Patents

Literature

180results about How to "Improve coal mining efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

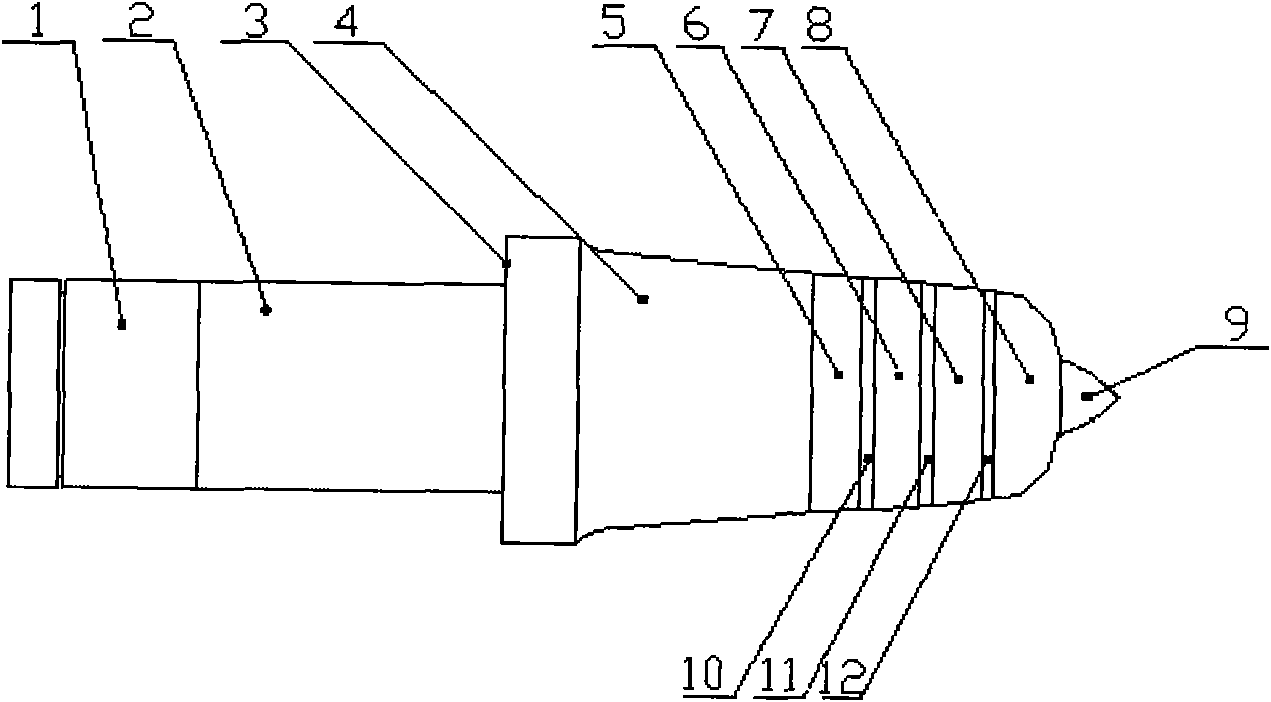

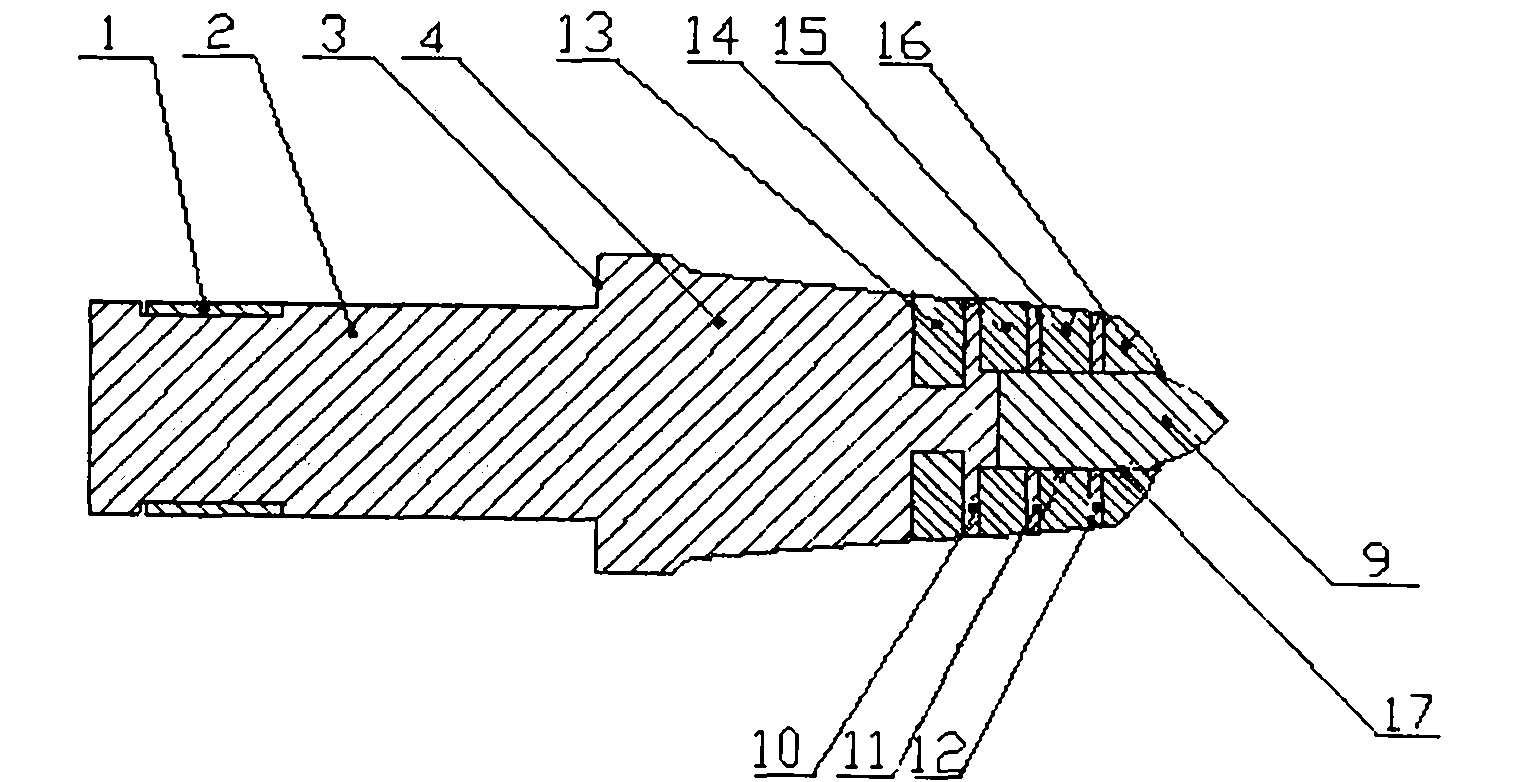

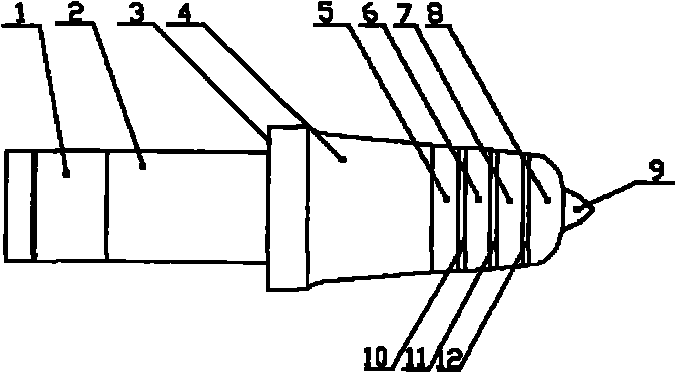

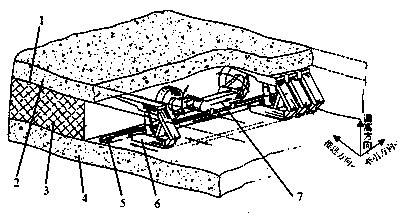

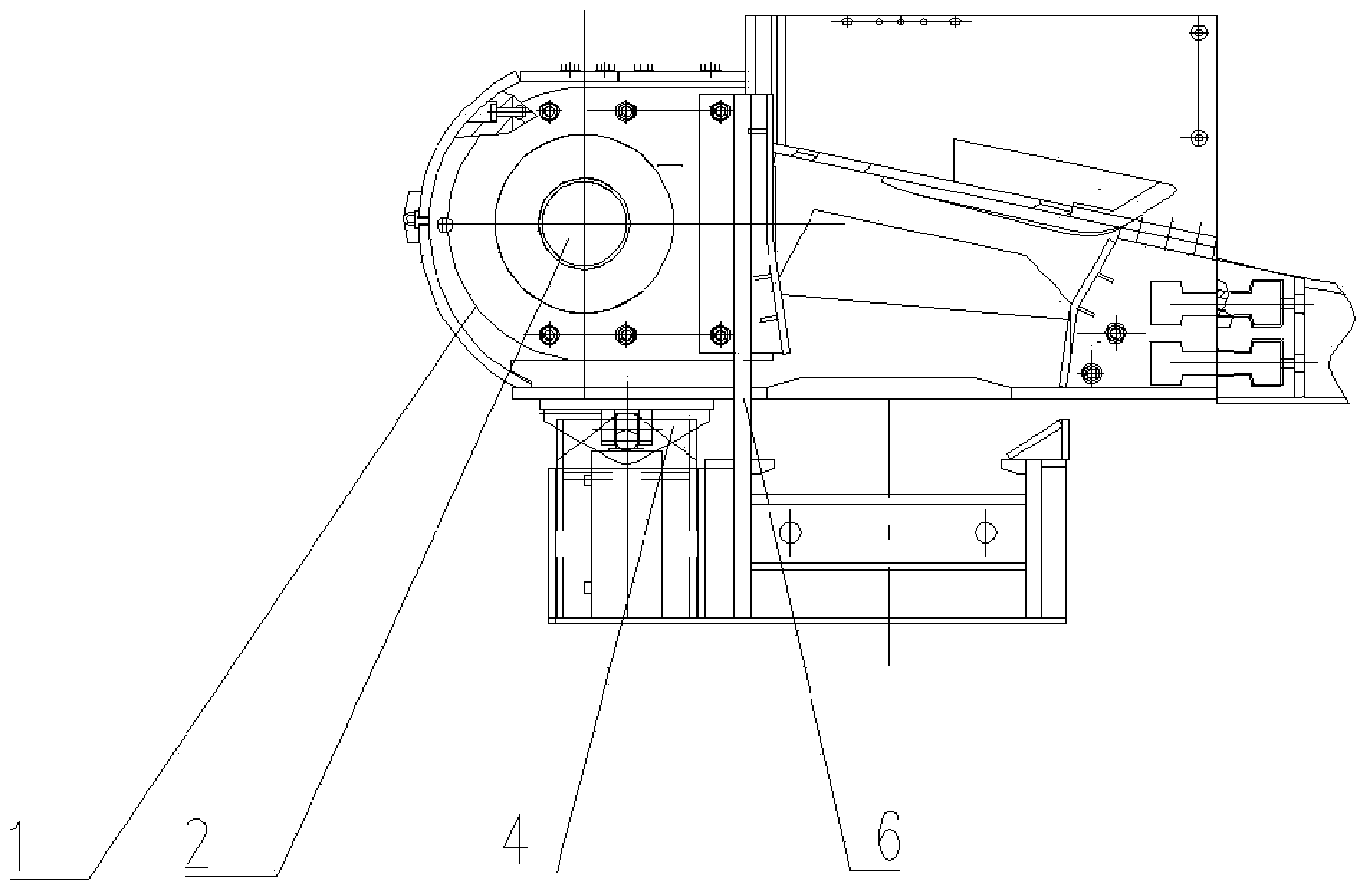

Coal mining method and coal mining apparatus implementing same

InactiveCN101725347AReduce lossImprove coal mining efficiencyDisloding machinesMining engineeringMechanical engineering

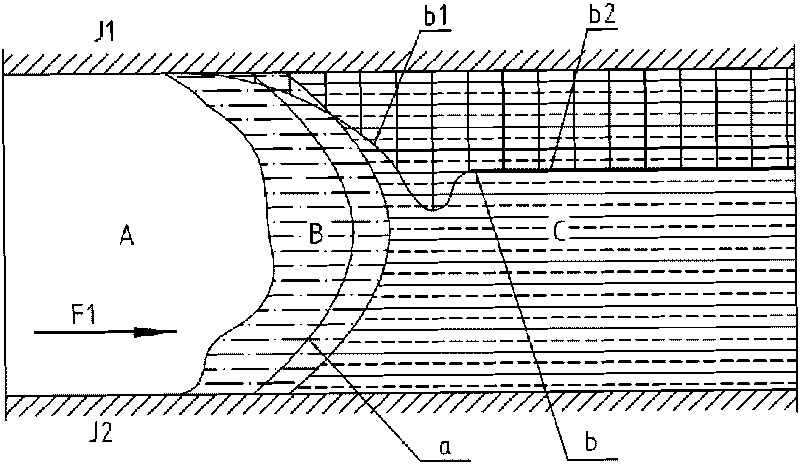

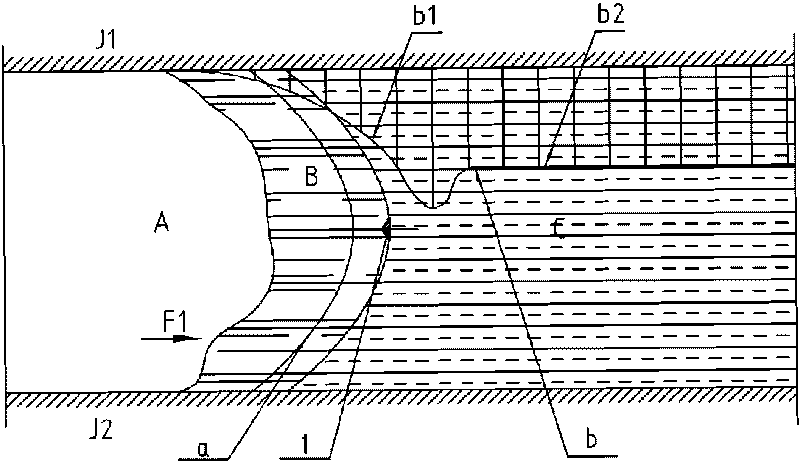

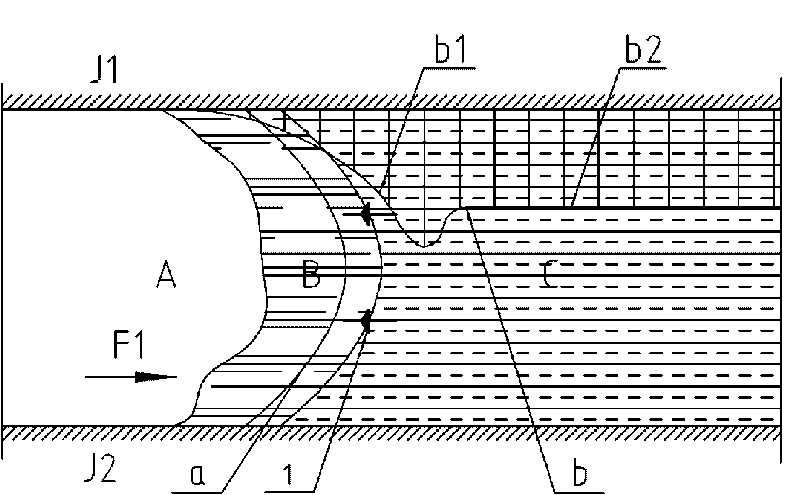

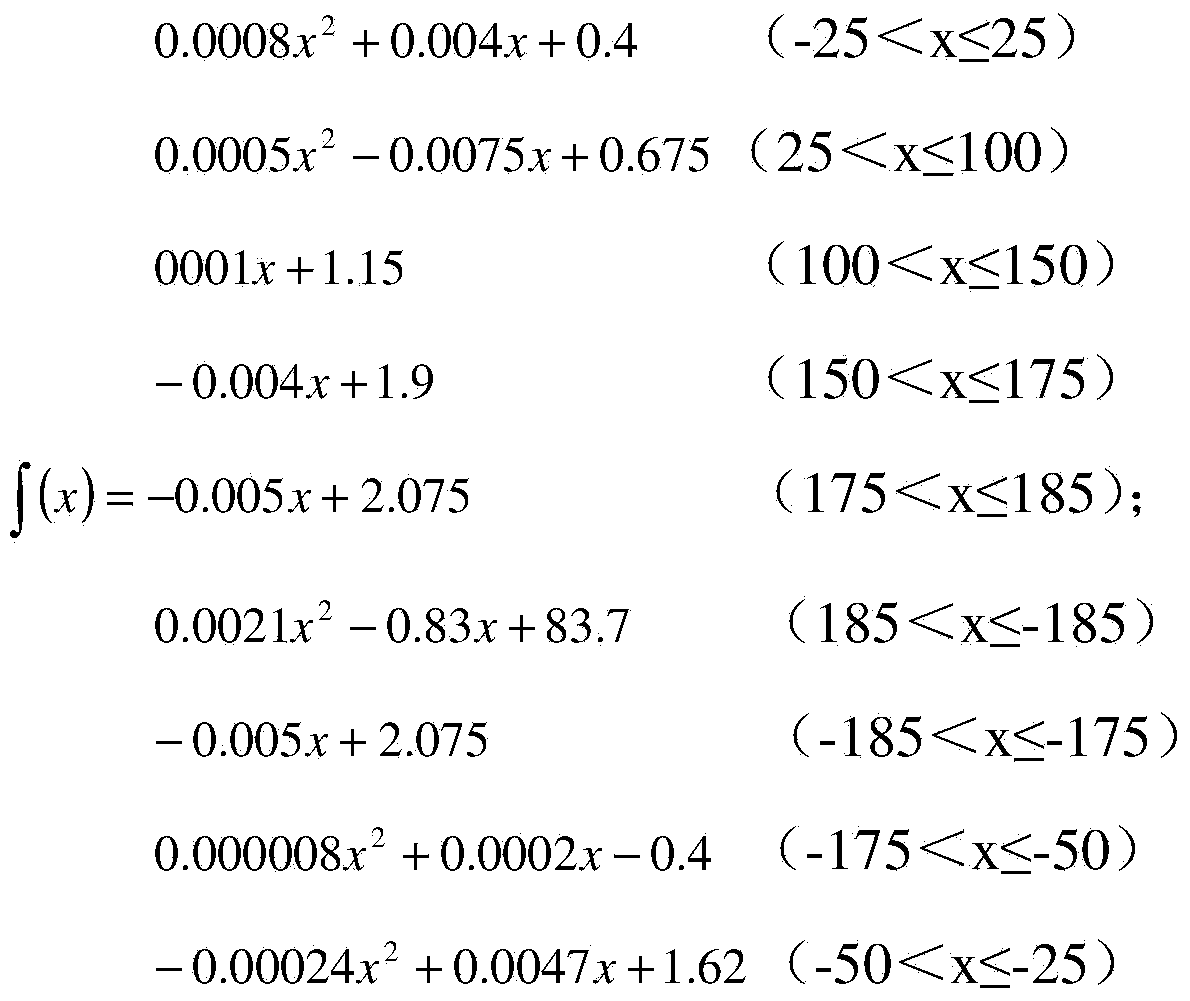

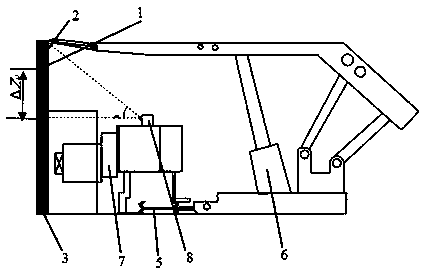

The invention relates to a coal mining method and a coal mining apparatus. The coal mining method comprises the following steps of: directly inserting a wedge-shaped body into a coal layer on the coal layer parallel to a goaf surface; continuously advancing the wedge-shaped body forwards; continuously cracking and collapsing coal bodies outside the wedge-shaped body and facing the direction of the goaf surface; continuously clearing a top plate, a bottom plate and dropped coals after the coal bodies are collapsed in the front; and continuously conveying the collapsed coal bodies and the cleared dropped coals by a conveyor to complete a continuous coal mining process. The apparatus implementing the coal mining method comprises a coal mining head and an auxiliary mechanism, wherein the coal mining head comprises the wedge-shaped body, a support and a plough-shaped plate; the wedge-shaped body and the plough-shaped plate are arranged on the support; the top plate and the bottom plate at the front end of the plough-shaped plate are respectively fixed with a top plate clearing mechanism and a bottom plate clearing mechanism; and the wedge-shaped body is arranged at the front end of the coal mining head. Compared with the prior art, the coal mining method and a coal mining apparatus have the advantages of high production efficiency, low energy loss and high block rate.

Owner:山东华智科技有限公司

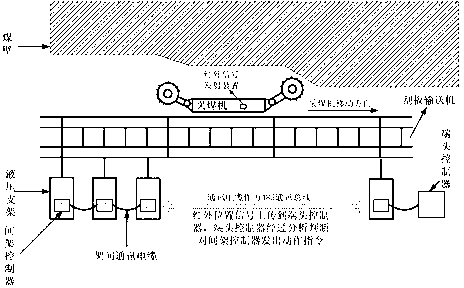

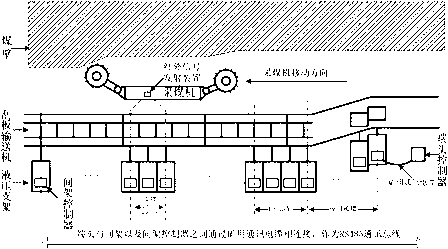

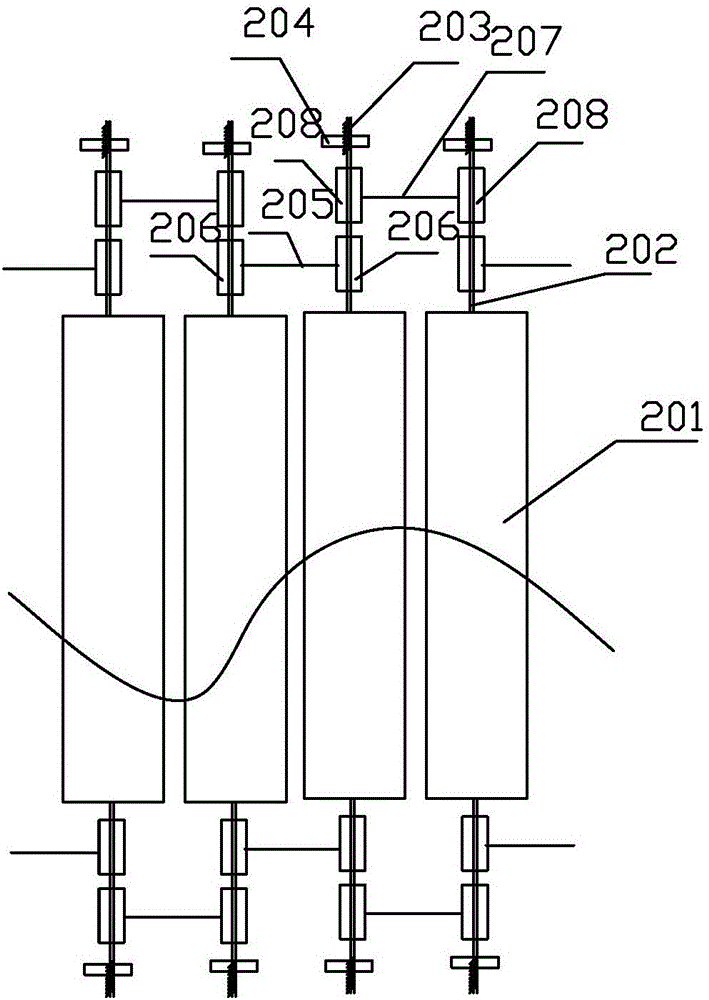

Adverse feedback conveying system for working face of underground coal mine

ActiveCN104358587APrevent pressure slipReduce wearMining devicesUnderground transportLow loadEngineering

The invention relates to an adverse feedback conveying system for a working face of an underground coal mine, and a control method of the system. The adverse feedback conveying system includes a coal cutter, a scraper conveyer, a transferring machine, a crusher and a belt conveyor, and is characterized by further including a control box respectively connected with the belt conveyor, the crusher, the transferring machine and the scraper conveyer, a coal quantity detection device mounted on the transferring machine, and a coal cutter positioning device, wherein the coal quantity detection device is connected with the control box, so as to provide transported coal information of the transferring machine; the coal cutter positioning device is connected with the control box, so as to provide position and forward direction information of the coal cutter relative to the scraper conveyer. After the adoption of the conveying system and the control method provided by the invention, starting signals of the belt conveyor, the crusher, the transferring machine and the scraper conveyer can be sent sequentially through the control box, so that the pressing and slipping can be avoided, equipment wear and power loss during low-load operation of the equipment can be reduced, the coal cutting efficiency is improved, and the requirement for coal cutting on the working face can be met.

