Isolated grouting-filling mining method for overburden rock without village migration under cut-side local pressed-coal conditions

A technology of isolated grouting and partial coal pressing, which is applied to filling materials, ground mining, mining equipment, etc., can solve the problems of large filling range, large filling volume, and increased filling cost, so as to reduce the cost of grouting filling and save consumption , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

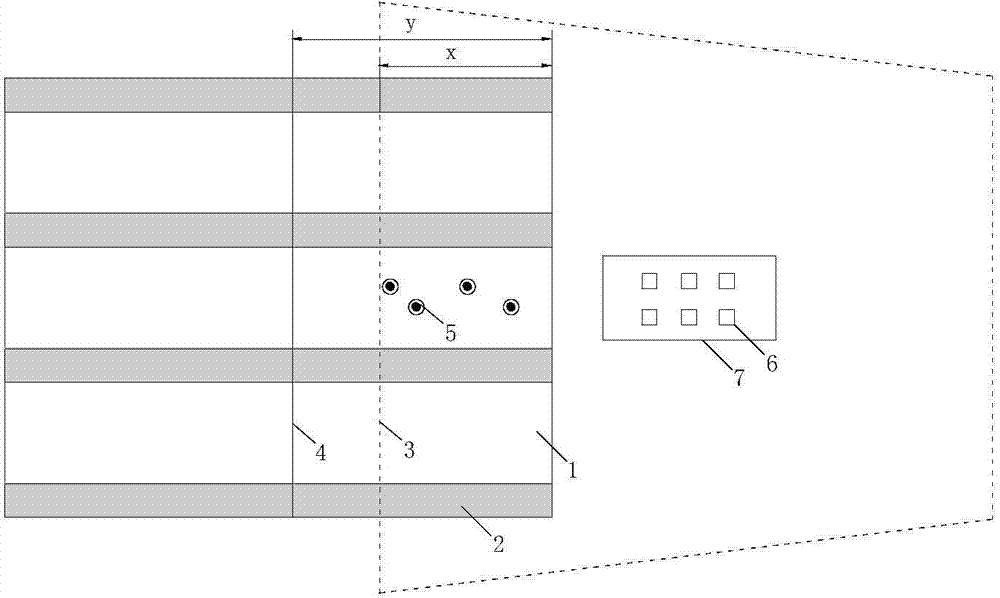

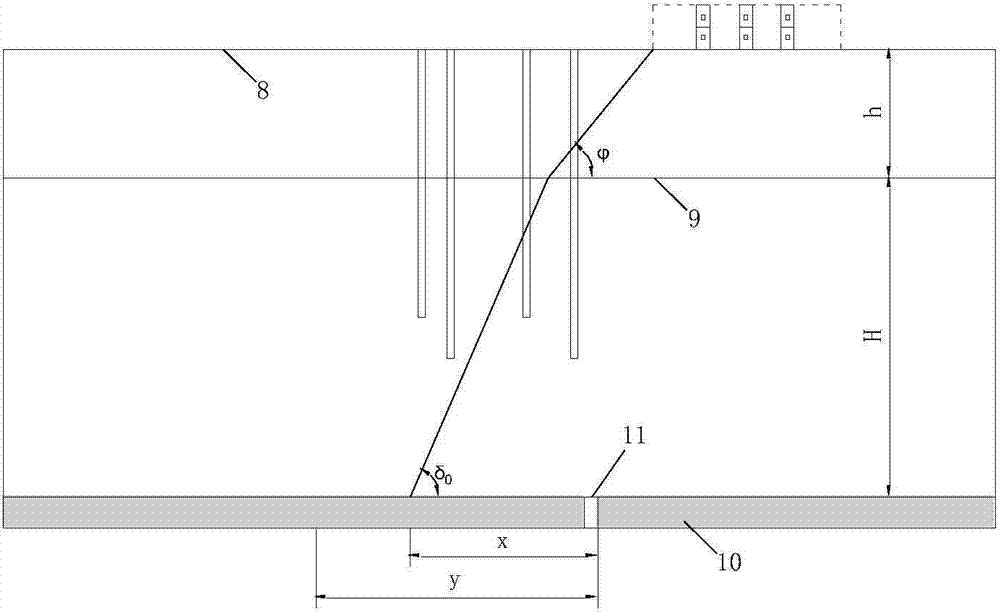

[0032] Embodiment 1, take the 36 mining areas of a certain mine as example, as figure 1 and figure 2 As shown, coal pressing distance x

