Patents

Literature

258results about "Testing machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

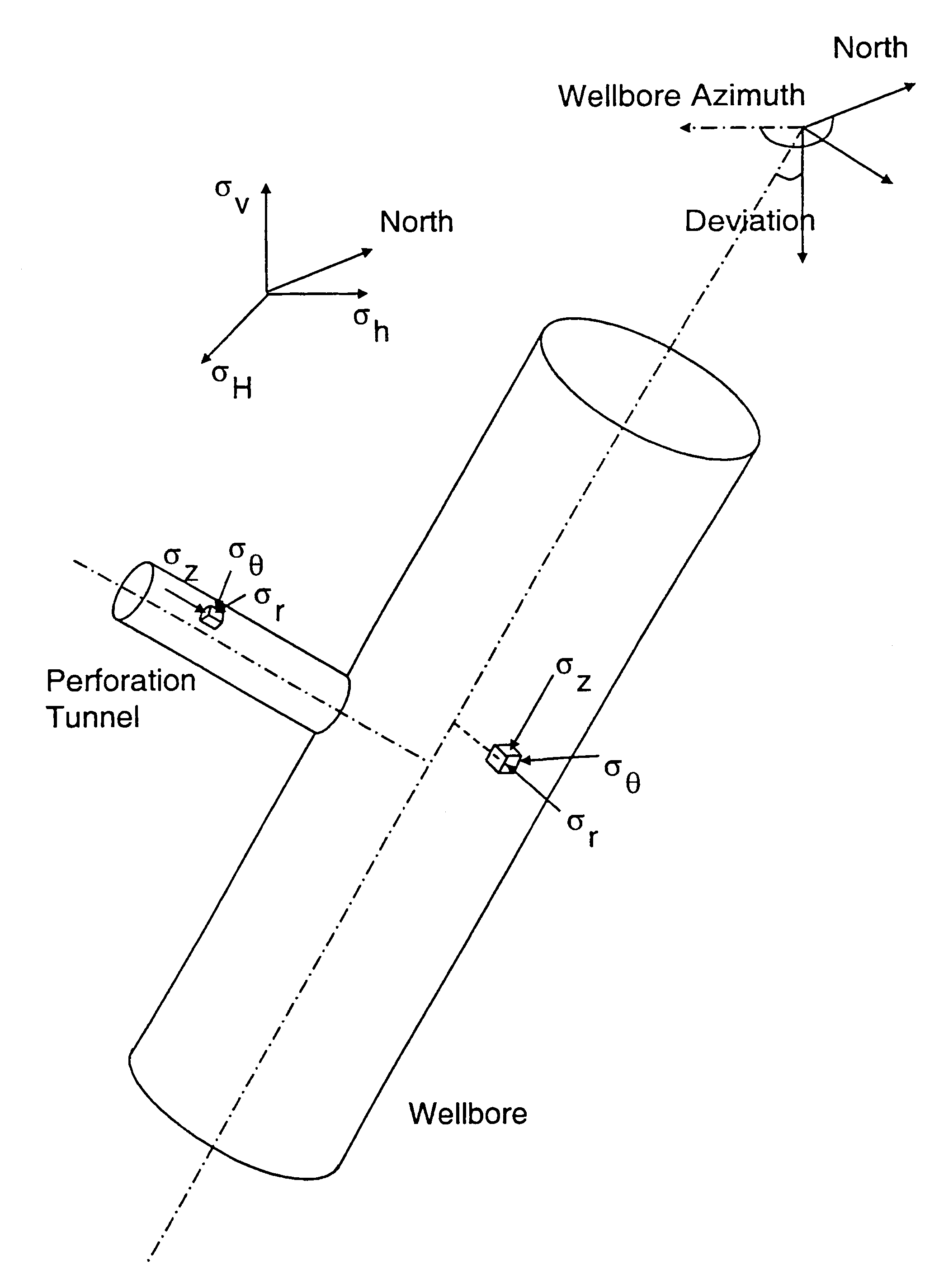

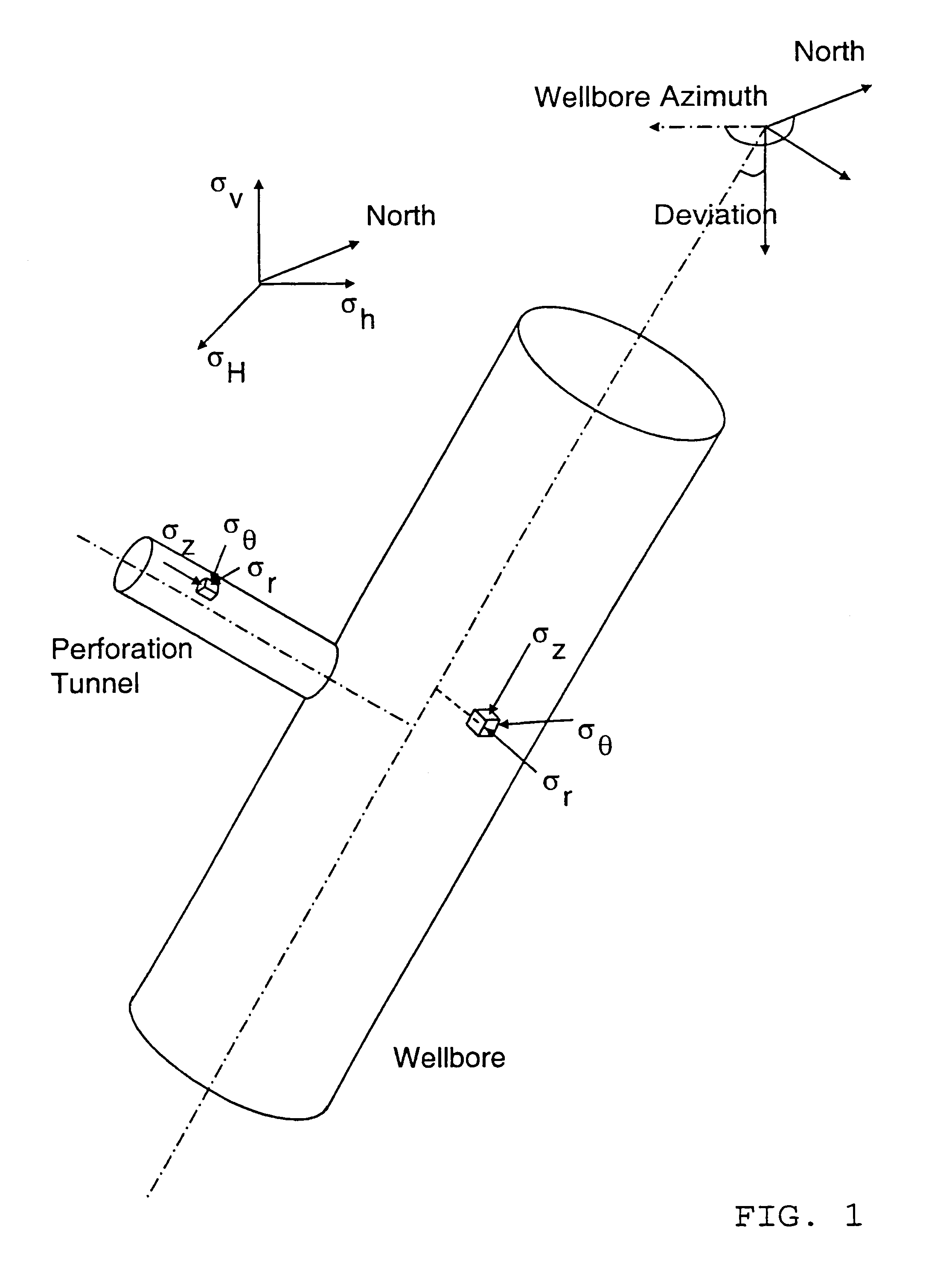

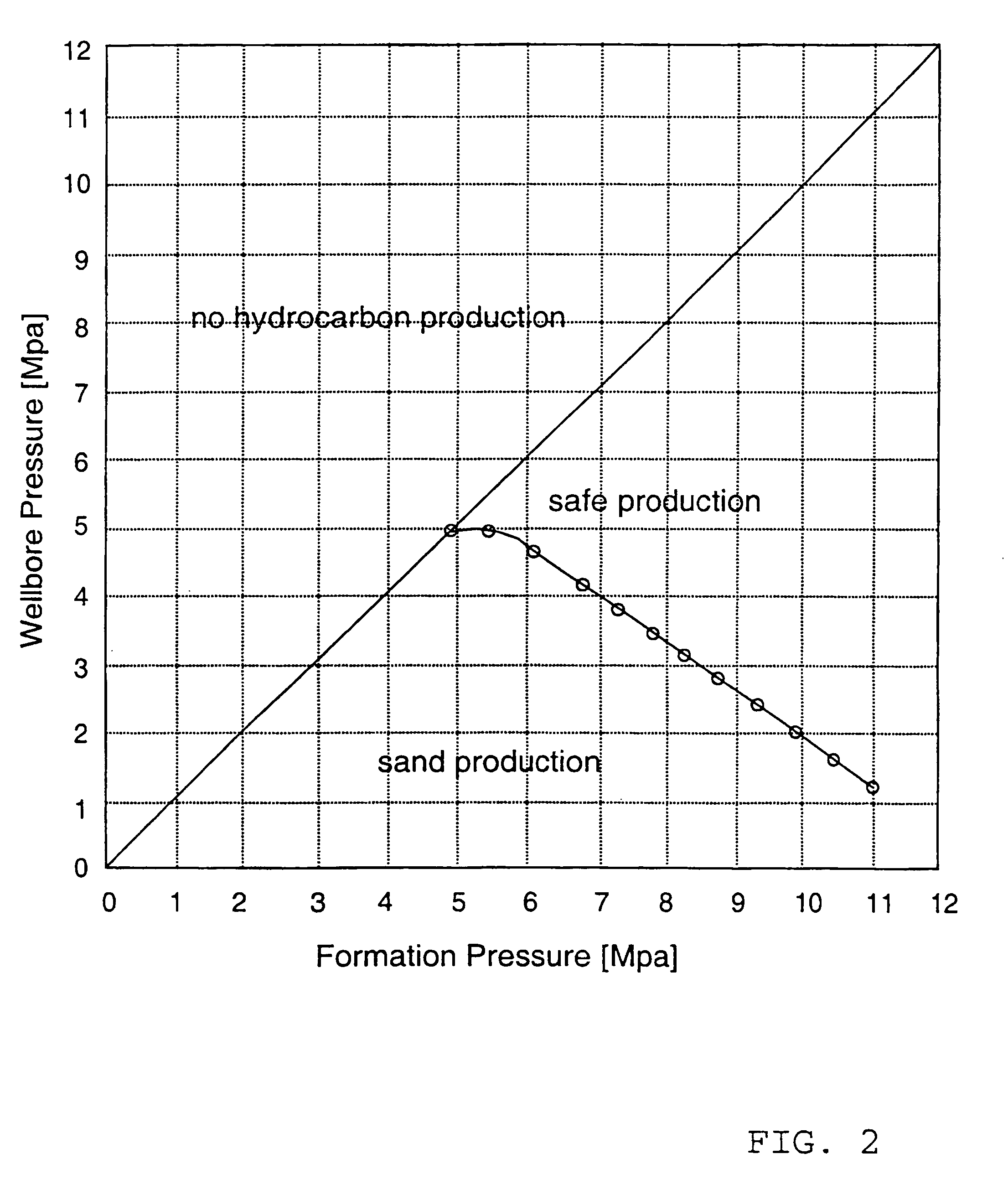

Cavity stability prediction method for wellbores

A method of predicting the failure of a rock formation surrounding a subterranean cavity, including a measuring set of parameters relating to pressure conditions and stresses in the rock formation surrounding the cavity; using the set of parameters to determine a rock strength; determining a first characteristic length relating to the size of the cavity; determining a second characteristic length relating to the grain size of the rock formation surrounding the cavity; using the first and second characteristic lengths to determine a correction for the rock strength; correcting said rock strength; and using a failure criterion and the corrected rock strength to predict a condition under which the rock formation is expected to produce debris. The results of the prediction can be used to monitor wellbore stability while drilling or optimize the production parameters for a hydrocarbon reservoir.

Owner:SCHLUMBERGER TECH CORP

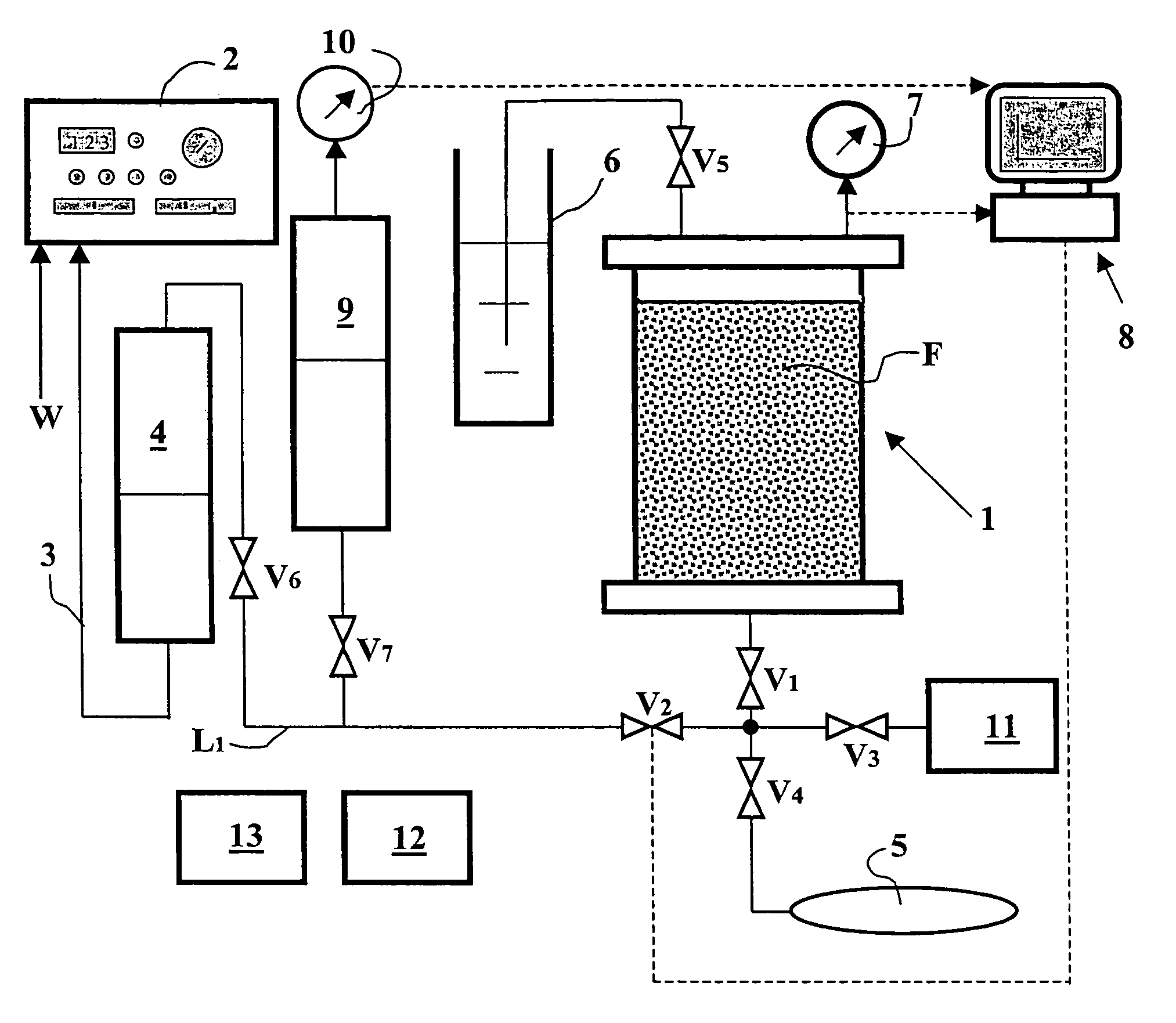

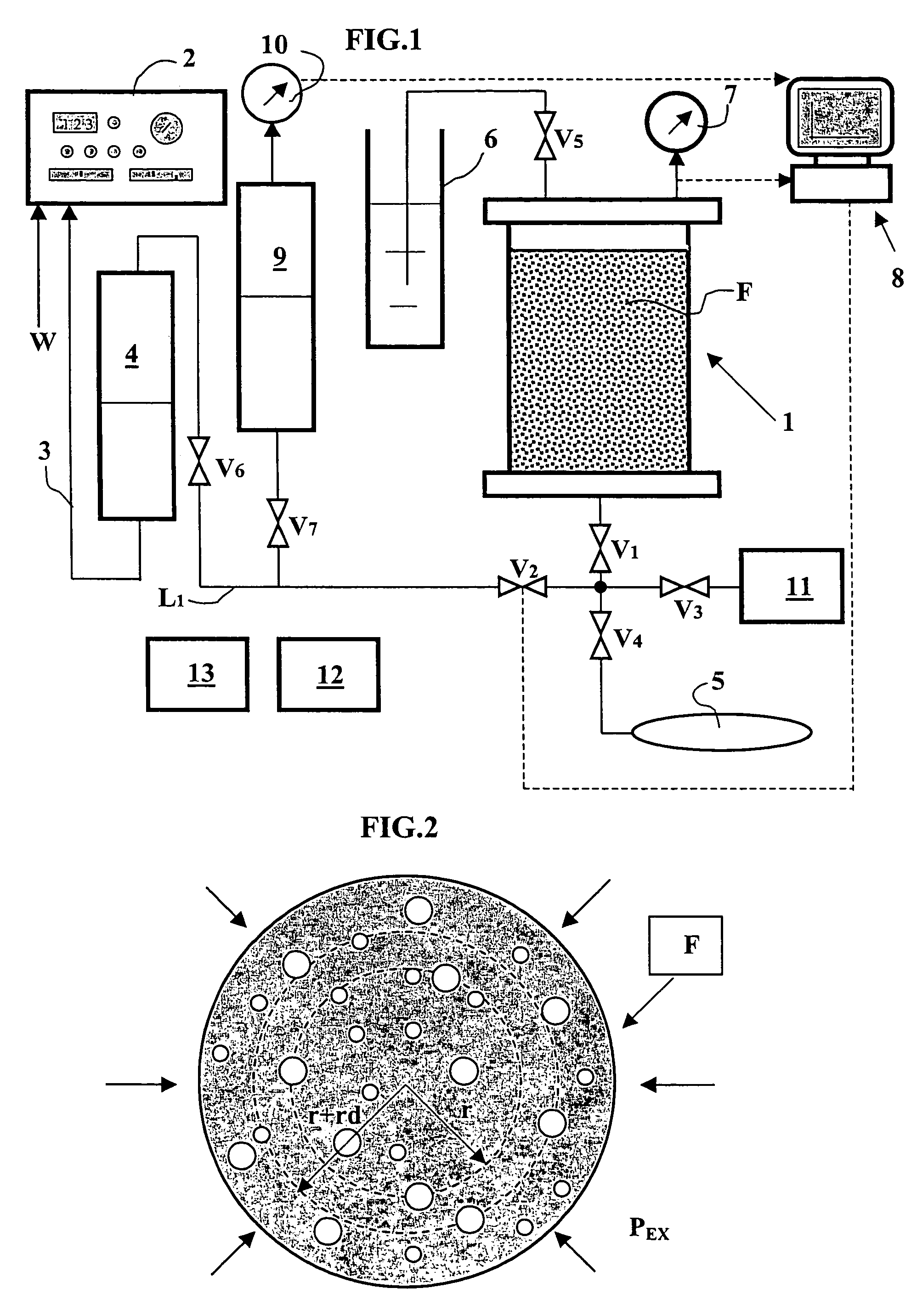

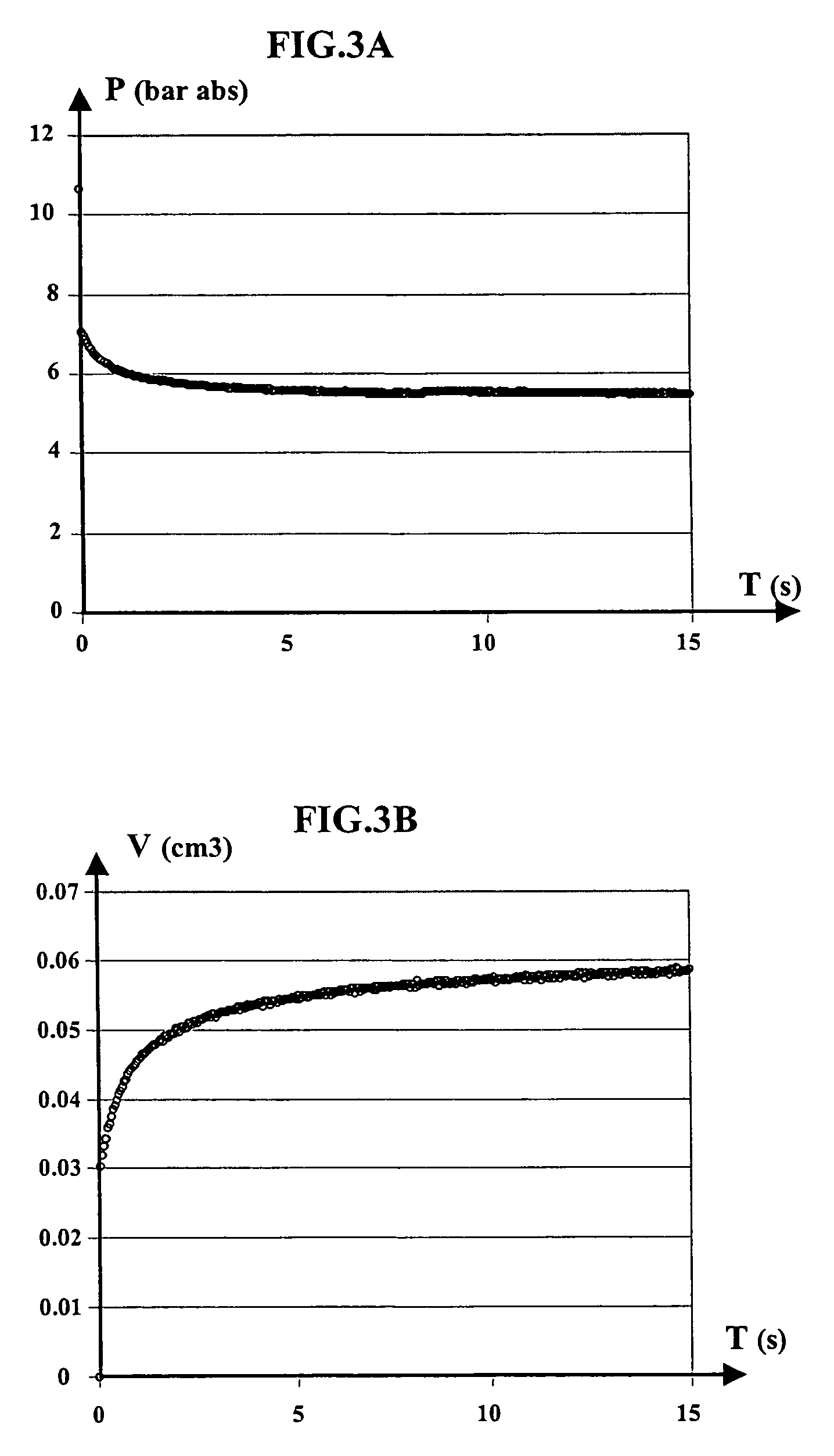

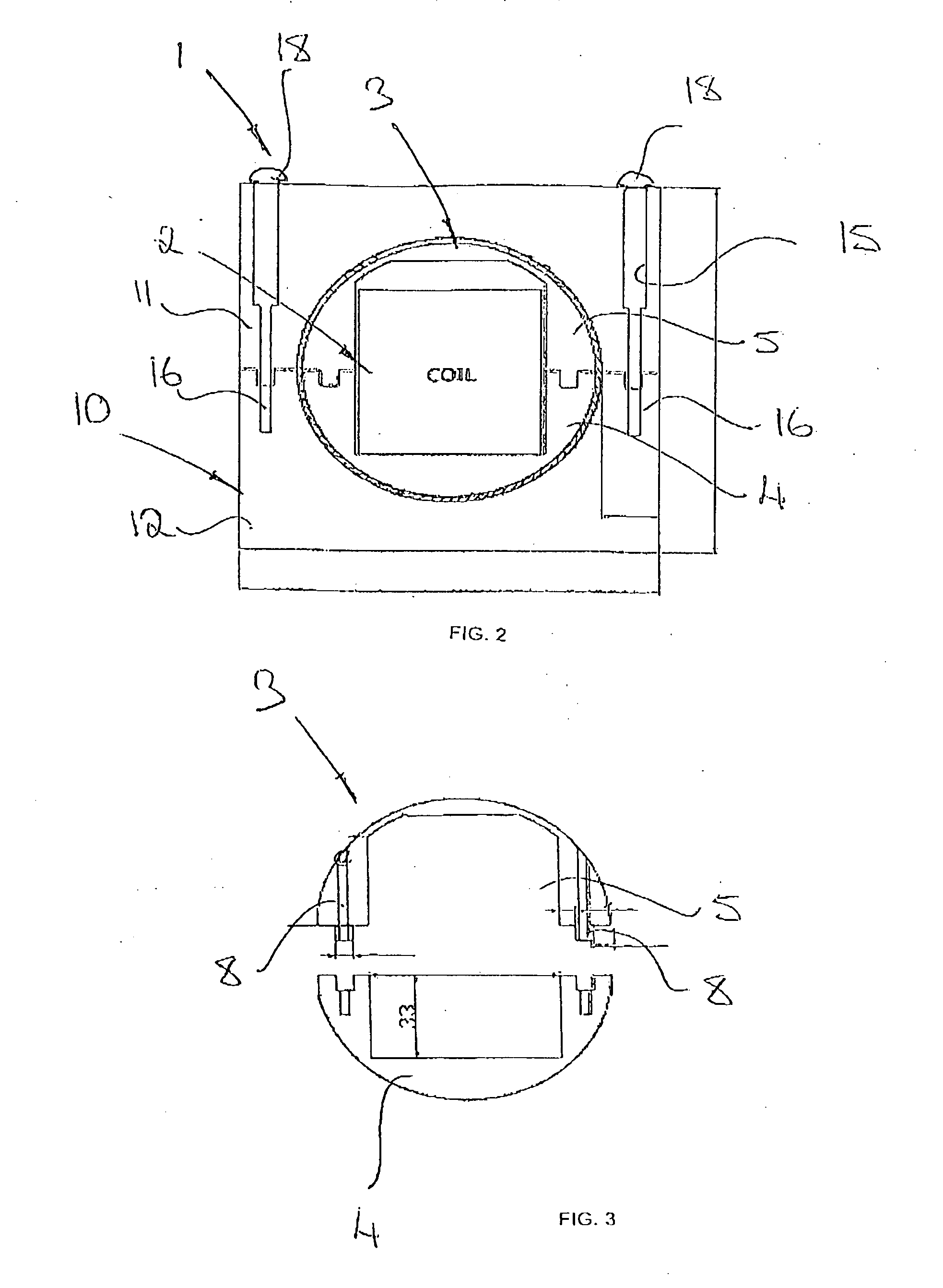

Method and device for evaluating physical parameters of an underground reservoir from rock cuttings taken therefrom

Method and device for evaluating, simultaneously and with a single equipment, physical parameters such as the absolute permeability and the porosity of fragments taken from a fragmented artificial or natural porous medium.The porosity of the fragments is measured by means of pressure tests using helium or any other gas, according to a protocol known in the art. Chamber (1) in which they are contained is communicated with a tank (11) of known volume containing helium at a known pressure. At pressure balance, the value of the solid volume can be deduced. The rock envelope volume and the mass in fragments are also measured. The porosity of the samples and the density of the rock are determined by combining these measurements. Their permeability is then measured by immersing them in a liquid and by communicating the chamber with a liquid initially at a predetermined pressure contained in an accumulator (9) so as to compress the gas trapped in the pores of the rock. The values of the physical parameters are determined by modelling the evolution of the volume of liquid injected in the chamber and by means of an iterative adjustment.Applications: petrophysical measurements from drill cuttings or crushed cores for example.

Owner:INST FR DU PETROLE

Filling mining multi-information dynamic monitoring method

InactiveCN101519963AReasonableness of judgmentJudgment stabilityMining devicesTesting machinesCombined testDynamic monitoring

The invention provides a filling mining multi-information dynamic monitoring method, which is applicable to dynamically monitoring the filling mining multi-information of a waste filling mining area. A vertical displacement meter, a horizontal displacement meter, a vertical pressure meter, a transverse pressure meter, a hydrographic comprehensive test instrument and a gas comprehensive test instrument are arranged in a goaf space of a monitoring section; a borehole stress meter and a multipoint displacement meter are arranged in the position corresponding to a sidewall waist line along a direction vertical to the surface, and a borehole arrangement separation layer indicator is arranged on the top part along a direction vertical to the surface; and the vertical displacement, horizontal displacement, vertical pressure, transverse pressure, water level, water flow, water quality, water pressure, gas concentration, CO concentration, temperature, stress of different positions in coal or rock, displacement and separation layer signals are acquired, and output lines through connection boxes are connected to form a bus which is connected with a multi-channel connection box, and the multi-channel connection box is sequentially connected with communication sub-stations under a mine and a main station, so that the monitored signals are dynamically outputted to a ground work station in real time so as to realize the dynamic monitoring of the filling mining multi-information.