Owner:NINGXIA TIANDI BENNIU IND GRP

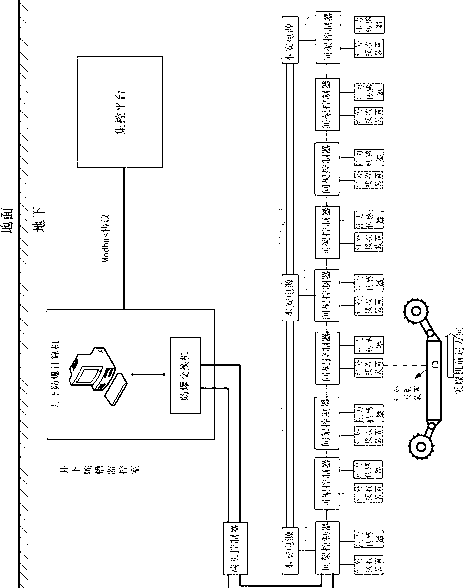

Control method of unattended operation for coal mine comprehensive mechanized mining face

ActiveCN103306700ARealize automatic controlImprove coal mining efficiencyMine roof supportsState parameterEngineering

The invention discloses a control method of unattended operation for a coal mine comprehensive mechanized mining face. The control method is realized on the basis of a centralized control function of an end head controller, a double RS 485 bus communication mode is adopted by the end head controller, one bus is used for polling a working condition parameter of a working face hydraulic support and sending the working condition parameter to a central explosion proof computer; the other bus is used for carrying out centralized-control, determining a running position of a coal cutter through polling the state parameter of the hydraulic support, sending a control command to an inter-frame controller through the buses, controlling the movement of the hydraulic support and matching the marching coal cutter to carry out automated operation, the end head controller forms a bent section through a control support push sliding, so as to assist the coal cutter to realize the technology of beveling, cutting feed and triangular coal slicing. According to the control method of the unattended operation for the coal mine mechanized mining face, the unattended operation automatic production of the working face is realized, the degree of automation is high, the communication is stable and reliable, the mining efficiency is improved, the safety production is guaranteed, the labor intensity is reduced and the range of application is wide.

Owner:TAIYUAN UNIV OF TECH

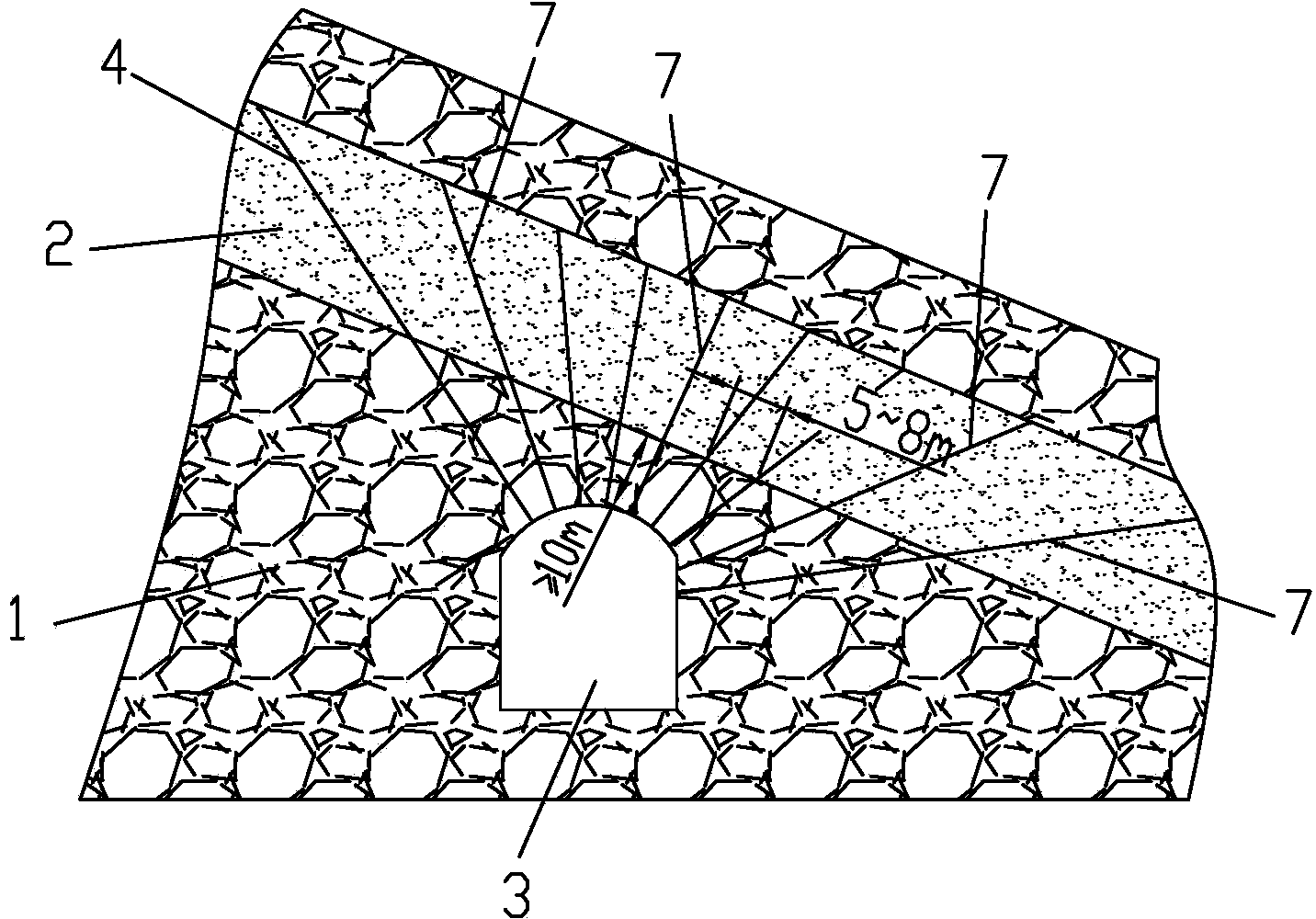

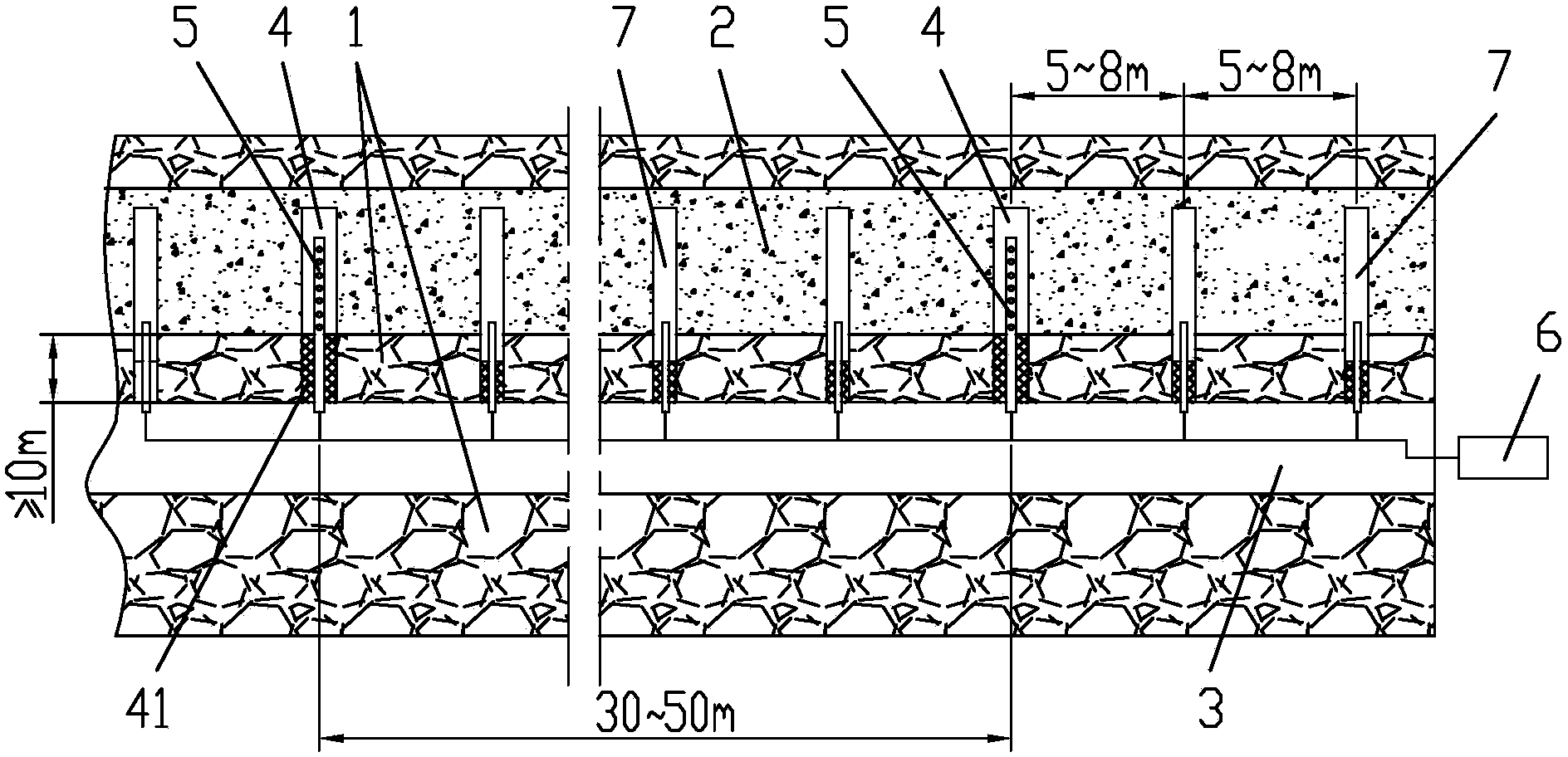

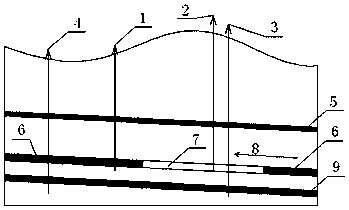

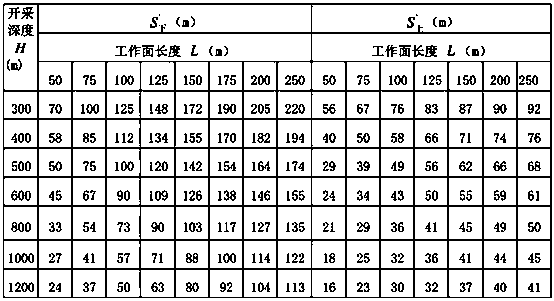

Method for fast extracting gas on coalface

The invention discloses a method for fast extracting gas on a coalface. The method includes that a bottom extraction roadway with the distance to a coal seam no smaller than 5 m is tunneled on a coal seam floor; a plurality of fracture drill holes extending into the coal seam are formed in the bottom extraction roadway, the center distance between every two adjacent fracture drill holes in the position entering the coal seam is between 30 m and 50 m, and the depth of the fracture drill holes in the rock stratum is not smaller than 10 m; the fracture drill holes are sealed according to fracture sealing requirements, and the coal seam is hydraulically fractured; the fracture drill holes are connected with an underground gas extraction system of a coal mine, and then coal seam gas can be extracted; a plurality of extraction holes extending into the coal seam are formed in the bottom extraction roadway, and the center distance from any extraction hole to the adjacent extraction holes or the position for the corresponding fracture drill hole to enter the coal seam is between 5 m and 8 m; the extraction holes are sealed according to extraction sealing requirements; coal seam gas is extracted through the extraction holes till the coal seam gas content reaches the standard. The method for fast extracting gas on the coalface has the advantages of having fewer drill holes and being high in extraction efficiency and coal mining efficiency, and roadway tunneling and coal mining work can be performed safely.

Owner:重庆市能源投资集团科技有限责任公司

Penetrant for coal-bed flooding

ActiveCN102337103AImprove water injection efficiencyHigh speedOther chemical processesDust removalCoal dustProcess engineering

The invention relates to a penetrant for coal-bed flooding. The penetrant comprises the following components by weigh percent: 0.01%-0.10% of sodium dodecyl sulfate, 0.01%-0.10% of sodium diisooctylester sulfosuccinate, 0.01%-0.10% of dodecylbetaine, 0.01%-0.10% of sodium oleoyl methyl ethanesulfonate, 0.1%-1.0% of calcium chloride and the balance of water. By using the penetrant for coal-bed flooding in the invention, the problems that a coal bed is not easily wetted and penetrated by water can be effectively solved, the efficiency of coal-bed flooding is improved, the flooding amount, wetting radius and flooding speed of the coal bed are greatly improved, the production amount of working face coal dust is effectively reduced, accident potential is eliminated, and coal mining efficiency is improved.

Owner:SHANDONG UNIV OF SCI & TECH

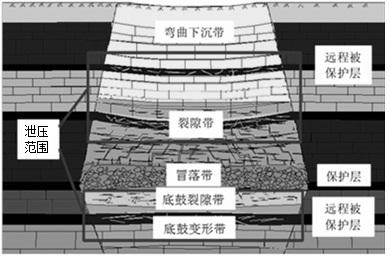

Ground and underground combined coal and coal-bed gas co-mining method for low-permeability coal bed group

ActiveCN111042791AReduce penetrationReduce air contentUnderground miningFluid removalMining engineeringCoal mine methane

The invention discloses a ground and underground combined coal and coal-bed gas co-mining method for a low-permeability coal seam group. The method is applied to a gas outburst mine, a mode that the protective layer mining is combined with the ground gas extraction is used for a coal reservoir with the characteristics of low permeability and low gas content, so that an adjacent coal bed is subjected to rapid pressure relief, coal-bed gas is efficiently and rapidly extracted from the ground, and a co-mining technology system that ground and underground are combined to extract the coal-bed gas and coal and the coal bed gas are extracted while being pumped is provided, so that a highly-located drainage roadway and an end-located drainage roadway are replaced to the maximum extent, the coal mine gas treatment cost is effectively reduced, the ground coal-bed gas well yield is increased, the coal mine gas outburst risk and the gas overrun accident occurrence frequency is reduced, the coal mining efficiency is improved, and the coal mine mining safety and efficiency are realized.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

Coal mining and transporting integrated machine

The invention discloses a coal mining and transporting integrated machine. The coal mining and transporting integrated machine comprises a machine frame, wherein the machine frame is connected with a power device, a bottom plate and a baffle are arranged on the machine frame, the bottom plate is horizontally arranged, a drive sprocket shaft and a driven sprocket shaft are vertically arranged on the bottom plate, the drive sprocket shaft is driven to rotate by a driving motor through a speed reducer, and the drive sprocket shaft is coaxially fixedly connected with a drive sprocket; the driven sprocket shaft is fixedly connected to the bottom plate, and the driven sprocket shaft is coaxially connected with a driven sprocket in a rotating way; the drive sprocket is connected with the driven sprocket by a chain, chain plates are fixedly connected to the links of the chain, at least one row of coal blocking teeth at a preset interval is formed in the length direction of each chain plate, and the coal blocking teeth on the adjacent chain plates are staggered with each other; the baffle is arranged between the two linear running sections of the chain, and is arranged in the length direction of the work surface. The coal mining and transporting integrated machine has the beneficial effects that coal mining and transporting are simultaneously finished by the same facility, the mechanical degree of coal bed excavation is high, the recovery rate is high, and the coal mining efficiency is high; convenient assembly, disassembly, maintenance and repair are realized.

Owner:王洁

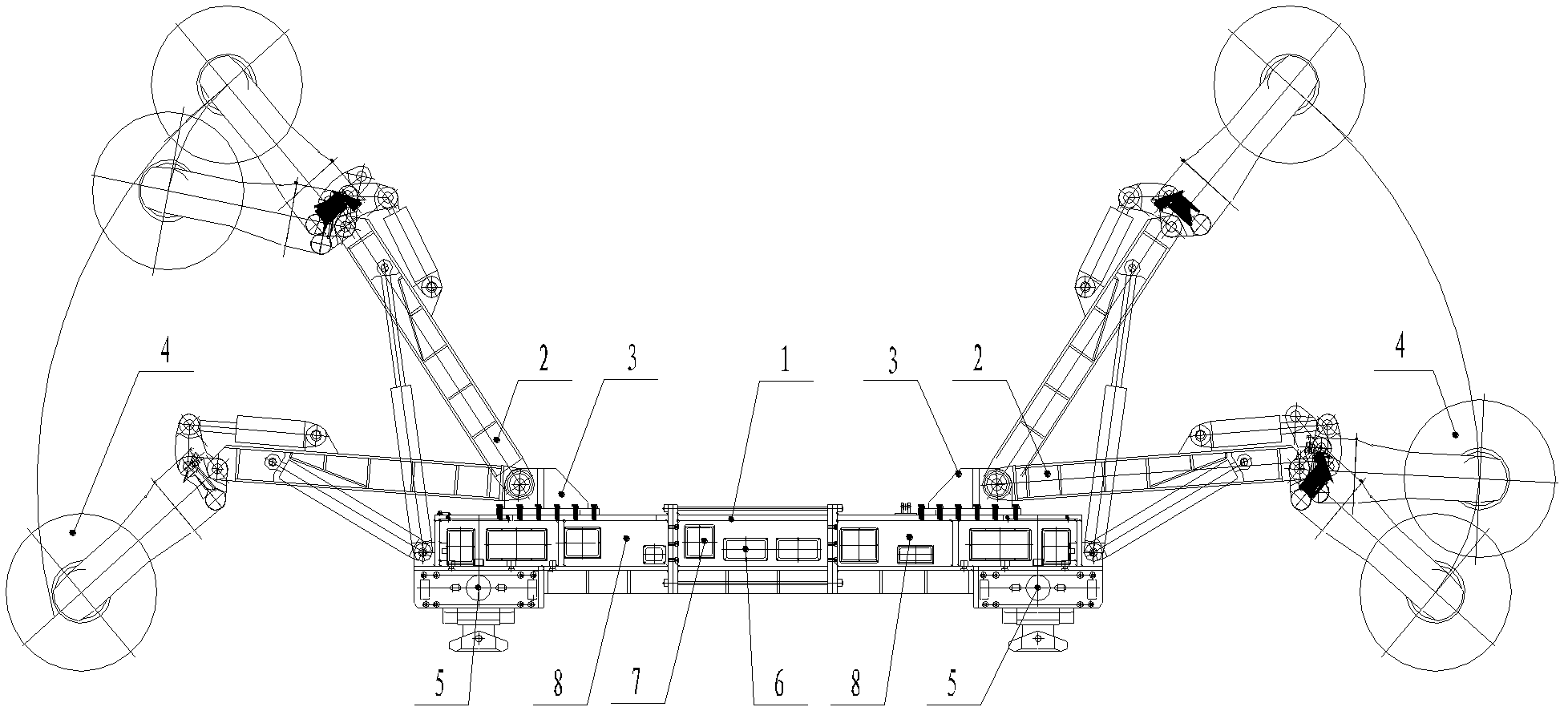

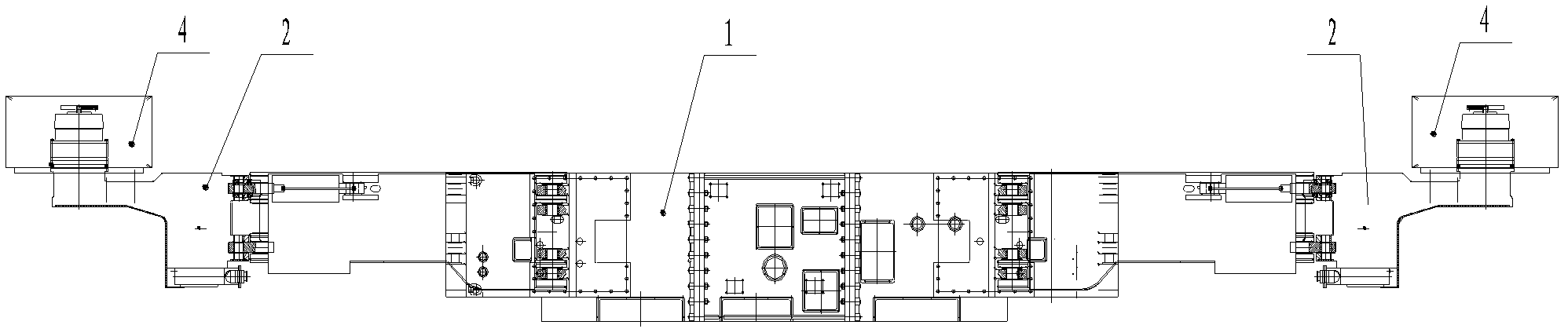

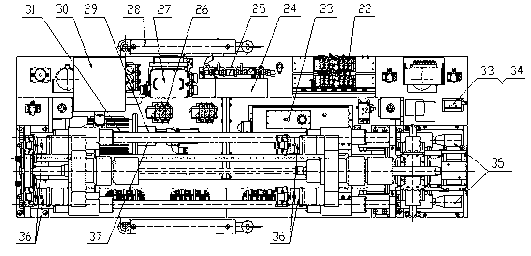

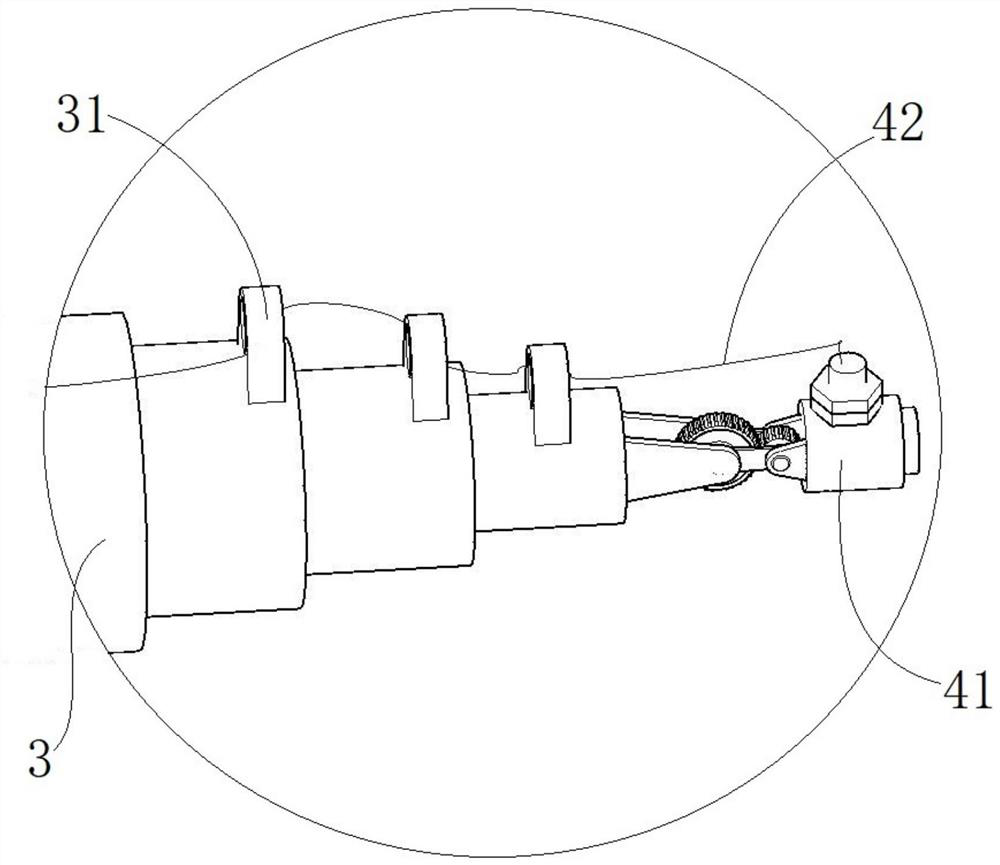

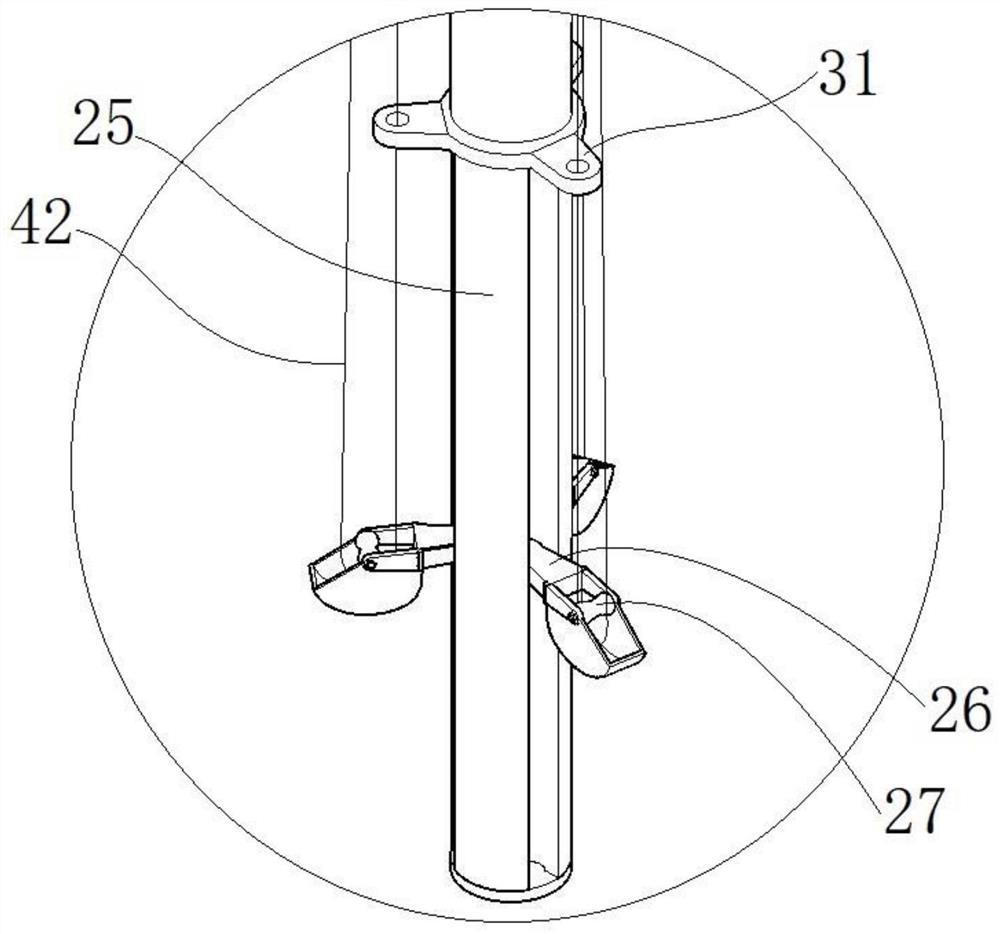

Combined height-adjustable coal cutting machine with small roller and large mining height, as well as coal cutting process of combined height-adjustable coal cutting machine

InactiveCN102536233AReduce energy consumptionReduce cutting resistanceUnderground miningSurface miningElectrical controlCoal

The invention relates to a combined height-adjustable coal cutting machine with a small roller and a large mining height, as well as a coal cutting process of the combined height-adjustable coal cutting machine. The combined height-adjustable coal cutting machine comprises a machine body assembly, coal cutting rollers, a travelling mechanism, an auxiliary device, a hydraulic control system and an electrical control system, and is characterized in that combined height-adjusting devices are symmetrically mounted on two side surfaces of the machine body assembly; and each combined height-adjusting device comprises a main height-adjusting oil cylinder, an auxiliary height-adjusting cutting arm and an auxiliary height-adjusting oil cylinder. The coal cutting process adopts a knife inserting method without notch cutting; the coal cutting roller at the front end of the coal cutting machine cuts residual coal bodies under the action of the oscillation of both the main height-adjusting cutting arm and the auxiliary height-adjusting cutting arm, wherein the moving trace is an arc, and the oscillation angle Alpha is at least 90 DEG; and the coal cutting roller at the rear end of the coal cutting machine cuts coal along a bottom plate, wherein the moving trace is a straight line. The coal cutting machine has the advantages that the structure is compact; the size and the weight are smaller; the suitability is strong; the mounting and the transportation are convenient; and the coal cutting machine is suitable for large, middle or small scale of coal mines with large mining heights.

