Patents

Literature

138 results about "Overburden" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mining, overburden (also called waste or spoil) is the material that lies above an area that lends itself to economical exploitation, such as the rock, soil, and ecosystem that lies above a coal seam or ore body. Overburden is distinct from tailings, the material that remains after economically valuable components have been extracted from the generally finely milled ore. Overburden is removed during surface mining, but is typically not contaminated with toxic components. Overburden may also be used to restore an exhausted mining site to a semblance of its appearance before mining began.

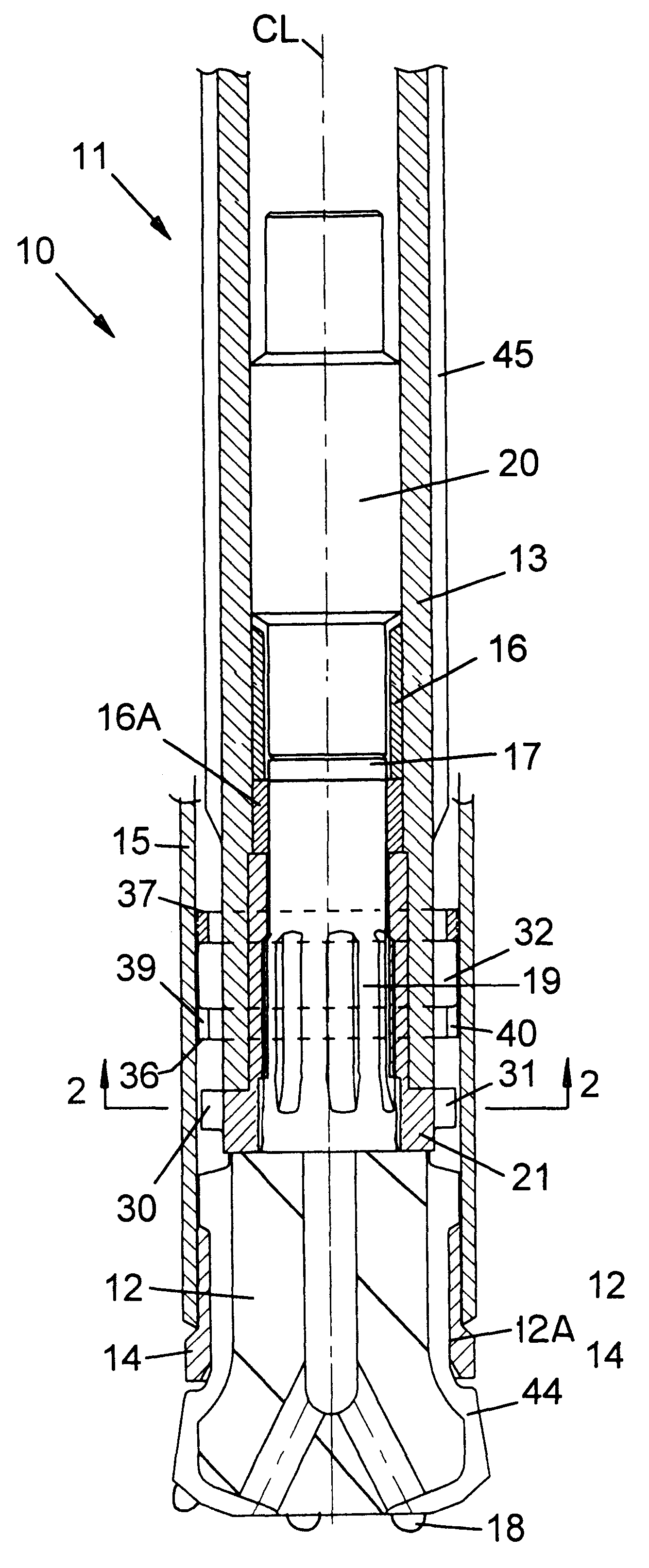

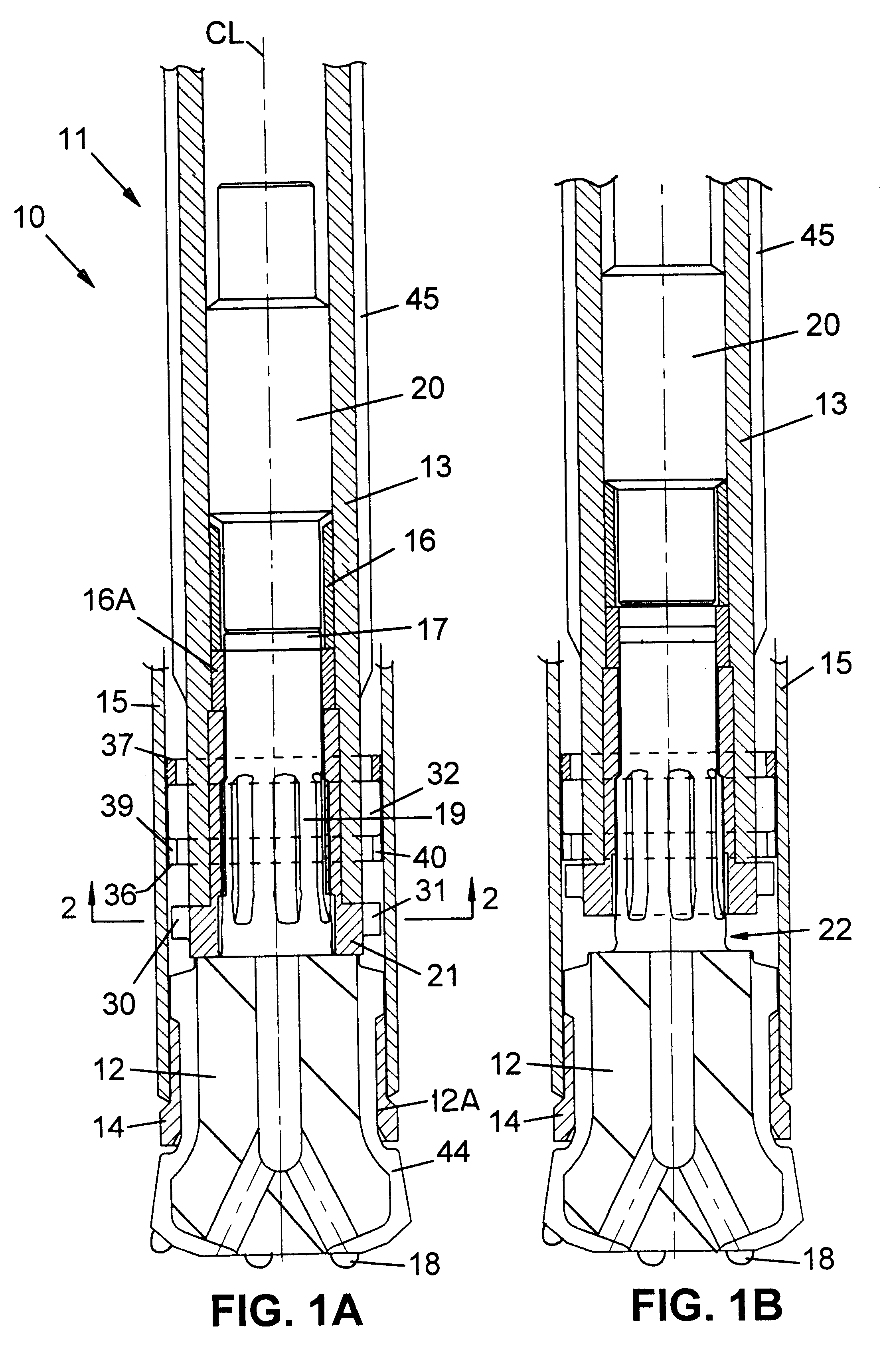

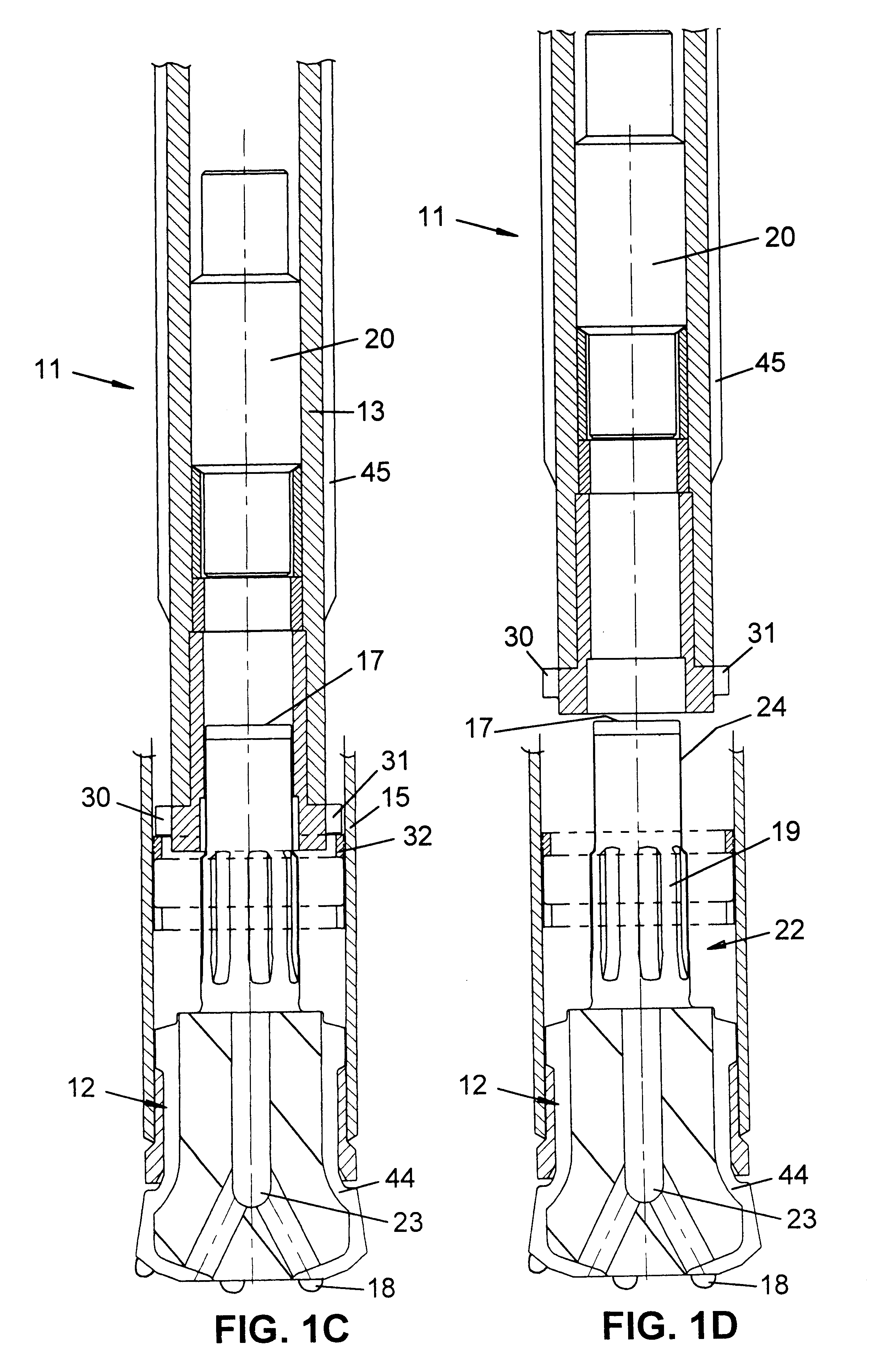

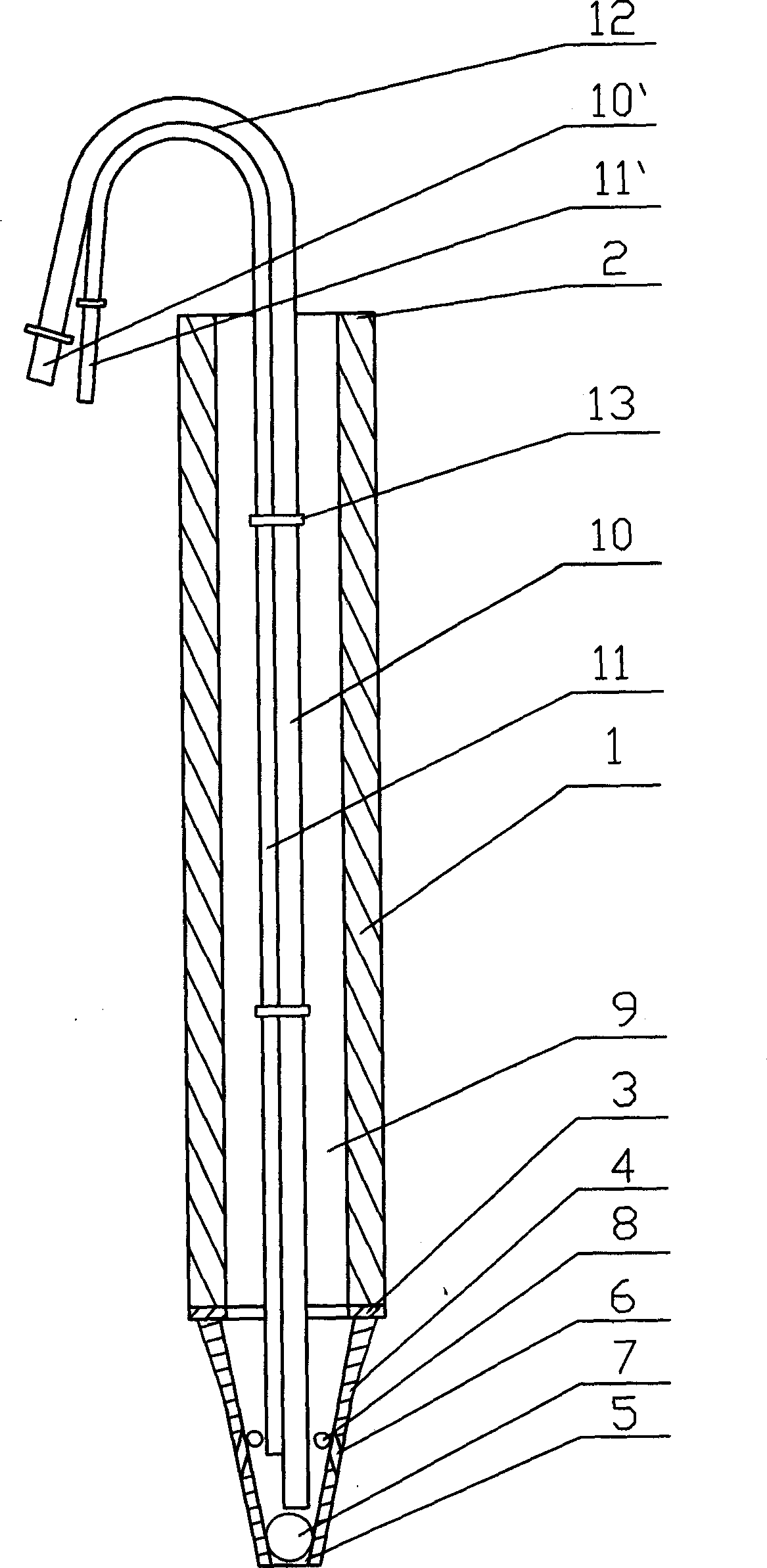

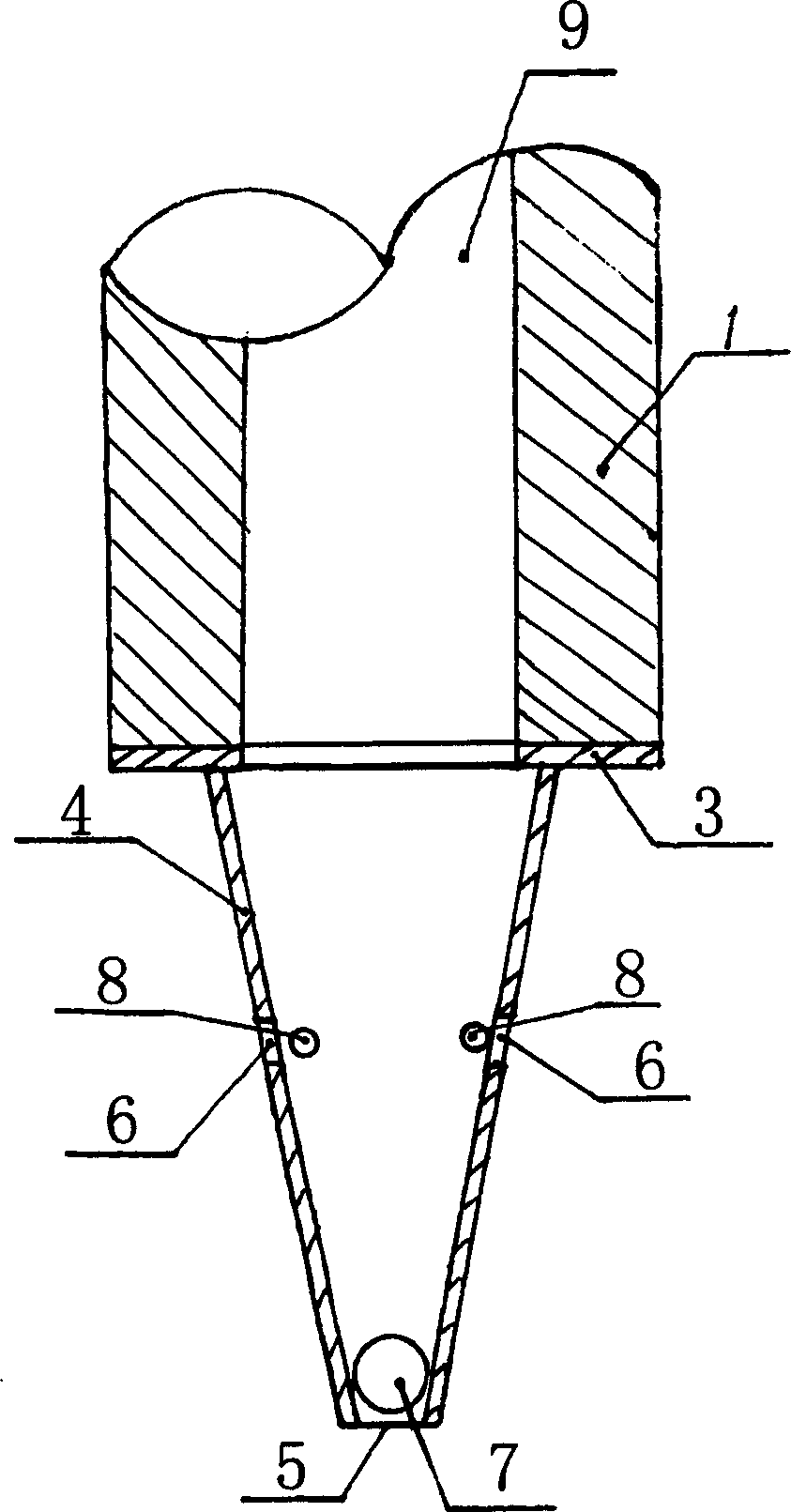

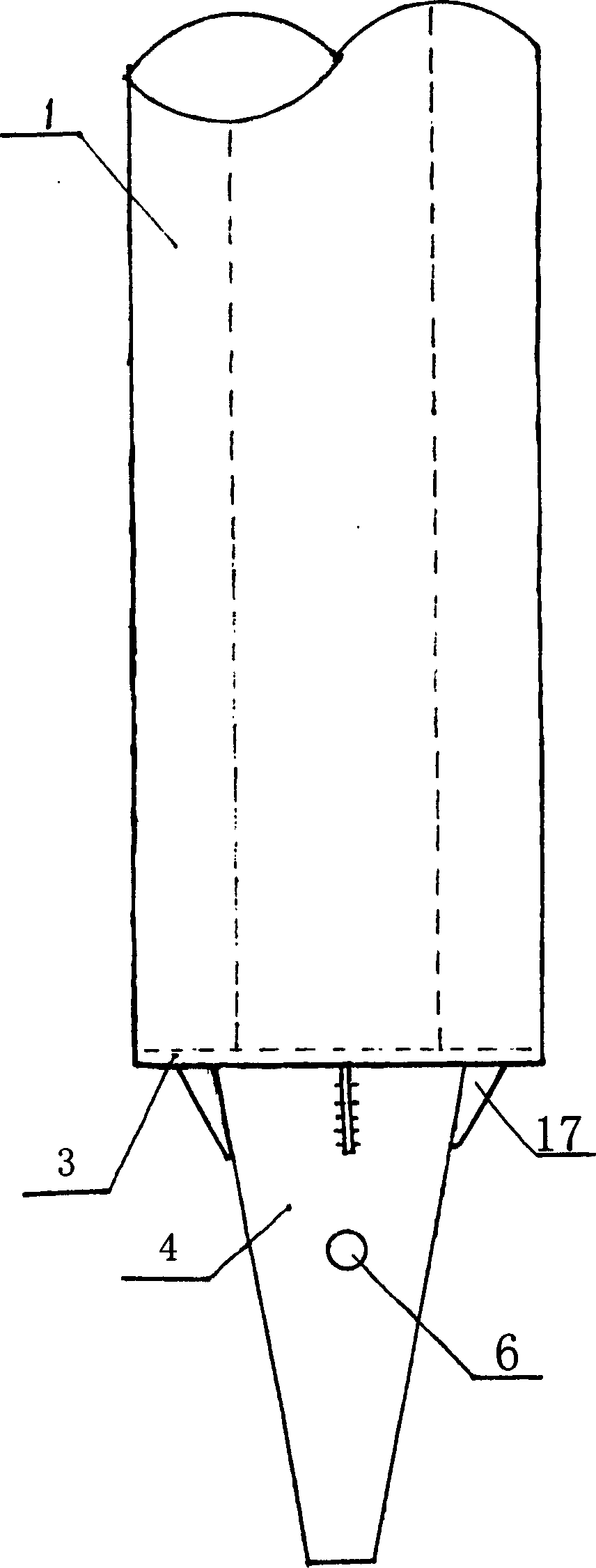

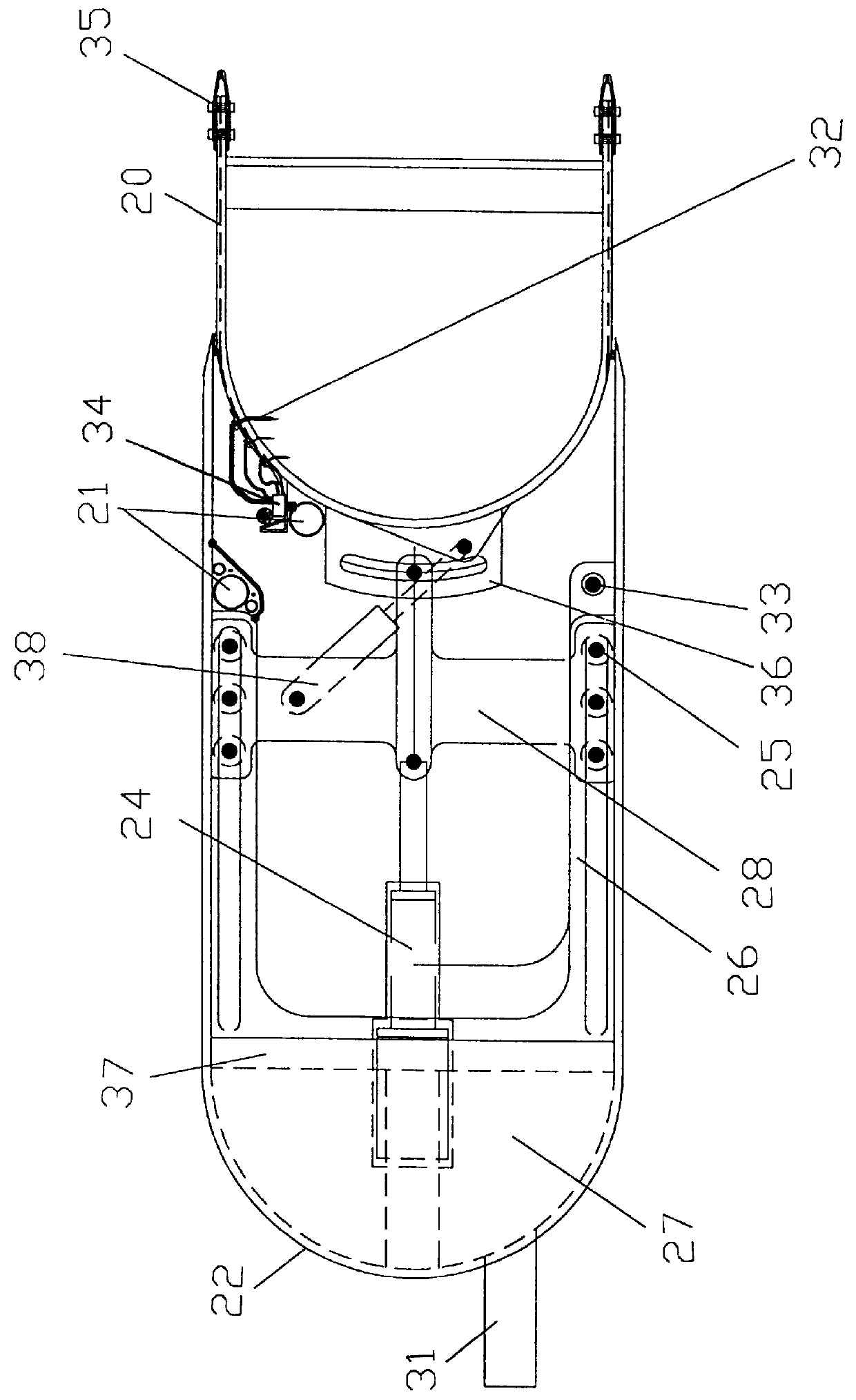

Overburden drilling apparatus having a down-the-hole hammer separatable from an outer casing/drill bit unit

Overburden drilling equipment for drilling a hole includes a down-the-hole hammer formed by a cylinder and a piston reciprocating in the cylinder due to pressurized water being directed alternately to the upper and lower ends of the piston. Each downward stroke inflicts an impact blow upon an anvil portion of a drill bit extending upwardly within the lower portion of the cylinder. A drill chuck is mounted at a lower end of the cylinder to receive the drill bit. A generally cylindrical casing shoe is attached to a casing and is rotatably connected to the drill bit to be longitudinally advanced thereby during drilling operation. The drill chuck includes at least one key which defines the largest radius of the drill chuck. The casing includes a diametrically reduced portion which has at least one keyway therein. The key and the diametrically reduced portion retain the hammer longitudinally in relation to the drill bit.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