Owner:CHINA UNIV OF MINING & TECH

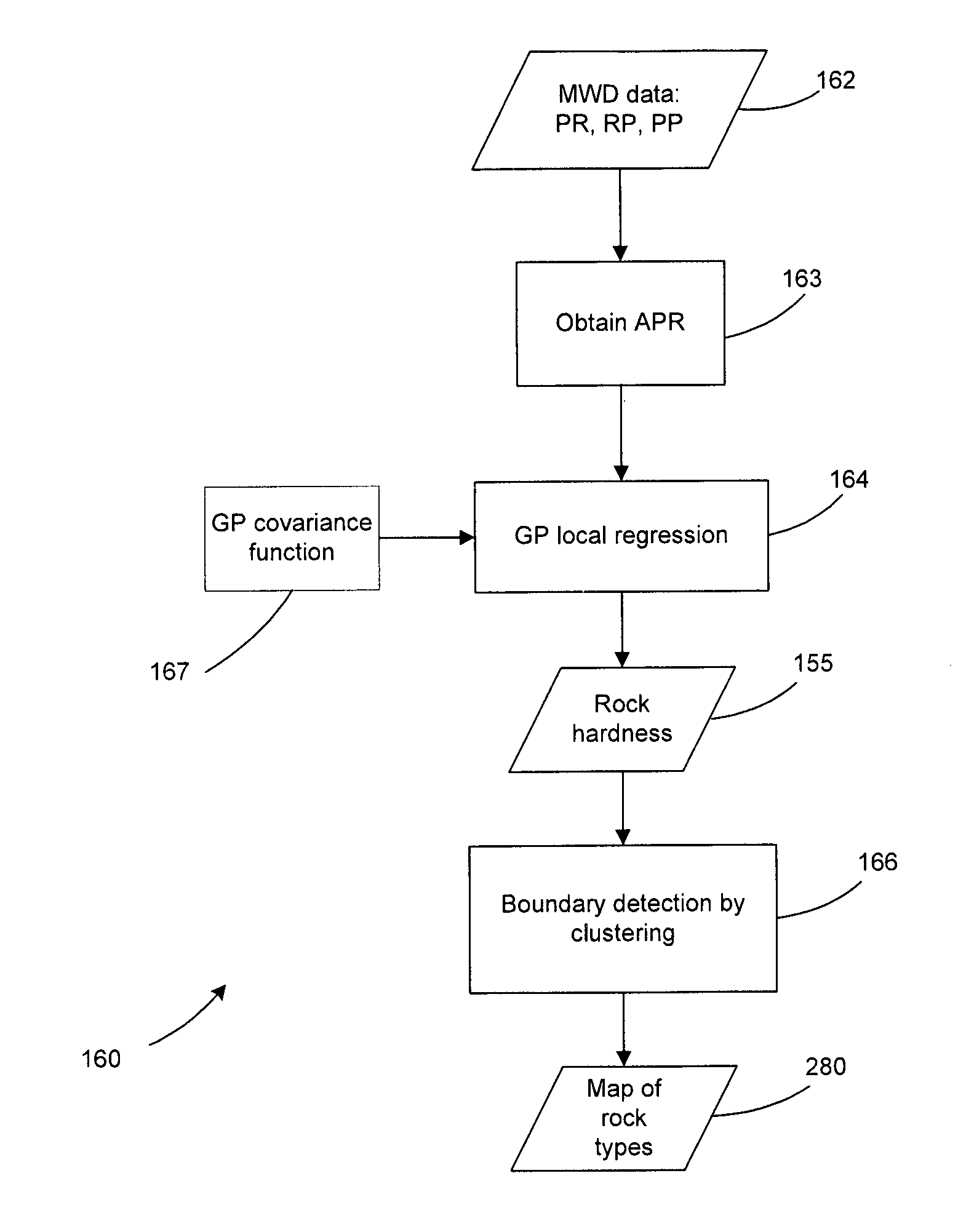

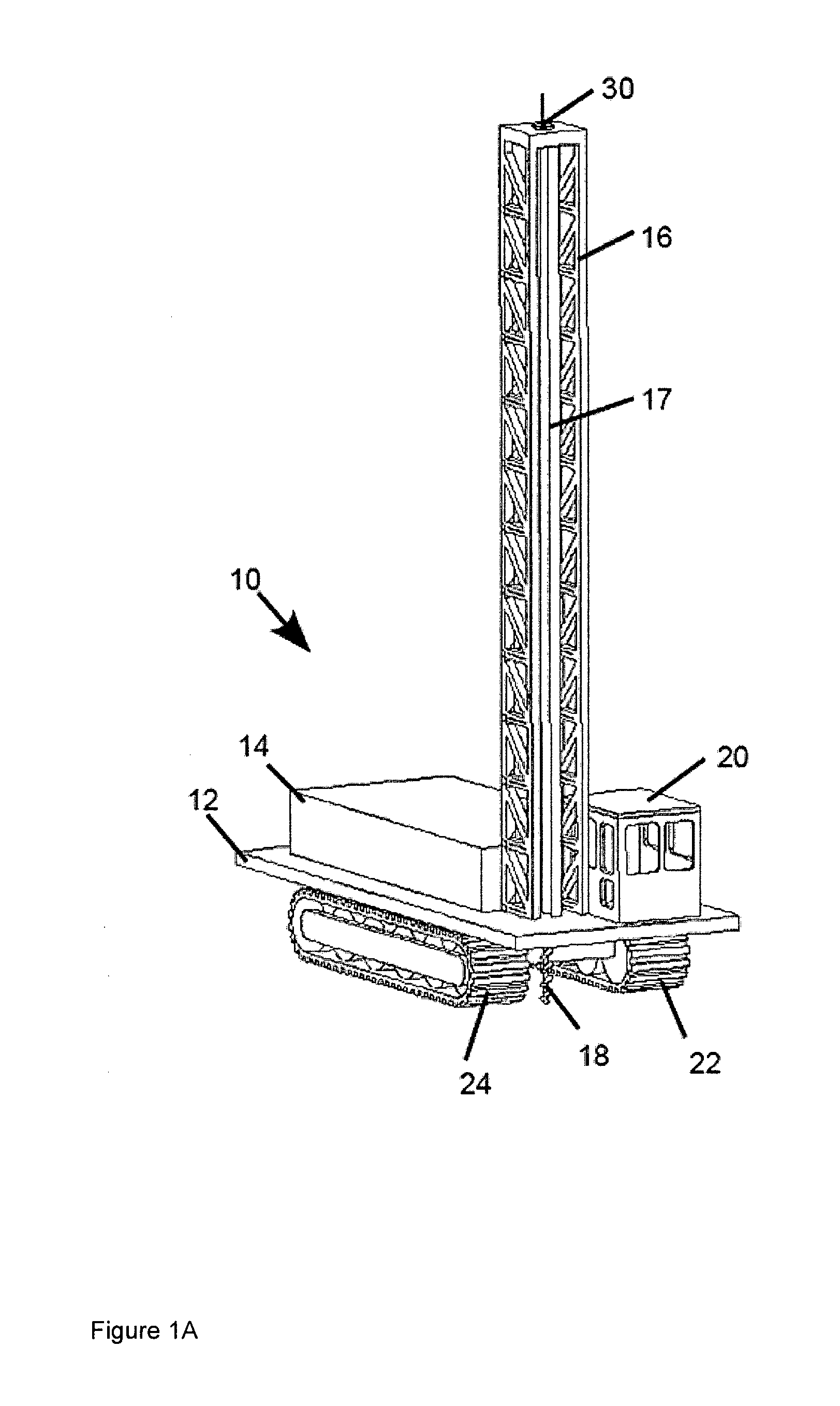

Rock property measurements while drilling

ActiveUS20120323495A1Electric/magnetic detection for well-loggingTesting machinesArray data structureHardness

Described herein is a method and system for characterizing in-ground rock types from measurement-while-drilling data in a mining environment. The method includes the steps of drilling holes at a plurality of selected locations within a region of interest; collecting measurements while drilling to obtain an array of data samples (162) indicative of rock hardness at various drilling depths in the drill hole locations; obtaining a characteristic measure (163) of the array of data samples; performing Gaussian Process regression (164) on the characteristic measure; and applying boundary detection (166) to the rock hardness output data obtained from the Gaussian process model to identify the distribution (280) of at least one cluster of rock type within the region of interest.

Owner:SYDNEY THE UNIV OF +1

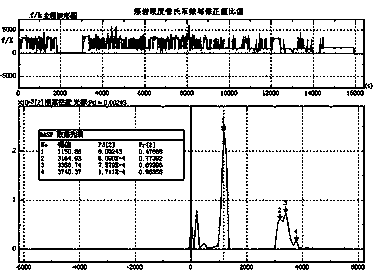

Method and device for testing geo-stress in deep soft rock based on flow stress restoration principle

InactiveCN102628716AConvenient researchGet goodForce measurement by measuring frquency variationsTesting machinesObservation dataSlurry

The invention discloses a method and device for testing a geo-stress of a deep soft rock. The device comprises a connecting rod; two three-direction pressure boxes are adjacently fixed on the connecting rod; the three-direction pressure box is provided with three vertical working surfaces; a direction cosine of any two working faces among the two three-direction pressure boxes is not 1; a device for measuring a normal pressure stress is mounted on each working face of the two three-direction pressure boxes; and the device is connected with a reading instrument outside a drilling hole through a data wire. A geo-stress testing method comprises the following steps of: sending the two three-direction pressure boxes to a test point after drilling; grouting the drilling hole and sealing the drilling hole after the drilling hole is entirely filled; and after slurry is solidified, substituting six pressure data measured by the two three-direction pressure boxes into a geo-stress testing principle formula after the data is stable, so as to obtain the geo-stress at the test position. With the adoption of the method, a stress value inside surrounding rocks can be directly observed, and observation data can be obtained for a long time. Therefore, the method and device provided by the invention is good for researches of coal deep rock geo-stress and the stability of a surrounding rock.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI +1

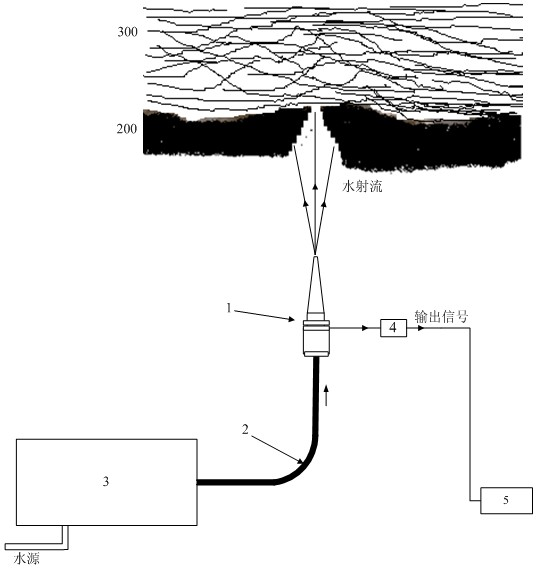

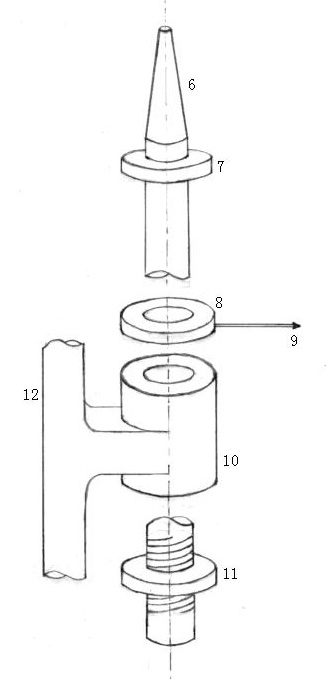

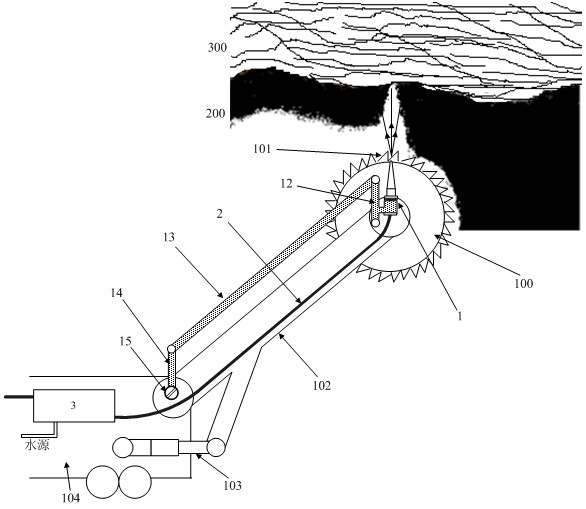

Coal-rock interface identification method, identification system and identification probe

ActiveCN101922290APromote recoveryImprove securityTesting machinesSlitting machinesMining engineeringHigh pressure water

In an underground exploitation process of a coal mine, the coal recovery rate needs improving, and a roller bit of a coal mining machine is prevented from cutting roof strata as far as possible so as not to damage equipment or even cause accidents, so an interface of a coal layer and a rock layer needs on-line identification. The invention provides a coal-rock interface identification method, a coal-rock interface identification system and a coal-rock interface identification probe. A specific energy-level high-pressure water jet which can penetrate the coal layer but cannot penetrate the rock layer is jetted to the coal layer above a tunnel, different acting forces of reflected flow reflected by the coal layer or the rock layer on a nozzle are sensed in real time, and a controller judges the distance between the upper end of the roller bit of the coal mining machine and the coal-rock interface to realize automatic heightening control of a rocker arm of the coal mining machine so that the coal exploitation process realizes the goals of high recovery rate, low mechanical abrasion rate, automatic operation and the like. The coal-rock interface identification method, the coal-rock interface identification system and the coal-rock interface identification probe provided by the invention have the advantages of low cost, high adaptability, high reliability, intrinsic safety and the like.

