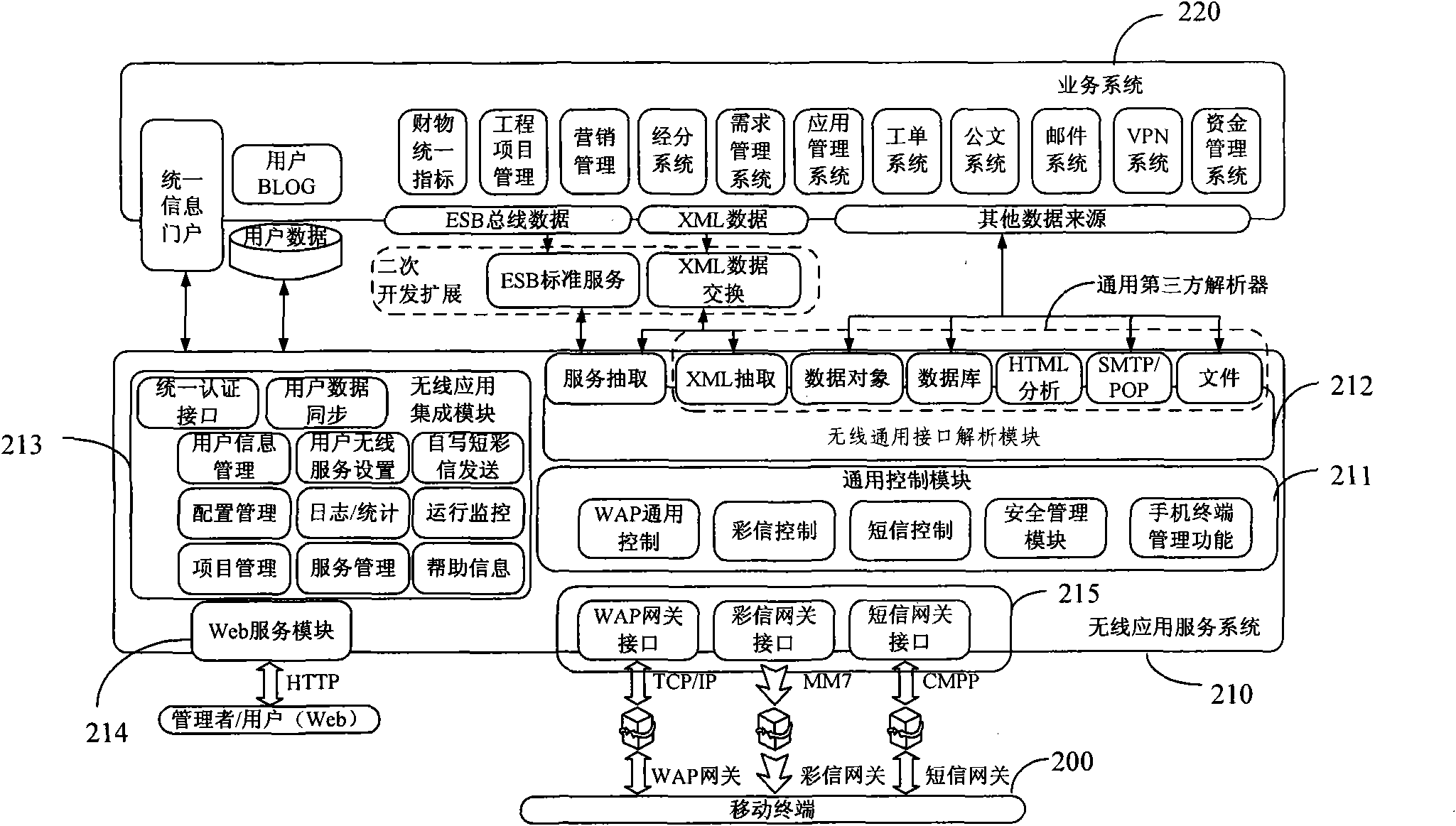

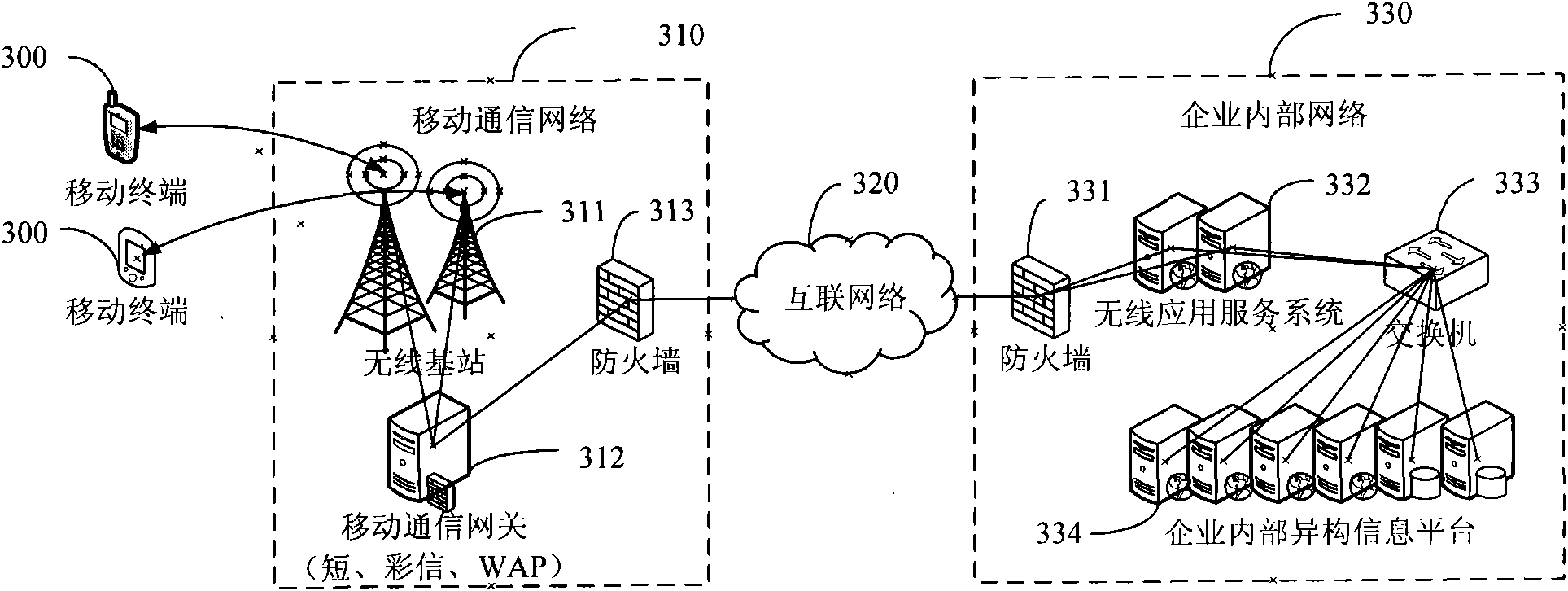

Mobile office system and implementation method thereof

ActiveCN102082992AAchieve sharingWireless commuication servicesSecurity arrangementWireless Application ProtocolInterface standard

The invention discloses a mobile office system, comprising a mobile communication system, a service system and a wireless application service system, wherein the mobile communication system, the service system and the wireless application service system are provided by a mobile operator; the service system comprises a wireless application universal interface module and more than one heterogeneousinformation platform; and the wireless application service system comprises an enterprise wireless gateway, a universal control module, a wireless application integrated module and a wireless universal interface analysis module. The invention also discloses an implementation method of mobile officing. According to the invention, the wireless application service system is arranged between the mobile communication system provided by the mobile operator and multiple types of heterogeneous information platforms in an enterprises network, thus providing uniform interface standards and functional supports for the multiple types of heterogeneous information platforms, and carrying out data exchange with the mobile communication system, thereby implementing sharing and loose coupling integration of a large number of heterogeneous information systems in an enterprise for short messages, multimedia messages, Push, wireless application protocols (WAP) and other wireless service means.

Owner:SHANXI CHINA MOBILE COMM CORP

Health state assessment method of retired electric automobile power cell

InactiveCN105988085AQuick checkAssess health statusElectrical testingCharge retentionStructure analysis

The invention provides a health state assessment method of a retired electric automobile power cell. The method comprises the steps of: carrying out basic performance detection, cell key performance sampling detection and cell internal characteristic detection on the retired electric automobile power cell, wherein the basic performance detection comprises cell appearance detection, cell open-circuit voltage and internal resistance detection, cell capacity and energy detection, and cell charge retention detection; the cell key performance sampling detection comprises cell life characteristic detection, cell environment adaptability detection, cell multiplying power characteristic detection and cell safety performance detection; and the cell internal characteristic detection comprises electrode slice form and material combination condition analysis, diaphragm form and aged condition analysis, material crystal structure analysis and composition analysis, material available capacity and electrochemistry cycling performance analysis, and electrode surface solid electrolyte interface analysis. By adopting the method, the basic parameters of the cell are comprehensively detected, sampling detection is carried out on the key parameters and internal characteristics of the cell, and the health state of the cell is accurately evaluated.

Owner:STATE GRID CORP OF CHINA +3

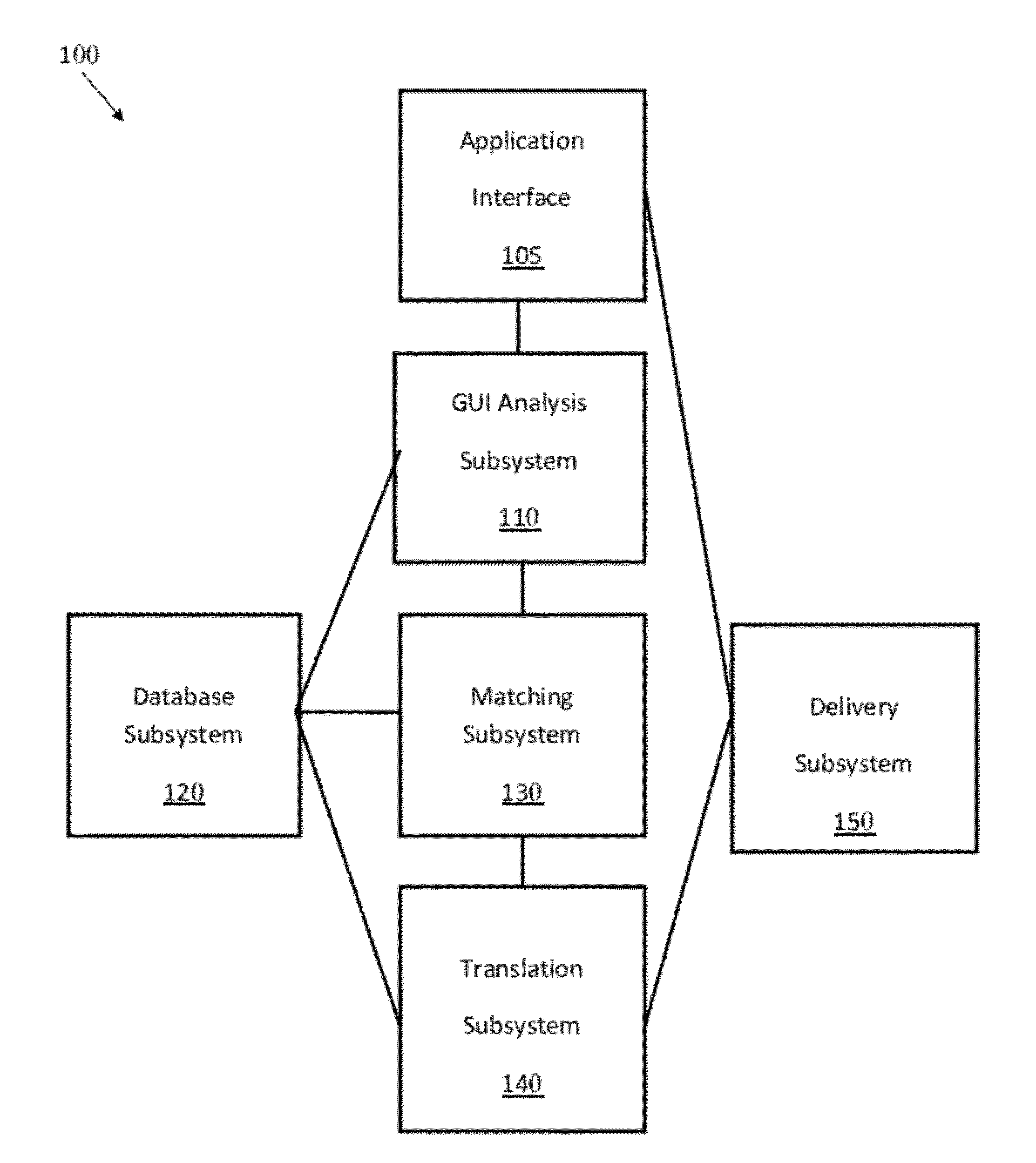

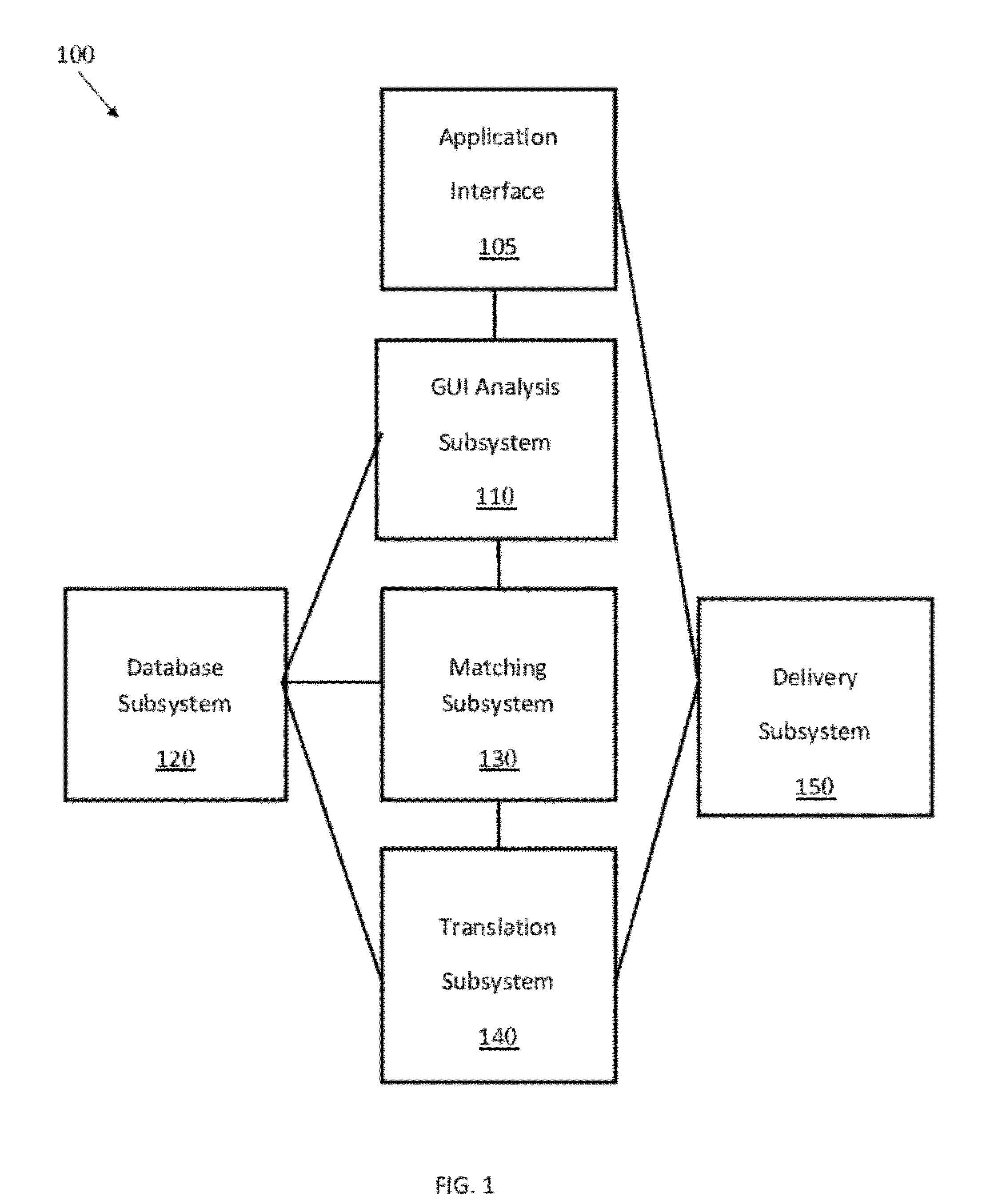

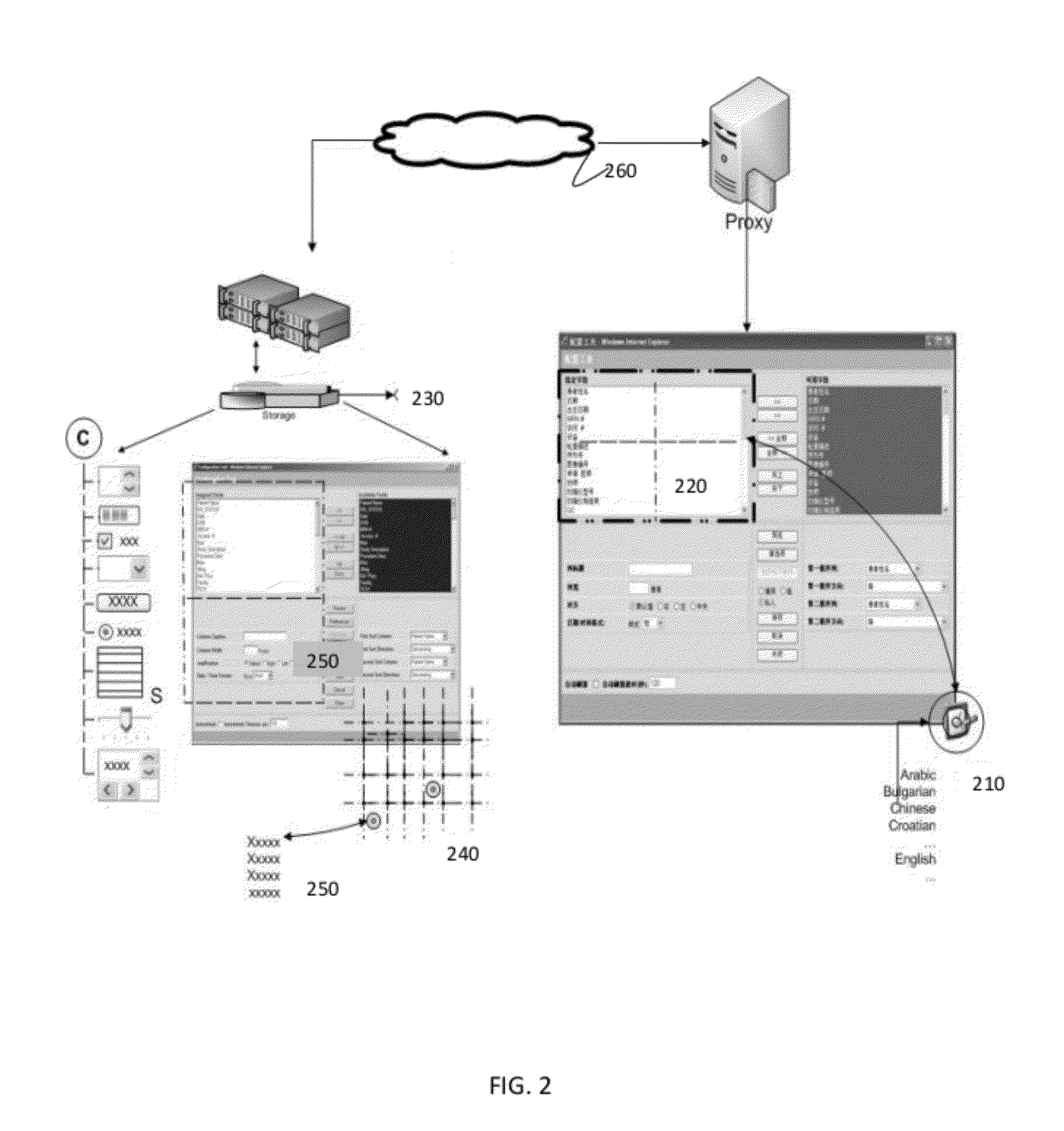

Context sensitive language assistant

InactiveUS20120166174A1Natural language translationExecution for user interfacesGraphicsGraphical user interface

An example user interface translator includes an interface analysis subsystem to analyze a selected portion of a graphical interface and to capture a topological representation of the selected portion. The selected portion of the graphical interface has a first textual context including a first language used to depict the selected portion of the graphical interface. The translator includes a matching subsystem to match the captured topological representation of the selected portion with a stored reference topological representation. The reference topological representation is to be associated with a second textual context including a second language. The translator includes a translation subsystem to translate the first textual context of the selected portion of the graphical interface to the second textual context of the reference topological representation. The translator includes a delivery subsystem to provide a translation of the selected portion of the graphical interface in conjunction with the graphical interface.

Owner:GENERAL ELECTRIC CO

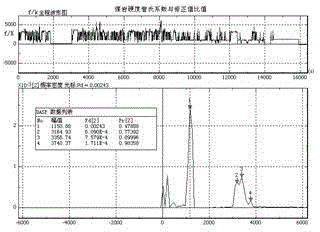

Coal rock interface analysis method based on coal mining machine perception

The invention relates to a coal rock interface analysis method based on coal mining machine perception, and is realized based on a coal rock interface analysis system based on the coal mining machine perception. The system is composed of a large-capacity data storage device, a coal mining machine electrical main controller, an intrinsically safe type vibration accelerated speed sensor and the like. In the method, through coal mining machine working parameters composed of vibration signals, voltage and current and temperature torque of coal mining machine cutting and traction motors, coal mining machine rocker arm lifting oil cylinder pressure, and traction motor speed signals, signal characteristics of coal mining machine drum cutting teeth cutting coal and rock different roofs and floors situations are analyzed, wavelet packets are used for analyzing energy features of different frequency bands of the vibration signals, probability and statistic samples are used for analyzing feature distribution of the cutting machine working parameters, a multi-sensor information fusion technology is used for comprehensive establishment of different coal rock character databases, a coal mining machine perception coal rock interface is defined through a fuzzy mathematic theory, and a coal rock interface membership degree is calculated according to the coal mining machine perception multi-sensor information, so as to be used as a coal rock interface recognition basis.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

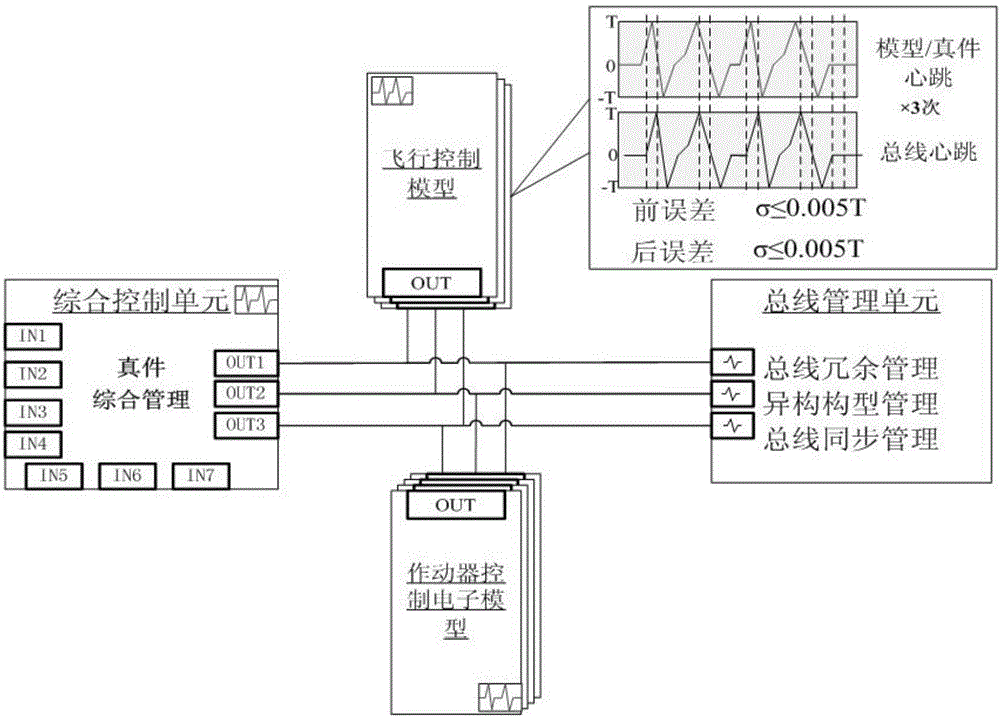

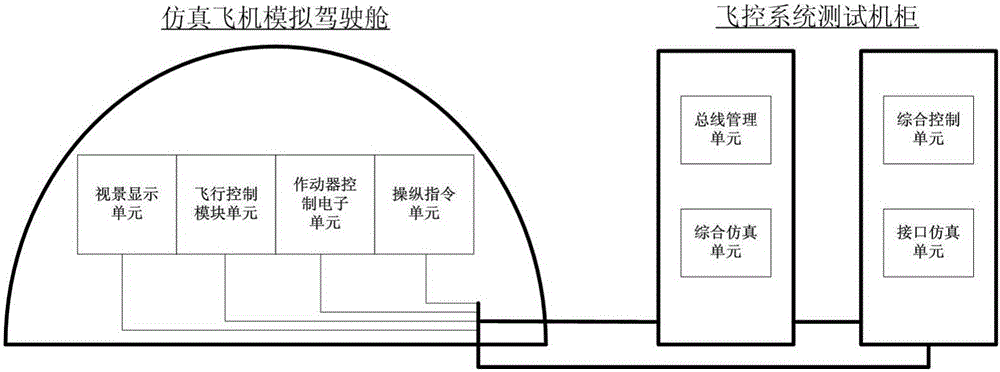

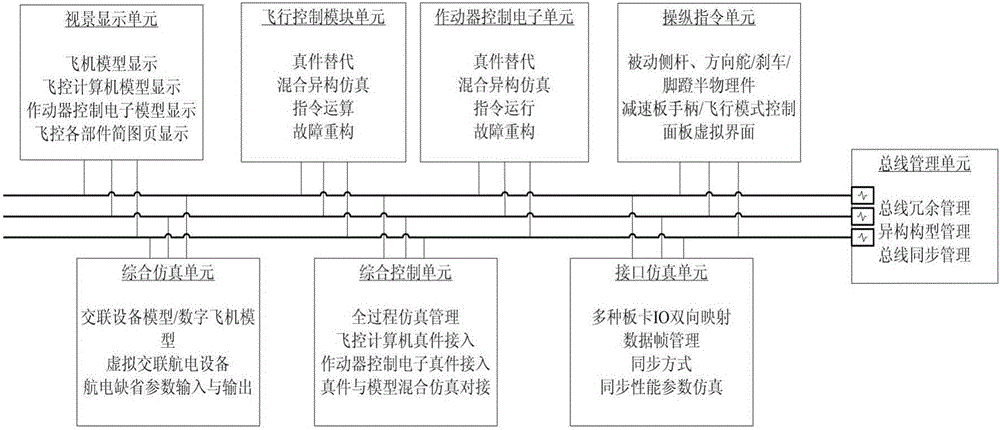

Civil airplane flight control system mixing heterogeneous simulation platform

ActiveCN106055728APerfect simulationIncrease the differenceGeometric CADElectric testing/monitoringJet aeroplaneFlight control modes