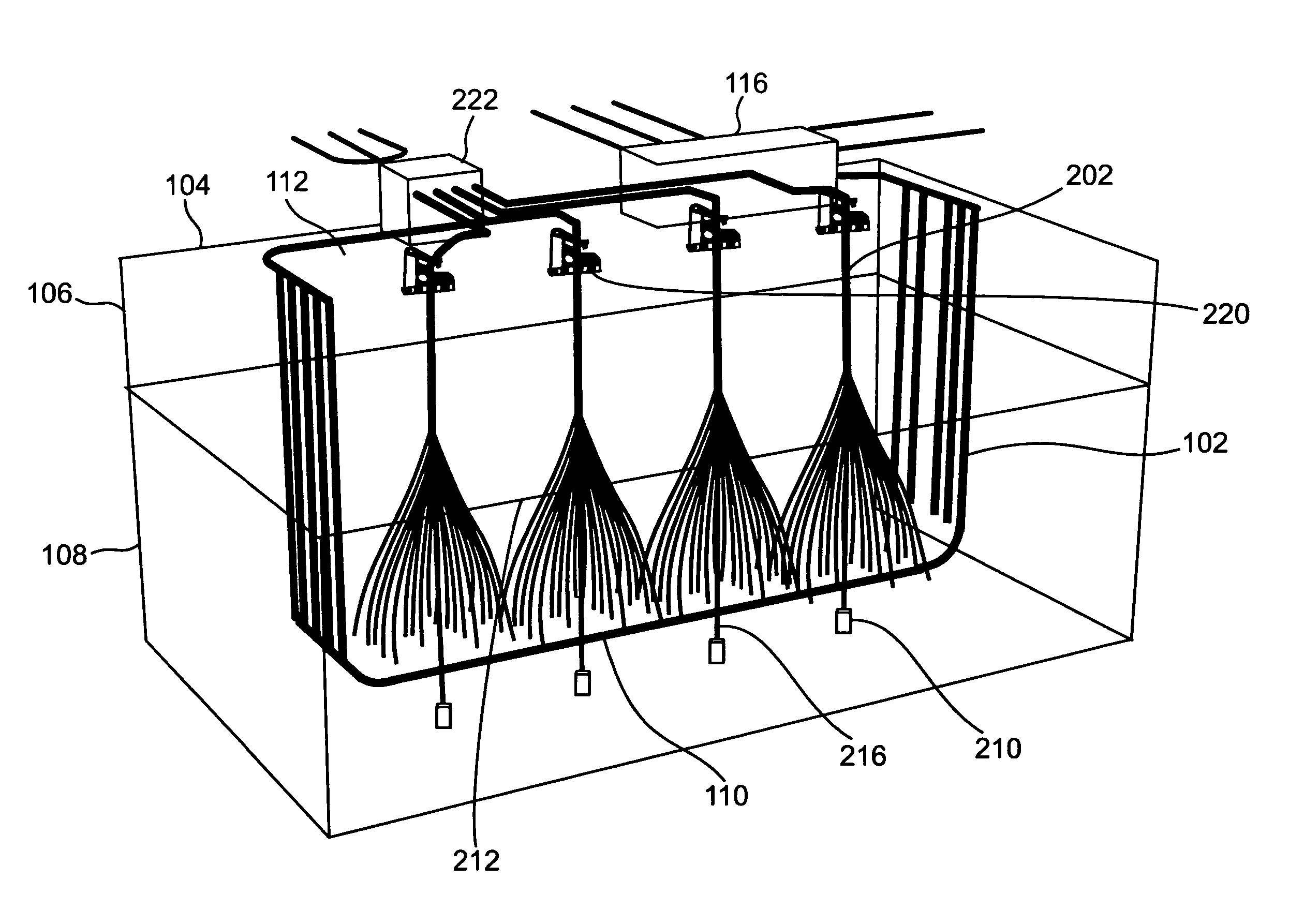

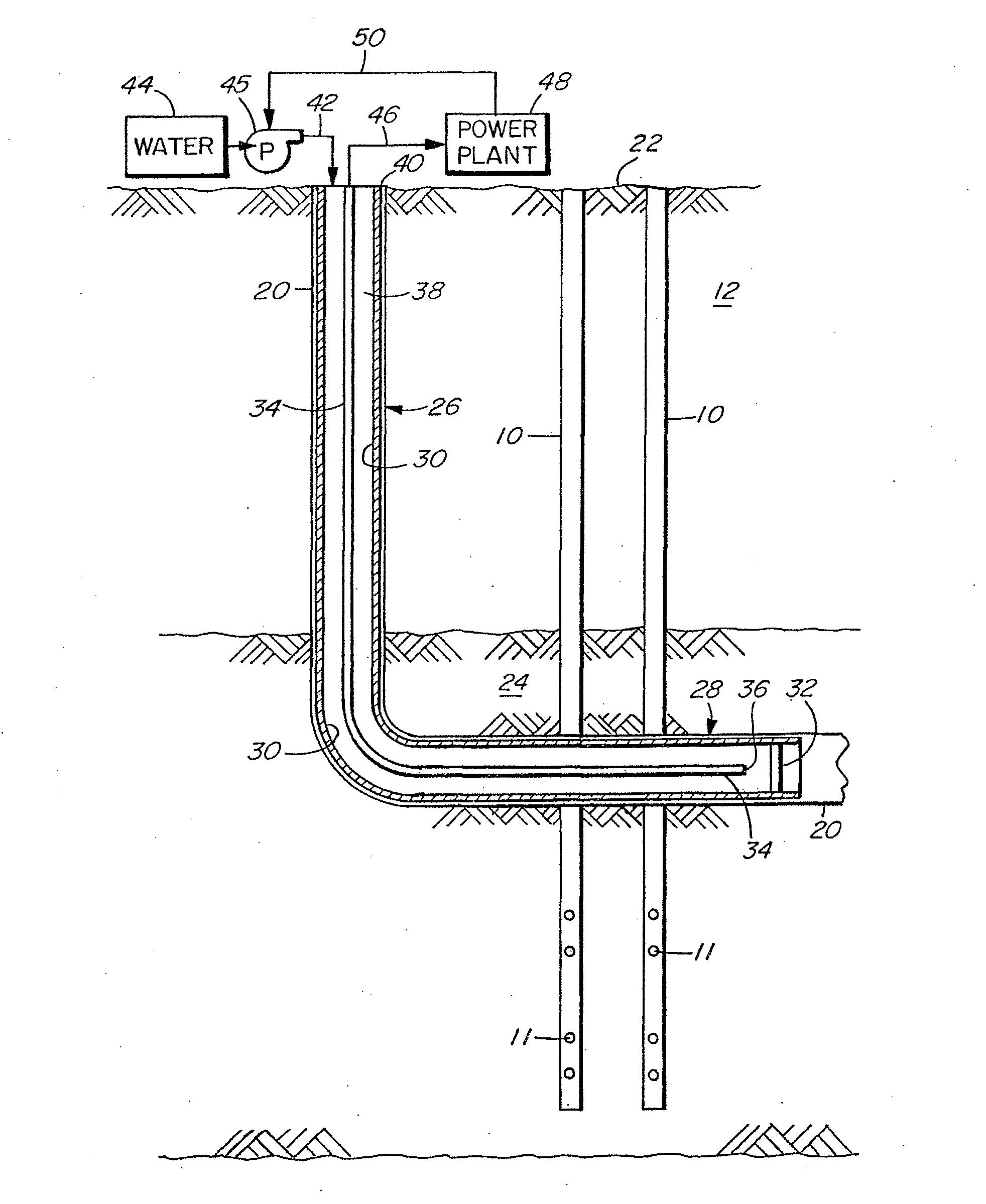

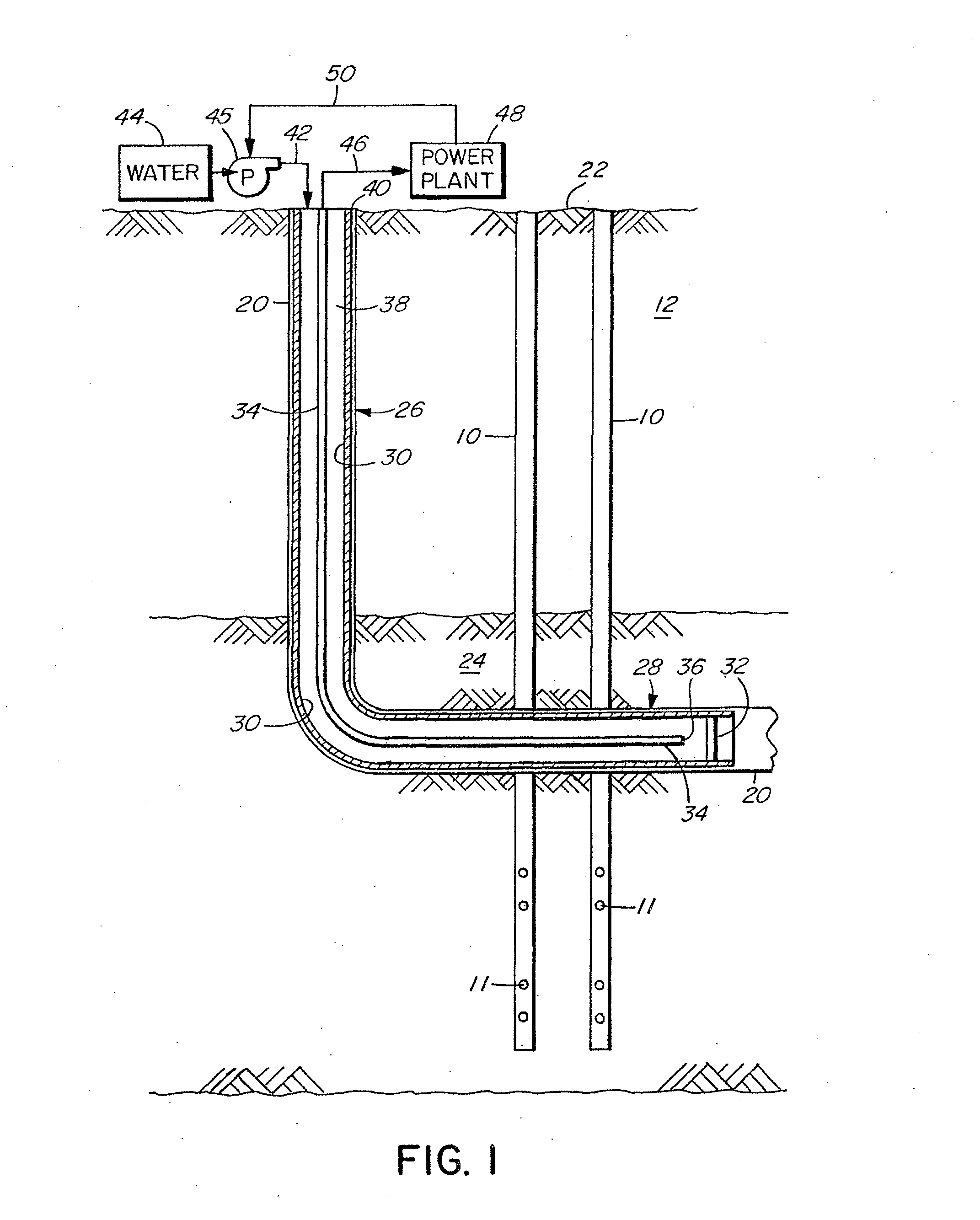

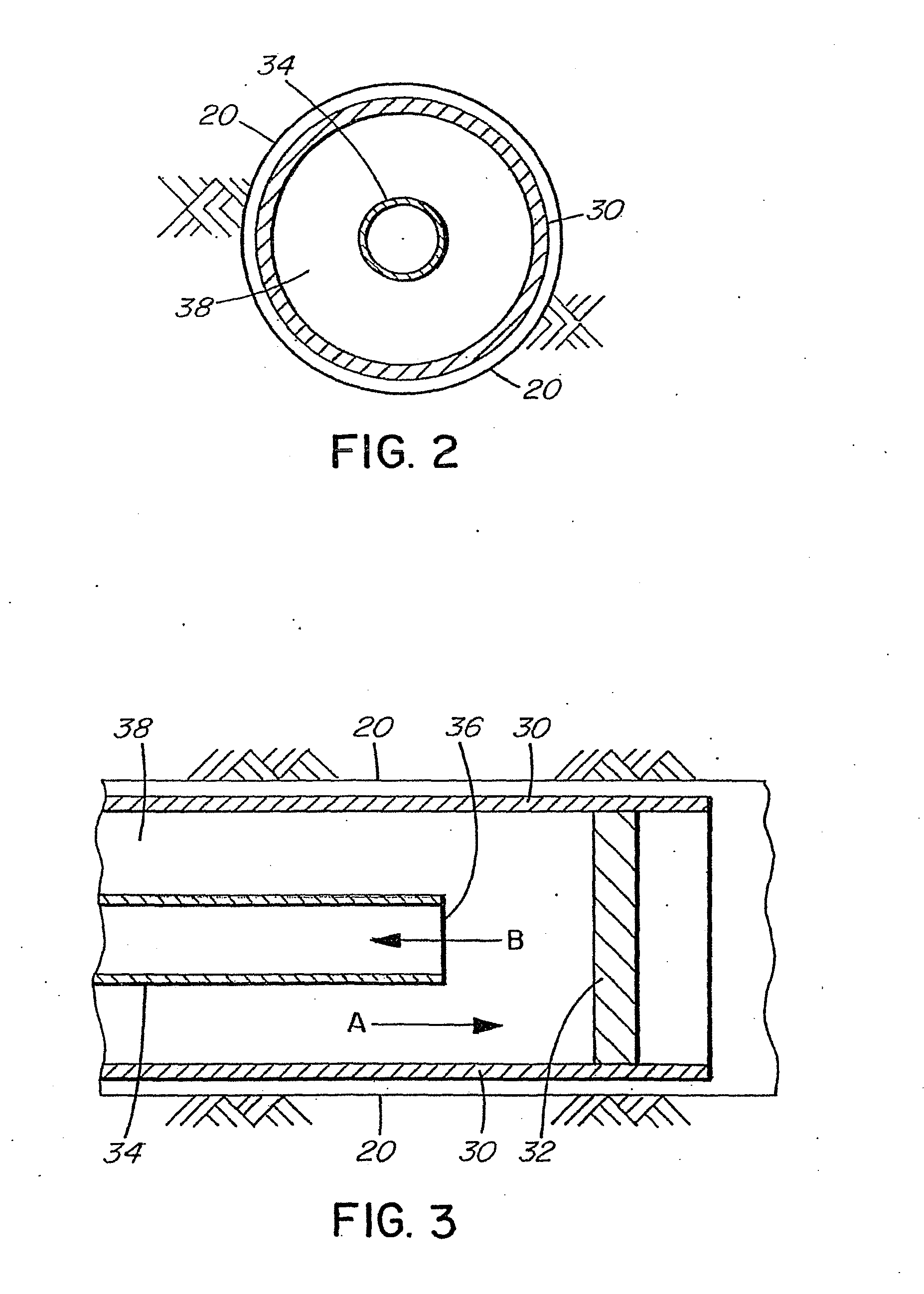

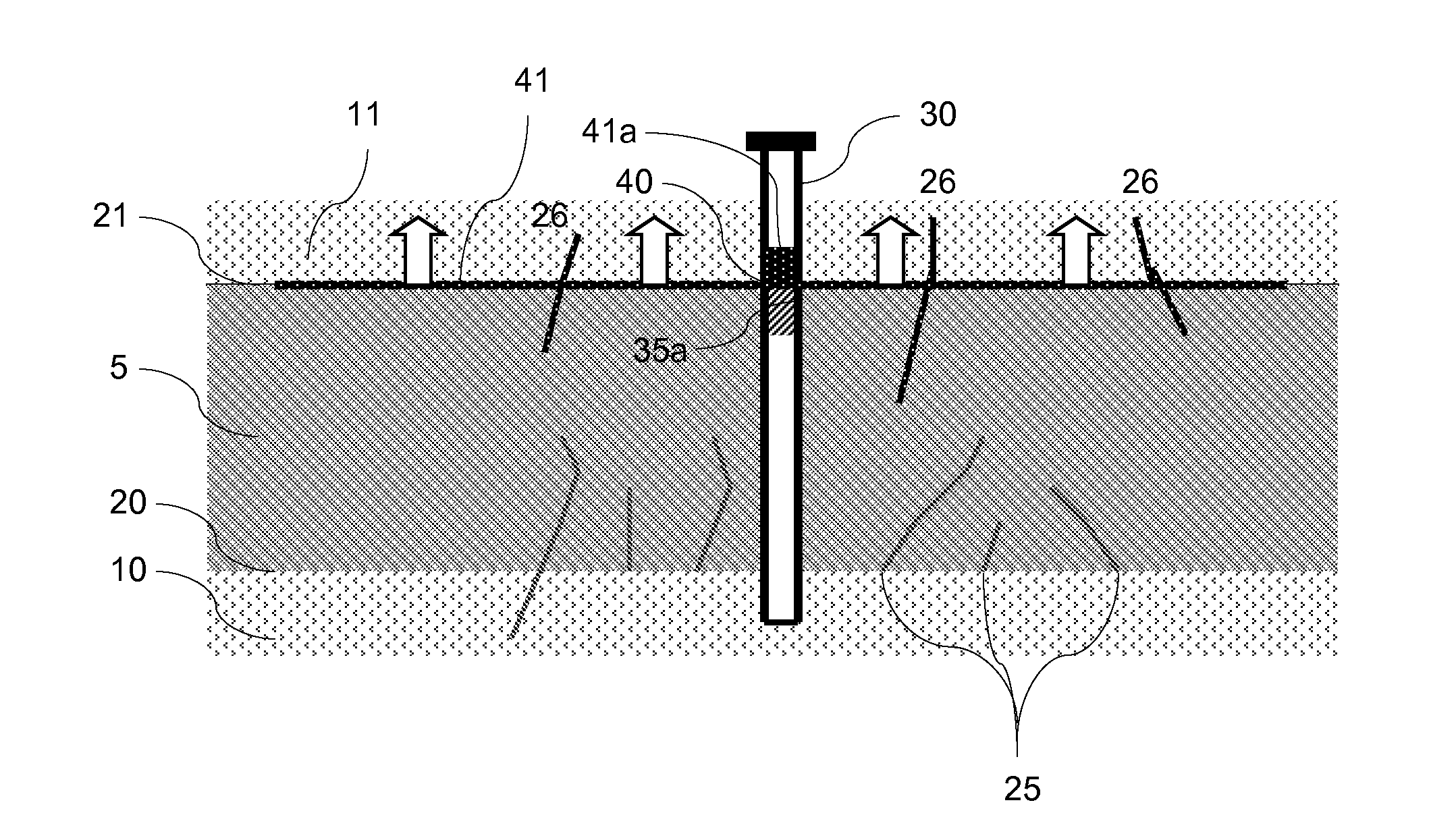

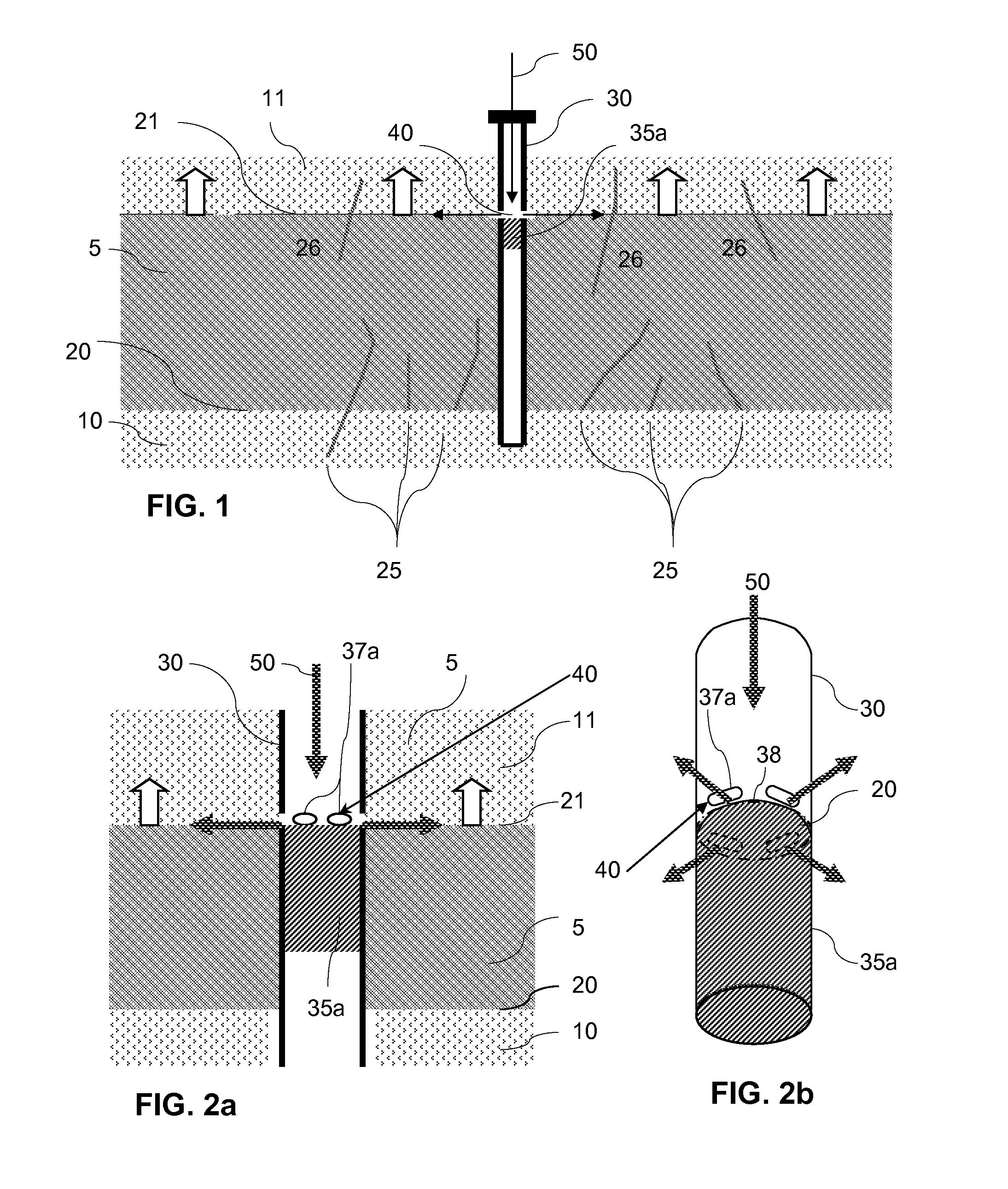

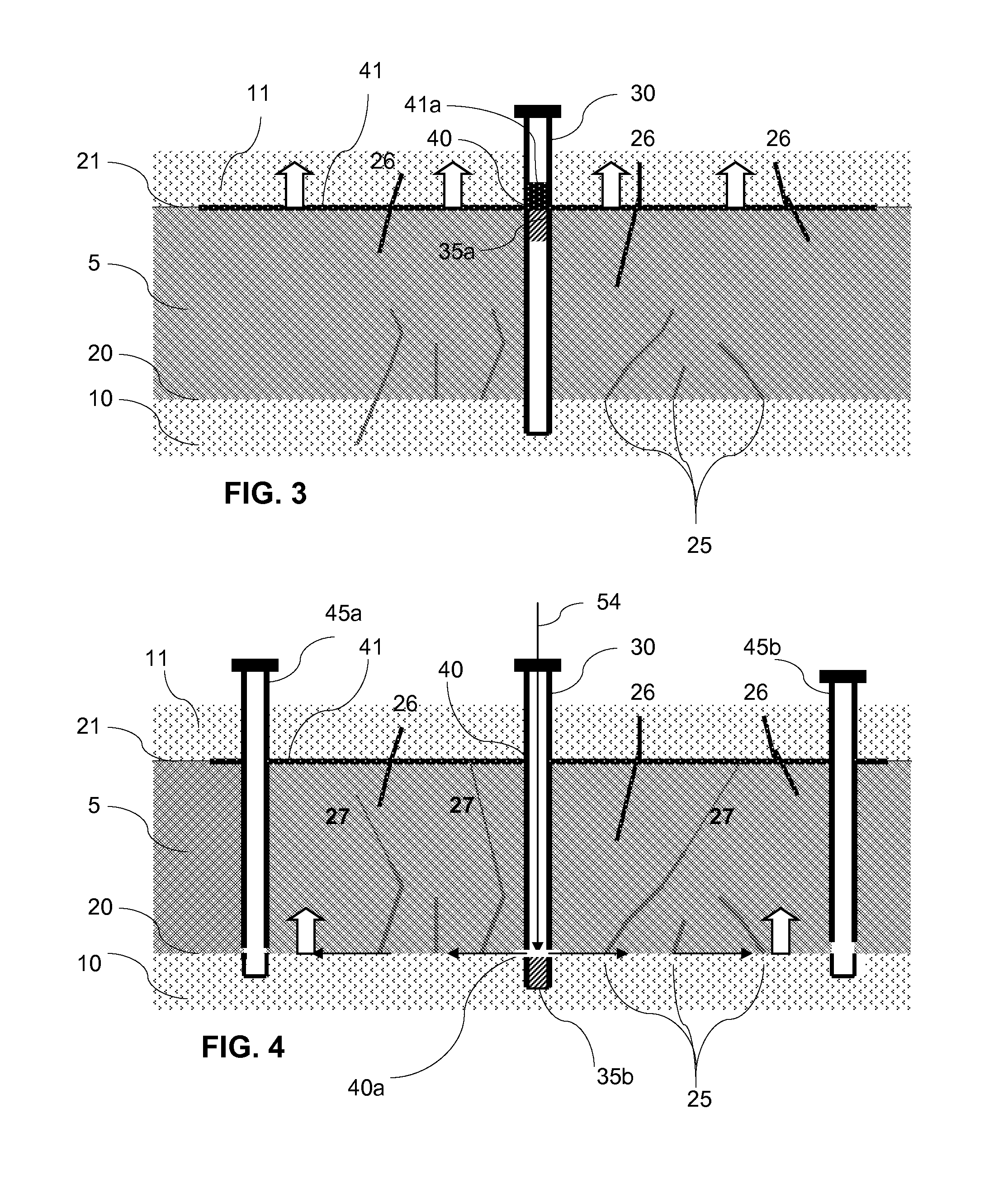

In situ method and system for extraction of oil from shale

ActiveUS20070193743A1Easy to moveAvoid insufficient temperatureInsulationFluid removalClosed loopEarth surface

A system and process is disclosed for retorting oil shale and extracting shale oil and other hydrocarbons therefrom, in which a cased heat delivery well is drilled generally vertically through an overburden and then through a body of oil shale to be retorted to the bottom thereof, generally horizontally under the body of oil shale to be retorted, and then back to the earth surface. Heat energy is transmitted conductively to the body of oil shale to be retorted from a closed loop heat delivery module in the well, the module comprising a fluid transmission pipe containing a heating fluid heated to at least a retorting temperature. Heat energy is also transmitted to the body of oil shale to be retorted above the fluid transmission pipe by vapor conduits that conduct retort vapors upward through the body of oil shale to be retorted; the ascending retort vapors condense and reflux, delivering their latent heat of vaporization to the body of oil shale to be retorted, and the condensed retort liquids descend. If not recycled, the retort liquids are collected in a sump at the bottom of a production well and are transmitted to the surface for processing. The vapor conduits communicate at upper ends thereof with the production well, so that vapors that do not reflux are collected in the production well and are transmitted to the surface for processing.

Owner:AMERICAN SHALE OIL

In situ method and system for extraction of oil from shale

ActiveUS7743826B2Easy to moveAvoid insufficient temperatureInsulationFluid removalClosed loopEarth surface

A system and process is disclosed for retorting oil shale and extracting shale oil and other hydrocarbons therefrom, in which a cased heat delivery well is drilled generally vertically through an overburden and then through a body of oil shale to be retorted to the bottom thereof, generally horizontally under the body of oil shale to be retorted, and then back to the earth surface. Heat energy is transmitted conductively to the body of oil shale to be retorted from a closed loop heat delivery module in the well, the module comprising a fluid transmission pipe containing a heating fluid heated to at least a retorting temperature. Heat energy is also transmitted to the body of oil shale to be retorted above the fluid transmission pipe by vapor conduits that conduct retort vapors upward through the body of oil shale to be retorted; the ascending retort vapors condense and reflux, delivering their latent heat of vaporization to the body of oil shale to be retorted, and the condensed retort liquids descend. If not recycled, the retort liquids are collected in a sump at the bottom of a production well and are transmitted to the surface for processing. The vapor conduits communicate at upper ends thereof with the production well, so that vapors that do not reflux are collected in the production well and are transmitted to the surface for processing.