Owner:ZHEJIANG UNIV

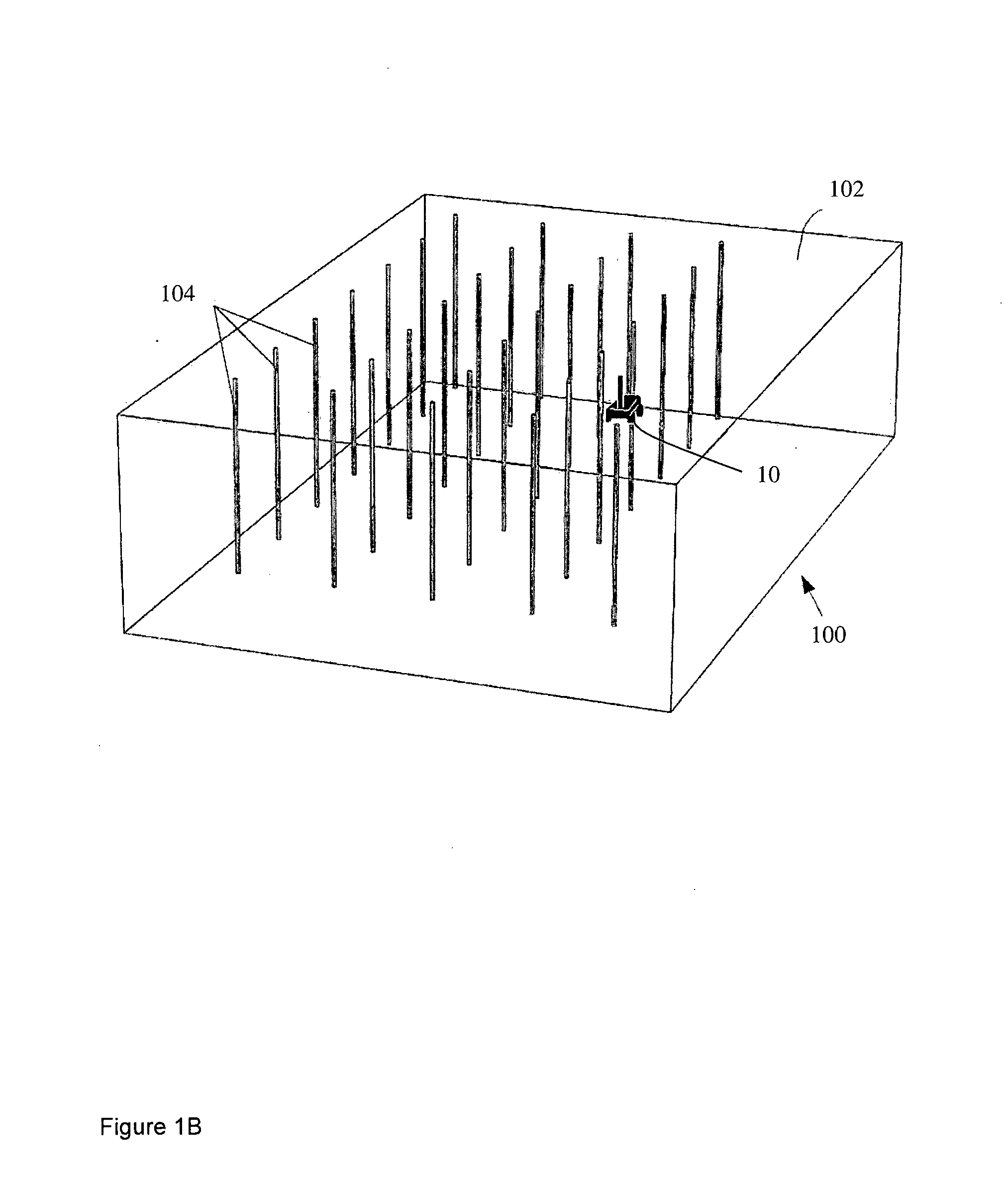

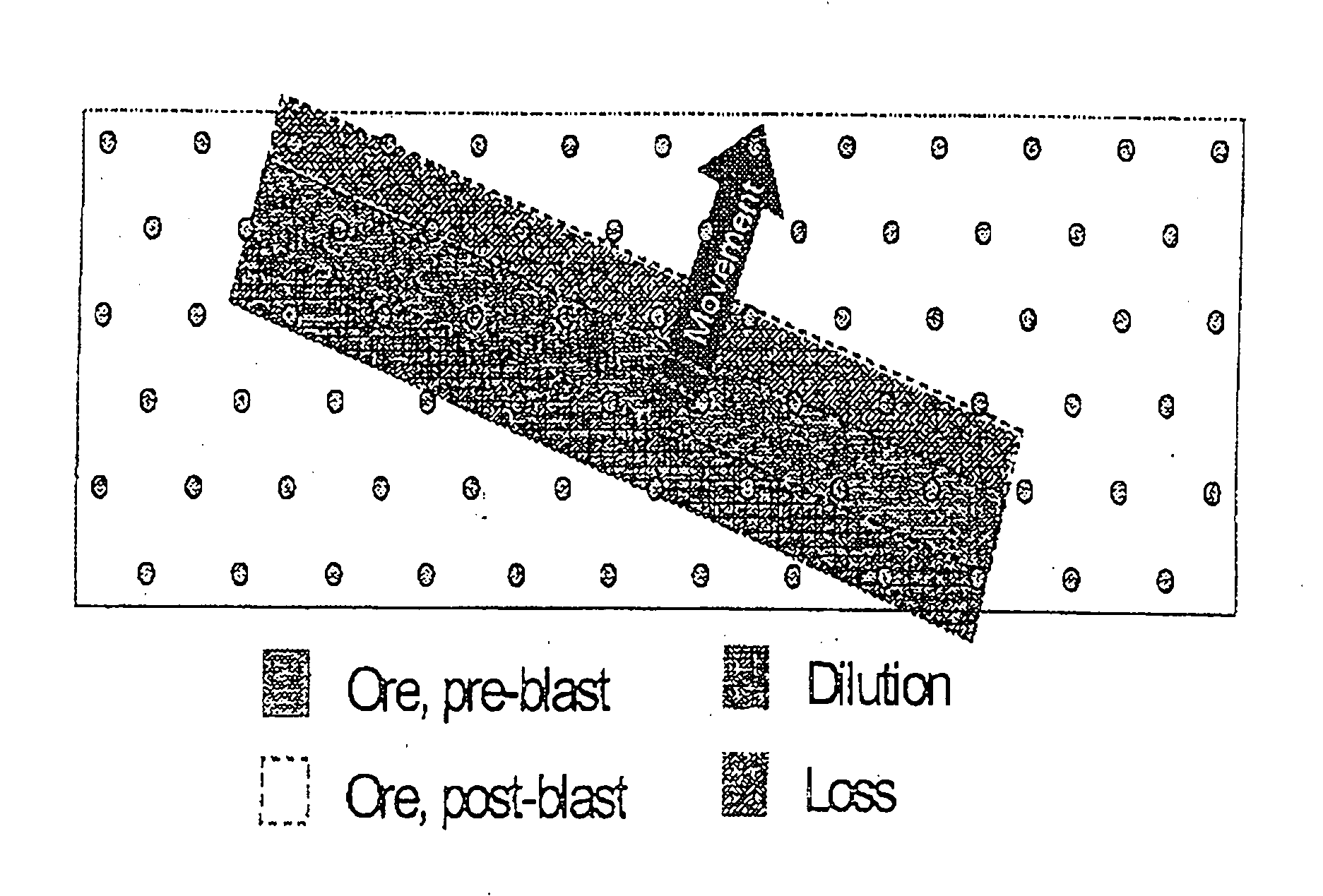

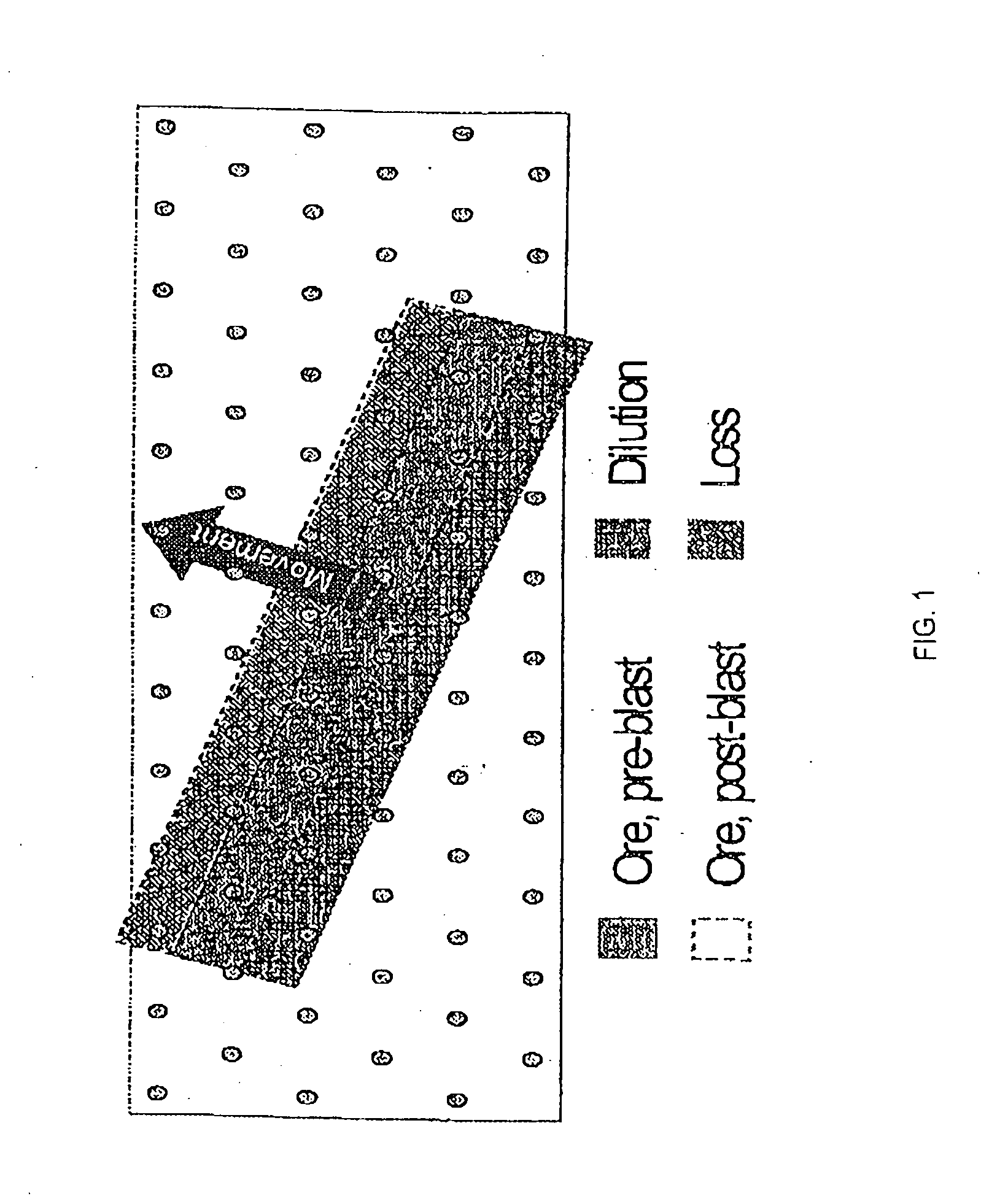

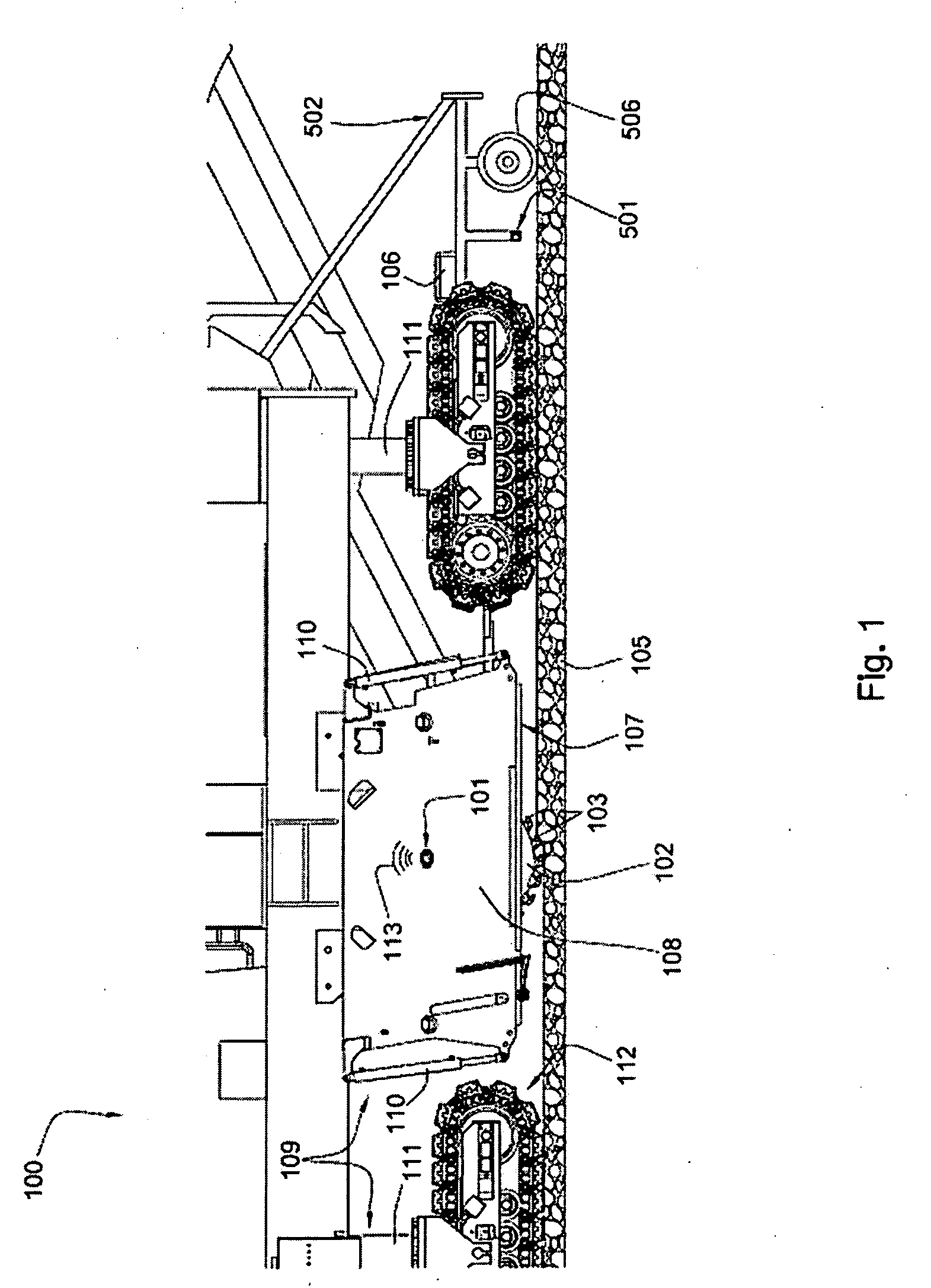

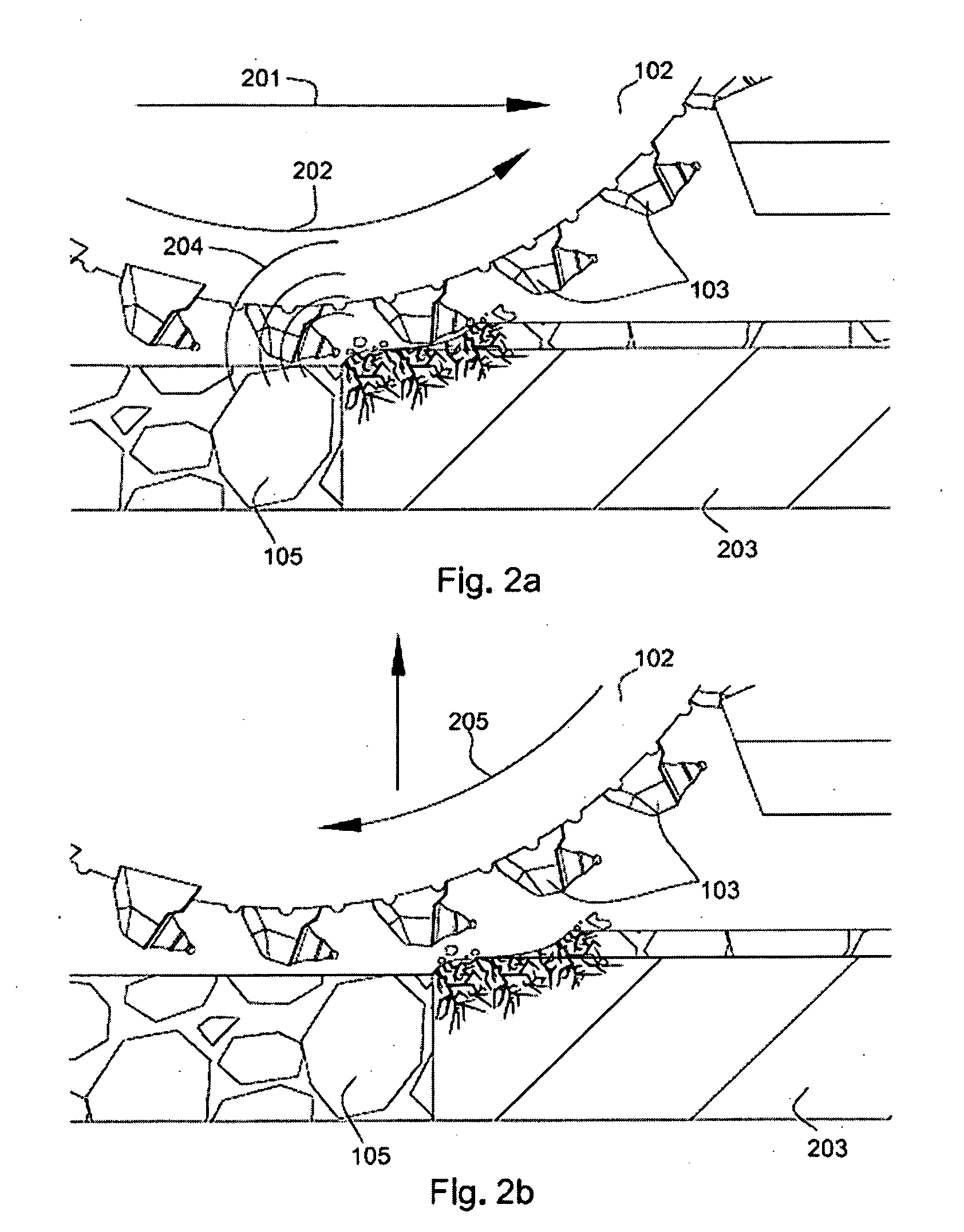

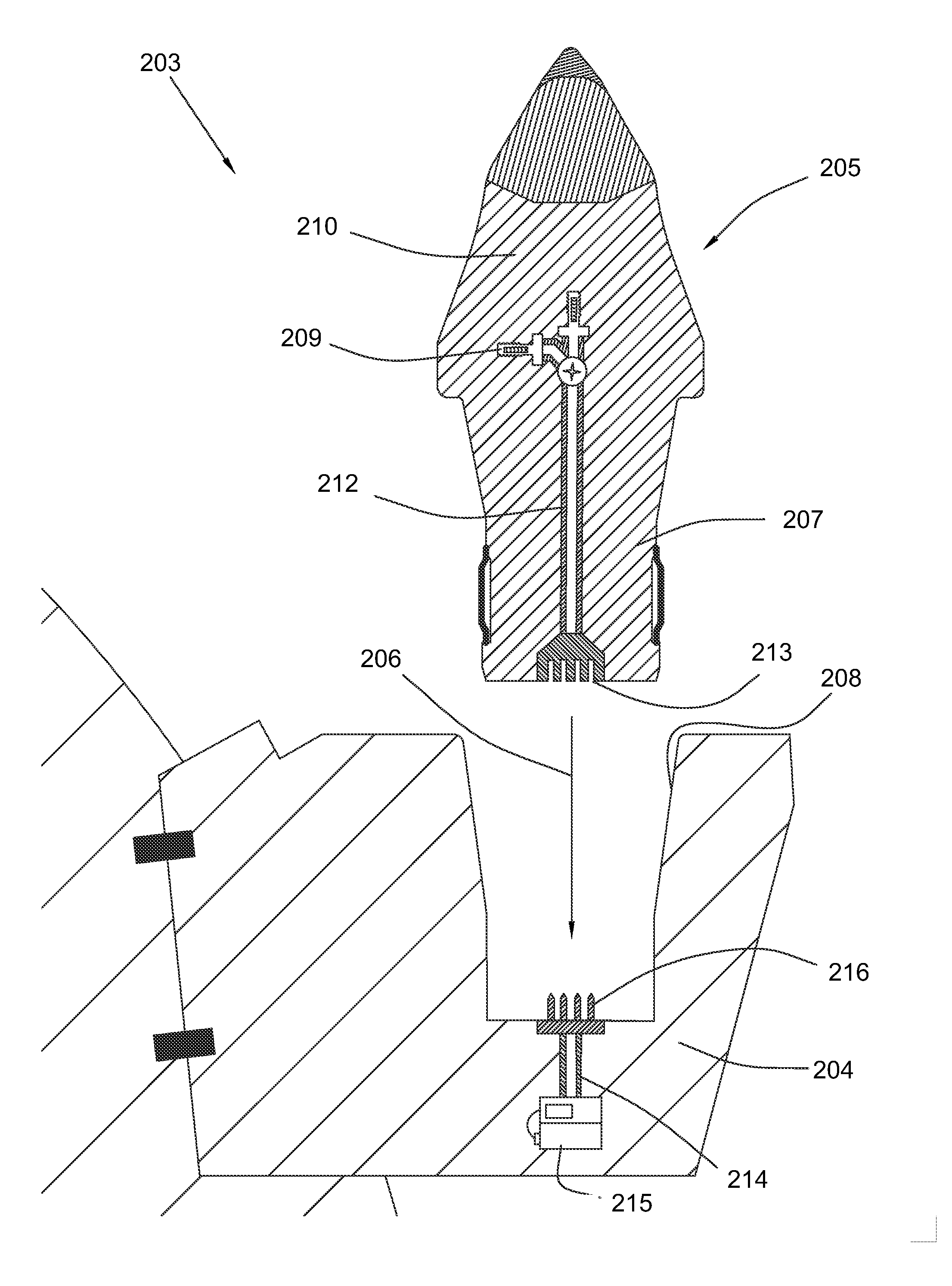

Blast movement monitor and method for determining the movement of a blast movement monitor and associated rock as a result of blasting operations

ActiveUS20050012499A1Reduce frictionReduce risk of damageMaterial analysis using sonic/ultrasonic/infrasonic wavesMagnetic measurementsTransmitterEnvironmental geology

A method for measuring the movement of boundaries between different portions of a heterogeneous rock body is disclosed. The method comprises placing a plurality of blast movement monitors 109 in a rock body prior to blasting and noting the position of each blast movement monitor. The rock body is then blasted to break it up into a plurality of pieces. Thereafter the position of the blast movement monitors 109 is located and based on this the boundaries of rock portions can be adjusted to account for the blast. This leads to a more accurate reporting of different ore bodies to the appropriate processor in a heterogeneous rock body. An apparatus for carrying out the method is also disclosed. The apparatus comprises broadly a said monitor 109 and a receiver. The monitor 1 comprises a transmitter 109 received within a casing 111 that in turn is received within a housing 126. Further the casing 111 can move within the housing 126 and self right so that it always transmits its signal in an upright direction.

Owner:LEICA GEOSYSTEMS PTY LTD +1

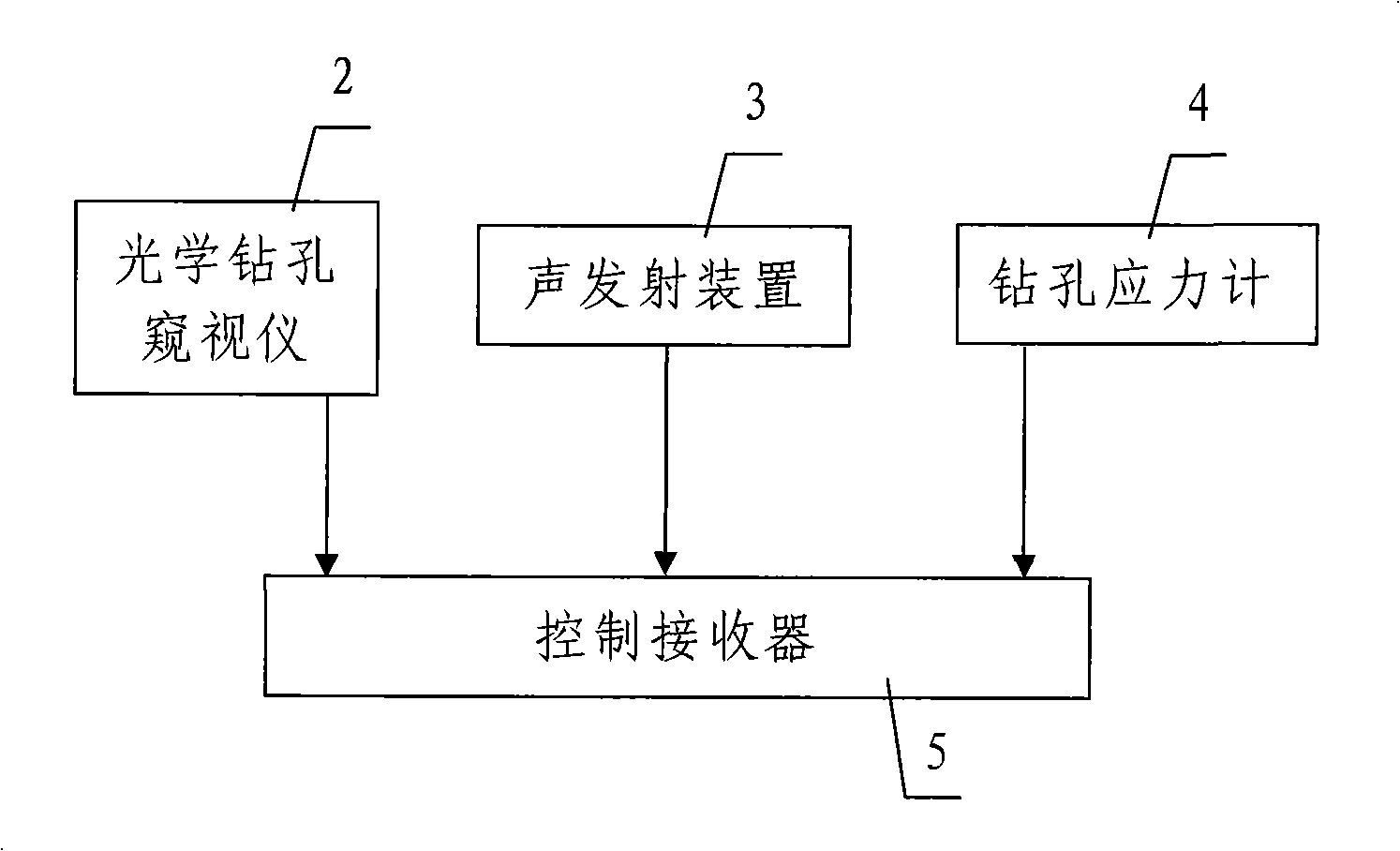

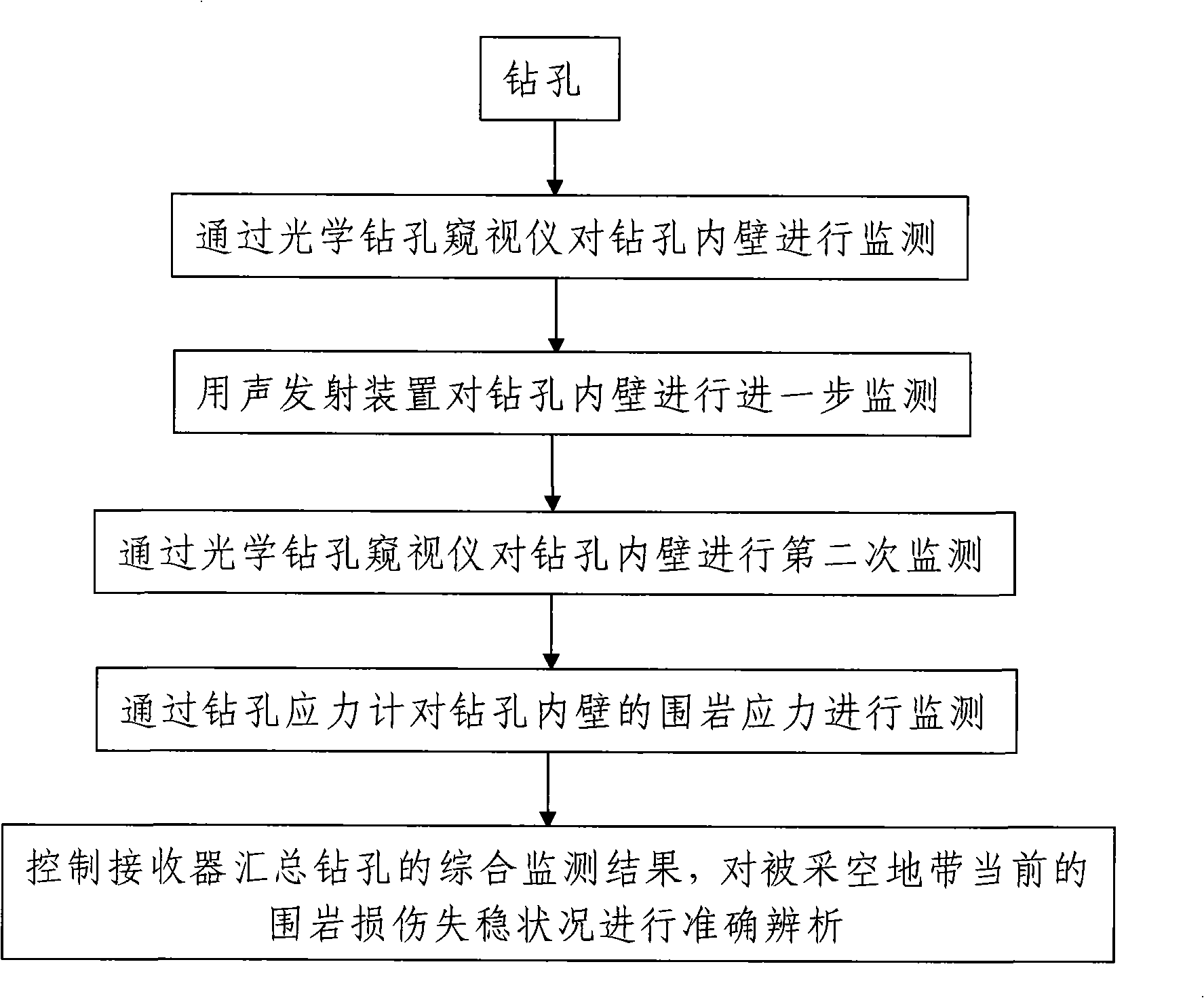

Wall rock destabilization acousto-optic-electric integrated monitoring system and monitoring method thereof

InactiveCN101526009AMake up for prone to distortionMake up for distortionMining devicesTesting machinesIntegrated monitoringAcoustic emission

The invention discloses a wall rock destabilization acousto-optic-electric integrated monitoring system and a monitoring method thereof, wherein the monitoring system comprises an optical drilling sighting apparatus fractionally monitoring the wall rock damage condition of the inner all of the same drilling hole, an acoustic emission device and a drilling hole stress meter, and a control receiver connected with the drilling hole stress meter, the acoustic emission device and the optical drilling sighting apparatus. The monitoring method comprises the following steps: firstly, drilling on the edge of a laneway; secondly, monitoring: monitoring the inner wall of the drilling hole by the optical drilling sighting apparatus, and then further monitoring the inner wall of the drilling hole by the acoustic emission device, secondarily monitoring the inner wall of the drilling hole by the optical drilling sighting apparatus, at last monitoring the wall rock stress of the inner wall of the drilling wall of the drilling hole stress meter; thirdly, collecting all monitoring results, and differentiating and analyzing the wall rock damage destabilization condition. The invention has reasonable design, simple use and operation, and accurate monitoring result, and can effectively solve the practical problems of poor accuracy, distorted data, failure monitoring under some special environment, and the like caused by the prior single monitoring method.

Owner:XIAN UNIV OF SCI & TECH

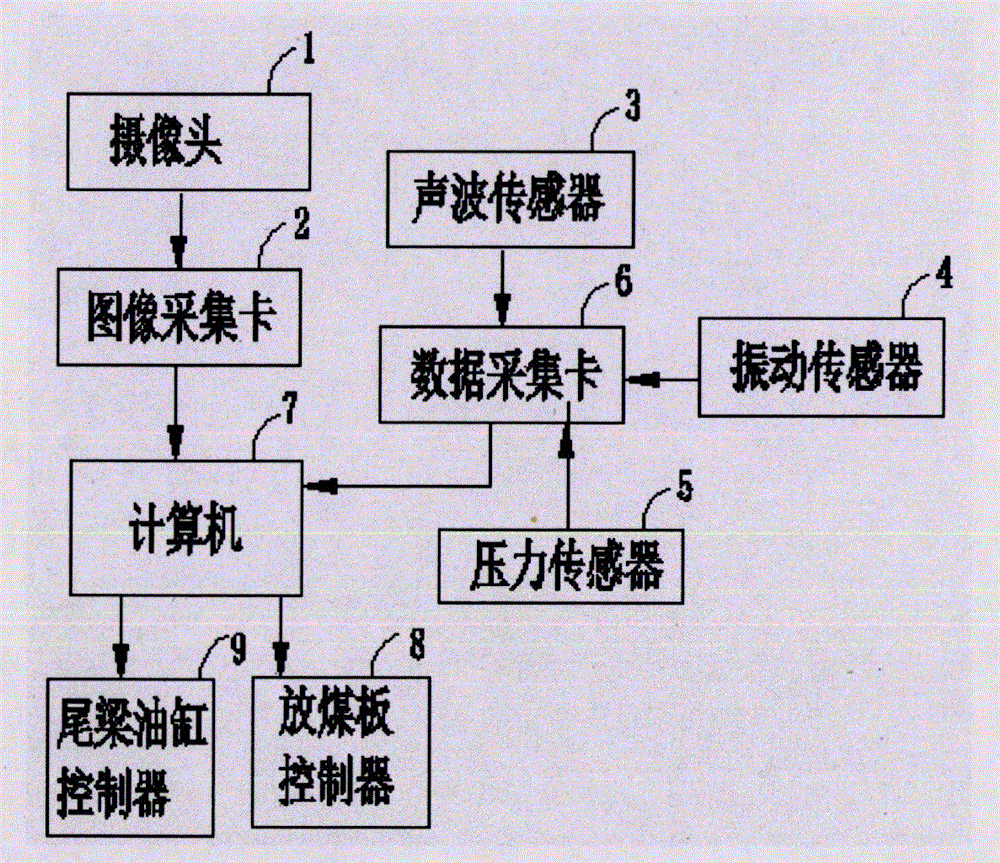

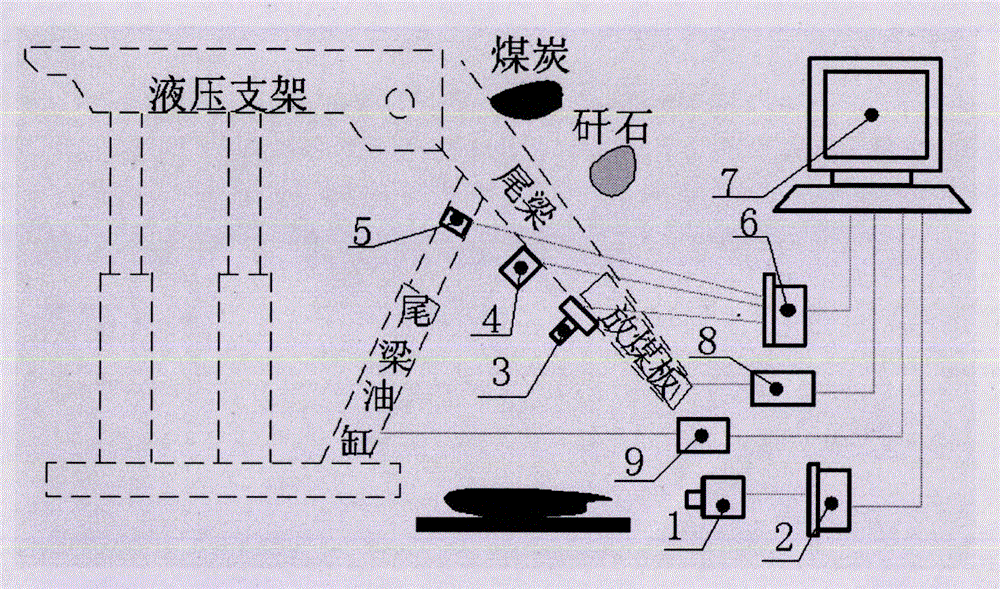

Automatic coal feeding apparatus for fully mechanized coal face and coal feeding process recognition method

InactiveCN106437713AAchieving crushing controlCoal discharge went smoothlyUnderground miningTesting machinesData acquisitionProcess engineering

The invention discloses an automatic coal feeding apparatus for fully mechanized coal face and a coal feeding process recognition method. In fully mechanized top coal feeding production process, full coal feeding phase, 0-30% gangue-coal mixed coal feeding phase, 30-50% gangue-coal mixed coal feeding phase, 50-70% gangue-coal mixed coal feeding phase, full gangue coal feeding phase and coal feeding faults of coal blockage and locking in the top coal feeding process can be recognized, coal feeding, coal feeding stop control and locked coal lump breakage control are achieved, and automatic coal feeding is achieved; the automatic coal feeding apparatus for fully mechanized coal face comprises a camera, a video collection card, an acoustic sensor, a vibration sensor, a pressure sensor, a data collection card, a computer, a coal feeding plate controller, and a tail beam cylinder controller, coal feeding phase recognition in the coal feeding process and recognizing the coal feeding faults of coal blocking and locking in the coal feeding process are achieved, a coal feeding plate or tail beam of a top coal feeding hydraulic support is under control, and automatic coal feeding and automatic coal breaking in case of coal blocking and locking faults are achieved; the coal feeding process recognition method is capable of recognizing full coal feeding phase, 0-30% gangue-coal mixed coal feeding phase, 30-50% gangue-coal mixed coal feeding phase, 50-70% gangue-coal mixed coal feeding phase, full gangue coal feeding phase, and coal feeding faults of coal blockage and locking in the top coal feeding process.

Owner:SHANDONG UNIV OF SCI & TECH +1

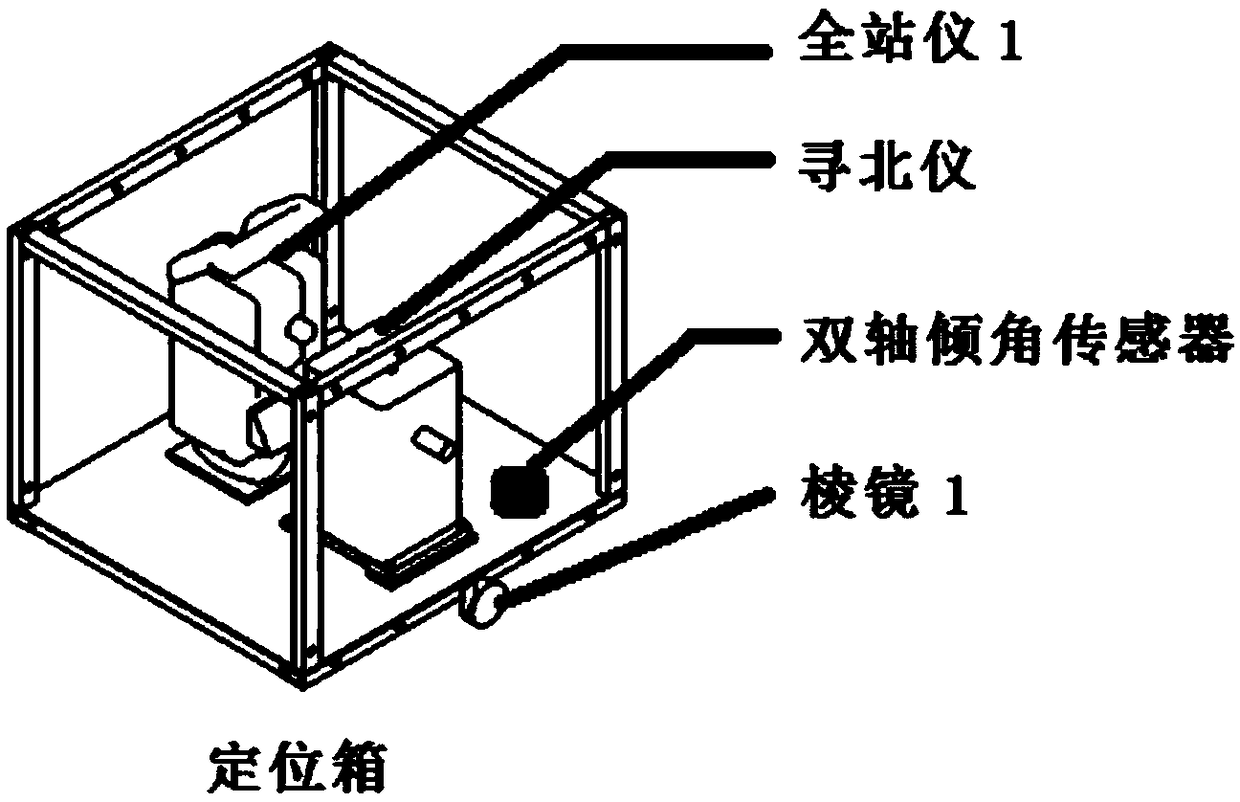

Roadheader, system and method

ActiveCN109356608AAchieve positioningSolve the fast-moving puzzleMining devicesTesting machinesAutomatic controlRemote control

The invention provides a roadheader, a system and a method. According to the roadheader, the system and the method, three-dimensional space coordinates of the roadheader can be tracked and measured inreal time to realize the millimeter levelpositioning accuracy of the set distance within the visual range, remote control operation and automatic control over the roadheader are facilitated, and themovement path and the speed of a cutting head as well as the direction, position and posture of a roadheader body can be automatically adjusted according to the position change of the roadheader and the rock wall hardness change of a heading working face roadway.