The invention provides a civil airplane flight control system mixing heterogeneous simulation platform. The platform employs three flight control module units and four actuator control electronic units for effectively supporting different frameworks in a flight control system 12, 8 actuating strategies of a flight control actuator, and balance and assessment of mixing heterogeneous integration simulation in a flight control system 96; a security analysis in theory is conducted according to the obtained test difference data; and the analysis is stored in an integrated control unit to construct a security analysis database. Each accessed true member and model are synchronized according to heartbeat synchronization. Fault is determined if time isn't synchronized, in this way, fault reproduction and analysis can be conducted; interface analysis and contrast among each accessed true members and the model are conducted according to a general bus management unit and an interface simulation unit; and difference between the model and a true member is improved by improving model simulation degree according to history data and test data.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

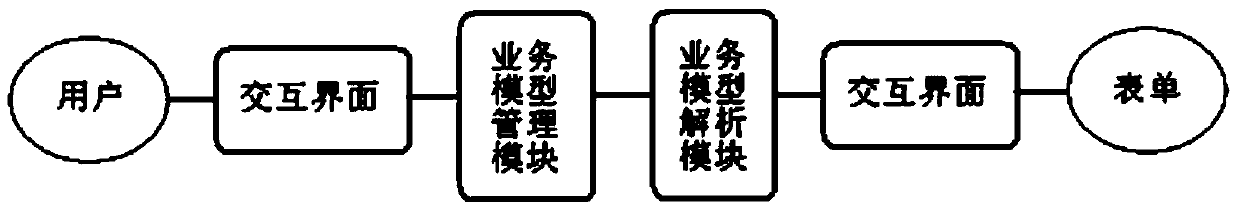

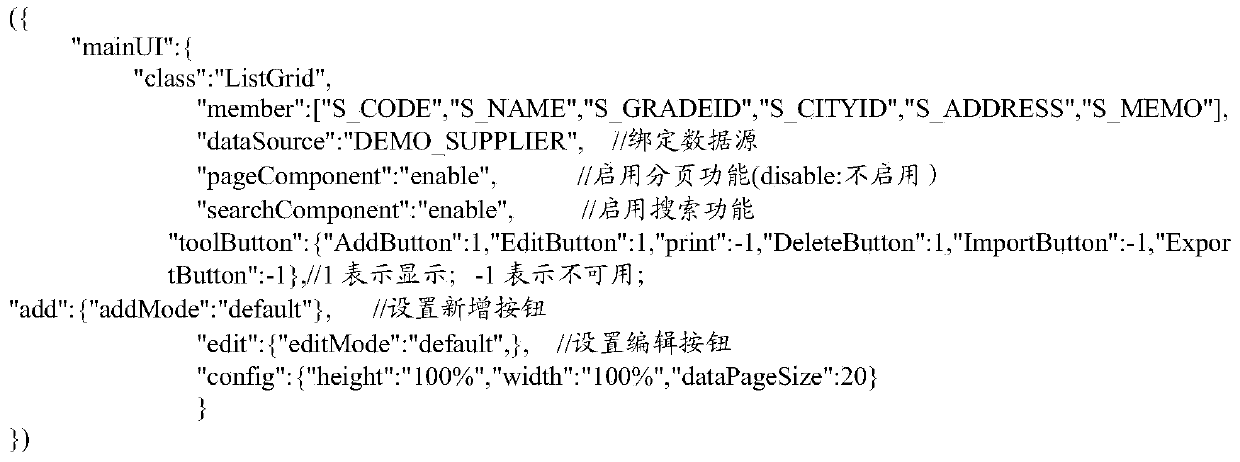

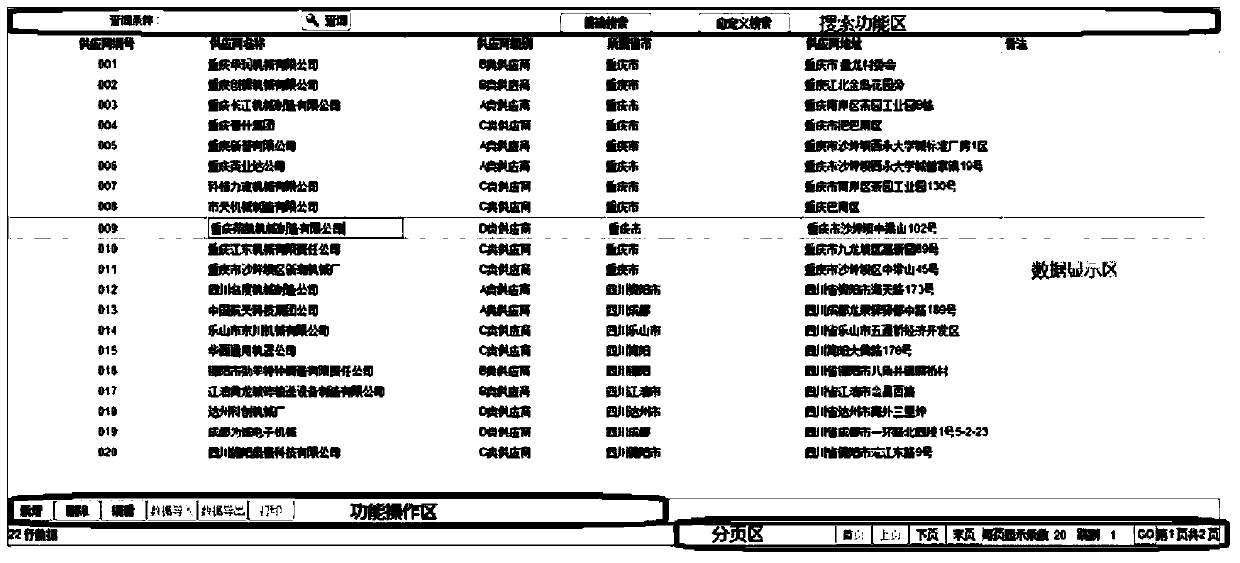

Application form agile development method and system oriented to business

InactiveCN103995698ALower skill requirementsReduce development costsSpecific program execution arrangementsModel managementUser input

The invention provides an application form agile development method and system oriented to business. The method includes the following steps that a form development module is built, where a business model management module and a business model analysis module are built; a user inputs business model demand information through a human-computer interaction interface, and the business model analysis module performs interface analysis through the business model management module to form a display interface according to the input business model demand information; the formed display interface is subjected to event analysis through the business model analysis module, and an application form is formed and displayed. The system comprises the interaction interface, the business management module and the business model analysis module. According to the method, the development period of the form can be shortened, and the working efficiency can be improved.

Owner:CHONGQING SIOU INFORMATION TECH CO LTD

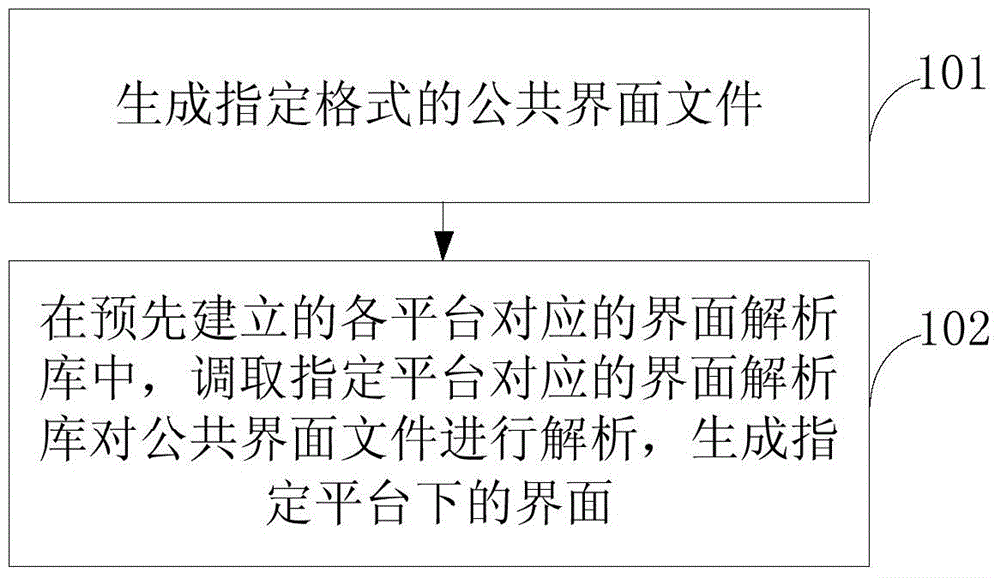

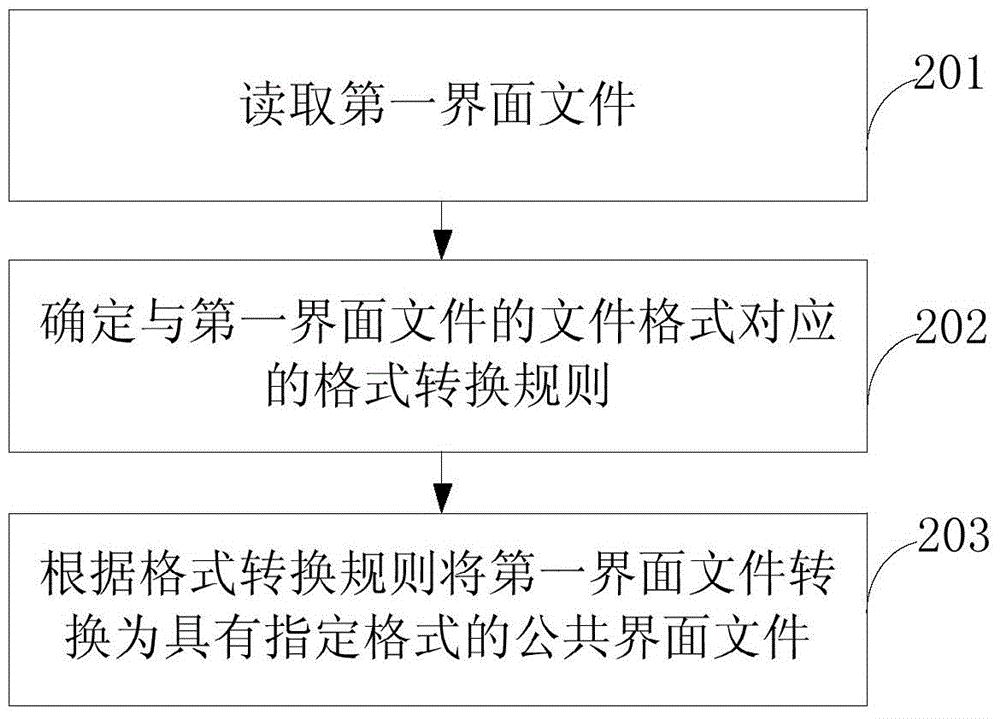

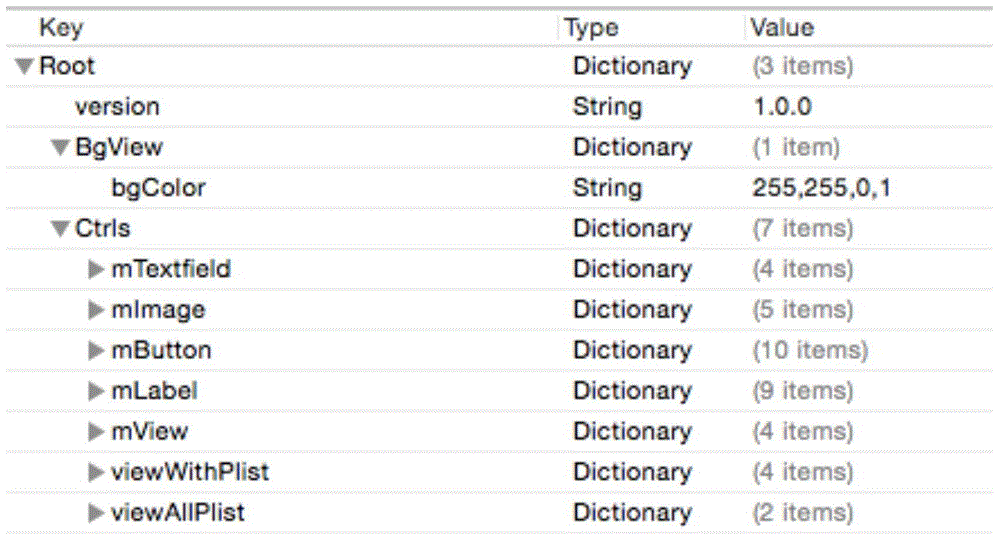

Interface generating method and device

InactiveCN104915201AEliminate differencesGuaranteed cross-platform useProgram loading/initiatingMultiple platformInterface analysis

The embodiment of the invention provides an interface generating method and device; the interface generating method comprises the following steps: generating common interface files with a specified format; in an interface analysis library corresponding to each platform preliminarily established, retrieving the interface analysis library corresponding to the specified platform to analyze the common interface files and generating an interface under the specified platform. According to the embodiment of the invention, by unifying the interface files into the common interface files with the specified format, the difference between interface files generated by different interface editors under different platforms is eliminated, and the cross-platform use of the interface files is guaranteed; then, by creating the interface analysis libraries corresponding to different platforms, the analysis on the common interface files is realized, so that the common interface files can be used for generating corresponding interfaces on the different platforms; the method realizes sharing of an interface research and development scheme under multiple platforms, and reduces the labor and the research and development cost; meanwhile, a quicker interface processing scheme can be provided and the purpose of interface editing is achieved very easily.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

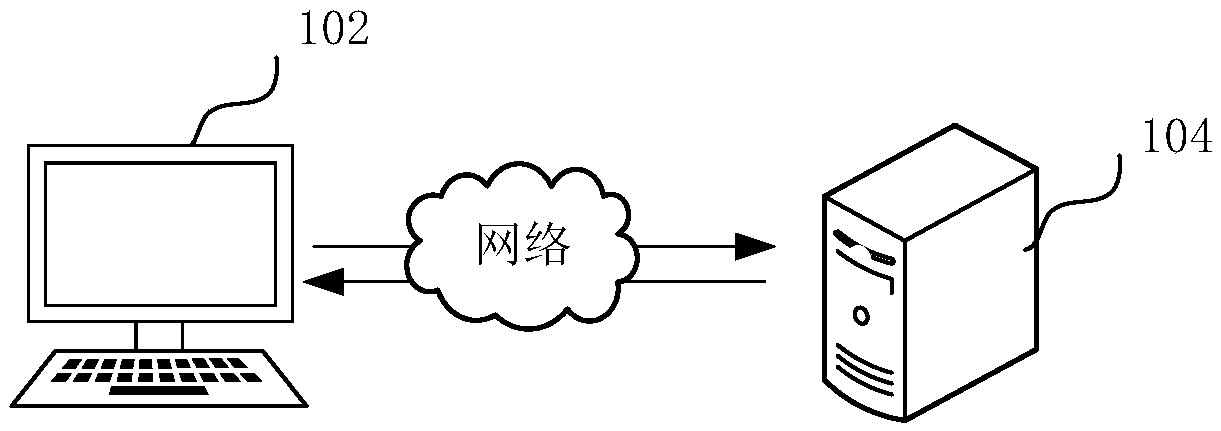

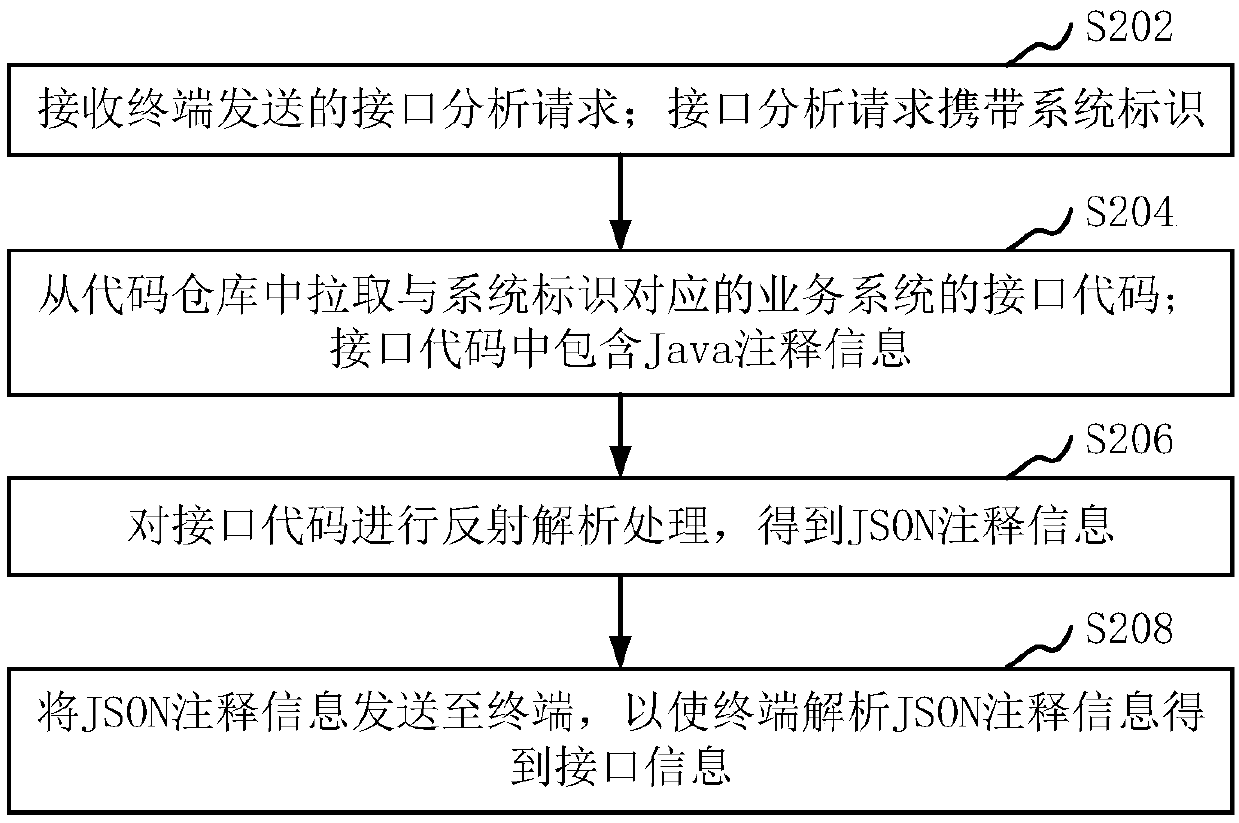

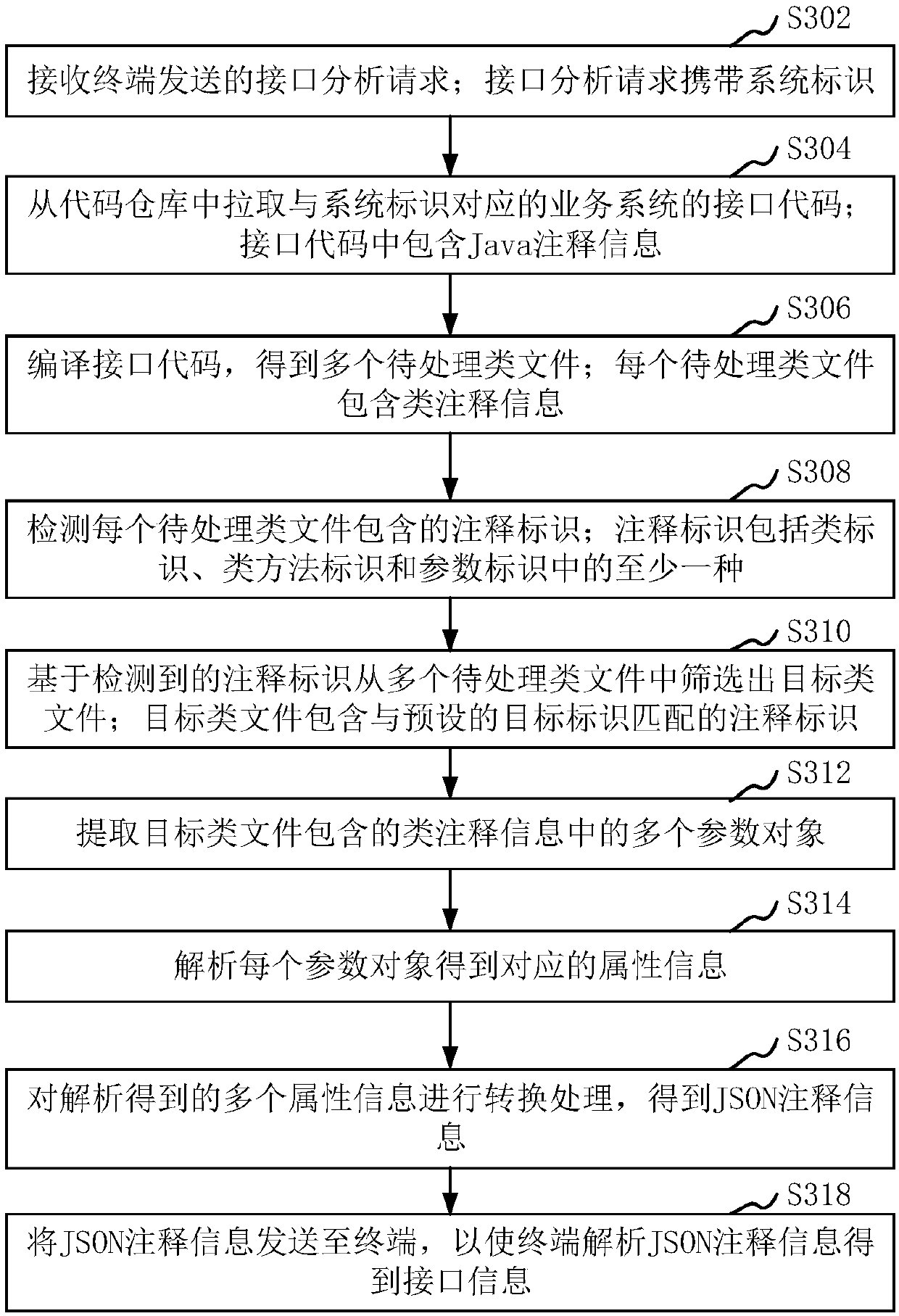

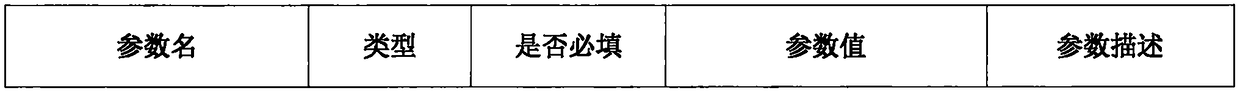

Interface information generation method and apparatus, computer device, and storage medium

PendingCN109542412AEasy to callImprove maintenance efficiencyCreation/generation of source codeGeneration processSoftware engineering

The present application relates to an interface information generation method and apparatus, a computer device and a storage medium based on the automatic programming technology. The method comprisesthe following steps: receiving an interface analysis request sent by a terminal, wherein the interface analysis request carries a system identification; pulling an interface code of a service system corresponding to the system identification from a code warehouse, wherein the interface code includes Java annotation information; carrying out reflection parsing on the interface code to obtain JSON annotation information; sending the JSON annotation information to the terminal so that the terminal parses the JSON annotation information to obtain interface information. The interface information generation process is optimized by the method, and the interface information can be generated automatically and efficiently.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