Owner:闫振东

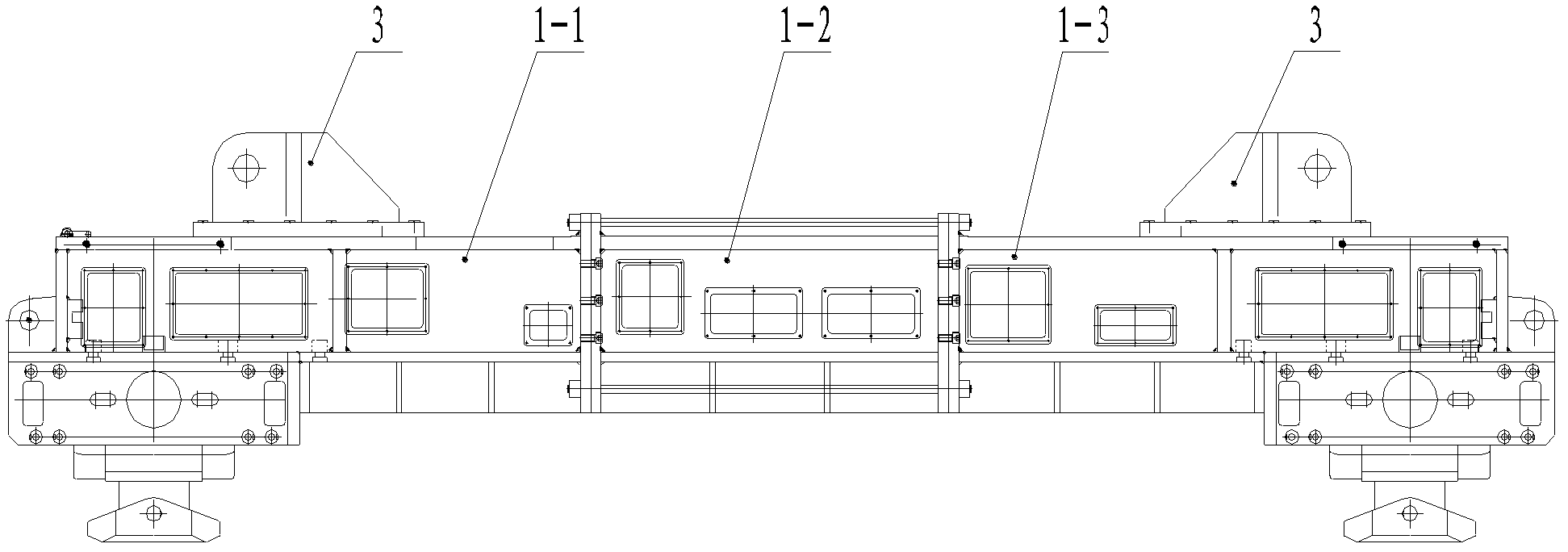

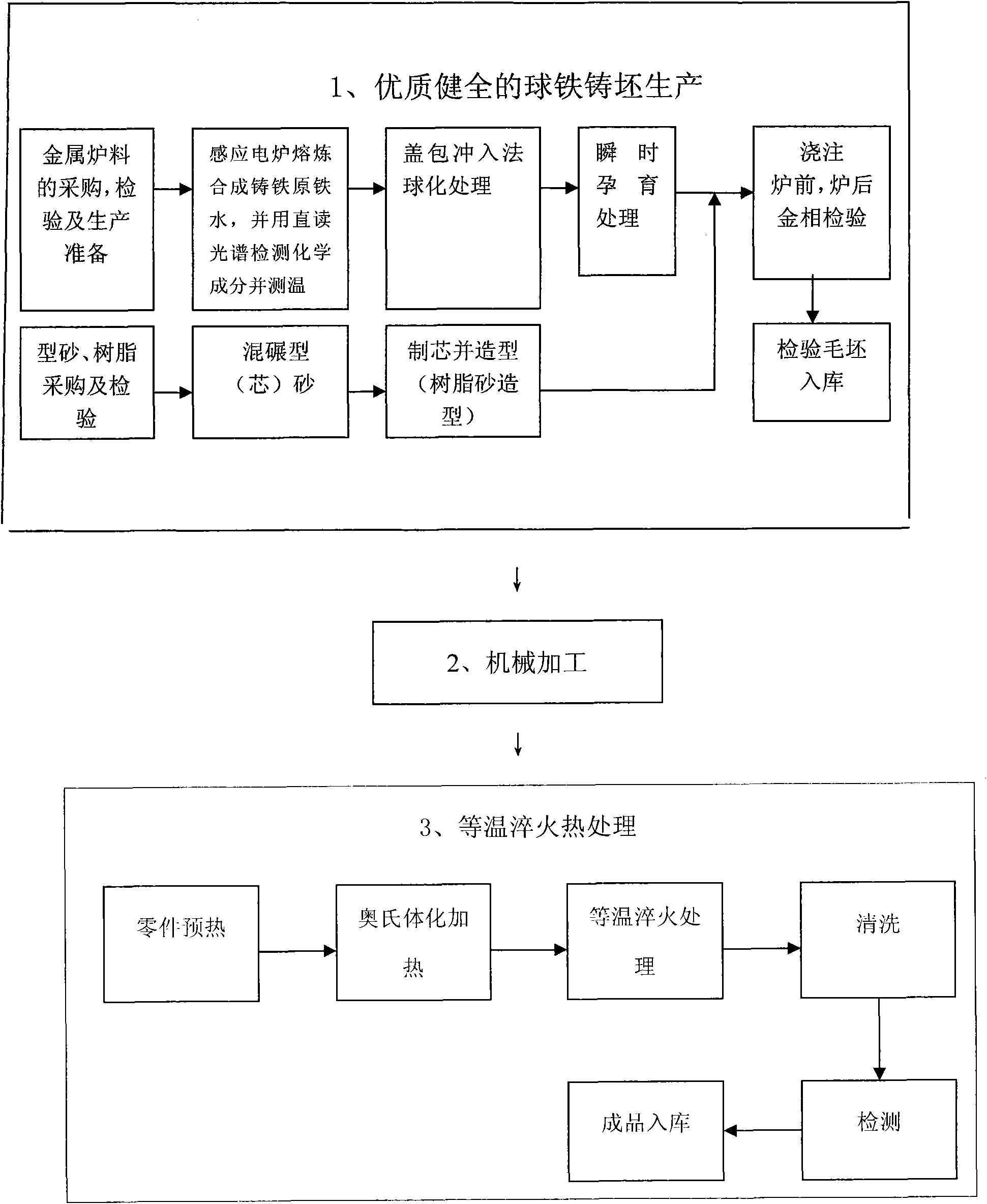

Integral intermediate groove of isothermal quenching ductile iron conveyor and preparation method

InactiveCN101602434AHigh strengthImprove wear resistanceConveyorsDuctile ironUltimate tensile strength

The invention discloses an integral intermediate groove of an isothermal quenching ductile iron conveyor. The raw material of the integral intermediate groove is isothermal quenching ductile iron, and the ductile iron comprises the following chemical components in percentage by weight: 3.40 to 3.60 percent of C, 2.00 to 2.40 percent of Si, less than 0.3 percent of Mn, less than 0.03 percent of P, less than 0.02 percent of S, 0.04 to 0.055 percent of Mg, 0.01 to 0.02 percent of Re, 0.60 to 0.80 percent of Cu, 0.20 to 0.30 percent of Mo, and the balance of iron. The integral intermediate groove has the following advantages of high strength, good abrasion resistance, light weight and the like; and the preparation method changes a combined structure of the prior intermediate groove which is formed by welding abrasion-resistant steel plates on a cast steel groove twice into the integral intermediate groove which is cast by a new single isothermal quenching ductile iron material, reduces the time for stopping a machine, and improves the coal mining efficiency.

Owner:宣化冶金工业有限责任公司

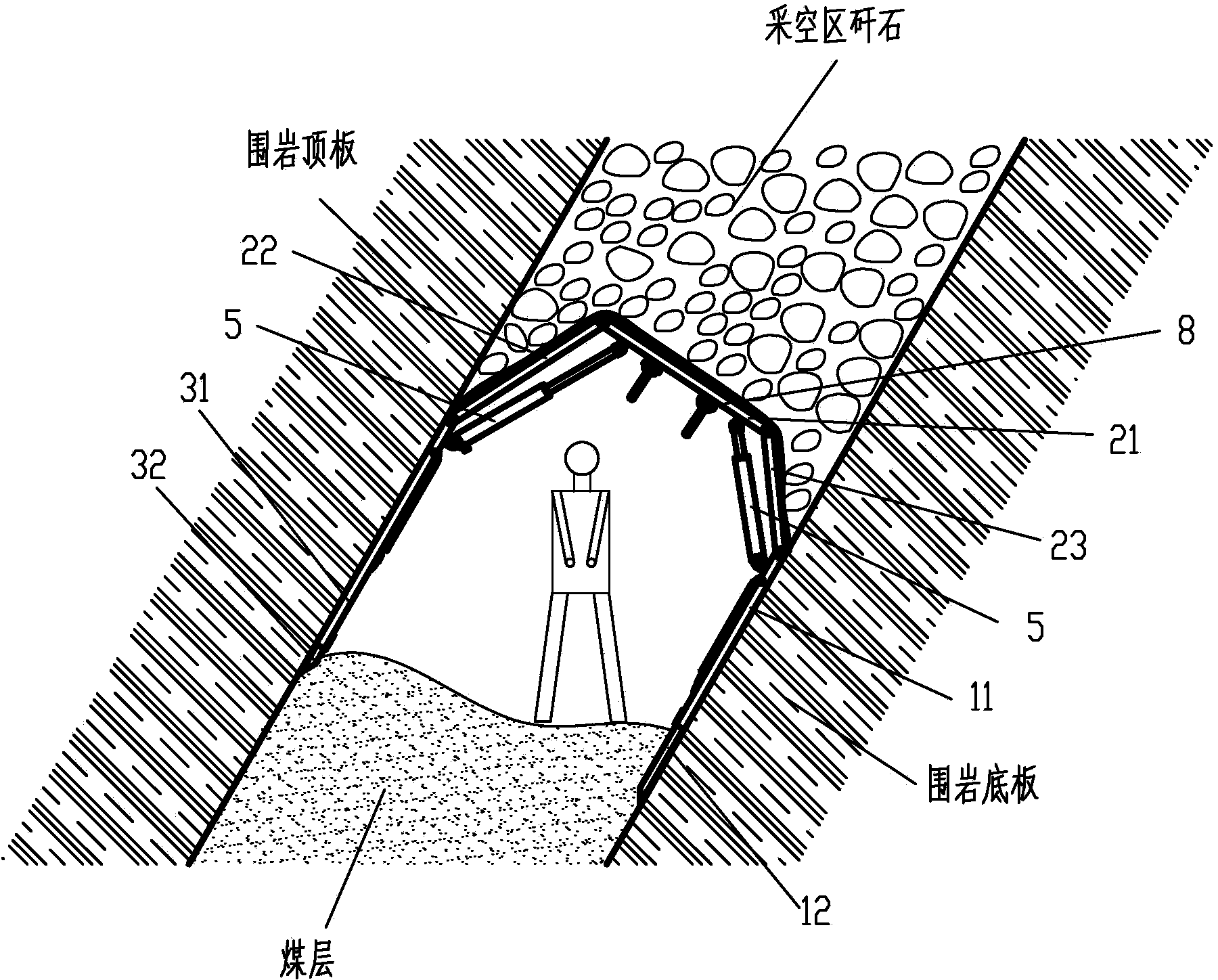

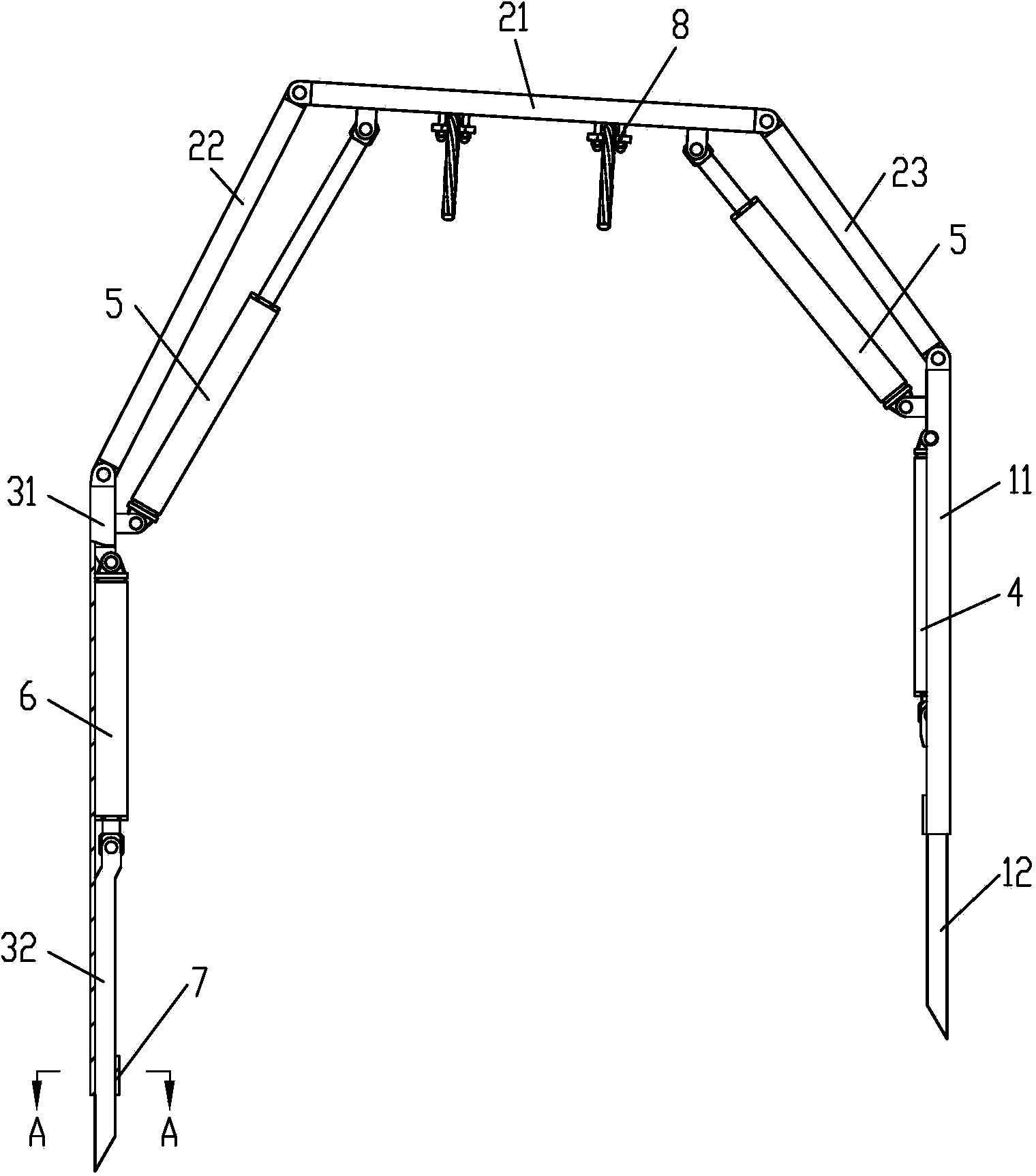

Shield support for steep medium-thickness coal seam

ActiveCN103643980AIncrease frictional resistanceImprove support strengthMine roof supportsHydraulic cylinderLeg extension

The invention discloses a shield support for a steep medium-thickness coal seam, which comprises a lower landing leg and a support beam mutually articulated, wherein the support beam is arched; a free end of the support beam is further articulated with an upper landing leg; the lower landing leg and the upper landing leg are linear; first hydraulic cylinders are movably connected between the upper landing leg and the support beam and between the lower landing leg and the support beam respectively; the lower landing leg comprises a lower landing leg main body and a lower landing leg extension body; the upper end of the lower landing leg main body is articulated with the support beam; a sharp head is arranged at a free end of the lower landing leg extension body; a second hydraulic cylinder is movably connected between the lower landing leg main body and the lower landing leg extension body; the first hydraulic cylinder on the lower landing leg is articulated with the lower landing leg main body by the bottom end of a cylinder body of the first hydraulic cylinder; and the tail ends of piston rods of the two first hydraulic cylinders are articulated with the support beam respectively. The support has the benefits that the support is good in stability and safety and can be adjusted with changes in coal seam thickness and a dip angle, and a coal seam recovery ratio and a level of mechanization are high.

Owner:重庆天巨承机械制造有限责任公司

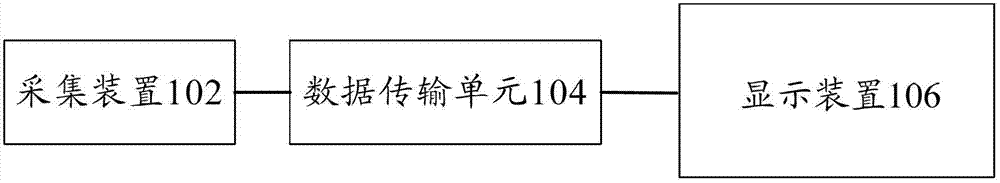

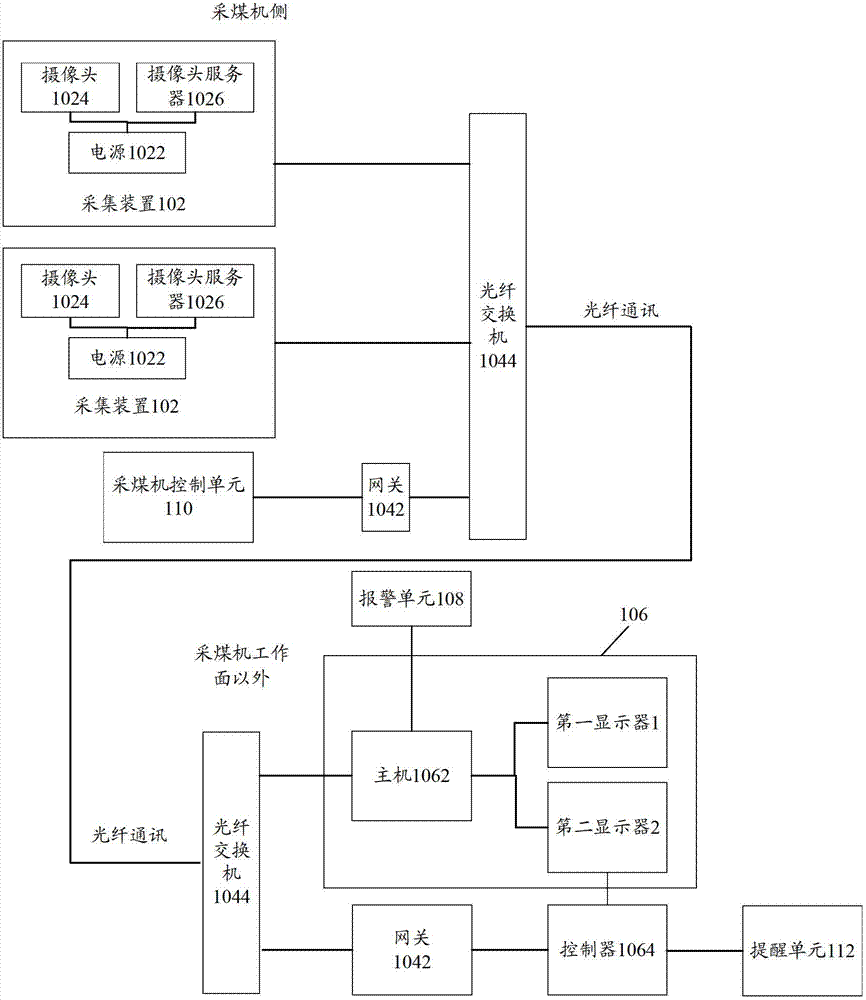

Fully mechanized working face monitoring system and coal mining machine

ActiveCN102759911AAvoid dangerImprove coal mining efficiencyProgramme total factory controlDisplay deviceMonitoring system

The invention provides a fully mechanized working face monitoring system which comprises at least one collecting device, a data transmission unit and a display device, wherein the at least one collecting device is installed on a coal mining machine, collects video information and / or audio information of a working face, and transmits the video information and / or the audio information to the data transmission unit; the data transmission unit transmits the video information and / or the audio information to the display device; and the display device processes the video information and / or the audio information respectively and plays processed audio information. According to the technical scheme provided by the invention, the audio information and the video information of the fully mechanized working face can be acquired directly through the collecting device, and can be monitored in real time through the display device, the collected audio information is played through an audio device, and the condition of the working face can be monitored intuitively. The invention also provides a coal mining machine comprising the fully mechanized working face monitoring system.

Owner:SANY HEAVY EQUIP

Pick having bimetal structure and preparation method thereof

InactiveCN101787887AMeet the bonding strengthImprove wear resistanceCutting machinesWear resistantMetallic materials

The invention relates to a pick having a bimetal structure and a preparation method thereof, in particular to a pick and a preparation method applicable to coal mining machines and tunneling machines capable of cutting coal seams and rock strata, belonging to the technical field of the research on mining machinery metallic materials and geotechnical engineering. The pick is characterized in that the pick body consists of two metals, wherein the most wear-prone top end of a pick head of the pick is made of tailor-made alloy steel; the wear-resistant lower ends of the pick handle and pick head are made of medium carbon alloy steel; a plurality of ring-shaped grooves are formed below the top end of the pick head; an interlayer is arranged between every two adjacent ring-shaped grooves; the ring-shaped grooves are subjected to full-surfacing process by using the tailor-made alloy steel welding rods; and since the interlayer is thin, the integral wear-resistant tailor-made alloy steel can be formed at the top end of the pick head. The pick of the invention has the advantages of simple structure, novel design, high practicability, convenient fabrication, high hardness and wear resistance and good impact-resisting and corrosion-resisting performance; and according to industrial tests, compared with the homemade pick, the service life of the pick is prolonged by 20 to 30 times, thus saving a great deal of alloy steel materials for our country and reducing the mining cost.

Owner:TAIYUAN UNIV OF TECH +1

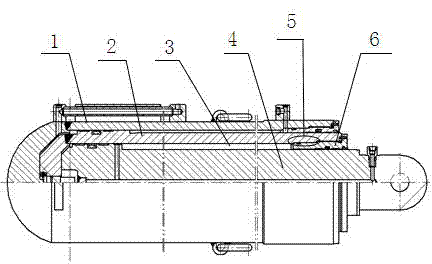

Hydraulic support oil cylinder with inner hole seal part treated by adoption of laser cladding technology

InactiveCN103883587AAvoid corrosionCreate pollutionFluid-pressure actuatorsMine roof supportsCorrosion resistant alloyEngineering

The invention discloses a hydraulic support oil cylinder with an inner hole seal part treated by the adoption of a laser cladding technology. The hydraulic support oil cylinder with the inner hole seal part treated by the adoption of the laser cladding technology comprises an outer cylinder tube, an intermediate cylinder and a movable column, the intermediate cylinder is arranged inside the outer cylinder tube, an inner hole is formed inside the intermediate cylinder, the movable column is inserted into the inner hole inside the intermediate cylinder, and a gap is reserved between a rod body part of the movable column and the wall of the inner hole and filled with emulsified liquid. A guide sleeve is arranged on an opening of the inner hole and seals the gap formed by the rod body part of the movable column and the wall of the inner hole, and an anti-corrosion alloy layer is formed at the inner surface, close to the opening and making contact with the outer wall of the guide sleeve, of the inner hole by the adoption of the laser cladding treatment technology. The device can not pollute the environment at all, a coating can not fall off, the service life is long and can be prolonged substantially, cost for maintaining the oil cylinder is saved for a user, and coal exploitation efficiency is improved.