Owner:山东新矿信息技术有限公司

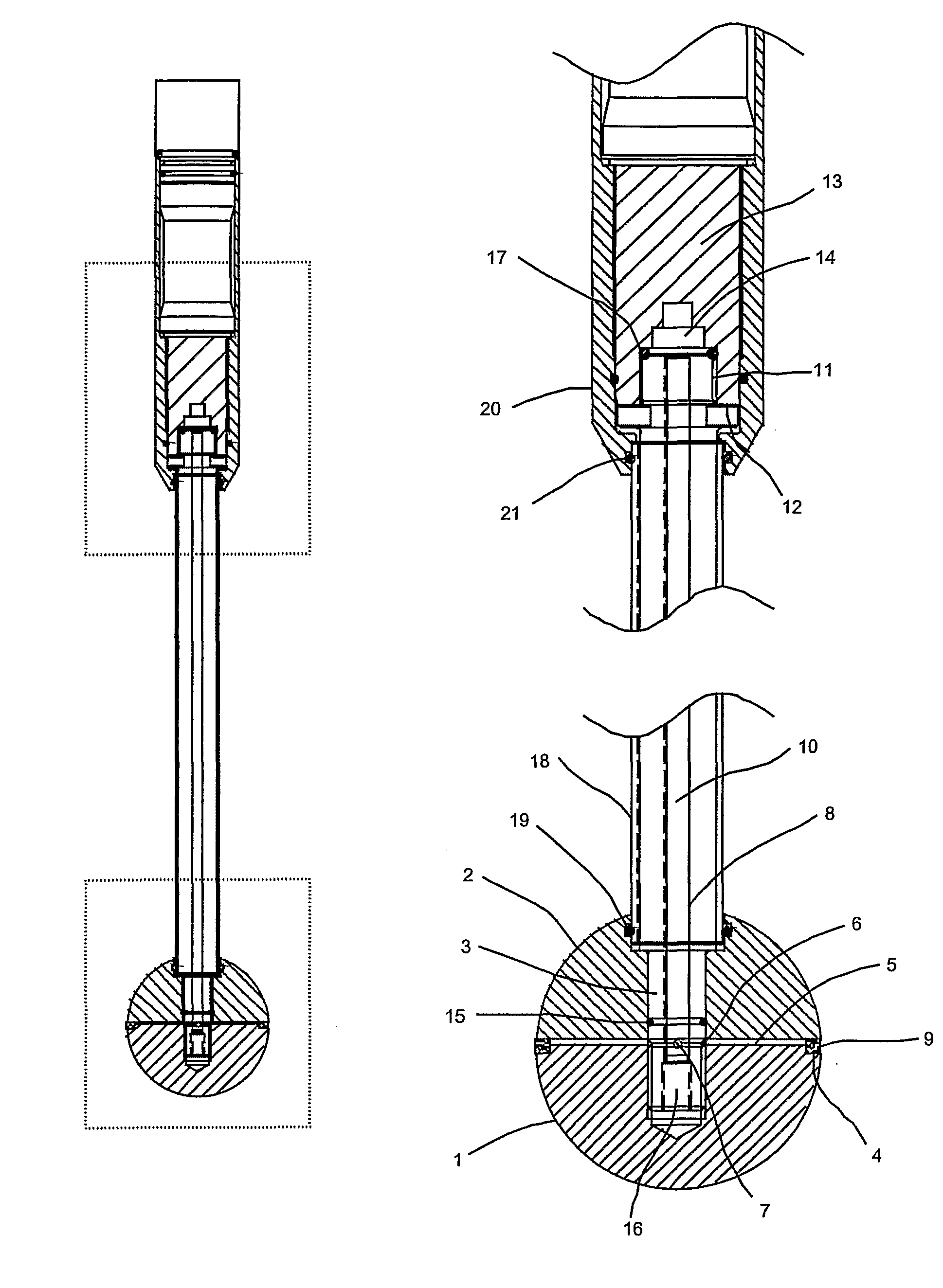

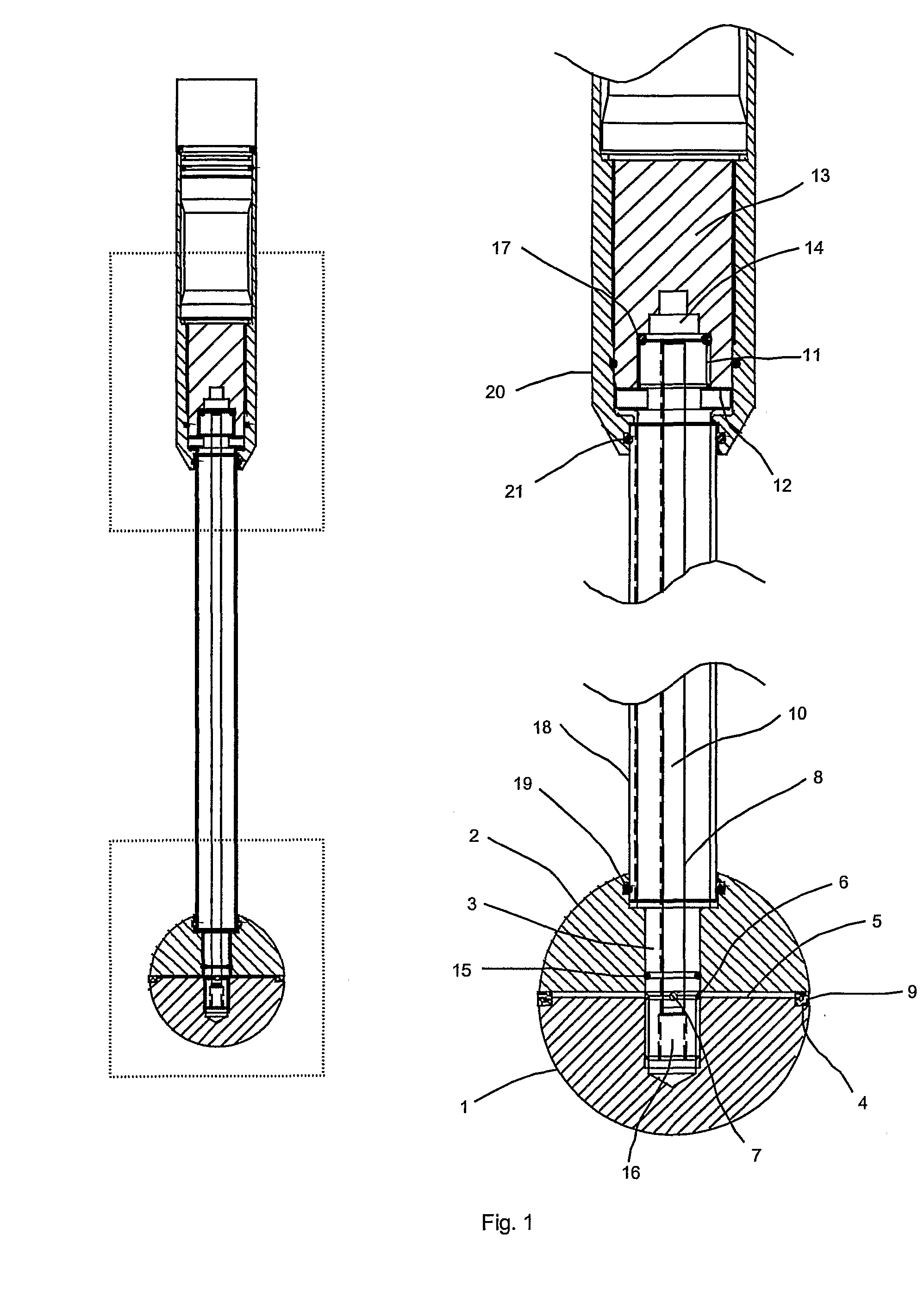

Ball penetrometer for soft soils testing

A ball penetrometer probe for in situ measurement of soft soil properties, particularly in the seabed, comprises a spherical body and slender shaft assembly, and either individually or in combination, an anti-friction sleeve enclosing the shaft and / or a peripheral porous ring on the spherical body with connecting internal passages through the shaft assembly, the shaft being adapted to attach to an electronic transducer module. The ball penetrometer is deployed to penetrate the soil bed, to continuously measure the soil bearing forces resisting penetration and withdrawal of the ball, to optionally measure the pore water pressure of the soil in contact with the ball and to transmit the measurement data from the probe to a remote operating station, either by wireless means such as an acoustic transducer or via a wired electrical connection.

Owner:BENTHIC GEOTECH PTY LTD

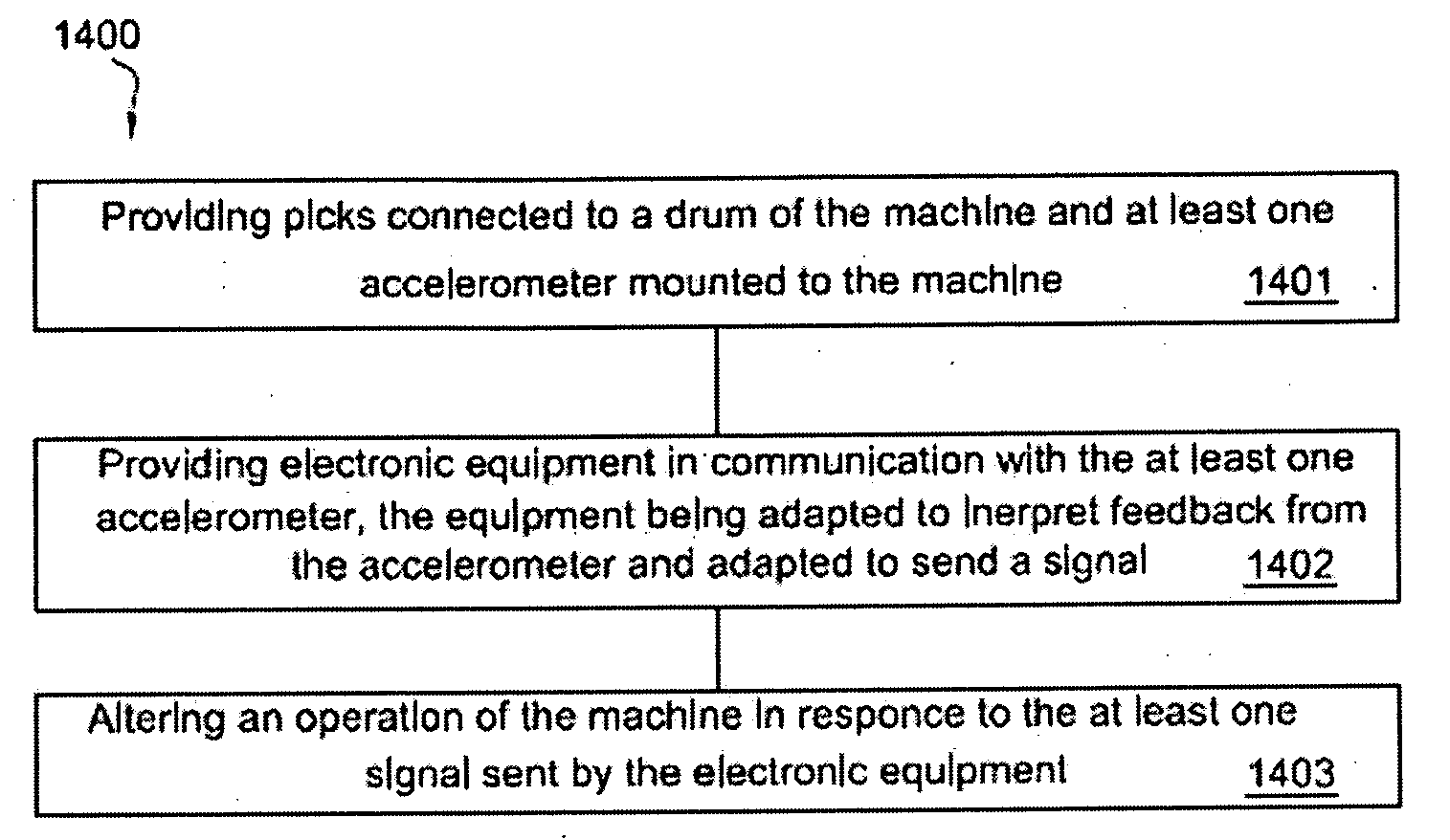

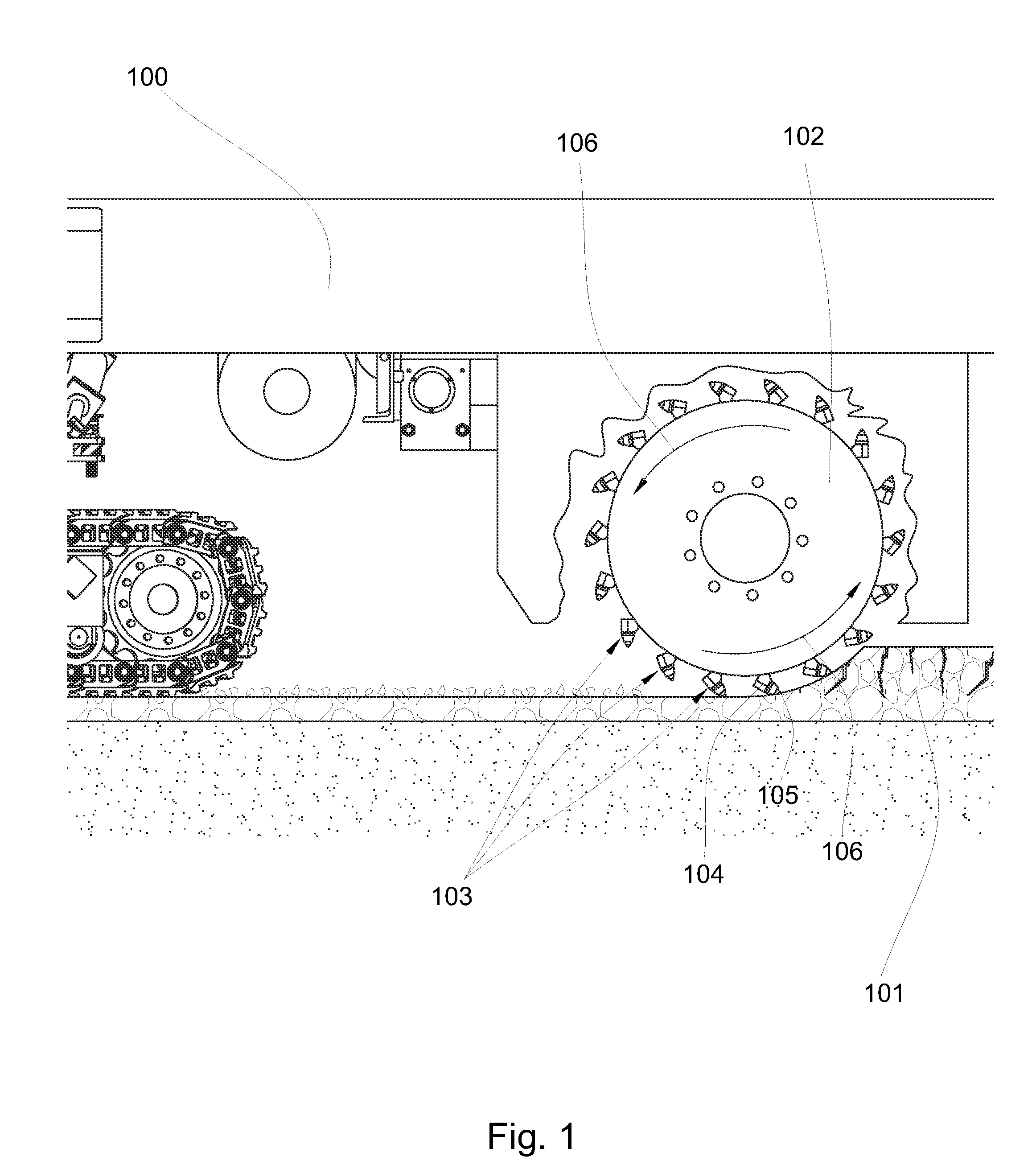

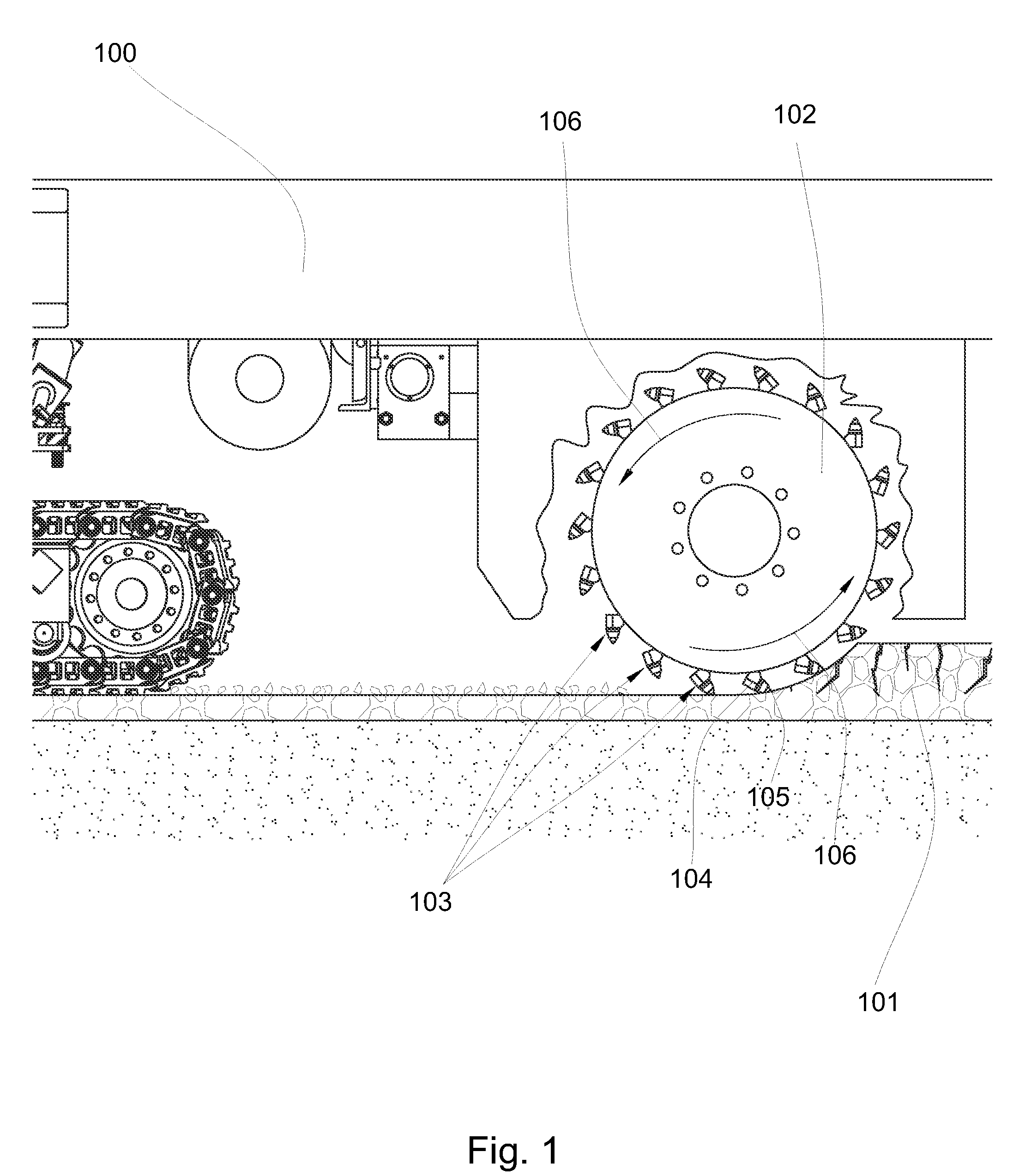

Sensors on a Degradation Machine

InactiveUS20100063691A1Reduce wearAnalogue computers for trafficTesting machinesAccelerometerMechanical engineering

In one aspect of the invention, a machine for degrading a natural and / or manmade formation has picks connected to a drum of the machine and at least one accelerometer mounted to the machine adapted to measure forces acting on the machine. Electronic equipment is in communication with the at least one accelerometer and the electronic equipment has a processor adapted to determine a change in the formation based off of input from the at least one accelerometer. The electronic equipment also is in communication with a mechanism adapted to control, at least in part, a location of the drum.