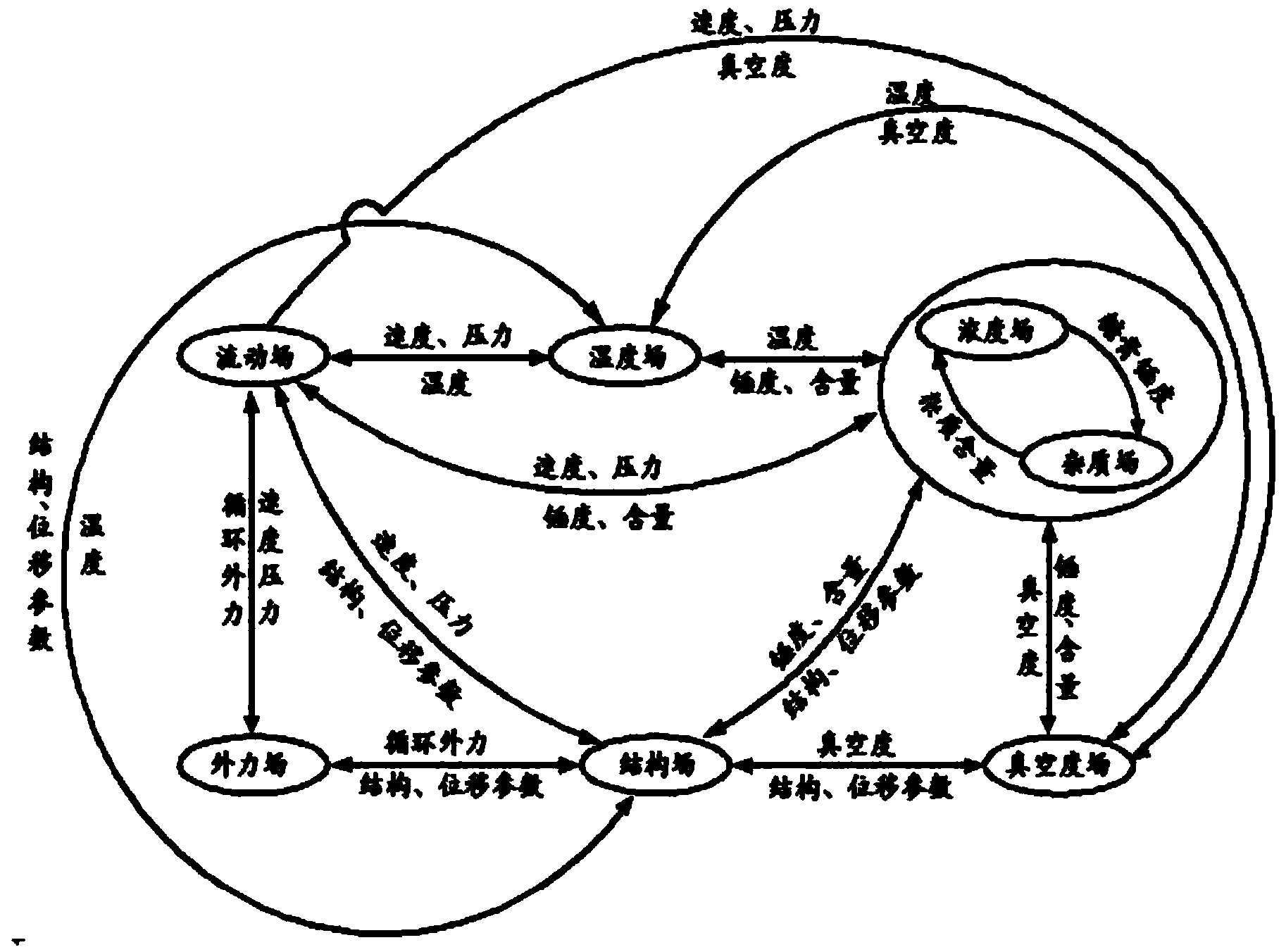

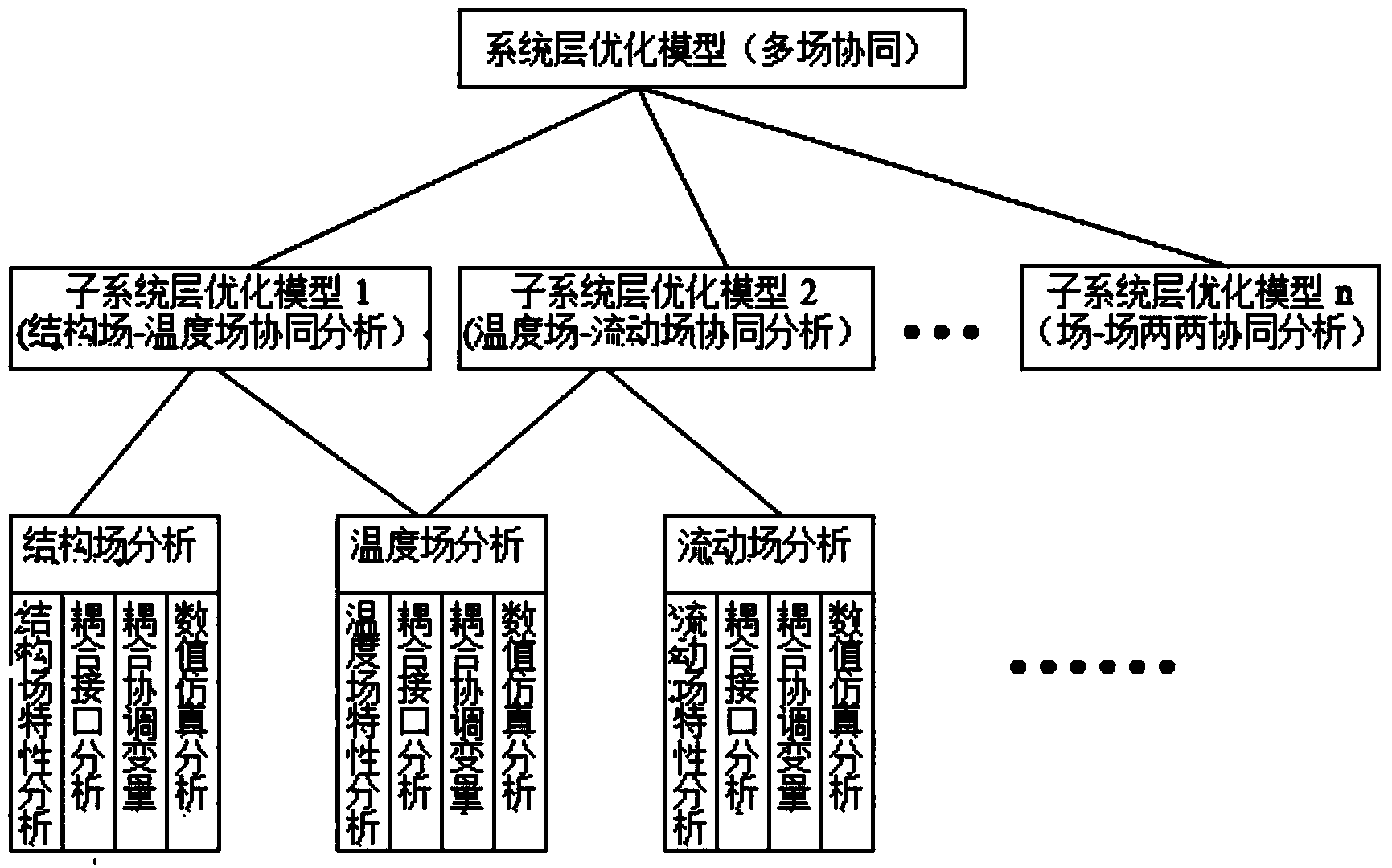

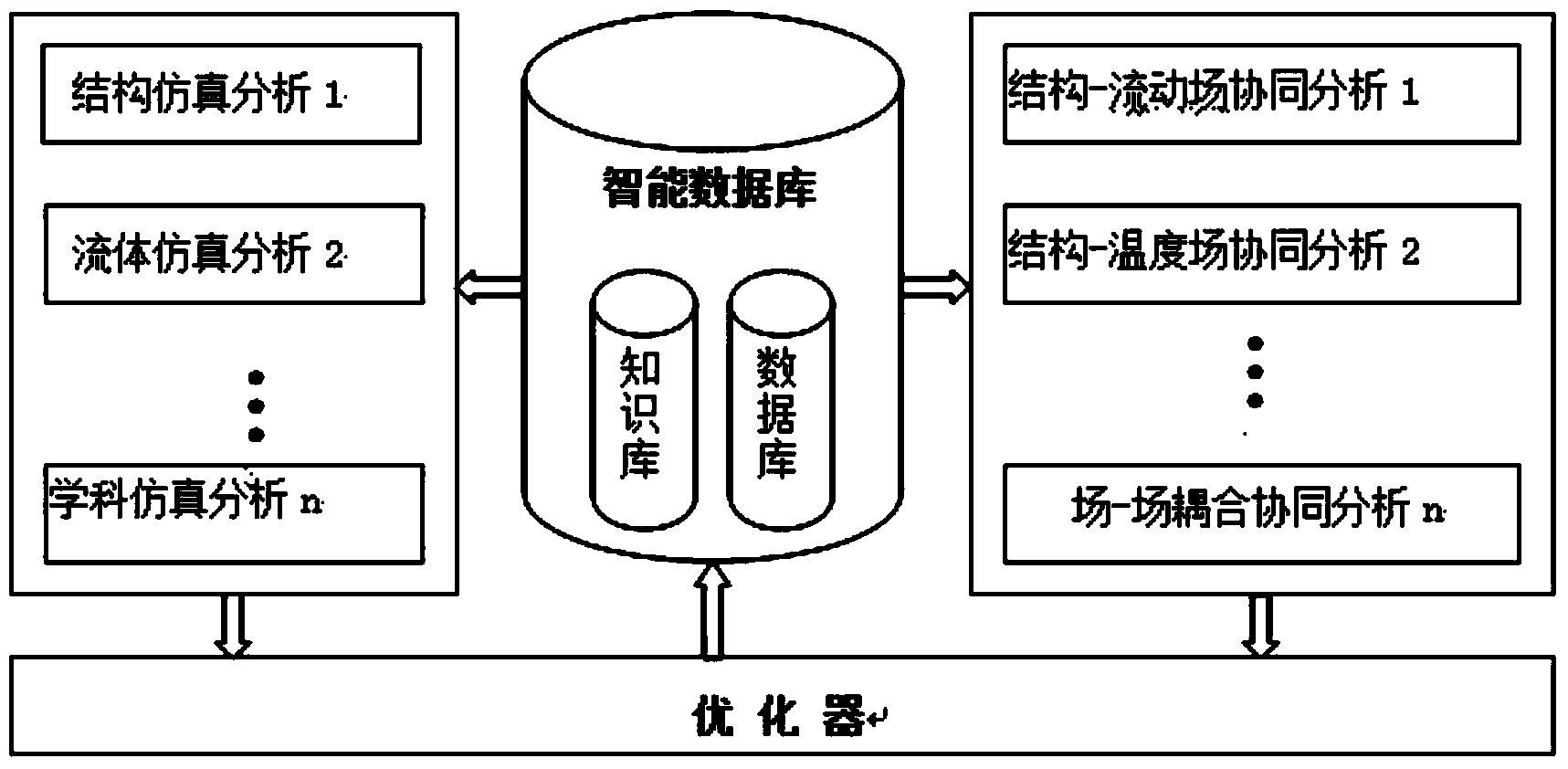

Sugarcane sugar boiling equipment optimizing design modeling and modeling method based on field synergy principle

ActiveCN103761383AIncrease productionQuality improvementSpecial data processing applicationsPhysical fieldField analysis

The invention provides a sugarcane sugar boiling equipment optimizing design modeling and modeling method based on the field synergy principle. The modeling comprises a subsystem analysis model, a subsystem optimization model and a system optimization model. The subsystem analysis model is used for analyzing a single physical field to form a module with certain functions; the module comprises field analysis, field coupling interface analysis, field coupling coordination variables and numerical simulation analysis. The subsystem optimization model is used for analyzing two different physical field coupling coordination in the subsystem analysis model; the target function is a minimized optimized function of the difference between coupling variables and shared variables, and constraint condition is the constraint of the system; the system optimization model is used for overall coordinating the system with a plurality of physical fields for boiling sugar coordinately, and constraint condition is consistent constraints of the coupling variables and shared variables of each subsystem. By the aid of the modeling method, structure, parameters and operating parameters of the batch-type sugar boiling equipment can be designed optimally, quantity of sugar is increased, quality of sugar is improved, sugar boiling time is shortened, and energy consumption is reduced.

Owner:GUANGXI UNIV

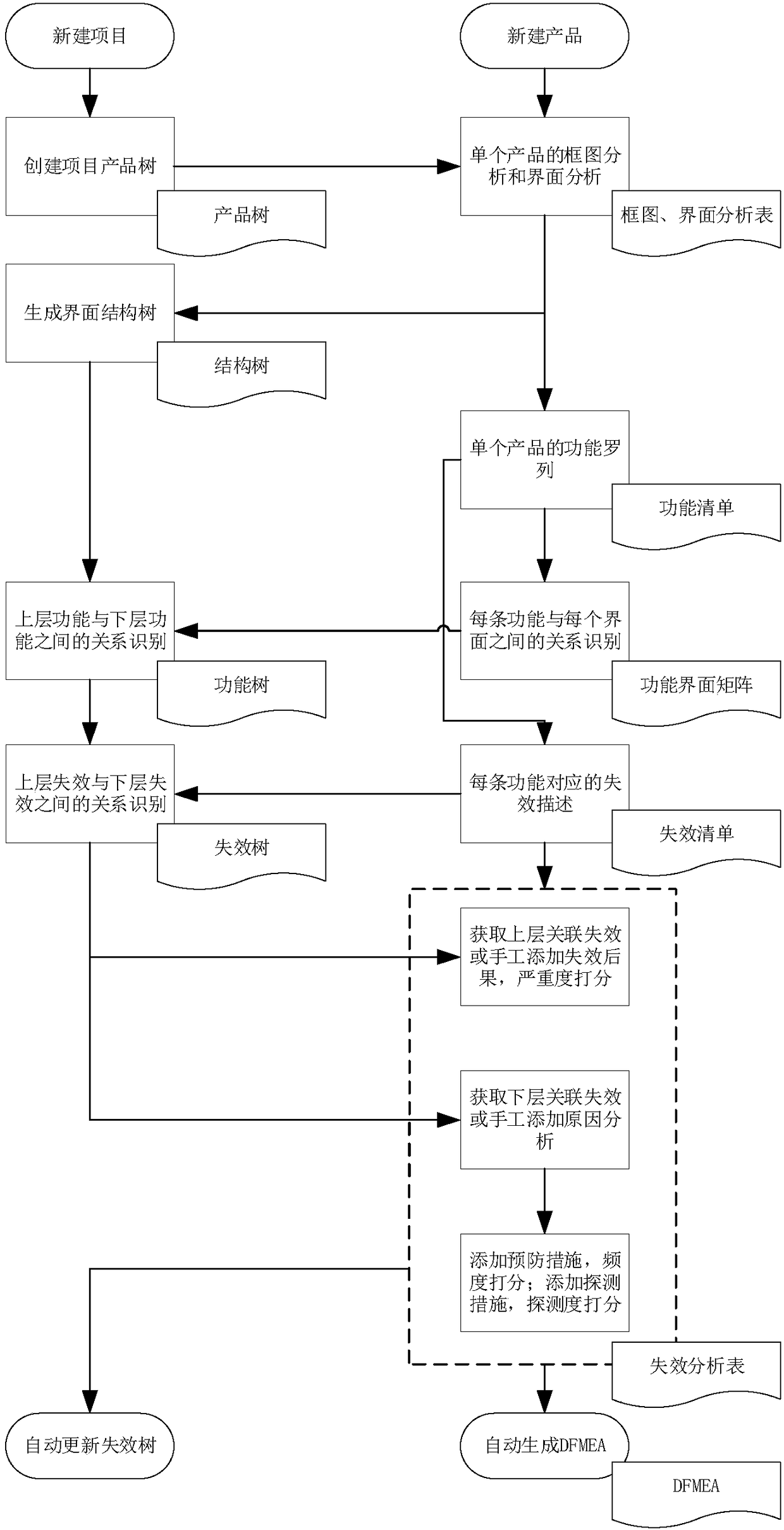

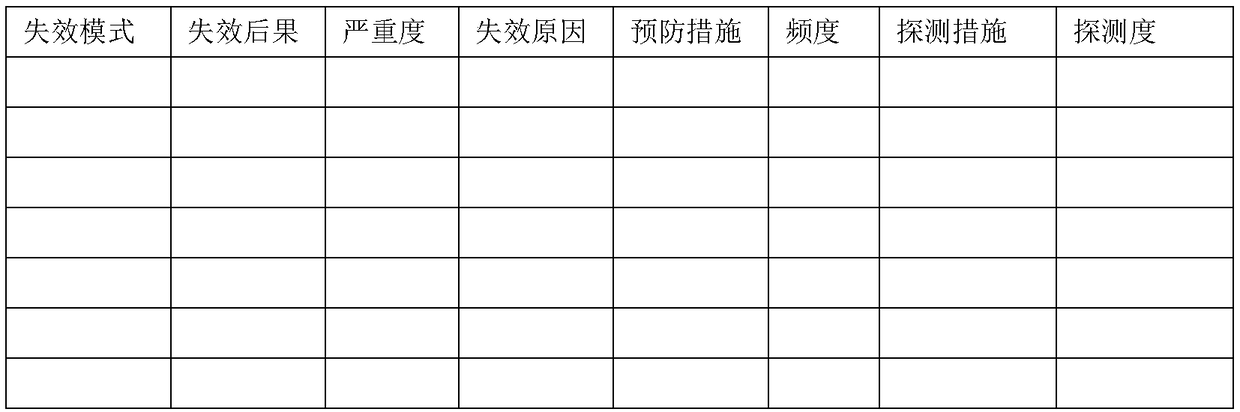

Structured DFMEA analysis method

PendingCN108197349AQuality improvementShorten the timeSpecial data processing applicationsStructured analysisWorkload

The invention relates to the technical field of failure analysis and provides a structured DFMEA analysis method. The method comprises the steps of creating a project; displaying all levels of productstructures contained in the project in a tree form manner to form a product tree; performing interface analysis on a single product by adopting a block diagram and an interface analysis table; and determining an internal interface and an external interface of the product. A structured analysis thought is creatively adopted; functional requirements and failure modes of an upper product and a lowerproduct are effectively sorted and combined skillfully, and finally a high-quality DFMEA report is automatically formed; and the manual filling and sorting time of working staffs is greatly shortened, and the workload is reduced.

Owner:聪脉(上海)信息技术有限公司

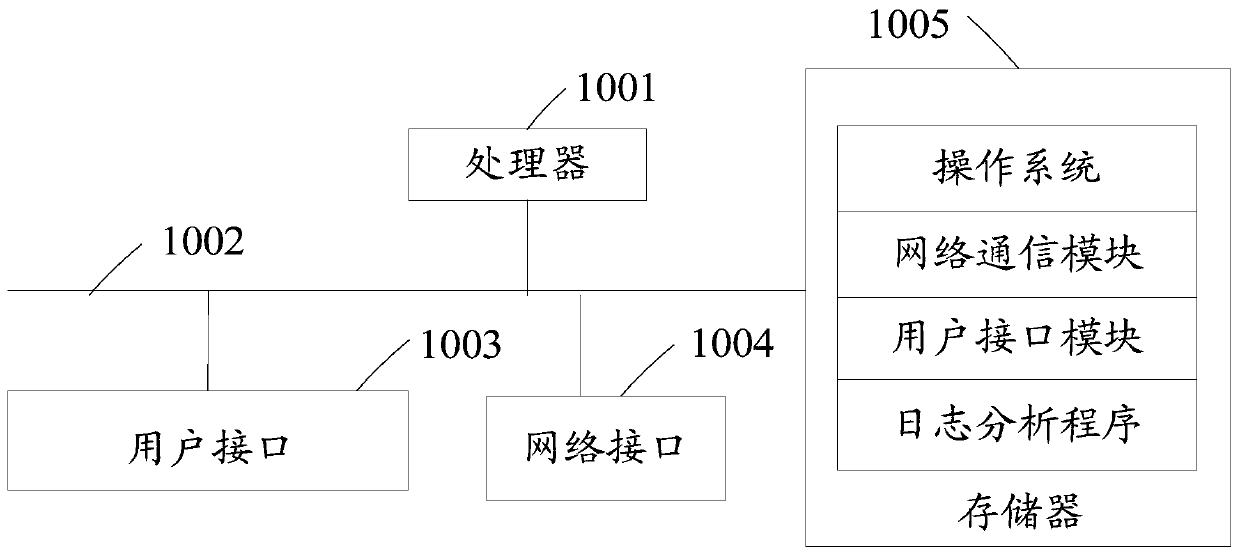

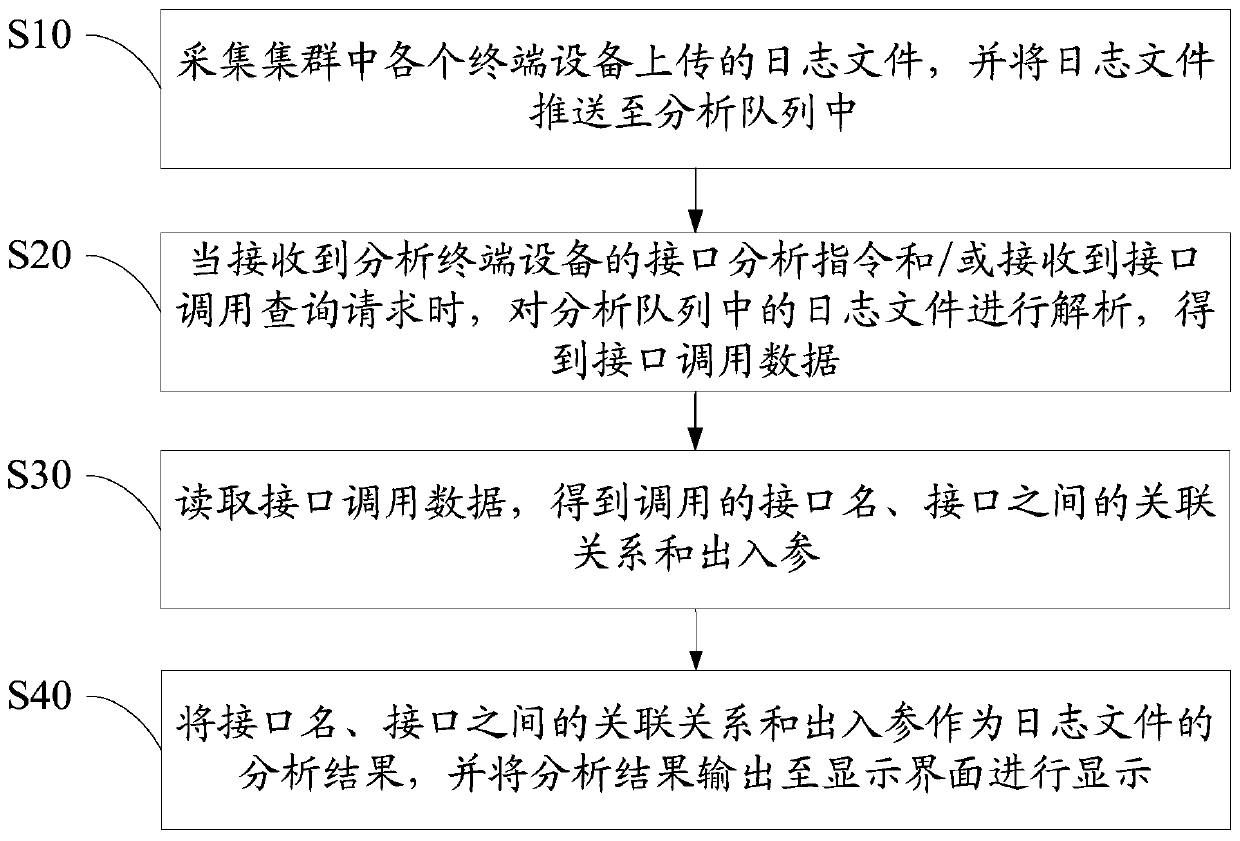

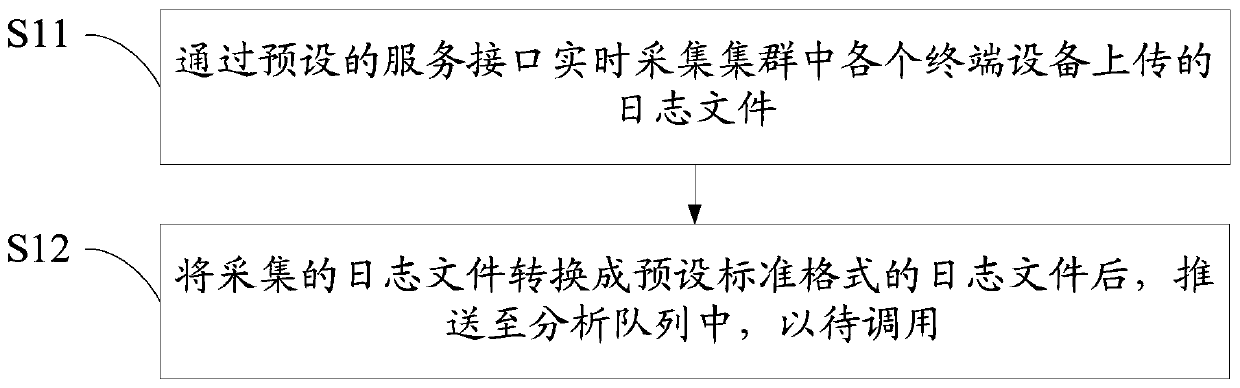

Log analysis processing method, device and equipment and readable storage medium

PendingCN110069464AEasy to callFile metadata searchingSpecial data processing applicationsTerminal equipmentSoftware engineering

The invention discloses a log analysis processing method which comprises the following steps: collecting log files uploaded by terminal devices in a cluster, and pushing the log files to an analysis queue; when an interface analysis instruction of the analysis terminal device is received and / or an interface call query request is received, analyzing the log file in the analysis queue to obtain interface call data; reading the interface calling data to obtain a called interface name, an association relationship between interfaces and an access parameter; and taking the interface name, the association relationship between the interfaces and the access parameters as an analysis result of the log file, and outputting the analysis result to a display interface for display. The invention furtherdiscloses a device, equipment and a readable storage medium. Through data analysis on the log file, the calling condition of the interface can be more conveniently and clearly displayed for an interface calling party or a called party or a project developer.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