Owner:CHONGQING JIANGLU LASER TECH

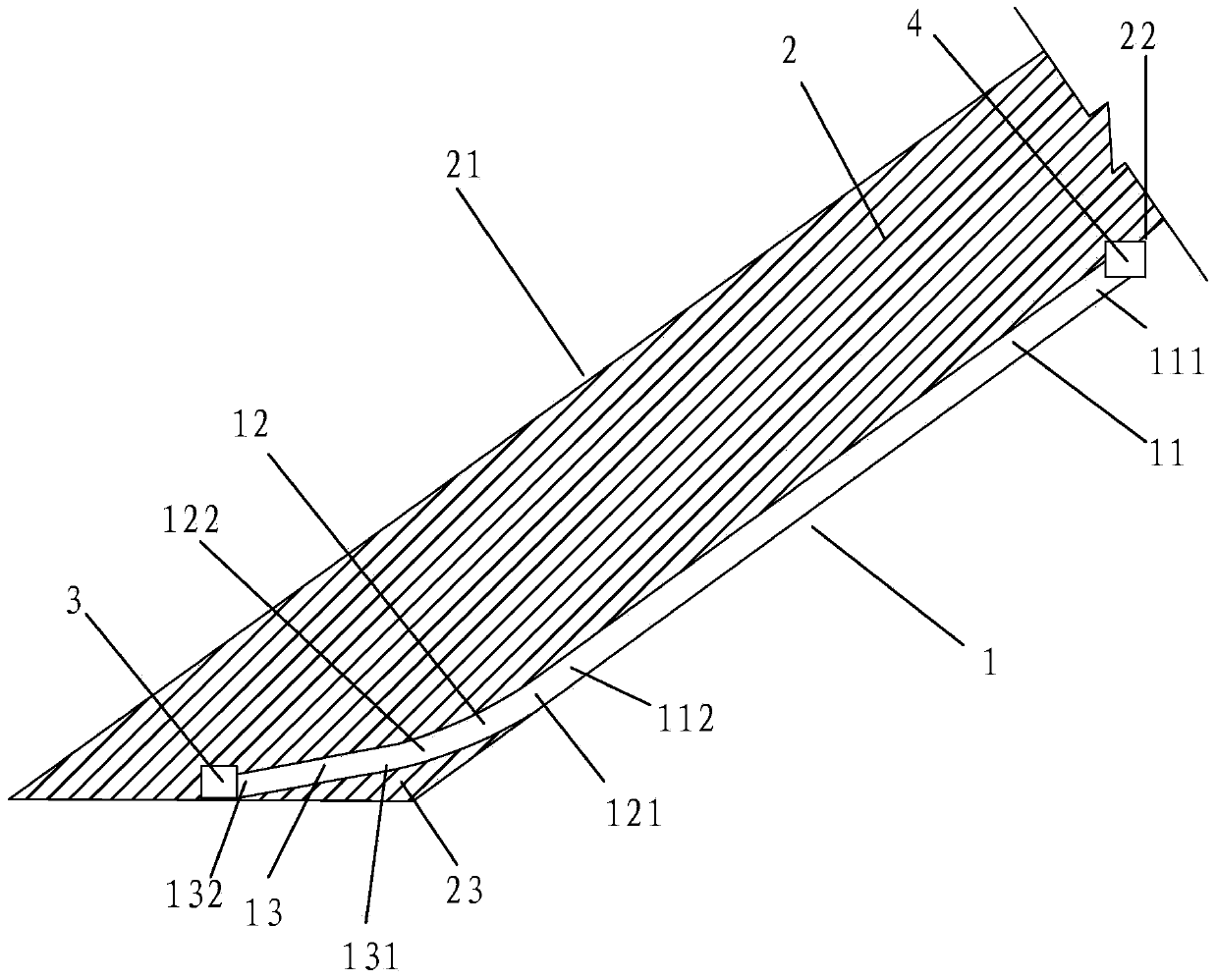

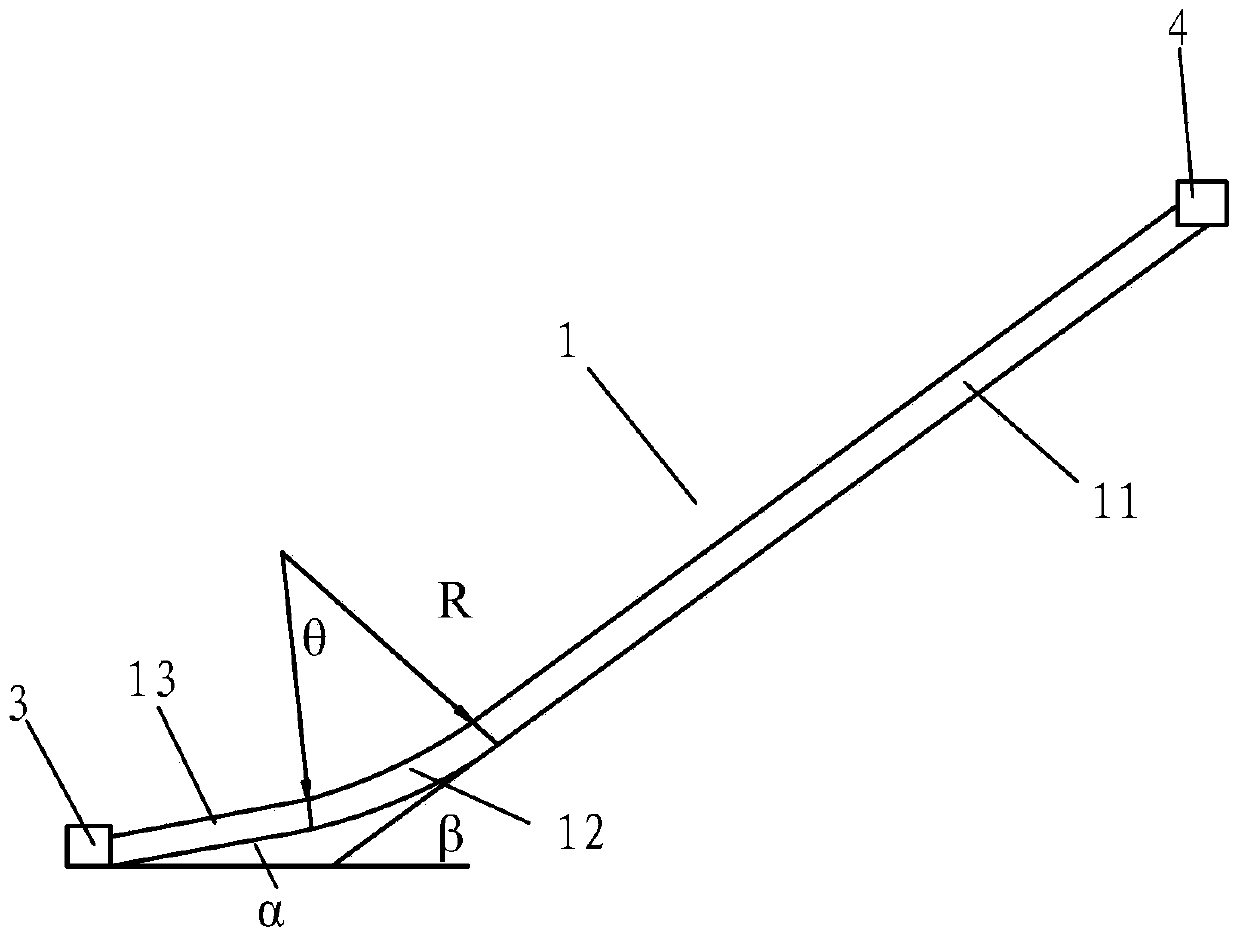

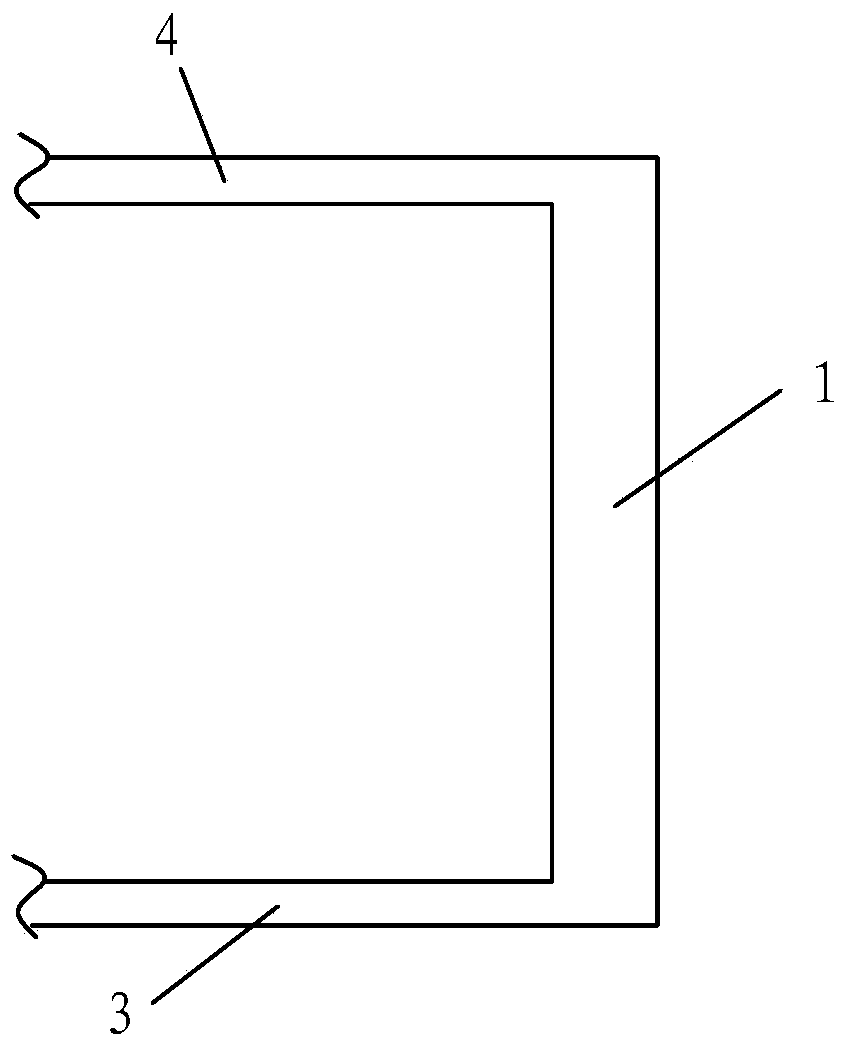

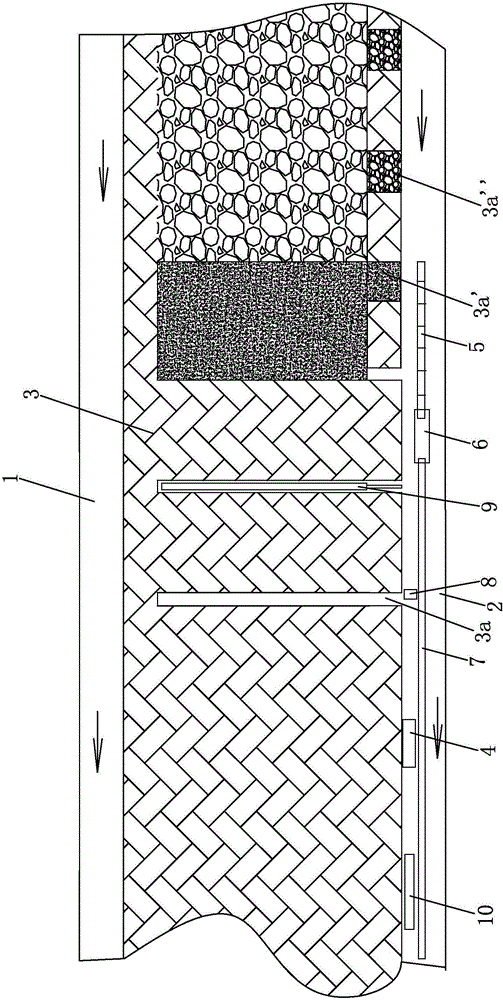

Coal mining roadway

InactiveCN103437777APrevent slippingImprove stress conditionTunnelsStress conditionsMechanical engineering

The invention discloses a coal mining roadway. The coal mining roadway comprises a working surface, a ventilation roadway and a transportation roadway, wherein the ventilation roadway is arranged on a seam floor of a coal seam, and the transportation roadway is arranged between a coal seam roof and the seam floor. The working surface comprises a shelving working surface section, a transition circular-arc working surface section and an inclined working surface section, wherein the working surface is arranged in an inclined mode in the longitudinal direction, the shelving working surface section and the inclined working surface section are smoothly connected together through the transition circular-arc working surface section, the shelving working surface section is arranged on the lower oblique portion of the transition circular-arc working surface section, and is communicated with the transportation roadway, the inclined working surface section is arranged on the seam floor, is arranged on the upper oblique portion of the transition circular-arc working surface section, and is communicated with the ventilation roadway, a shelving included angle alpha is formed between the shelving working surface section and the horizontal plane, an inclined included angle beta is formed between the inclined working surface section and the horizontal plane, and the shelving included angle alpha is smaller than the inclined included angle beta. The coal mining roadway can improve the stress condition of an end support and the stress condition of a crab bearer of a large-dip-angle fully mechanized caving face, has control over downward sliding of the end support and the crab bearer of the large-dip-angle fully mechanized caving face, and is high in coal mining efficiency.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

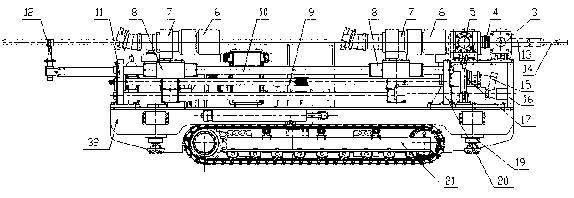

Super-deep hole double-tube drilling directional drilling rig

InactiveCN103061675AEasy to handleStable jobConstructionsDirectional drillingHydraulic motorFeeding force

The invention relates to a coal mine tunnel drilling rig, specifically relates to a drilling rig which can perform super-deep hole directional drilling in non-soft coal layers and perform deep hole double-tube directional drilling in soft coal layers and solves the problem that existing drilling rigs can not perform super-deep hole directional drilling in the non-soft coal layers and can not perform deep hole directional drilling in the soft coal layers. According to the drilling rig, two power heads, a shackle mechanism and a clamp holder are mutually cooperated; by means of a combination drilling mode which combines technologies of hole bottom dynamic directional drilling, sleeve revolving drilling and hole deslagging, the problem of hole collapse in the soft coal layers can be solved, and drilling efficiencies are improved; the drilling rig uses a split self-walking structure, the whole drilling rig can independently walk when the drilling rig is divided into two parts, the size of the whole drilling rig is controlled, and adaptivity to a roadway is improved; a feed mechanism uses a hydraulic motor to drive a spiral pair to provide feed forces so that the two power heads can achieve large-stroke independent action and coordination action on the same axis; and the drilling rig is provided with a support oil cylinder and a ground anchor cylinder and is high in intensity of a rig body and work stability.

Owner:SHENYANG NORTH TRAFFIC HEAVY IND

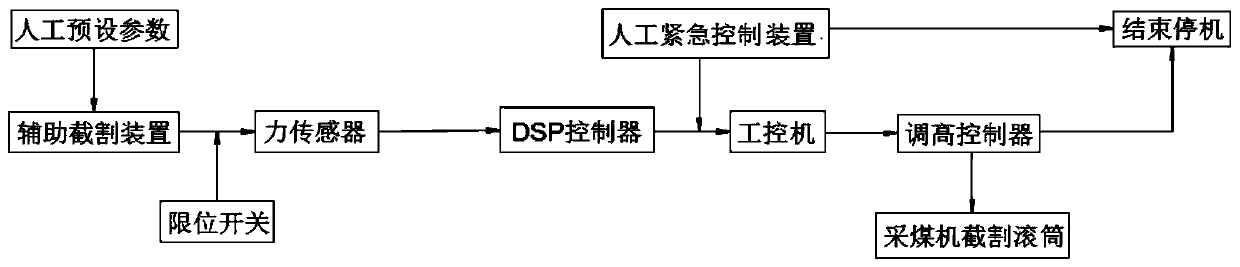

Fully mechanized coal mining face coal rock identification device and method

PendingCN110080766AImprove working precisionImprove coal mining efficiencyTesting machinesSlitting machinesLoop controlClosed loop

The invention discloses a fully mechanized coal mining face coal rock identification device and method. According to the device, an embedded industrial personal computer is used as a data processing platform, coal mining machine controller software, a coal mining machine positioning system and a coal rock identification system are fused, and thus a comprehensive working face coal rock identification system is established. By applying the system, the working precision of a coal mining machine is improved, a measuring track is provided for cutting of the coal mining machine on a fully mechanizedcoal mining face, the problem that the cutting height of a roller cannot be adaptively adjusted when the coal mining machine works is solved, control over the coal mining machine is changed into closed-loop control from open-loop control, and the coal mining efficiency and reliability of the coal mining machine are improved.

