Sugarcane sugar boiling equipment optimizing design modeling and modeling method based on field synergy principle

An optimized design and field synergy technology, applied in computing, electrical digital data processing, special data processing applications, etc., to achieve the effects of avoiding pseudocrystals, improving yield and quality, and shortening cooking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

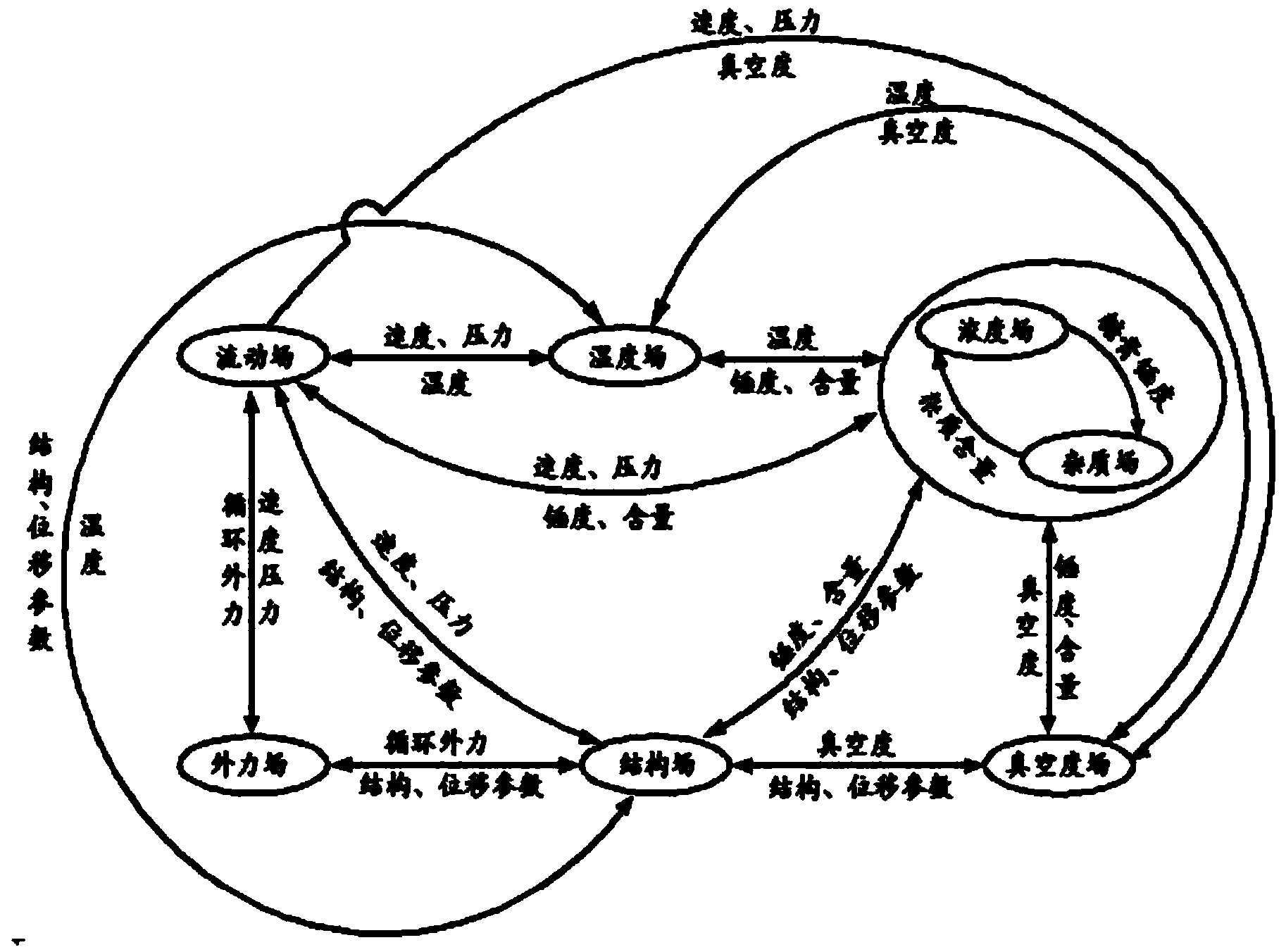

[0027] like figure 1 As shown, the mutual coupling relationship of each field in the sugar cooking system, the sugar cooking system is a complex system of multi-field coupling effects, including the complex multi-field coupling effects of temperature field, flow field, vacuum field, concentration field, impurity field, and external force field. Working conditions, through the analysis of some coupling phenomena in the sugar cooking process and the inherent characteristics of each physical field, the preliminary analysis of the mutual influence relationship between the physical fields, considering that the impact of the external force field on the vacuum degree of the sugar cooking process is not obvious, and the concentration The interaction between the field and the temperature field is realized through the flow field, and other physical fields have mutual coupling effects. For example, the relationship between the coupling effect of the flow field and the external force fiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com