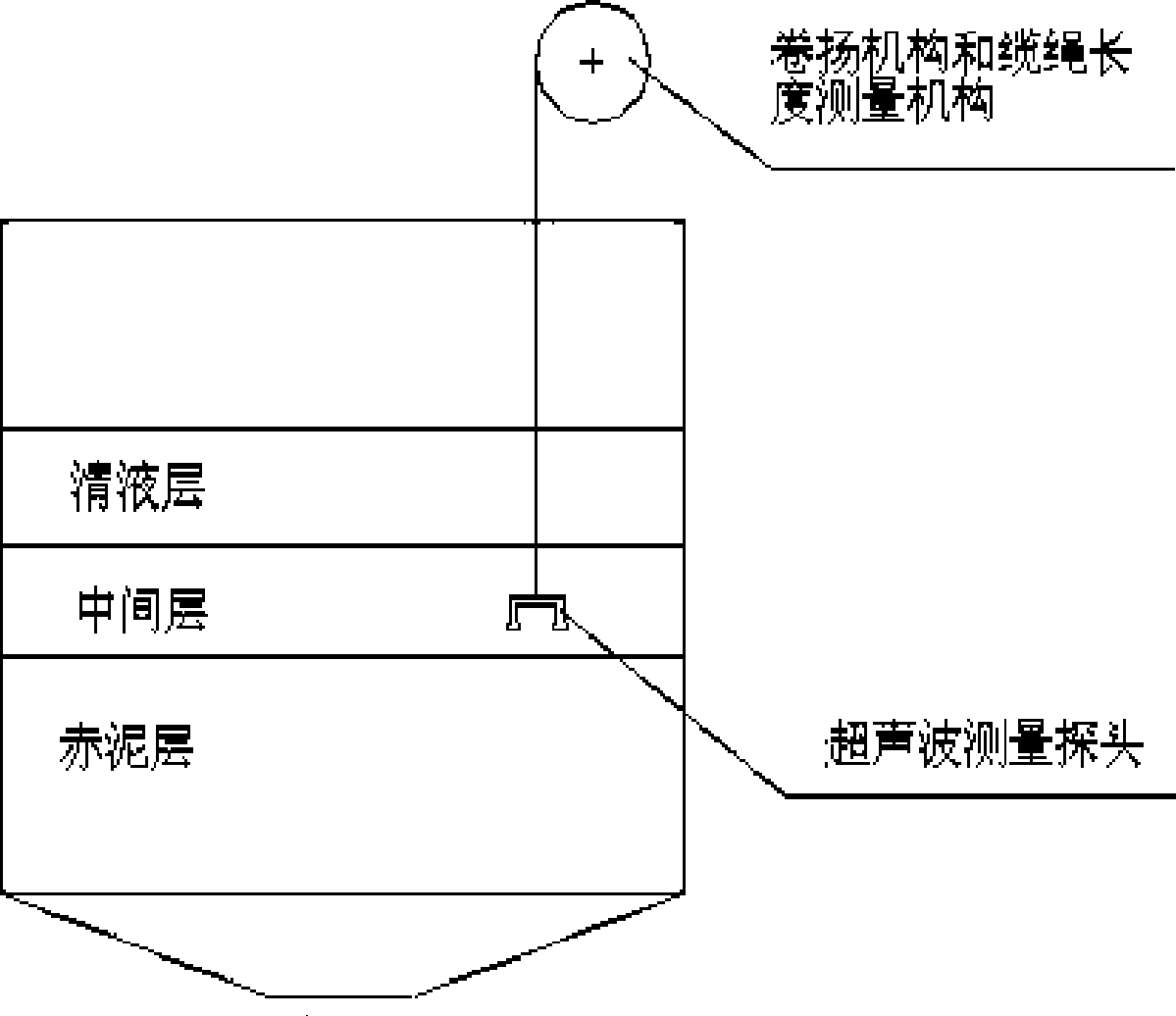

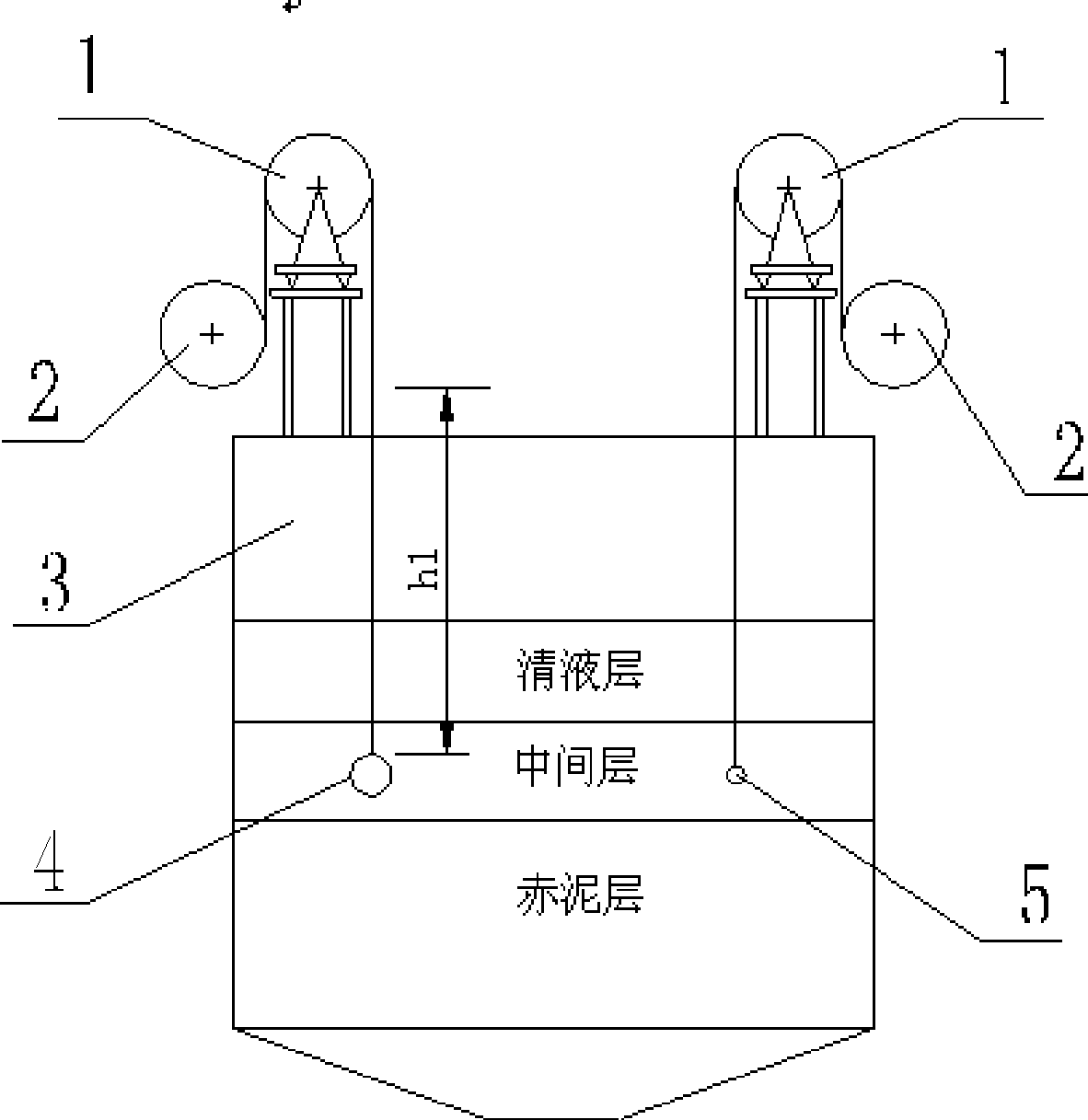

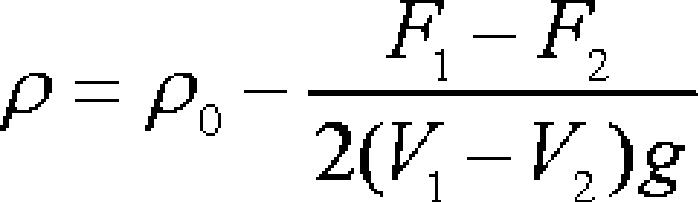

Interface analysis apparatus for double-floating ball red mud setting tank

ActiveCN101487785AReliable measurementLess investmentMaterial analysis by measuring buoyant forcesControl systemDirect effects

The invention discloses a device for analyzing the interface of a double-float ball red mud setting tank, comprising: a setting tank, a hoisting mechanism and a cable length measuring device. Two sets of pulley sets (1) with measuring scale racks controlled by a PLC control system are arranged on the setting tank (3); the hoisting mechanism and the cable length measuring device (2) are respectively connected with a large float ball (4) and a small float ball (5) in the setting tank (3) through the cables; the large float ball (4) and the small float ball (5) have different volume and identical density; the shells of the large float ball (4) and the small float ball (5) are made of stainless steel with lead sands filled therein; and the cables connected with the float balls are made of a material with high temperature resistance (greater than 100 DEG C), alkali / acid corrosion resistance and small ductility. The invention solves the problem that the sensitivity of the measuring detector is directly influenced as the measuring detector is easy to have scars in the prior art; the device has the advantages of reliable measurement, investment conservation and low cost; and the maintenance time and the labor intensity are reduced.

Owner:GUIYANG AL-MG DESIGN & RES INST

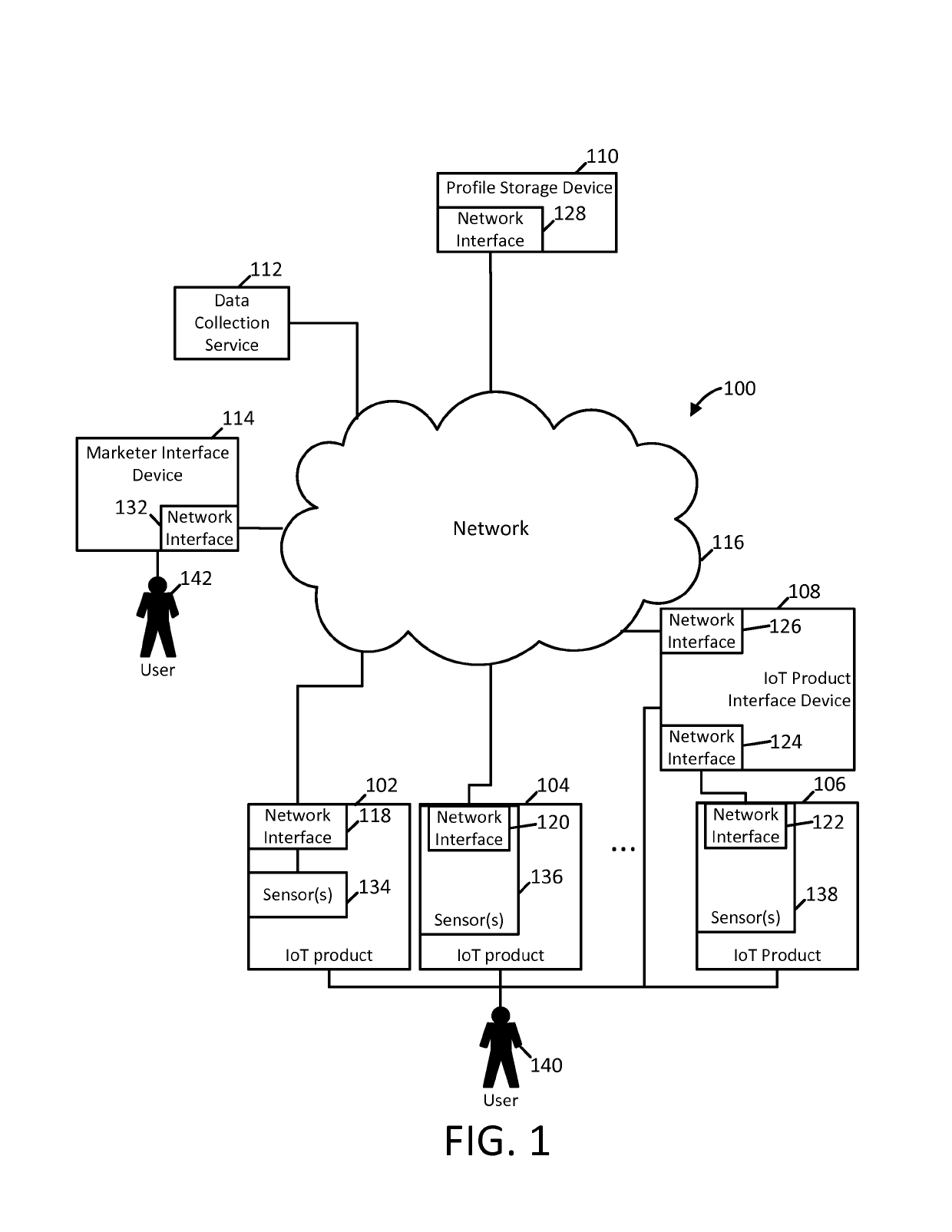

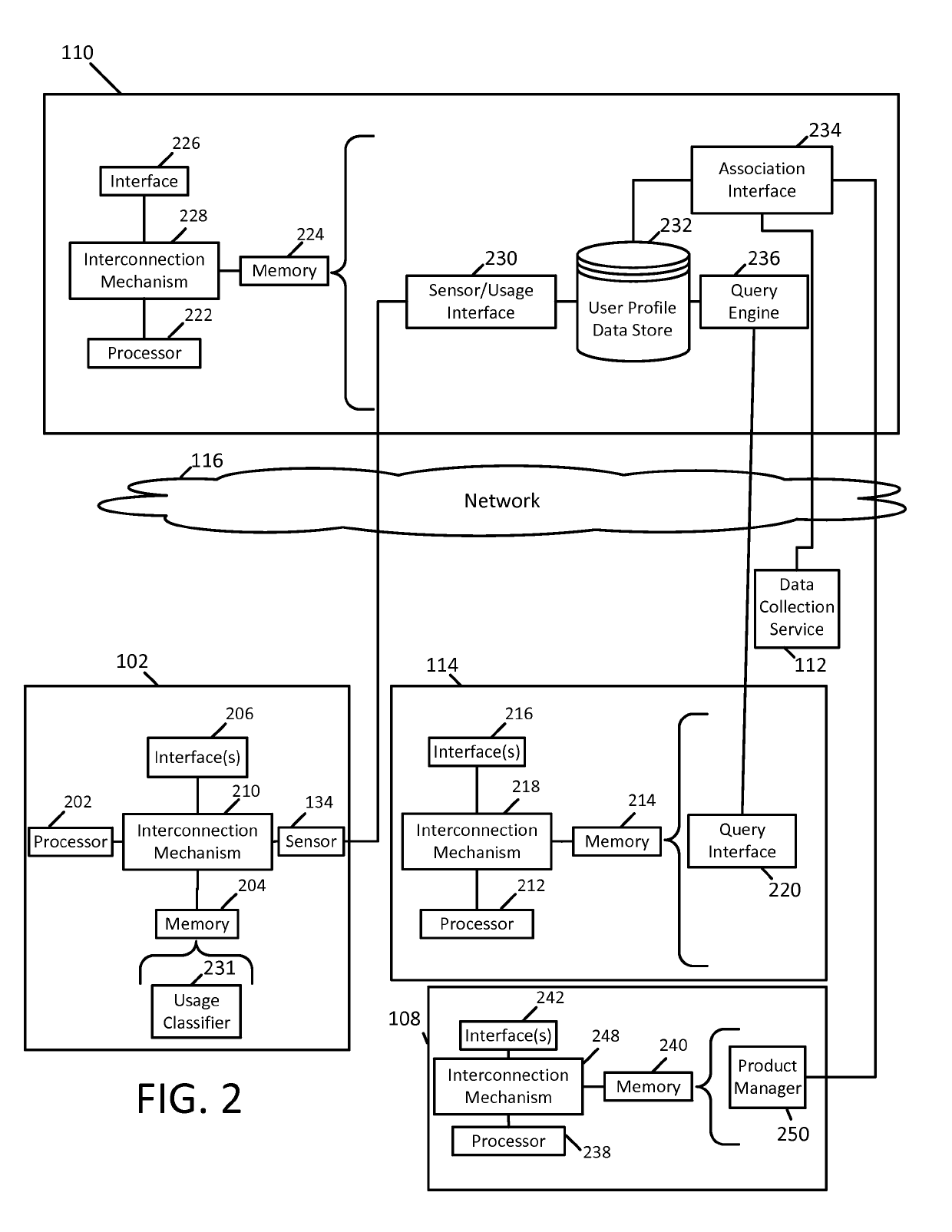

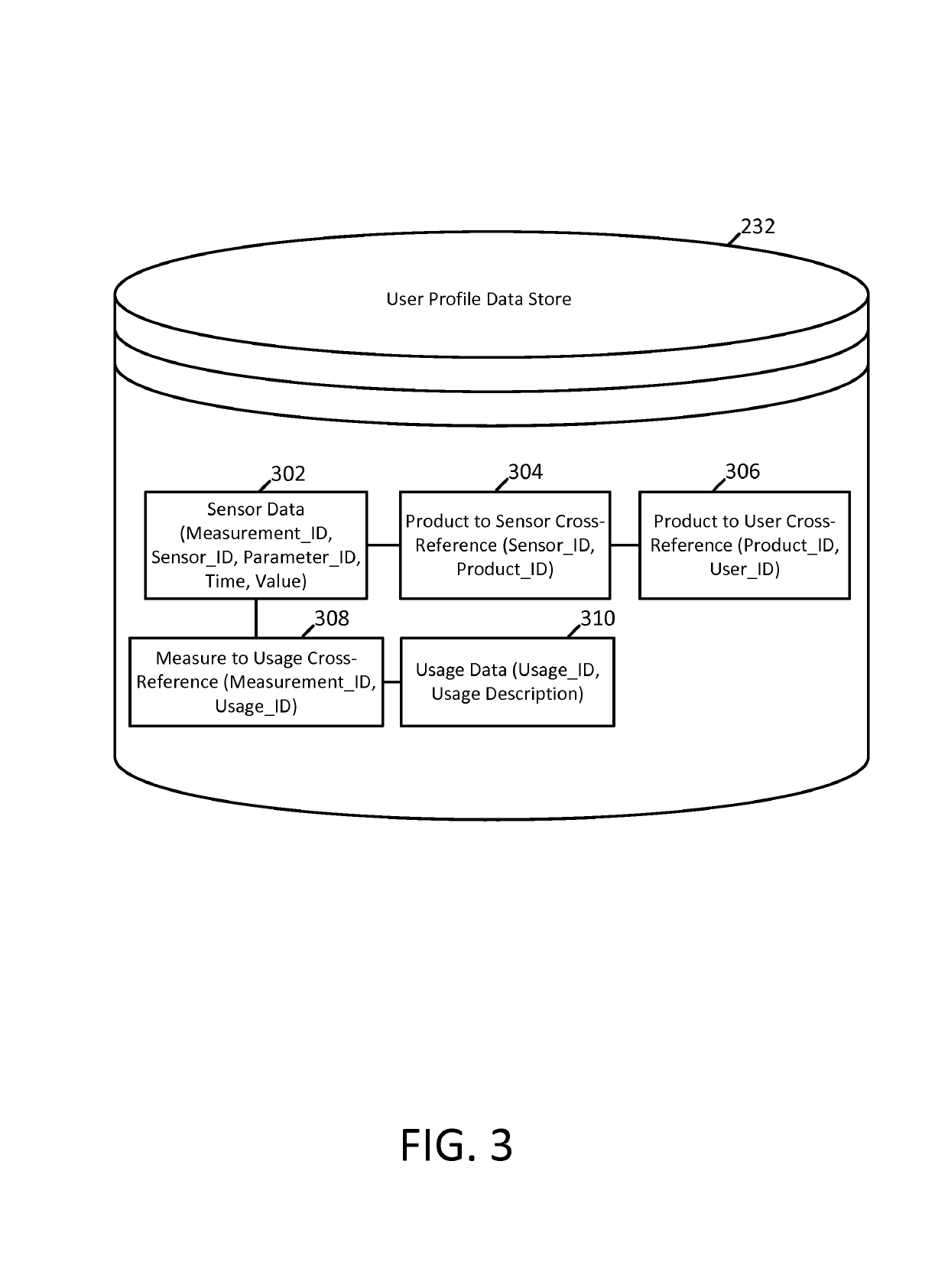

Real-world user profiles via the internet of things

Techniques are disclosed for generating enhanced user profiles that include “off-line” activities omitted from conventional user profiles. In one embodiment, each of two or more Internet of Things (IoT) products records usage data descriptive of a user's interactions with the IoT product. This usage data is based on values of physical parameters measured by sensors embedded within the IoT products. In recording the usage data, an IoT product may transmit the usage and sensor data to a user profile storage device. In response to receiving the usage and sensor data from the IoT products, the user profile storage device stores the usage and sensor data and associates the usage and sensor data with the user. Additionally, the user profile storage device exposes an interface through which marketing personnel can analyze user profiles made up of the stored usage and sensor data.

Owner:ADOBE INC

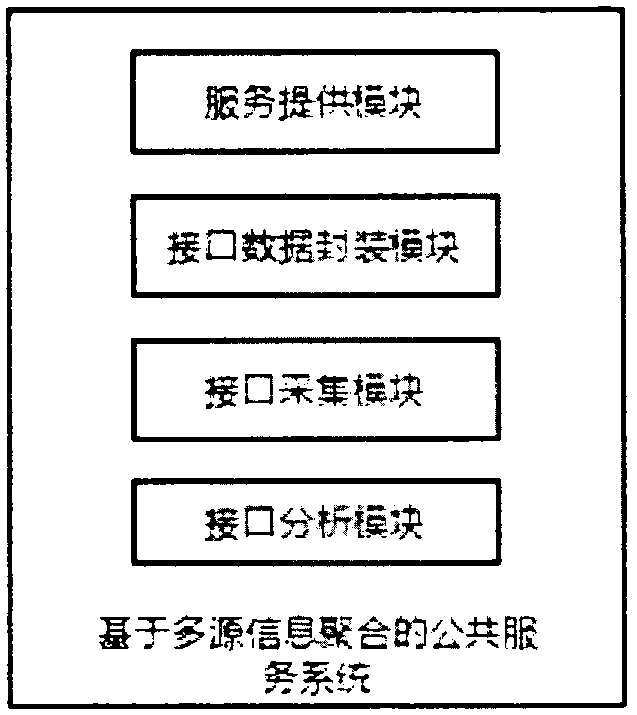

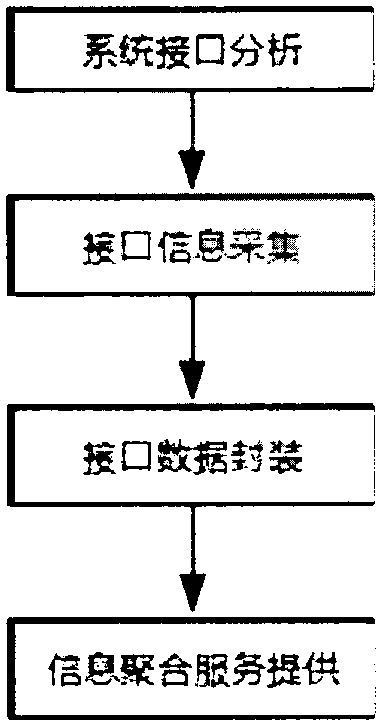

A public service system based on multi-source information aggregation and a construction method thereof

ActiveCN108989427AImprove classification efficiencyImprove retrieval efficiencyData switching networksThird partyData source

Through the interface analysis of the structure of the multi-source heterogeneous system, interface acquisition, interface data encapsulation, providing of a multi-source data aggregation service, displaying of multiple aggregation data, a public service system based on multi-source information aggregation is constructed. The system can provide one-key registration of multiple data sources, simplify the complex process, aggregate third-party services at low cost, quickly integrate, improve the efficiency of service classification and retrieval, and provide a network dynamic proxy mechanism toensure the rapid response of services efficiently, which solves the problems of data islands, information islands and data fragmentation.