Owner:AMERICAN SHALE OIL

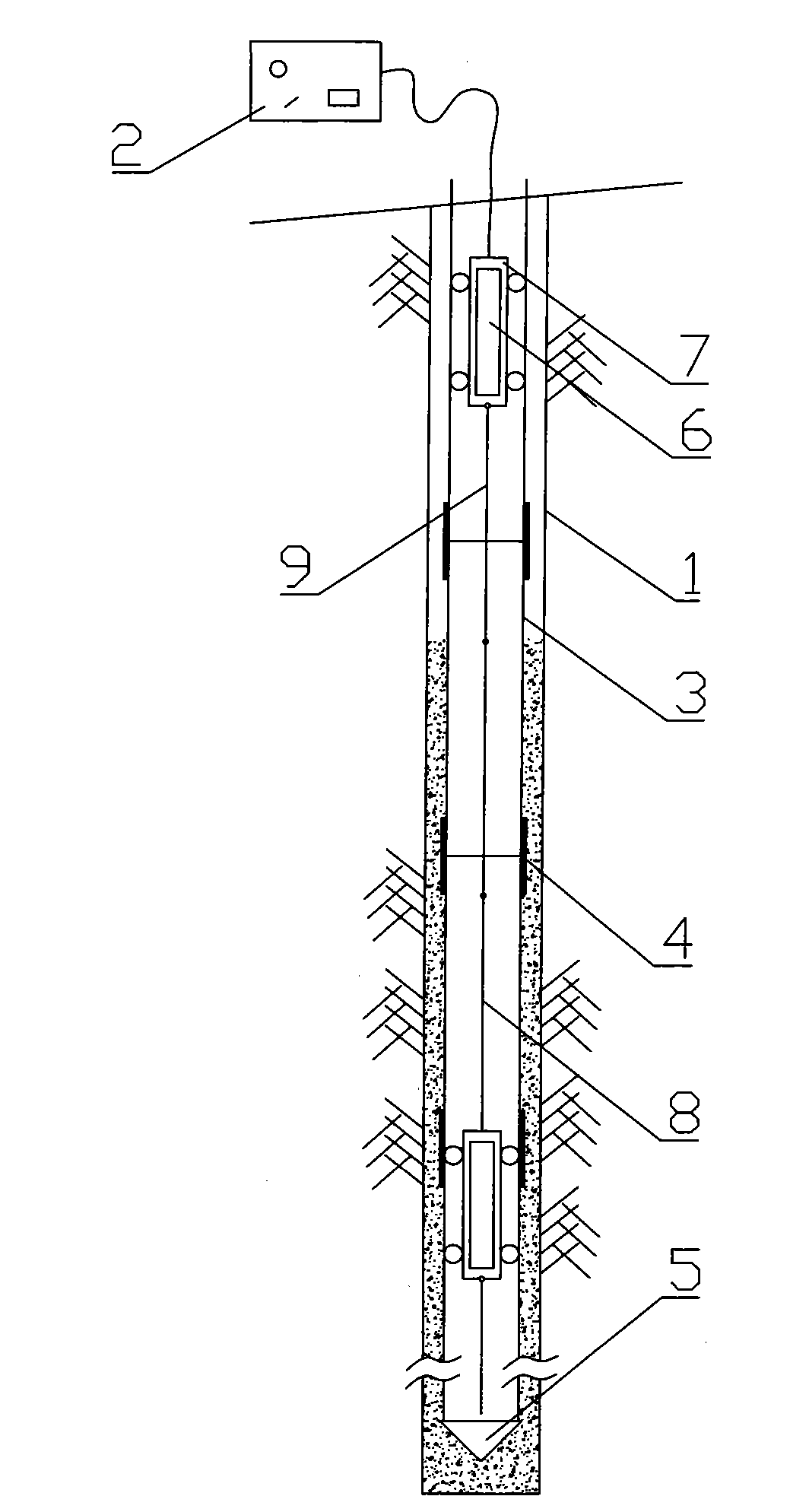

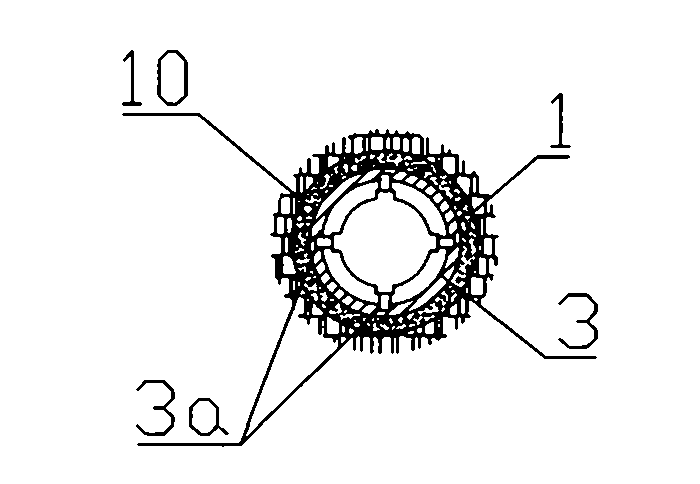

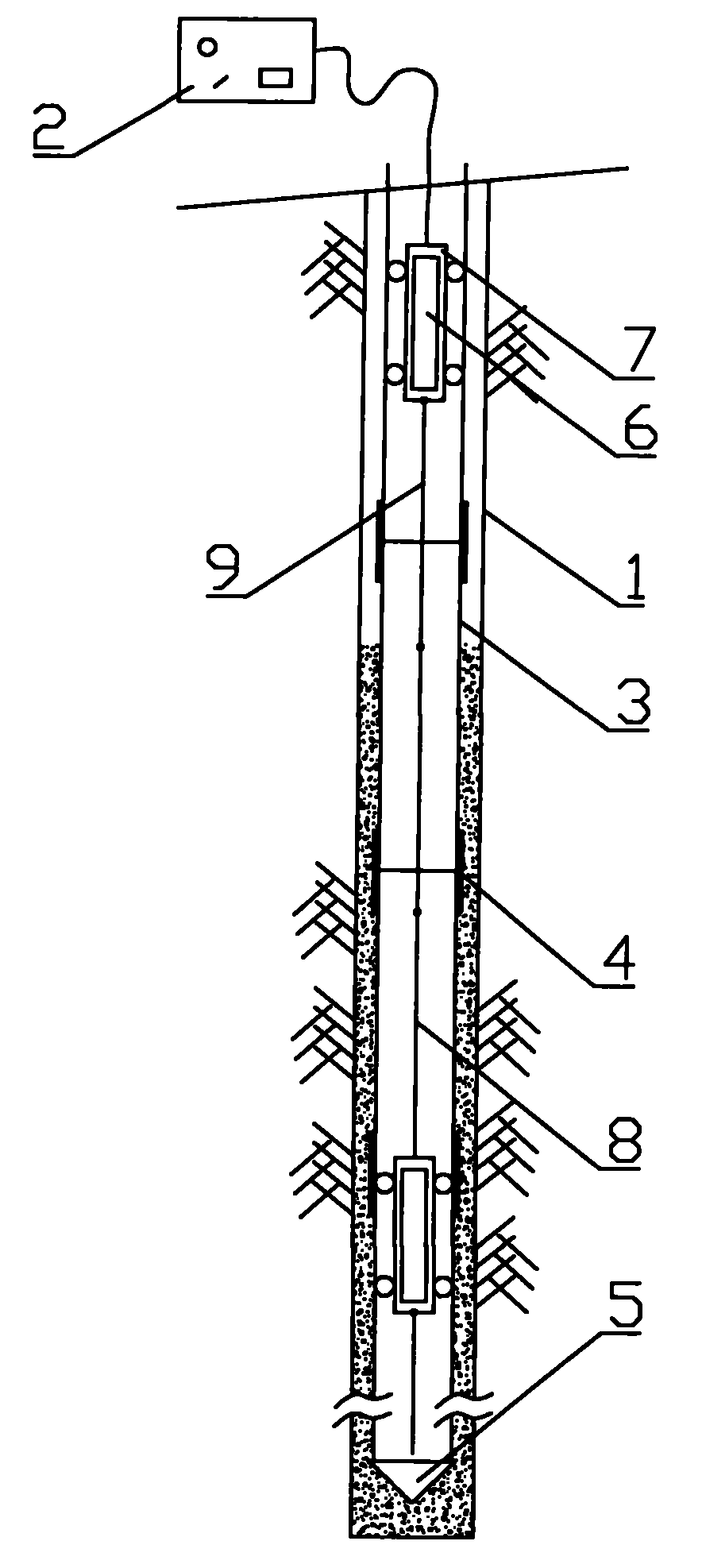

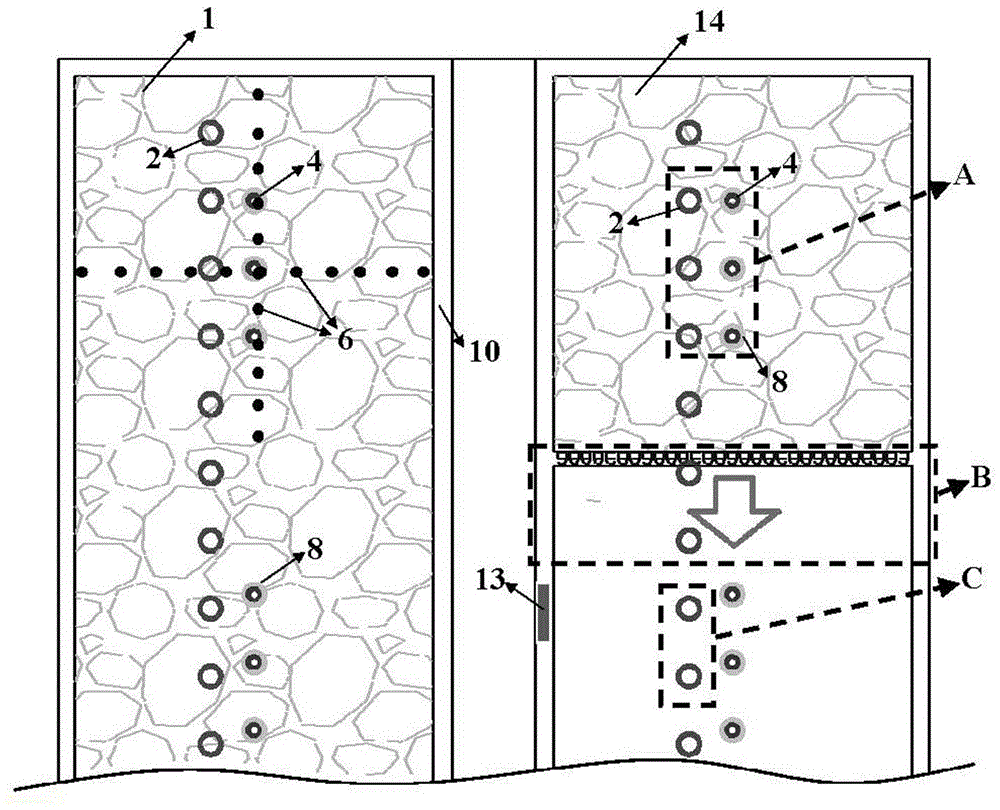

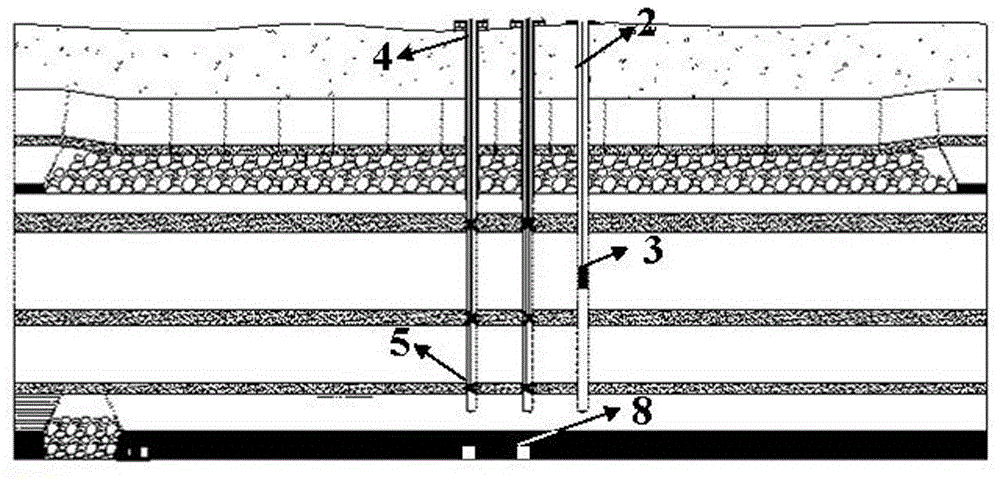

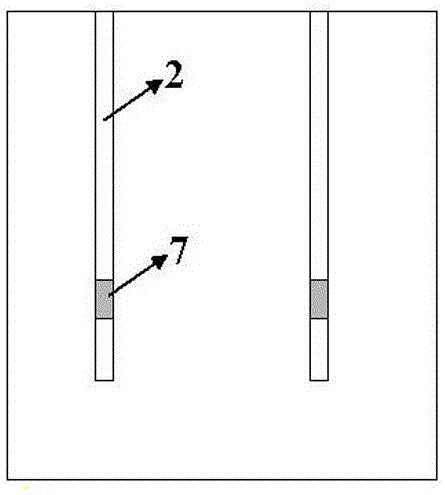

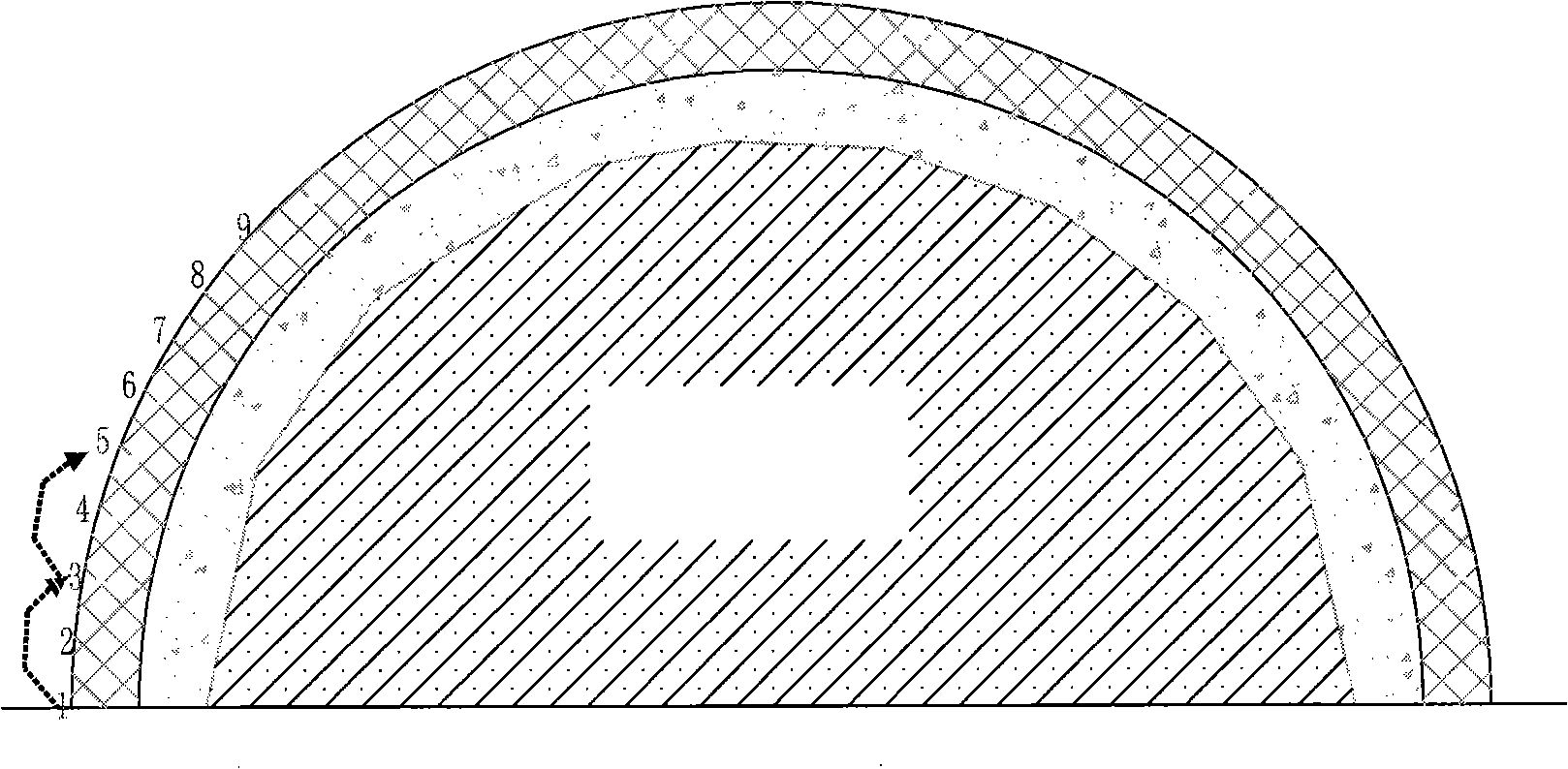

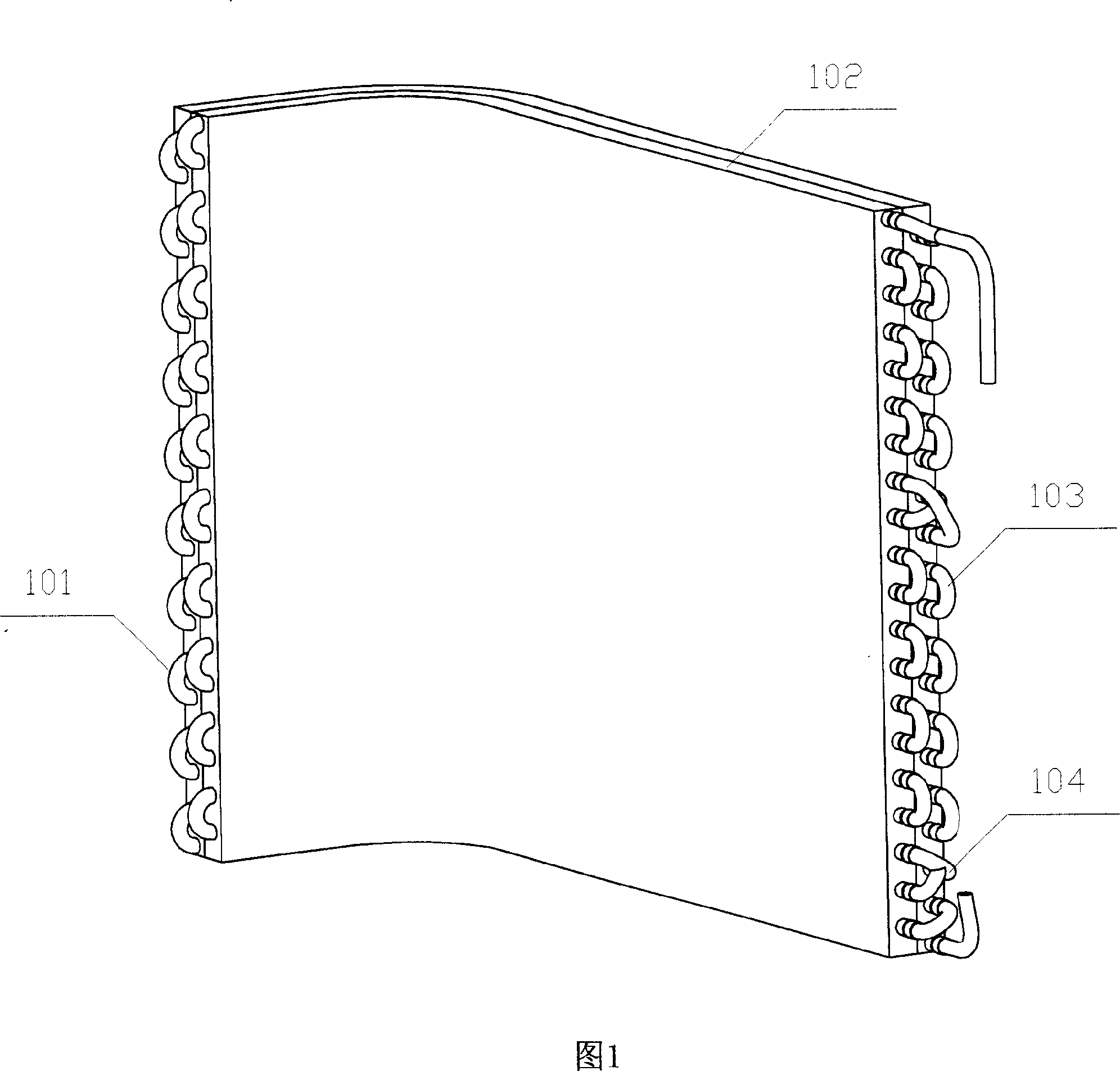

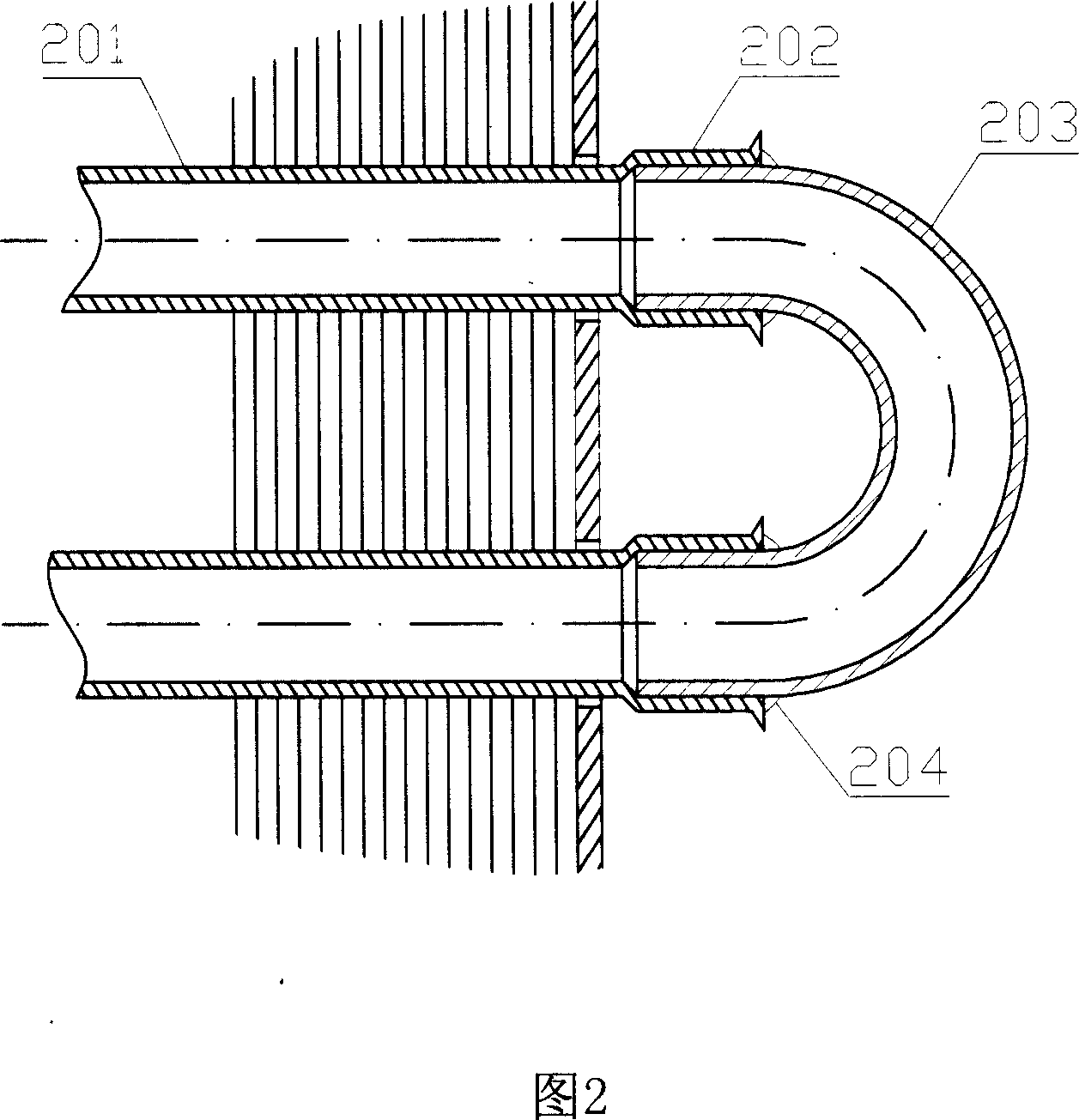

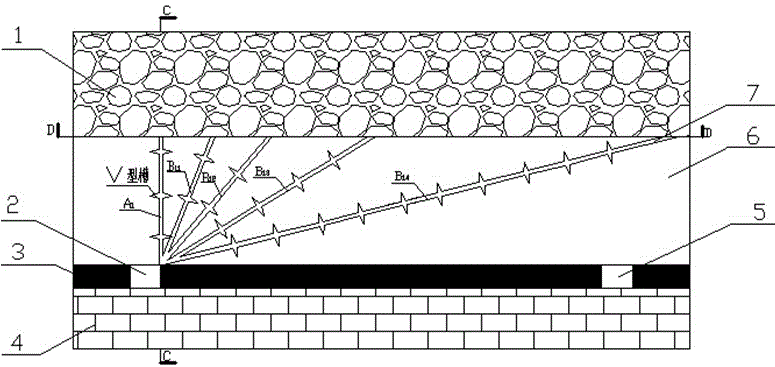

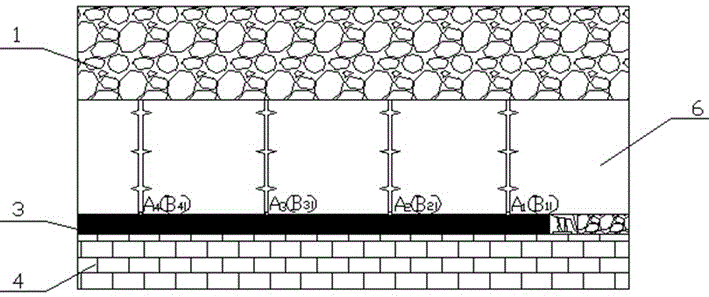

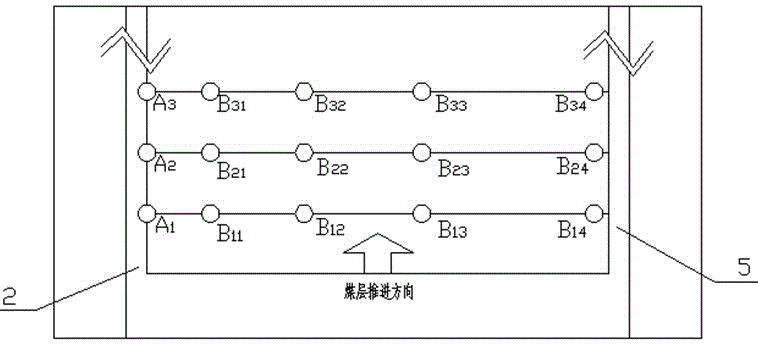

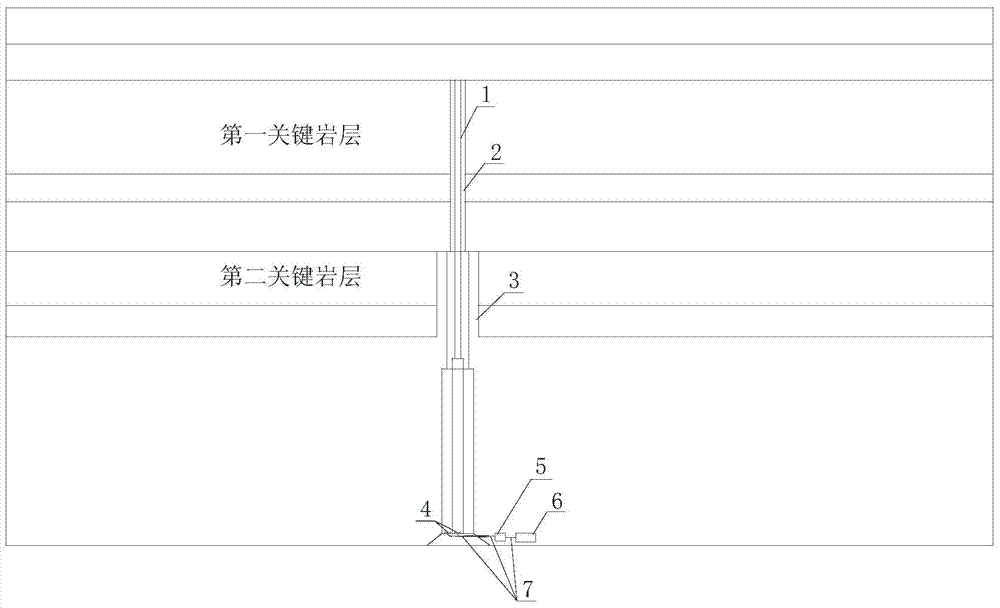

Continuous monitoring system of overburden rock displacement in ore bed mining process and structuring method thereof

ActiveCN101915094ARealize the whole process of continuous monitoringAvoid damageSurveyOverburdenChain structure

The invention discloses a continuous monitoring system of overburden rock displacement in an ore bed mining process, which comprises an inclination measuring drilling hole, an inclination measuring pipe assembly, a monitoring device and a monitoring station. When in use, a plurality of fixed inclinometers are arranged at different positions as required so as to realize the continuous whole-coursemonitoring on mined overburden rock displacement; meanwhile, the monitoring device for a flexible chain structure can be used for preventing the damage of overburden rock movement on instruments so as to ensure monitoring is carried out smoothly; and the monitoring system is used for evaluating the space-time influence degree of the mining to overburden rock so as to provide a basis for the judgment of the influenced degree and the safety of deep mining operation execution, facilities in an overburden rock stratum, ground facilities, and the like. In addition, the invention also discloses a method for structuring the monitoring system, wherein methods for embedding an inclination measurement pipe, carrying out anti-sliding safety protection during lowering the inclination measurement pipe, lowering the inclination measurement pipe when water or no water exists in the drilling hole, fixing the inclination measurement pipe by deep hole grouting, and the like not only effectively solve the problem of huge difficulty on installing deep-hole inclination measurement pipes, but also effectively improve the construction efficiency and the safety.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

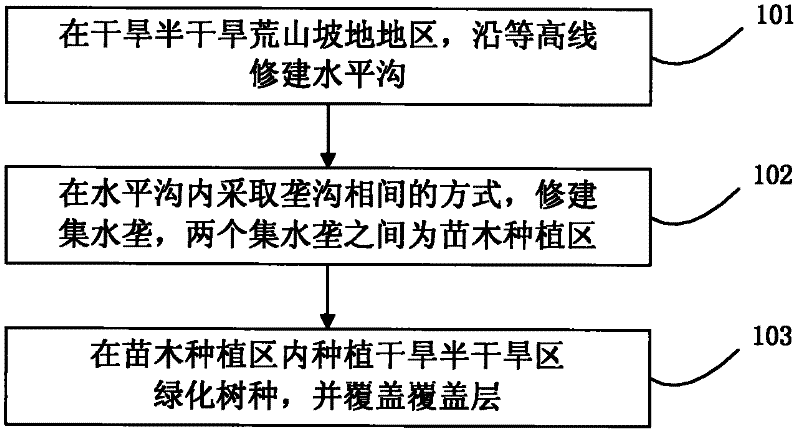

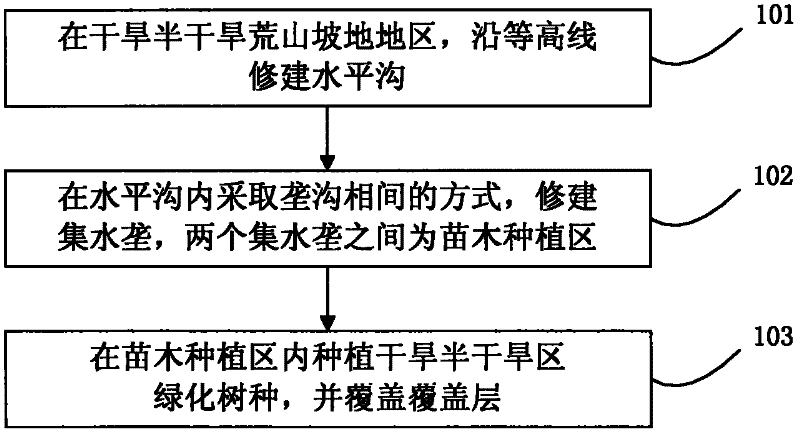

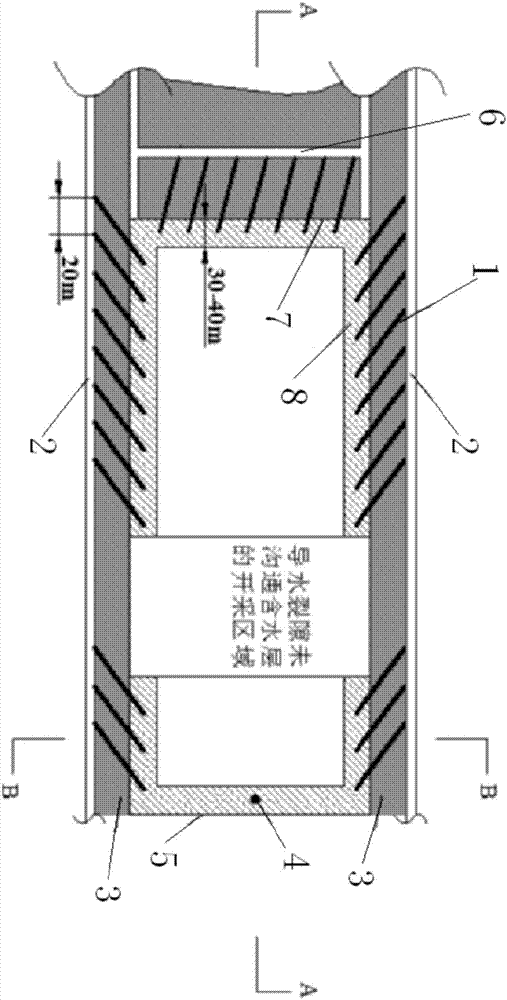

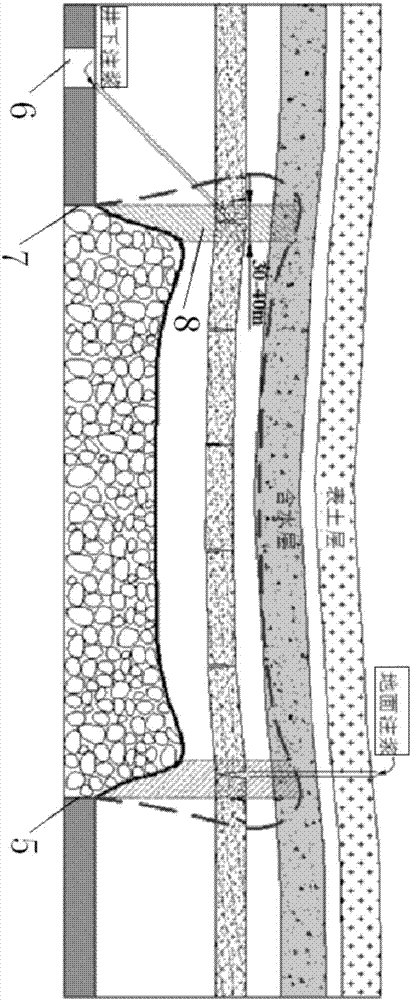

Method for restoring vegetation on barren mountains and sloping fields in arid and semi-arid regions

InactiveCN102499003AImprove survival rateReduce churnWatering devicesCultivating equipmentsRevegetationOverburden

The invention discloses a method for restoring vegetation on barren mountains and sloping fields in arid and semi-arid regions. The method comprises the following steps of: building a horizontal ditch in an arid and semi-arid barren mountain / sloping field region along a contour line; building semi-arc-shaped water collecting ridges in the horizontal ditch in an earth furrow spacing way, wherein a ditch is formed in the two water collecting ridges and is taken as a seedling planting region; and planting arid and semi-arid region greening trees in a seedling planting region and covering a covering layer. The technical scheme of the invention is suitable for arid and semi-arid regions, and has the advantages of easiness for operating, low cost, high wood survival rate, quick vegetation growth and good water and soil holding effect.