Owner:CHINA UNIV OF MINING & TECH

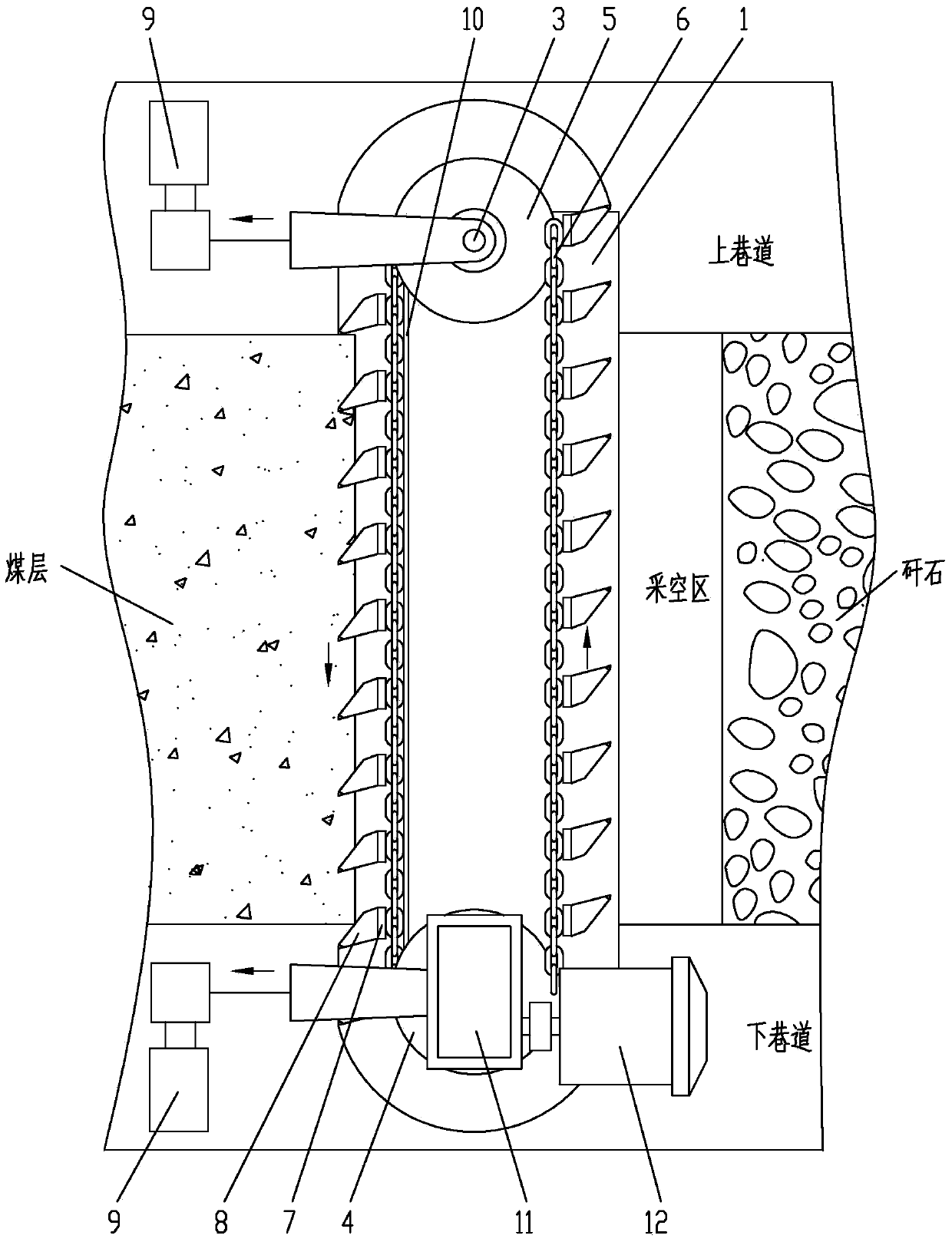

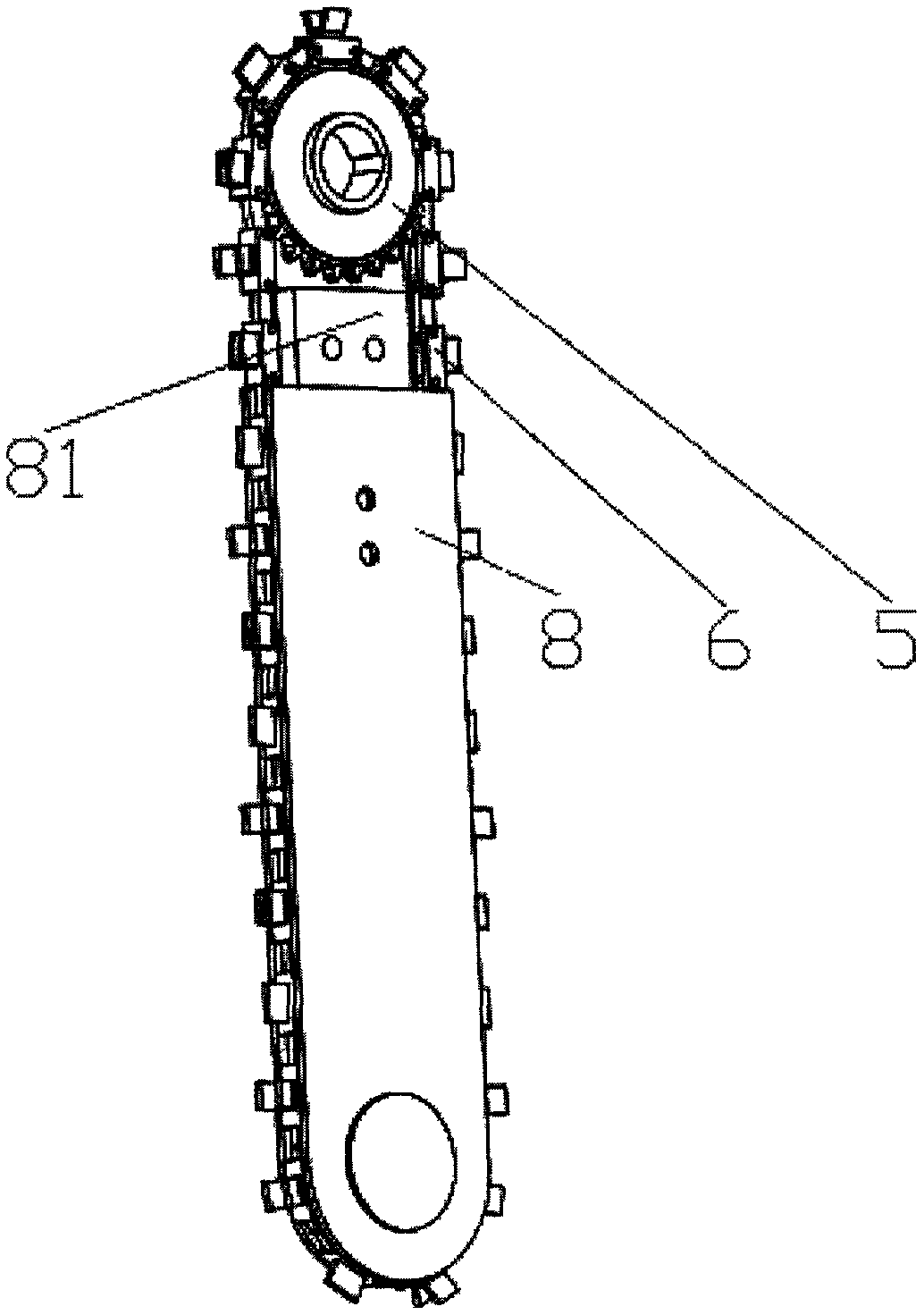

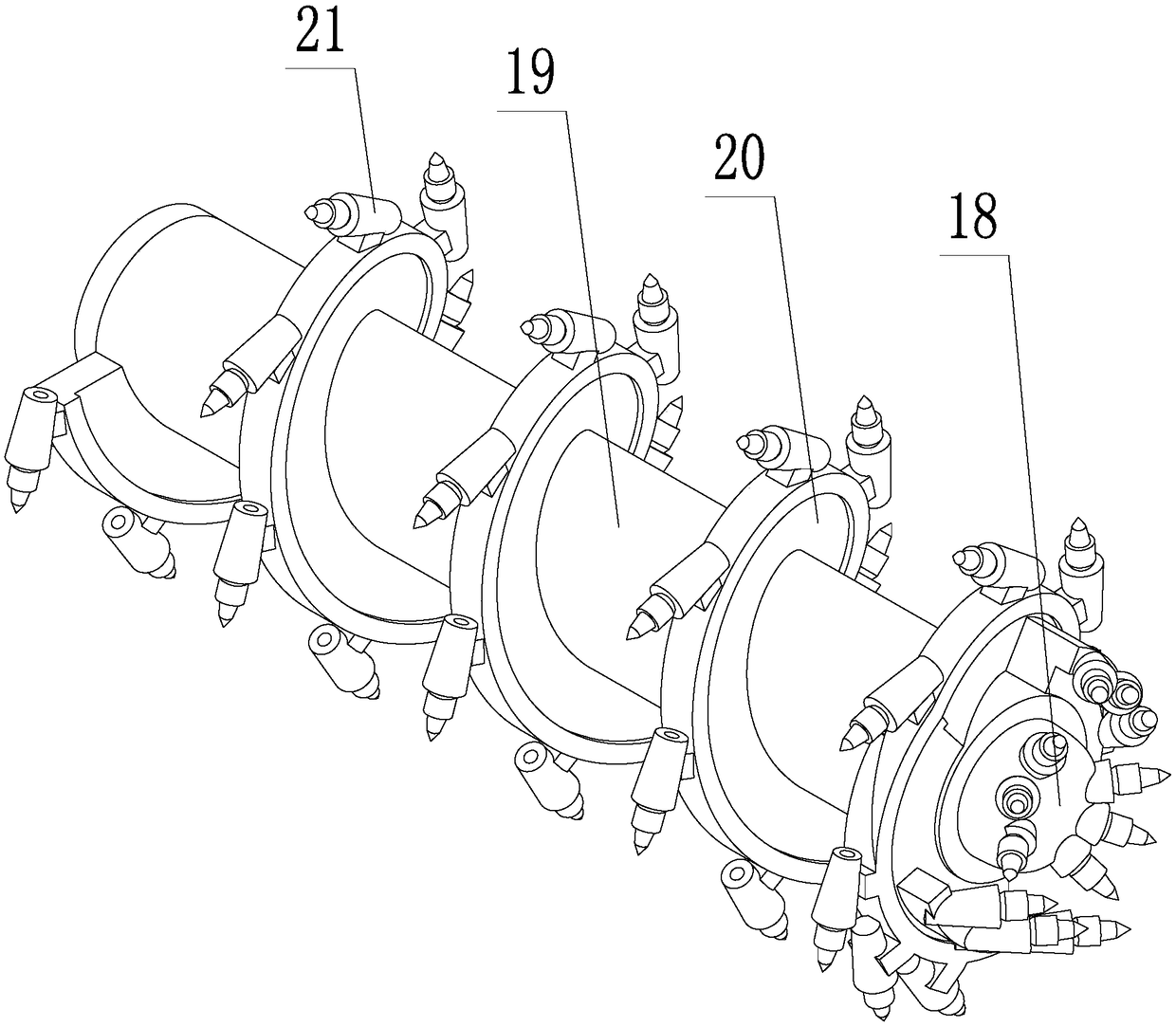

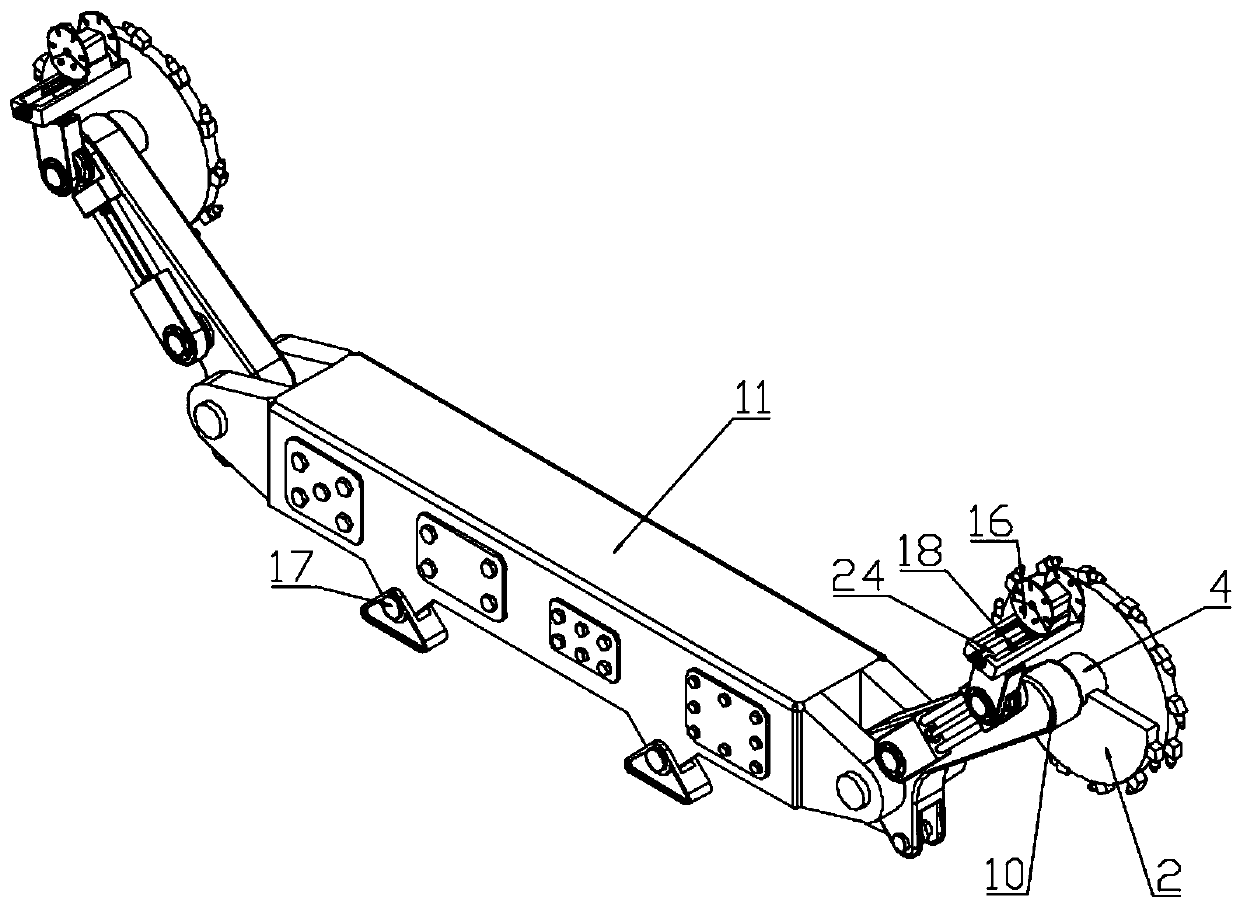

Chain coal cutter

InactiveCN103924971ACoal mining area is largeImprove coal mining efficiencyCutting machinesCoalSprocket

The invention discloses a chain coal cutter, and belongs to the technical field of coal mine machines. The chain coal cutter comprises a traction portion, a motor portion and a coal cutting portion. The traction portion is connected with the motor portion, and the motor portion is connected with and drives the coal cutting portion through a transmission portion. The motor portion and the transmission portion are located in a box body, and the coal cutting portion is arranged outside the box body and is used for cutting a coal bed below the box body. The coal cutting portion is provided with a plurality of chains, and the upper ends of the chains are arranged on chain wheels in a sleeved mode. The chain coal cutter has the advantages of being large in coal cutting area, high in coal cutting efficiency and high in adaptability, saving energy, being environmentally friendly and low in manufacturing cost and the like. The cutting portion works on the coal bed below a coal cutter body, and the prostrating mining function of the chain coal cutter is achieved.