Owner:BEIJING UCAP INTERNET TECH +1

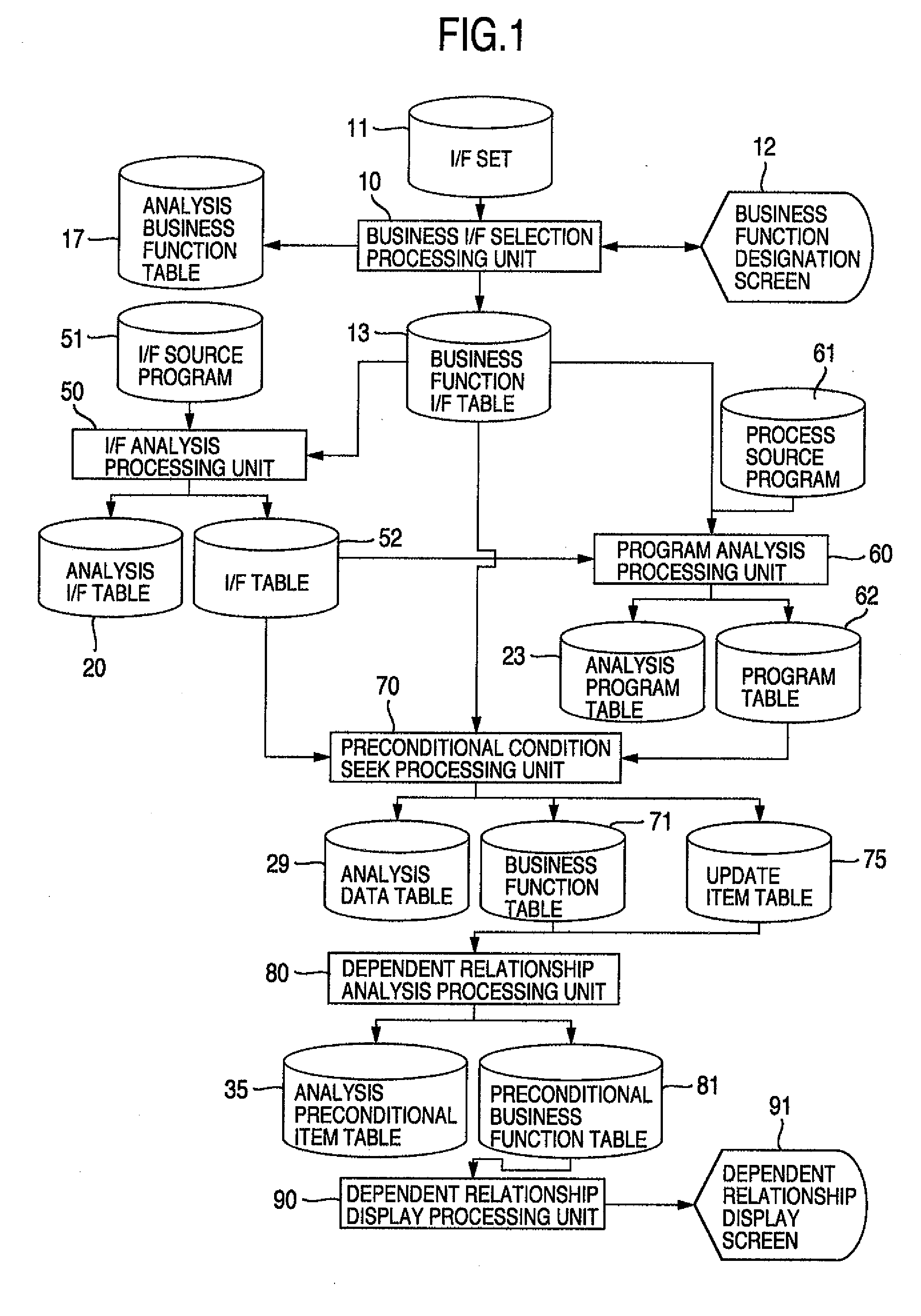

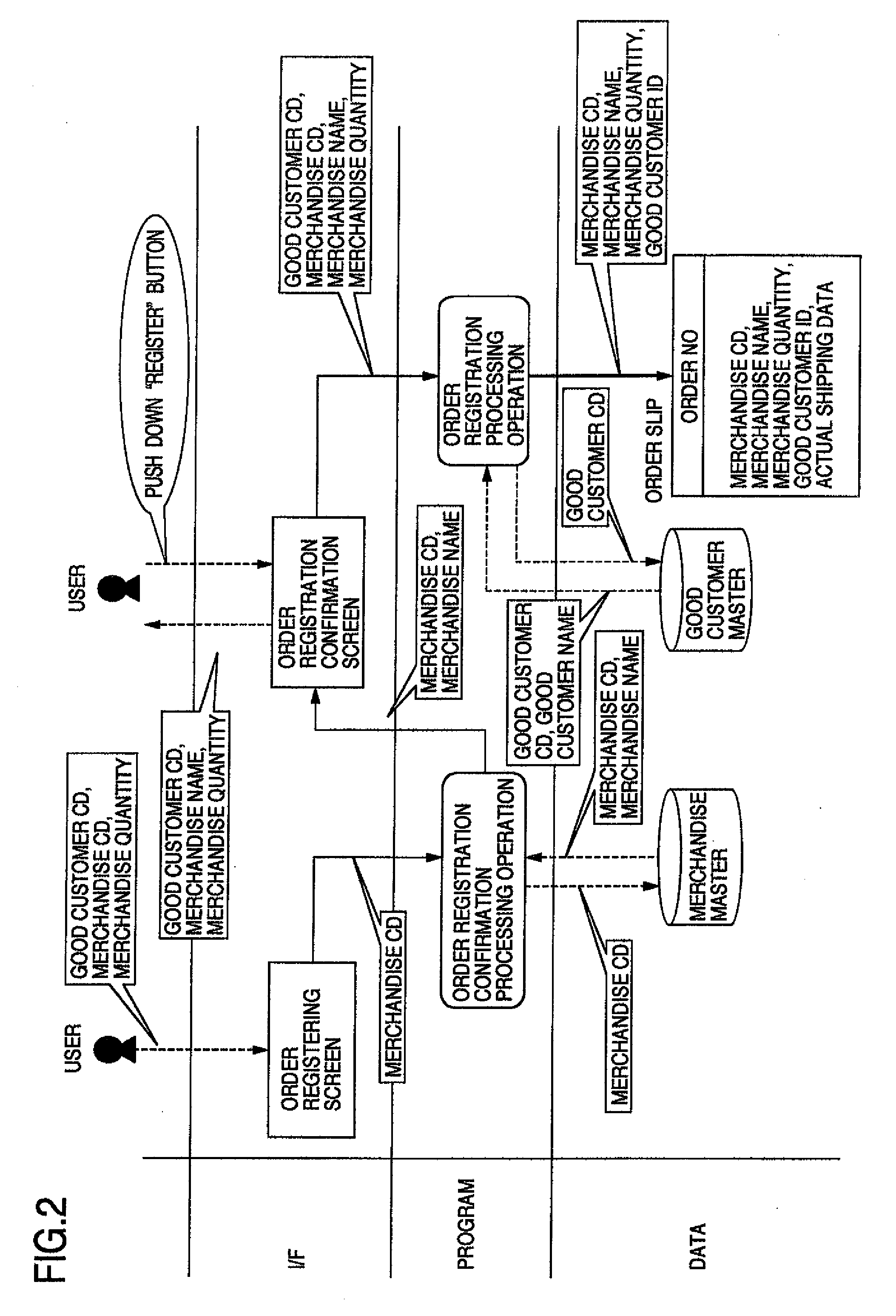

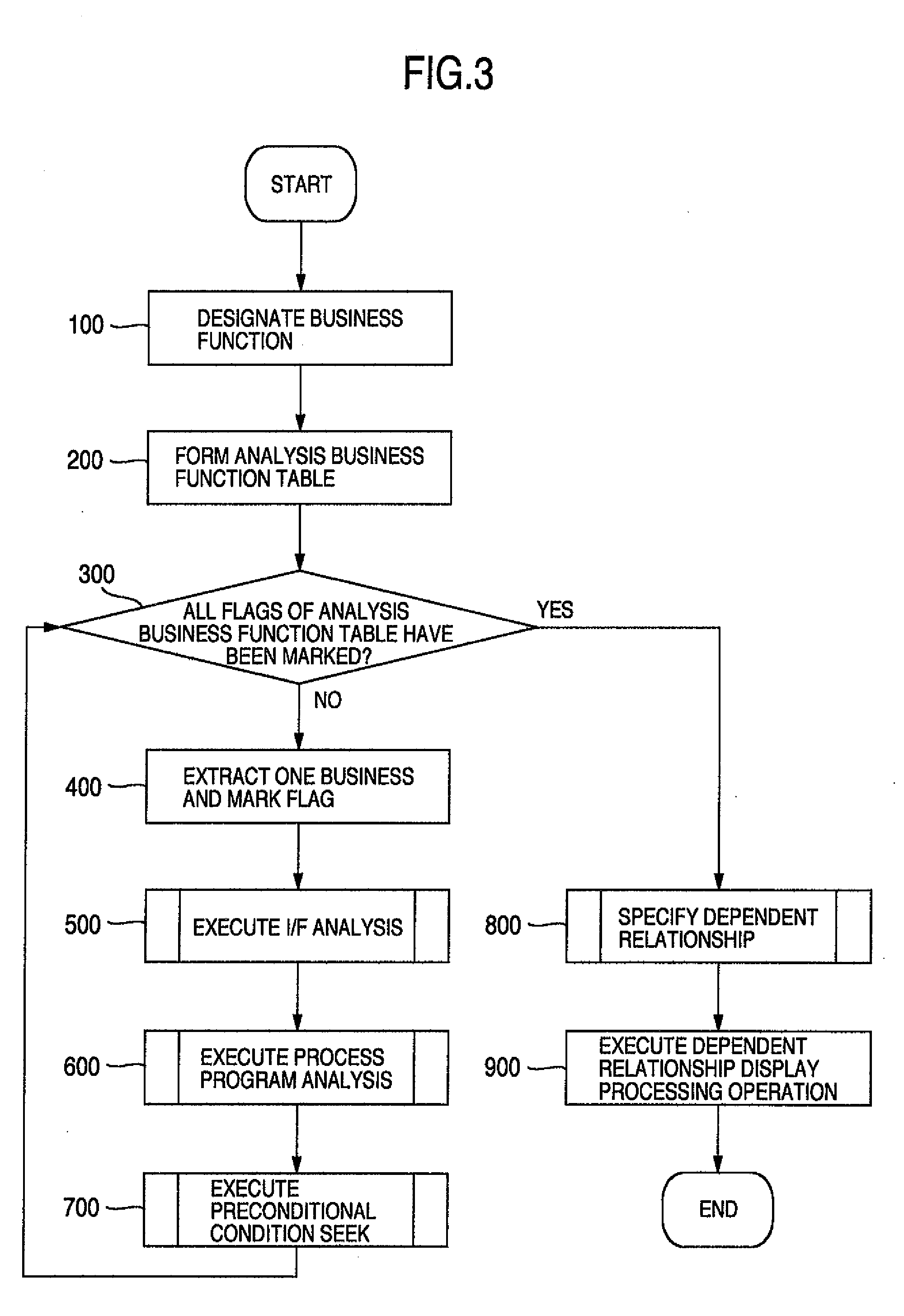

Business specification comprehension assistance system and method

A business specification is extracted so as to be represented by performing an analysis in a data item level by employing information which can be readily defined by a person who inputs business knowledge. While business functions and interfaces such as a series of screens corresponding to the business functions are employed as inputs, such a data item is extracted which is updated by employing an interface analysis and a program analysis. If a data item required for producing data which is updated in one business function is not inputted within this business function, the data item is defined as a preconditional condition item so as to be specified. If it is required that a business function for updating the preconditional condition item prior to the business function has been processed, a dependent relationship established between two pieces of the above-explained business is extracted so as to be represented.

Owner:HITACHI LTD

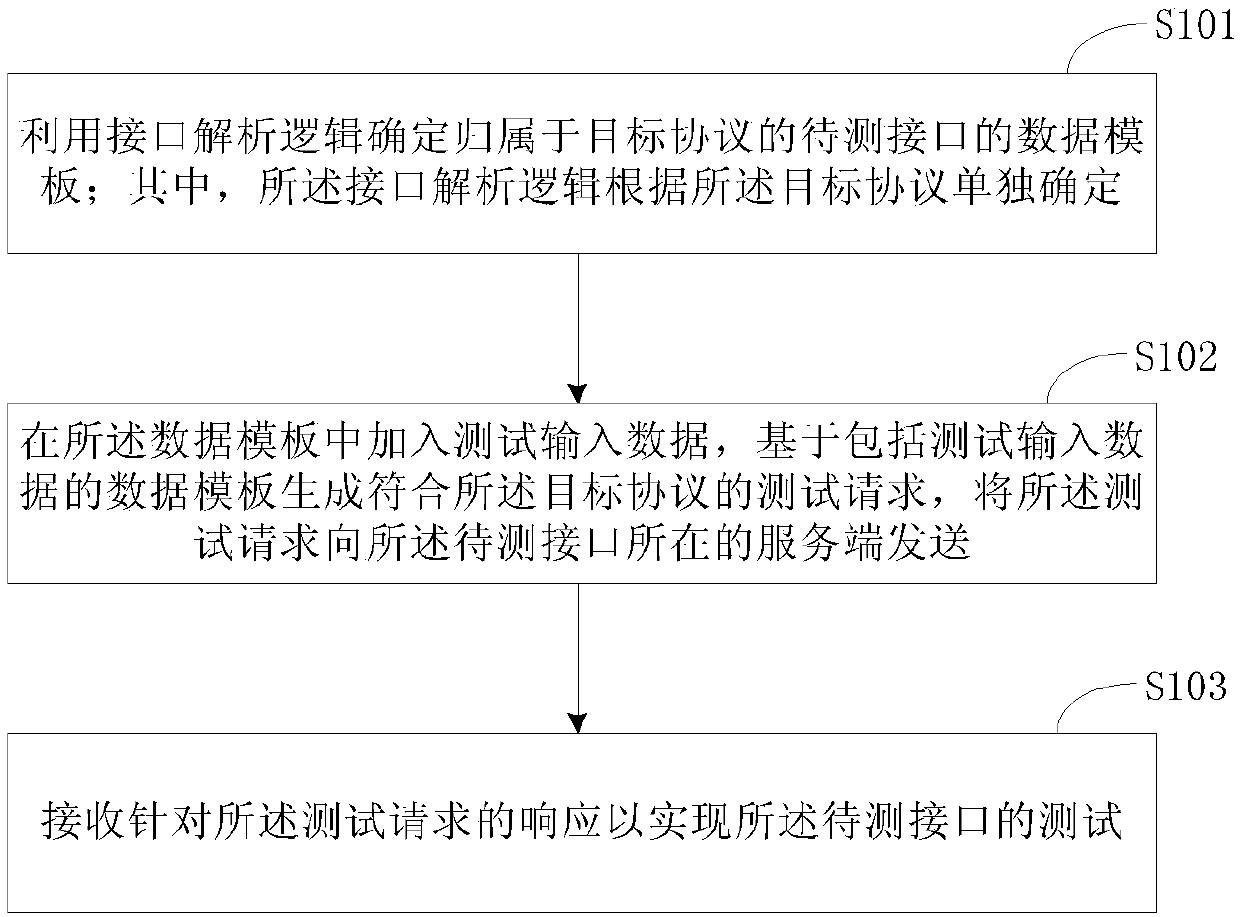

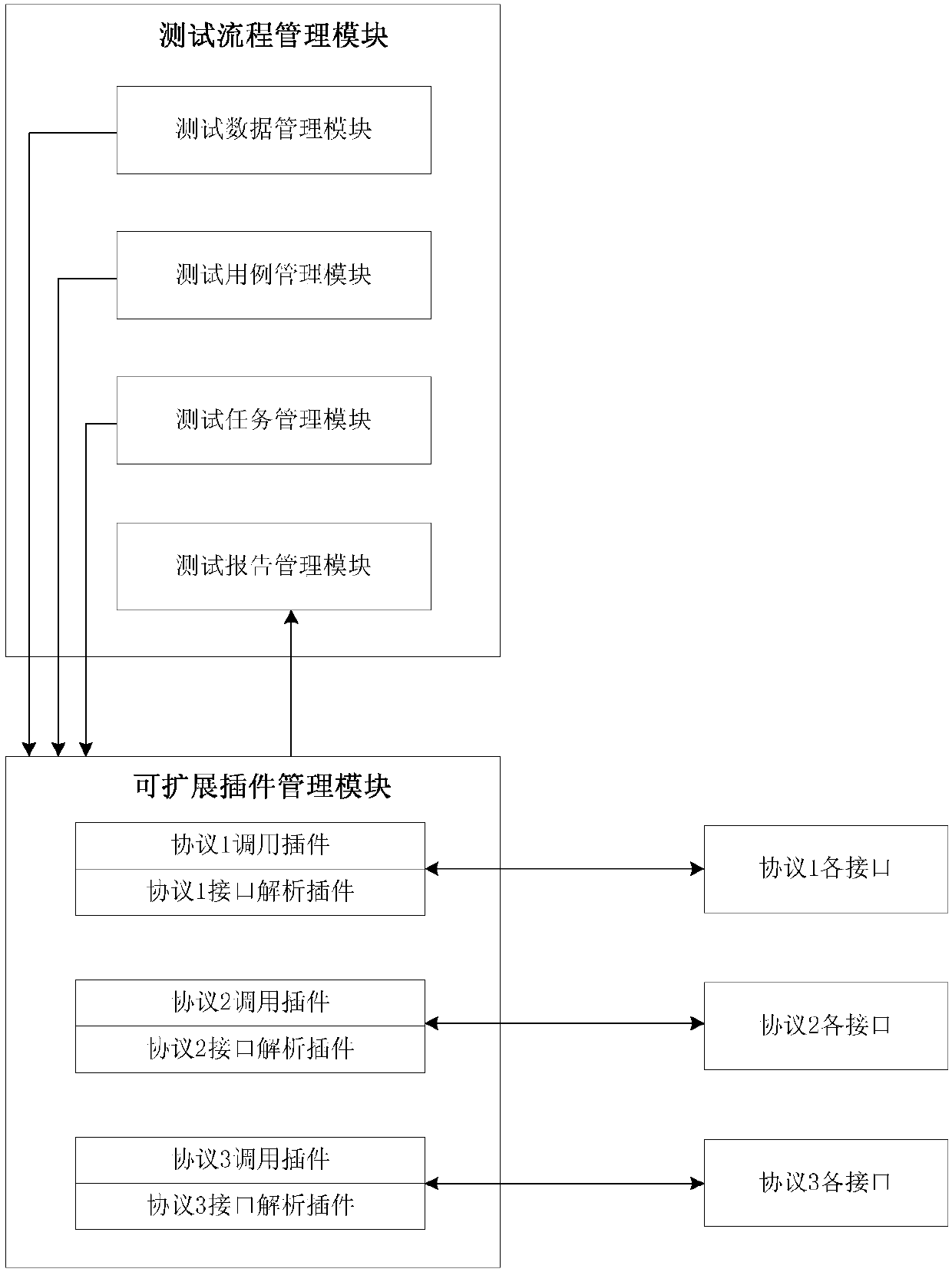

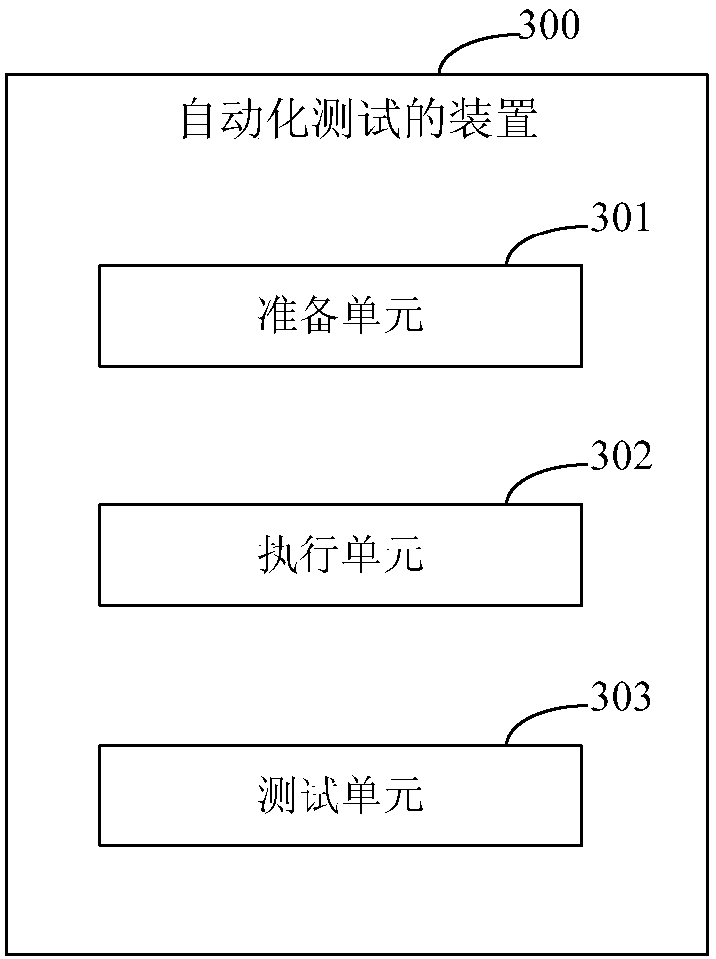

Automatic testing method and device

ActiveCN109815107AImplement featuresImprove scalabilitySoftware testing/debuggingComputer hardwareTest efficiency

The invention discloses an automatic testing method and device, and relates to the field of computers. One specific embodiment of the method comprises the following steps: 1, determining a data template of a to-be-tested interface belonging to the target protocol by utilizing the interface analysis logic; wherein the interface analysis logic is independently determined according to the target protocol; adding test input data into the data template, generating a test request conforming to the target protocol based on the data template including the test input data, sending the test request to aserver where the to-be-tested interface is located, and receiving a response to the test request to test the to-be-tested interface. According to the embodiment, the maintenance workload of the testtool can be reduced and the test efficiency is improved.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

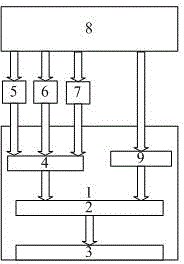

Multi-interface protocol analysis system

A device may include a first network module to capture network data at a first location in a network and a second network module to capture network data at a second location in the network different from the first location in the network. The device may include a control module to receive control commands relating to the first network module and the second network module. The control module may forwarded the control commands to the first network module and the second network module. The control module may receive the captured network data from the first network module and the second network module.