Owner:BEIJING NORMAL UNIVERSITY

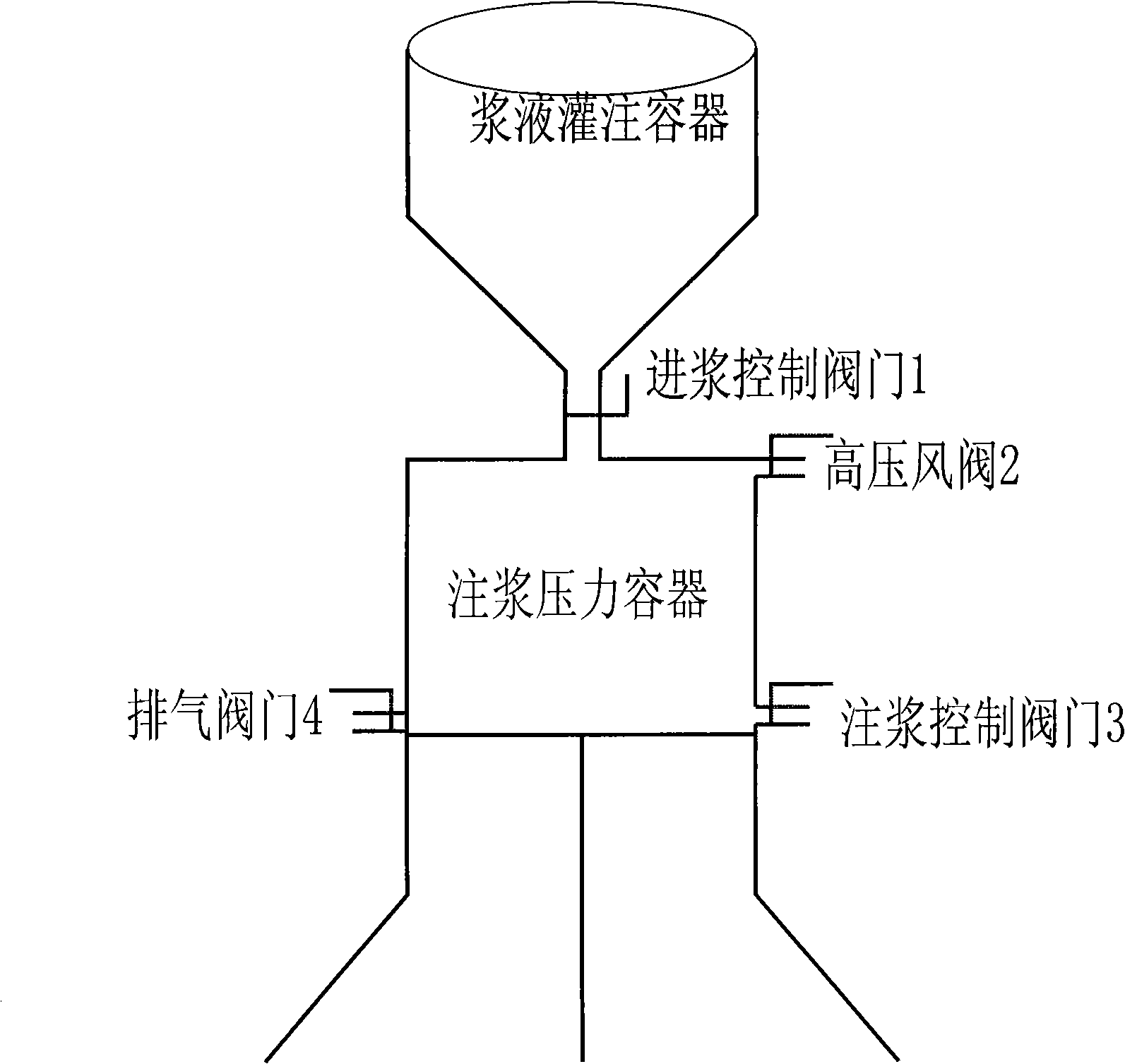

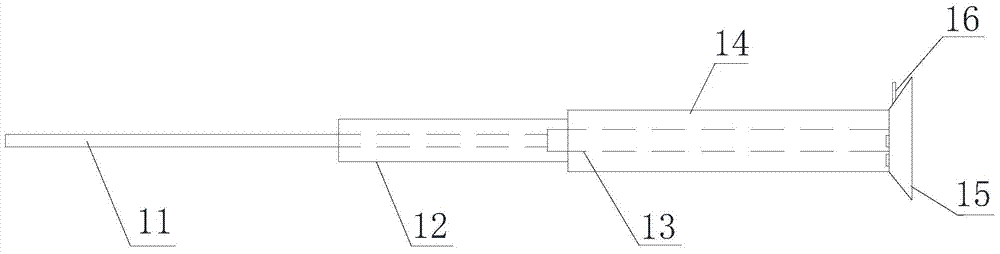

Flooding damage control method for water-diversion fracture main channels of drill-hole-grouting plugged overburden rock

ActiveCN107044289AReliable method of usePracticalUnderground chambersTunnel liningFracture zoneMain channel

The invention discloses a flooding damage control method for water-diversion fracture main channels of drill-hole-grouting plugged overburden rock. The method comprises the steps: collecting surface-drilling columnar data of all coal mining areas according to development characteristics of altitude of water-diversion fractured zones of overburden rock mined under specific mining conditions, determining stratum positions of all key strata in the overburden rock by adopting a key stratum position distinguishing method, then, determining development altitude of a water-diversion fractured zone of each area and areas of distribution of communicating strata and water-bearing strata of each area by an overburden rock water-diversion fractured zone altitude prediction method, finally, laying out the range of distribution of the water-diversion fracture main channels in areas of the communicating water-bearing strata of the water-diversion fractured zones. and determining a grouting drilling type and drilling construction parameters according to borehole tunnel positions, coal bed cover depth and ground drill distribution conditions; after drilling construction is completed, pumping slurry to areas of the water-diversion fracture main channels so as to plug water-diversion fracture channels. The flooding damage control method for the water-diversion fracture main channels of the drill-hole-grouting plugged overburden rock, disclosed by the invention, is determined, can adapt to different mining conditions and can provide a guarantee for water resource protection, flooding damage control and the like of coal mining of mining areas, the use method is reliable, and the practicability is high.

Owner:CHINA UNIV OF MINING & TECH

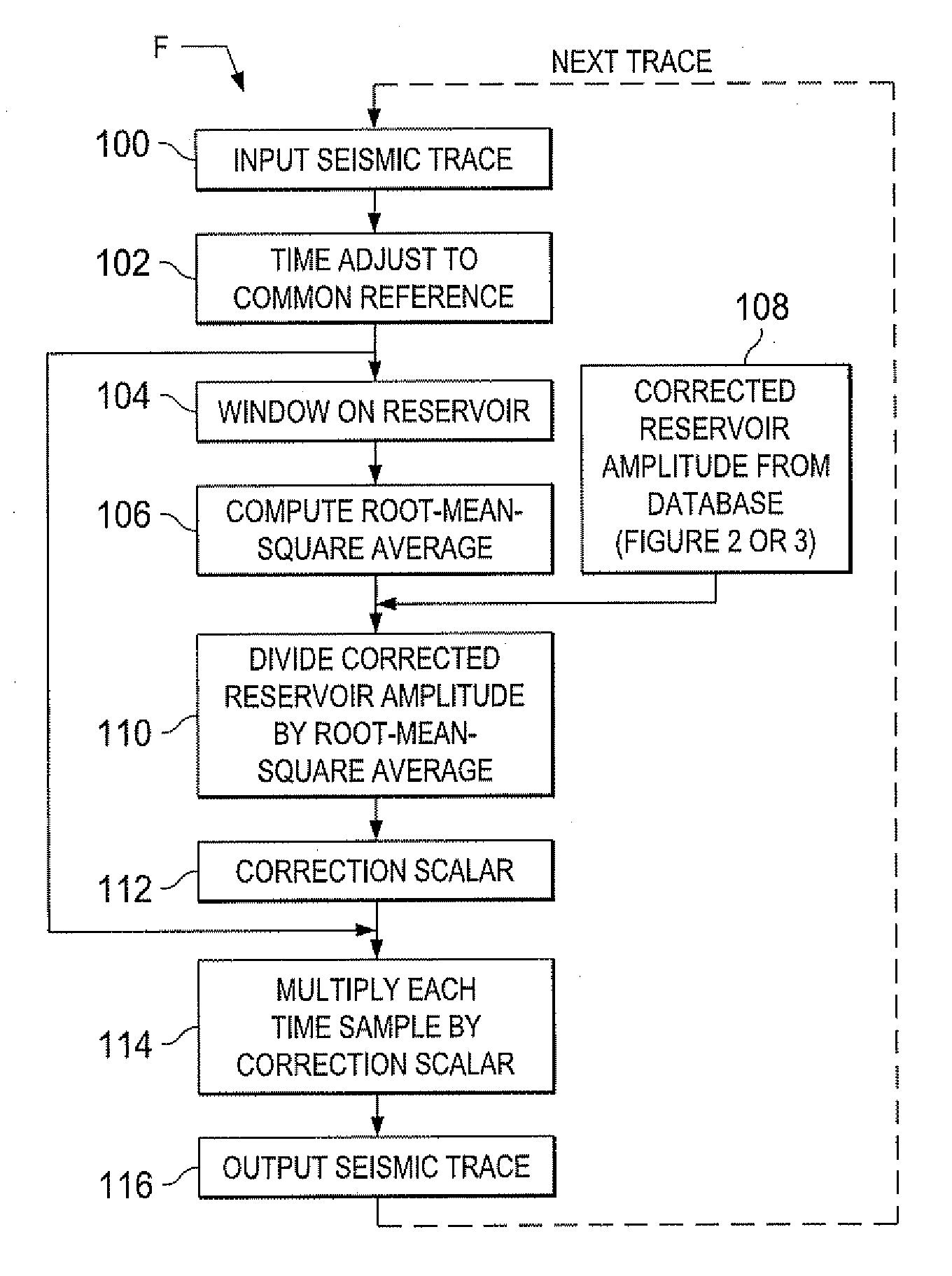

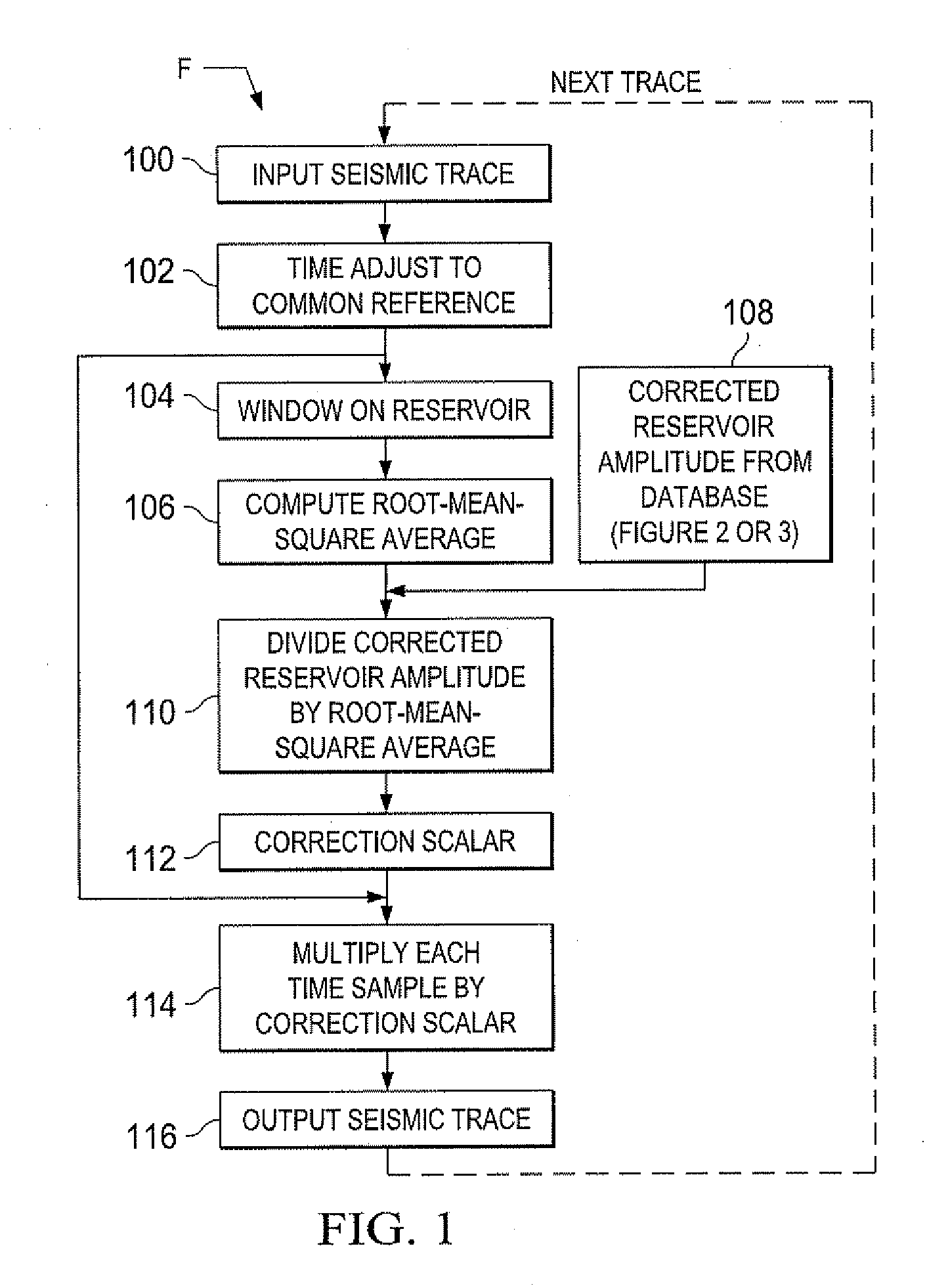

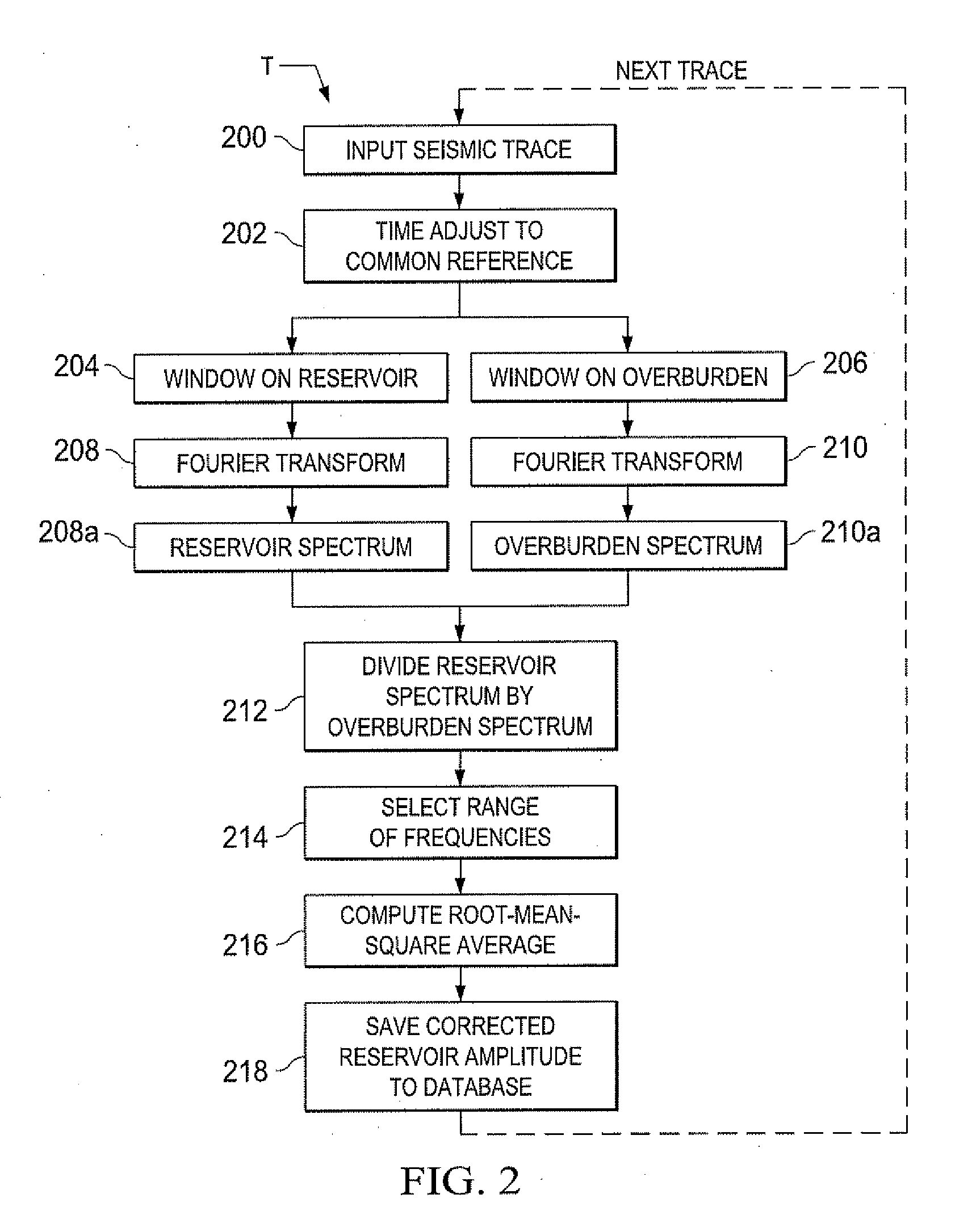

Correcting Time Lapse Seismic Data for Overburden and Recording Effects

Time lapse or 4D seismic data are corrected for geologic overburden and seismic recording system effects. The data from a survey at one time of interest is processed within a selected frequency band and the reservoir level is normalized by the overburden. The results are used to extract reservoir amplitudes from the data of that same survey. Frequencies where overburden signal-to-noise ratios vary dramatically between time lapse surveys may then be avoided in processing of data from the area of interest.

Owner:SAUDI ARABIAN OIL CO

In-situ monitoring method of large space motion of coal mine mining stratum

ActiveCN106703888AGood for detailed descriptionMany monitoring methodsMining devicesConstructionsOverburdenMonitoring methods

The invention relates to a monitoring technic of stratum motions before and after the coal bed mining, particularly relates to a 1:1 in-situ monitoring method of the large space range overlying rocks before and after the coal bed mining, and is specifically an in-situ monitoring method of the large space motions of the coal mine mining stratum. The problem that monitoring means for rock strata movements do not yet exist at present for large space ranges either within the nation or outside the nation is solved. The in-situ monitoring method comprehensively adopts a means based on the 'one form three places' method of the subsidence-overburden rock migration-underground mine pressure, and the in-situ monitoring method further adopts the geophysical prospecting methods of well upper and lower linkage observation, the drill hole television observation, the hole gap CT observation and the micro-seismic monitoring and the like, and the in-situ monitoring method also adopts the integration monitoring methods of the working face surrounding rock stress-strain monitoring and the like. The in-situ monitoring method creatively integrates various observation means, and through the reasonable arrangements, designs, observations and analyses of various monitoring means in large space ranges, mutual complements, comparisons and verifications between the various observation means are achieved, meanwhile each separate monitoring technic is innovated and promoted, and the in-situ precise measurement of the large space motions of the coal mine mining stratum is achieved.

Owner:DATONG COAL MINE GRP

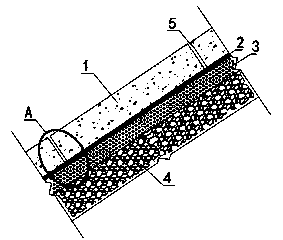

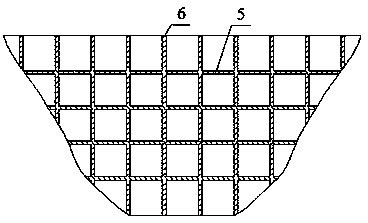

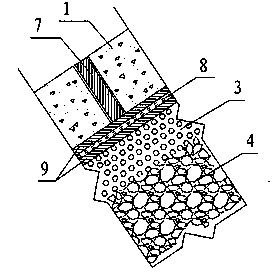

High rock-fill dam membrane anti-seepage body on deep coverage layer and construction method of high rock-fill dam membrane anti-seepage body

InactiveCN103643656AStrong adaptability to deformationNo crackEarth-fill damsRock-fill damsOverburdenFiber

The invention discloses a high rock-fill dam membrane anti-seepage body on a deep coverage layer and a construction method of the high rock-fill dam membrane anti-seepage body. The membrane anti-seepage body is composed of a concrete protection layer, a geomembrane anti-seepage layer, a flexibility cushion layer and a transition layer. The concrete protection layer is a cast-in-place fiber concrete layer for a reserved cross joint and a vertical joint and located on a surface layer to protect a geomembrane. The geomembrane anti-seepage layer is a two-cloth and one-membrane composite geomembrane and is located in the middle to play a role of preventing seepage. The flexibility cushion layer is a polyurethane pervious concrete layer and located at the bottom of the anti-seepage body to support the geomembrane and to transmit and disperse water loads. The rough granule transition layer is arranged between the flexibility cushion layer and a rock-fill dam body. The construction method comprises the technical steps of filling and building the transition layer, pouring the flexibility cushion layer, paving the composite geomembrane, pouring the concrete protection layer and the like. The membrane anti-seepage body can keep stable on a high rock-fill dam slope, the ability of adapting to deformation of a coverage layer dam foundation and the dam body is high, the structural form is simple, construction is fast, and the anti-seepage problem of the high rock-fill dam on the deep coverage layer can be effectively solved.

Owner:HOHAI UNIV

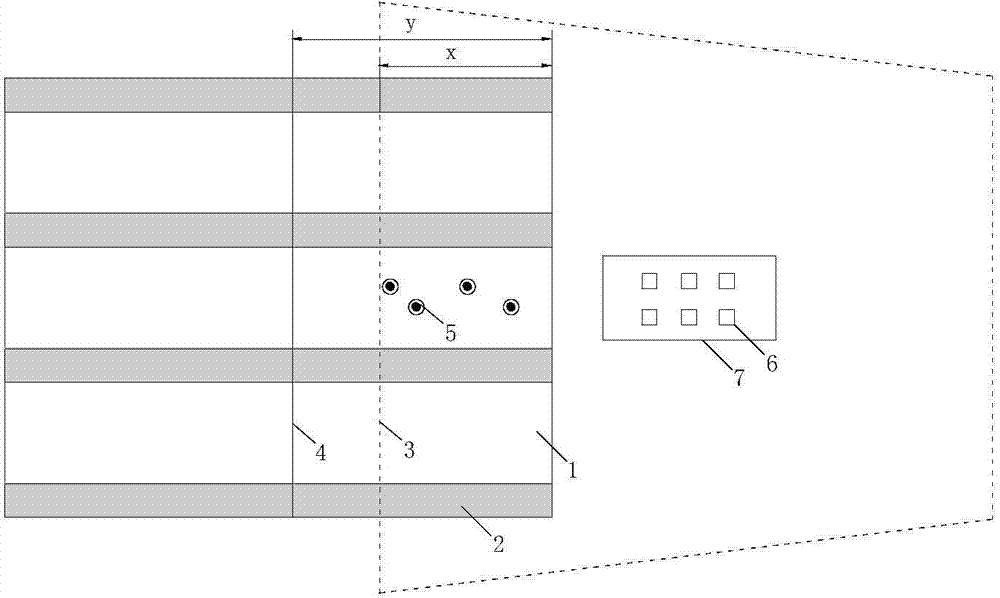

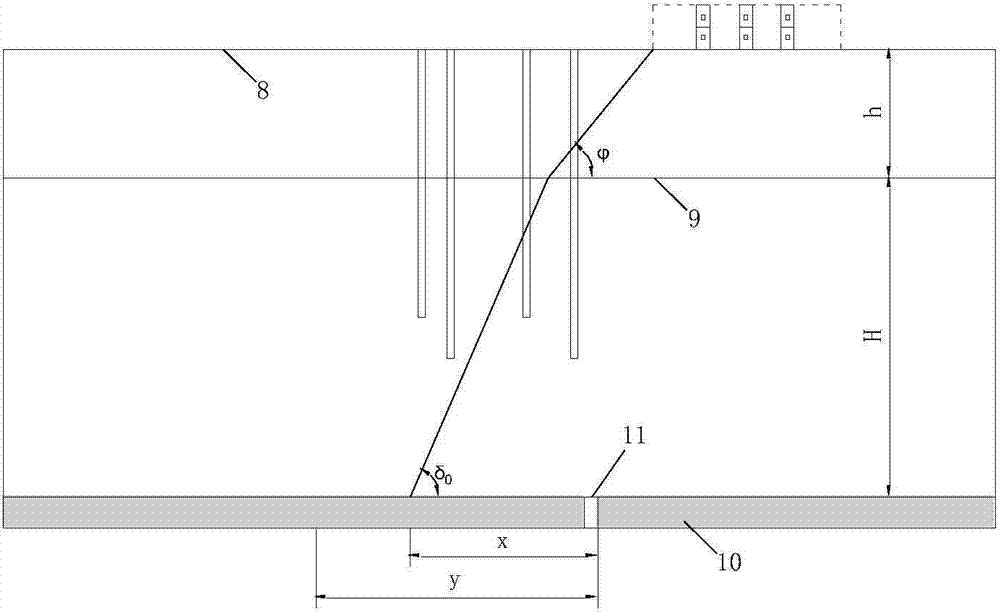

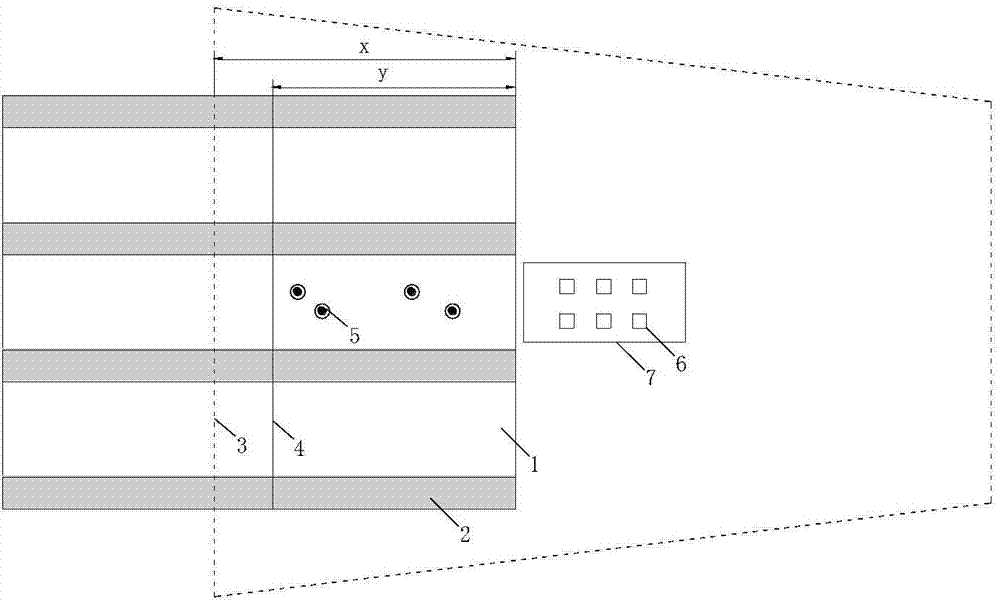

Isolated grouting-filling mining method for overburden rock without village migration under cut-side local pressed-coal conditions

The invention provides an isolated grouting-filling mining method for overburden rock without village migration under cut-side local pressed-coal conditions. The method comprises the following steps: according to the geological information of a mine and geographical position of a village, determining distance between the boundary line of a protective coal pillar at the cut side of a working face and a cut, determining sufficient mining distance in the direction of the working face, and comparing the distance with the sufficient mining distance so as to determine an isolated grouting-filling control area for the overburden rock; drilling a plurality of inlet wells in the control area towards a coal bed direction, wherein the final hole depth of the inlet wells is 15 to 40 times higher than the coal bed mining height above the coal bed; and when the coal face is mined to 10 to 30 m away from the inlet wells, injecting coal ash slurry in abscission zones in the rock strata above the coal face through the inlet wells until the grouting-filling control area is mined in the coal face, and completing grouting-filling coal-mining at the cut side. The method is applicable to mining of cut-side local pressed coal and can reduce loss of cut-side pressed coal and improve a mining rate; and compared with a full-working face isolated grouting-filling mining method for overburden rock, the method provided by the invention has the advantages of a small filling amount, low filling cost, good control effect on surface subsidence, and capacity of realizing coal mining without village migration under cut-side pressed-coal conditions.