Owner:HUNAN UNIV OF SCI & TECH

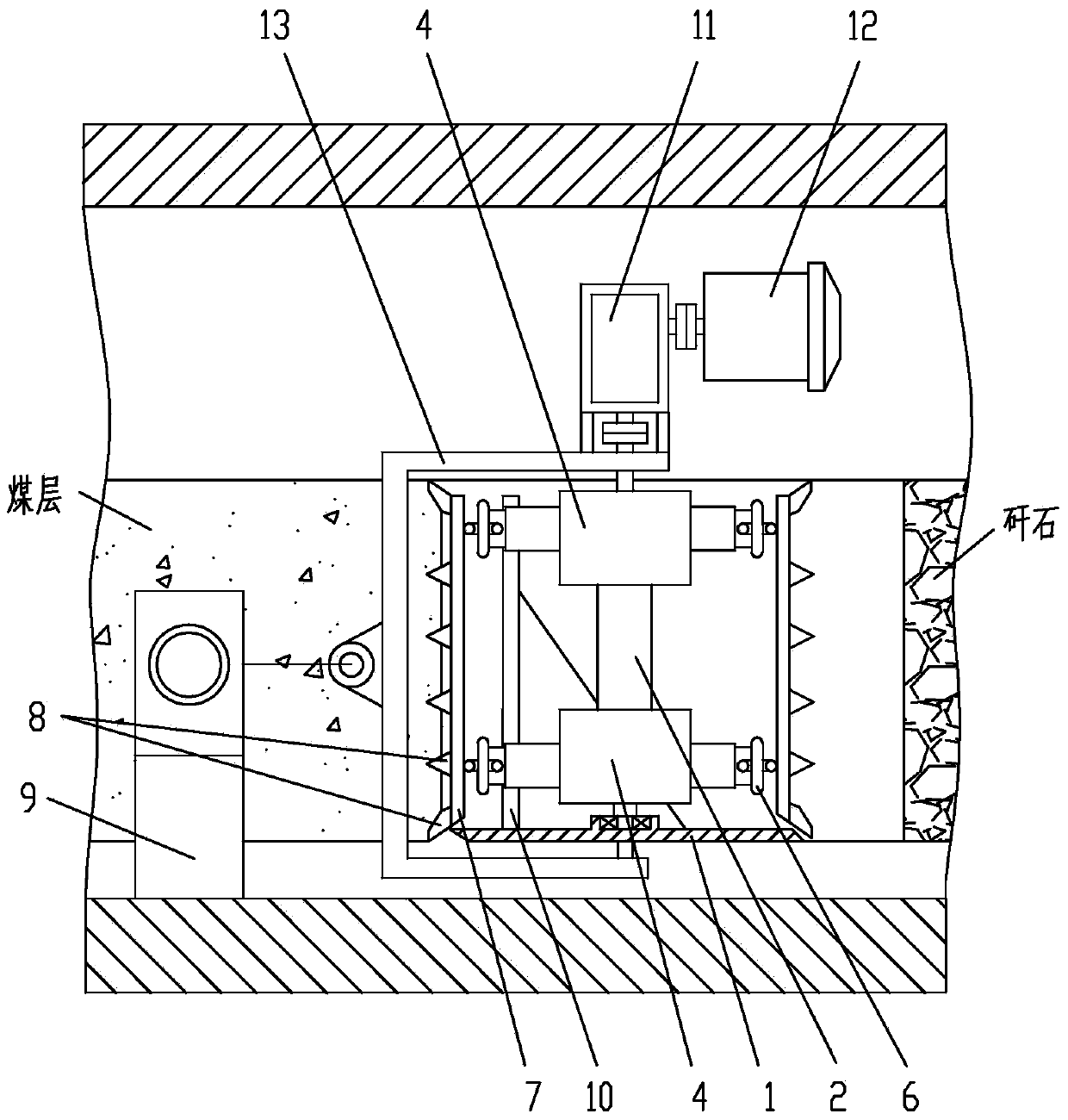

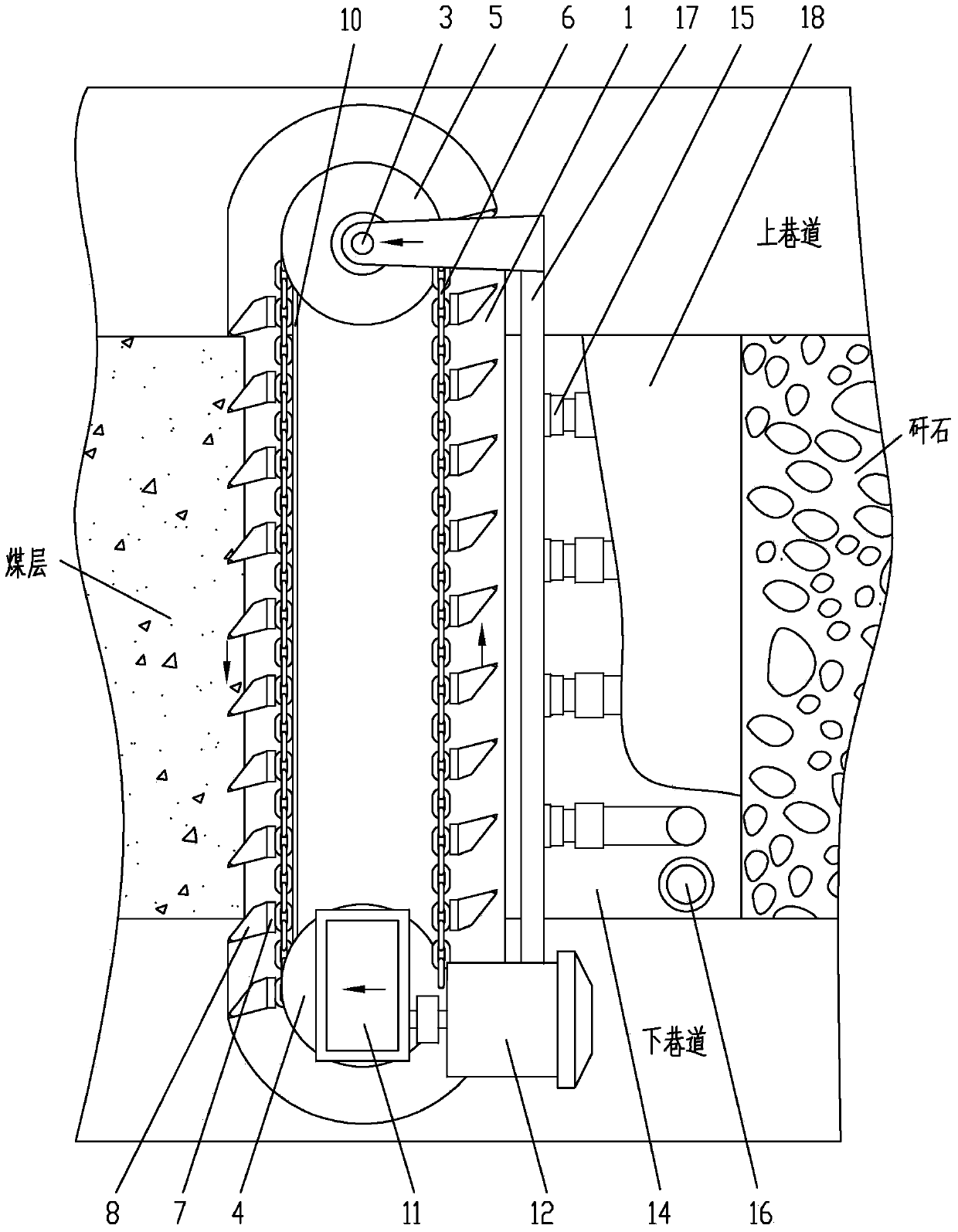

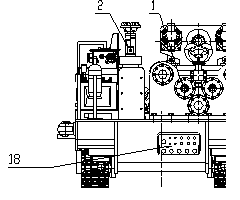

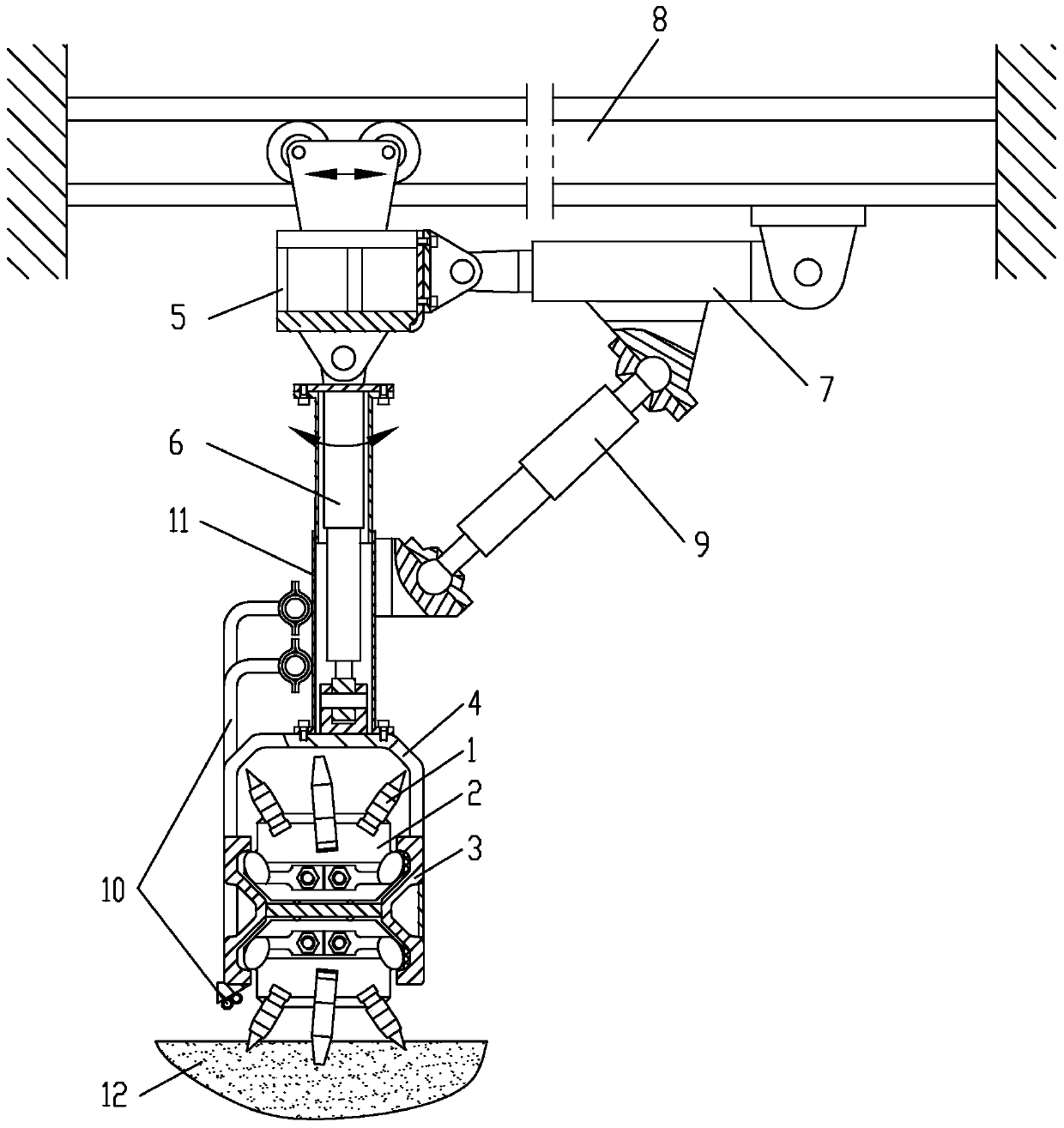

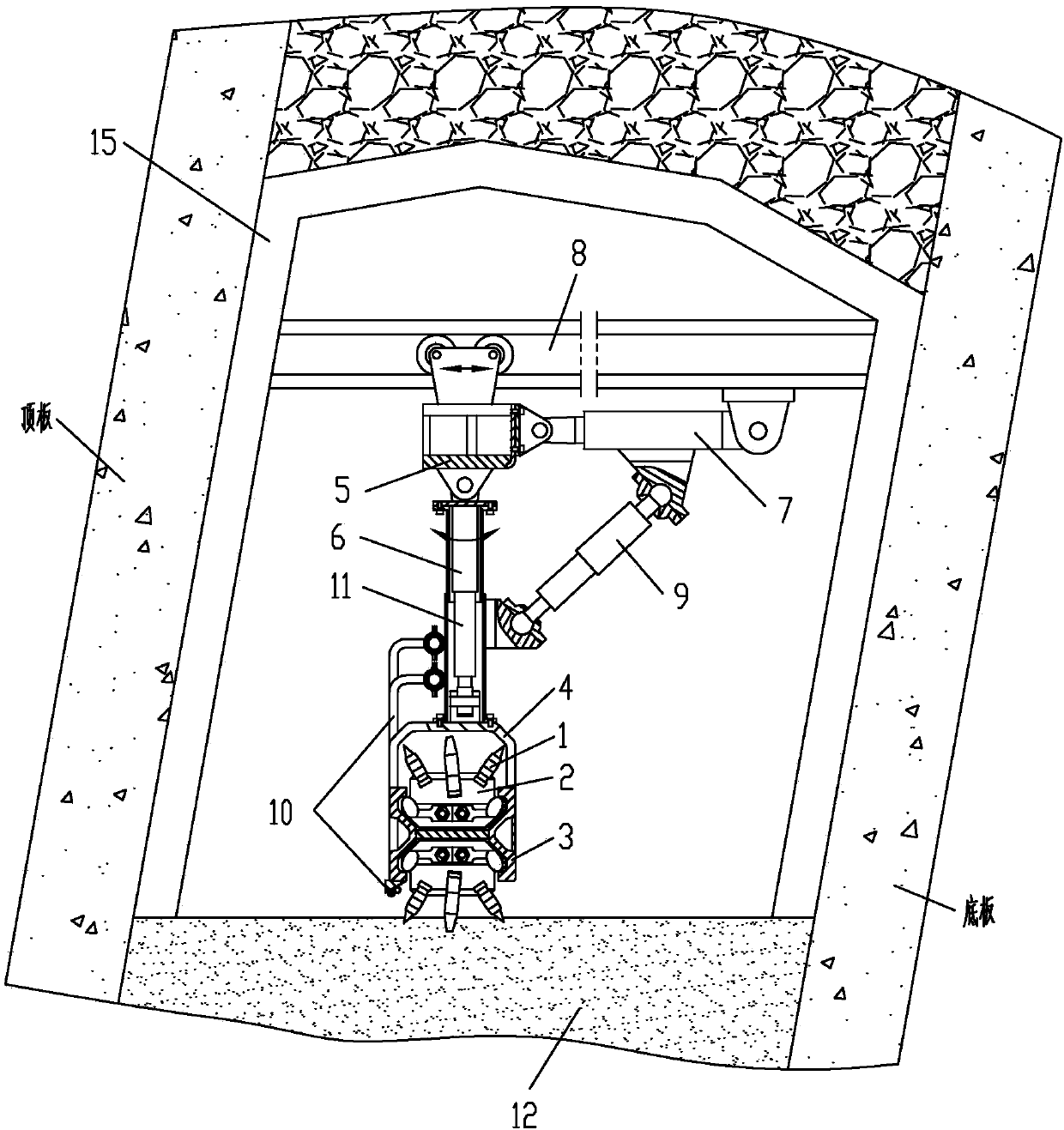

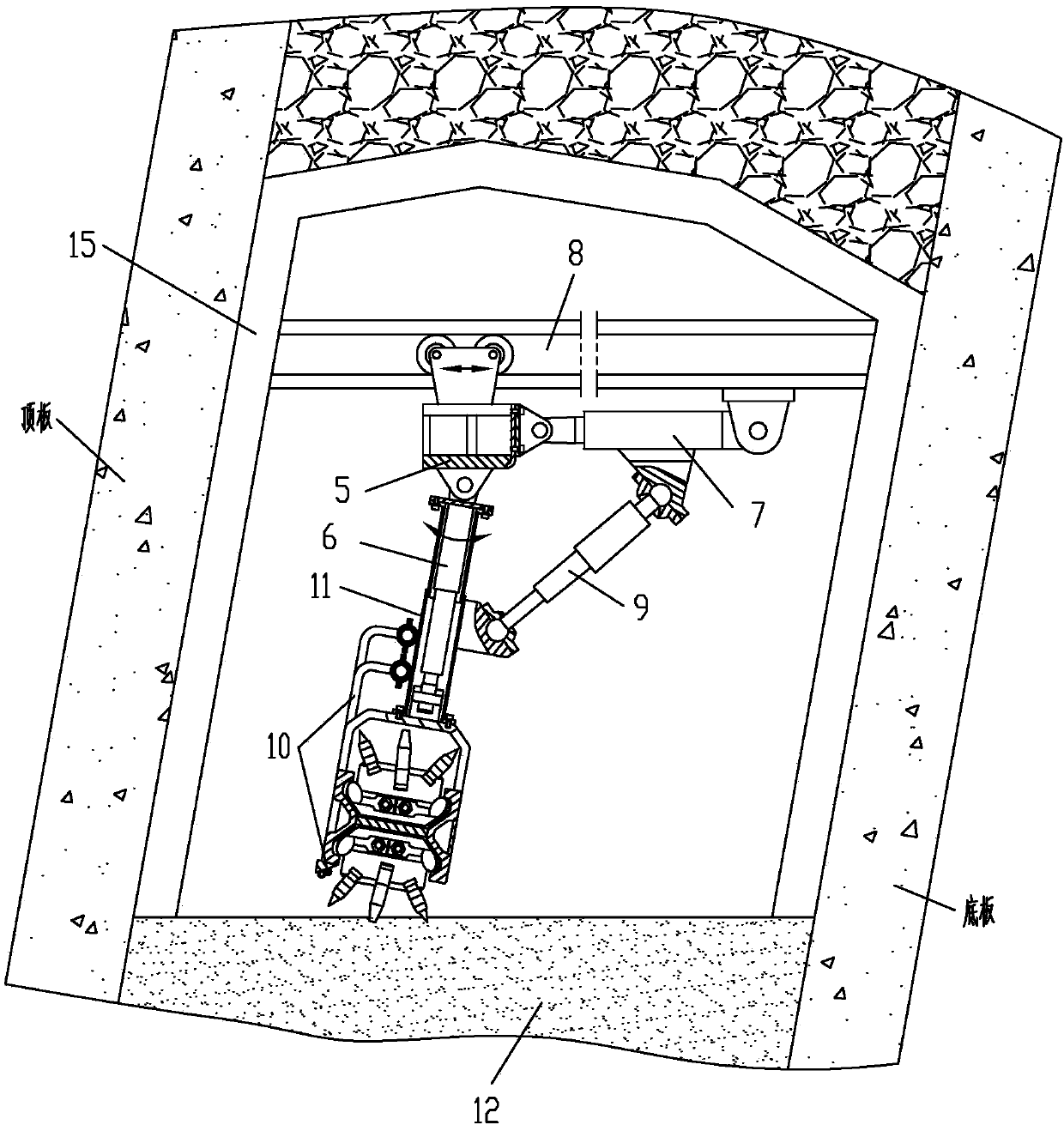

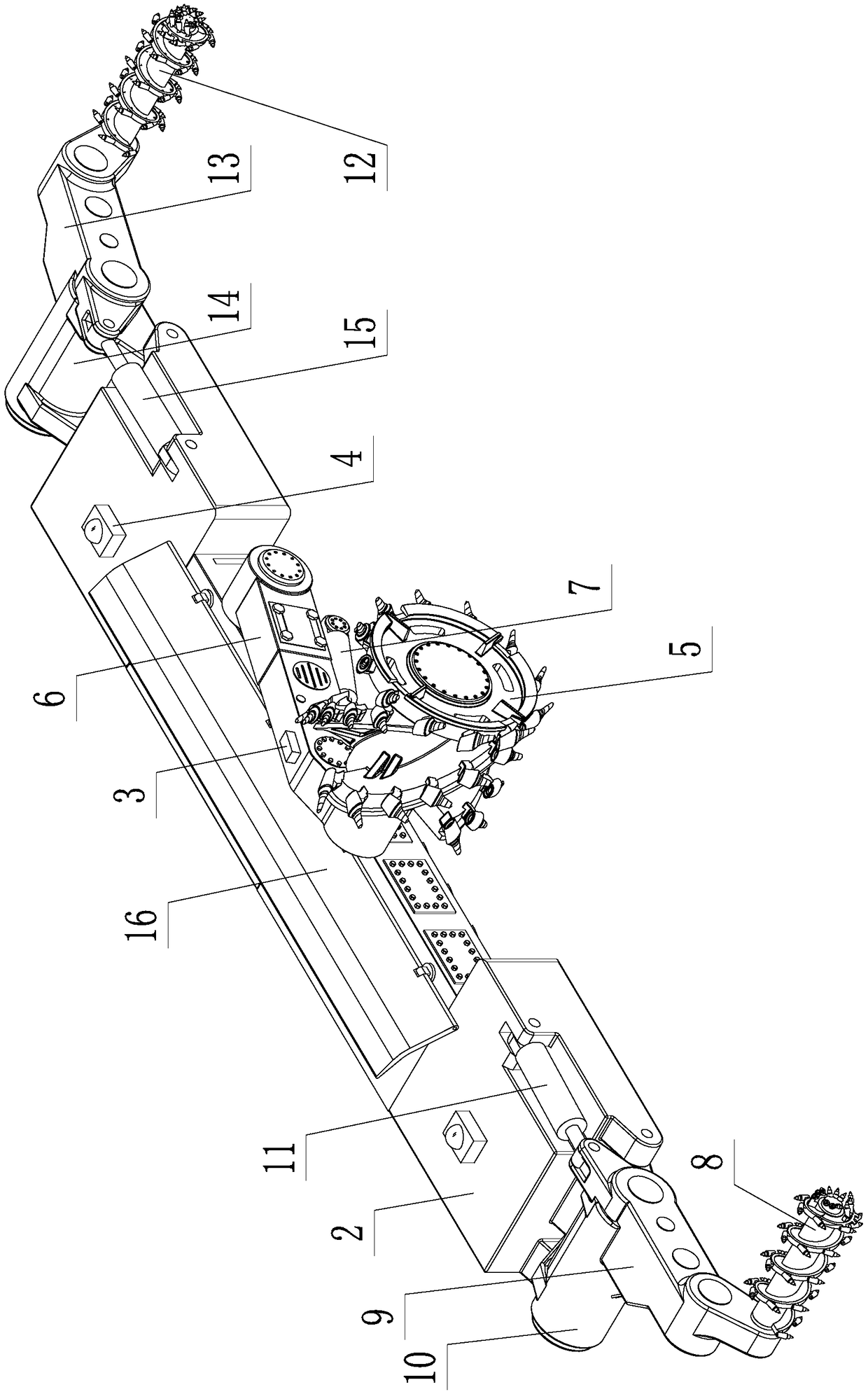

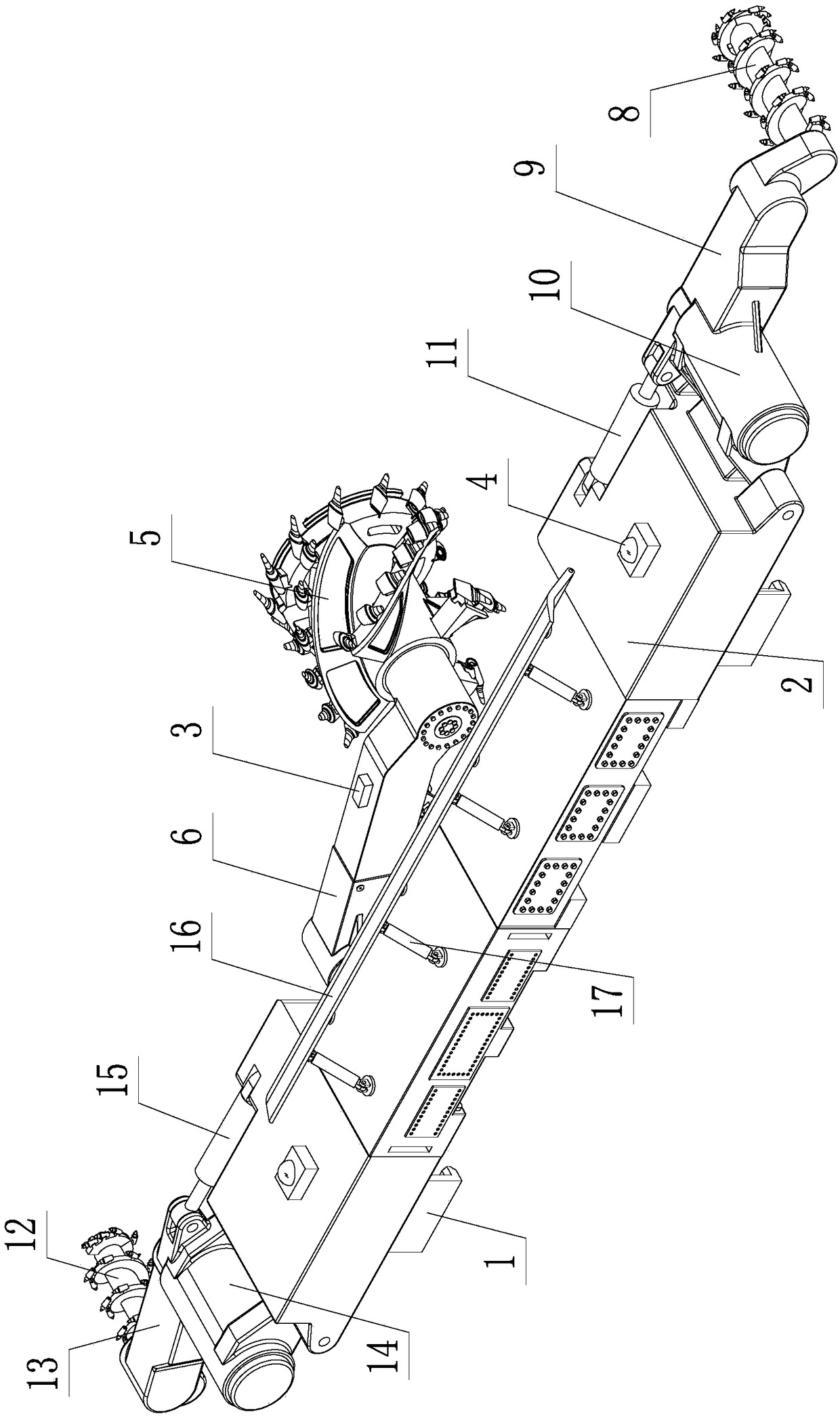

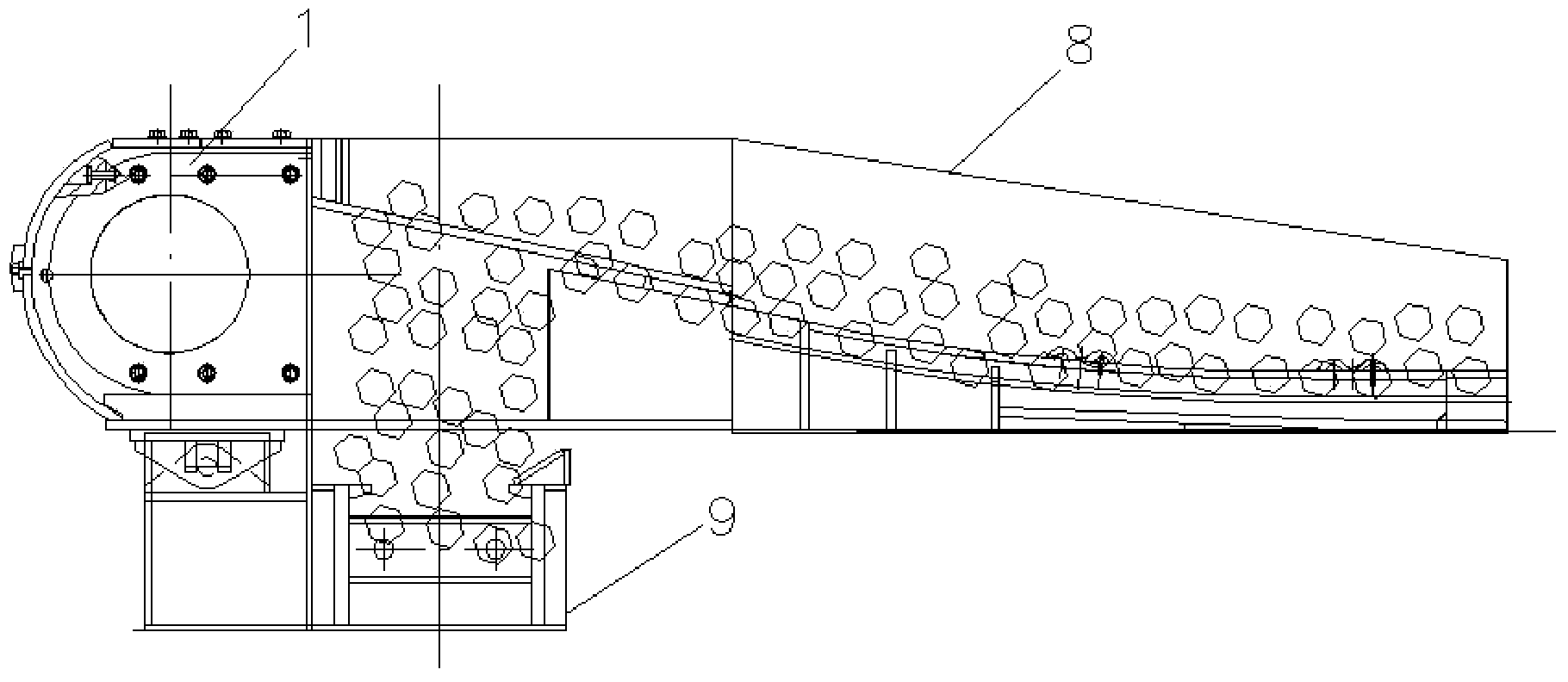

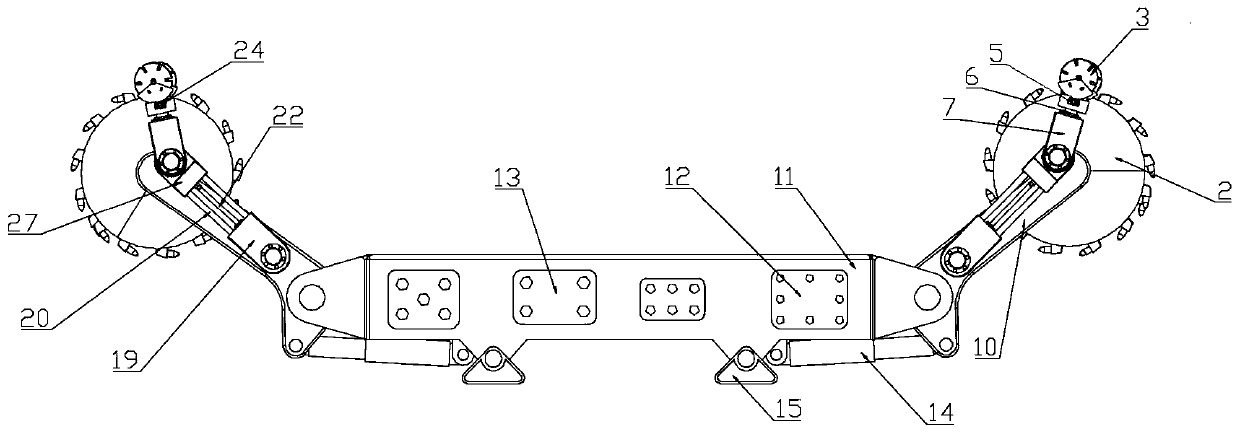

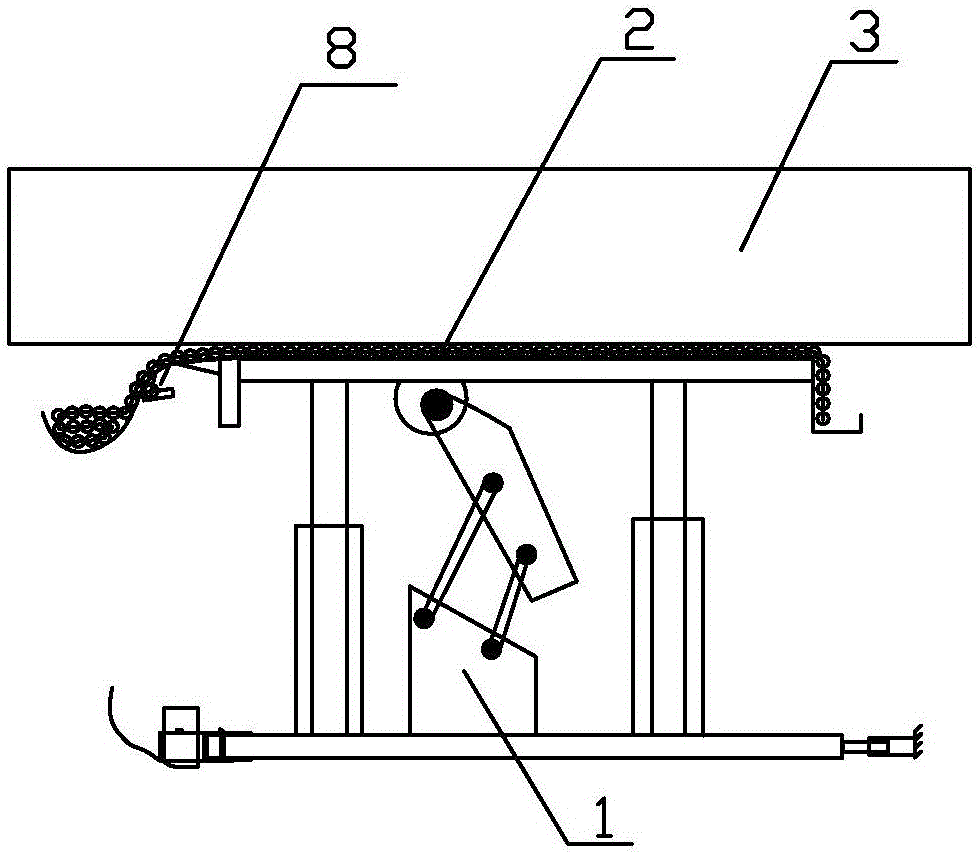

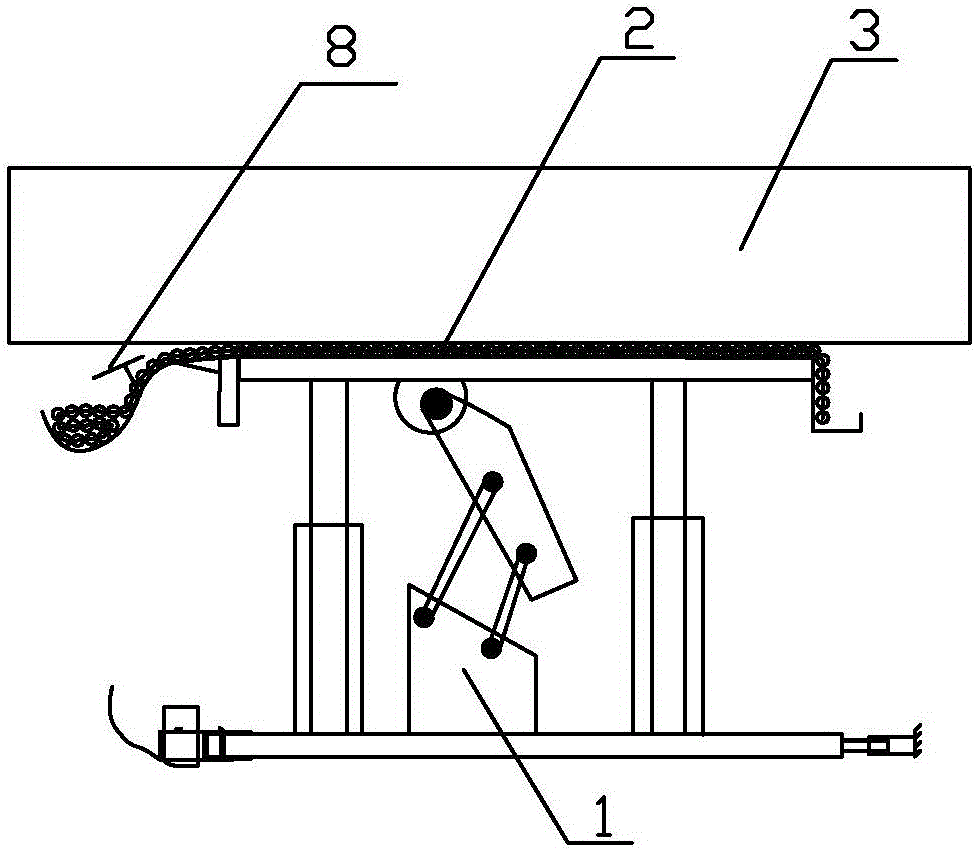

Steep dip medium-thickness coal seam coal-mining device and mechanical method

ActiveCN103953347AImprove coal mining efficiency and recovery rateReduce the labor intensity of coal miningUnderground miningSurface miningCoal miningMoving parts

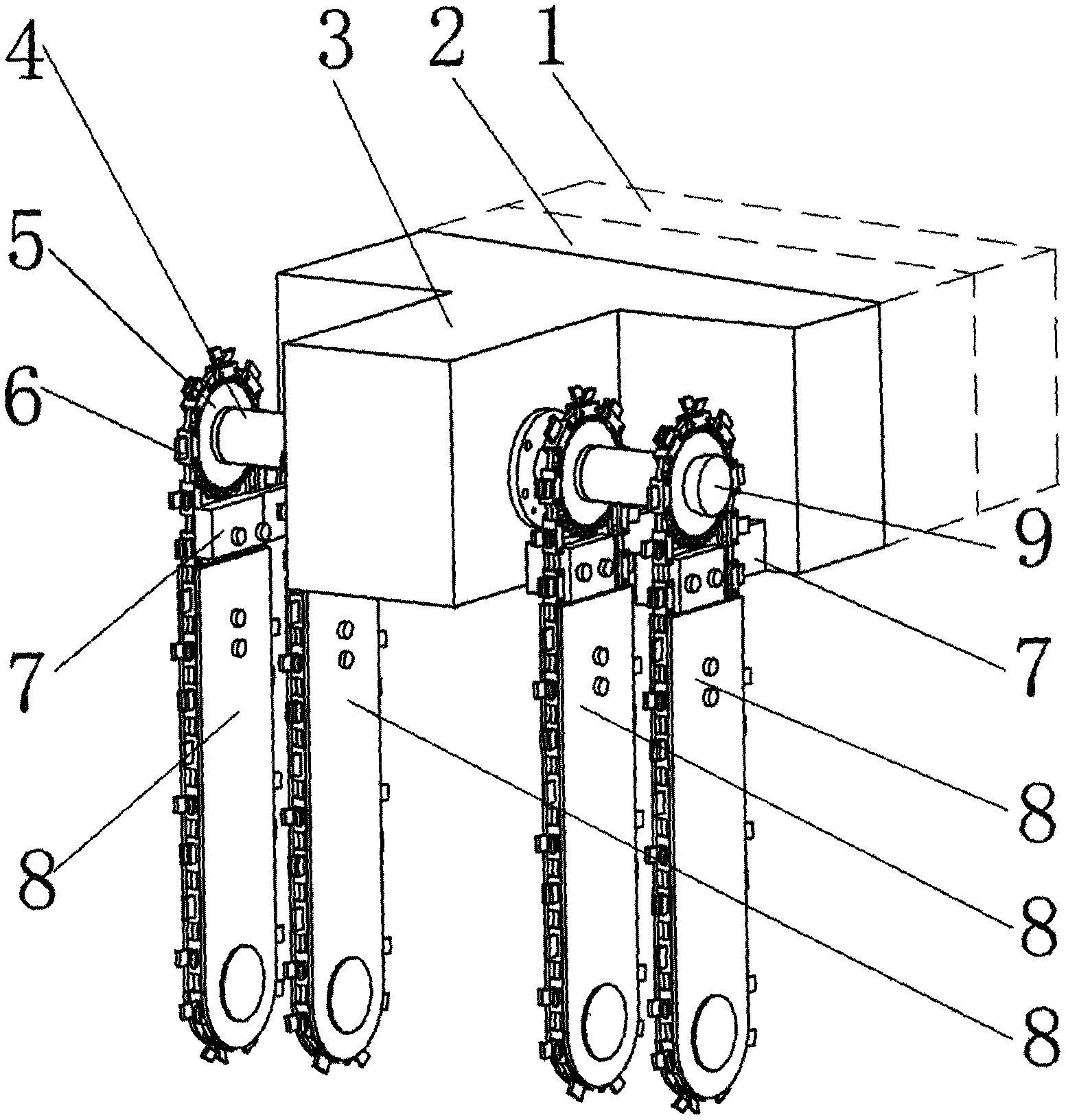

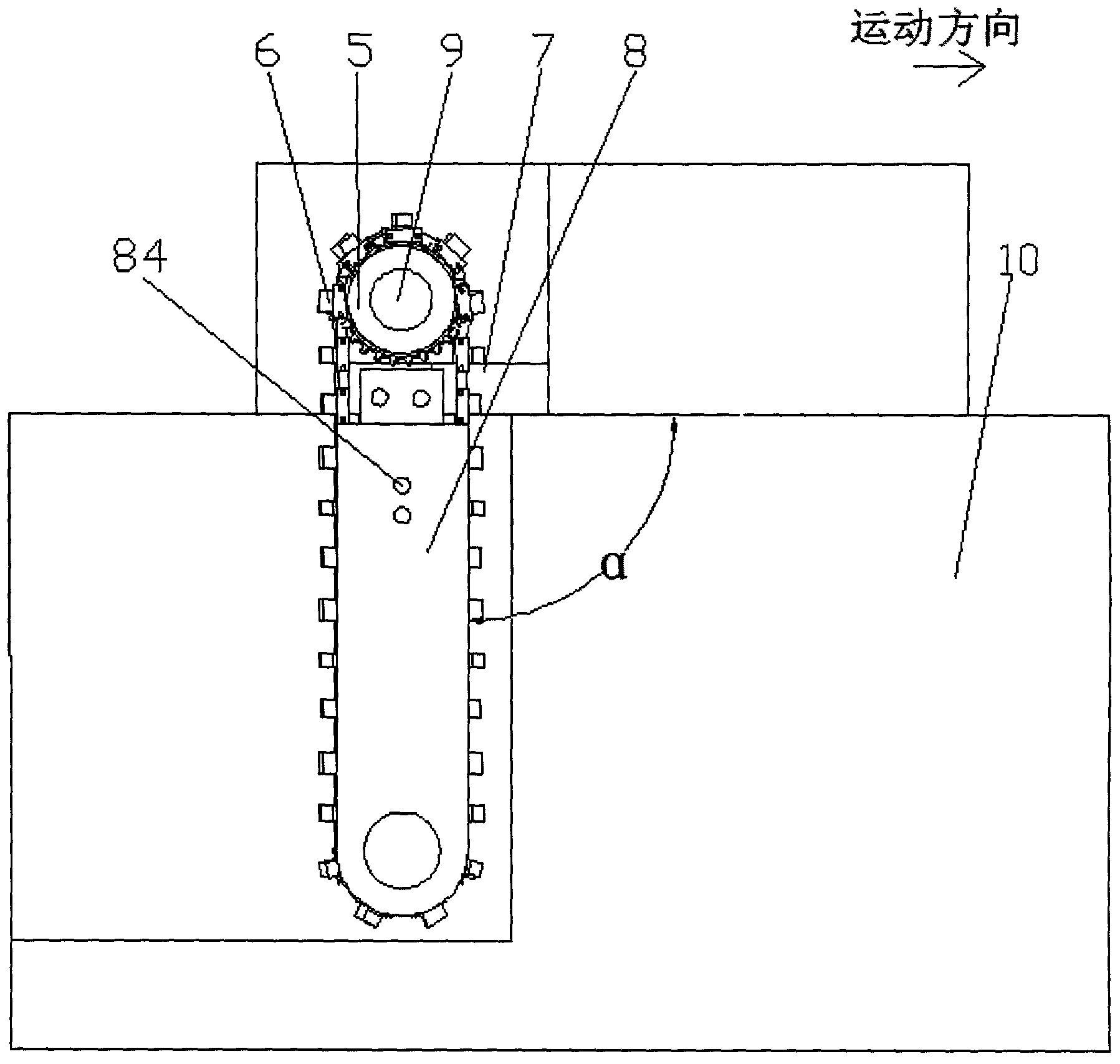

The invention discloses a steep dip medium-thickness coal seam coal-mining device and a mechanical coal mining method. The device comprises a coal mining and conveying all-in-one machine, a hydraulic system and a control system, wherein coal interception teeth are arranged on a conveying scraper blade of the coal mining and conveying all-in-one machine; the upper ends of two sides of a stander of the coal mining and conveying all-in-one machine are fixedly connected with portal hanging brackets; cross beams are arranged above the hanging brackets and are connected with moving components hinged to feeding oil cylinders; the other end of each feeding oil cylinder is connected with the corresponding hanging bracket; a transverse pushing oil cylinder is connected between each moving component and the corresponding cross beam; all the feeding oil cylinders and all the transverse pushing oil cylinders are connected with the hydraulic systems; piston rods of all the feeding oil cylinders and all the transverse pushing oil cylinders respectively correspond to form synchronous telescoping. The coal mining method realizes laying-down continuous coal mining and conveying by adopting the device. The steep dip medium-thickness coal seam coal-mining device and the mechanical coal mining method have the beneficial effects that the coal mining efficiency and the recovery rate can be effectively increased, the coal mining labor intensity is alleviated, and the mechanical degree is high; the coal mining method is the specific application of the coal mining device, so that the coal seam recovery rate is high, and the mechanical degree is high.