Owner:VERIZON PATENT & LICENSING INC

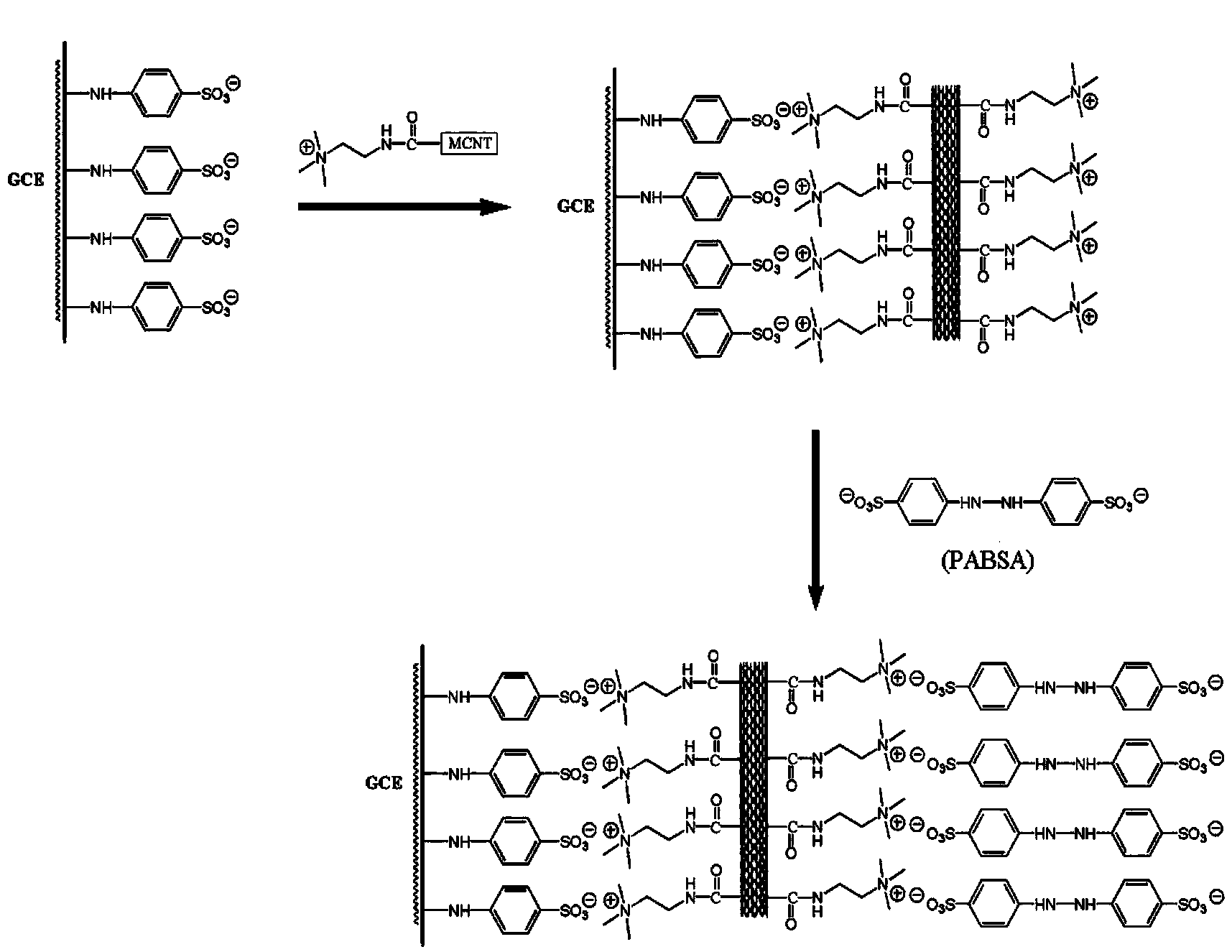

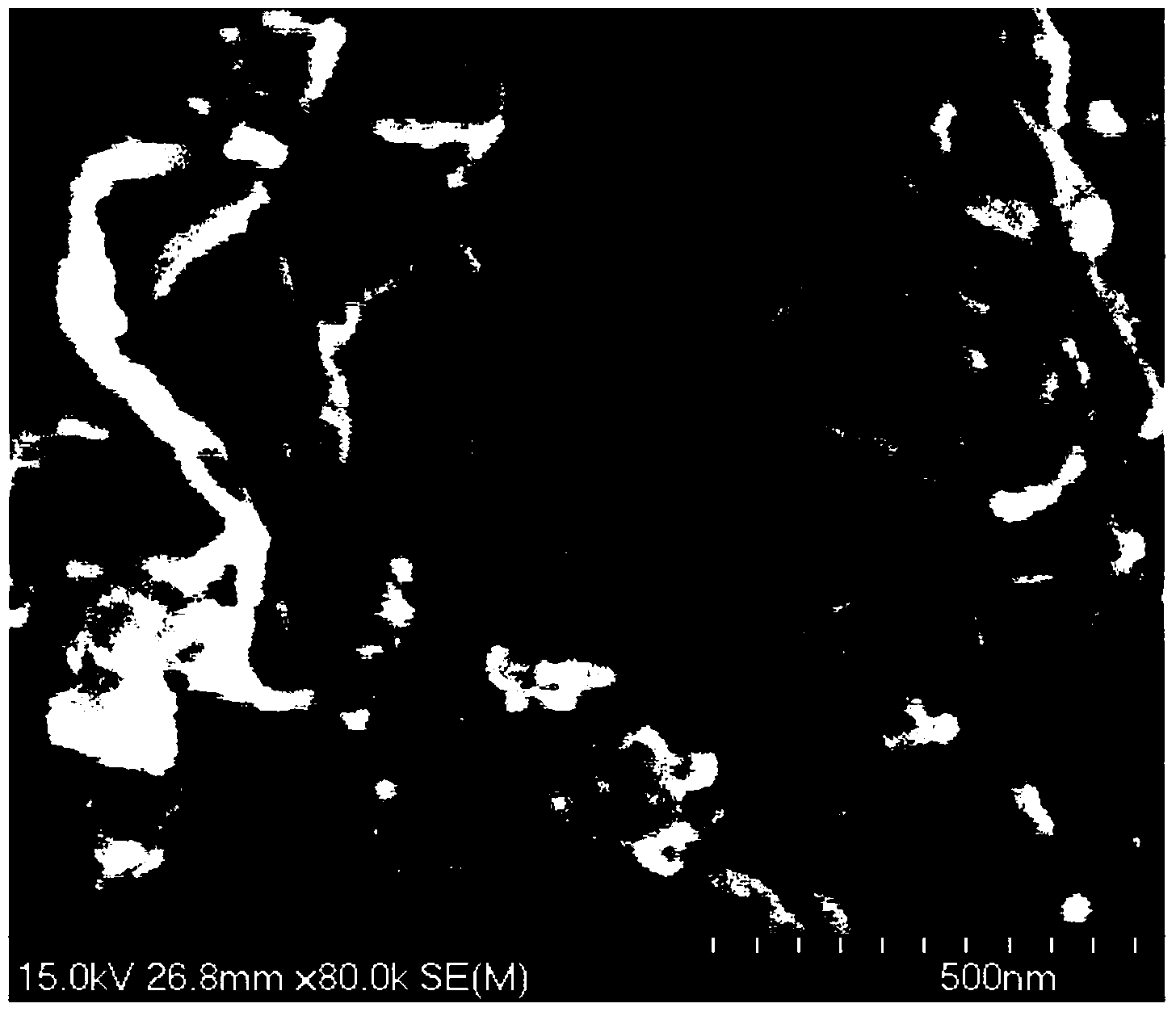

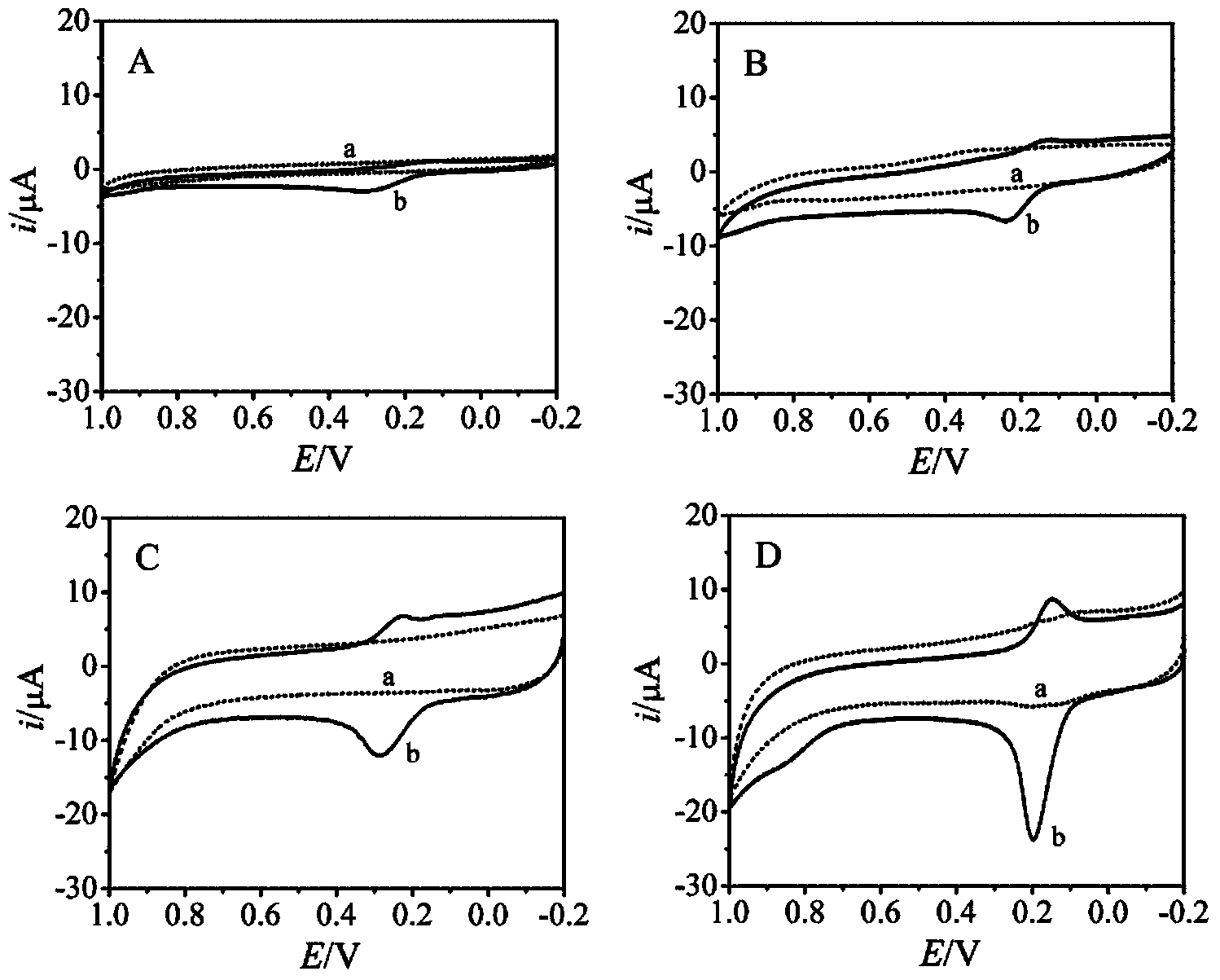

Novel carbon nano tube electrochemical sensing interface and preparation method thereof

InactiveCN103969318AAvoid reunionHighly ordered assemblyMaterial electrochemical variablesQuaternary ammonium cationComposite film

The invention discloses a novel carbon nano tube electrochemical sensing interface and a preparation method thereof. The novel carbon nano tube electrochemical sensing interface is characterized in that based on a novel functional carbon nano tube static compound monomolecular layer and a modified electrode electrochemical sensing interface analysis system of a polymer film, and through the use of surface negative charge activity of the anion conducting polymer film and the adoption of layered electrostatic self-assembly, a novel poly sulfanilic acid / quaternary ammonium functional carbon nano tube / monomolecular layer sulfanilic acid nano-composite film modified electrode sensing interface is prepared. Through the electrostatic self-assembly of the poly sulfanilic acid / quaternary ammonium cation functional carbon nano tube / monomolecular layer sulfanilic acid nano-composite film electrode sensing interface, the whole preparation process is simple and time-saving, the condition is controllable, the prepared sensing interface is good in stability and repeatability, the repeatability of the preparation process of the sensing interface is high, and the problem that the stability and the repeatability of an electrochemical sensor are poor in practical application is solved to a great degree.

Owner:ZHEJIANG UNIV

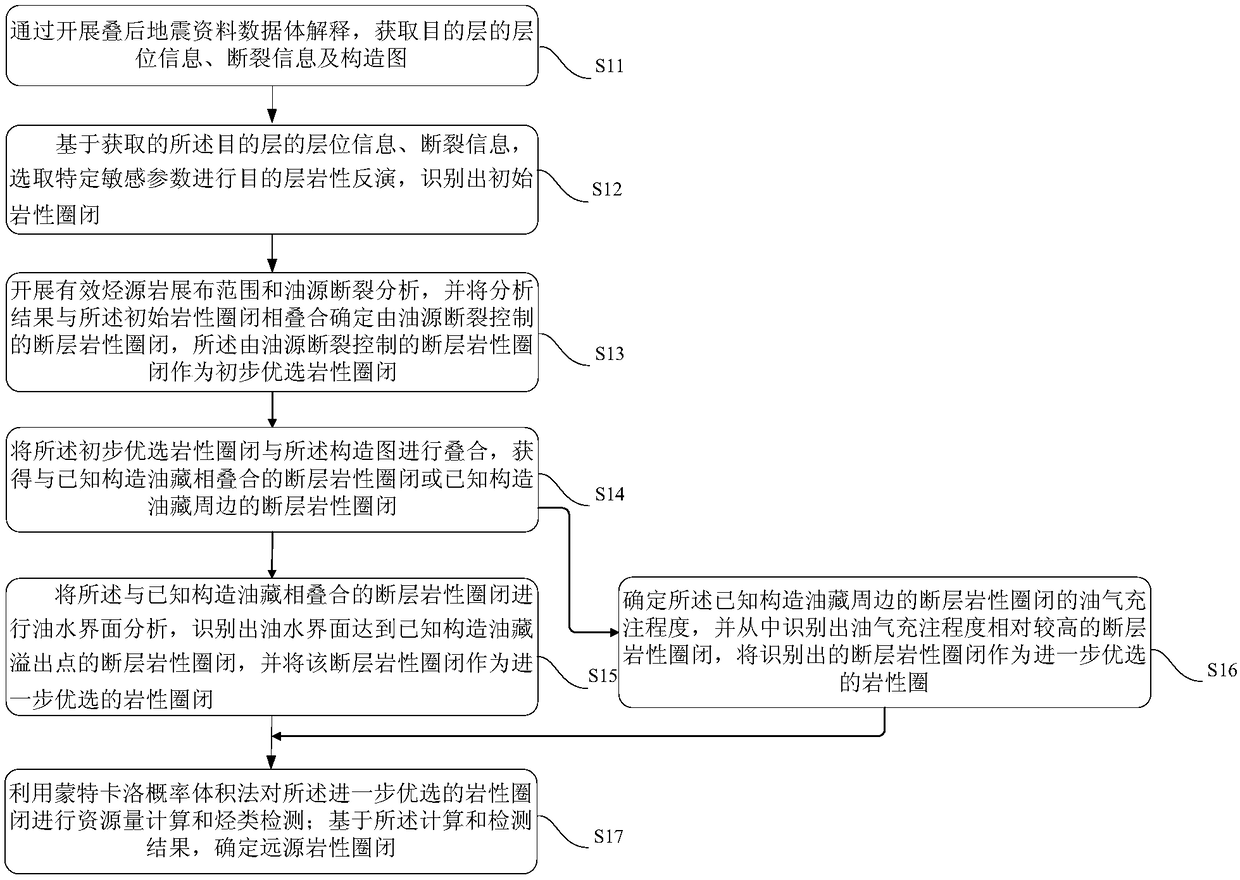

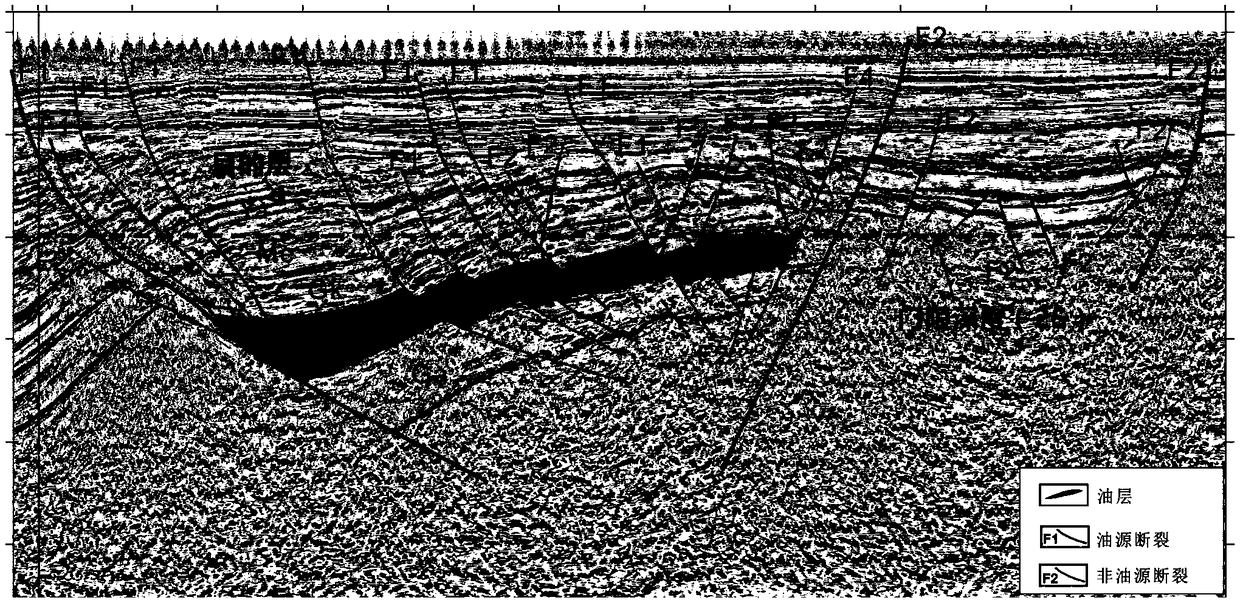

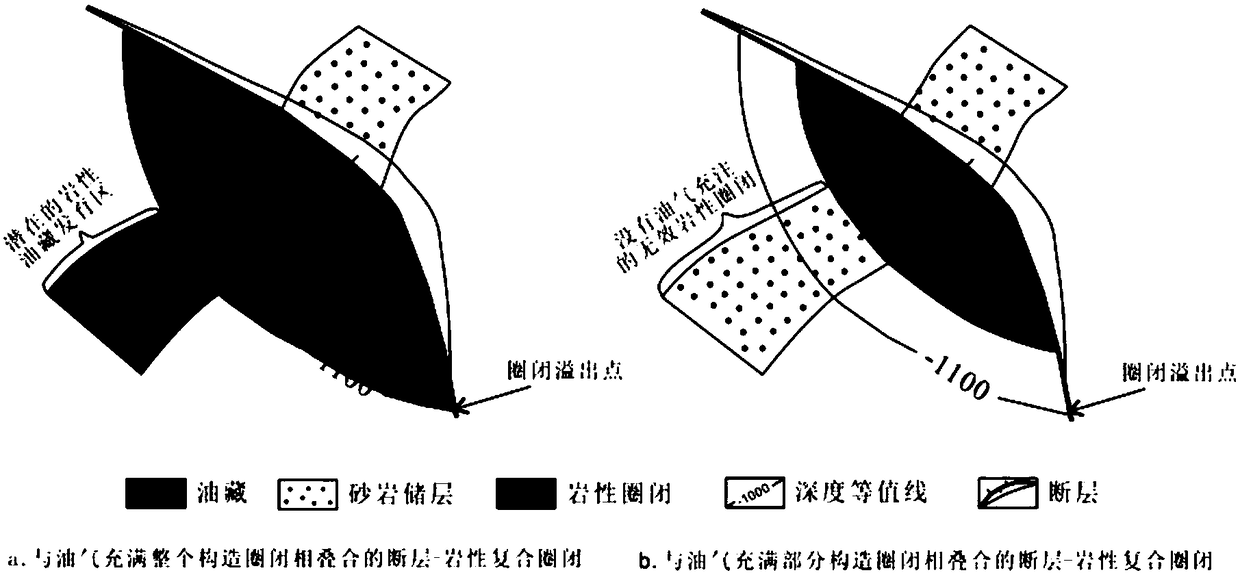

Method and device for determination of distal lithologic trap

ActiveCN108957541AIncrease success rateImprove efficiencySeismic signal processingLithologyOil water

The present invention discloses a method and a device for determination of a distal lithologic trap. The method comprises the steps of: developing post-stack seismic information data volume interpretation; selecting special sensitive parameters to perform target stratum lithology inversion and identify an initial lithologic trap; determining a fault lithologic trap controlled by oil source fracture as a preliminarily optimal lithologic trap, and performing overlapping of the fault lithologic trap and a structural map to obtain a fault lithologic trap overlapped with a known structure oil poolor a fault lithologic trap around the known structure oil pool; performing oil-water interface analysis of the fault lithologic trap overlapped with the known structure oil pool to identify further optimal lithologic trap; determining the oil and gas charging degree of faults around the known structure oil pool to identify a further optimal lithologic trap; and employing the Monte Carlo probability volumetric method to perform resource quantity calculation and hydrocarbon detection for the further optimal lithologic trap to determine a distal lithologic trap. The method and the device for determination of a distal lithologic trap can accurately determine the distal lithologic trap.

Owner:PETROCHINA CO LTD

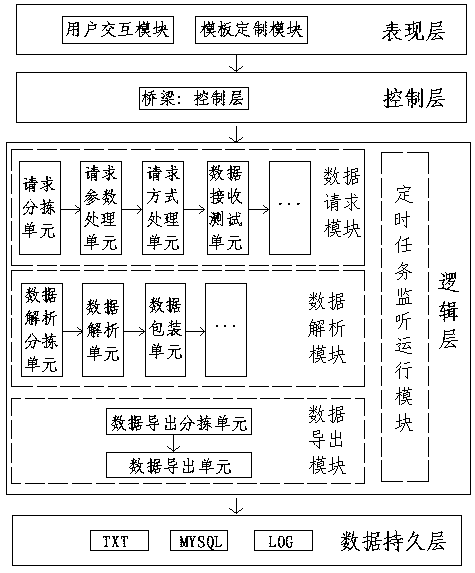

Visual interface data intelligent extracting system and design method thereof

ActiveCN108287923AIncrease productivityImprove data acquisition efficiencySpecial data processing applicationsControl layerCode redundancy

The invention discloses a visual interface data intelligent extracting system and a design method thereof, and belongs to the technical field of system construction. The visual interface data intelligent extracting system comprises an expression layer, a control layer, a logic layer and a data persistence layer. The expression layer is composed of a user interaction module and a template customizing module. The control layer is connected with the expression layer and controls and monitors the visual customizing of a task imported by the expression layer. The logic layer is composed of a data requiring module, a data analyzing module, a data export module and a timed task monitoring and operating module. The logic layer is connected with the control layer. The data persistence layer is connected with the logic layer. The data persistence layer conducts persistence treatment on obtained data to obtain interface analysis data. By means of the visual interface data intelligent extracting system, the interface data treatment efficiency in enterprise production is greatly improved, the code redundancy of a project is reduced, and the system has quite good application and popularization value.