Owner:CHINA UNIV OF MINING & TECH

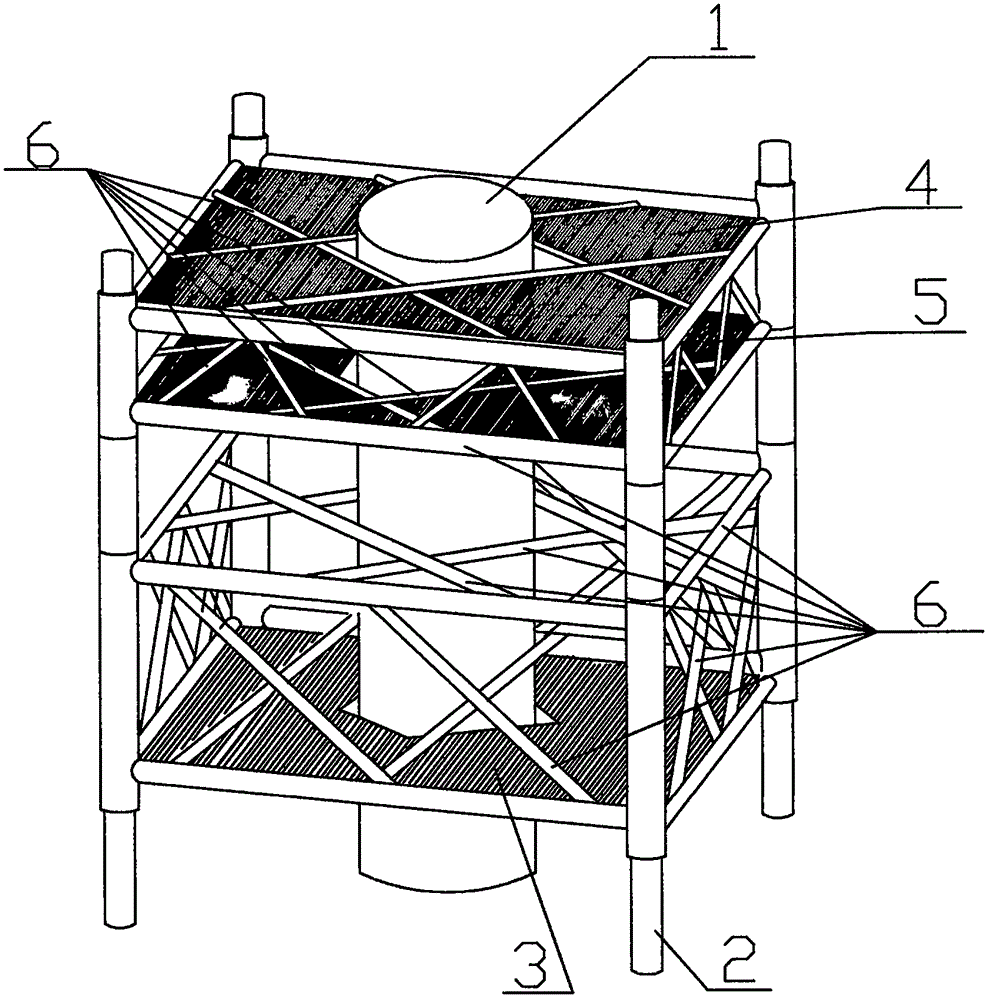

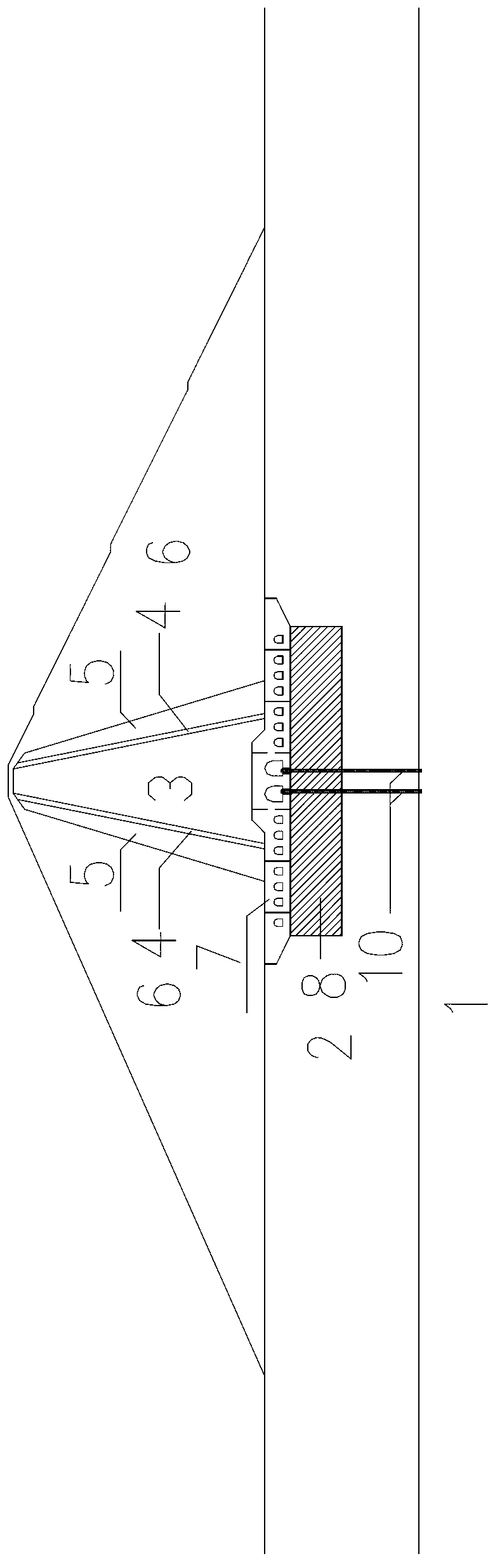

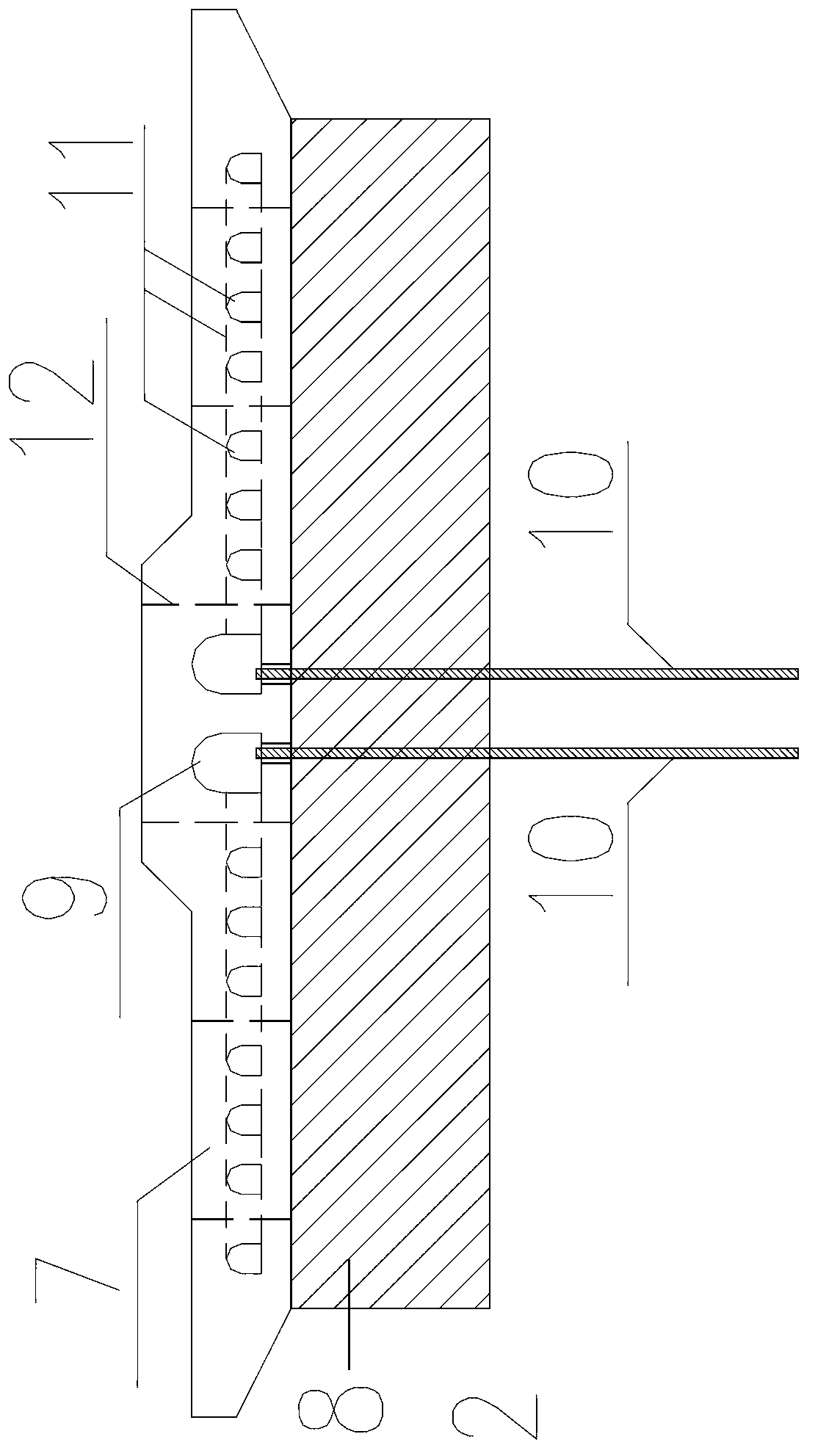

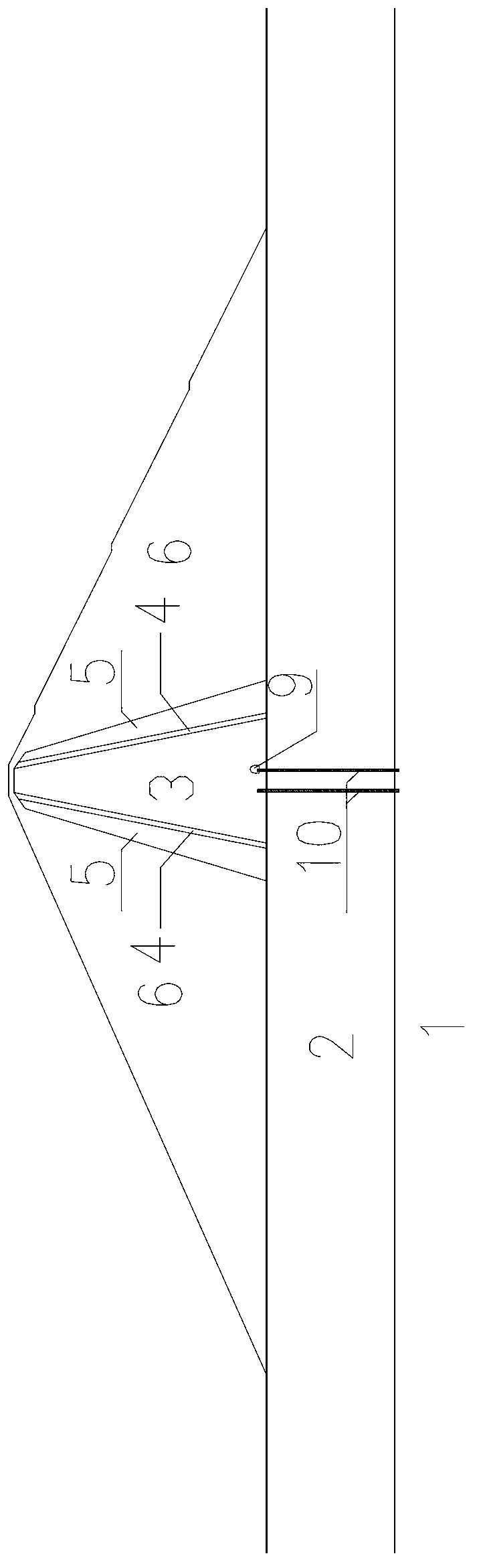

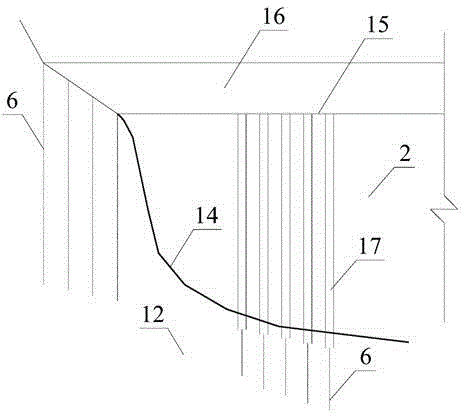

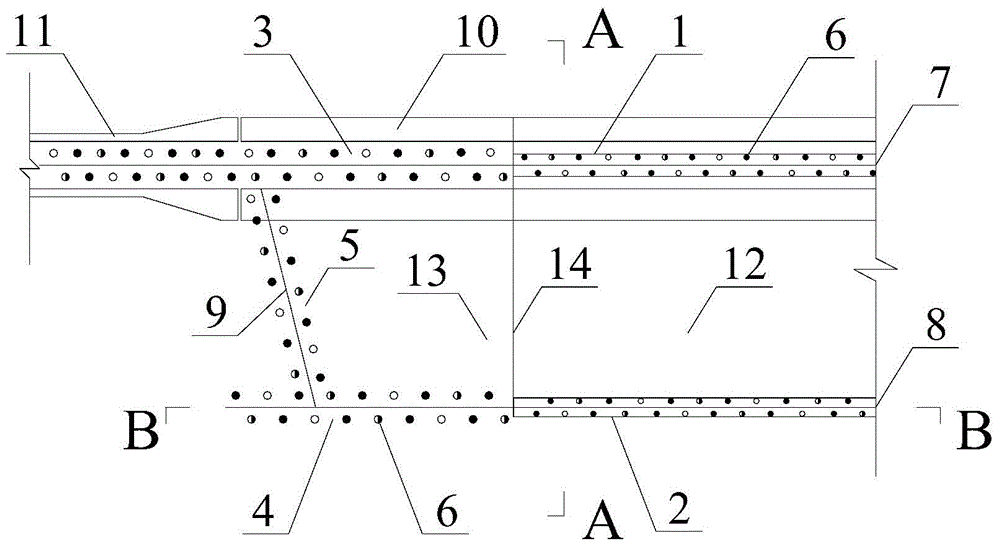

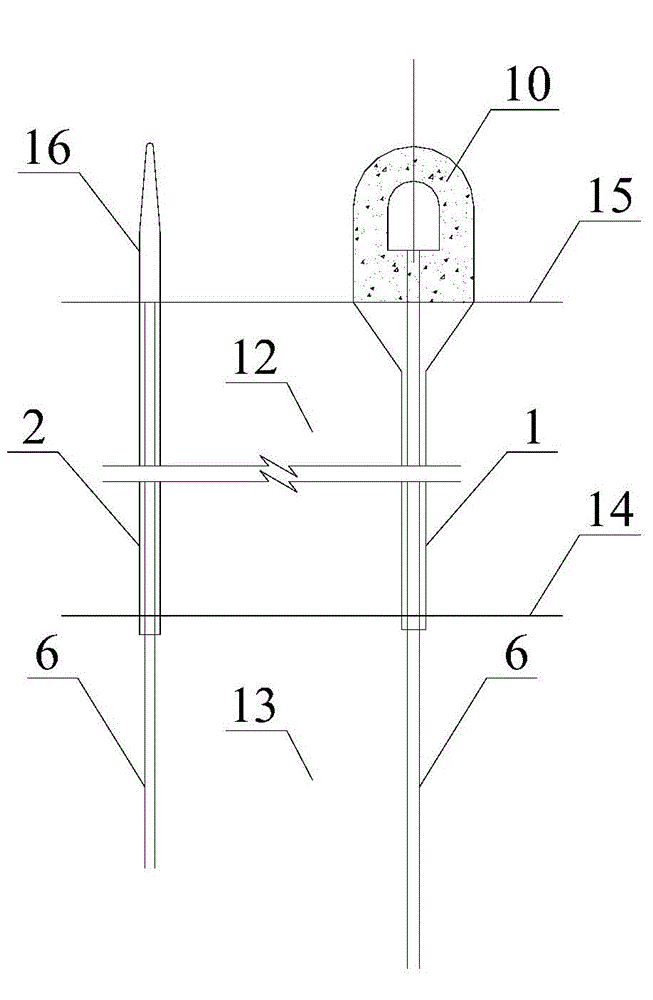

Temporary construction platform of rock-socketed single pile foundation of offshore wind turbine

The invention discloses a temporary construction platform of a rock-socketed single pile foundation of an offshore wind turbine. The temporary construction platform of the rock-socketed single pile foundation of the offshore wind turbine is a jacket structure formed by connecting four auxiliary tubular piles (2) and stay bars (6), and is characterized in that pile distances among the four auxiliary tubular piles (2) are 18 m, and the height of a jacket platform is 20 m; a second platform (5) and a first platform (4) are respectively arranged at positions which are distant from the top end of the jacket structure by 5 m and 2 m, and jacks are respectively mounted on the second platform (5) and the first platform (4) and are used for adjusting perpendicularity of a steel casing (1); a mudmat (3) is arranged at the bottom of the jacket structure; and a limiting component is arranged on the first platform (4), and brackets are shelved on the limiting component and stop the steel casing against sinking. By the temporary construction platform of the rock-socketed single pile foundation of the offshore wind turbine, the problem that the rock-socketed single pile foundation of the offshore wind turbine is difficult to construct on a rock supported sea floor with a shallow surface residual overburden is solved effectively, a powerful support is provided for introduction of an offshore wind turbine rock-socketed single pile foundation technology to the offshore wind powder industry, and project cost is reduced.

Owner:JIANGSU LONGYUAN OFFSHORE WIND POWER GENERATION +1

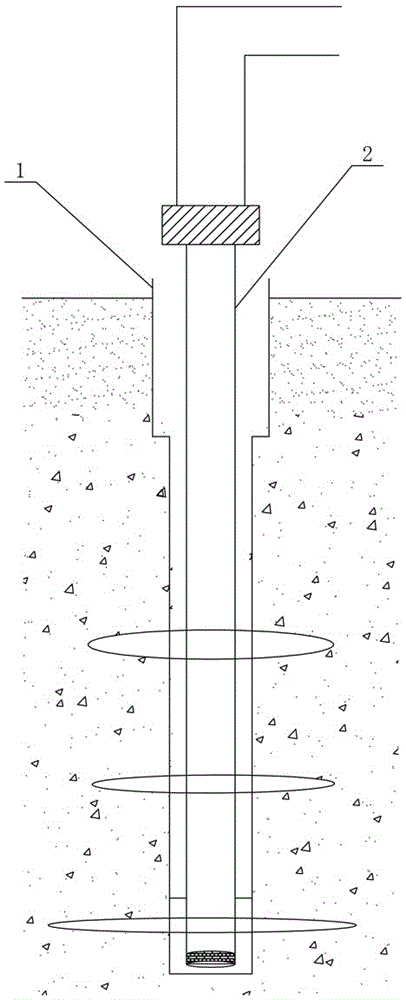

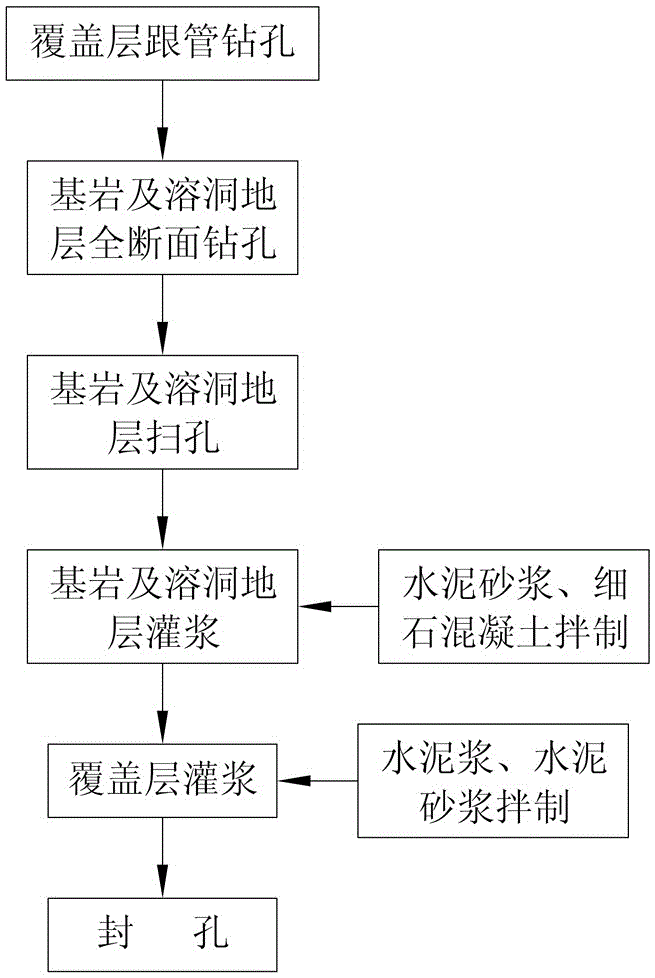

Anti-seepage construction method for karst cave development stratum under overburden

ActiveCN106320354AImprove bearing capacityImprove deformation resistanceFoundation engineeringBasementOverburden

The invention discloses an anti-seepage construction method for karst cave development stratum under overburden. The anti-seepage construction method comprises the following steps: S1, overburden drilling with a casing; S2, full-section drilling of basement and karst cave stratum; S3, drill-hole cleaning of basement and karst cave stratum; S4, grouting of basement and karst cave stratum; S5, grouting of overburden; and S6, hole sealing. The anti-seepage construction method has the advantages of simplicity in construction, favorable quality, controllable cost and high efficiency.

Owner:SINOHYDRO BUREAU 8 CO LTD

PHC pile and water flush gas lift static pressure pile-sinking method

The present invention is new type of PHC pile and its water flushing-air lifting hydrostatic pile sinking process. The water flushing-air lifting hydrostatic pile sinking process includes the following steps: hydrostatic pile sinking in the surface soft soil layer; water flushing and air lifting hydrostatic pile sinking in the sand and pebble layer; and hydrostatic pile sinking in the soft soil layer or sandstone layer below sand and pebble layer until reaching the designed level. Compared with available perforating and pile grouting process, the present invention has 40-50 % lower cost and is superior in engineering quality, construction period and environment protection. The pile can penetrate any covering layer and its end can be reach ideal bearing course fast.