Owner:NOVATEK IP

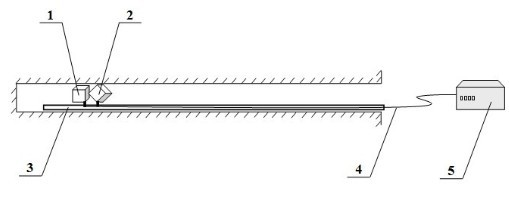

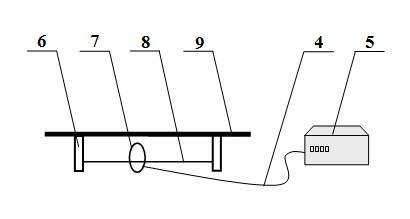

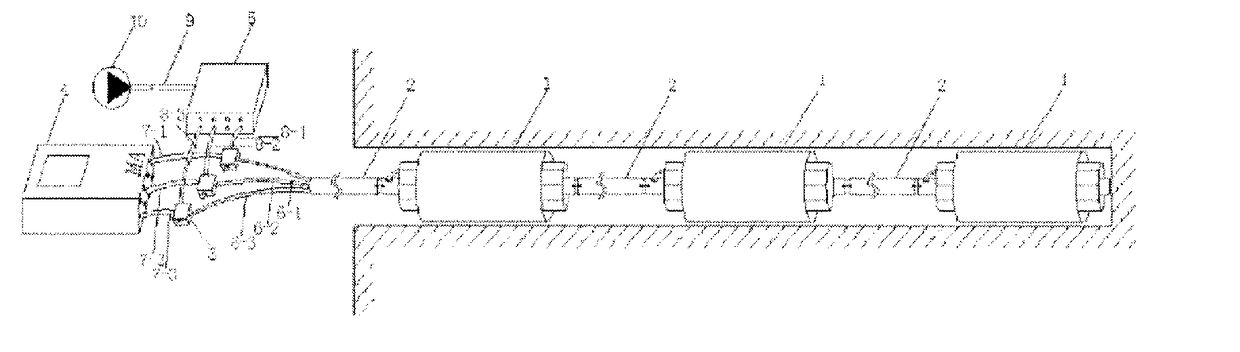

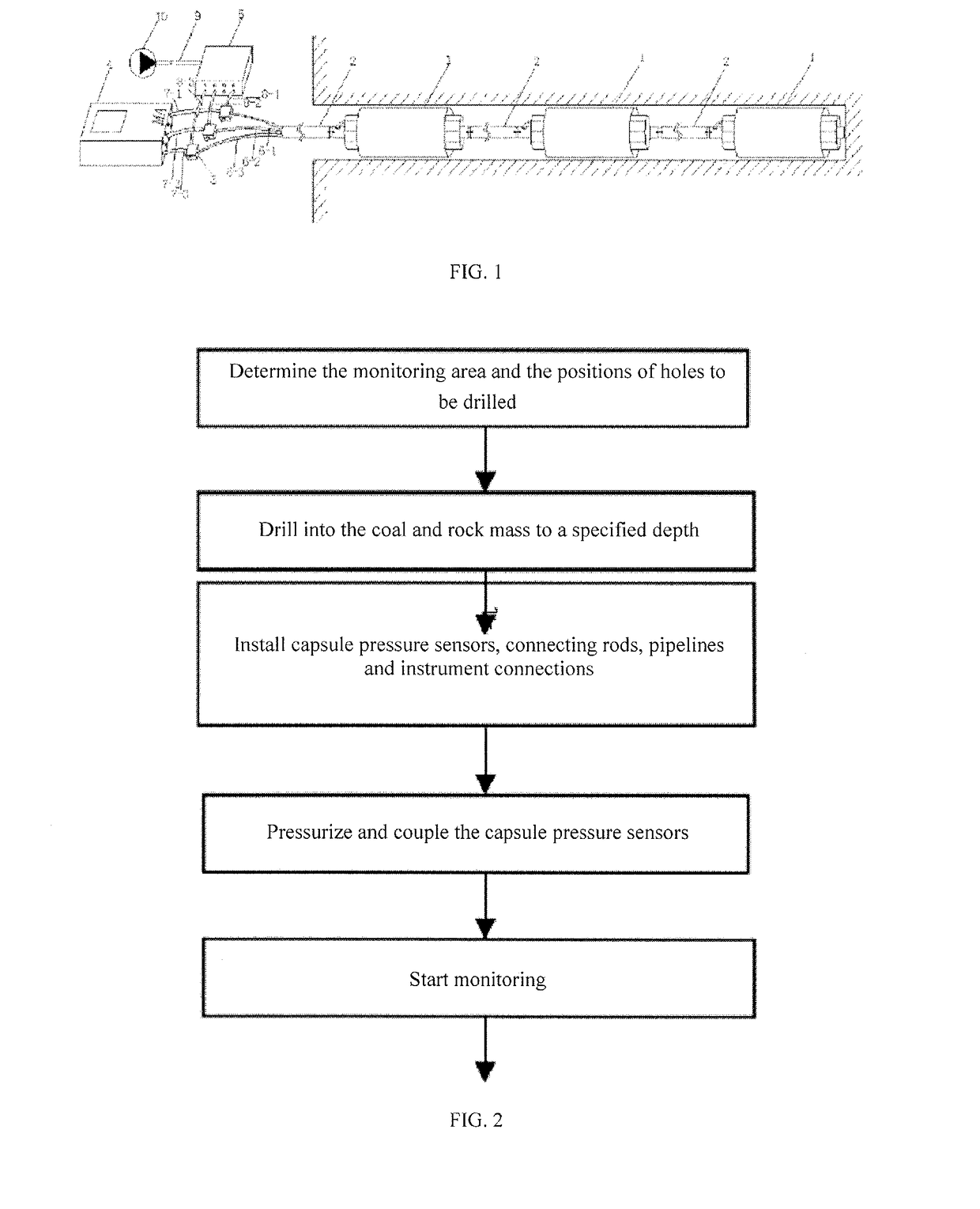

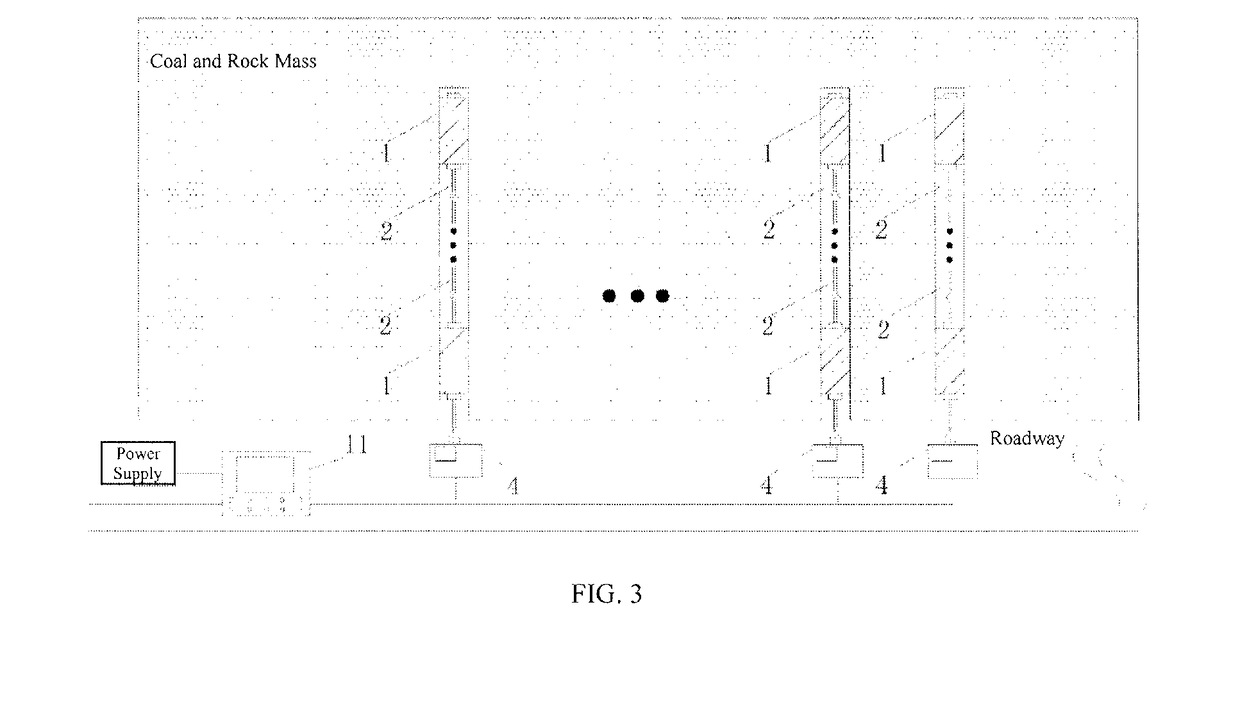

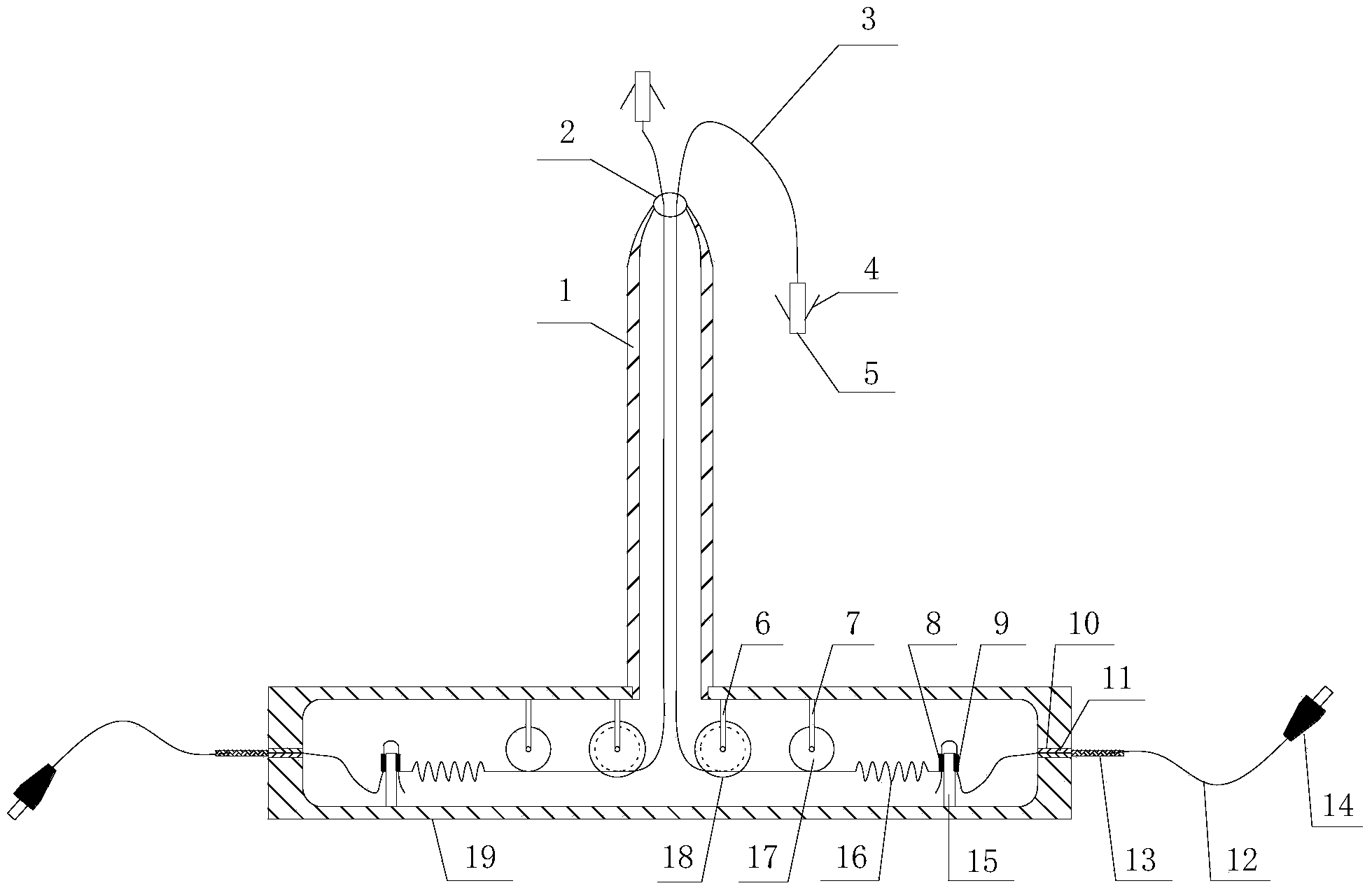

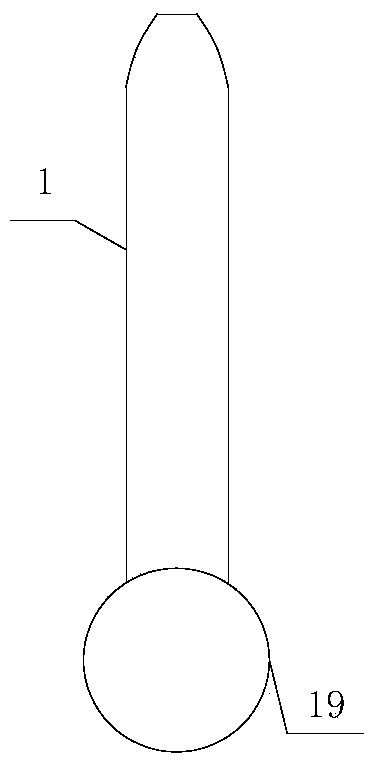

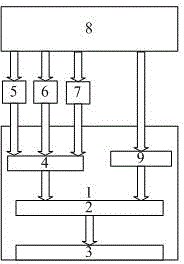

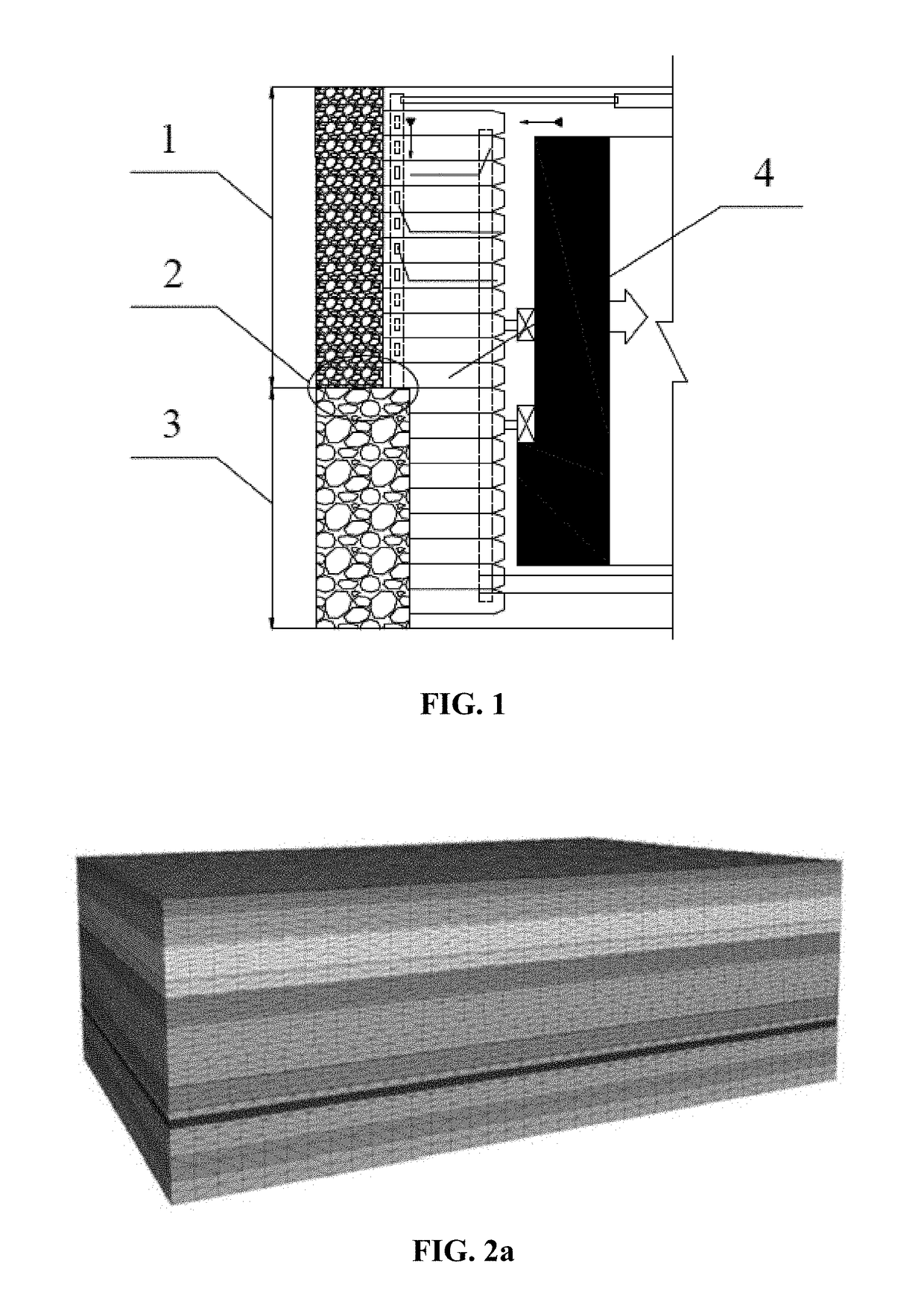

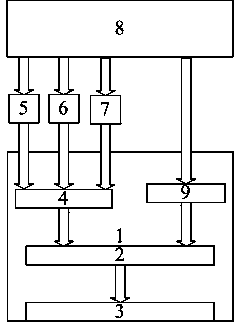

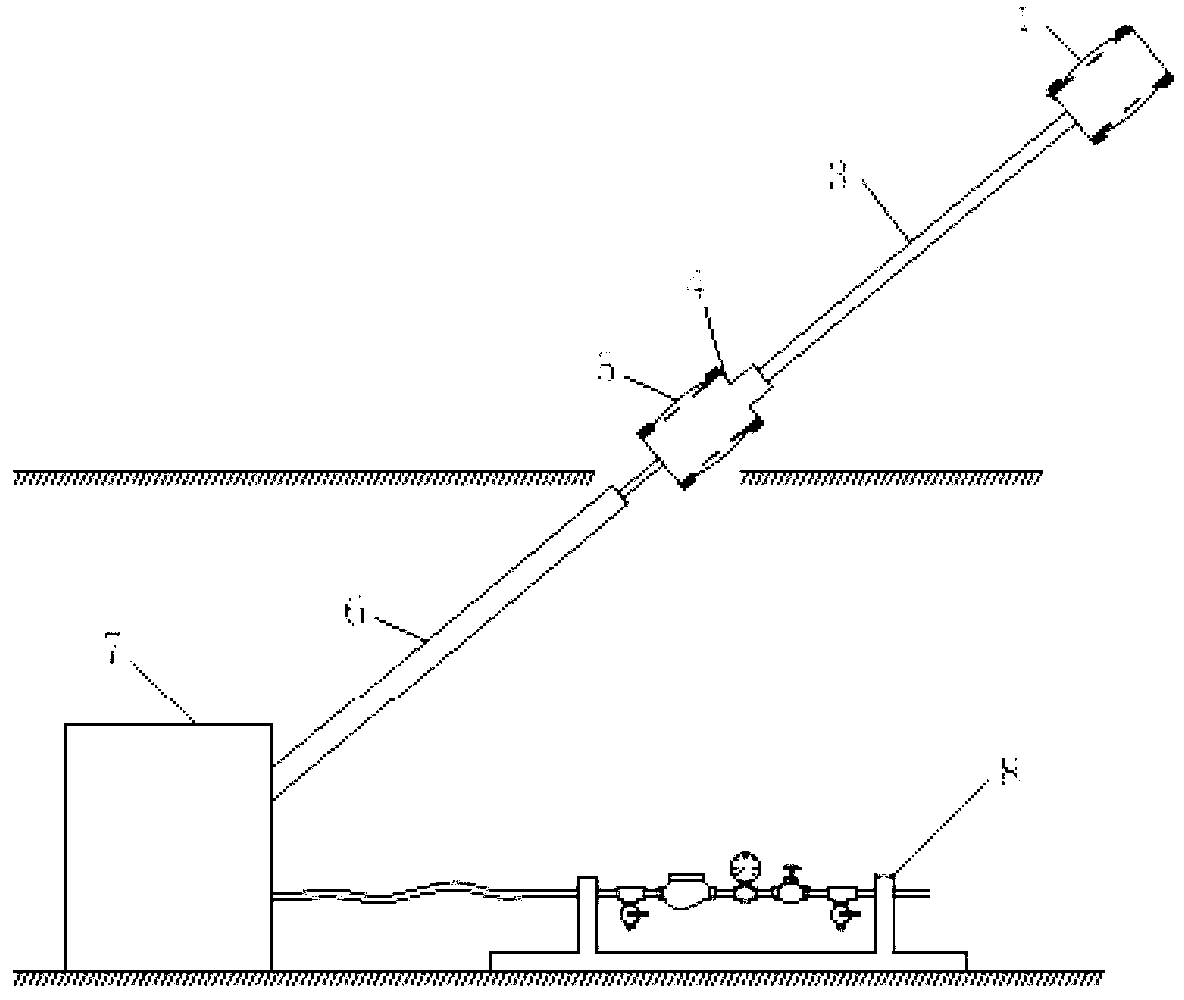

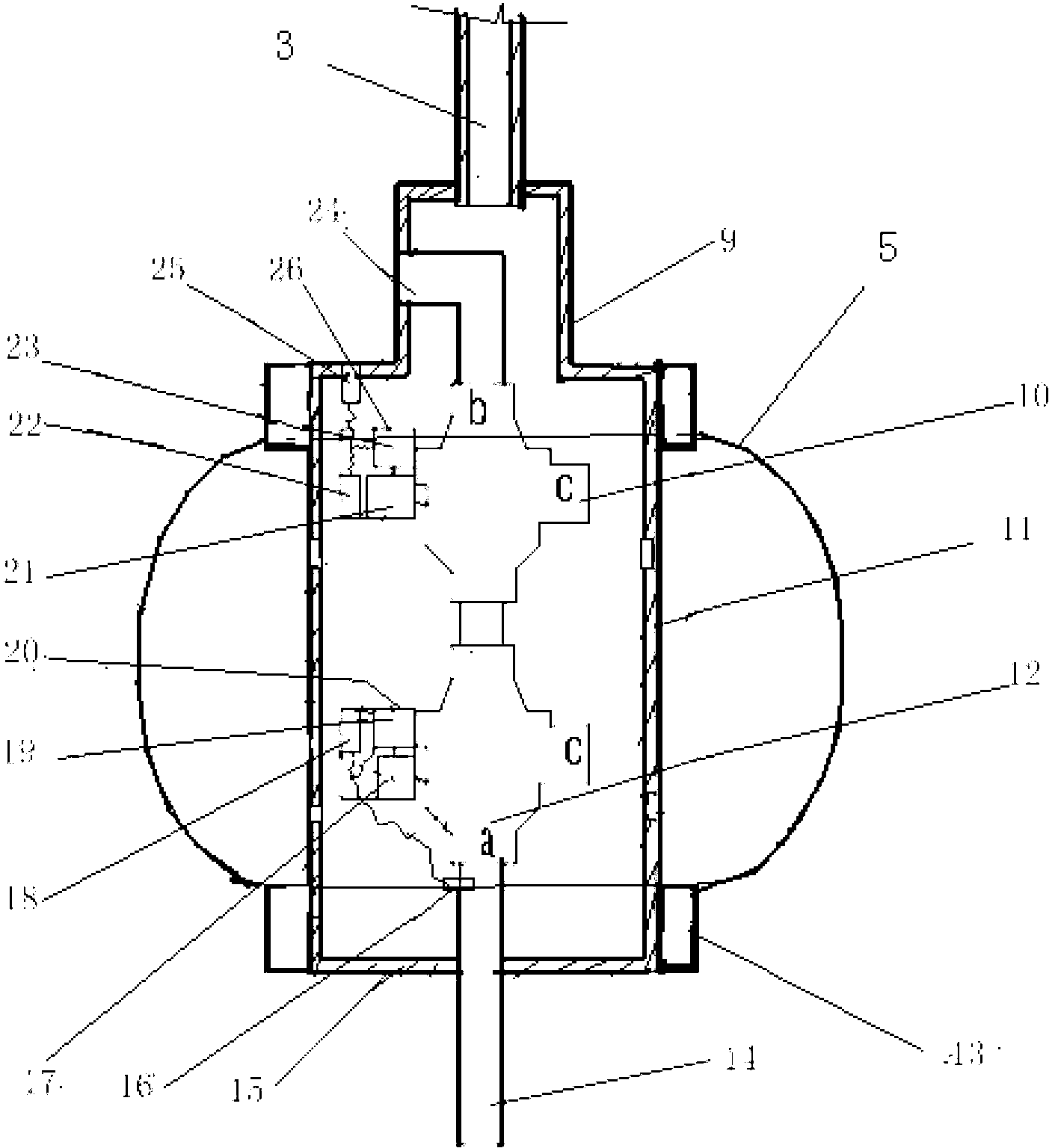

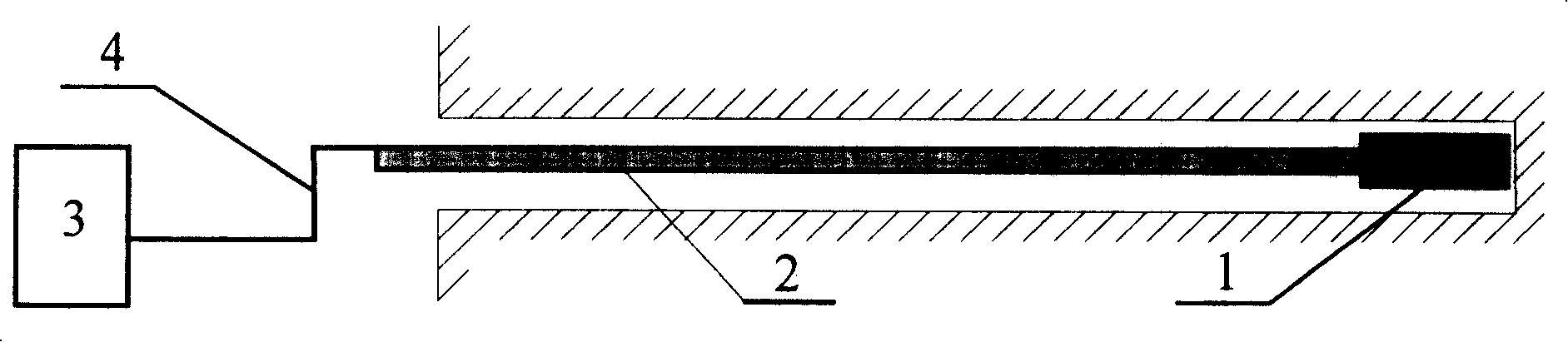

Multipoint Coal and Rock Mass Stress Real-Time Monitoring Device and Method

ActiveUS20170122822A1Improve adaptabilityImprove stabilityMining devicesTesting machinesDisaster monitoringMeasurement point

A multipoint coal and rock mass stress real-time monitoring device. The device is composed of a plurality of capsule pressure sensors (1), connection rods (2), three-way valves (3), a multichannel monitor (4), a multichannel control valve (5), first high-pressure oil pipes (6), second high-pressure oil pipes (7), third high-pressure oil pipes (8), a four high-pressure oil pipe (9), a high-pressure oil pump (10) and monitoring substations (11). The present invention also relates to a multipoint coal and rock mass stress real-time monitoring method. Oil is injected into each capsule pressure sensor (1) that is arranged in a drilled hole through the multi-channel control valve (5), so that oil pressure inside each capsule pressure sensor (1) reaches the preset pressure, and the capsule pressure sensors and the coal and rock mass are well coupled; monitoring signals are synchronously collected, converted, stored and displayed by the multichannel monitor (4) or are transferred to a remote monitoring center through the monitoring substations (11). The device and method can be used for coal and rock dynamic disaster monitoring early warning such as coal and rock mass stress monitoring, mine pressure analysis, rock burst and coal and gas rush, and the stress and changes of the stress of multiple measuring points can be measured at the same time in the multiple drilled holes of the coal and rock mass.

Owner:CHINA UNIV OF MINING & TECH

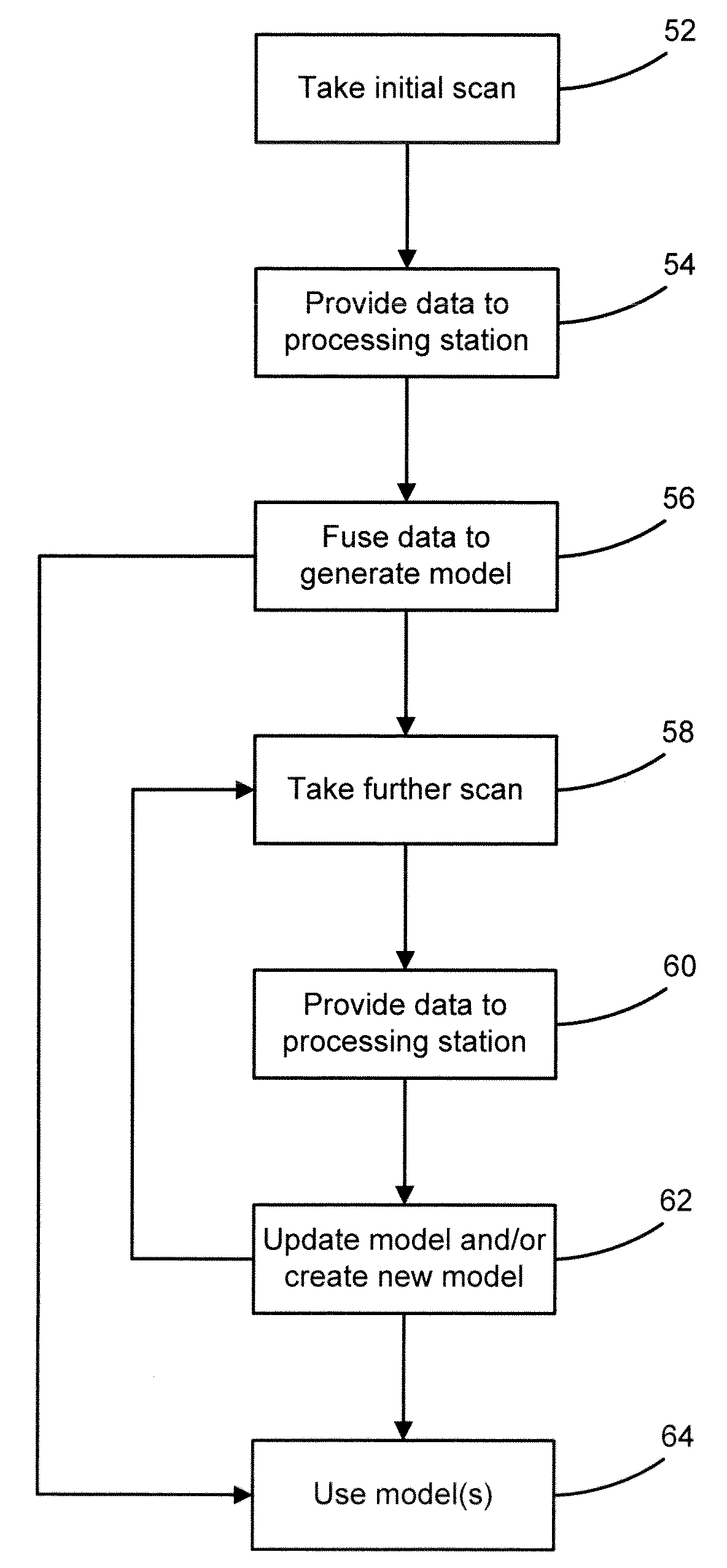

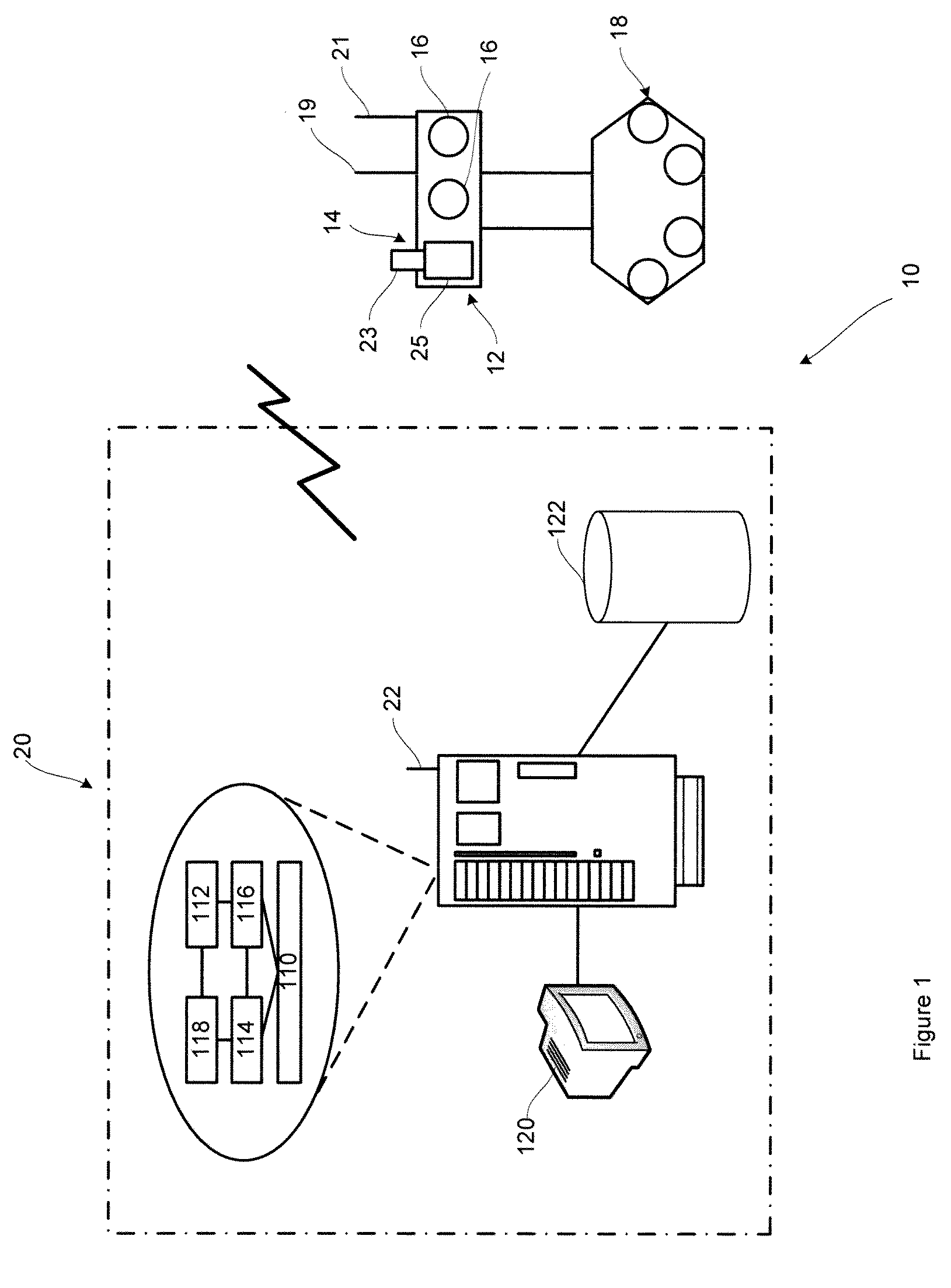

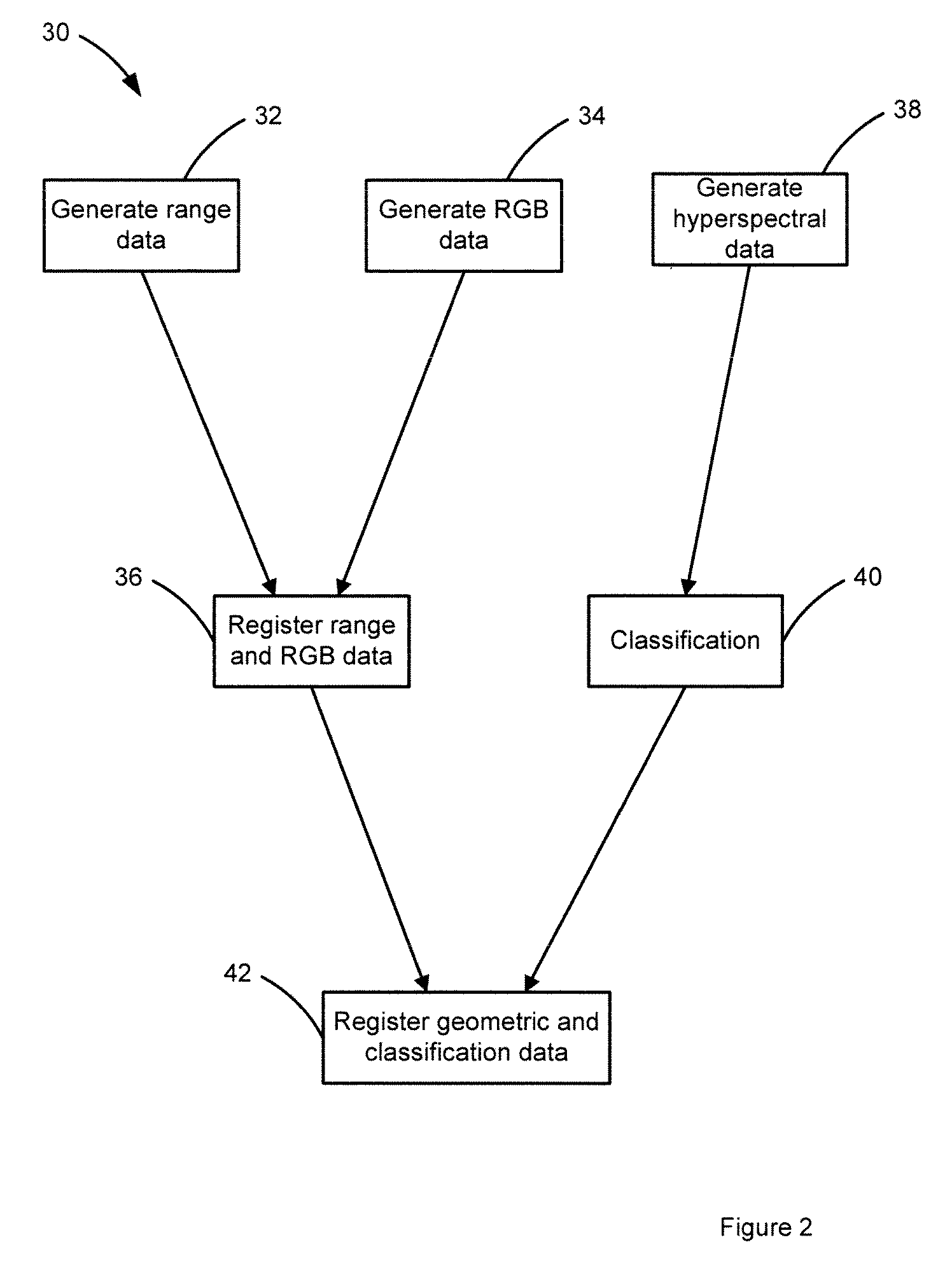

Scanning system for 3D mineralogy modelling

A method of mining comprising: using a vehicle fitted with scanning module to scan a bench face of a mine bench for both geometric and geological information; making ore grade assessments of material at the bench face from the information provided by the bench face scan; removing material from the bench; and transporting removed material for processing. At least one of said removing, transporting, and processing is performed at least partially dependent on the ore grade assessments.

Owner:TECHNOLOGICAL RESOURCES

Monitoring device and monitoring method for mining FBG (fiber bragg grating) roof separation layer

ActiveCN103528530ARealize online measurementTimely warningMining devicesTesting machinesGratingBoundary values

The invention provides a monitoring device and a monitoring method for a mining FBG roof separation layer. The device comprises a vertical measurement barrel and a packaging casing, wherein fixed pulleys, tape pulleys and constant-strength cantilever beams are symmetrically arranged in the packaging casing; a steel wire rope penetrates through the tape pulleys and the fixed pulleys and penetrates out from a steel wire rope guide hole in the top part of the vertical measurement barrel; one end of the steel wire rope is connected with an anchor head; a shallow part measurement point and a deep part measurement point are distributed inside a drill hole; the anchor head is pushed to the measurement points in the drill hole; when the stress of the steel wire rope changes, the stress change is displayed through wavelength values of an FBG A and an FBG B; a wavelength demodulation device is used for demodulating the wavelength values into digital signals, the digital signals are sent to a computer for real-time processing, and a separation layer numerical value is combined for drawing a separation layer quantity changing curve and a set separation layer boundary value; whether the separation layer exists is judged; and the data change of the roof separation layer is monitored in real time. Temperature compensation is performed with a differential form, on-line measurement of the roof separation layer is realized, the reliability and the accuracy are high, an early warning signal can be issued, and roof fall accidents can be avoided.