Owner:SHANDONG LANGCHAO YUNTOU INFORMATION TECH CO LTD

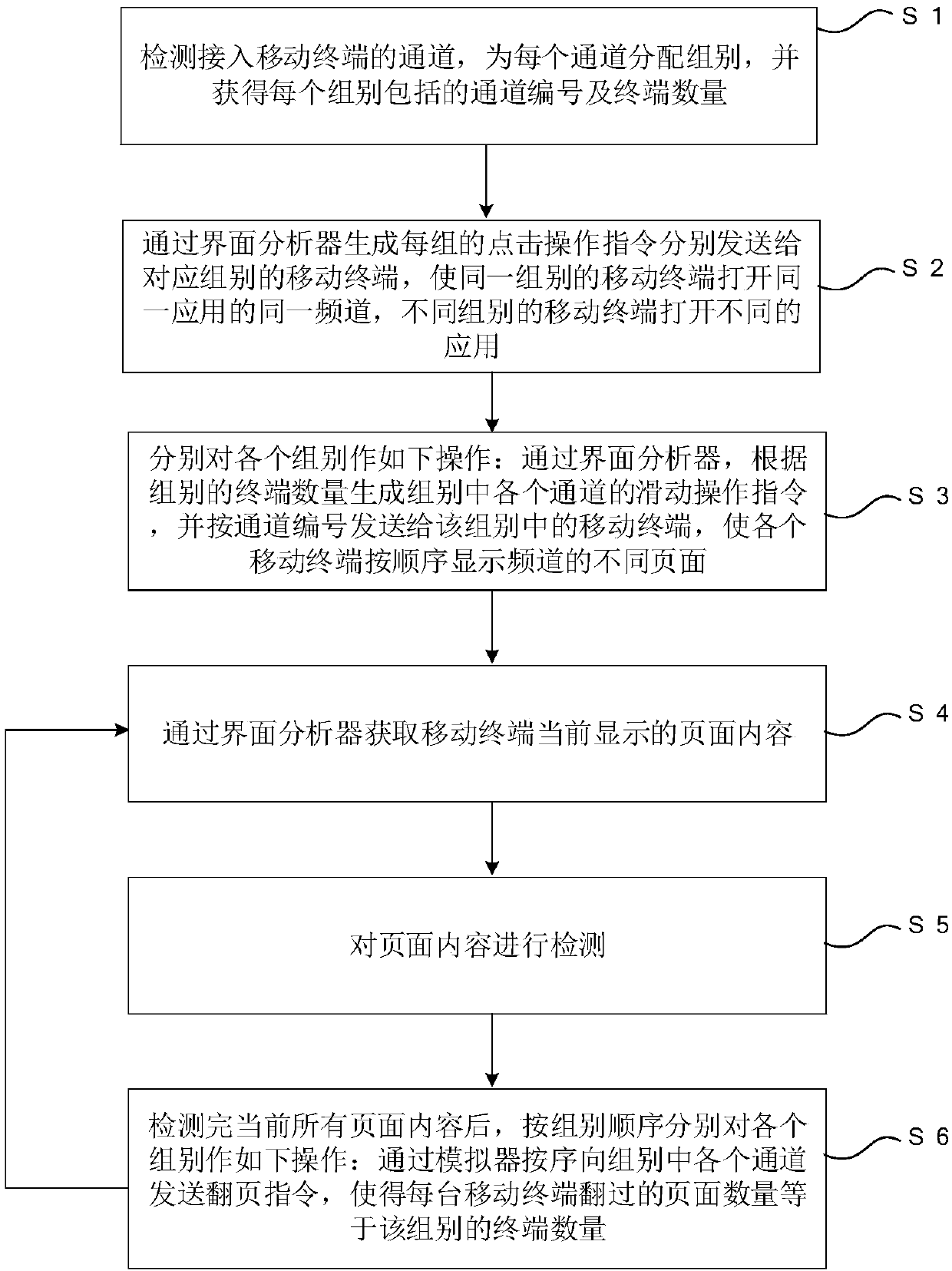

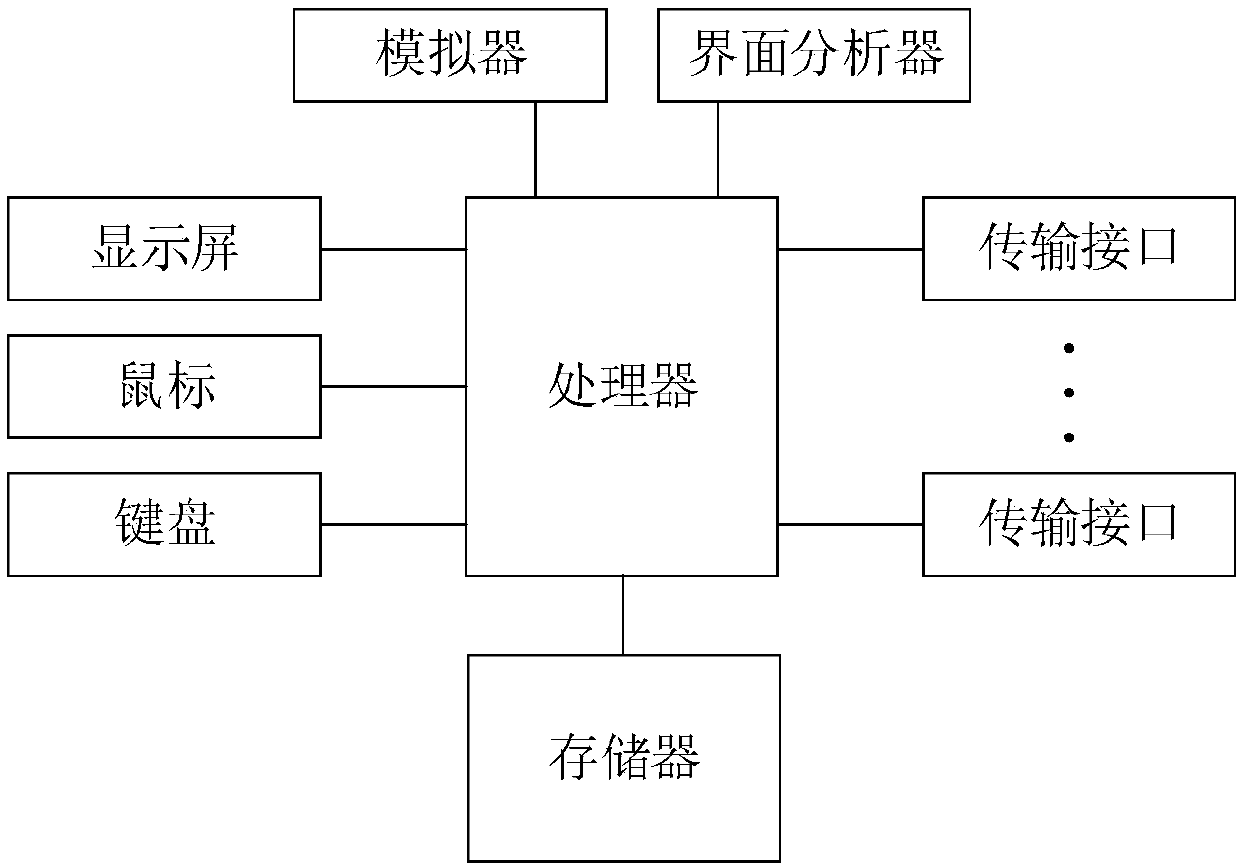

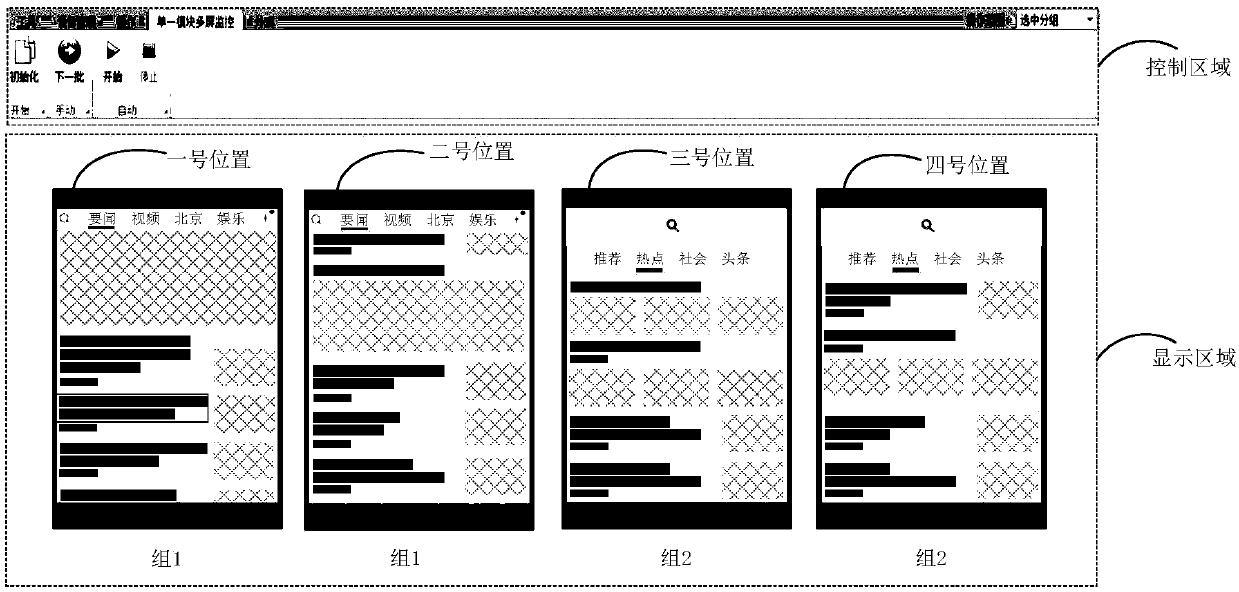

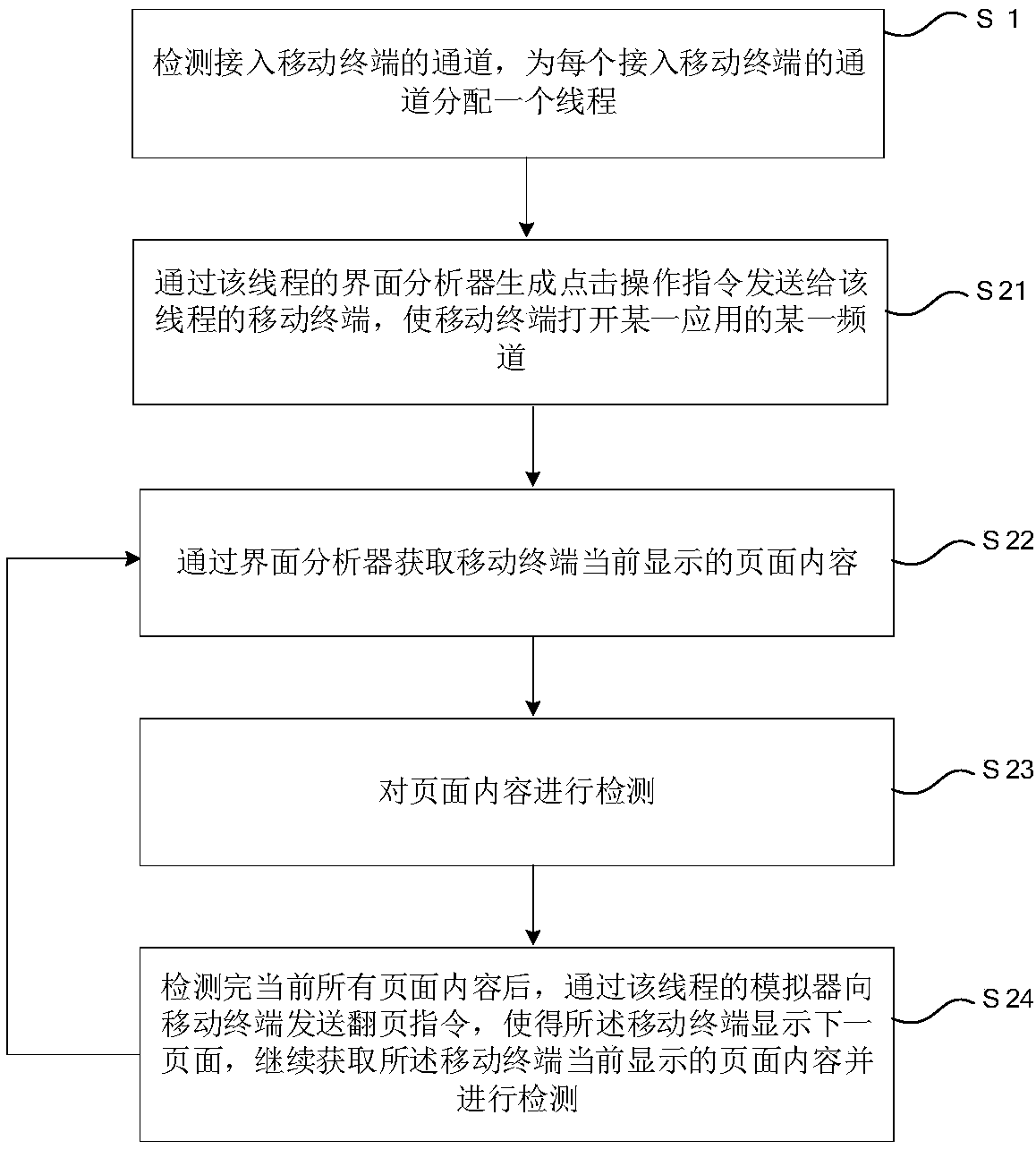

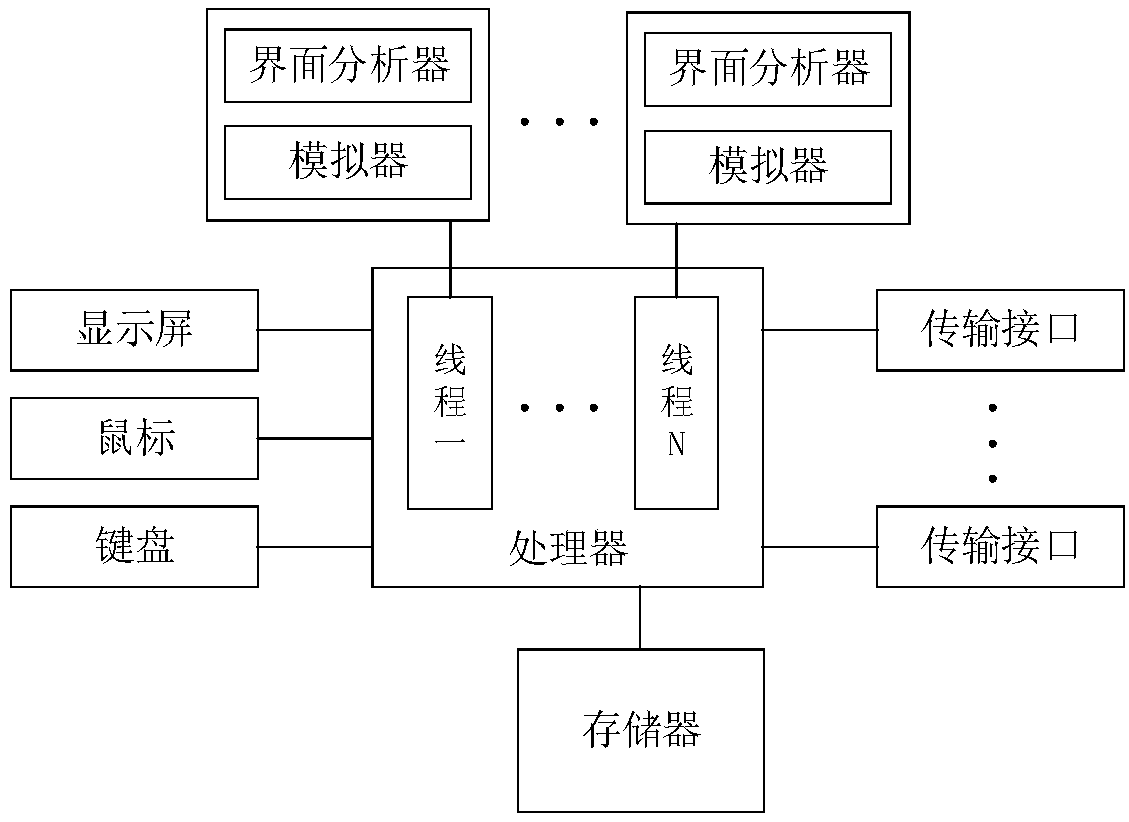

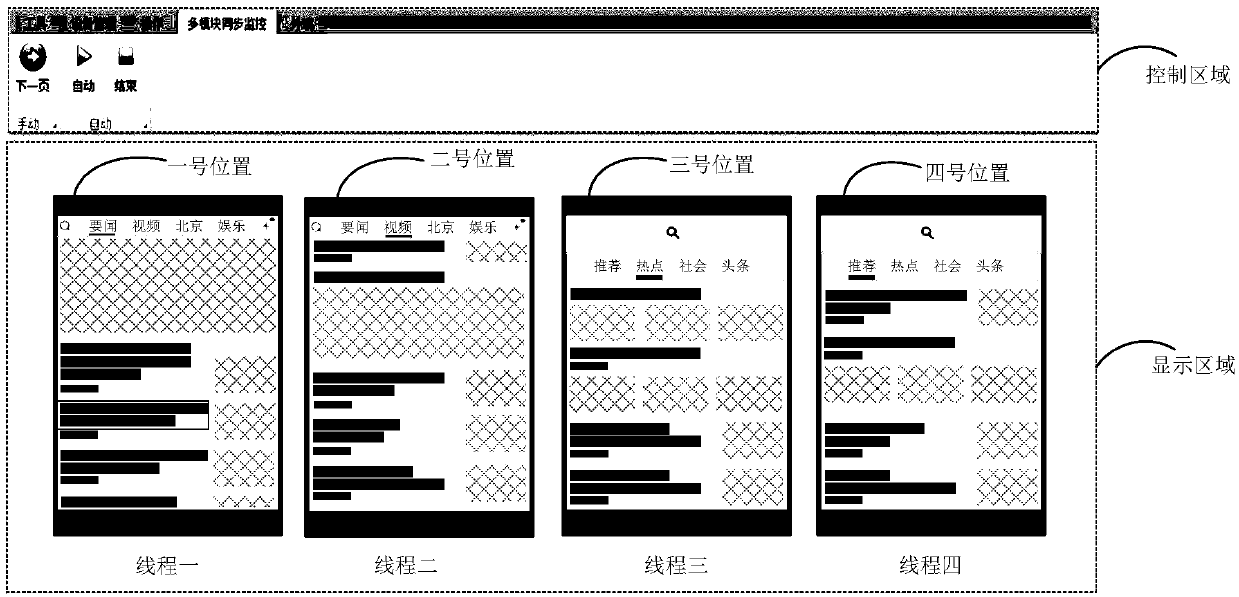

Method and system for supervising mobile terminal application

ActiveCN107911388AImprove detection efficiencyImprove regulatory efficiencyTransmissionComputer terminalMultiple applications

The invention relates to a method and system for supervising a mobile terminal application. The method comprises the following steps: detecting a path accessing to a mobile terminal, distributing a group for each path, and acquiring a path serial number and terminal amount included in each group; generating a click operation instruction of each group through an interface analyzer, respectively sending the click operation instruction to the mobile terminal of the corresponding group; generating a sliding operation instruction of each path in the group according to the terminal amount of the group, and sending the sliding operation instruction to the mobile terminal in the group according to the path serial number; detecting page content; respectively performing the following operations on various groups according to group order after completely detecting all page content: sending a page turning instruction to each path in the group in order through a simulator, thereby enabling the amount of the page turned by each mobile terminal to be equal to the terminal amount of the group. The belonged group of the mobile terminal can be flexibly configured to detect the application and the channel in group; multiple applications and multiple channels can be monitored at the same time, and the detection efficiency is improved.

Owner:信通院(广州)科技创新有限公司

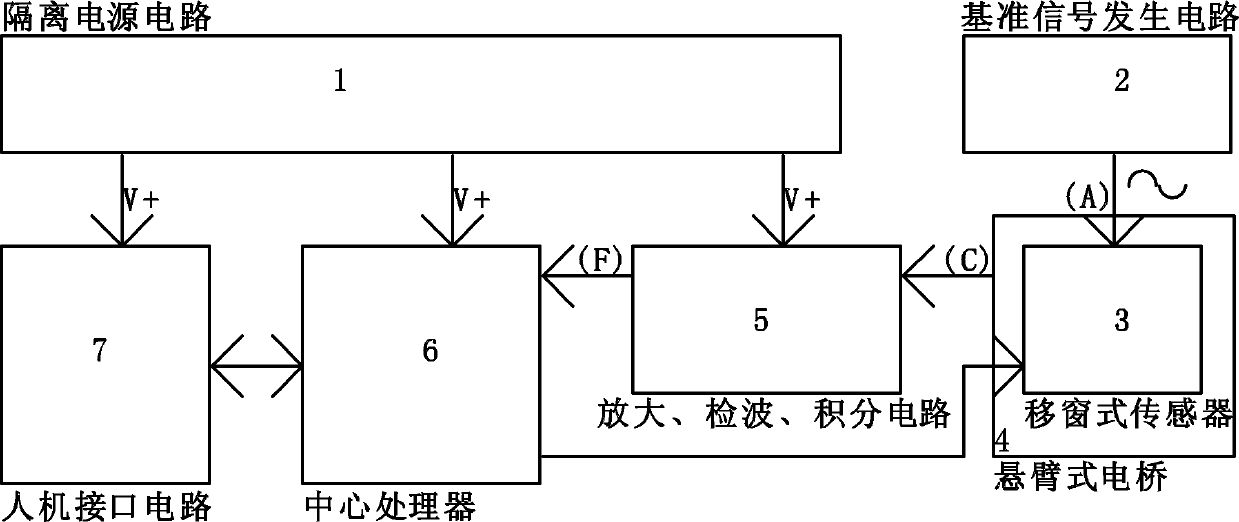

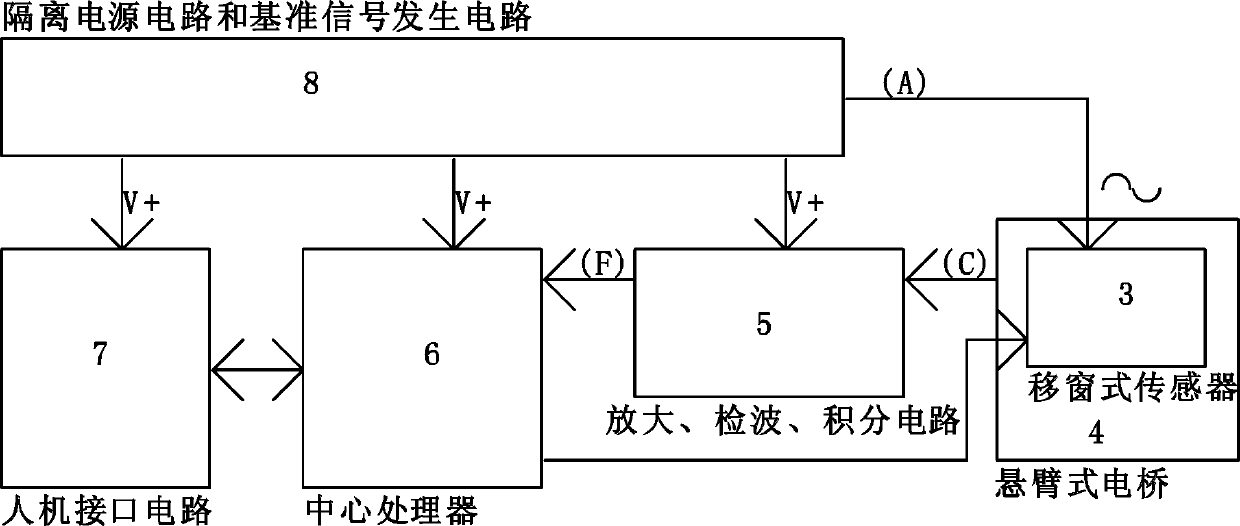

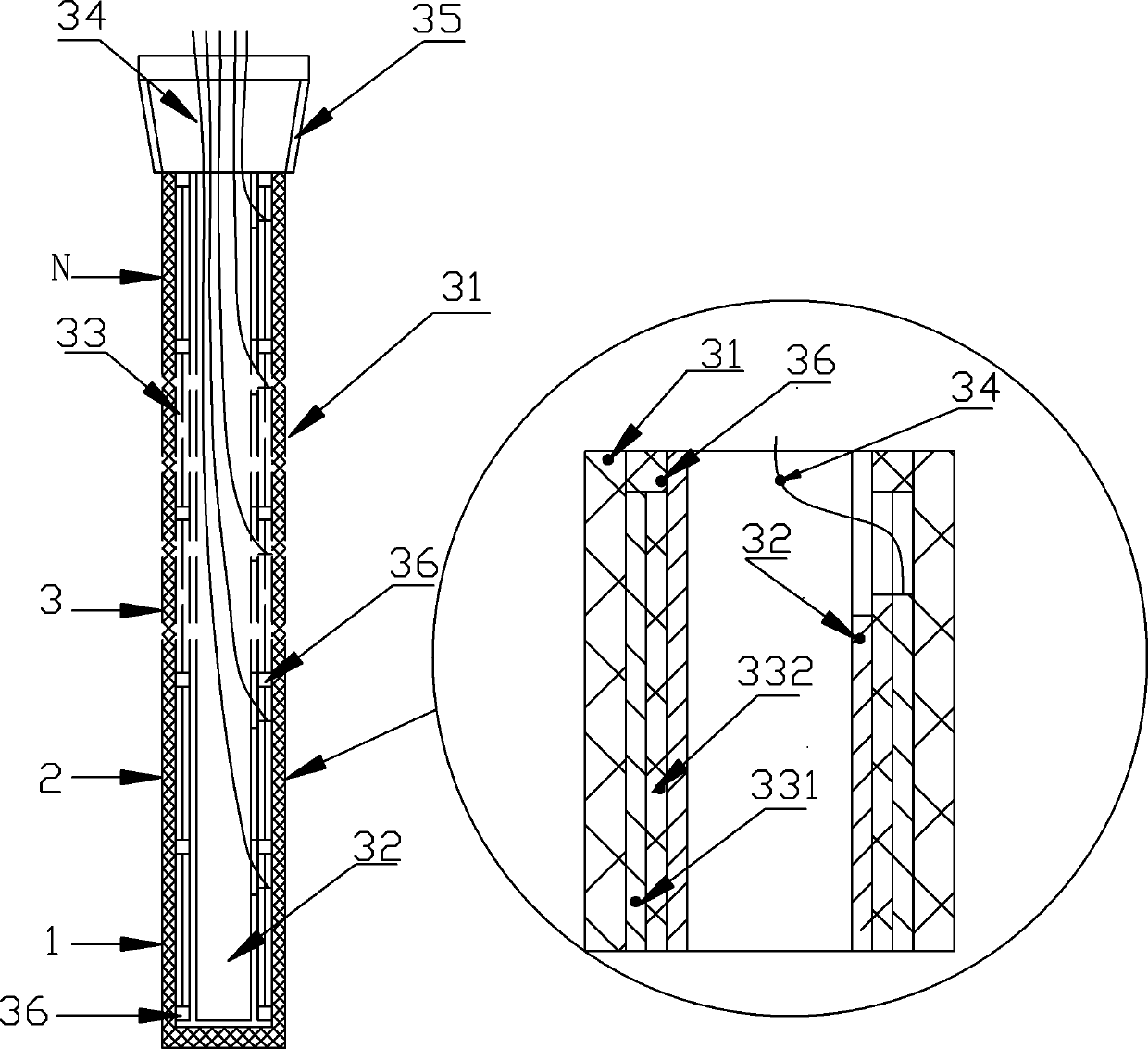

Float process shift window interface analyzer based on continuous capacitance measurement

InactiveCN102636236AImprove efficiencyHigh precisionLevel indicators by physical variable measurementContinuous measurementCapacitance

The invention relates to a float process shift window interface analyzer based on continuous capacitance measurement, comprising shift window-type sensors which are sequentially connected serially, are used for converting the physical information of an interface to be measured into electronic information and comprise a plurality of sections of rapiers, a cantilever-type bridge circuit, an amplification detection integral circuit which amplifies and rectifies an input signal to be measured into an integral signal which is in linear corresponding relationship, a central processing circuit whichis used for controlling the on and the off of a shift window-type sensor window body and a man-machine interface circuit which is used for outputting a final processing result; and according to the float process shift window interface analyzer based on continuous capacitance measurement, an electric structure is novel and simple, a substance interface analysis circuit which has high reliability and high precision and does not need manual debugging is arranged, the circuit works reliably and has high efficiency, and the result analysis precision is high. The float process shift window interface analyzer based on continuous capacitance measurement can be widely applied in the measurement of a gas-liquid interface, a gas-solid interface and a liquid-liquid interface.