Owner:李小云

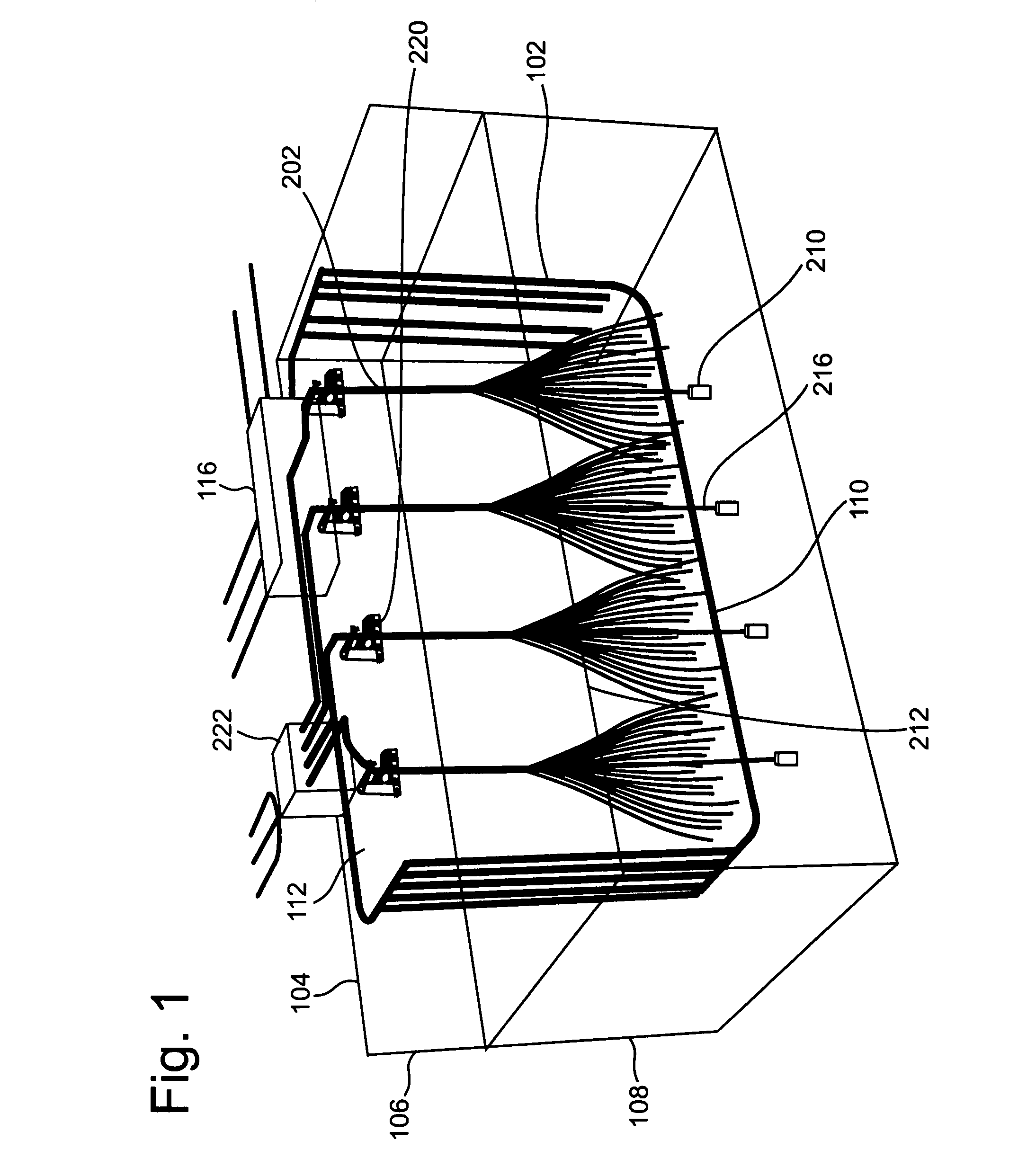

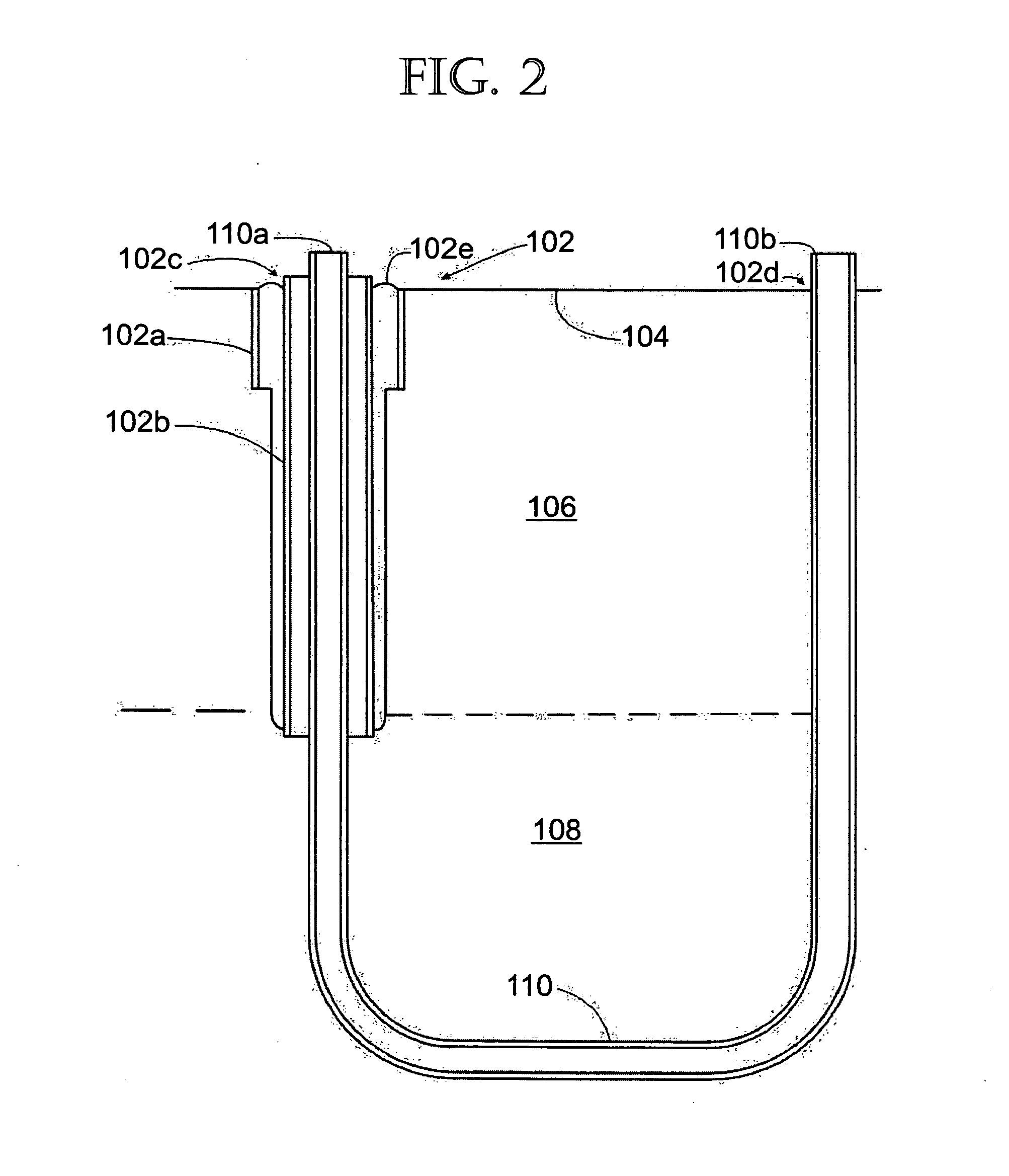

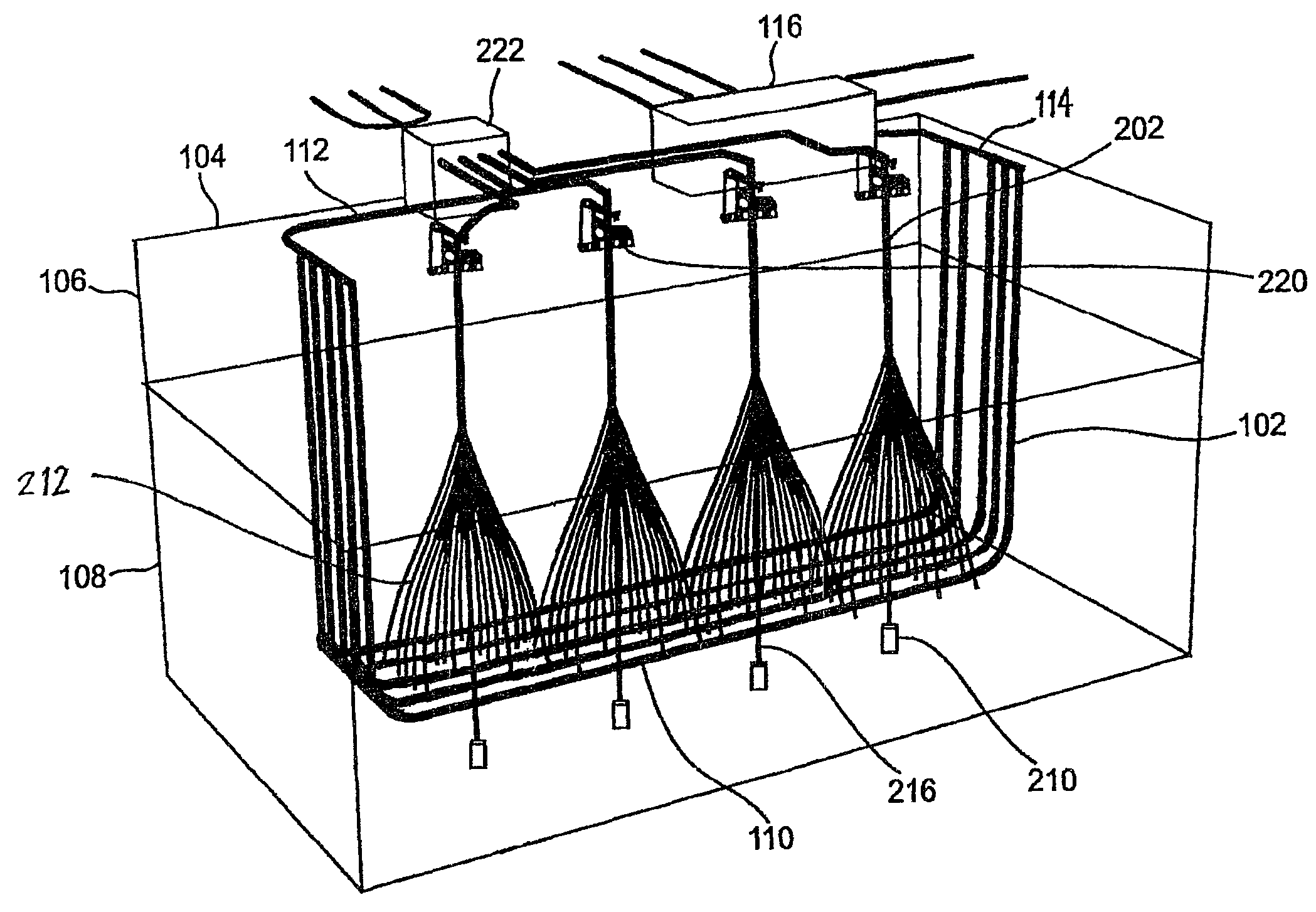

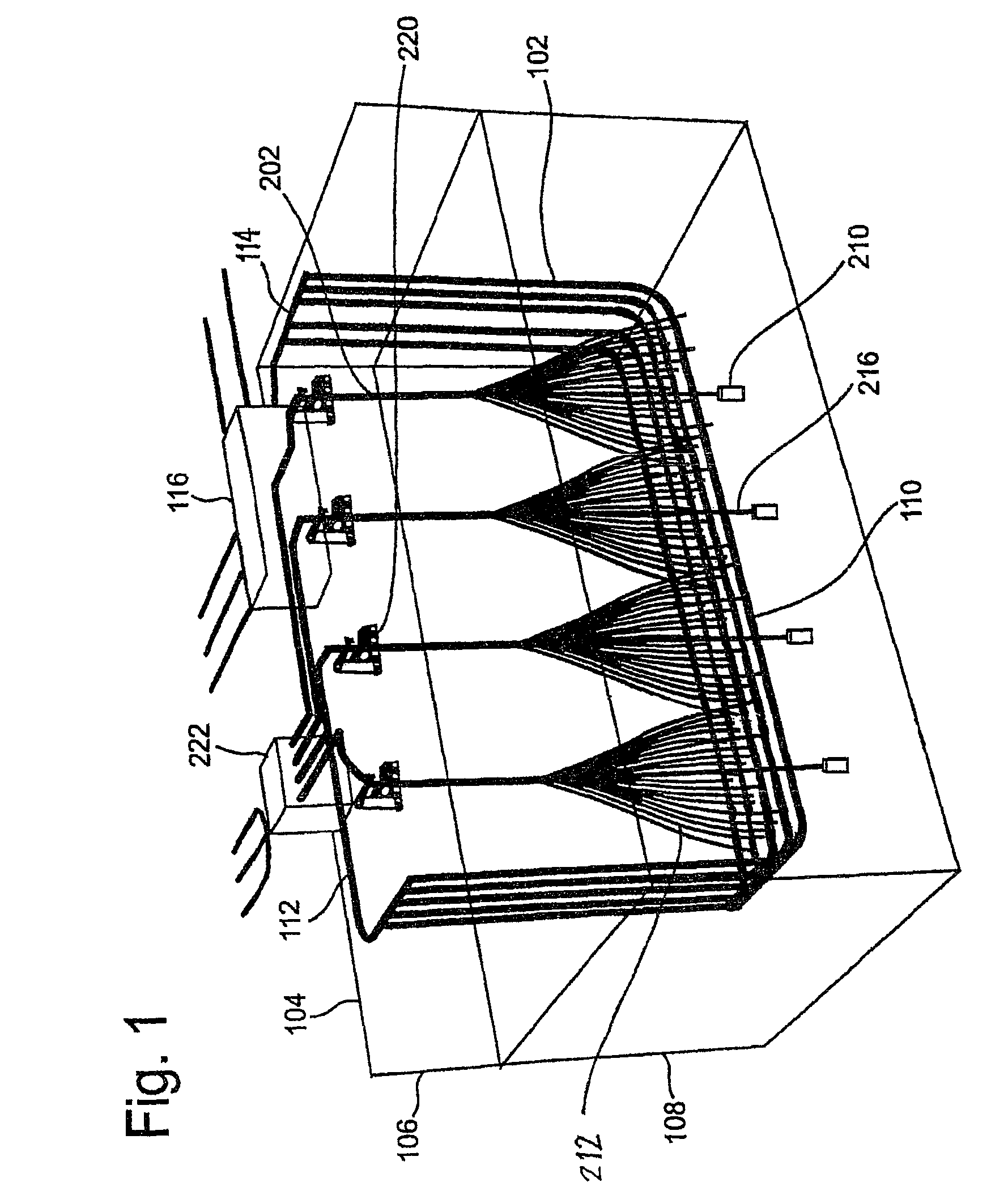

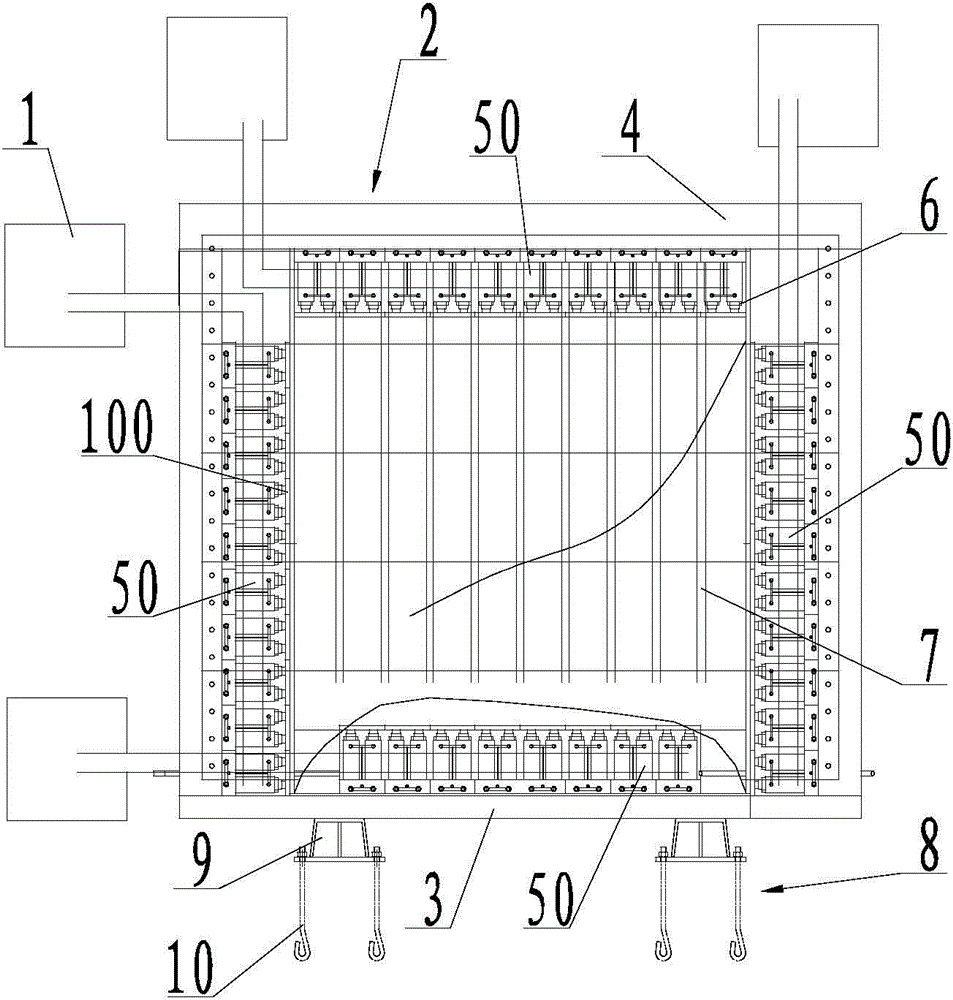

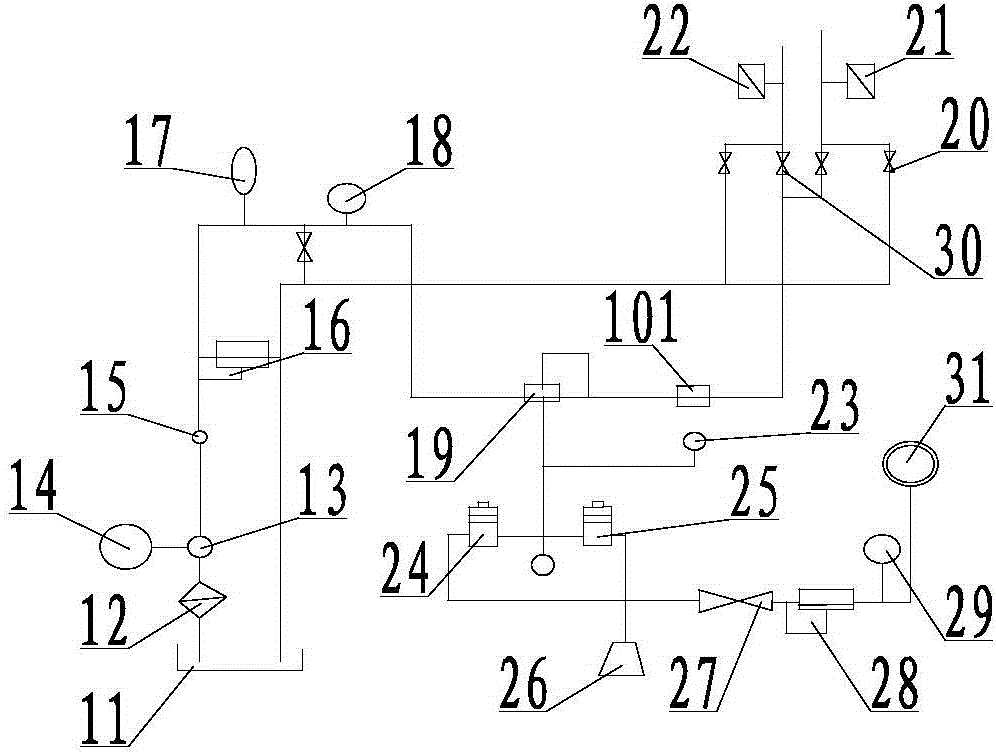

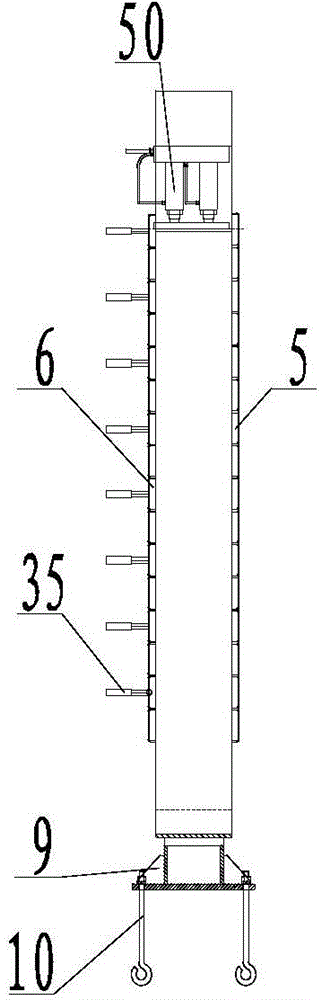

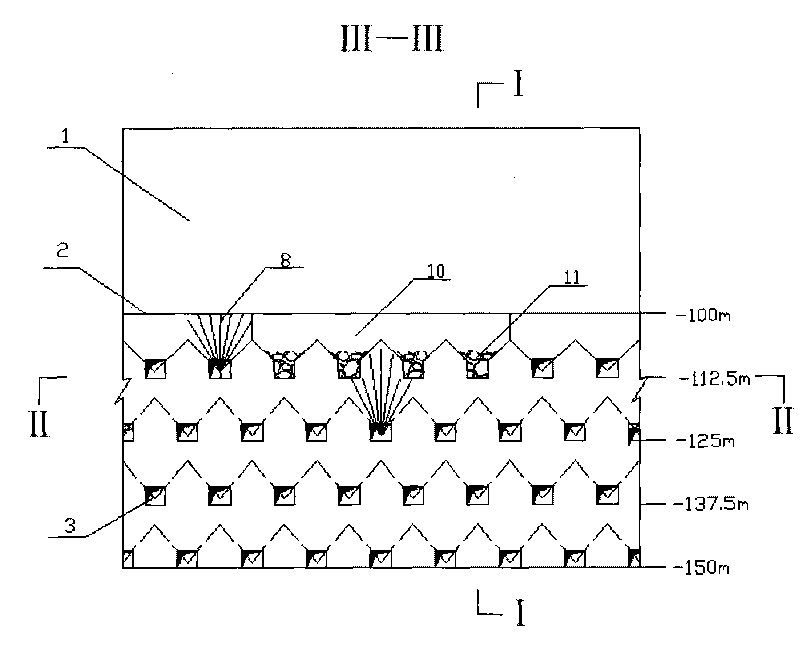

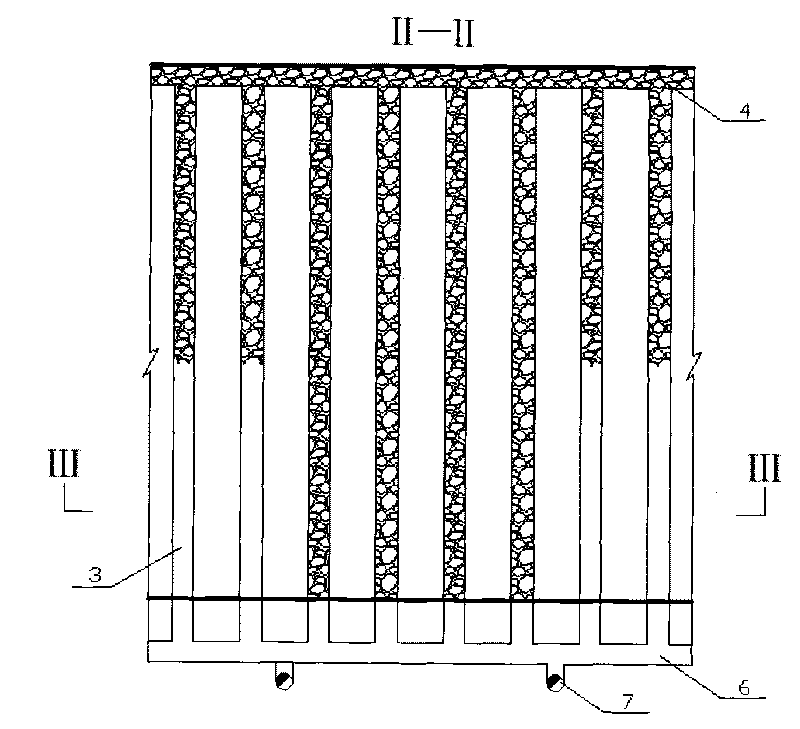

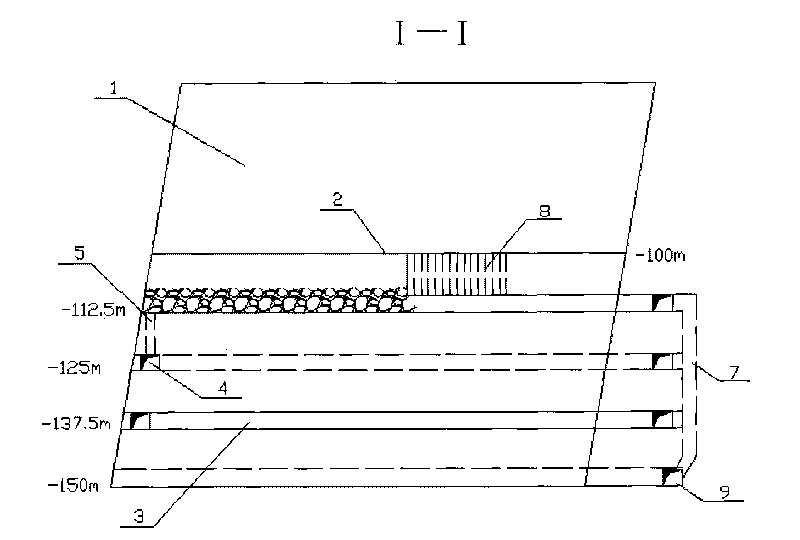

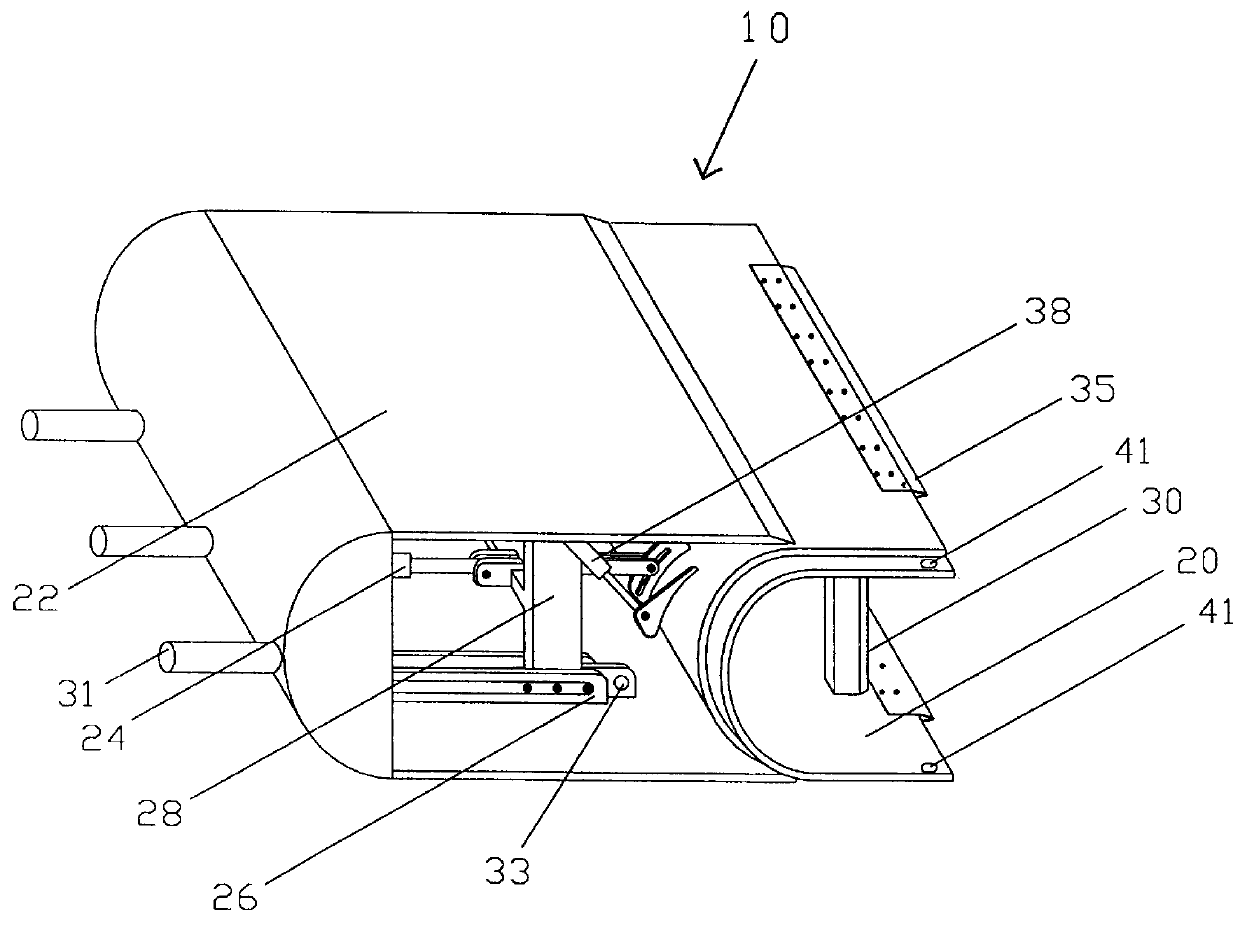

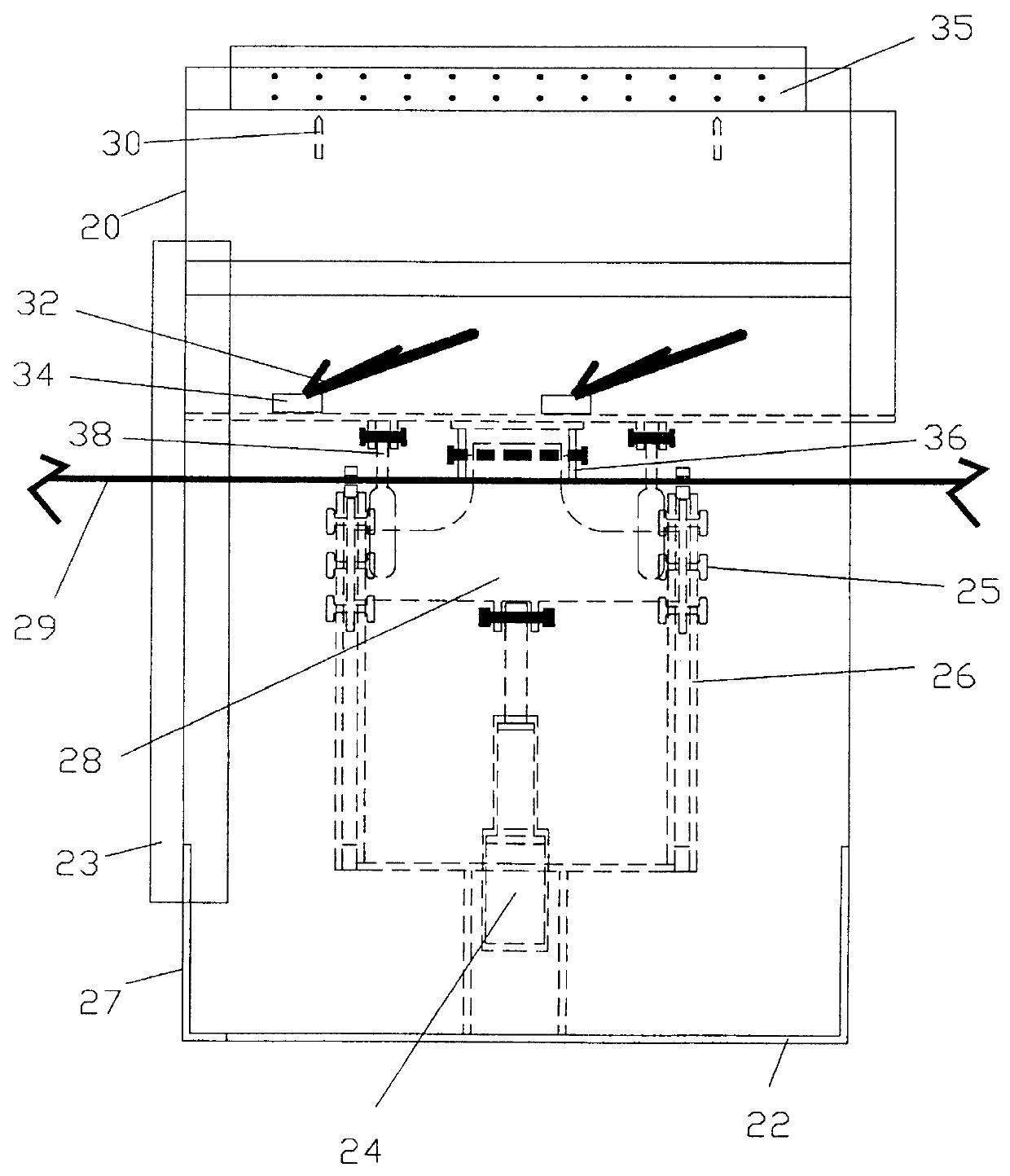

Coal bed overburden strata broken coal and rock mass gas transport and extraction experiment system

The invention discloses a coal bed overburden strata broken coal and rock mass gas transport and extraction experiment system which comprises four static servo hydraulic control systems and a model base, wherein the model base comprises a bottom plate, front, rear, left and right side walls on the bottom plate, and a top plate, which define a cubic space filled with simulation materials; an air vent pipe is arranged on the rear side wall; the four static servo hydraulic control systems are connected with lifting jacks on the bottom plate, the top plate, the left side wall and the right side wall, respectively; a steel wire corrugated pipe is arranged in the model base; a model base supporting device is arranged at the bottom of the model base. The limitation of conventional computer numerical simulation for solving a discontinuous large deformation problem is eliminated, and a phenomenon that stratum movement caused by mining in a mining process under specific conditions cannot be completely and accurately reflected is avoided. Meanwhile, a gas transport law and a gas extraction law in a pressure relief area can be tested.

Owner:CHONGQING UNIV

Artificial composite foundation for building clay core rock-fill dam on deep overburden and construction method for artificial composite foundation

ActiveCN102852121AImproved deformation coordinationImprove stress-deformation propertiesEarth-fill damsRock-fill damsOverburdenBedrock

The invention provides an artificial composite foundation for building a clay core rock-fill dam on a deep overburden. The artificial composite foundation comprises a base rock (1) and an overburden (2) arranged on the base rock (2); a filter layer (5) is arranged at the outer side of a reversed filter layer (4); a rock-fill (6) is arranged at the outer side of the filter layer (5); the rock-fill (6), the filter layer (5), the reversed filter layer (4) and a core (3) form a dam body, wherein the thickness of the overburden (2) is more than 50m; a concrete cover board (7) is arranged in the overburden (2); and the height of the dam body is more than 150m. The shortages of large digging work amount, increased scale of river diversion works, increased scale of waste slag field, prolonged engineering construction period and increased engineering investment are avoided by using the artificial composite foundation. According to the artificial composite foundation, the diaphragm wall construction and the reinforcing grouting construction are conducted in gallery of the concrete cover board, and the dam filling construction can be synchronously performed, so that the construction period is shortened effectively. The invention simultaneously discloses a construction method for the artificial composite foundation.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

High core wall rock-fill dam foundation seepage prevention structure on deep overburden layer

InactiveCN104358270AIncrease head ratioRealize joint anti-seepageProtective foundationEarth-fill damsOverburdenBedrock

The invention discloses a dam foundation seepage prevention structure, in particular to a high core wall rock-fill dam foundation seepage prevention structure on a deep overburden layer. The invention provides the high core wall rock-fill dam foundation seepage prevention structure on the deep overburden layer with a better seepage prevention effect. The high core rock-fill dam foundation seepage prevention structure comprises a main seepage prevention wall, an auxiliary seepage prevention wall, a main seepage prevention wall plane grouting curtain, an auxiliary seepage prevention wall plane grouting curtain and connecting curtains, wherein the bottoms of the main seepage prevention wall and the auxiliary seepage prevention wall respectively penetrate a riverbed covering layer to be inserted into bed rock, and the auxiliary seepage prevention wall is arranged on the upstream side of the main seepage prevention wall; the main seepage prevention wall plane grouting curtain is arranged on the junction of the main seepage prevention wall and the bed rock, and the auxiliary seepage prevention wall plane grouting curtain is arranged on the junction of the auxiliary seepage prevention wall and the bed rock; two connecting curtains are respectively arranged on two river banks, and the connecting curtains are connected with the main seepage prevention wall plane grouting curtain and the auxiliary seepage prevention wall plane grouting curtain. By adopting the connecting curtains, the leakage of water when the water flows around the auxiliary seepage prevention wall on a bank slope can be reduced, the water head ratio borne by the auxiliary seepage prevention wall can be increased, and the combined seepage prevention of the main seepage prevention wall and the auxiliary seepage prevention wall can be realized.

Owner:POWERCHINA CHENGDU ENG

Heat energy extraction system from underground in situ combustion of hydrocarbon reservoirs

ActiveUS20130234444A1Function increaseImprove efficiencyOther heat production devicesGeothermal energy generationHydrocotyle bowlesioidesFuel oil

A system and method to extract heat energy from underground heat sources, then transport that heat to the surface in the form of a high temperature liquid or gas, and deliver the contaminant-free heat energy to a surface user of heat. The heat captured in the working fluid of the system is gained by heat transfers and can be extracted from the in situ combustion of any oil sands, heavy oil, conventional or unconventional oil, bitumen, coal, conventional or unconventional natural gas, methane or oil shales, or from various other sources. The invention creates a closed circulation system, in which the working fluid and steam circulating in the system are protected from any direct contact with the hydrocarbon reservoir, and gases produced by the in situ combustion are sequestered in the reservoir by the overlying overburden.

