PHC pile and water flush gas lift static pressure pile-sinking method

A PHC pile, a new type of technology, is applied in the direction of sheet pile wall, building, foundation structure engineering, etc. It can solve the problems of large pile sinking resistance, static pressure PHC piles cannot pass, and unfavorable environmental protection, so as to reduce pile sinking resistance, construction period and Excellent environmental protection, easy to operate and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In the first step, the soft soil layer on the ground surface is driven into the soil by static pressure. Static pressure is used until the pile pressure does not sink with the maximum pile pressure. At this time, the pile tip sinks to the top surface of the sand or crushed pebble layer.

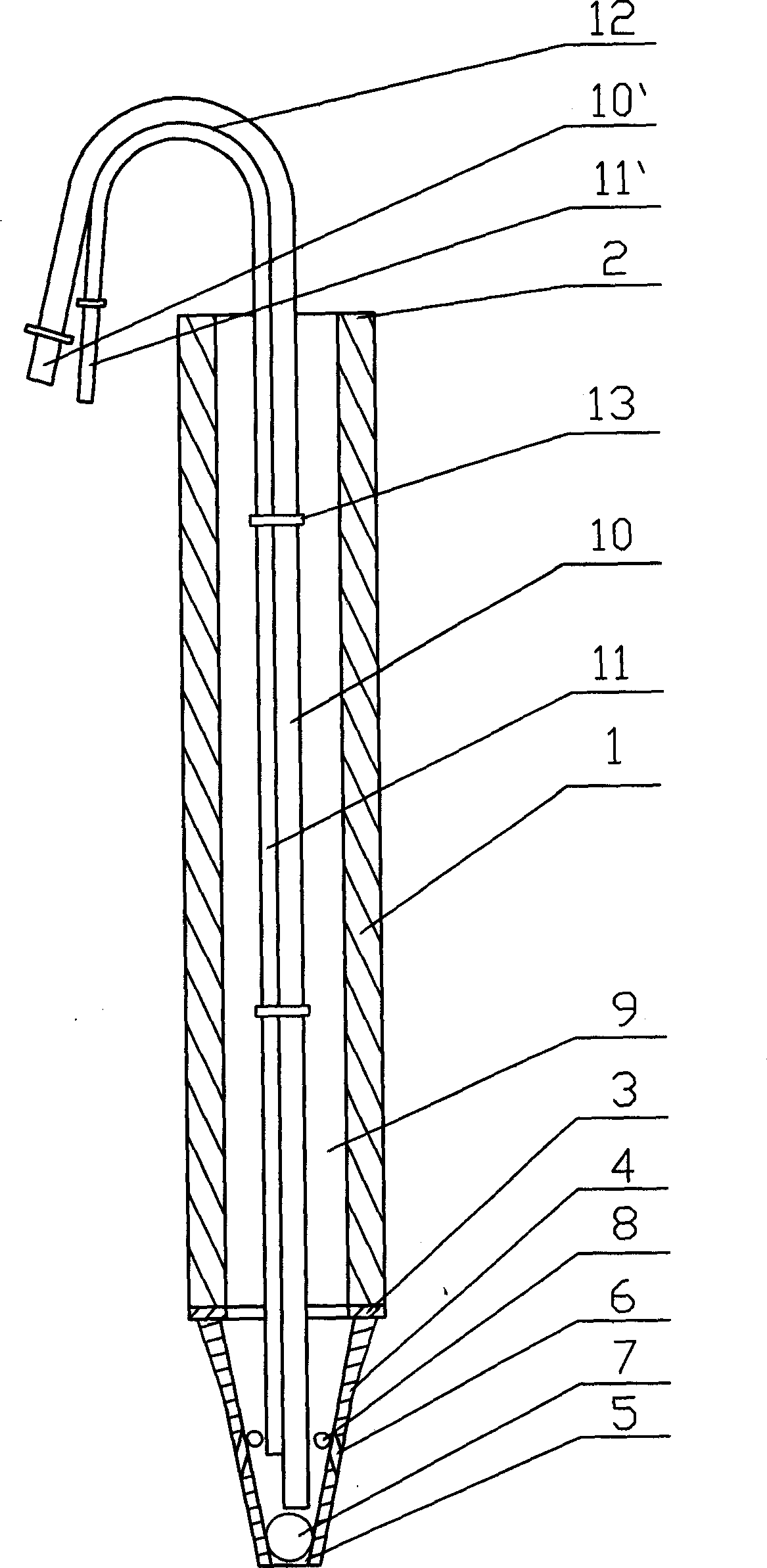

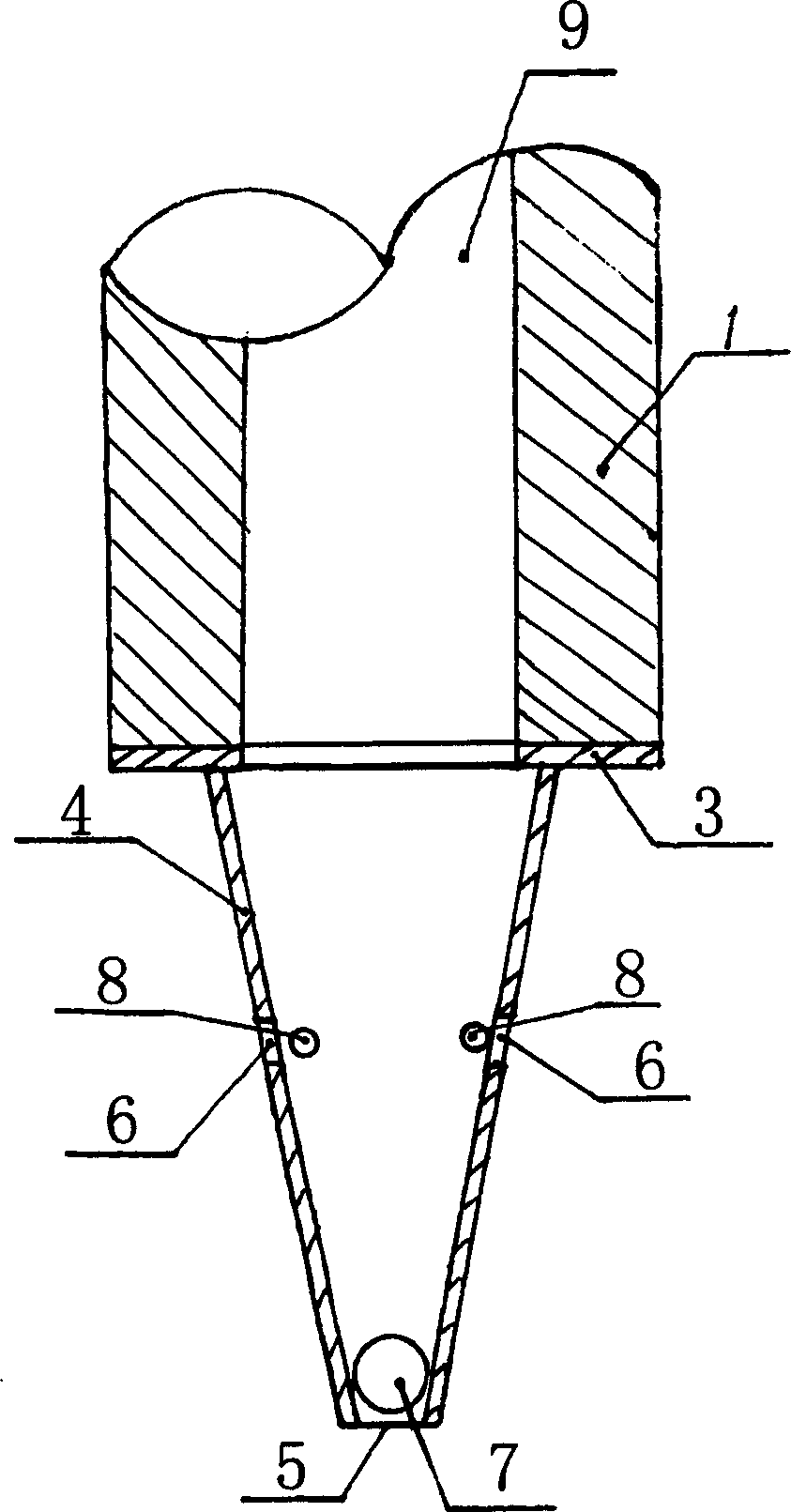

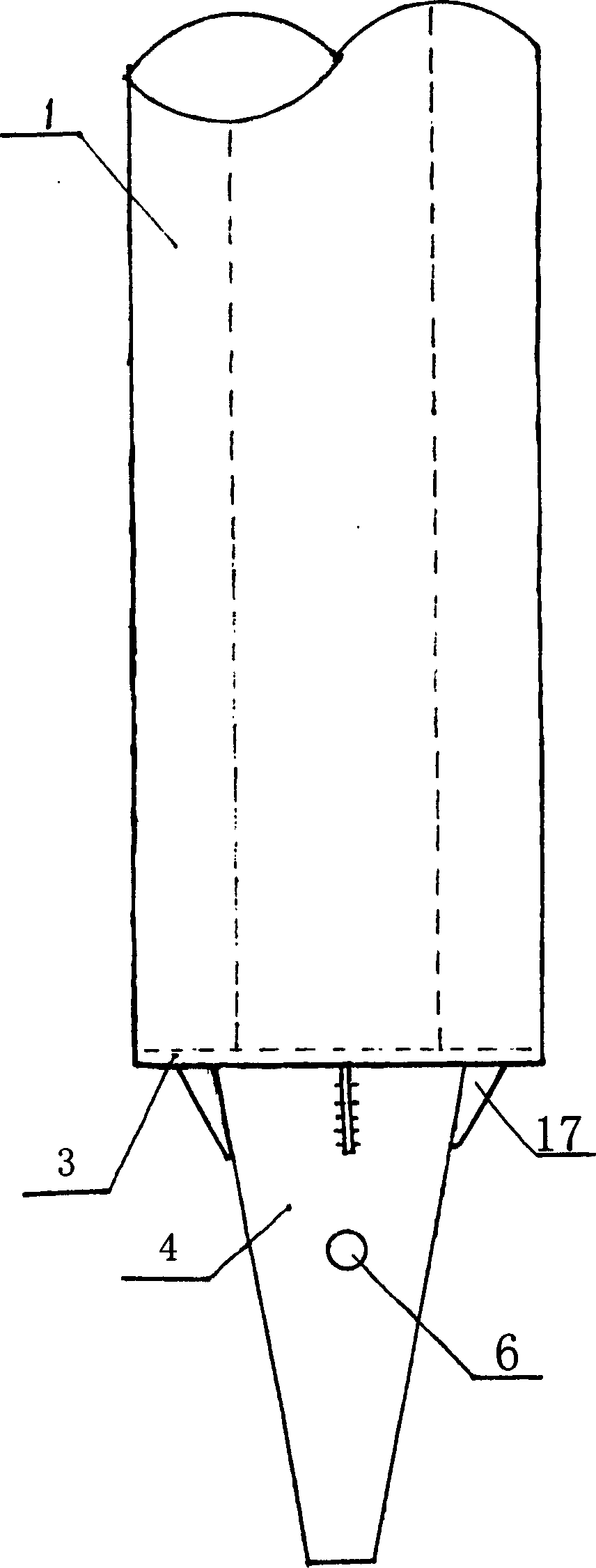

[0023] In the second step, when the pile tip sinks to the sand or gravel layer, insert a water-gas combination pipe from the pile top 2 to the hollow cavity 9, such as figure 1 shown. After the water-air combined pipe sinks to the pile tip, high-pressure water and compressed air are input to the water delivery hose and the air delivery hose respectively. ; The sand and gravel mixed water is discharged from the top of the pile along the hollow cavity of the pile from the bottom to the top by the gas lift method. After the sand and gravel are discharged with the water, the resistance of the pile is greatly reduced. The pile is sunk into a layer of sand and crushed pebbles. In this wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com