Owner:TIANJIN HENGLIYUANDA INSTR

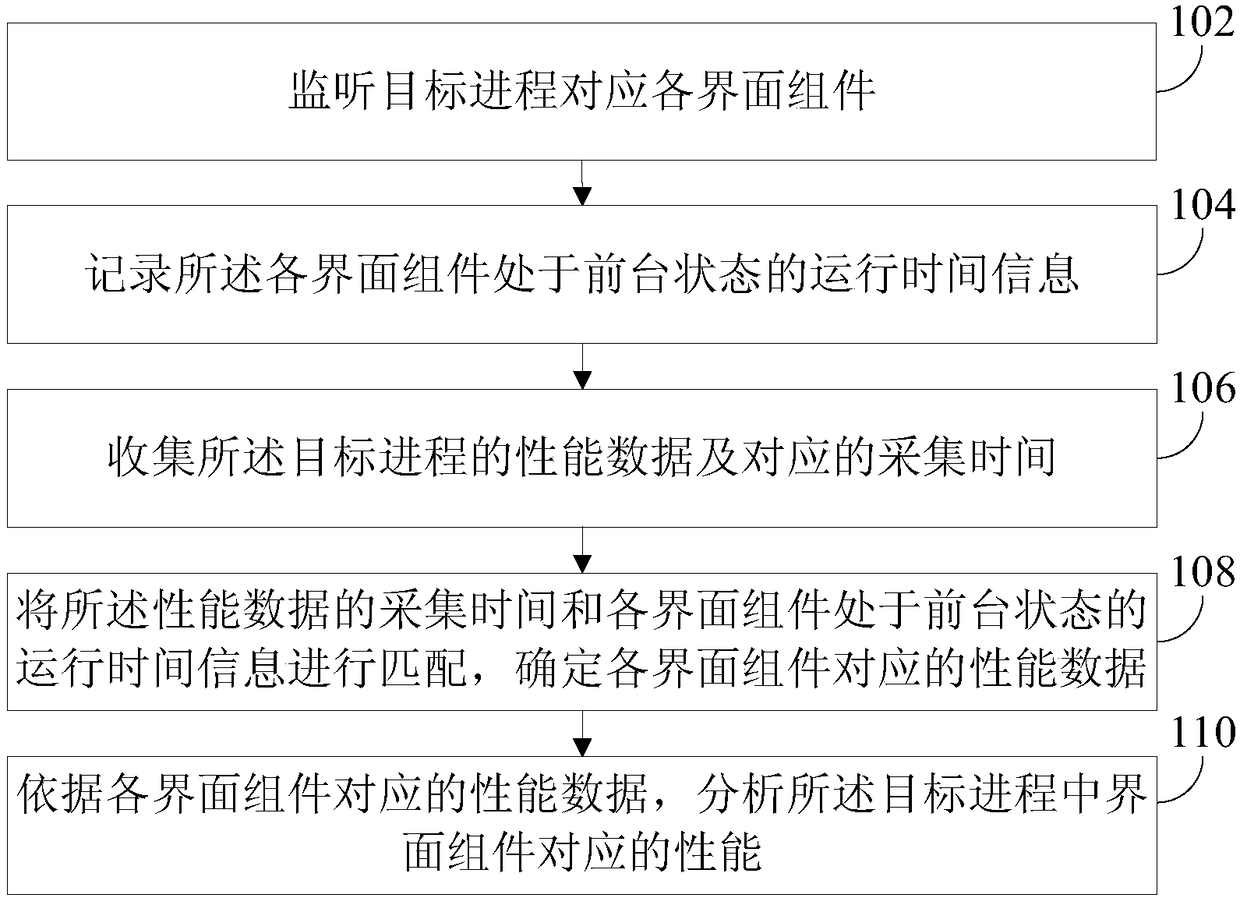

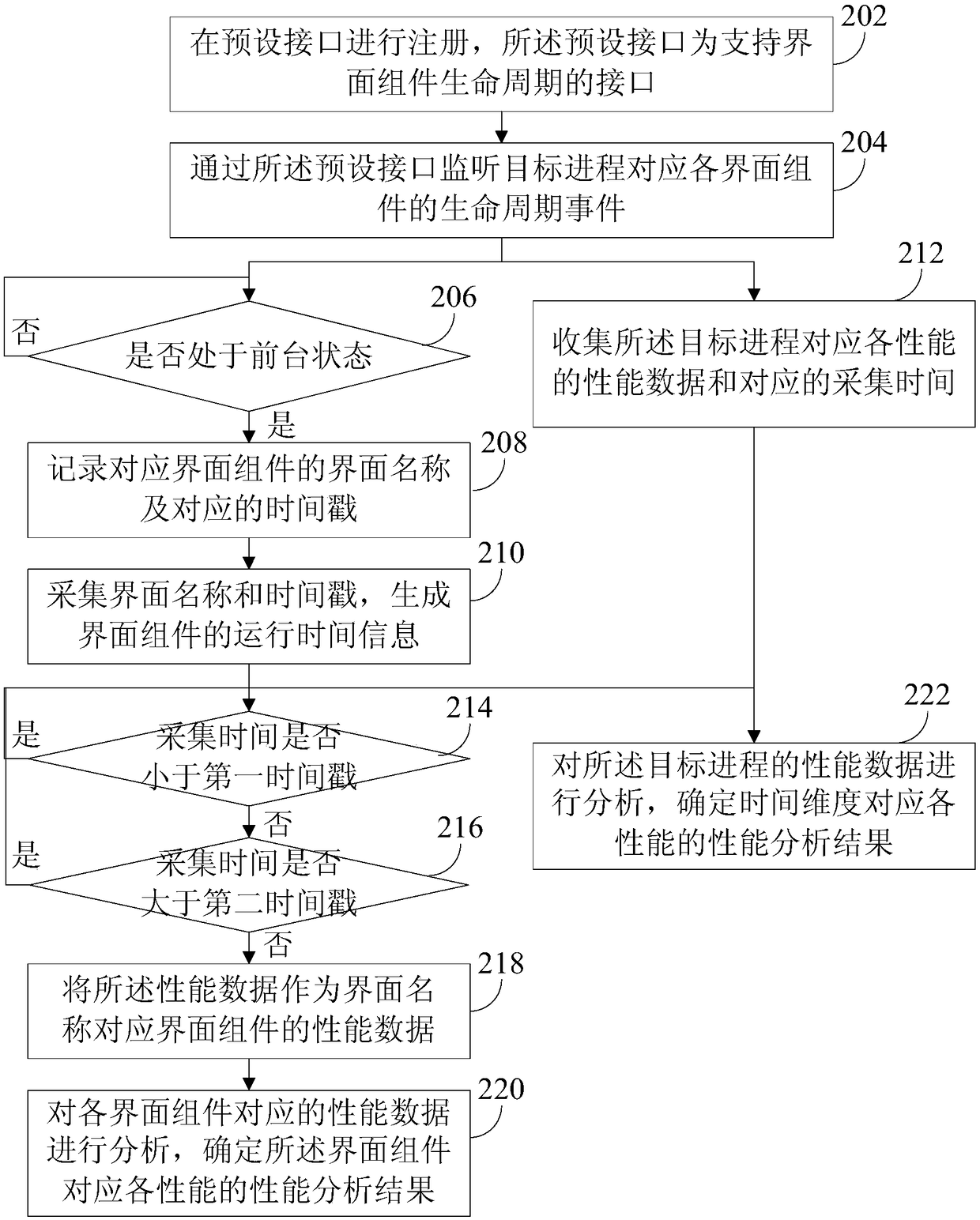

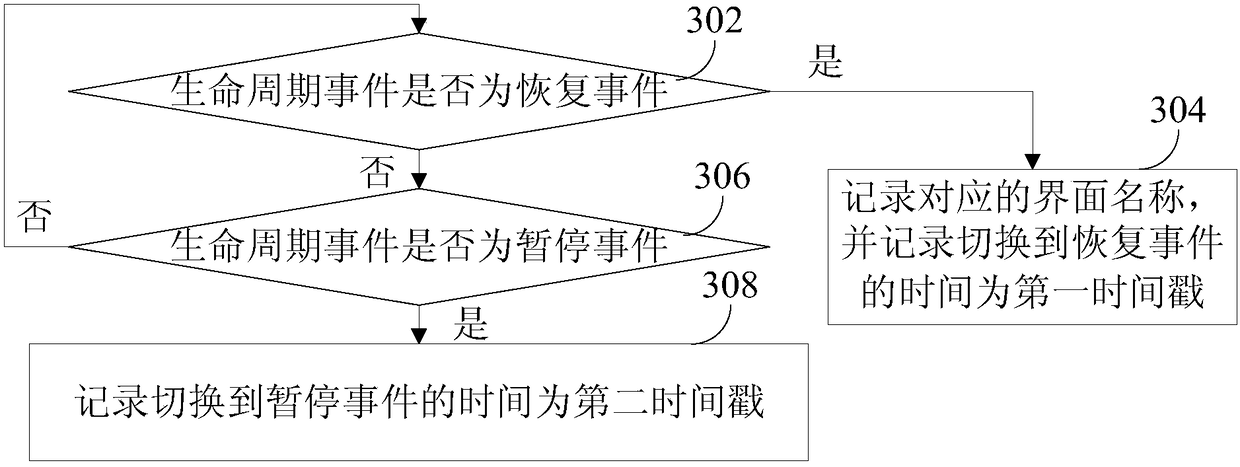

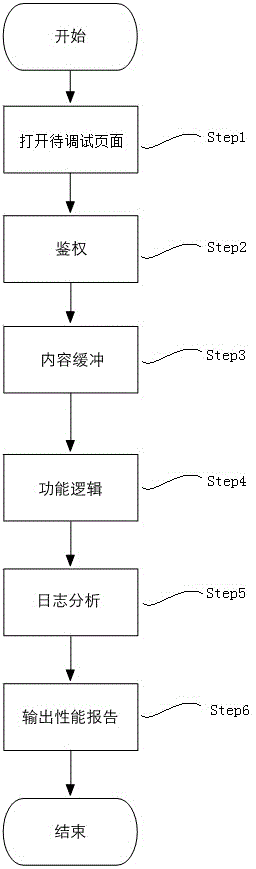

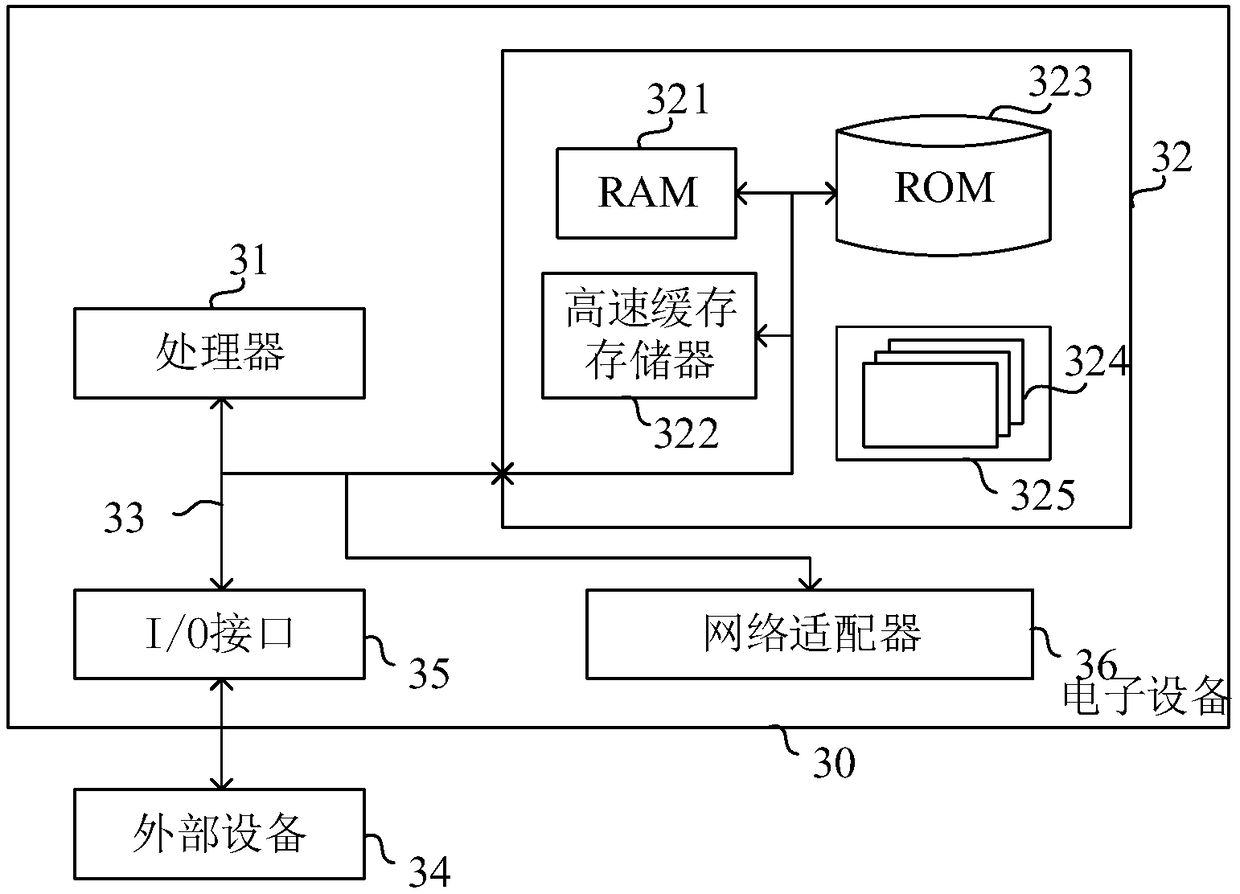

Performance test method, device, electronic device, and storage medium

ActiveCN109298995AImprove accuracyHardware monitoringSoftware testing/debuggingRunning timeInterface analysis

The embodiment of the invention provides a performance test method, a device, an electronic device and a storage medium, so as to improve the accuracy of the performance test. The method comprises thefollowing steps of: listening to the interface components corresponding to the target process; Recording the running time information of the interface component in the foreground state; collecting performance data of the target process and recording a corresponding collection time; matching the collecting time of the performance data with the running time information of the interface component inthe foreground state to determine the performance data corresponding to the interface component; according to the performance data corresponding to the interface components, the performance corresponding to the interface components in the target process is analyzed. It can establish the relationship between interface components and performance data, and analyze the performance of the target process based on the interface, which can effectively improve the accuracy of performance analysis.

Owner:BEIJING SOGOU TECHNOLOGY DEVELOPMENT CO LTD

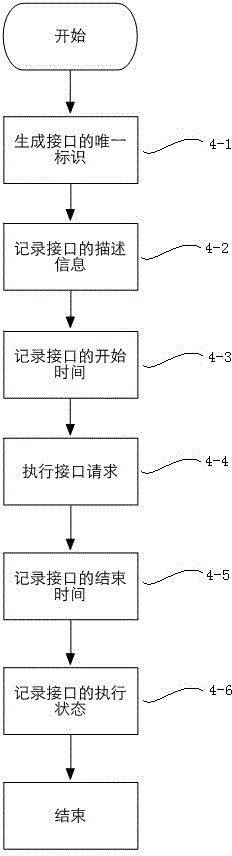

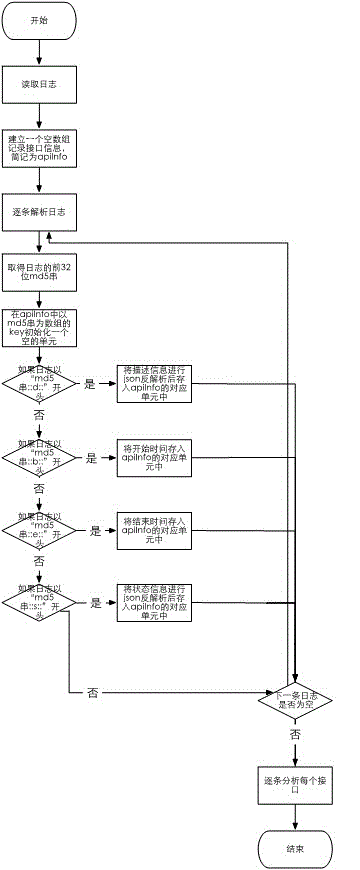

Method and system for remotely analyzing performances of external system interfaces in real time

ActiveCN104598348ARealize remote real-time analysisSave hard disk resourcesDetecting faulty computer hardwareInternal memoryContent format

The invention discloses a method and a system for remotely analyzing performances of external system interfaces in real time. The method comprises the following steps: interface information when external interface access is performed in each time can be recorded as an internal memory log, log analysis is started to be performed after an application program is executed, an analysis report for displaying the performance of each interface is outputted in a browser's debugging page window, so that the remote real-time analysis on the performances of the external interfaces is realized. As the log is stored in an internal memory, and a magnetic disk storage space on a server is not utilized, server hard disk resources are fully saved, and the problems of network resource waste and low efficiency caused by the fact that the log information is dragged from the remote server to perform artificial view are also solved. In addition, the interface analysis report can be displayed according to an output content format of the application program, and the user experience is improved.

Owner:NANJING TUNIU TECHNOLOGY CO LTD

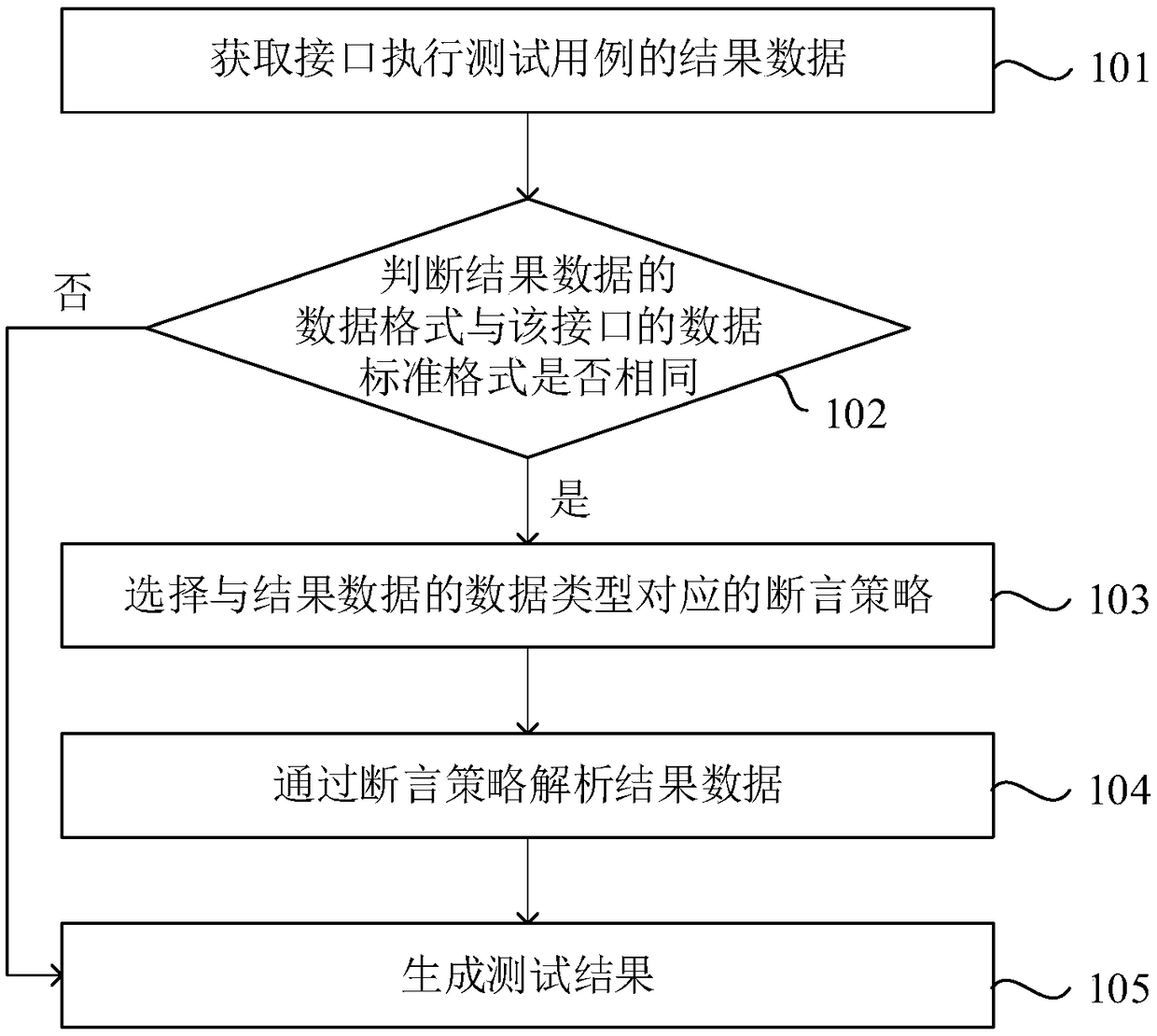

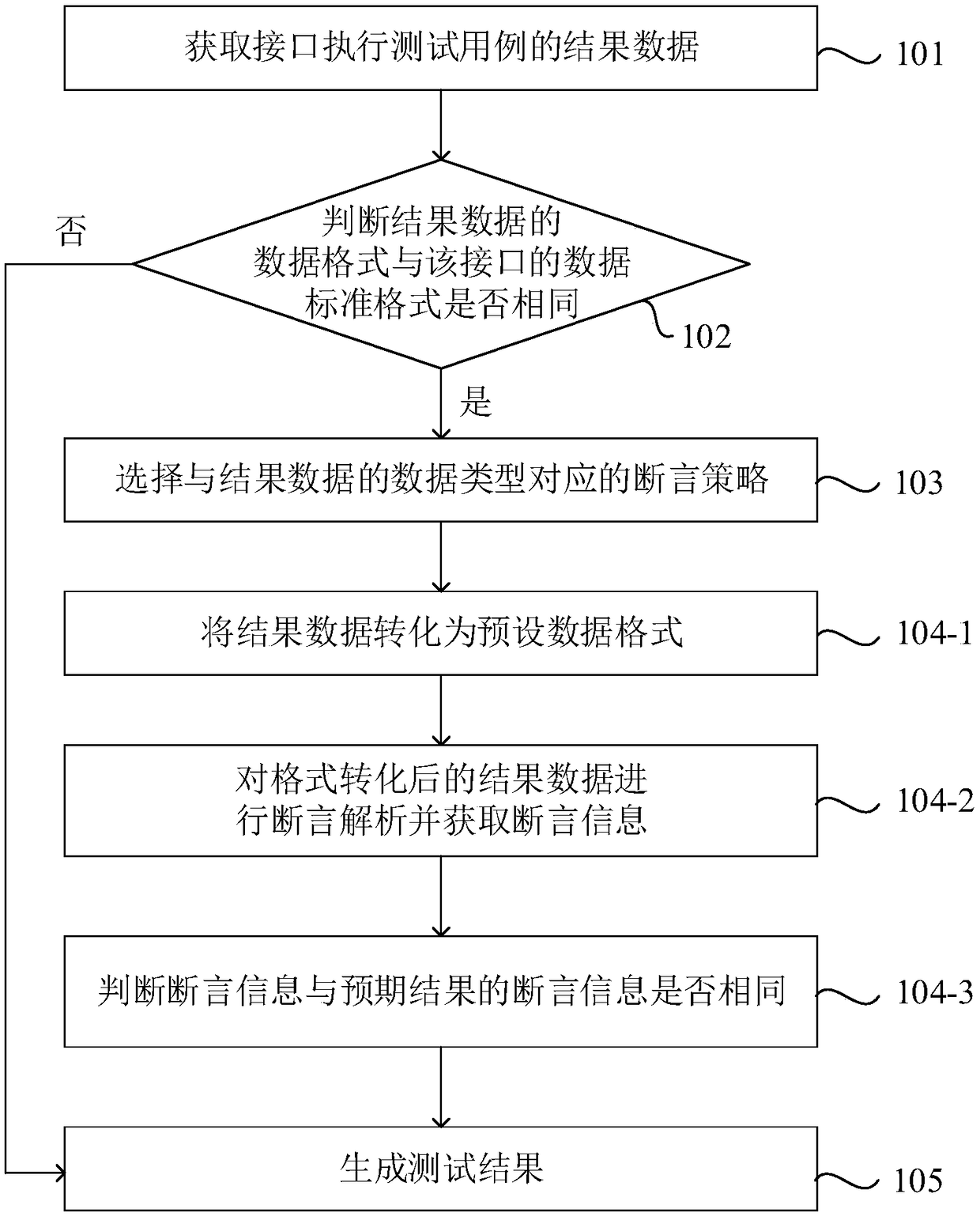

Interface testing method and system, electronic device, and storage medium

PendingCN109189679AAchieve refinementImprove accuracySoftware testing/debuggingTechnical standardData type

The invention discloses an interface testing method and system, an electronic device and a storage medium. The interface testing method comprises the following steps: obtaining the result data of an interface execution test case; judging whether the data format of the result data is the same as the data standard format of the interface; selecting an assertion strategy corresponding to the data type of the result data when the judgment is yes; parsing the result data according to the assertion strategy and generating test results. The invention is applicable to the testing of various types of interfaces. The format of the interface is analyzed first. If the returned format is abnormal, the format of the interface analysis is considered to be wrong, and the test result that the interface test does not pass the test can be obtained, thereby avoiding the cost of related further comparison. If the format is confirmed to be correct, different types of result data can be parsed to achieve fine and focused judgment of the results, which improves the accuracy of the assertion and further improves the accuracy of the test.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

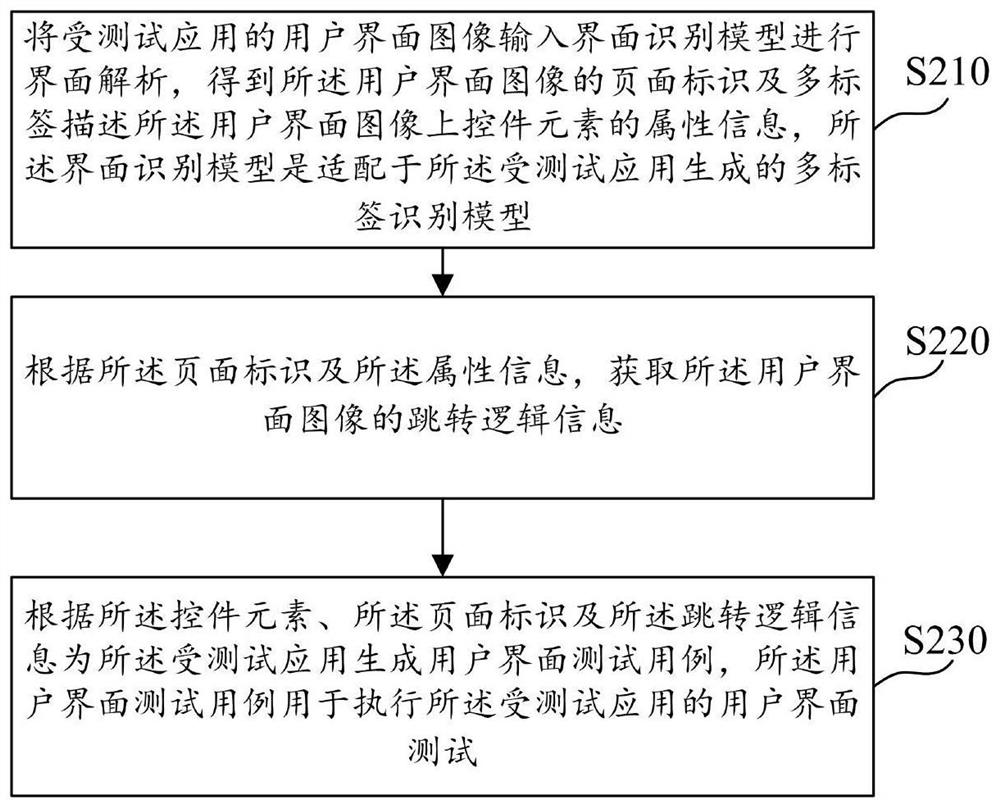

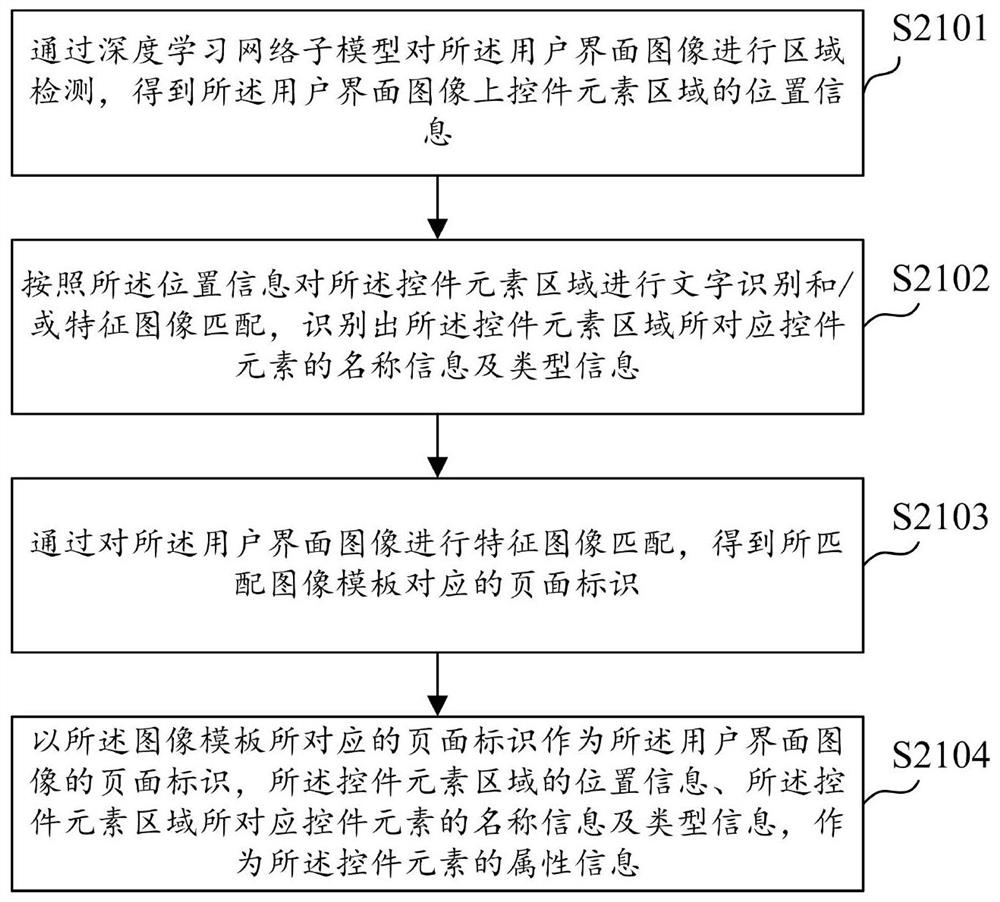

User interface test method and related device

PendingCN112749081AImprove test efficiencyImprove test reliabilitySoftware testing/debuggingExecution for user interfacesHuman–computer interactionUser interface

The invention provides a user interface test method and a related device, and belongs to the technical field of user interface testing. The method comprises the following steps: inputting a user interface image of a tested application into an interface identification model for interface analysis to obtain a page identifier of the user interface image and attribute information of a control element on the user interface image described by multiple tags, the interface identification model being a multi-label identification model generated by adapting to the tested application; acquiring jump logic information of the user interface image according to the page identifier and the attribute information; and generating a user interface test case for the tested application according to the control element, the page identifier and the jump logic information, wherein the user interface test case is used for executing a user interface test of the tested application. According to the embodiment of the invention, the user interface testing efficiency and reliability are effectively improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Multi-thread monitoring method and system for monitoring application of mobile terminal

ActiveCN108123937AImprove detection efficiencyReduce CatonWeb data indexingTransmissionTerminal equipmentMultiple applications

The invention relates to a multi-thread monitoring method and system for monitoring application of a mobile terminal. The method comprises the steps of detecting a channel in connection with a mobileterminal, allocating a thread to each channel accessed to the mobile terminal, wherein each thread independently executes the following steps: an interface analyzer generates a click operation instruction and sends the click operation instruction to the mobile terminal of the thread; the click operation instruction is generated through the interface analyzer of the thread and is sent to the mobileterminal of the thread; a page content which is currently displayed by the mobile terminal is obtained; the page content is detected; a page turning instruction is sent to the mobile terminal througha simulator, so that the mobile terminal displays a next page; and the page content currently displayed by the mobile terminal is continuously acquired and detected. The multi-thread detection methodis adopted so that applications and channels detected by the terminal equipment can be flexibly configured; all threads do not interfere with each other; multiple applications and channels can be monitored in parallel at the same time, so that the detection efficiency is improved, and the phenomena of blockage, false death and the like in the detection process are reduced.

Owner:信通院(广州)科技创新有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com