Owner:7238703 CANADA

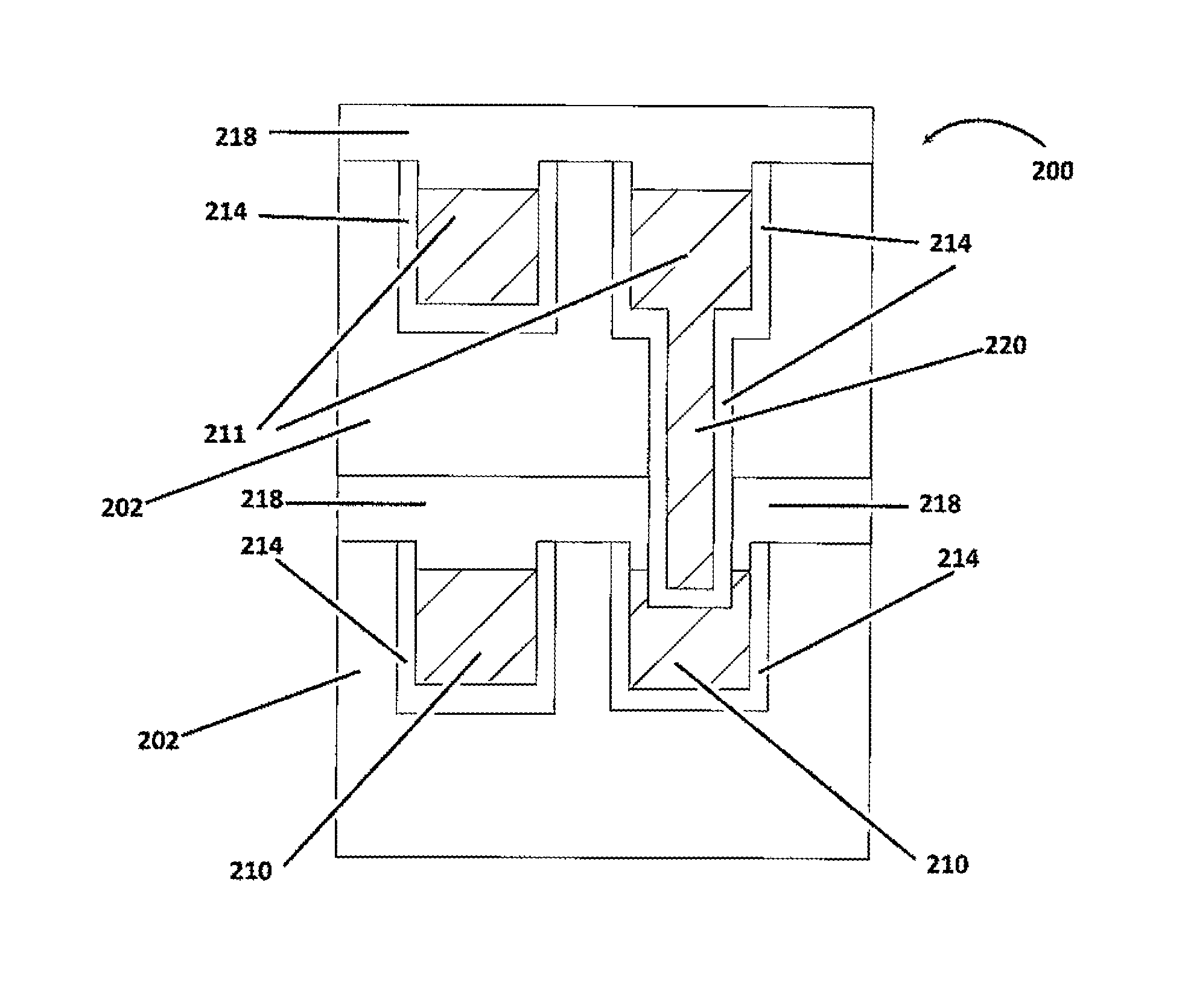

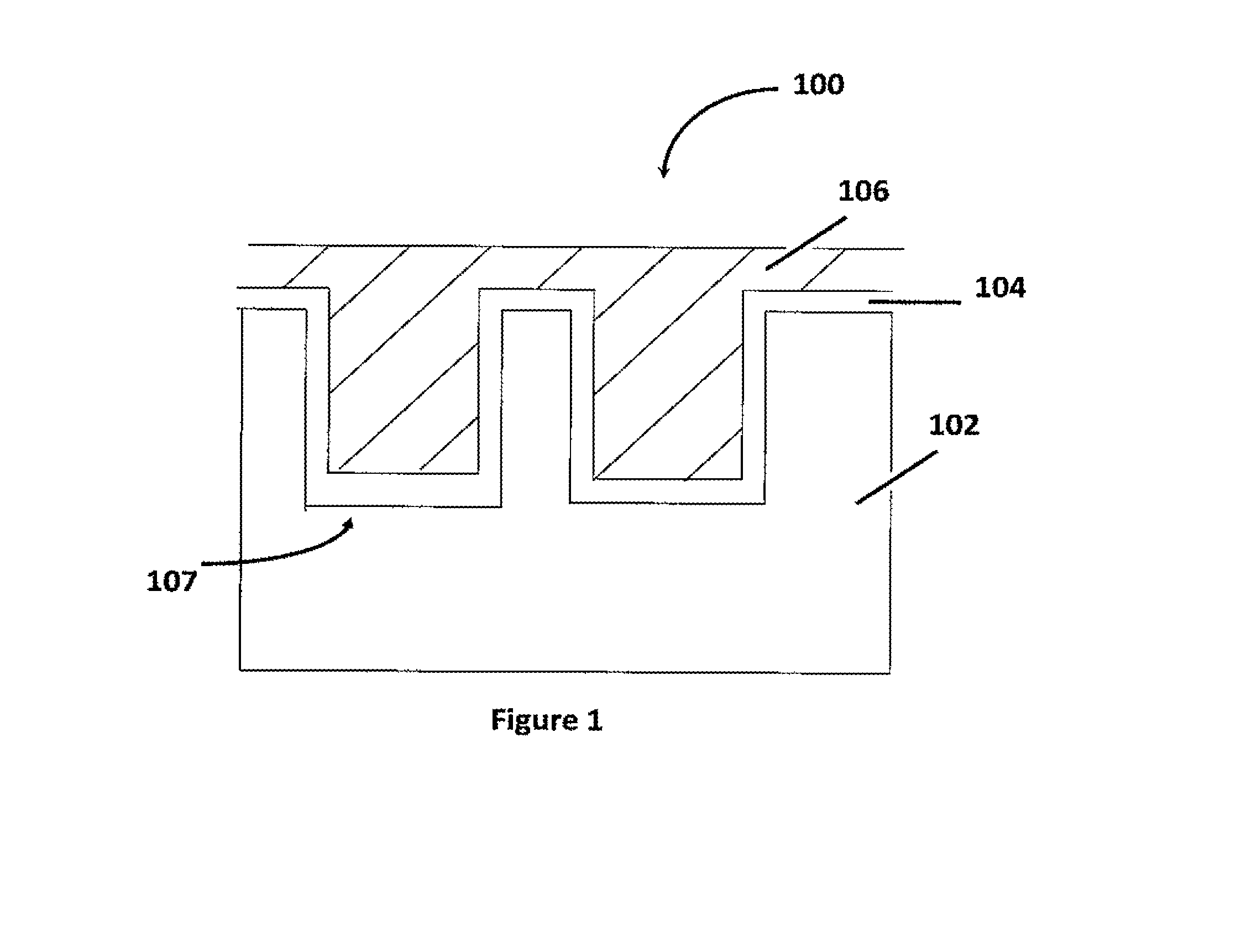

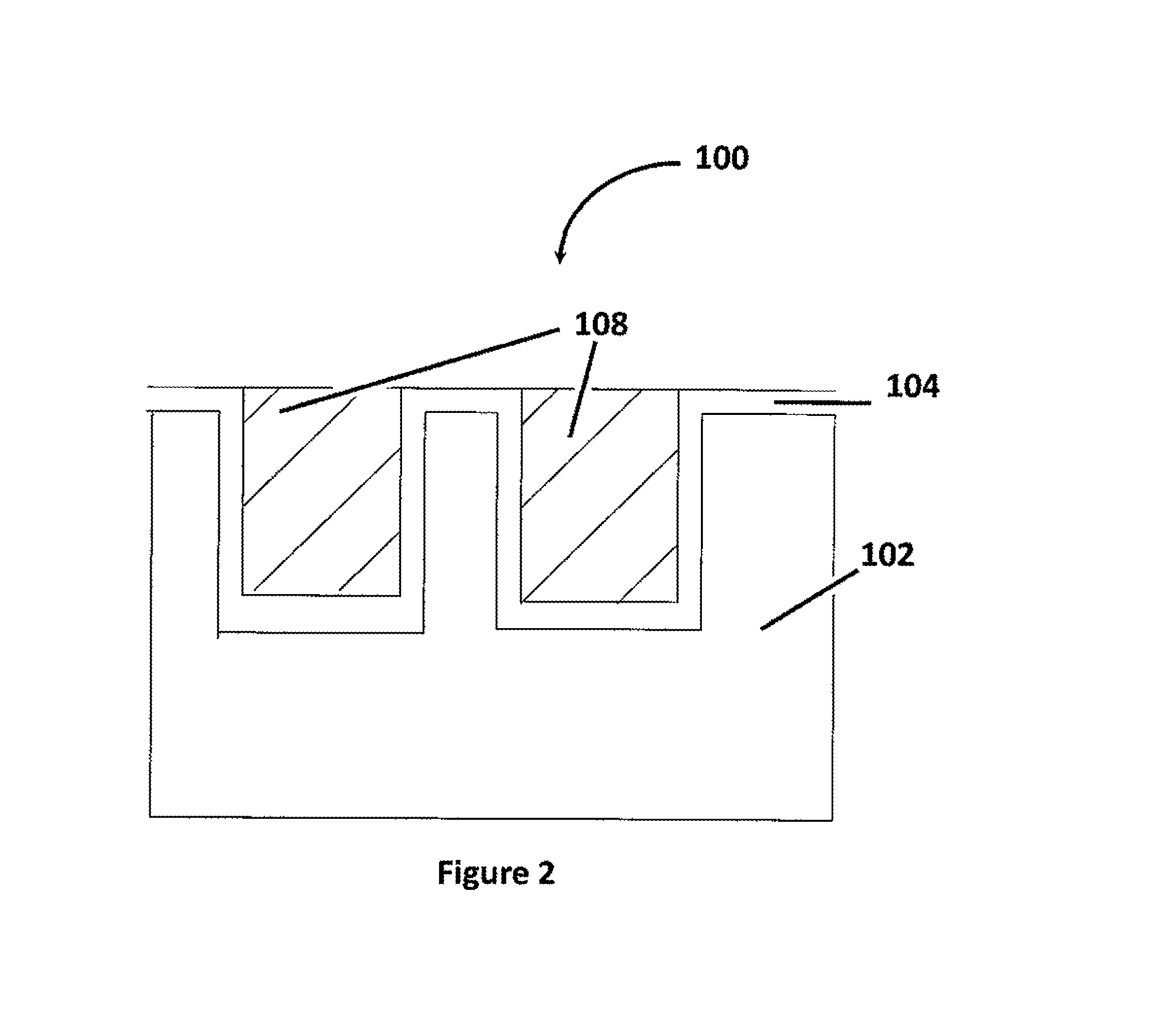

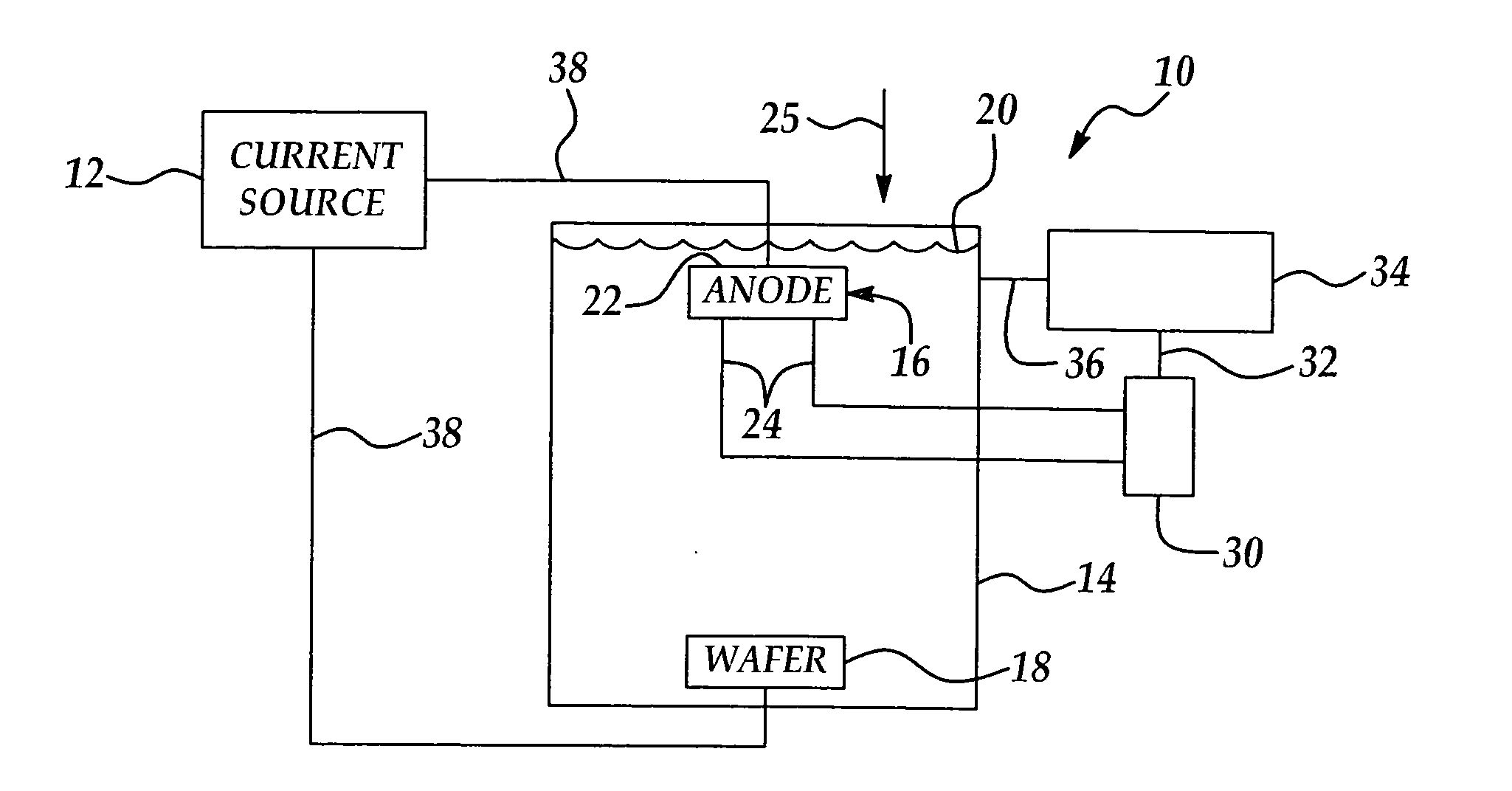

BEOL integration scheme for copper CMP to prevent dendrite formation

ActiveUS20140065815A1Eliminate exposureAvoid formingSemiconductor/solid-state device manufacturingElectroless depositionDendrite

Disclosed herein are various methods of forming copper-based conductive structures on integrated circuit devices by performing a copper deposition process to fill the trench or via with copper, which can be performed by fill, plating or electroless deposition. Copper clearing of copper overburden is performed using CMP to stop on an existing liner. Copper in the trenches or vias is recessed by controlled etch. An Nblok cap layer is deposited to cap the trenches or vias so that copper is not exposed to ILD. Nblok overburden and adjacent liner is then removed by CMP. Nblok cap layer is then deposited. The proposed approach is an alternative CMP integration scheme that will eliminate the exposure of copper to ILD during CMP, will prevent any dendrite formation, can be used for all metal layers in BEOL stack, and can be utilized for multiple layers, as necessary, whenever copper CMP is desired.

Owner:GLOBALFOUNDRIES US INC

Method to minimize brine contamination and/or gas migration during in situ trona solution mining

InactiveUS20160356118A1Minimizing brine contaminationMinimize contaminationFluid removalSealing/packingOverburdenSaline water

A method for in situ solution mining of trona in which an aqueous solvent dissolves trona and forms a brine, which comprises: applying a hydraulic pressure greater than the overburden pressure at an interface between trona roof and overburden to lithologically displace the overburden from the trona roof and form a gap; flowing a liquid settable and / or sealing composition into such interface gap and allowing such composition to solidify inside such gap to form a water-impermeable and optionally gas-impermeable barrier inside. This technique should limit contamination from the overburden; should seal or plug fractures transversing the trona roof; should prevent water infiltration from overburden; and / or should minimize gas migration into the overburden from the cavity. The lithological displacement whereby the interface gap is formed may be carried out at the same time as the composition is flowed inside the gap being formed.

Owner:SOLVAY SA

Covering layer forming method of blind ore bodies

The invention discloses a covering layer forming method of blind ore bodies with stable and massive roof surrounding rocks applying a bottom pillar-free subsection collapse method. The method can obviously reduce the work quantity of caving, has low caving cost and a little ore dilution, and improves the production efficiency and economic benefit of mines. The key points of the technical scheme are as follows: a first subsection mining tunnel is distributed in an ore body, and continuous gobs provided after the first subsection mining are used for inducing the roof rocks to collapse; and with the performing of the mining work, the areas of the gobs are expanded continuously, when the areas of the gobs reach the critical exposed area, the roof rocks at the gobs are unstable gradually and collapsed under the effects of stress and gravity so as to form a covering layer. When the first subsection mining tunnel distributes blast holes, the ore bodies among the access roads are required to be thoroughly collapse so as to cut off the support of the roof surrounding rocks completely and form continuous gobs with exposed area. The forming method is applicable to forming the covering layer of more stable and massive blind ore bodies of the roof surrounding rocks.

Owner:KUNMING UNIV OF SCI & TECH

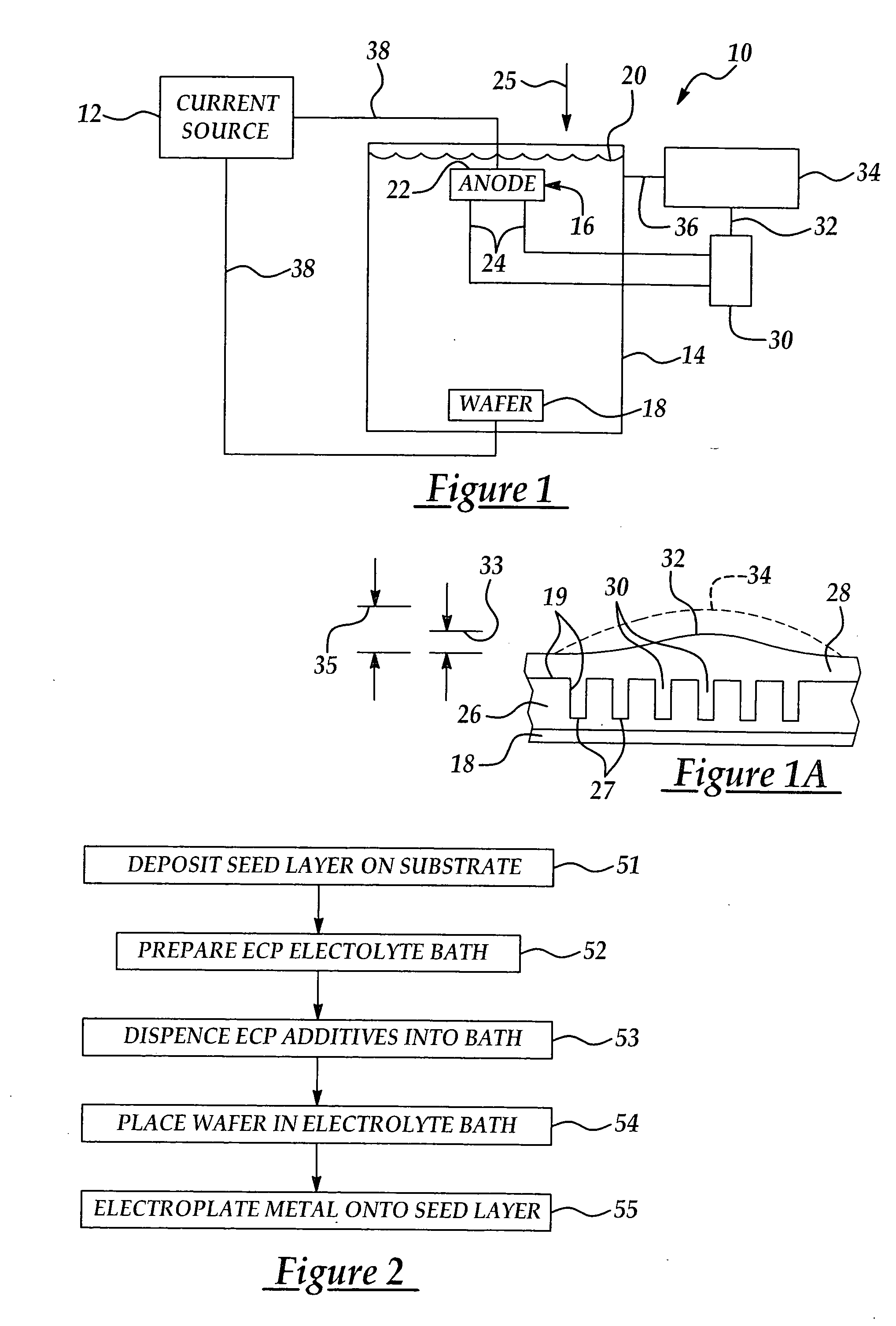

ECP polymer additives and method for reducing overburden and defects

InactiveUS20050189233A1Reduces overburdenExcellent gap fillingSemiconductor/solid-state device manufacturingOverburdenBenzene

Electrochemical plating polymer additives and method which reduces metal overburden in an electroplated metal while optimizing gap fill capability are disclosed. The polymer additives are provided in an electrochemical plating bath solution and may include low cationic charge density co-polymers having aromatic and amine functional group monomers. The low cationic charge density polymers may include benzene or pyrollidone functional group monomers and imidazole or imidazole derivative functional group monomers.

Owner:TAIWAN SEMICON MFG CO LTD

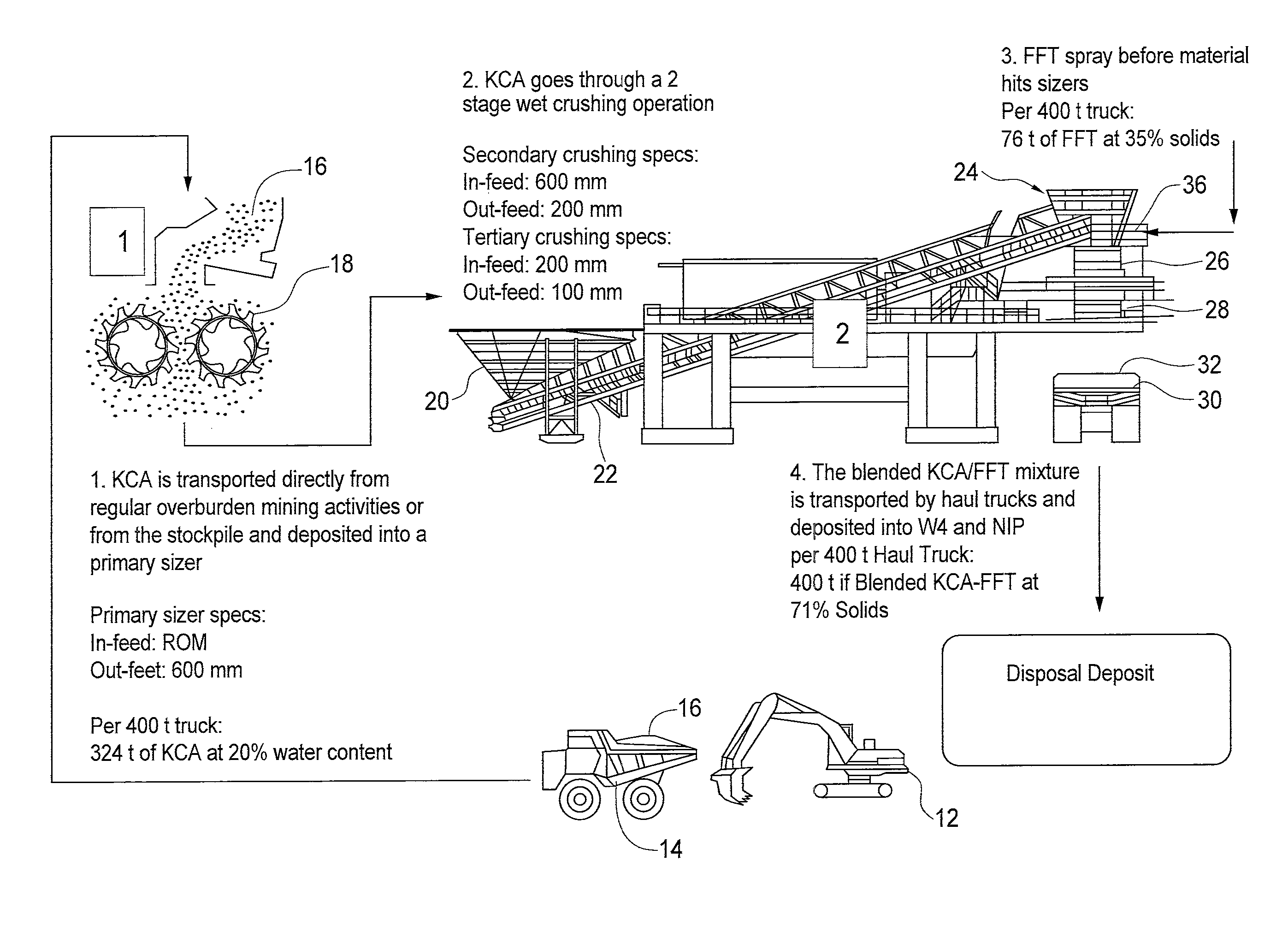

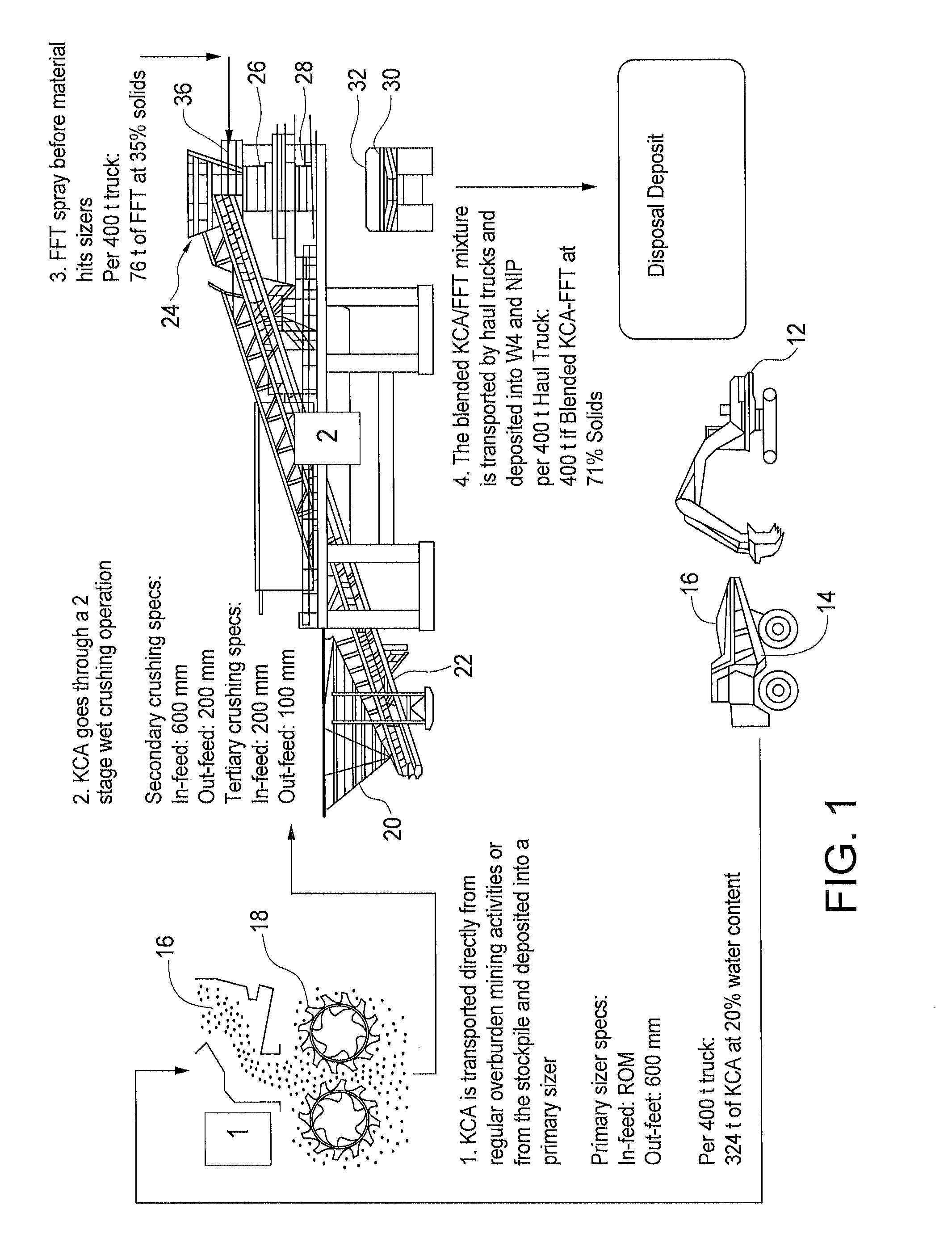

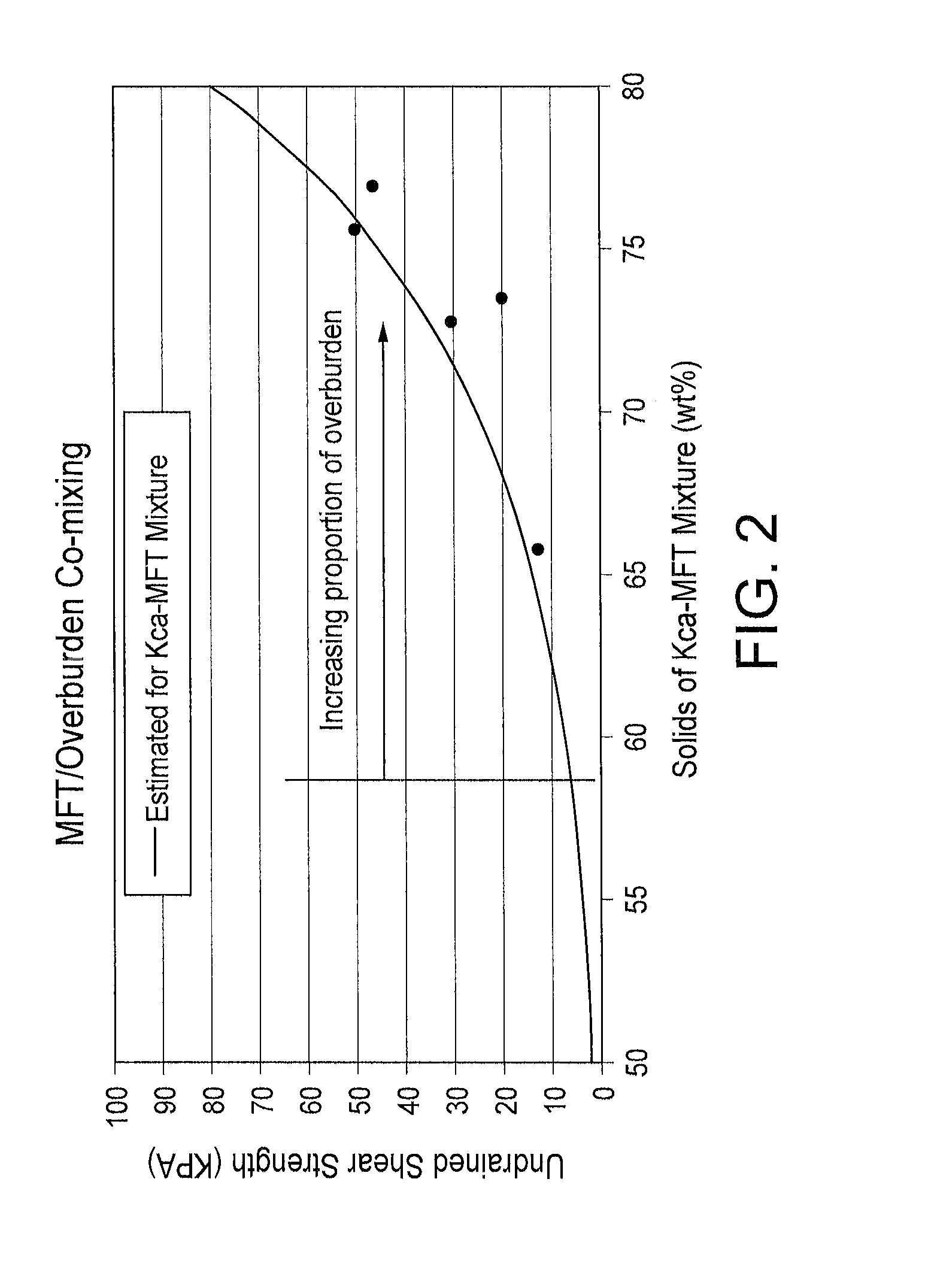

Overburden/tailings mixtures for engineered tailings deposit control

InactiveUS20140119832A1Increases undrained shear strengthImprove plasticitySolid waste disposalContaminated soil reclamationOverburdenMedicine

A process of dewatering tailings is provided comprising providing overburden having a moisture content ranging from about 15 wt % to about 25 wt % and comminuting the overburden to a first size; providing tailings having a solids content ranging from about 10 wt % to about 60 wt %; adding the tailings to the first sized overburden to form treated overburden and comminuting the treated overburden to a second size; and depositing the second sized treated overburden to produce a solidified deposit.