Owner:CHINA UNIV OF MINING & TECH

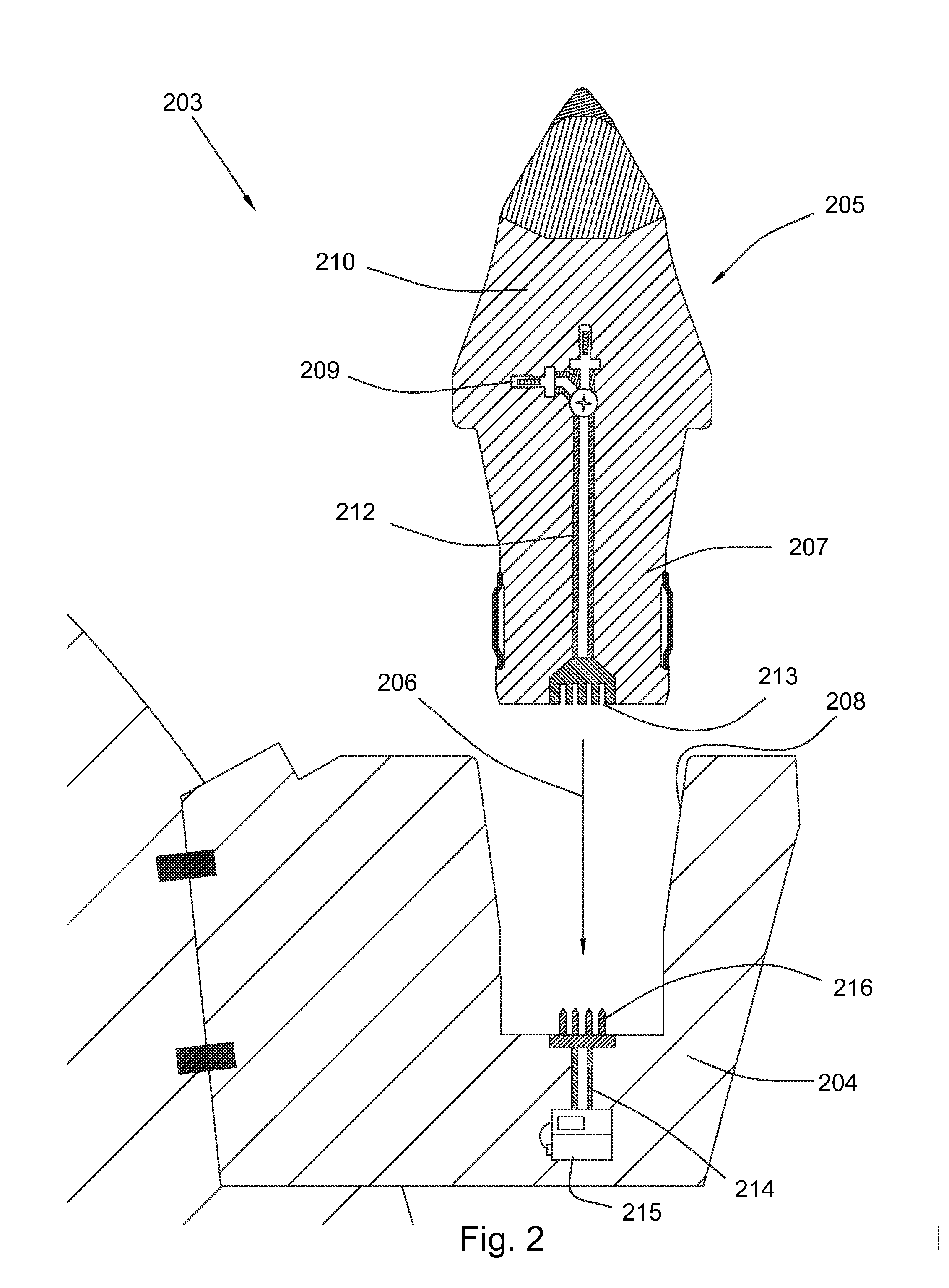

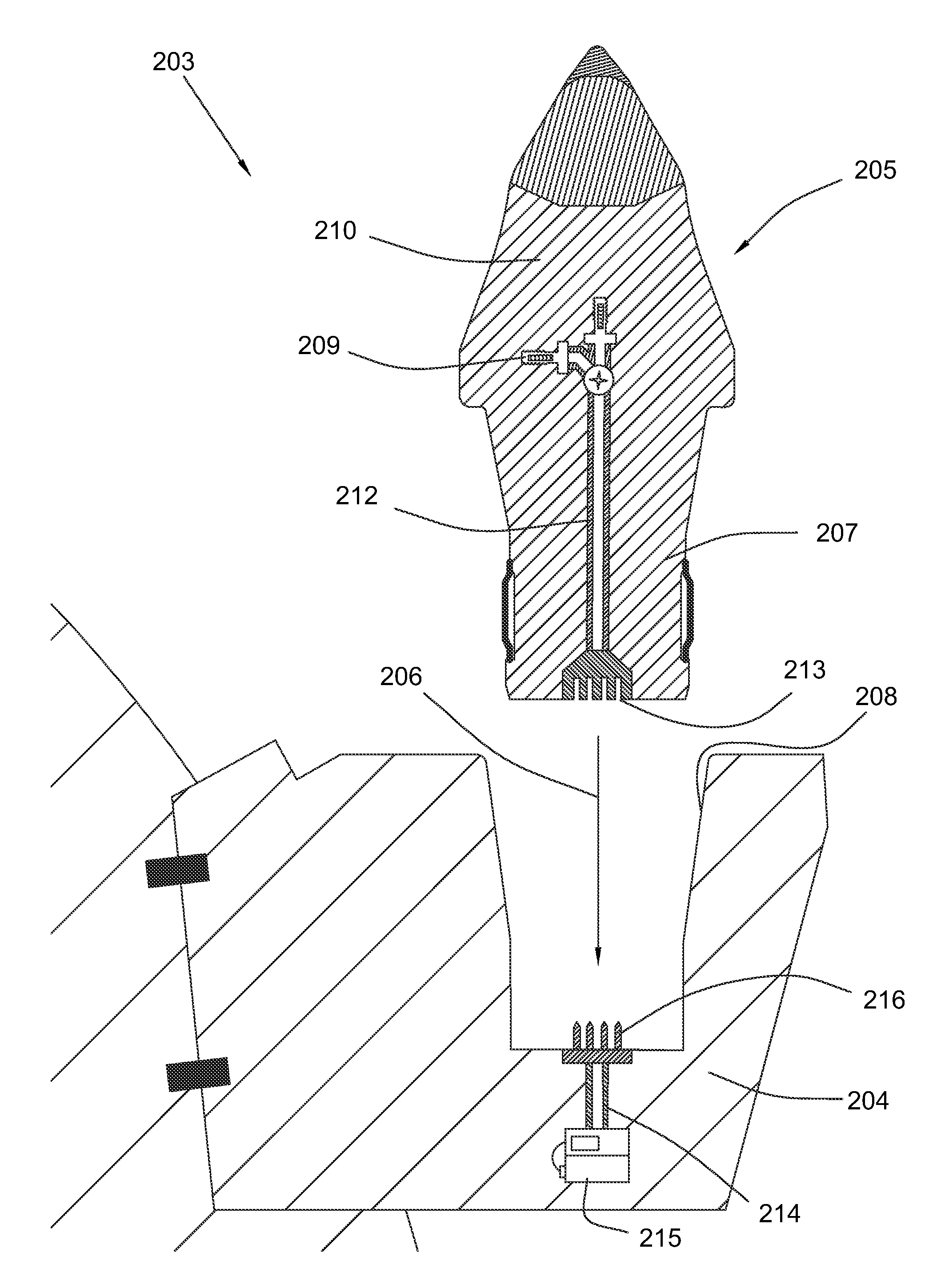

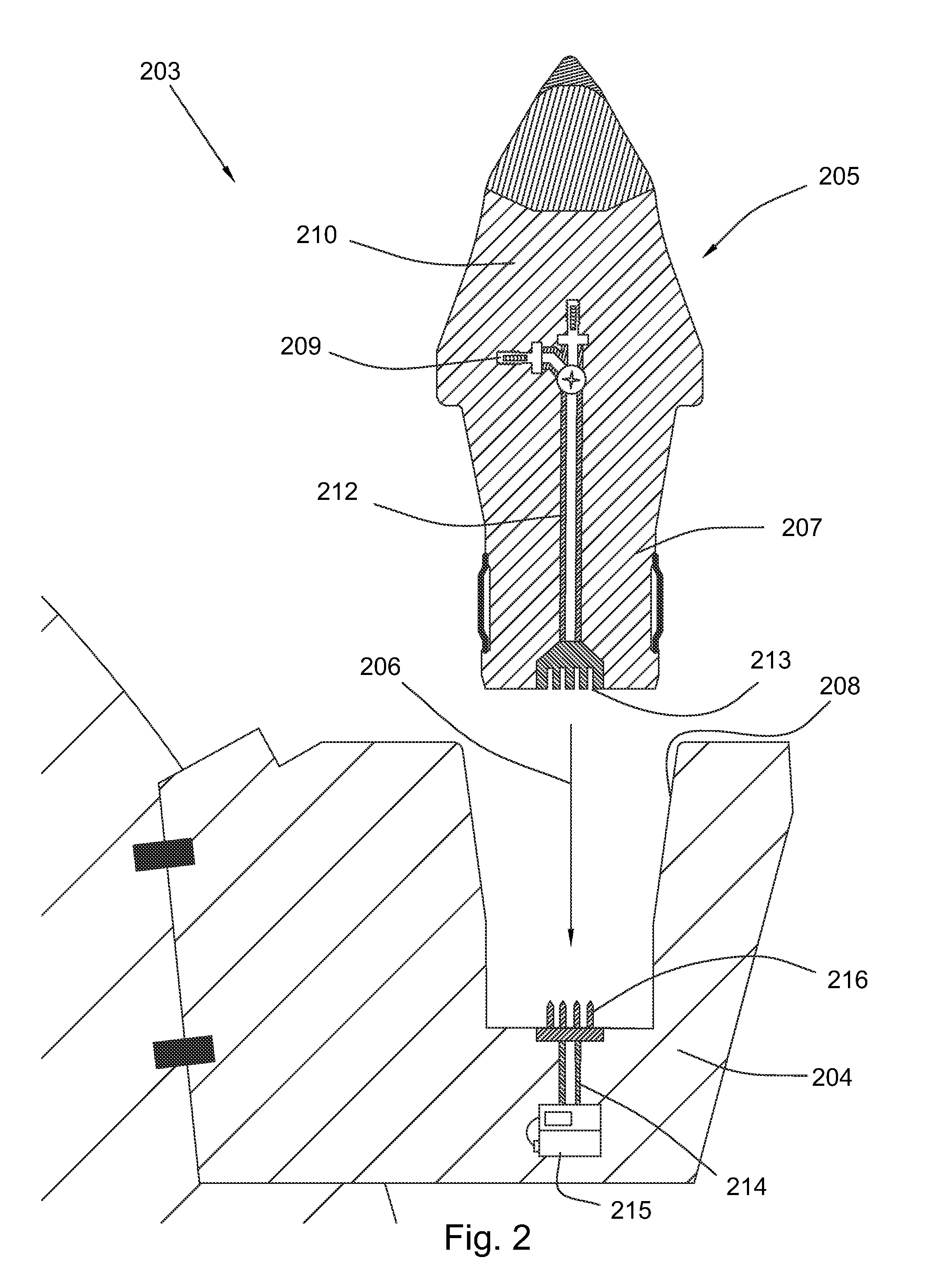

Sensored Pick Assembly

A degradation assembly may comprise at least one sensor mounted on a pick; the pick comprising a first conductor in communication with the sensor. The assembly may also comprise a receiving element including a bore comprising a second conductor. The first and second conductors may combine to create a connection as the pick is inserted into the bore of the receiving element.

Owner:SCHLUMBERGER TECH CORP

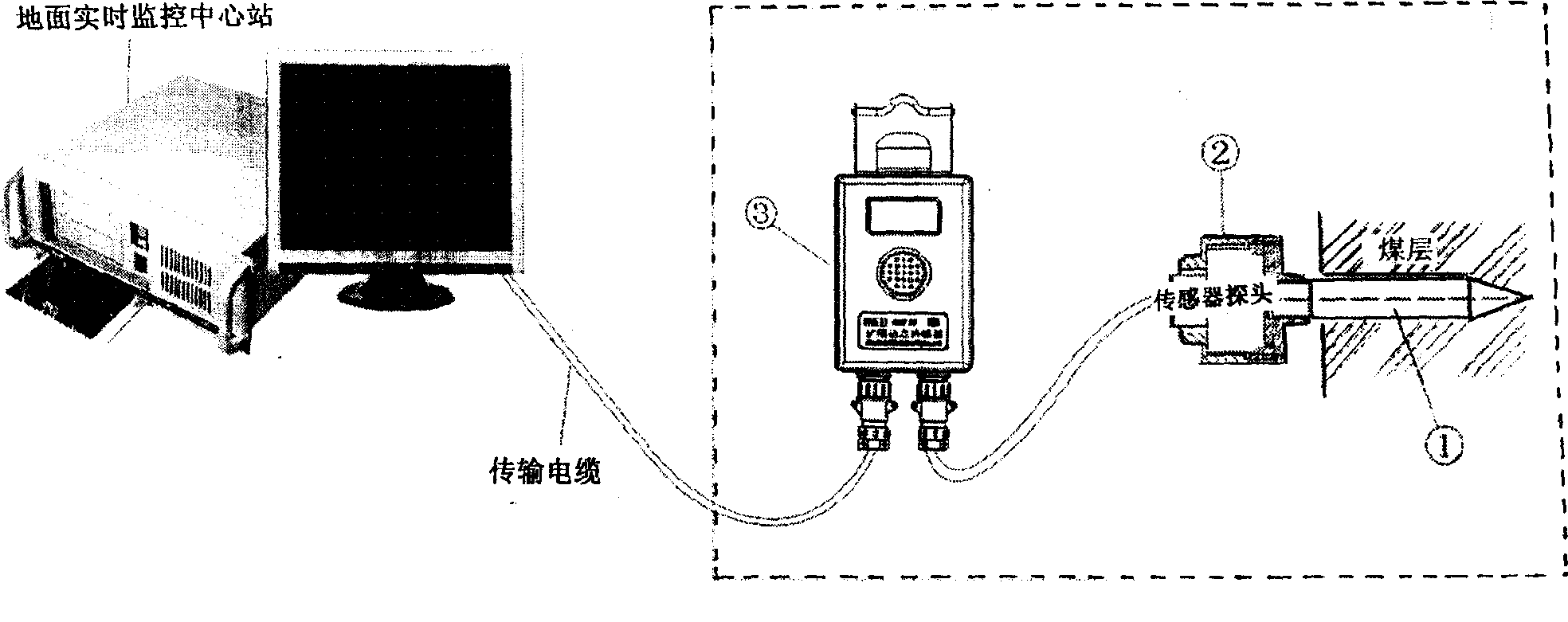

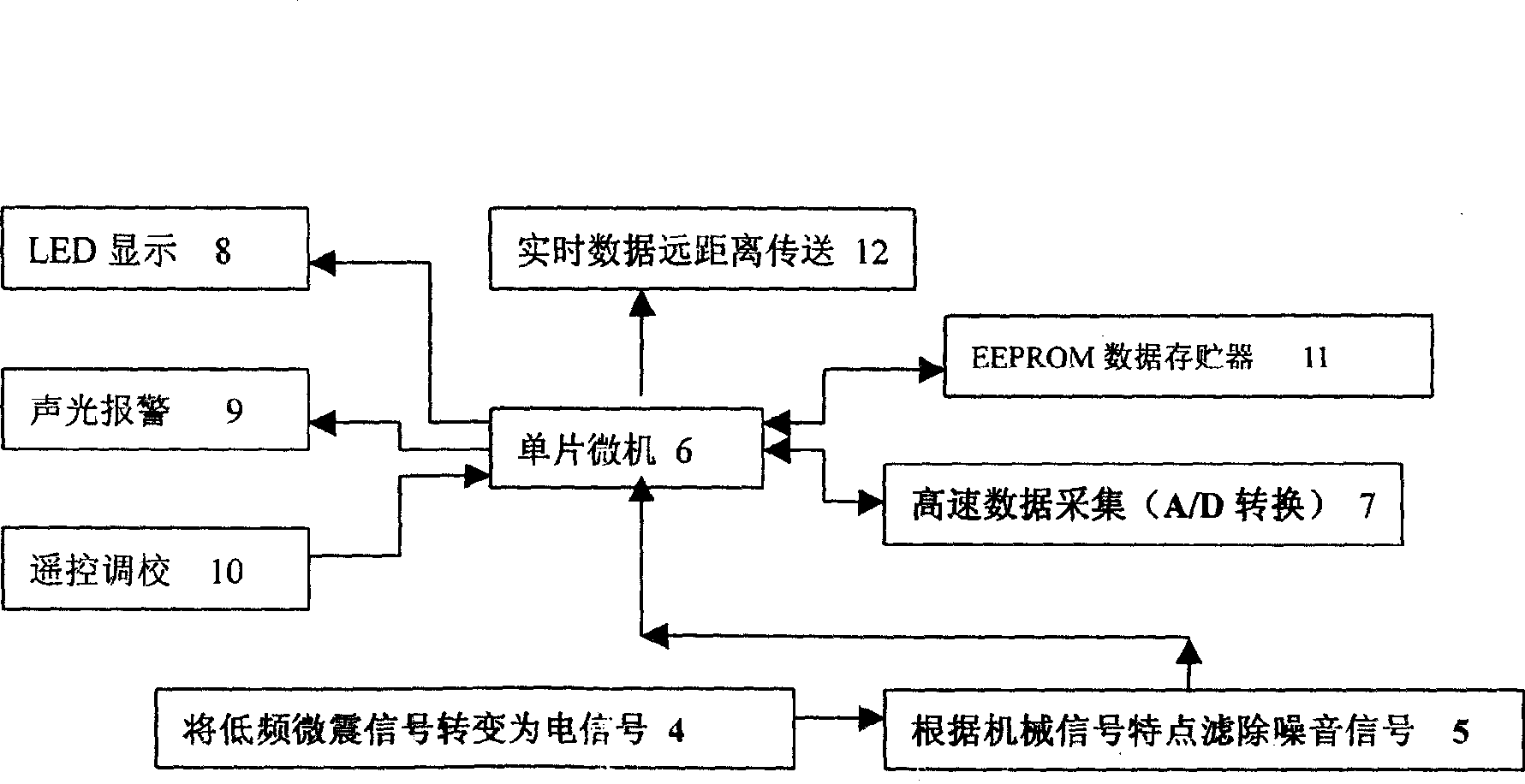

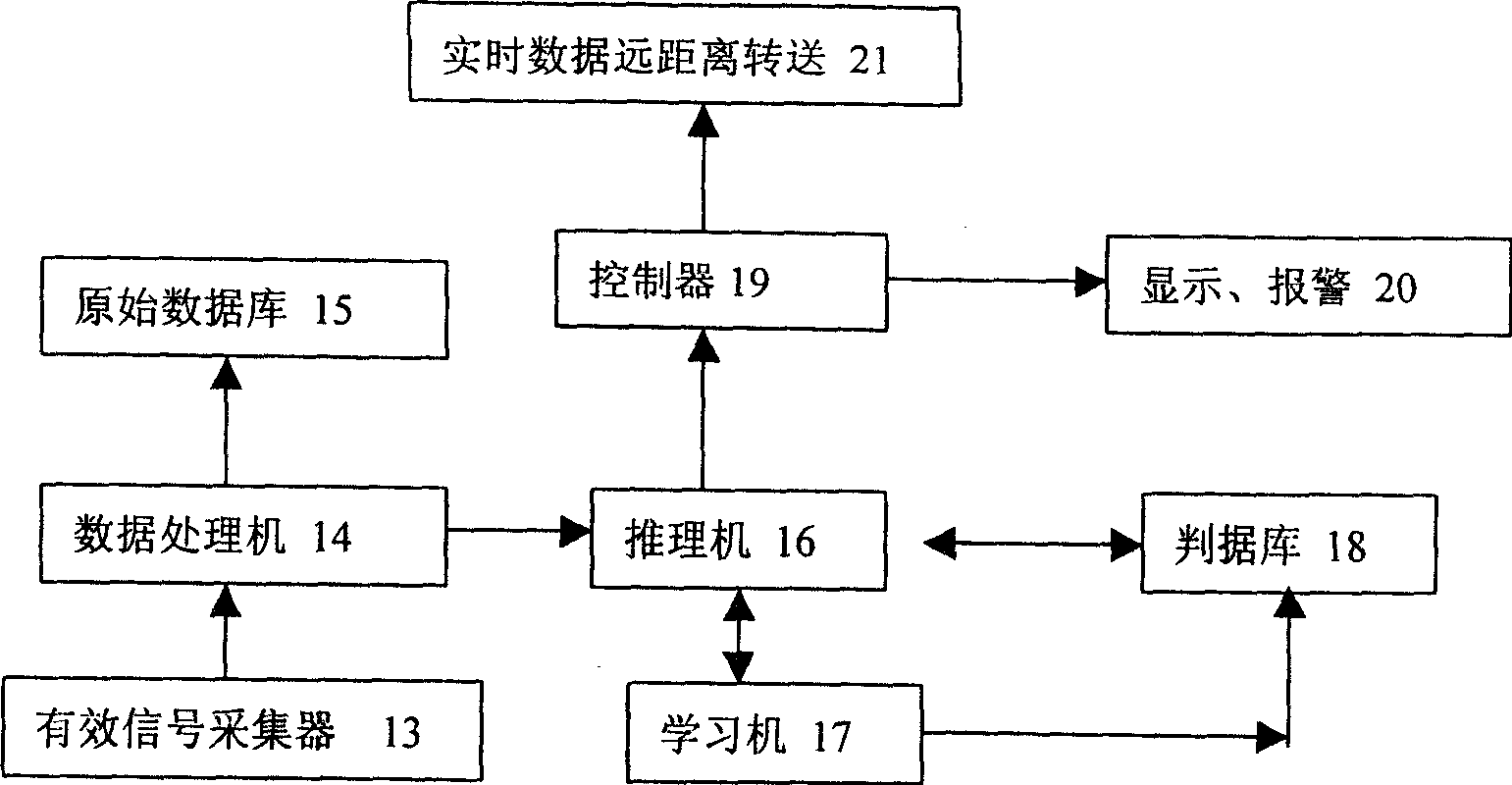

Device for real time monitoring mine roof rock formation or concrete structure stability

ActiveCN101363824AImprove rigidityHigh strengthUltrasonic/sonic/infrasonic wave generationTesting machinesMetro stationEngineering

The invention relates to a device for monitoring the stability of roof strata of a mine or concrete engineering in real time. The device mainly comprises a microseism signal conduction rod, a microseism signal sensing element and a microseism signal collection and analysis host computer. The microseism signal collection and analysis host computer is provided with a filter circuit for filtering the affection of ambient noise signal, a rapid data sampling circuit and a professional diagnosis and analysis software for analyzing the stability of the roof strata of the mine or the concrete structure in real time by utilizing artificial intelligence technology. The device is suitable for coal mines or other mines, can be used for the stability monitoring of underground construction which adopting concrete bar and concrete as the materials, such as metro stations or tunnels, and can also be used for the stability monitoring of dams, bridges, tall buildings and mountain landslides. Through a set of technology of digital filtering recognition and collection for the microseism signal, the recognition rate for acoustic signal released during rock breaking can be improved above 80 percent, and the purpose of monitoring the stability of the roof strata of the mine or the concrete structure is well completed.

Owner:西安西科测控设备有限责任公司

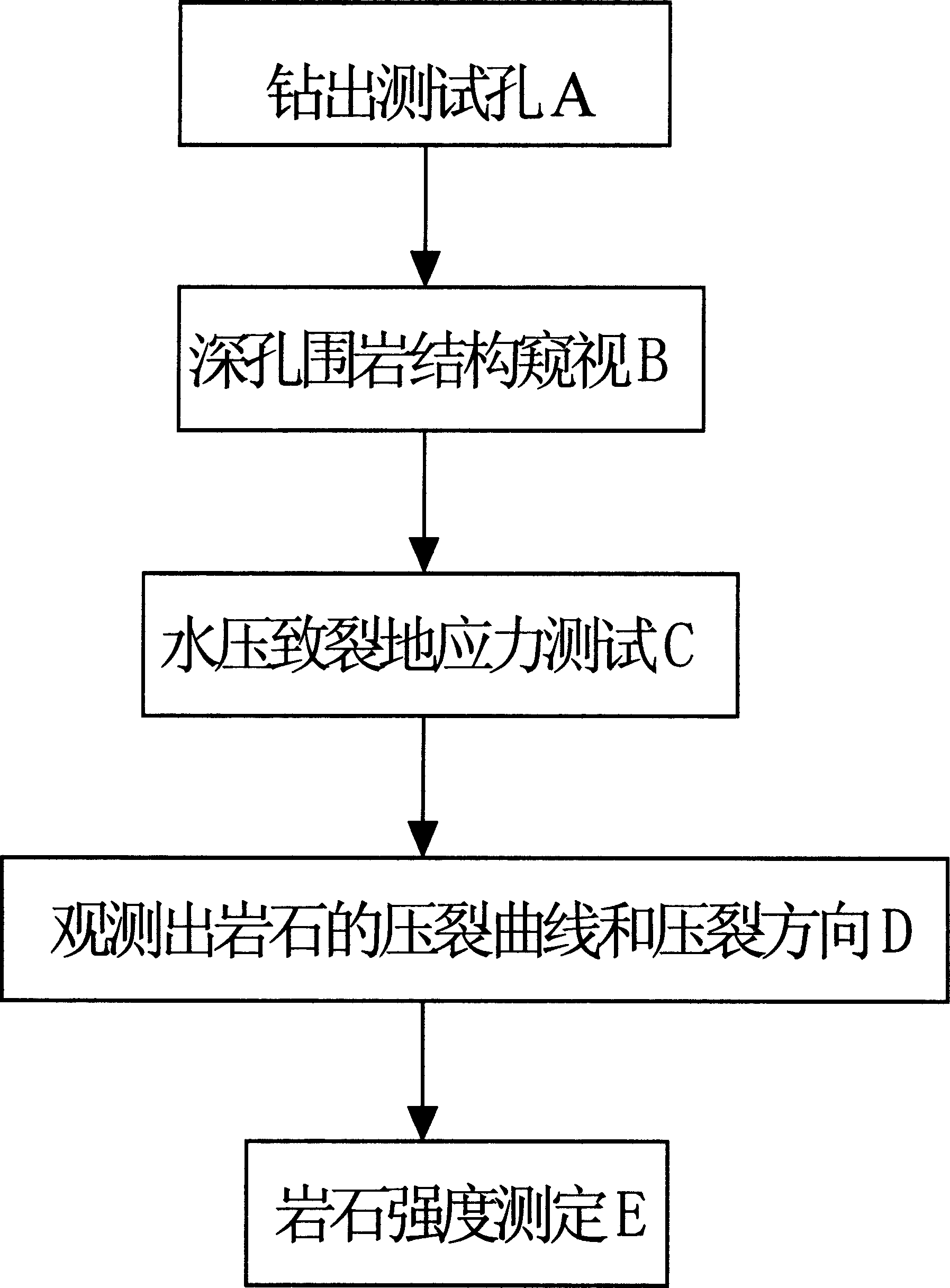

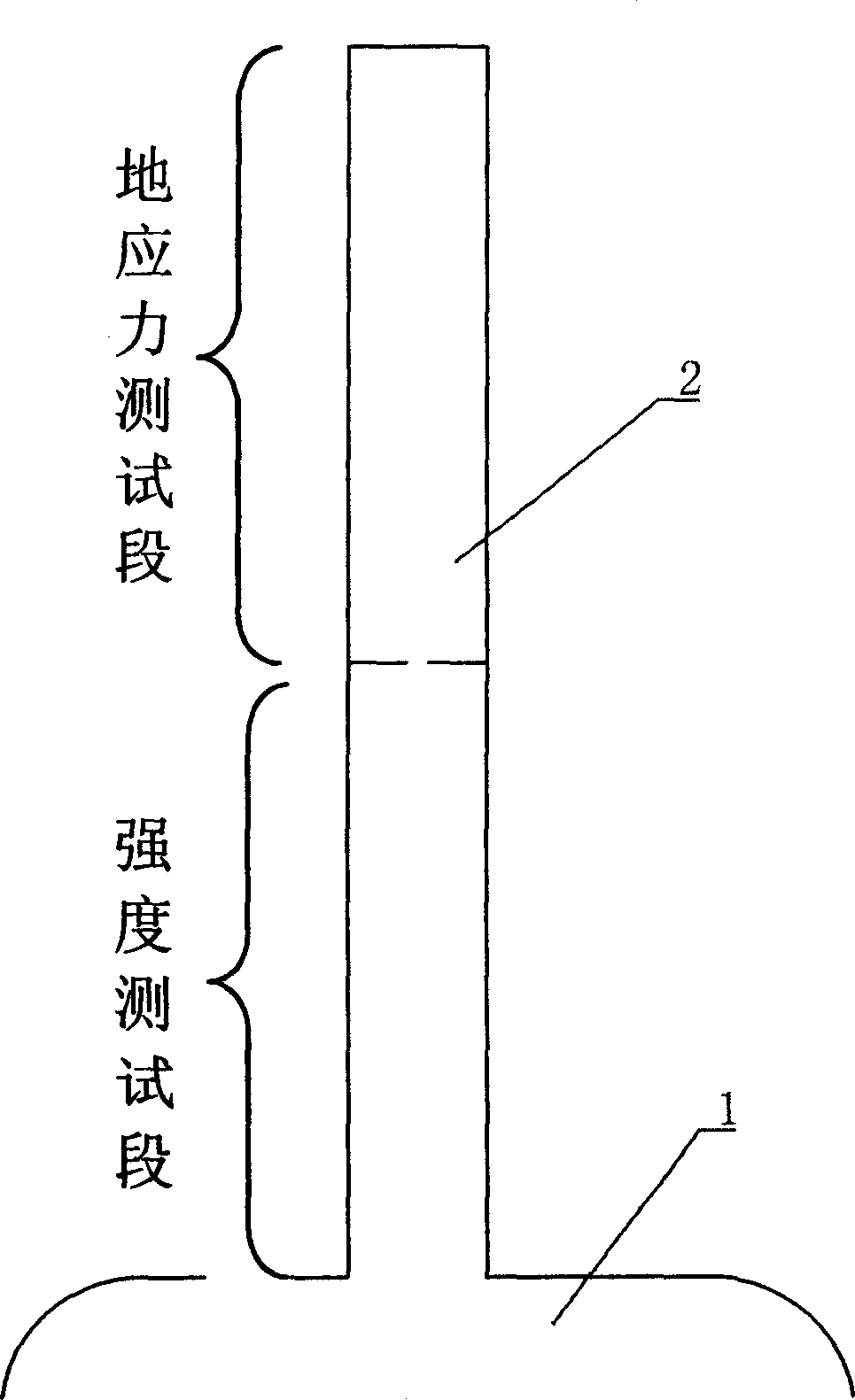

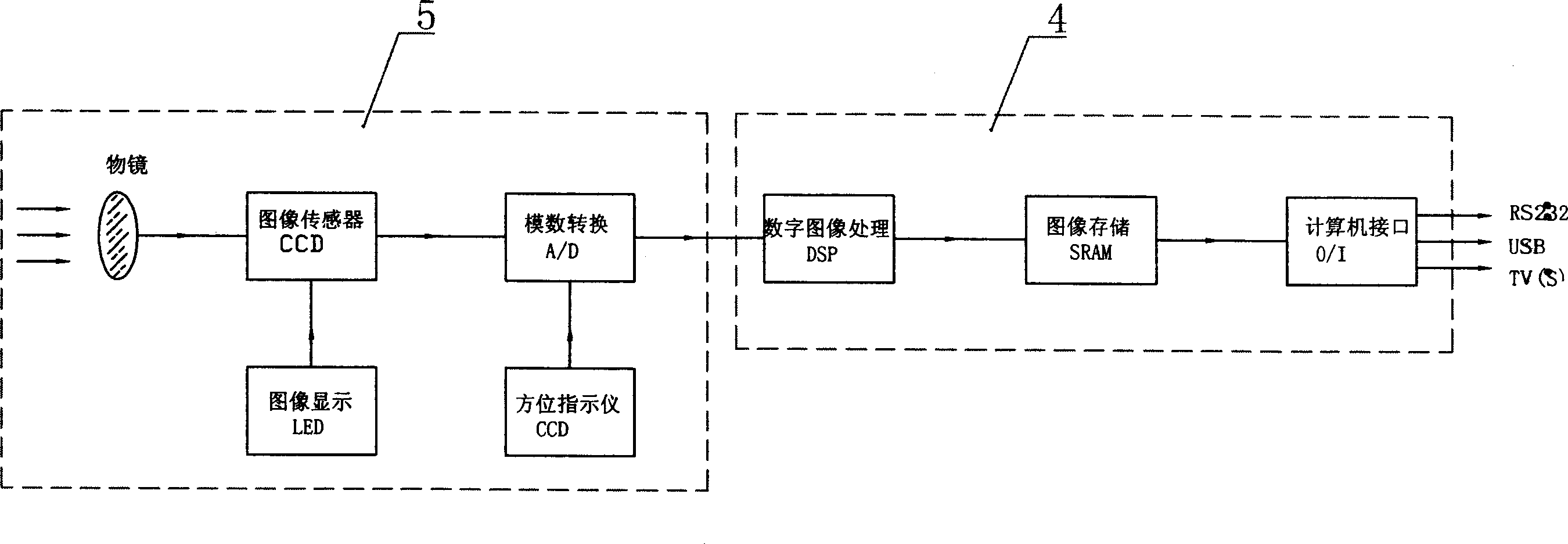

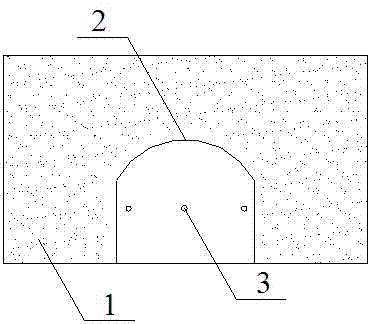

Testing method and apparatus for geological mechanics parameter under coal mine

InactiveCN1818337ASimple structurePractical and reliable functionTesting machinesStressed stateUltimate tensile strength

A geology mechanics parameter speedy test method and the equipment of underground colliery: drill test hole at operating face; measure the design value of the surrounding rock by sight scope which has lateral direction device deep-lying sightglass; speedy measure the stress state of the rock by using the method of hydraulic pressure leading split; then put the sightglass into the test hole, measure the split curve and direction by using the directional device on it; measure the intensity of resistant to compression and modulus of elasticity in the test hole. The invention offers a new method and the sight scope has double functions which are screen and save the images of front and side drilling-hole.