Owner:王洁

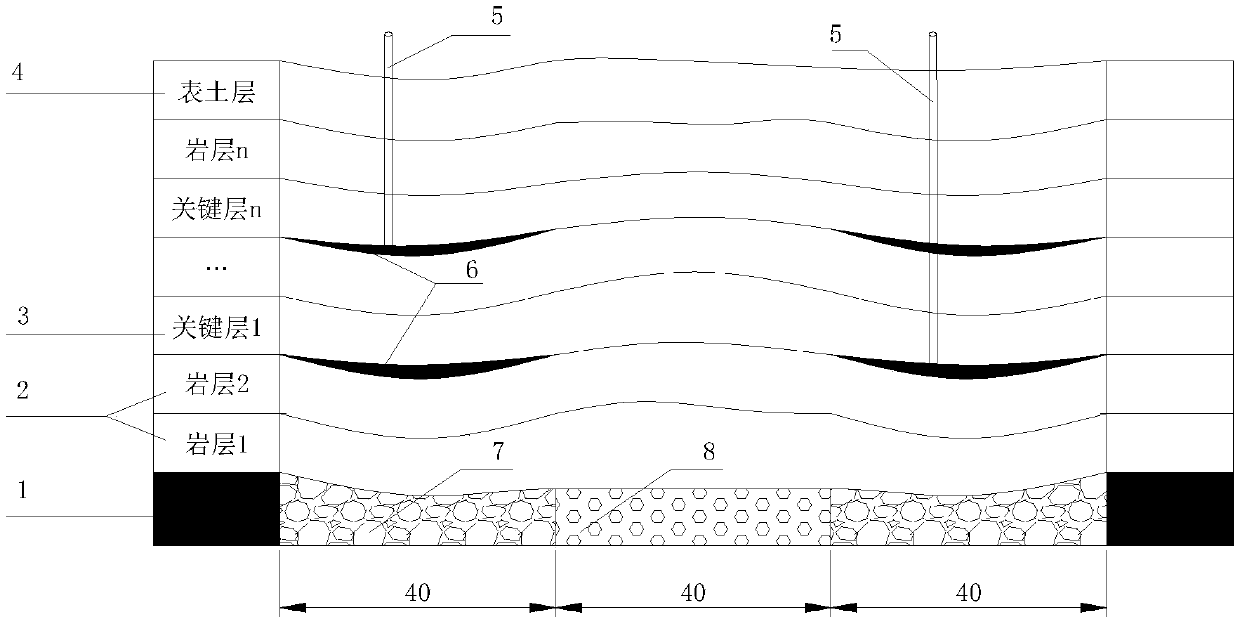

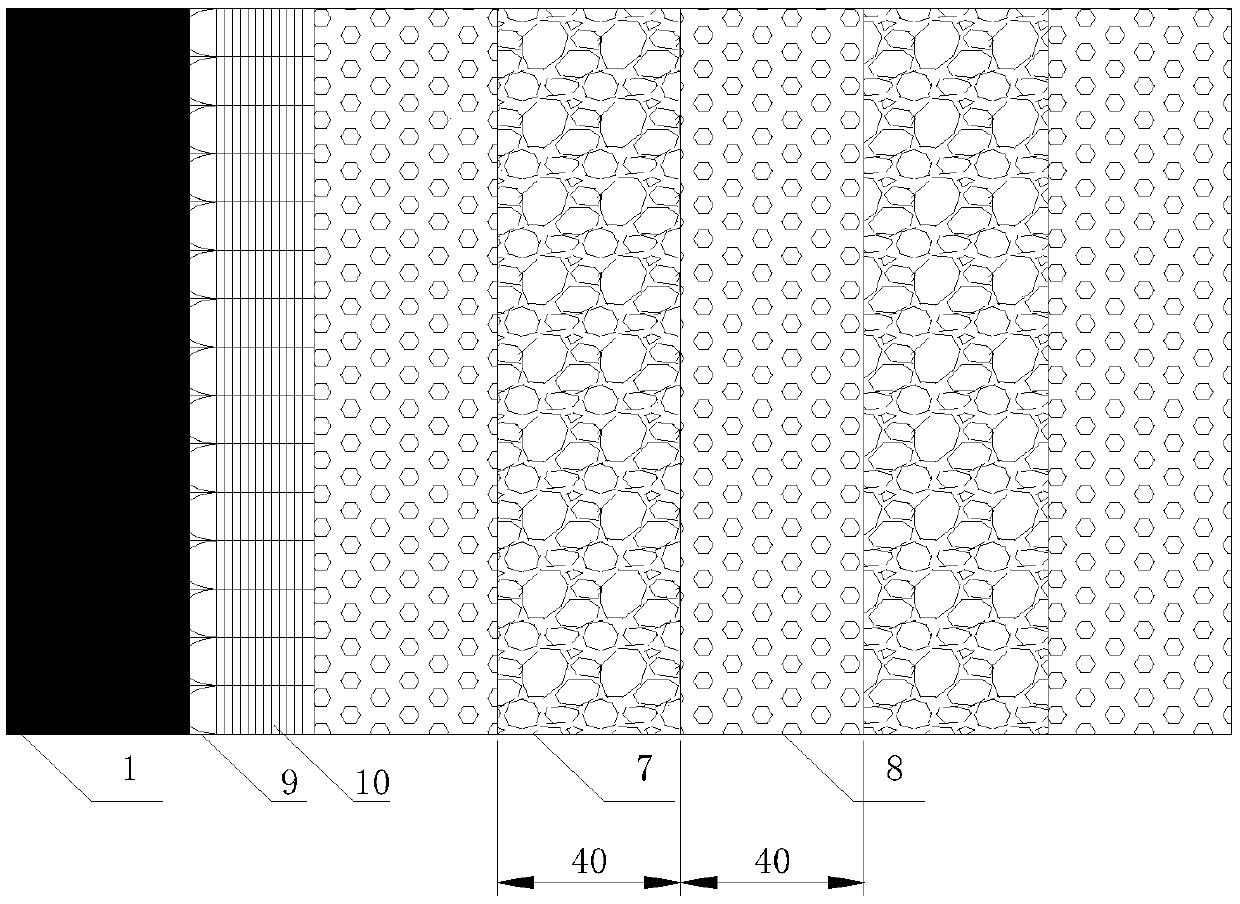

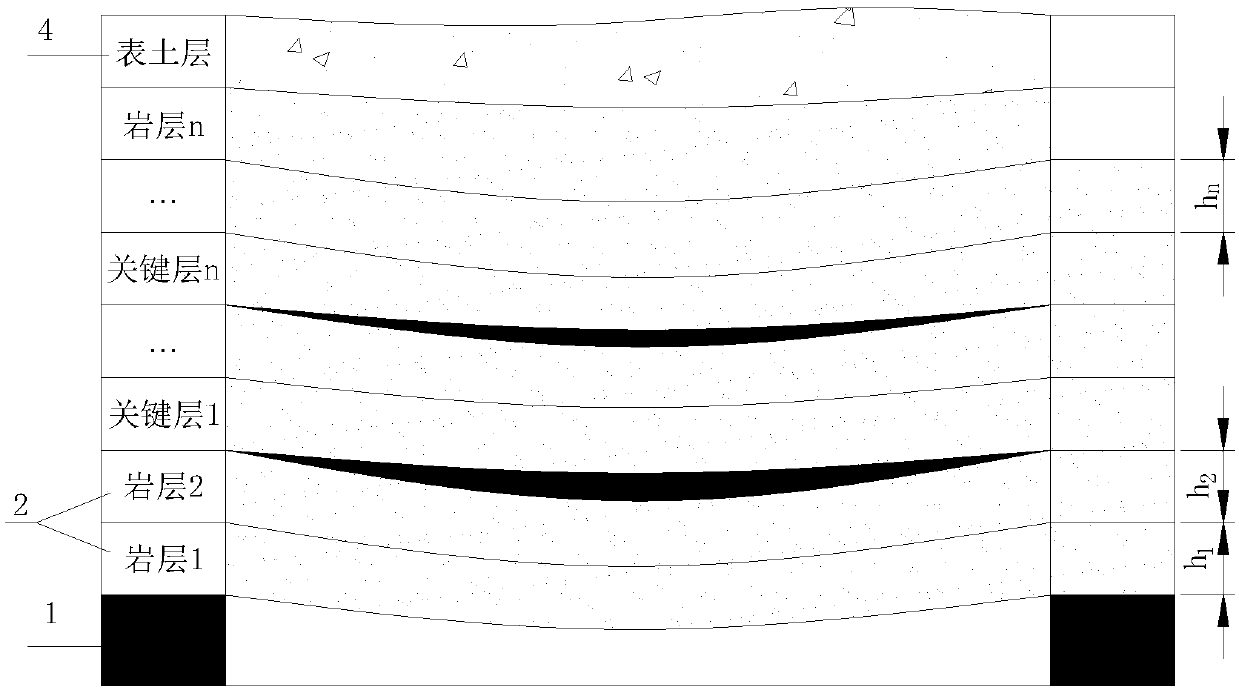

Method for controlling ground surface subsidence through coal mining filling

InactiveCN109681206AReduce dosageSpeed upUnderground miningSurface miningSupporting systemMining engineering

The invention discloses a method for controlling ground surface subsidence through coal mining filling. The method comprises the following steps that the load of each rock stratum is calculated according to the physical and mechanical properties of mine rock strata, if the load of the corresponding rock stratum is smaller than the load of the lower-layer rock stratum, the corresponding rock stratum serves as a key stratum, and all the key strata are found out; the side face of a coal bed serves as a coalface, a filling support is arranged on the coalface, in the coal mining process, every timewhen the coalface is propelled by a distance, gangue filling strips are constructed in the propelling direction, caving top plate strips are formed through a caving method, and the gangue filling strips and the caving top plate strips are arranged at intervals; in the caving process, a bed separation space is formed; and the bed separation space is filled with a high-water material to form a high-water filling body, and a combined support system of the filling strips and the high-water filling body is realized. The method for controlling the ground surface subsidence through coal mining filling has the advantages that gangue filling and high-water material filling are combined so as to control the ground surface subsidence, and therefore the supporting effect is improved, and the cost islowered.

Owner:NORTH CHINA INST OF SCI & TECH

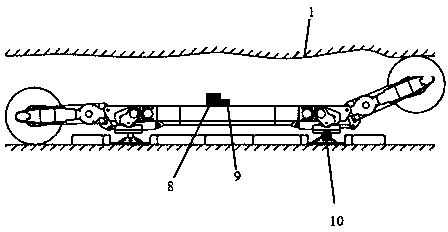

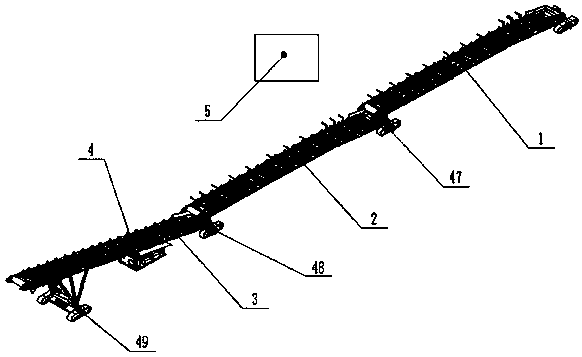

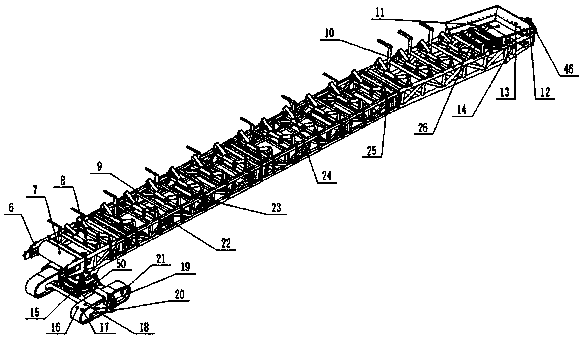

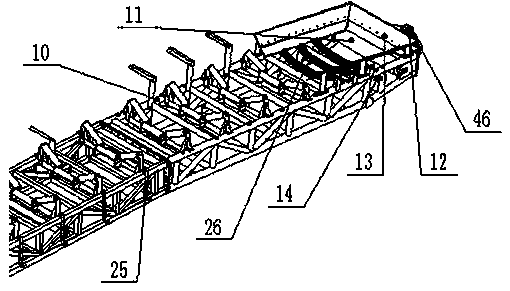

Walking belt type transferring system

The invention discloses a walking belt type transferring system. The system is used in cooperation with a continuous coal mining machine. The system comprises multiple belt type transferring machinesof a strip-shaped conveying belt, continuous track walking mechanisms, a power platform and a remote control chamber, wherein the belt type transferring machines are connected end to end, the belt type transferring machines are connected through circular ring chains, the continuous track walking mechanisms are arranged on the connecting portions of the adjacent belt type transferring machines andbelow the suspending ends of the belt type transferring machines, connected with the belt type transferring machines and used for driving walking, the power platform is arranged below the belt transferring machine located on the discharging side, and the remote control chamber is connected with the continuous track walking mechanisms and the power platform. The belt type transferring machine on the feeding side is connected with the continuous coal mining machine through a cross-shaped hinge base and a hinge pin. According to the system, the combination structure of multiple units is adopted,each unit comprises one continuous track walking mechanism, a hinge disc, a machine head frame, a middle frame and a machine tail frame, due to the combination design, and the system has the advantages that the conveying ability is high, the structural member is relatively small in size, assembling, disassembling and transporting are convenient, traction force is large, the system is flexible, reliability and safety are high, and adaptability is high.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Roadway roof support device and support method

InactiveCN107218069AEasy constructionImprove securityUnderground chambersTunnel liningRaw materialBuilding construction

The invention discloses a roadway roof support device and support method. A roadway support mode is changed, and a top support mode is changed from anchor rod and anchor cable support in cooperation with a T140 steel belt to anchor rod and anchor cable separation support. By adopting an advance and temporary support device as a support, the time of manually contacting the steel belt in the whole process is short, the procedure of ascending operation is omitted, the risk coefficient of artificially installing the steel belt is effectively reduced, the construction speed is increased, the operation method is simple, the manpower is saved, the support density is increased without adding the purchase process of extra tools and raw materials, and the roadway roof support device and support method are suitable for popularization.

Owner:陕西陕煤黄陵矿业有限公司

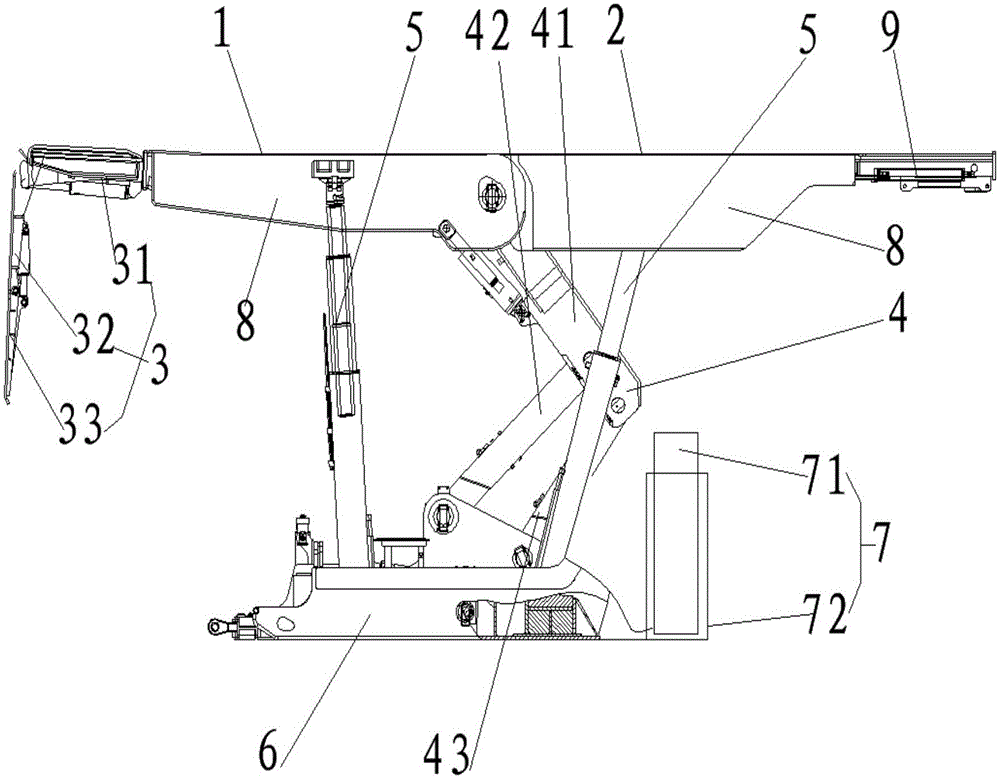

Intelligent self-adaption coal mining machine for thin coal seam and coal mining cutting method

InactiveCN108952704AImprove coal mining efficiencyReduce workloadUnderground miningSurface miningEngineeringElectric control

The invention discloses an intelligent self-adaption coal mining machine for a thin coal seam and a coal mining cutting method. The coal mining machine comprises walking parts, a machine body part, cutting parts, a hydraulic part, an electronic control part, an intelligent detection part and a fault warning part. The walking parts are arranged at both ends of the machine body part in the length direction of a scraper conveyor. The cutting parts include a main cutting part and two auxiliary cutting parts, the main cutting part is located in the middle of the machine body part, and the two auxiliary cutting parts are located at both ends of the machine body part. The hydraulic part and the electric control part are installed in the inner side of the machine body. The intelligent detection part is arranged on the main cutting part. The fault warning part is arranged on the machine body part. The coal mining cutting method comprises the steps that information is collected by the intelligent detection part, and processed and analyzed by the electronic control part, inclined cutting grooving is carried out through the auxiliary cutting part on one side for unloading, the coal walls on the peripheries of unloading grooves are cut by the main cutting part, the remaining coal walls are cut or profile modification of bottom edges is carried out by the auxiliary cutting part on the otherside, intelligent obstacle-navigation during the cutting process is carried out until a cutting surface is completed, the direction is turned and cutting is carried out continuously.

Owner:LIAONING TECHNICAL UNIVERSITY

Hydraulic support for high-water cut and fill mining

InactiveCN105065049AGuaranteed filling effectCoal mining works smoothlyMaterial fill-upMine roof supportsEngineeringCut and fill

The invention relates to the technical field of coal mining and discloses a hydraulic support for high-water cut and fill mining. The hydraulic support comprises a front top beam, a rear top beam, a length-changeable extension structure, a connection structure, a telescopic stand column, a base and a height-adjustable baffle structure. According to the hydraulic support, the front top beam and the rear top beam are integrated at the same base at the same time, the front top beam and the rear top beam are supported through the telescopic stand column, the front top beam can support a coal mining region and a coal wall, and smooth operation of the coal mining work is guaranteed; the rear top beam conducts supporting and cut and fill supporting on the top face of a goaf in the next process while conducting coal mining, and the baffle structure can isolate the goaf, so that high-water packing materials can achieve cut and fill forming in the goaf so as to form the thickness having the supporting function quickly, and the cut and fill effect is guaranteed; by means of the hydraulic support, the coal mining work and the cut and fill work are conducted at the same time, and the coal mining efficiency and the cut and fill efficiency are improved greatly.

Owner:冀中能源股份有限公司邢东矿

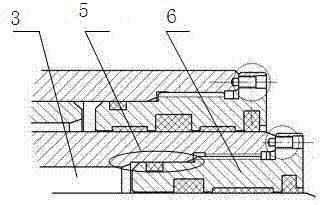

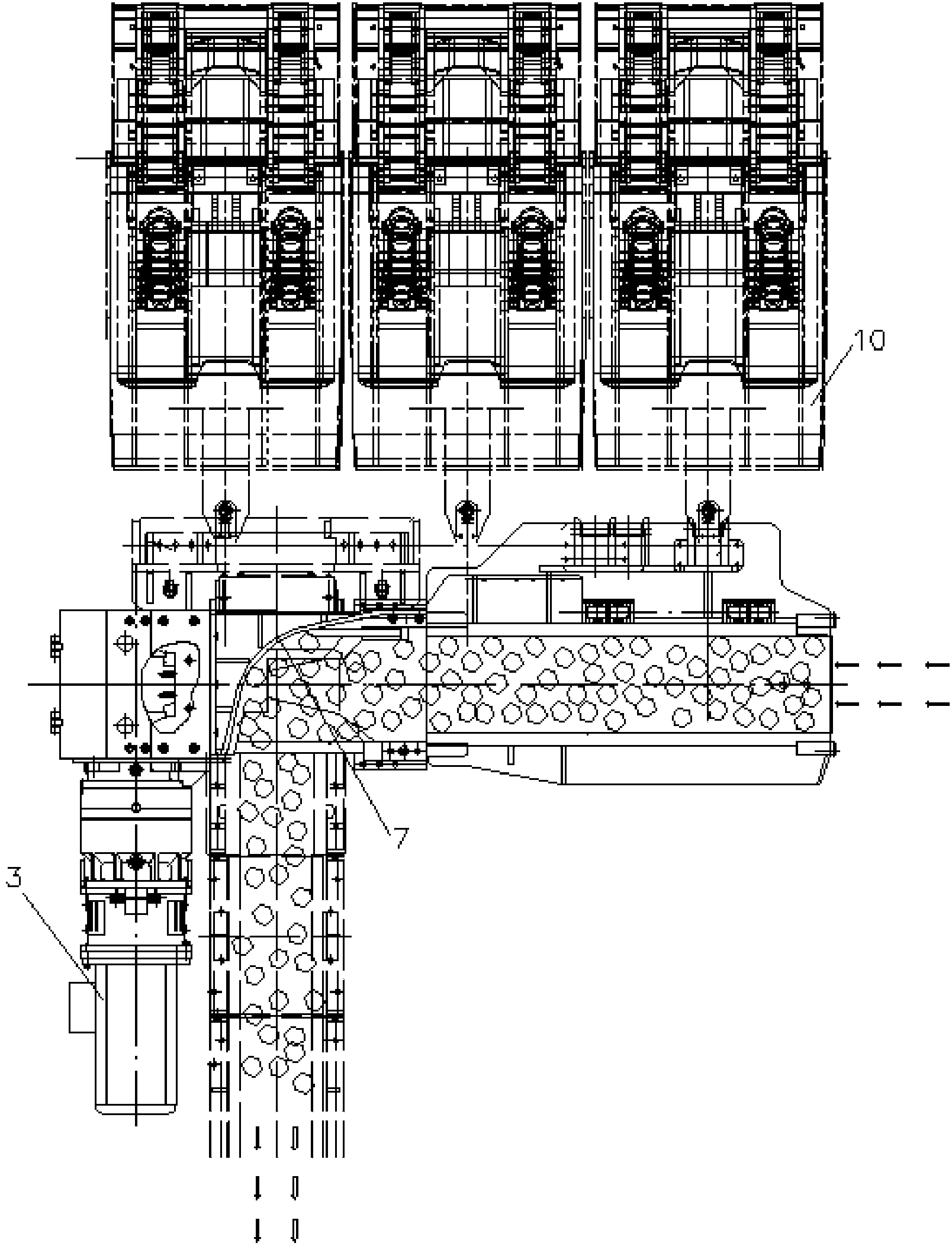

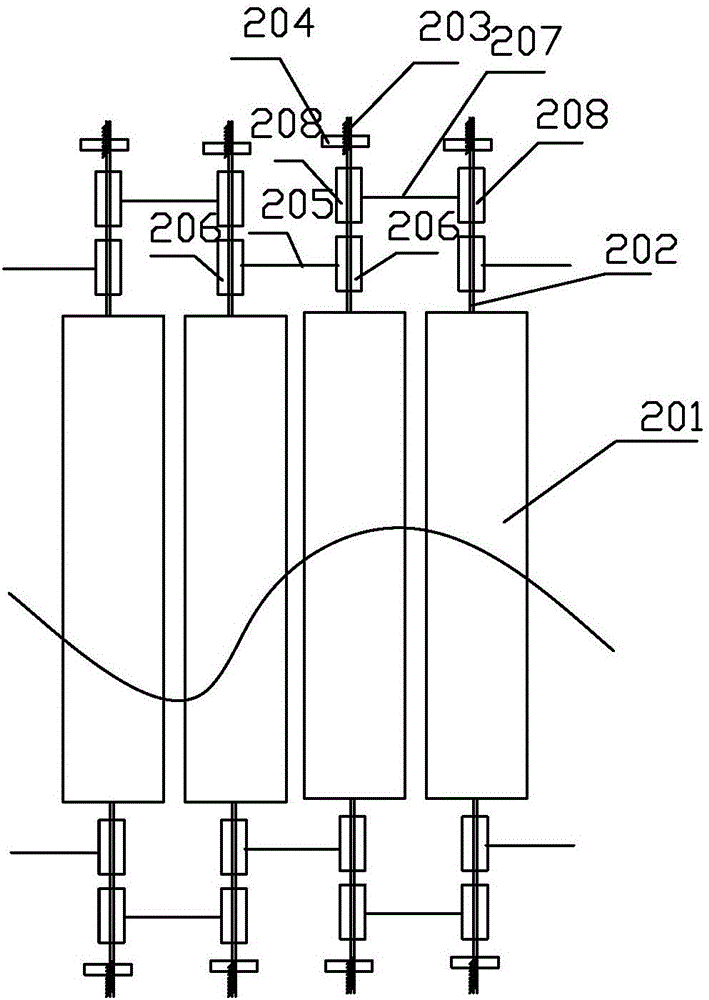

Novel thin coal seam overlapped side-unloading structure

ActiveCN103775082AUnreasonable solutionAvoid excessive lag problemsSlitting machinesHysteresisEngineering

The invention relates to a working surface scraper conveyer and a reversed transportation roadway loader, and in particular relates to a novel thin coal seam overlapped side-unloading structure. The novel thin coal seam overlapped side-unloading structure comprises a conveyor (8) and a reversed loader (9), and is characterized in that an unloading connection groove (5) is formed in the tail of the reversed loader (9); the head of the conveyor (8) is fixedly lapped to the unloading connection groove (5) in the tail of the reversed loader (9). According to the technical scheme, the problem of unreasonable installation position of a power part caused by an existing end-unloading mode is solved, and the problems of over-hysteresis and non-smooth ventilation of an end hydraulic support and a hydraulic support on a working surface are avoided. According to the technical scheme, by changing the loading mode of the head, the structure of the head and the installation position of the power part, the arrangement spaces of the head of the conveyor, the tail of the reversed loader and the hydraulic supports are improved, the roadway support difficulty of the head is reduced, and the safety and coal mining efficiency of the working surface are improved.