Owner:SYNCRUDE CANADA LTD

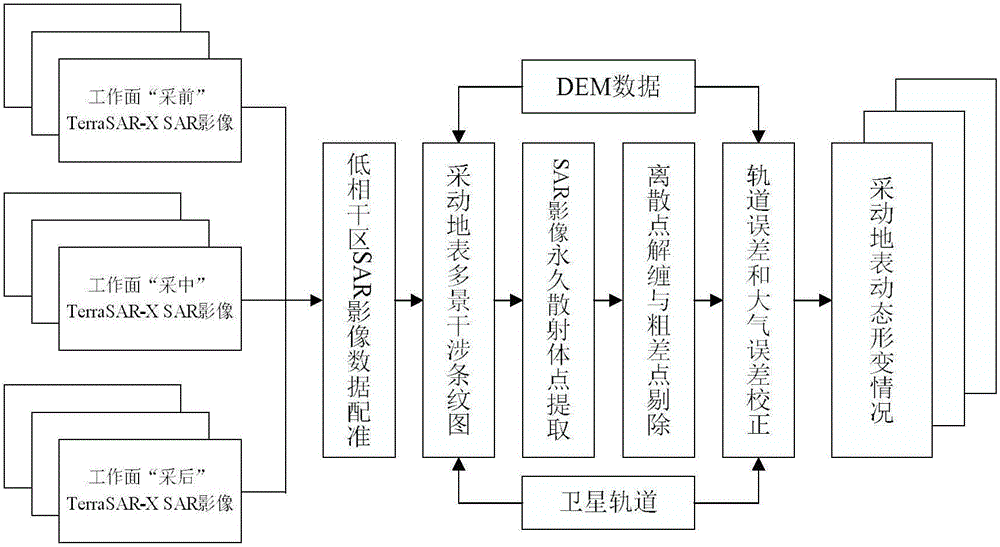

Method for detecting dynamic activity rule of overburden of western shallow coal seam during mining

ActiveCN105929462AImprove extraction accuracyOvercoming qualityGeological measurementsOverburdenCoherence condition

The invention discloses a method for detecting a dynamic activity rule of the overburden of a western shallow coal seam during mining, and the method comprises the steps: selecting a typical working face side of a western mine, and mastering the specific mining parameters of a working face; processing the earth surface radar satellite SAR image data of the whole mining process of the working face through employing a D-InSAR image high-precision registering algorithm under a low coherence condition, and obtaining the earth surface deformation condition of the working space in the mining process; detecting the dynamic developmental situation of mining-induced fractures in the underground working face overburden with radon; analyzing the dynamic coupling relation among the specific mining parameters of the working face, the mining earth surface deformation and the mining fracture development, wherein the dynamic coupling relation represents the dynamic activity rule of the overburden of the western shallow coal seam during mining. The method introduces a satellite remote sensing method and a radioactivity measurement method to the field of underground coal mining, and can reveal the dynamic activity characteristics of the overburden of the western shallow coal seam accurately, quickly and effectively during mining.

Owner:CHINA UNIV OF MINING & TECH

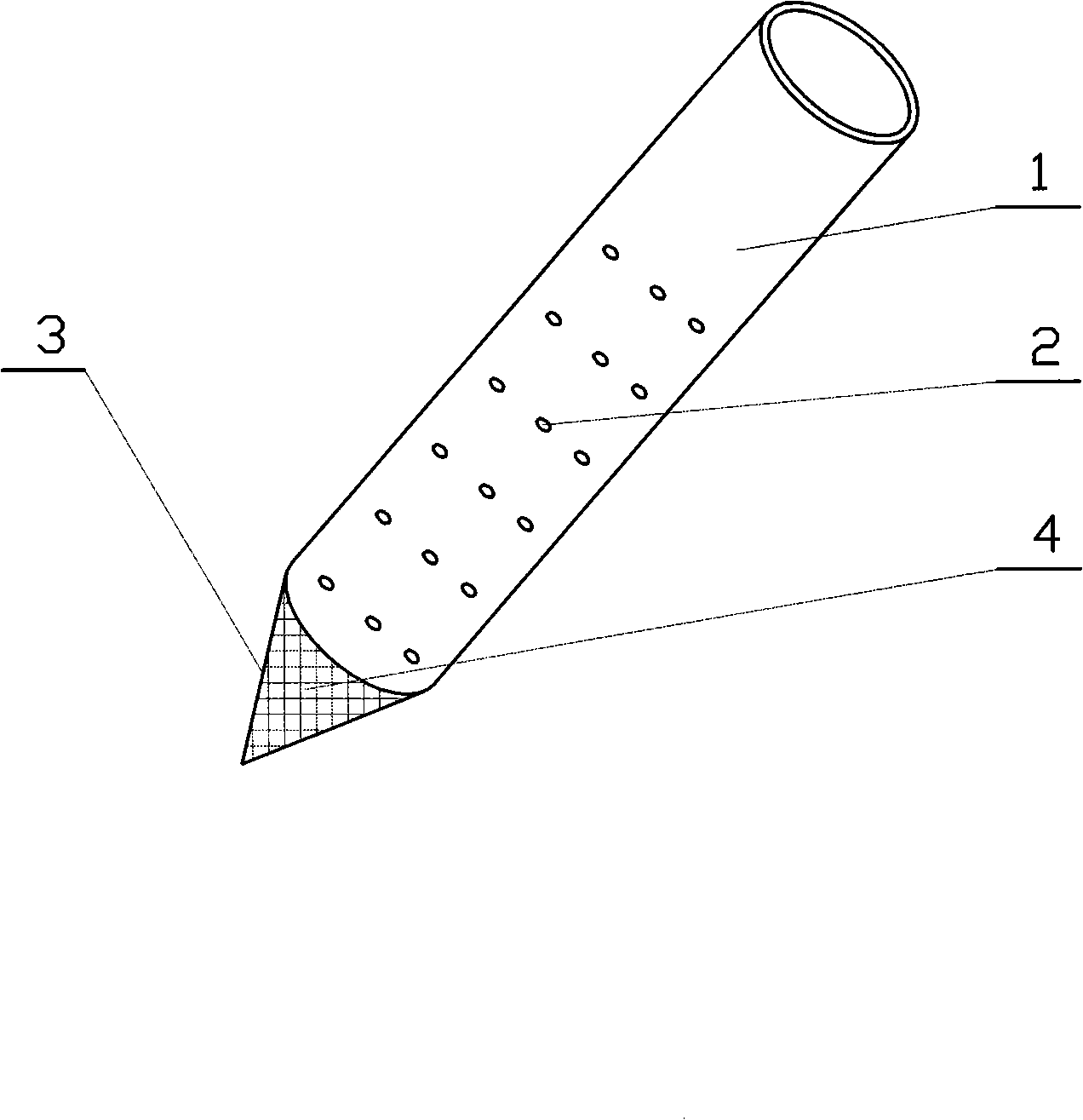

Short tube and short tube sand consolidation agent strengthening construction process

InactiveCN101358529AReduce pollutionSurrounding rock reinforcement effect is goodUnderground chambersTunnel liningYarnOverburden

The invention relates to a short canal and a short canal sand consolidation agent reinforcing construction technique. The short canal includes a steel pipe; the body of the steel pipe is provided with a plurality of holes; one end of the steel pipe is provided with a pyrometric cone; the cone part is provided with a cotton yarn. The short canal sand consolidation agent reinforcing construction technique includes inserting and beating the short canal as well as locating the short canal; grouting and closing a tunnel face; grouting construction on the tunnel face. The technique solves the problem of large pollution to the underground water and not good rock surrounding and reinforcing effects during the consturction process and has the characteristics of less pollutoin to the underground water, good rock surrounding and reinforcing effects, being not restrained by time, being simply and easily operated, low cost, high safety factor, and the like. The short canal and a short canal sand consolidation agent reinforcing construction technique can be broadly applied to the tunnel construction of underground cutting with shallow overburden of a water-enriched sandy stratum.

Owner:THE FIFTH ENG CO LTD OF CHINA TIESIJU CIVIL ENG GRP

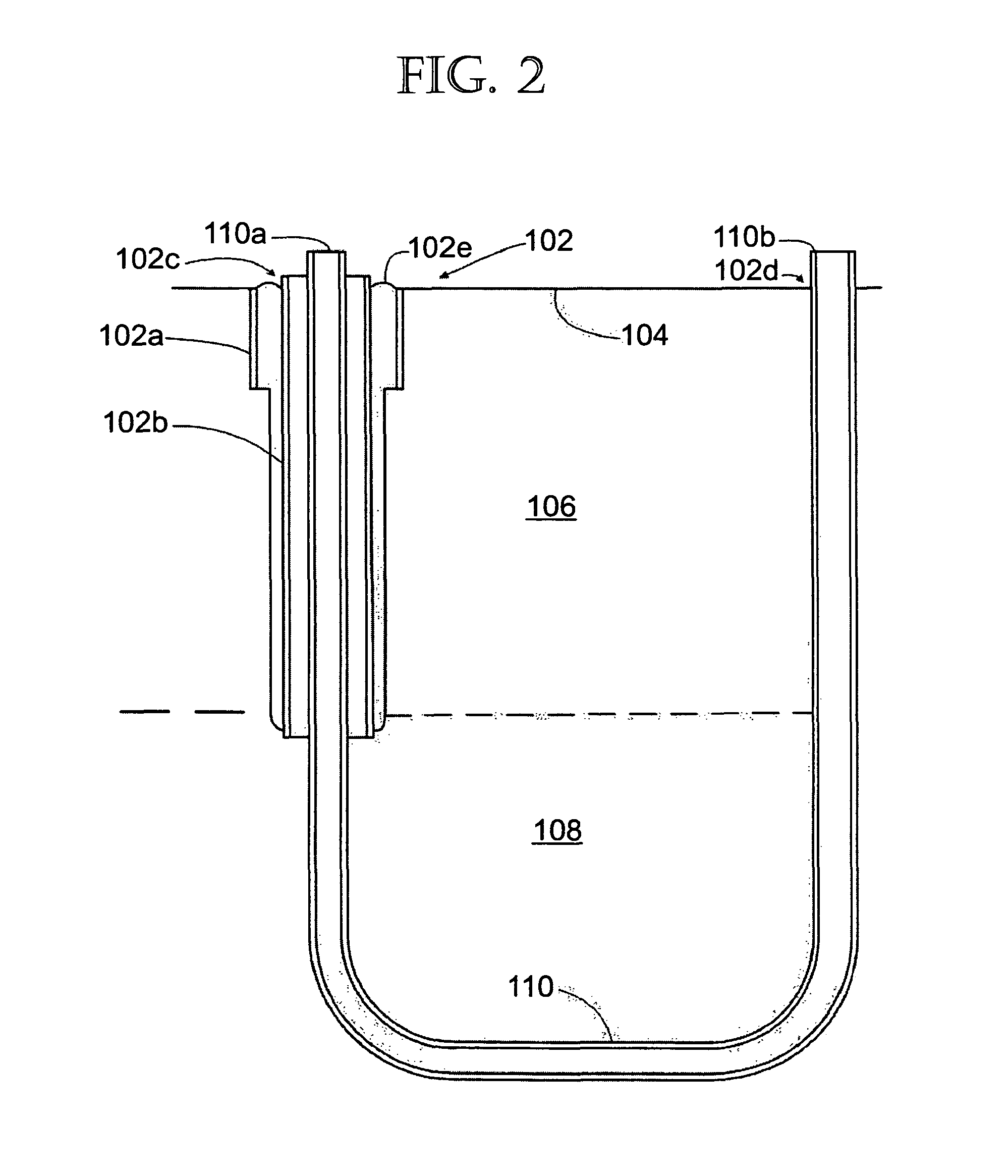

Heat exchanger

InactiveCN101033926AReduce consumptionReduce manufacturing costEvaporators/condensersTubular elementsState of artOverburden

The invention discloses a kind of heat exchanger which some U shaped pipes possessing two parallel straight pipe and includes some fin array disposed at certain distance along the vertical direction of the straight pipe. U shaped pipes connect each other with elbow and other connecting pieces which are made of aluminium or A-alloy material, overburden of copper is set on the outside wall. Overburden can be also set on the inside wall of elbow or other connecting pieces. Compared with existing technology, the heat exchanger making use of elbow compounded by and aluminium reduces wastage of copper and debases manufacturing cost of heat exchanger; it has a good compatibility with fluids such as refrigerant and anti-friction material; the connecting joints is welded by same kinds of metal. It is simple to weld the craft and the quality is reliable.

Owner:HISENSE HOME APPLIANCES GRP CO LTD

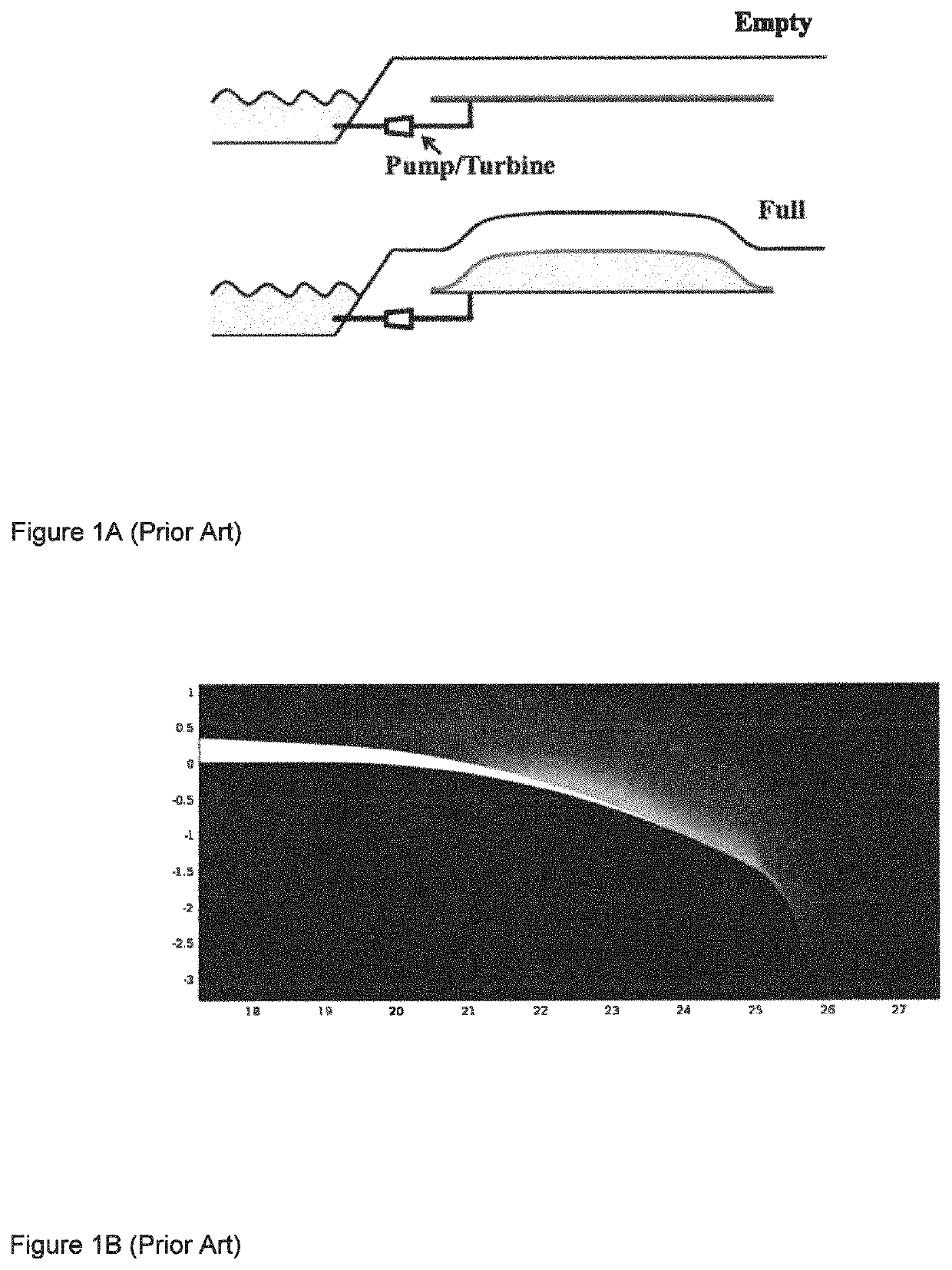

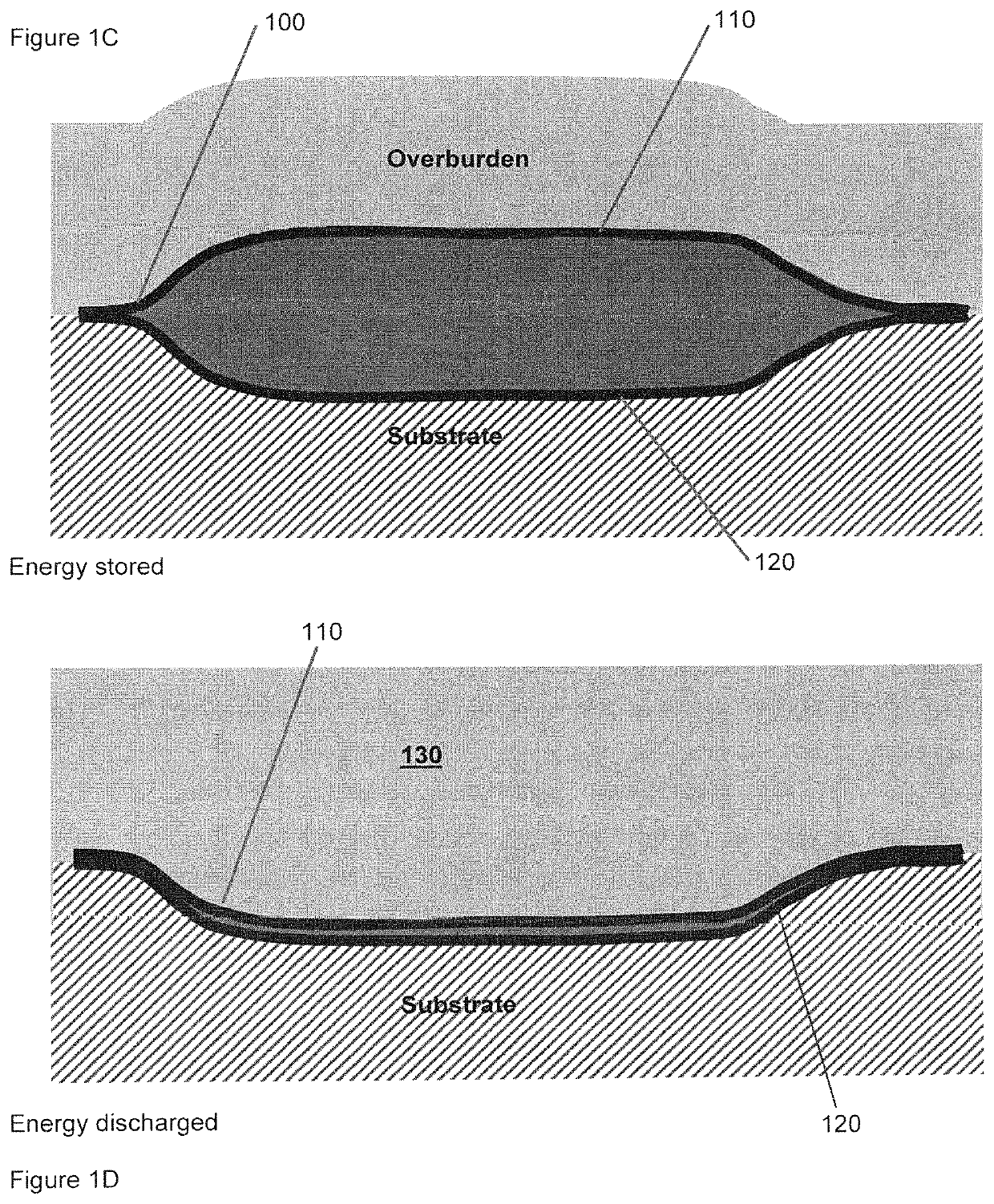

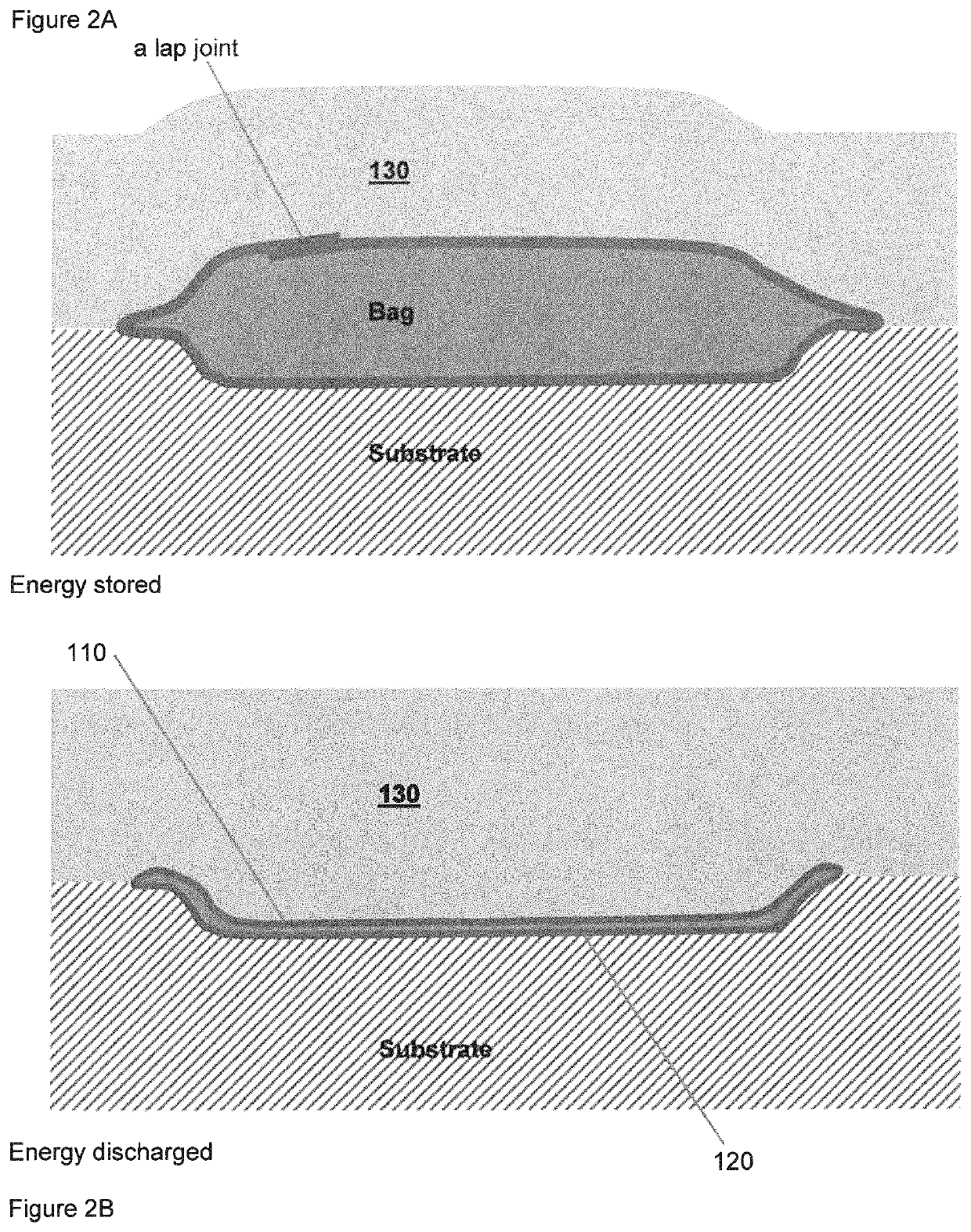

Pressurized pumped hydro storage system

ActiveUS10707802B1Raised and loweredPhotovoltaic supportsSolar heating energyWater storageOverburden

An energy or water storage system can comprise a storage reservoir, a discharge reservoir, a pump for charging the storage reservoir, and a turbine or similar discharge device. The storage reservoir can comprise a flexible bag covered by overburden that creates pressure inside the bag. Energy is stored by raising the overburden. The bag can comprise a shaped internal filler piece to prevent formation of a crease at the bag edge. Solar panels can be mounted above any bag to make additional use of the land. Solar panels mounted on overburden can have tracking mechanisms and controls suitable to achieve desired orientation regardless of the slope of overburden. Elevation difference between the storage reservoir and discharge reservoir can be used, including an underground cavity. The bag can have internal tethers to influence bag shape.

Owner:AQUAENERGY LLC

Softwall mining method and device

Slurryable ore where the overburden is unstable and subject to collapse is mined from substantially parallel elongated main trenches connected by a perpendicular trench at the bottom of the mineral seam. A plurality of softwall mining devices supported by face equipment is placed in the perpendicular trench. The devices slurry the mineral material and move into the mineral seam as the overburden sloughs behind the mining devices. The subsided overburden is supplemented as necessary with injected material. Slurried mineral flows to the parallel trenches for removal to the surface. After the softwall devices have advanced the length of the parallel trenches, the devices are withdrawn and placed in additionally developed trenches elsewhere in the ore reserve.

Owner:ROTHSCHILD KEITH R

Method for weakening main control coal and rock seam in situ by utilizing wastewater of overburden gob area

InactiveCN106150501AGood cracking effectReduce wasteUnderground miningTesting machinesOverburdenInstability

The invention provides a method for weakening a main control coal and rock seam in situ by utilizing wastewater of an overburden gob area. The method comprises the step of carrying out pre-splitting by utilizing slotting and vertical stage blasting and inducing the wastewater of the overburden gob area to enter the main control coal and rock seam, so as to prevent coal and rock instability and catastrophic phenomena including abnormal pressure of a stope support, water burst of a coal roof and the like. The method provided by the invention sufficiently utilizes coal mine wastewater which is deposited for many years in the overburden gob area; the wastewater of the gob area gradually seeps into a hard coal and rock seam needing to be softened; and control on the length of a hanging roof length of the main control coal and rock seam and prevention and management on stope disasters are realized, and the method has an obvious effect.

Owner:TAIYUAN UNIV OF TECH

On-line monitoring device and method of mining overburden stratum movement of shallow coal seam

The invention provides an on-line monitoring device and a method of mining overburden stratum movement of a shallow coal seam and belongs to the field of monitoring equipment for coal mines and metal mines. The shallow coal seam is buried shallowly, after the coal seam is mined, a stratum controlling the overburden stratum movement is just a key layer, and not all strata are required to be monitored, so that the device and the monitoring method can monitor multiple strata simultaneously movably. The device comprises a ladderlike compressor, pressure sensors, a converter and a data acquisition device. The ladderlike compressor is connected with the pressure sensors; an inner rod of the compressor moves down due to sinking movement of an overburden stratum; the pressure sensors generate signals and are connected with the converter; the converter converts pressure signals into data signals; and the data acquisition device is connected with the converter and acquires data converted by the converter. The device and the method realize real-time monitoring of the overburden stratum movement of the shallow coal seam through data acquisition, data transmission and data processing, and can visually show overburden stratum movement and deformation.

Owner:SHANDONG UNIV OF SCI & TECH

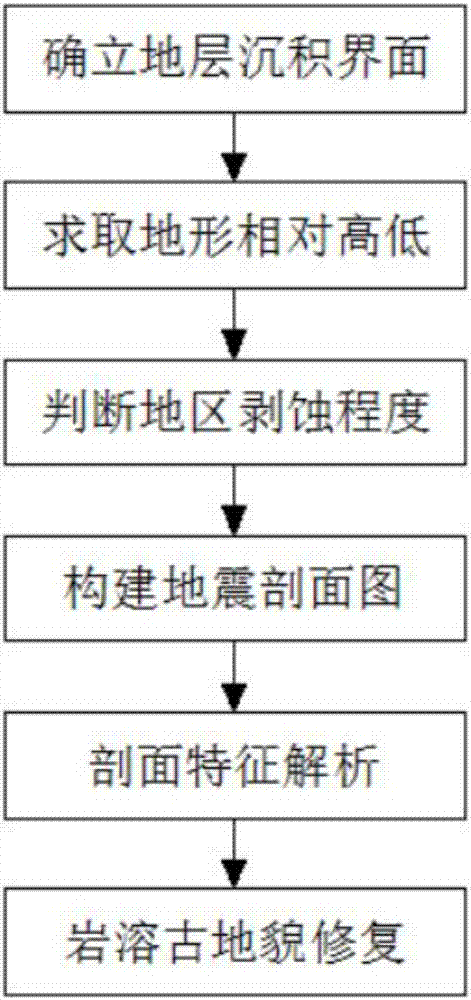

Method for finely recovering karst topography

PendingCN107167853AIntuitive and realistic image restorationRestoration work completeGeological measurementsTerrainOverburden

The invention discloses a method for finely restoring karst paleogeomorphology in the technical field of paleogeomorphology restoration. The specific steps of the method for finely restoring karst paleogeomorphology are as follows: S1: Find a relatively accurate representative paleosea in the overlying stratum of ancient weathering crust Plane stratigraphic depositional interface; S2: Obtain the relative height of the topography on the weathering crust through the stratum thickness between the depositional interface and the weathering crust; S3: Use the method of high-resolution sequence stratigraphy to calculate the relative height of the topography in step S2 S4: Construct the seismic profile; S5: Analyze the seismic profile features on the seismic profile, and restore the karst ancient landform. The restoration image of the karst ancient landform in the present invention is intuitive and realistic, with low cost and easy Realized that the restoration of ancient landforms is relatively complete, and at the same time, the impact of the later structure of the landforms is considered, and the restoration accuracy is high.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com