Owner:康红普

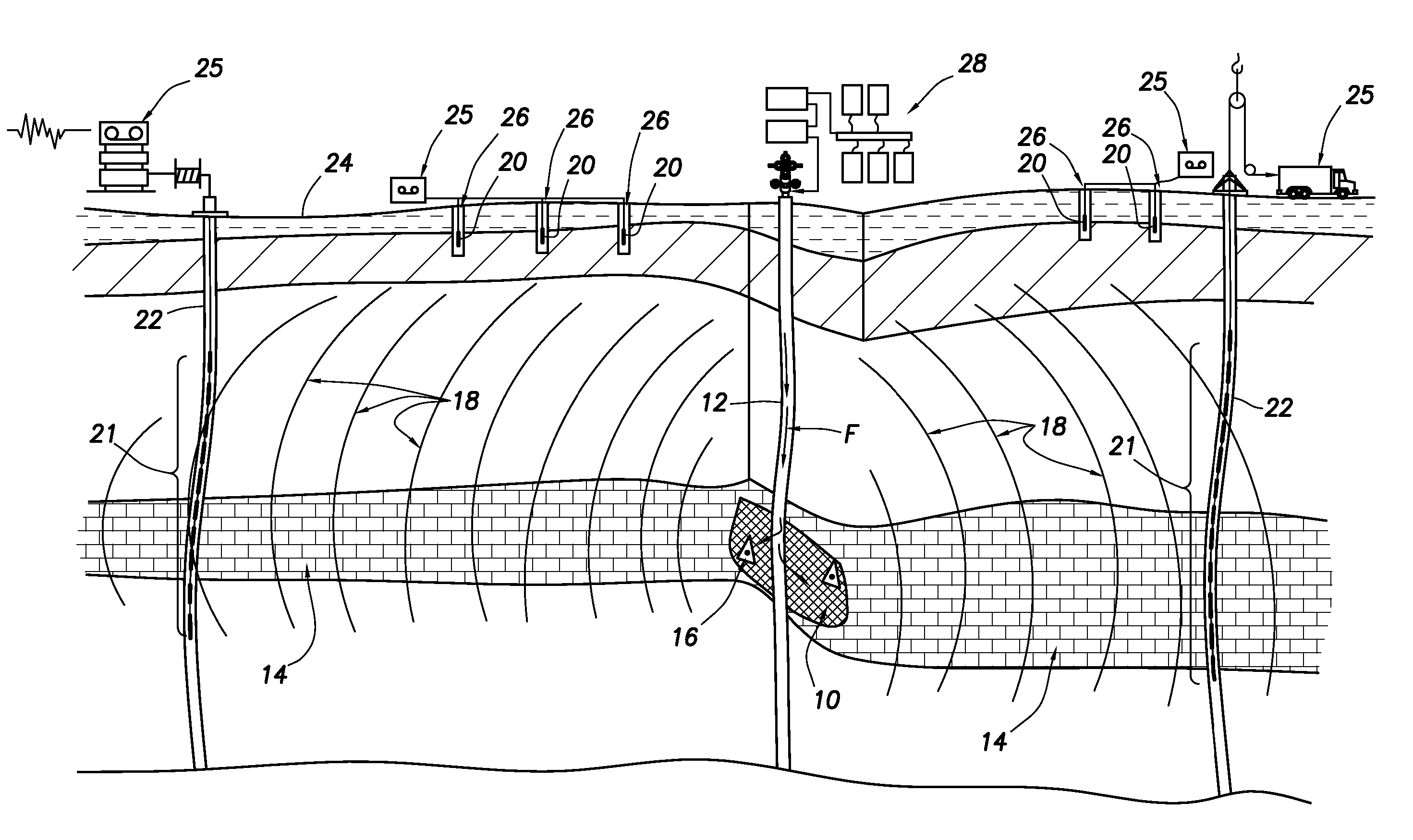

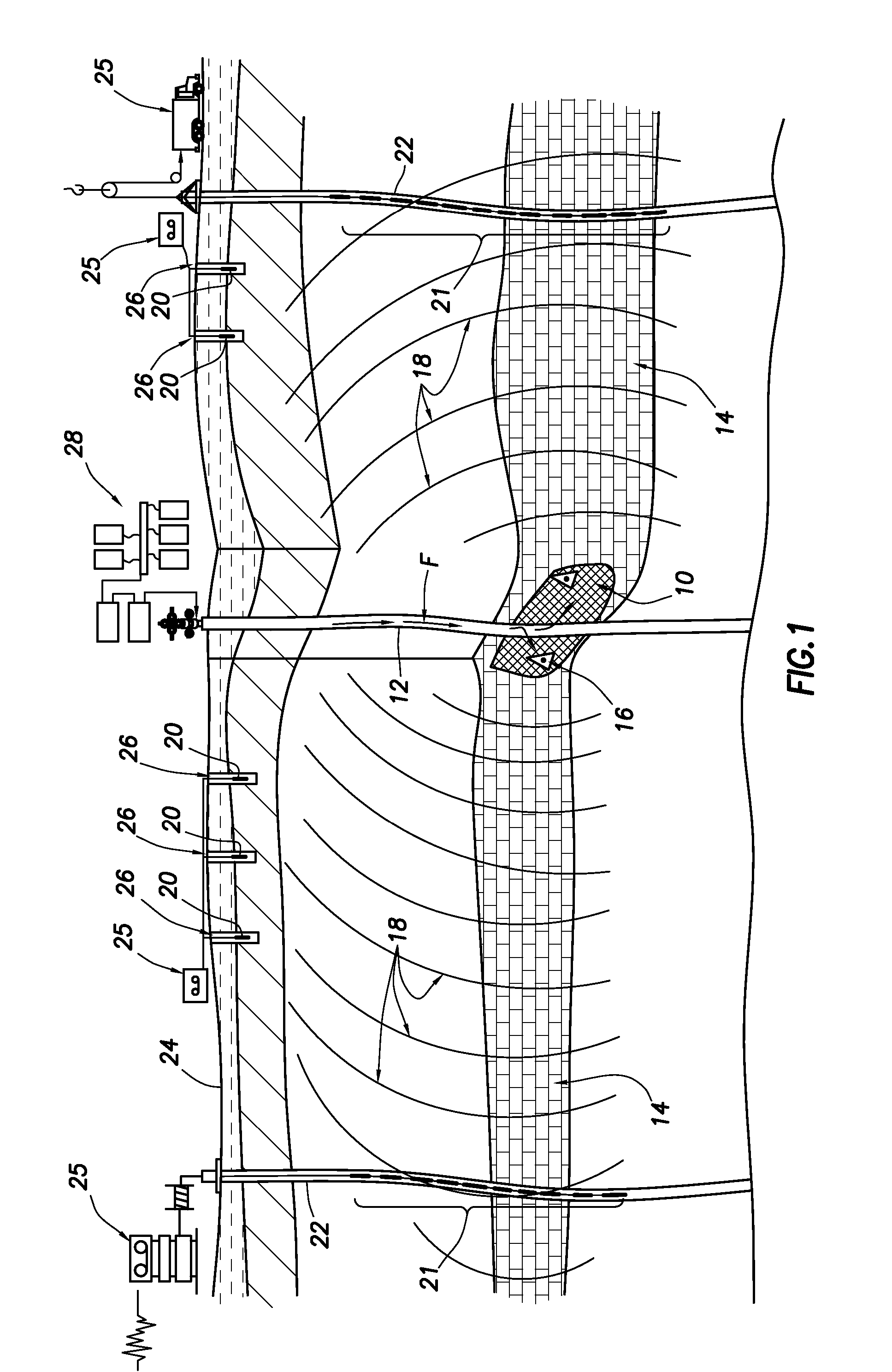

Method and apparatus for generating seismic pulses to map subterranean fractures

The methods described are for determining distribution, orientation and dimensions of networks of hydraulically-induced fractures within a subterranean formation containing fluids. Micro-seismic events are generated, after cessation of fracturing and establishment of fracture networks, by particles introduced into the fractures which are capable of explosive or chemical reaction. In one method, attachment site particles are positioned within the formation during fracturing and additional reactive particles are later introduced. The reactive particles attach to the attachment sites and, upon a triggering event, react to produce micro-seismic events. The waves generated by the micro-seismic events are used to provide mapping of the effective fracture space. Additionally, time-lapse mapping is provided with use of “species” of attachment sites and reactive particles.

Owner:HALLIBURTON ENERGY SERVICES INC

Sensored pick assembly

A degradation assembly may comprise at least one sensor mounted on a pick; the pick comprising a first conductor in communication with the sensor. The assembly may also comprise a receiving element including a bore comprising a second conductor. The first and second conductors may combine to create a connection as the pick is inserted into the bore of the receiving element.

Owner:SCHLUMBERGER TECH CORP

Coal rock interface analysis method based on coal mining machine perception

The invention relates to a coal rock interface analysis method based on coal mining machine perception, and is realized based on a coal rock interface analysis system based on the coal mining machine perception. The system is composed of a large-capacity data storage device, a coal mining machine electrical main controller, an intrinsically safe type vibration accelerated speed sensor and the like. In the method, through coal mining machine working parameters composed of vibration signals, voltage and current and temperature torque of coal mining machine cutting and traction motors, coal mining machine rocker arm lifting oil cylinder pressure, and traction motor speed signals, signal characteristics of coal mining machine drum cutting teeth cutting coal and rock different roofs and floors situations are analyzed, wavelet packets are used for analyzing energy features of different frequency bands of the vibration signals, probability and statistic samples are used for analyzing feature distribution of the cutting machine working parameters, a multi-sensor information fusion technology is used for comprehensive establishment of different coal rock character databases, a coal mining machine perception coal rock interface is defined through a fuzzy mathematic theory, and a coal rock interface membership degree is calculated according to the coal mining machine perception multi-sensor information, so as to be used as a coal rock interface recognition basis.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

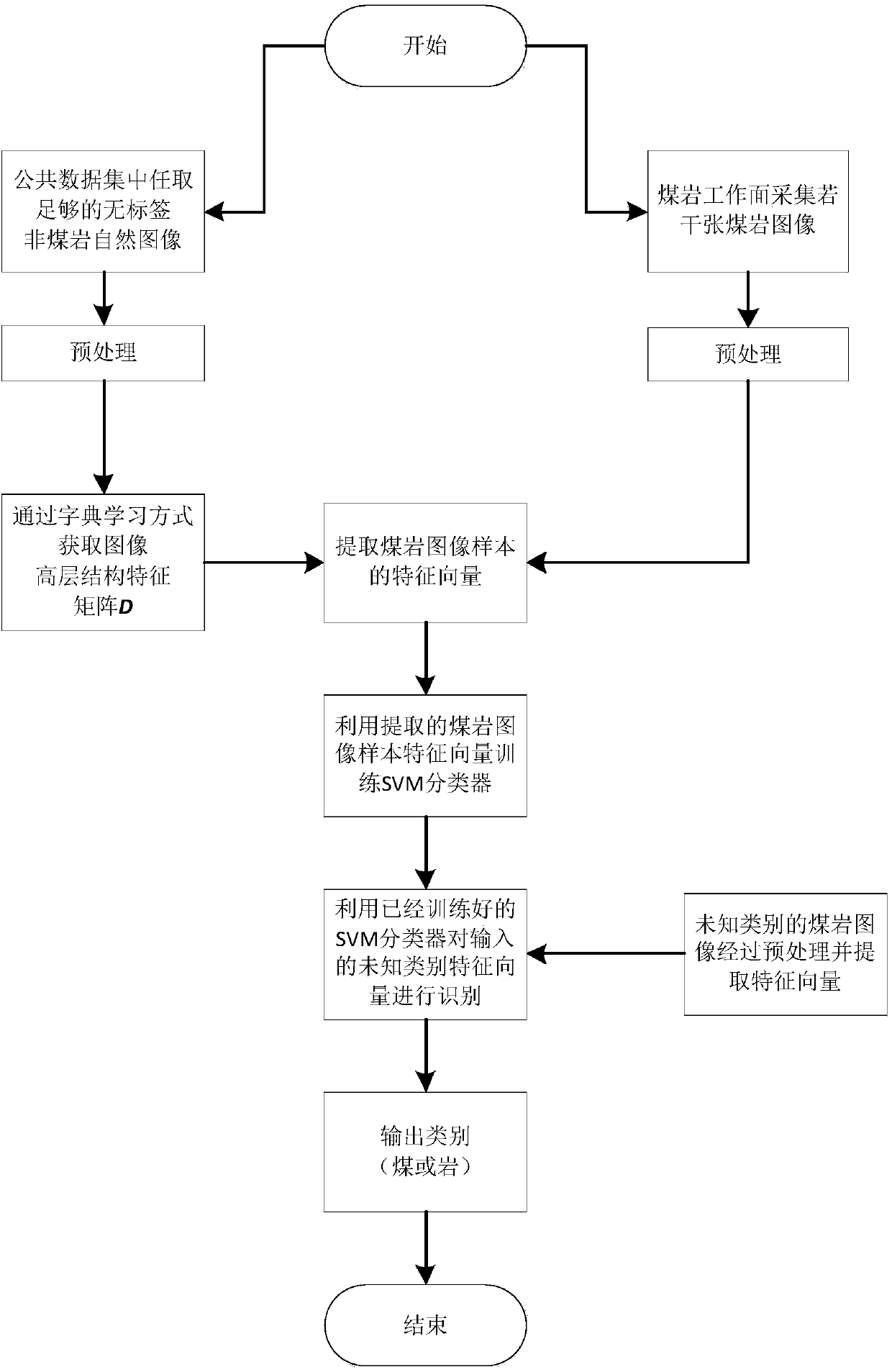

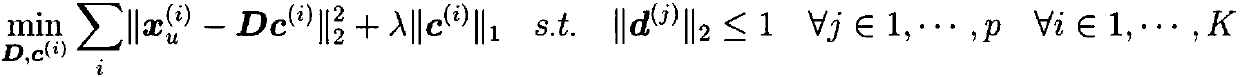

Self learning-based coal rock recognition method

PendingCN108197630AEasy to identifyImprove robustnessTesting machinesSlitting machinesFeature vectorLearning based

The invention discloses a self learning-based coal rock recognition method. The method comprises steps: a high-layer structure feature matrix D is firstly learnt from auxiliary data in an offline mode, wherein the auxiliary data are non-labeled non-coal rock natural images and are acquired more easily; the coal rock images are represented as a linear combination of a plurality of high-level characteristic atoms, and the coefficient of the linear combination forms a new eigenvector as the eigenvector of the coal rock image; the extracted coal rock eigenvector is then used to train a classifier;and in a recognition process, an eigenvector of an unknown category of a coal rock image is extracted and inputted to the classifier which completes training, and the category of the coal rock imageis finally outputted. The method uses non-labeled non-coal rock natural images which are acquired easily as training samples, the overhead of marking a large amount of coal rock samples is saved, theextracted coal rock eigenvector has strong discriminability and robustness, and good recognition effects are achieved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