Owner:NINGXIA TIANDI BENNIU IND GRP

Fluidized coal mining large-range coal breaking device and using method

ActiveCN112832764AIncrease the effective spray distanceAvoid entanglementDisloding machinesSlitting machinesThermodynamicsWell drilling

The invention discloses a fluidization coal mining large-range coal breaking device and a using method. The coal breaking device comprises a supporting stand column, a spraying distance control telescopic cylinder and a spray head assembly; the bottom end of a cylinder body of the spraying distance control telescopic cylinder is hinged and installed on a telescopic cylinder mounting base of the supporting stand column, and a cylinder body swing control mechanism is further arranged between the spraying distance control telescopic cylinder and the supporting stand column; and the spray head assembly comprises a spray head and a water conveying high-pressure hose, the spray head with the spraying direction arranged in the radial direction of the supporting stand column is installed at the telescopic end of the spraying distance control telescopic cylinder through a spray head swing mechanism, the top end of the water conveying high-pressure hose is in closed communication connection with a high-pressure conveying pipe, and the bottom end of the water conveying high-pressure hose is in closed communication connection with the spray head. According to the fluidization coal mining large-range coal breaking device, the effective spraying distance of the spray head can be effectively increased, the coal mining area range of a single drilling well for ground drilling coal mining can be greatly increased on the premise that the construction cost of ground drilling is not increased, the coal mining efficiency is improved, and the mining cost is reduced.

Owner:CHINA UNIV OF MINING & TECH

Full-automatic coal mining machine with coal rock identification function and working method of full-automatic coal mining machine

ActiveCN109798110AImprove working environmentAvoid wastingUnderground miningTesting machinesSpiral bladeWorking environment

The invention relates to a full-automatic coal mining machine with a coal rock identification function and a working method of the full-automatic coal mining machine, belongs to the technical field ofcoal rock cutting identification. The full-automatic coal mining machine comprises a coal mining machine main body, a cutting portion and an auxiliary cutting device, wherein the coal mining machinemain body controls the height of the cutting portion through a rocker arm; the cutting portion comprises spiral blades and a cutting drum, and is used for cutting operation; the auxiliary cutting device is arranged on the rocker arm, an identification device cuts and judges a coal rock boundary through cooperation of a rotary support, a rotary mechanical arm, a cutting support and a telescopic support, the lifting operation of the cutting portion is judged through data acquired by the identification device, the full-automatic coal mining machine is suitable for underground coal mining operation under complex working conditions, is high in identification rate, is accurate, and is high in stability, the working environment of workers can be greatly improved, and meanwhile, the coal mining efficiency is also improved.

Owner:SHANDONG UNIV OF SCI & TECH

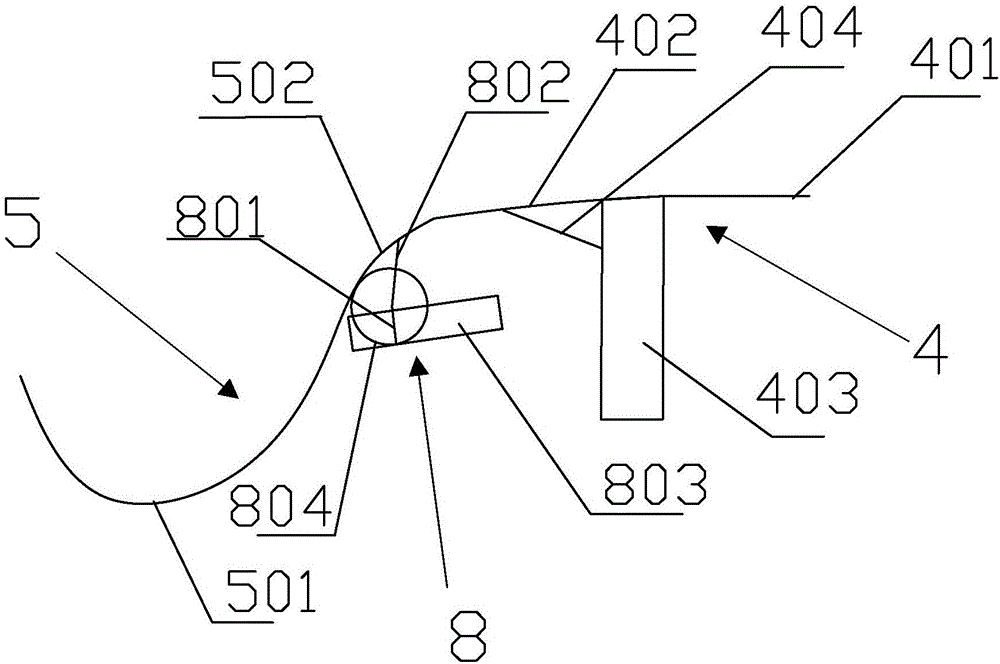

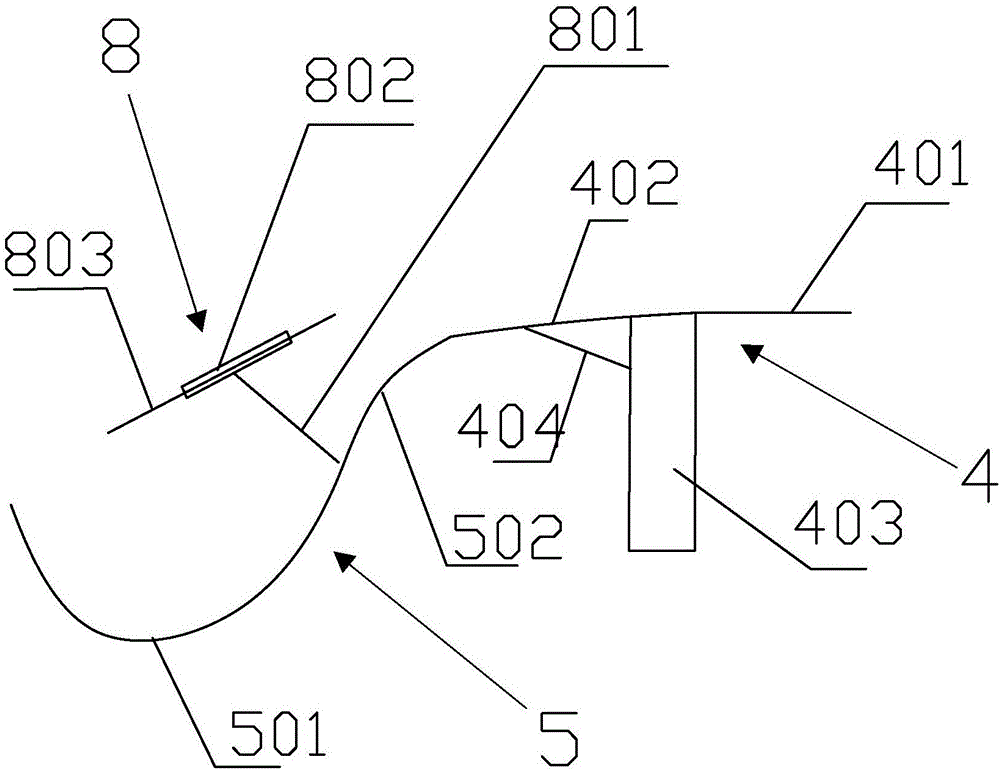

Improved advance support body and using method thereof

InactiveCN106285749AImprove production safetyImprove coal mining efficiencyMine roof supportsFuel tankEngineering

The invention discloses an improved advance support body. The improved advance support body comprises a roof support body and a floor support body; the roof support body comprises an advanced hydraulic support (1), a cylindrical pressure-bearing array (2) and a lubricating brush (8), wherein the lubricating brush (8) comprises a fixing rod (801), supporting rods (802), an oil tank (803) and a cylindrical brush (804); the floor support body comprises a bearing block (9), an anti-drilling bottom baffle plate (10) and a guide plate (11); the bearing block (9) is connected with the front end of a base of the advanced hydraulic support (1); a fixed groove (12) which penetrates vertically is formed in the middle of the bearing block (9). The improved advance support body disclosed by the invention has a simple structure, and is reliable and practical.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Hydraulic drilling and bursting exploitation method for ultra-thin coal seam

ActiveCN105804747AReduce labor intensityAvoid defectsDisloding machinesHydraulic miningEngineeringUltimate tensile strength

The invention discloses a hydraulic drilling and bursting exploitation method for an ultra-thin coal seam. The hydraulic drilling and bursting exploitation method is characterized by comprising the following steps that a, a power pump, a scraper conveyor; a transfer conveyor, a belt conveyor, a hydraulic auger miner, a bursting device and a bastard coal washing mud-water separating system are placed in a machine tunnel; b, holes are drilled through hydraulic power, and specifically a set of hydraulic power drilled holes are formed in a coal face; c, coal discharging holes are formed in the lower ends of the hydraulic power drilled holes; d, the bursting device is placed in one hydraulic power drilled hole, and crushed coal passes through the coal discharging holes and falls onto the scraper conveyor; e, the crushed coal is transported through the scraper conveyor, the transfer conveyor and the belt conveyor; f, each coal discharging hole is sealed after the coal in the corresponding hydraulic power drilled hole is completely discharged; and g, the step c to step f are repeated in the pushing exploitation direction. According to the exploitation method, a coal worker does not need to enter the coal face, so that the safety is greatly improved, the labor intensity of the coal worker is relieved, and mechanical unmanned exploitation of the ultra-thin coal seam mining face larger than 50 degrees is achieved.

Owner:XIAN UNIV OF SCI & TECH +1

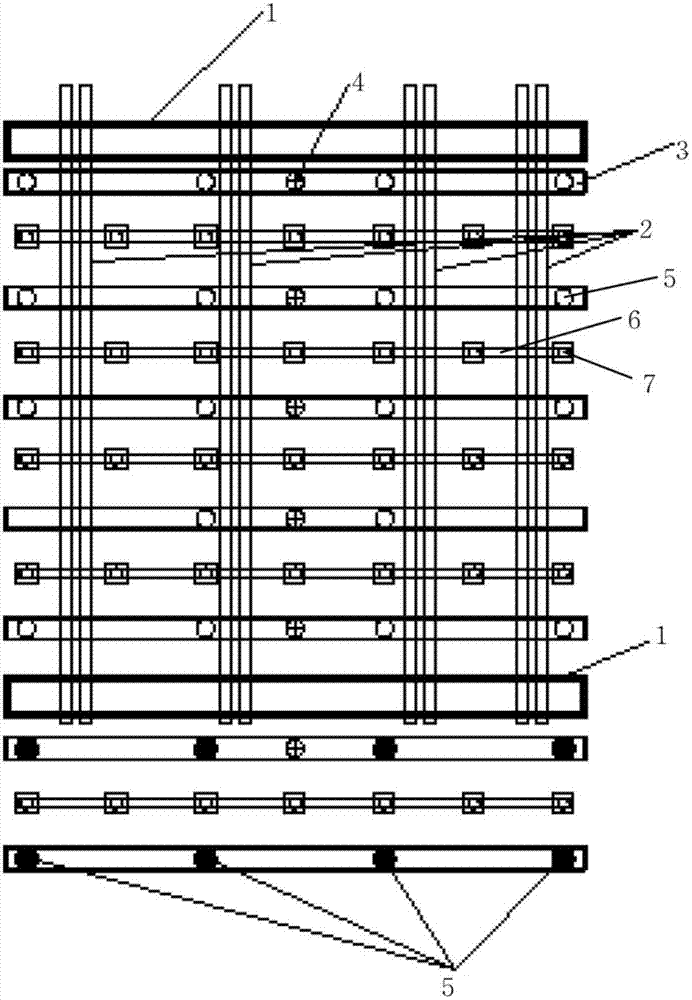

Advanced supporting system for bolt-mesh supporting and supporting method

ActiveCN106321135AImprove production safetyImprove coal mining efficiencyMine roof supportsSupporting systemEngineering

The invention discloses an advanced supporting system for bolt-mesh supporting. The advanced supporting system comprises a floor supporting body and a roof supporting body. The floor supporting body comprises a bearing block (9), a floor drilling preventing baffle (10) and a guiding plate (11), a vertically-through fixing groove (12) is formed in the middle of the bearing block (9), the guiding plate (11) is arranged in the fixing groove (12), and the floor drilling preventing baffle (10) is an arc plate. The roof supporting body comprises a front top beam protecting plate arranged at the front end of a top beam of an advanced hydraulic support (1), a rear top beam protecting plate arranged at the rear end of the top beam of the advanced hydraulic support (1), and a cylindrical pressure-bearing row (2), and the front top beam protecting plate comprises a plate-type pressure-bearing baffle (4) and a bar-type containing hopper (5). The advanced supporting system is simple in structure, low in cost and easy and convenient to operate.

Owner:ANHUI UNIV OF SCI & TECH

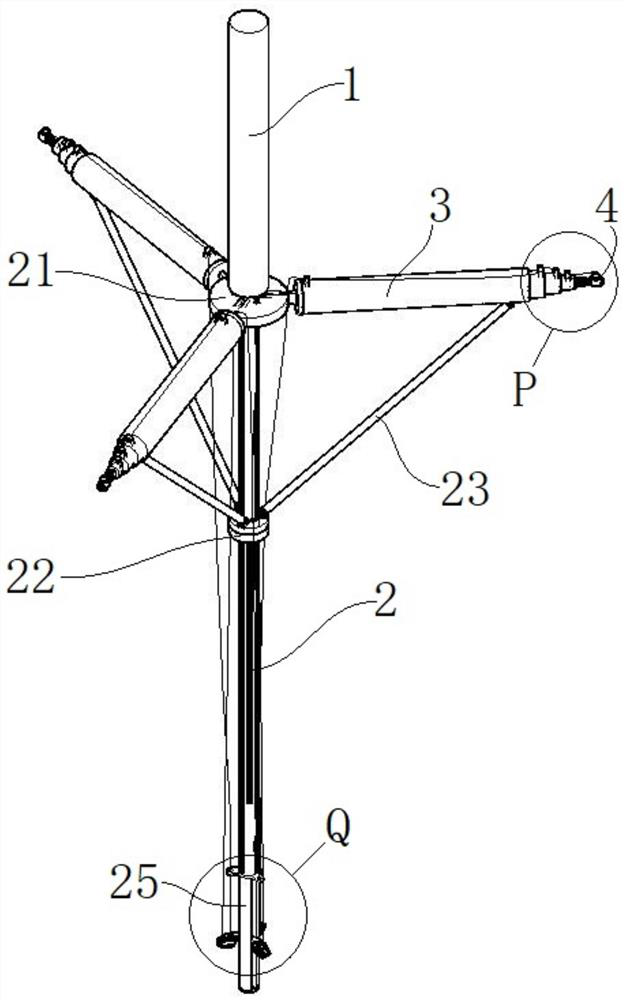

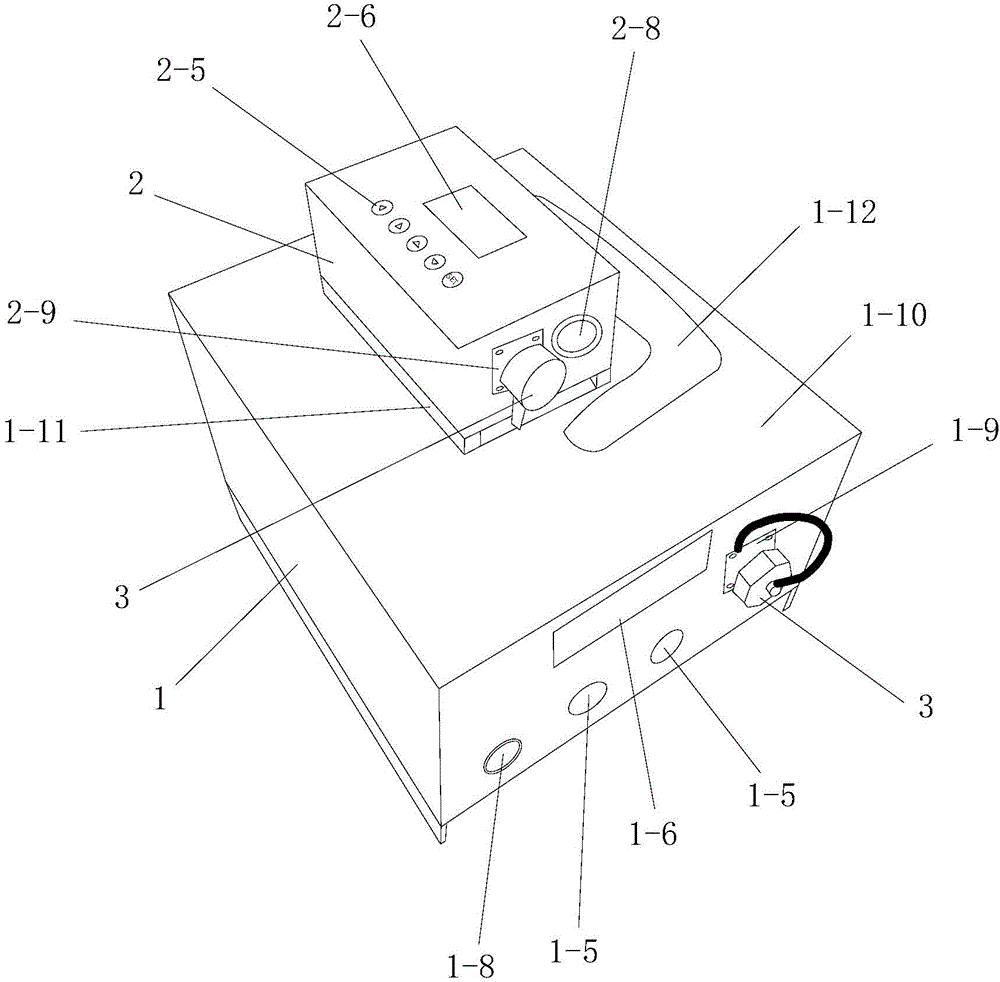

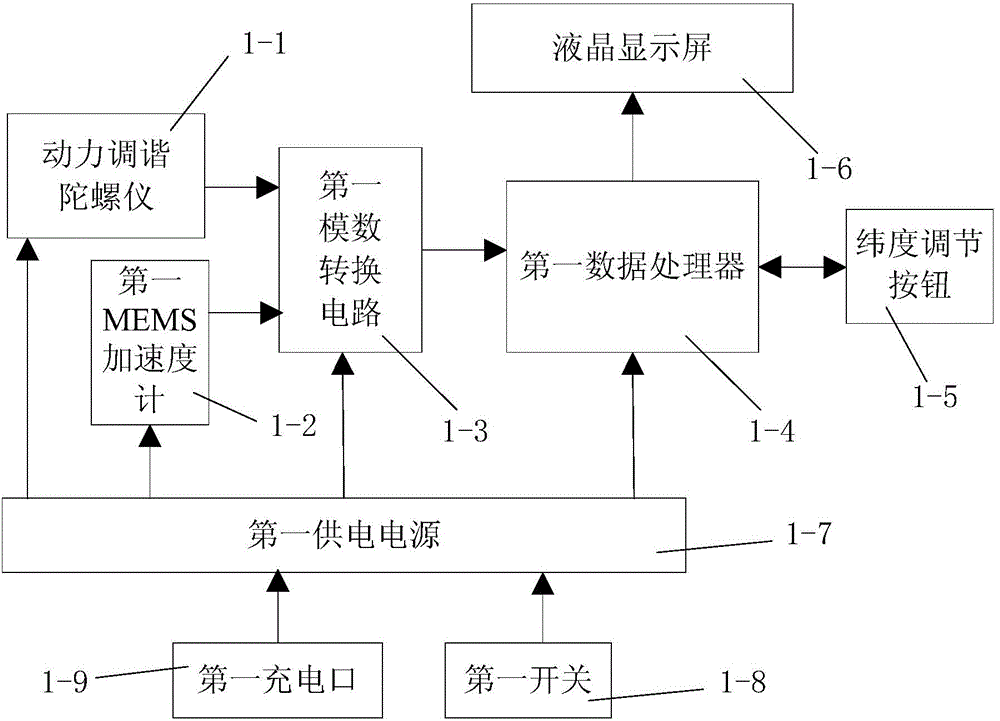

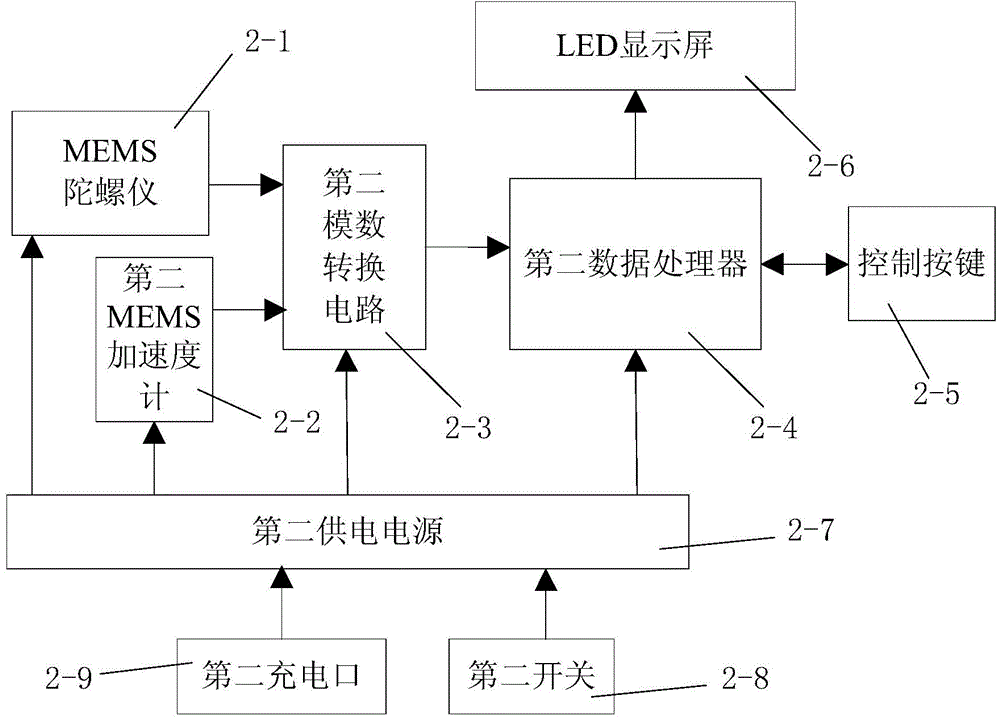

Drill attitude measuring instrument and drilling direction adjustment method

The invention discloses a drill attitude measuring instrument and a drilling direction adjustment method. The drill attitude measuring instrument comprises a north seeker and a direction adjustment instrument, wherein the direction adjustment instrument is used for measuring a horizontal included angle between the north seeker and a to-be-measured drill; the direction adjustment instrument is horizontally arranged on the north seeker and comprises a second data processor, a three-axis gyroscope, a second three-axis accelerometer, a second analog-to-digital conversion circuit and a second power supply. The drilling direction adjustment method comprises the steps: (1) seeking the north in a static state: measuring a true azimuth angle Phi1 through the north seeker; (2) adjusting the drilling direction: measuring the horizontal included angle Delta Phi between the north seeker and the to-be-measured drill by adopting the direction adjustment instrument, and rotating the to-be-measured drill according to a measurement result of the direction adjustment instrument until Delta Phi + Phi1 is equal to Phi0, wherein Phi0 is a predetermined target true azimuth angle of the to-be-measured drill. The drill attitude measuring instrument and the drilling direction adjustment method have the advantages of reasonable design, simplicity and convenience in use and operation, convenience in realization, good use effect and high orienting accuracy, the drilling direction of the drill can be accurately measured, and the drill can be oriented.

Owner:XIAN CHINASTAR M&C

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com