[0033] 1. Divide the working face and leave isolated coal pillars, divide the 36 mining area into 3 working faces, respectively 364, 366, and 368 working faces, and leave 40m isolated coal pillars between the working faces;

[0034] 2. Calculate the distance between the boundary line of the building protection coal pillar along the direction of the coal mining face and the cut eye. The ground building in mining area 36 is a village, which is located 50m outside the cutting eye of the working face, and the width of the building enclosure is 10m. 0 They are 45° and 83.8° respectively. According to the vertical section method stipulated in China's "Buildings, Water Bodies, Railways, Railways and Main Shaft Coal Pillars and Coal Mining Regulations", the position of the protected coal pillar boundary line is calculated, ...

Embodiment 2

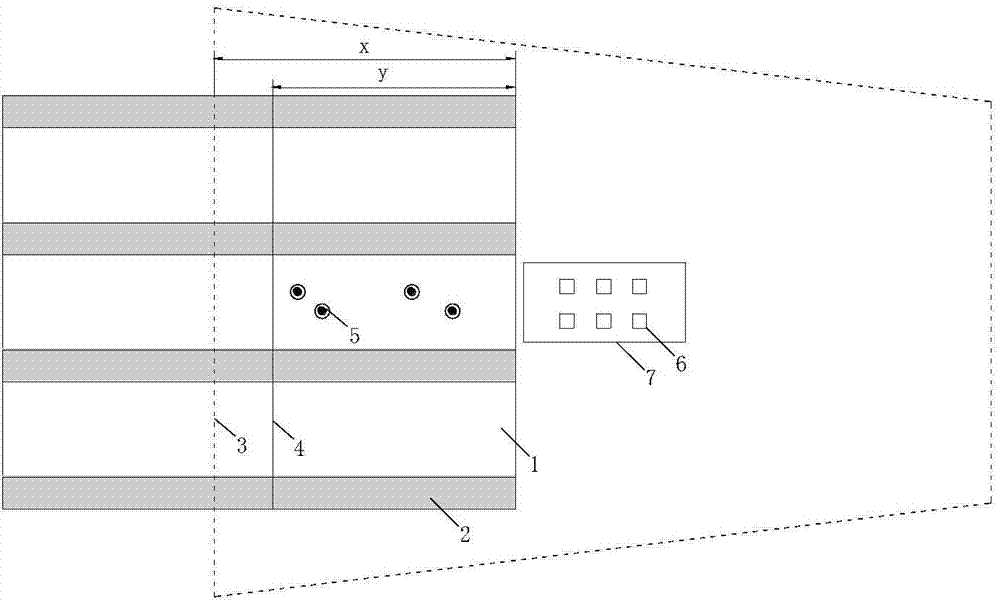

[0040] Embodiment 2, take the 76 mining areas of a certain coal mine as an example, as image 3 and Figure 4 As shown, coal pressing distance x>full mining distance y

[0041] 1. Divide the working face and set up isolated coal pillars. Divide mining area 76 into 3 working faces, namely 766, 764 and 762 working faces, and leave 40m isolated coal pillars between the working faces;

[0042] 2. Calculate the distance between the boundary line of the building protection coal pillar along the direction of the coal mining face and the cutting hole, that is, the coal pressing distance. The ground buildings in mining area 76 are villages, which are located 10m outside the cutting eye of the coal mining face, and the width of the building enclosure is 10m. 0 They are 45° and 74.9°, respectively. According to the vertical section method stipulated in China's "Buildings, Water Bodies, Railways, Railways, and Main Shafts and Roadway Coal Pillar Retention and Coal Mining Regulations", ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com