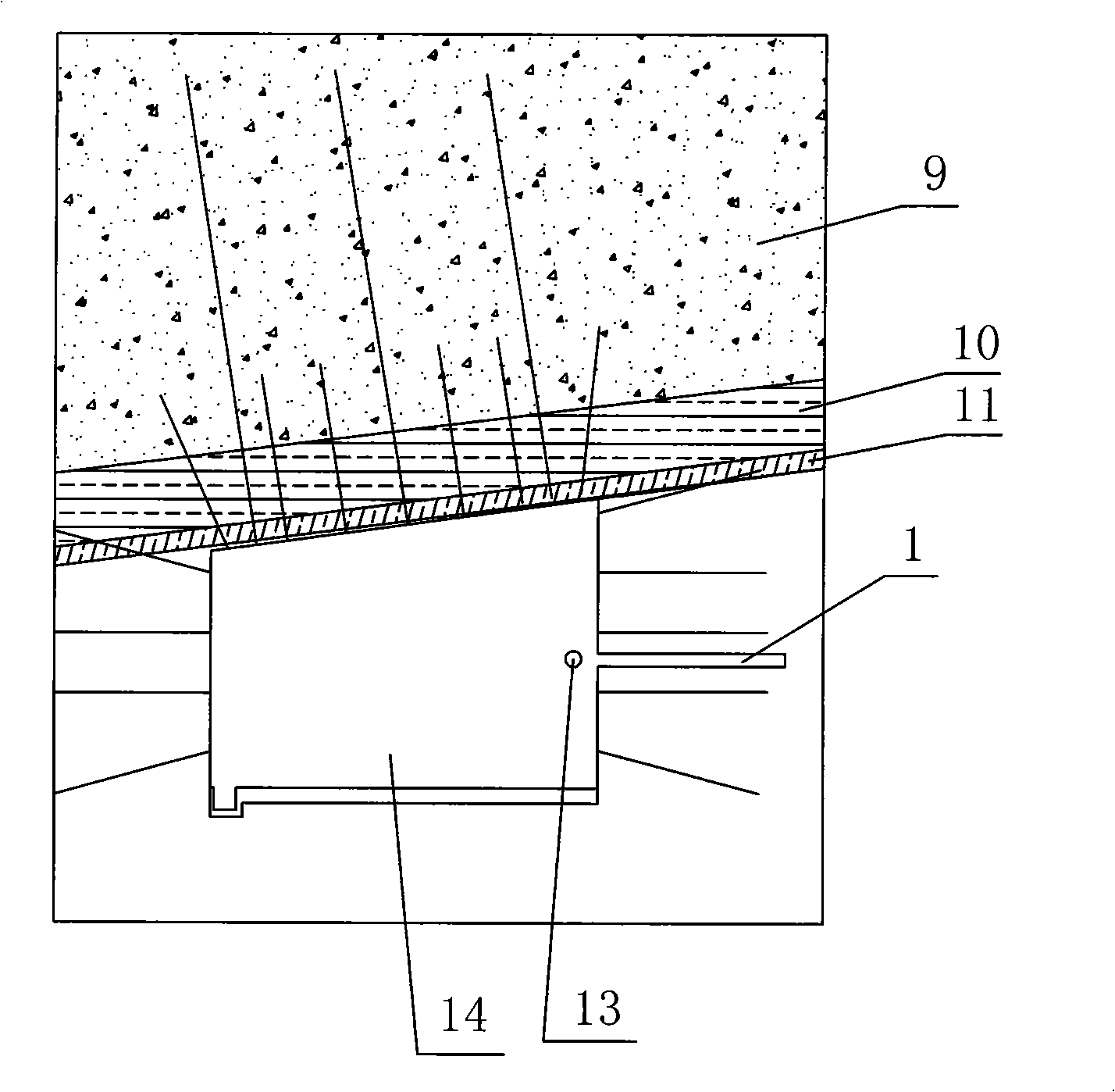

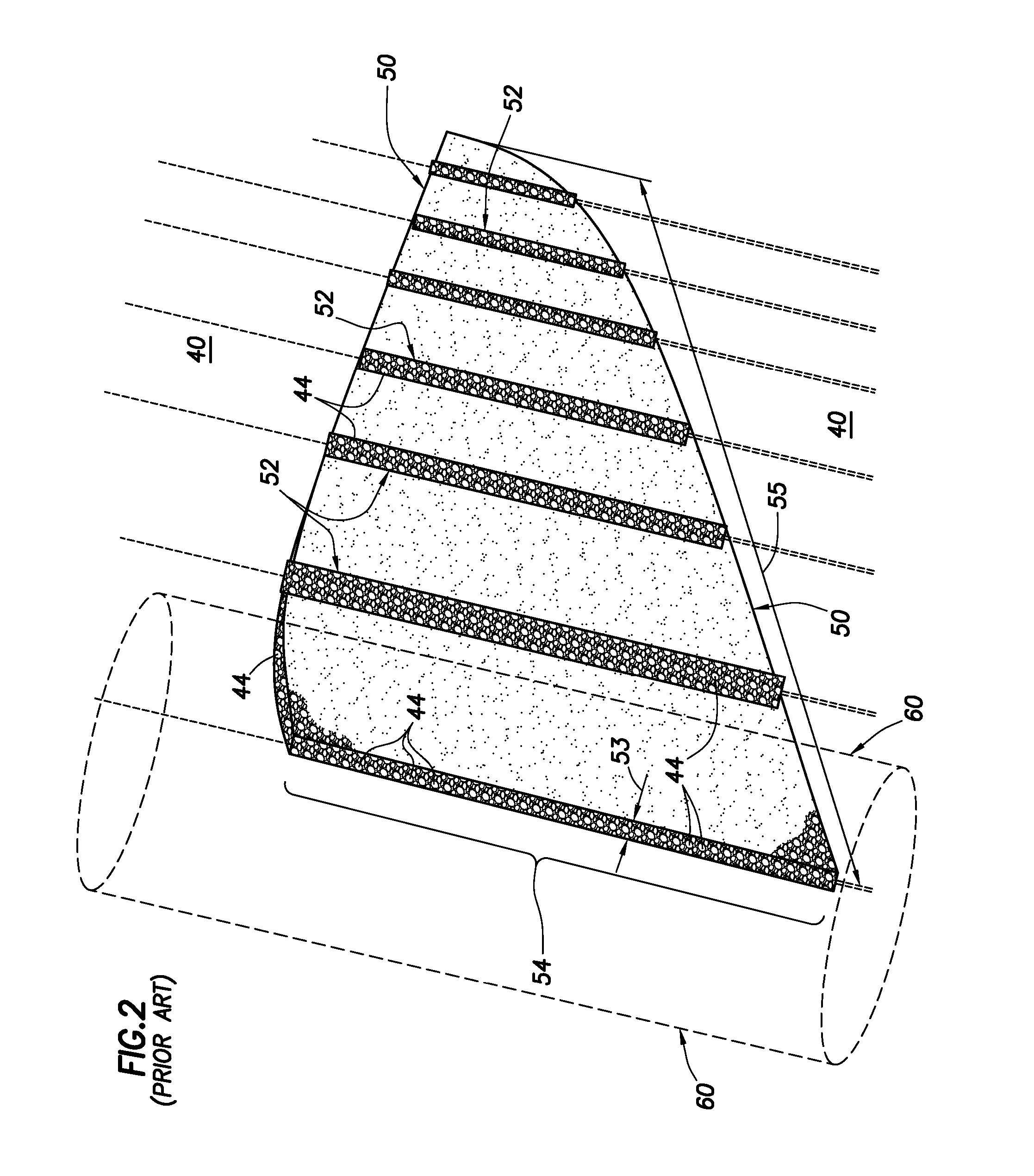

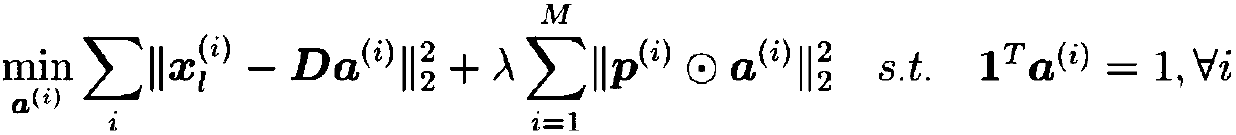

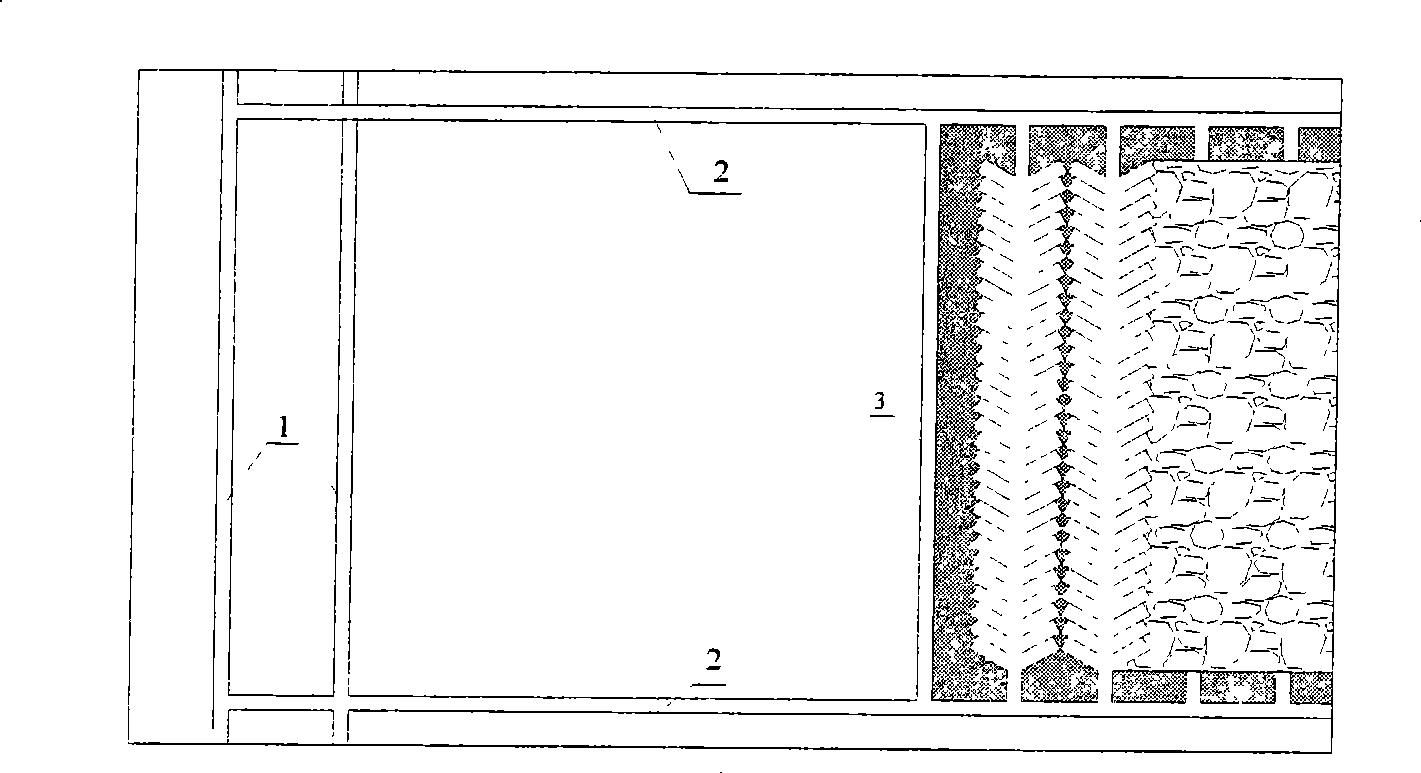

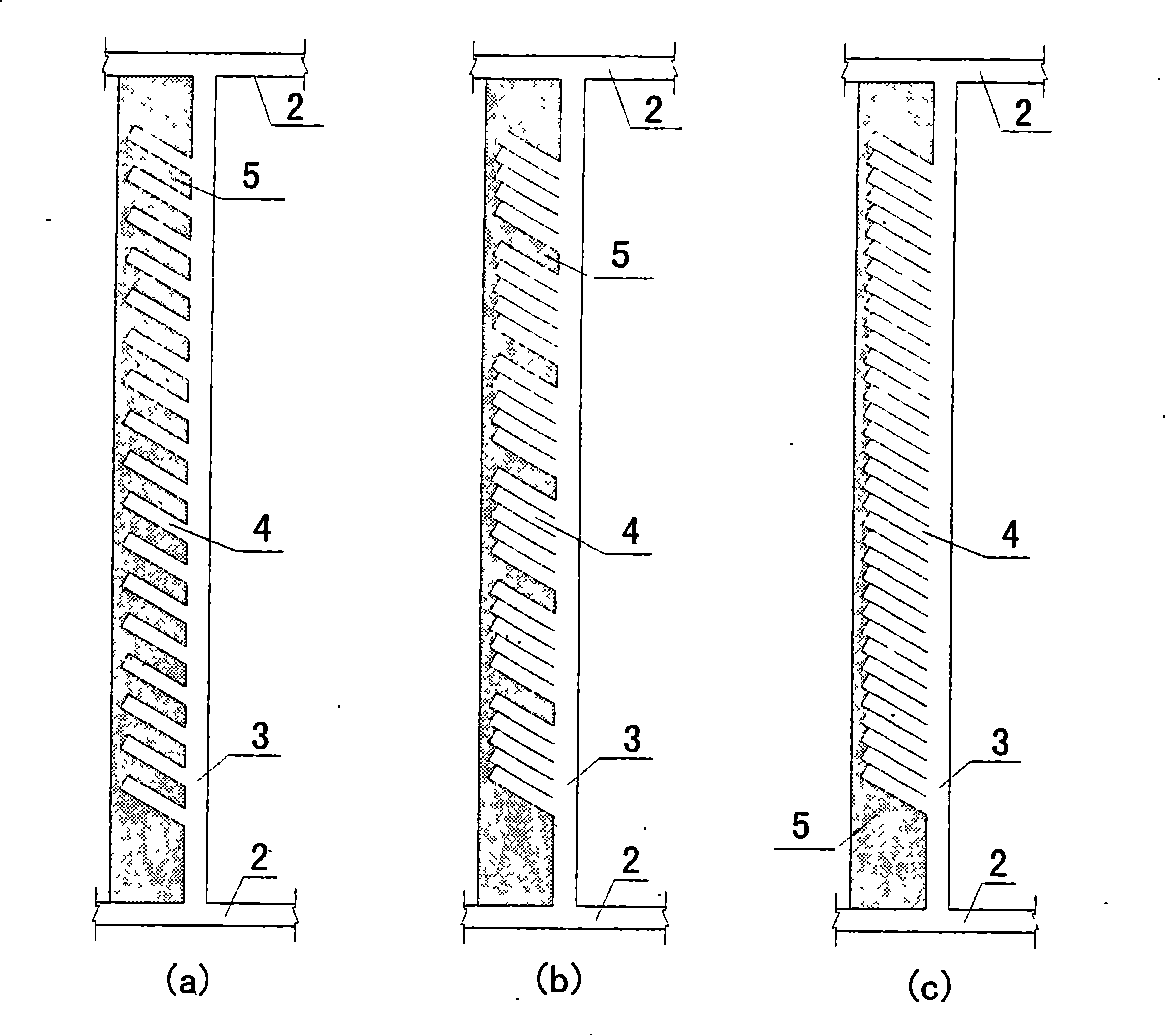

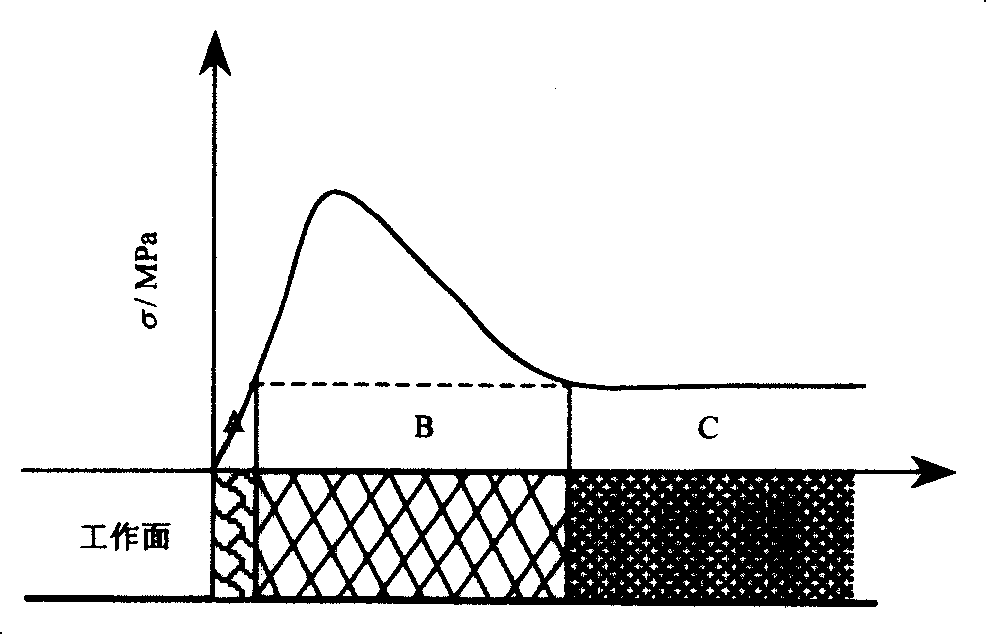

Method for designing supporting parameters of transition support for mixed mining face of filling and fully-mechanized mining

ActiveUS20180314770A1Easily feasibleImprove accuracyGeometric CADData processing applicationsCorrelation coefficientFilling rate

Disclosed is a method for designing supporting parameters of a transition support for a mixed mining face of filling and fully-mechanized mining. The method includes: first, determining a total length of a mixed mining working face and a length of a filling section according to requirements of a coal mining production capacity of the mixed mining working face and a filling capacity of the filling section working face; then, establishing a mixed mining numerical model of filling and fully-mechanized mining by using three-dimensional distinct element software, and simulating and calculating a caving height of a roof of a transition section and a stress influence range of the transition section when a filling rate of a mined-out area of the filling section changes; based on a result of numerical simulation and calculation, performing curve fitting according to a correlation coefficient to obtain a functional relationship between the filling rate and the caving height and a functional relationship between the filling rate and the stress influence range of the transition section; and finally designing supporting parameters of a transition support in combination with actual engineering geological parameters. The method can provide a reference for supporting design of a support, and enables a smooth transition between a filling support and a fully-mechanized mining support for a mixed working face, thereby further enriching filling mining theories and expanding the application range of filling mining.

Owner:CHINA UNIV OF MINING & TECH +3

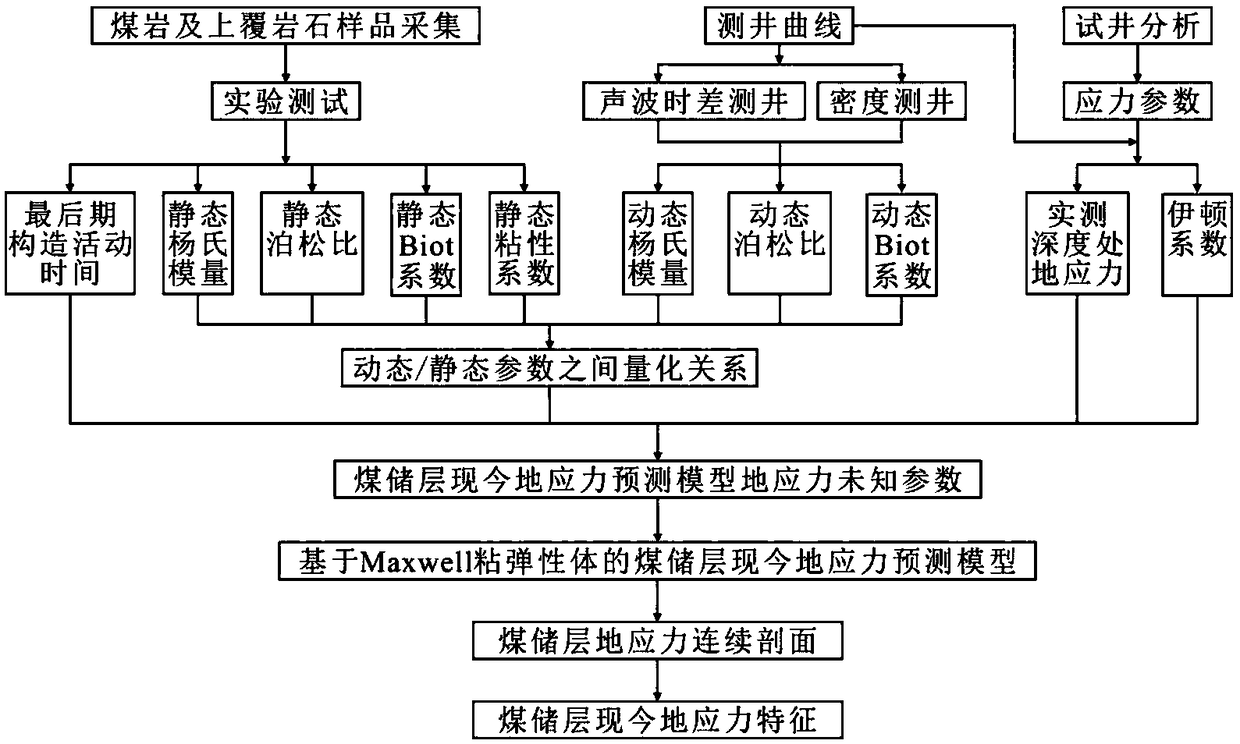

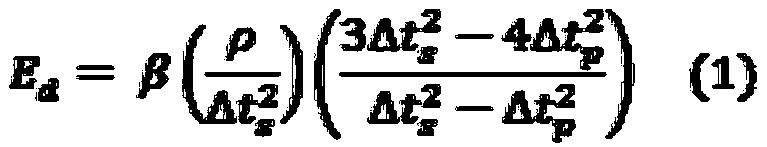

Coal reservoir present geostress prediction method

ActiveCN109113742ALow Young's modulusLow high Poisson's ratioMining devicesData processing applicationsYoung's modulusUltimate tensile strength

The invention relates to a coal reservoir present geostress prediction method, which is characterized in that on the coal rock parameter experiment test and logging curve calculation basis, the quantitative relationship between the static parameter and the dynamic parameter is built; the rock mechanical characteristics of low Young modulus, high poisson ratio, low intensity, easy damage and the like of the coal rock are considered; unknown parameters in the present geostress module based on a Maxwell cola reservoir are obtained through inversion; the coal reservoir geostress profile based on the logging curve is built; the goal of predicting the coal reservoir present geostress is achieved. The targeted performance is high; the coal reservoir present geostress can be accurately predicted;the foundation is laid for the effective exploration and development of coal bed gas; the risk and the cost are reduced; the method can be widely applied to the technical field of coal bed gas exploration and development.

Owner:CHINA UNIV OF MINING & TECH

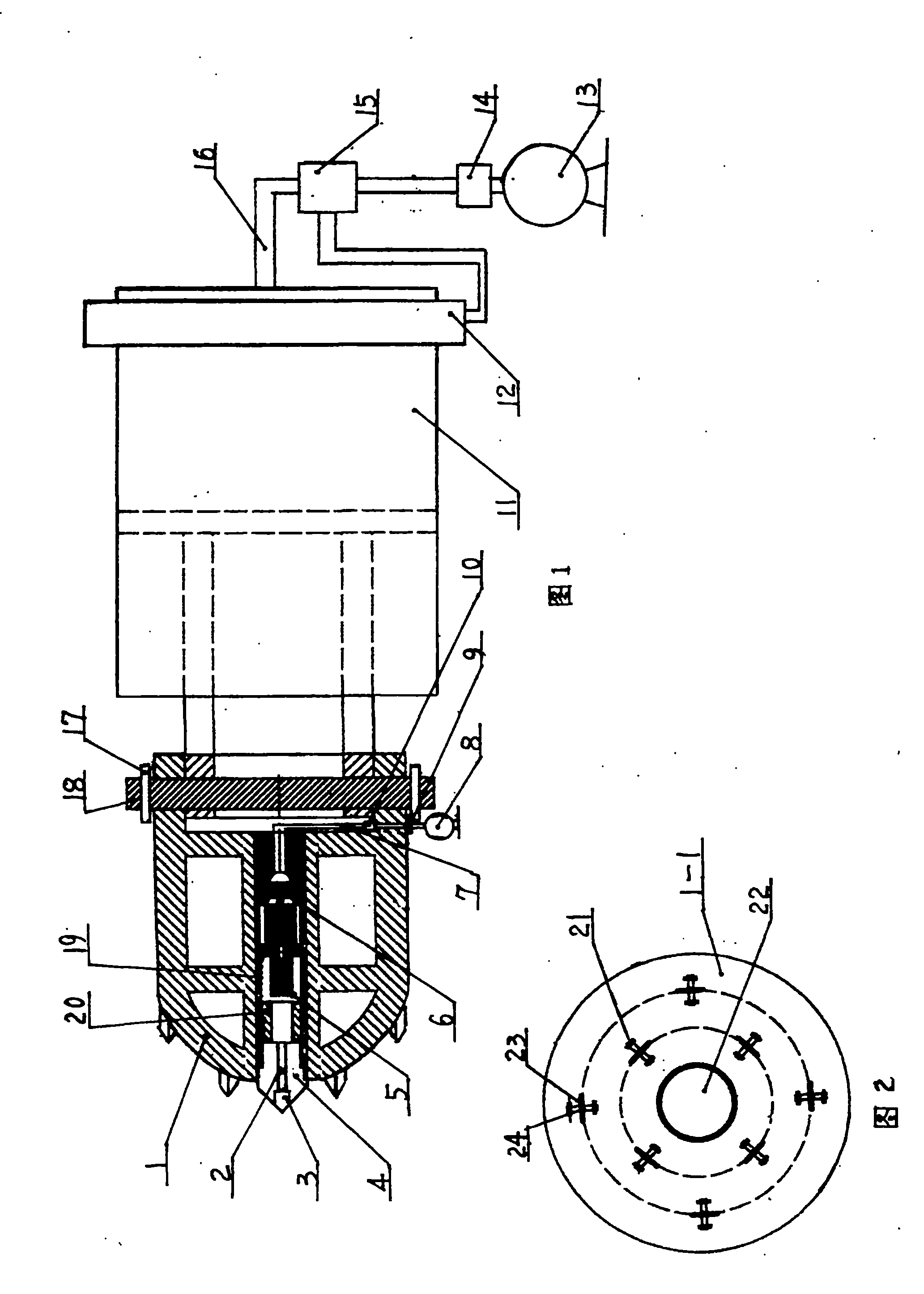

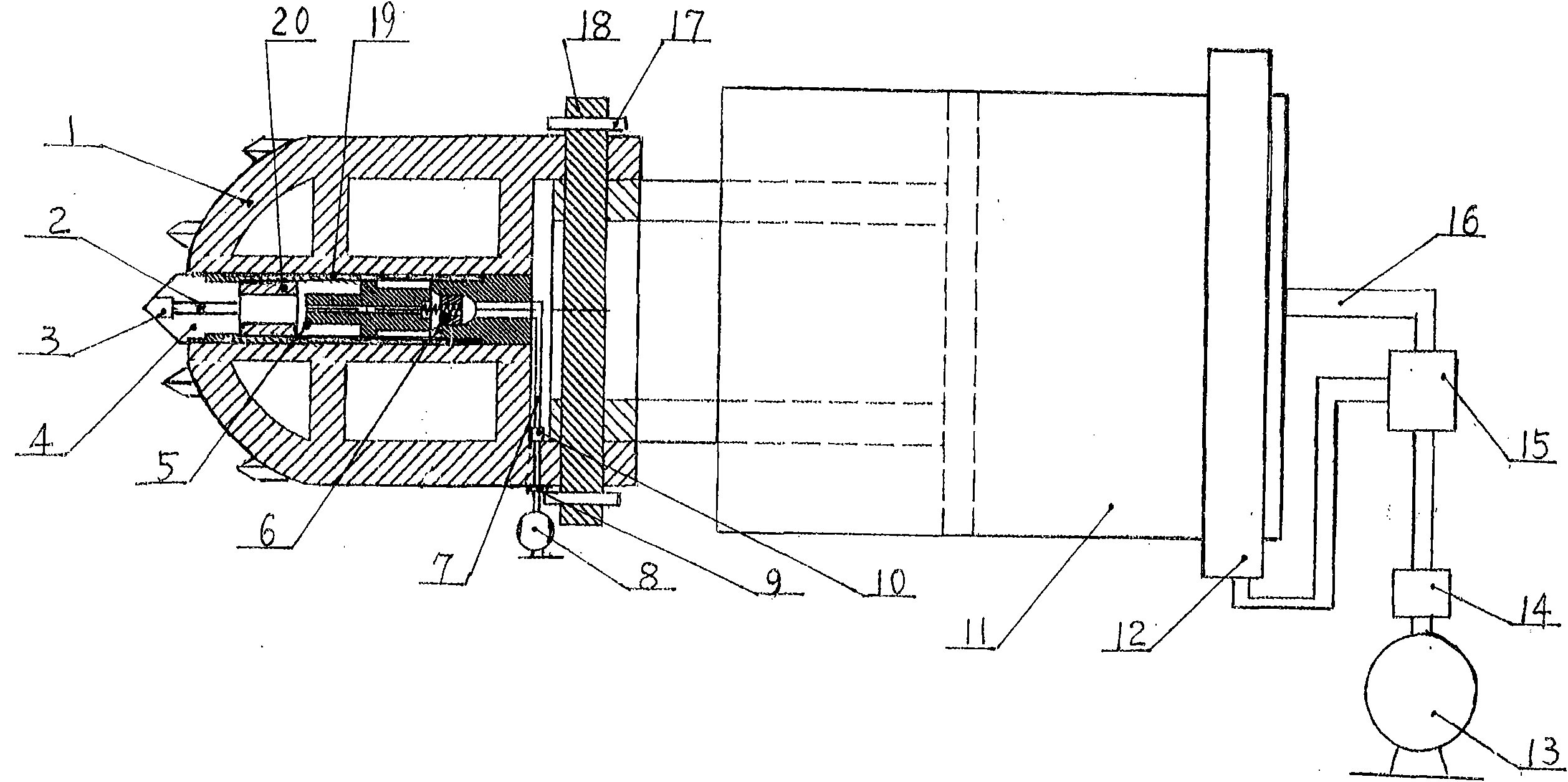

Adaptive hard-rock impact rotary crushing system

InactiveCN102042016AImprove abilitiesQuality improvementTesting machinesSlitting machinesHydraulic motorFailure rate

The invention belongs to coal mine tunneling and crushing machinery, in particular to an adaptive hard-rock impact rotary crushing system. The system comprises a hydraulic pump (13), a hydraulic control module (14), a hydraulic control valve (15), a hydraulic pipeline (16), a hydraulic motor (12) and a thrust hydraulic main cylinder (11); a rotating knife rest (1) is sleeved at the left end of the thrust hydraulic main cylinder (11); the thrust hydraulic main cylinder (11) and the rotating knife rest (1) are connected through a supporting pin (18); two ends of the supporting pin (18) are fixedly limited by a locking pin (17) respectively; a hob head supporting surface (1-1) and a central hole are formed on a front end face of the rotating knife rest (1); and a plurality of angle adjustable disc-shaped hobs (23) are uniformly and fixedly arranged on the hob head supporting surface (1-1) and are supported by a hob supporting bearing (21). The adaptive hard-rock impact rotary crushing system has a simple structure, light weight, low failure rate and low maintenance, and is low in cost, easy to repair and low in maintenance expense.

Owner:LIAONING TECHNICAL UNIVERSITY

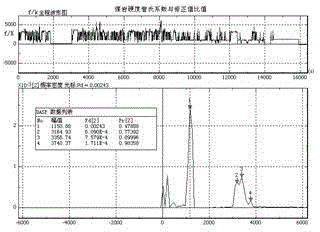

Coal rock character identification system and method based on multiple parameters of cutting motors of coal cutter

The invention relates to a coal rock character identification method based on multiple parameters of cutting motors of a coal cutter. The coal rock character identification method is achieved by virtue of a coal rock character identification system based on the multiple parameters of the cutting motors of the coal cutter. The coal rock character identification system comprises a large-volume data storage device, an electrical main controller of the coal cutter, an intrinsically safe vibration acceleration sensor, a vibration data transmission cable, a communication data transmission wire and an onboard power supply of the coal cutter. The coal rock character identification method and the coal rock character identification system are achieved in the manners that working parameters consisting of vibration signals, the voltages, currents and temperature torques of left and right cutting motors and a traction motor of the coal cutter, the pressures of left and right rocker arm lifting oil cylinders of the coal cutter as well as speed signals of the traction motor are collected and stored, the signal features of coal and rock cut by cutting teeth of a roller of the coal cutter at different top and base plates are analyzed, the energy features of the vibration signals at different frequency bands are analyzed by virtue of a wavelet packet, the feature distribution of the working parameters of the cutting motors is analyzed by virtue of probability statistic samples, and different coal rock character databases are established by virtue of a multi-sensor information fusion technique.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Electronically controlled single-loop water-plugging overburden strata fracture detection method

The invention discloses an electronically controlled single-loop water-plugging overburden strata fracture detection method. The method comprises the following steps that: an electronically controlled single-loop water-plugging overburden strata fracture detector is prepared firstly, wherein the detector is provided with an upper hole sealing capsule and a lower hole sealing capsule respectively at the two ends of a connecting tube; an electronically controlled water flow control device is arranged in the lower hole sealing capsule; and when the detector is used, the operation of detection can be performed just by directly connecting a water inlet pipe of the detector to a drill pipe of a drilling machine, pressing the water inlet pipe of the detector into a drilled hole by using the drill pipe, and connecting an injected water observation device to a water inlet pipe of the drill pipe. According to the invention, hole plugging and water injection are implemented by using the same loop and without using an external high-pressure air duct, so that the situation that an effect of effective hole plugging can not be achieved due to the occurrence of fractures caused by that the high-pressure air duct is rubbed and extruded with the wall of a drilled hole is avoided, a detection system is simplified, operation steps are simplified, and the reliability of water plugging is greatly improved.

Owner:SHANDONG UNIV OF SCI & TECH

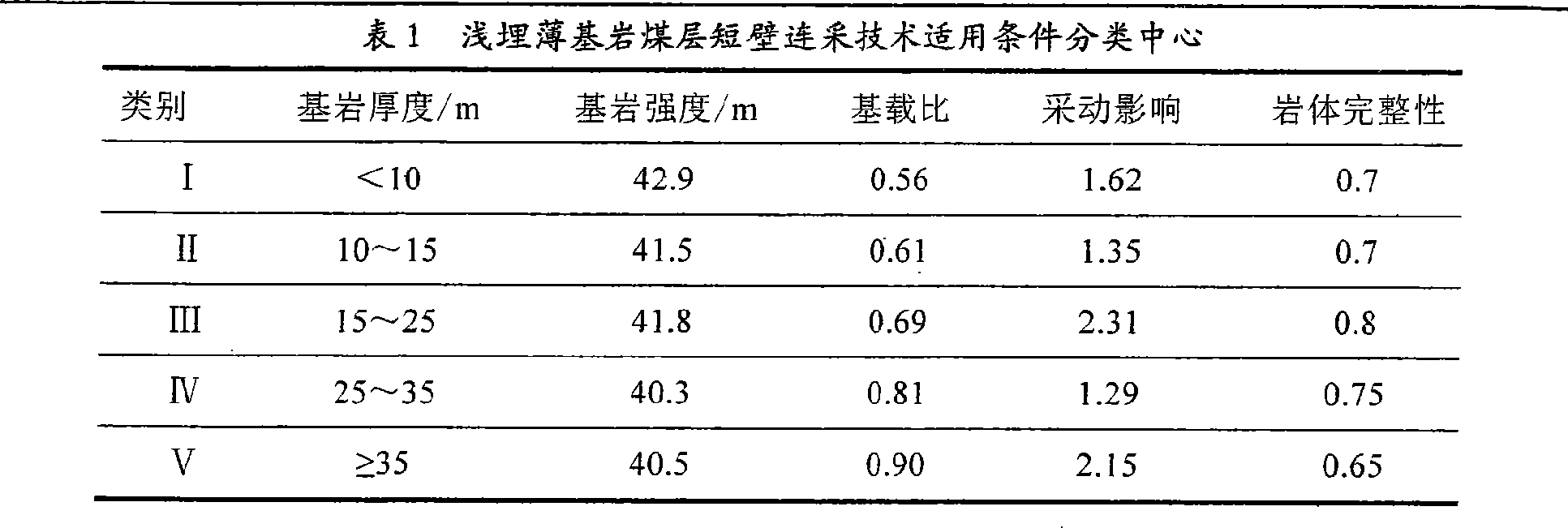

Shallow buried thin bedrock coal bed short wall continuous mining technology suitable condition classification method

InactiveCN101509378ASolving the Problem of Reasonable Technology in Short-wall Continuous MiningUnderground miningTesting machinesBedrockLoad ratio

A method for classifying the application conditions of a shortwall mining (shortwall continuous mining) technology of a shallow coal seam with thin bedrock is applicable to the rational layout and safe and efficient extraction technology mode of roadway excavation of shortwall continuous mining of the shallow coal seam with thin bedrock. The interval of roof breaking of key stratum of main roof is taken as the aggregative indicator of the classification and the uniaxial compressive strength, bedrock thickness, bedrock-load ratio, influence index of working face mining and index of rock mass integrity of overburden rocks are taken as classification indicators; by adopting the fuzzy clustering method, a classification center of the application conditions of the shortwall continuous mining technology of the shallow coal seam with thin bedrock is obtained, with the bedrock thickness as the main indicator; the specific conditions of the seam to be mined are classified according to the indicator of the classification center and each key technical parameter reasonable in classification is determined. The method can effectively improve the production efficiency and recovery ratio of the shallow coal seam with thin bedrock and has wide practicability.

Owner:刘玉德 +2

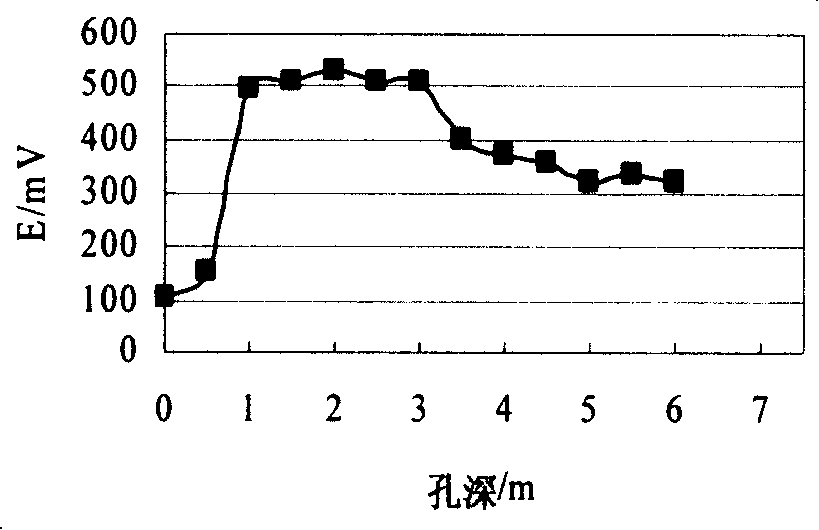

Method for monitoring mine rock stress state by electromagnetic radiation method

The present invention discloses electromagnetic radiation method for monitoring the stress status of mine. Electromagnetic radiation signal of rock stratum in mine is monitored with one electromagnetic radiation monitoring system and applied in analyzing the stress status of rock stratum in mine based on the corresponding relation between the electromagnetic radiation signal and the stress status of the rock stratum. The electromagnetic radiation monitoring system includes sensors, and one monitoring instrument. The sensor has one push-pull rod connected to detect the stress status in different area in the mine. The method is practical, accurate and suitable for various kinds of mine, especially coal mine.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

System for rapidly measuring in-situ wall rock strength of coal mine tunnel

InactiveCN103195425AIntensity Quickly MasteredGood effectTesting machinesLithologyRegression analysis

The invention discloses a method for rapidly measuring in-situ wall rock strength of a coal mine tunnel, and is suitable for rapidly measuring the in-situ wall rock strength of the coal mine tunnel. The method comprises the following steps of: collecting multiple groups of rock sample data so as to obtain the rock strengths of different lithology rock samples and the required time spent on carrying out drilling holes on collecting points of the corresponding rock samples; and then carrying out processing and regression analysis on the collected data, and fitting a mathematical relationship of the rock strength and the time spent on hole drilling according to the collected data, When the strength of a wall rock needs to be measured, only the drilling time of the wall rock is measured, and the strength of the wall rock is calculated by using fitted the mathematical relationship according to the measured drilling time. The method can be used for measuring the strength of the wall rock of the coal mine tunnel in a rapid and in-situ manner, and can provide the basis for parameter designs such as tunnel blasting engineering and supporting engineering. The method provided by the invention has the advantages of being simple, convenient to operate, and good in effect.

Owner:CHINA UNIV OF MINING & TECH

Popular searches

Earth material testing Apparatus for force/torque/work measurement Geological measurements Strength properties Permeability/surface area analysis Force measurement Electrical/magnetic solid deformation measurement Seismology for water-logging Special data processing applications Nuclear radiation detection

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com