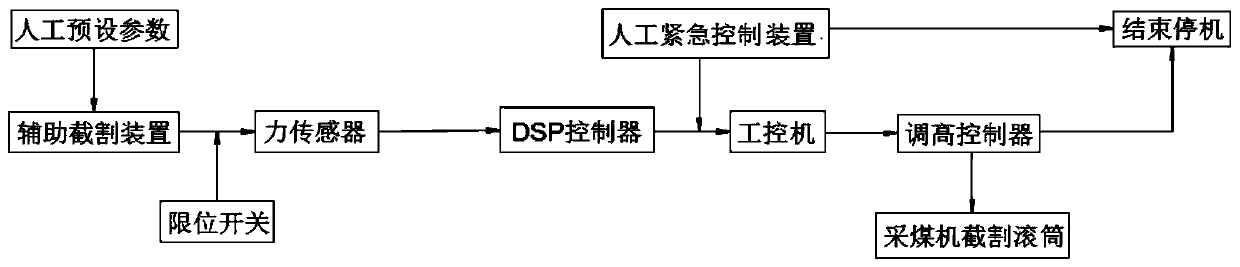

Full-automatic coal mining machine with coal rock identification function and working method of full-automatic coal mining machine

A technology for coal rock identification and shearer, which is applied to cutting machinery, driving devices, testing machinery, etc., can solve the problems of increasing the burden of system processing data, increasing structural complexity and volume, and increasing the force of the identification device, etc. To achieve the effect of improving coal mining efficiency, improving work efficiency and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

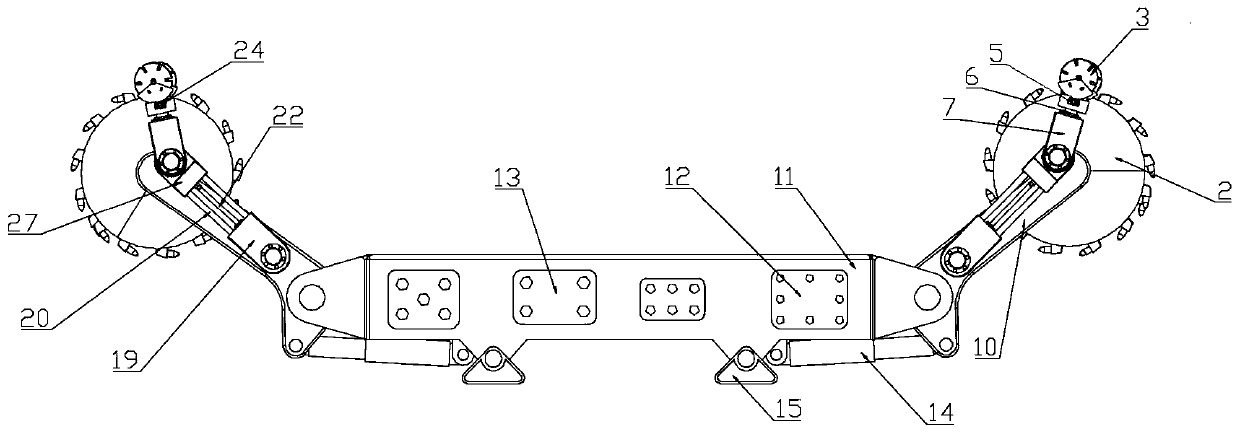

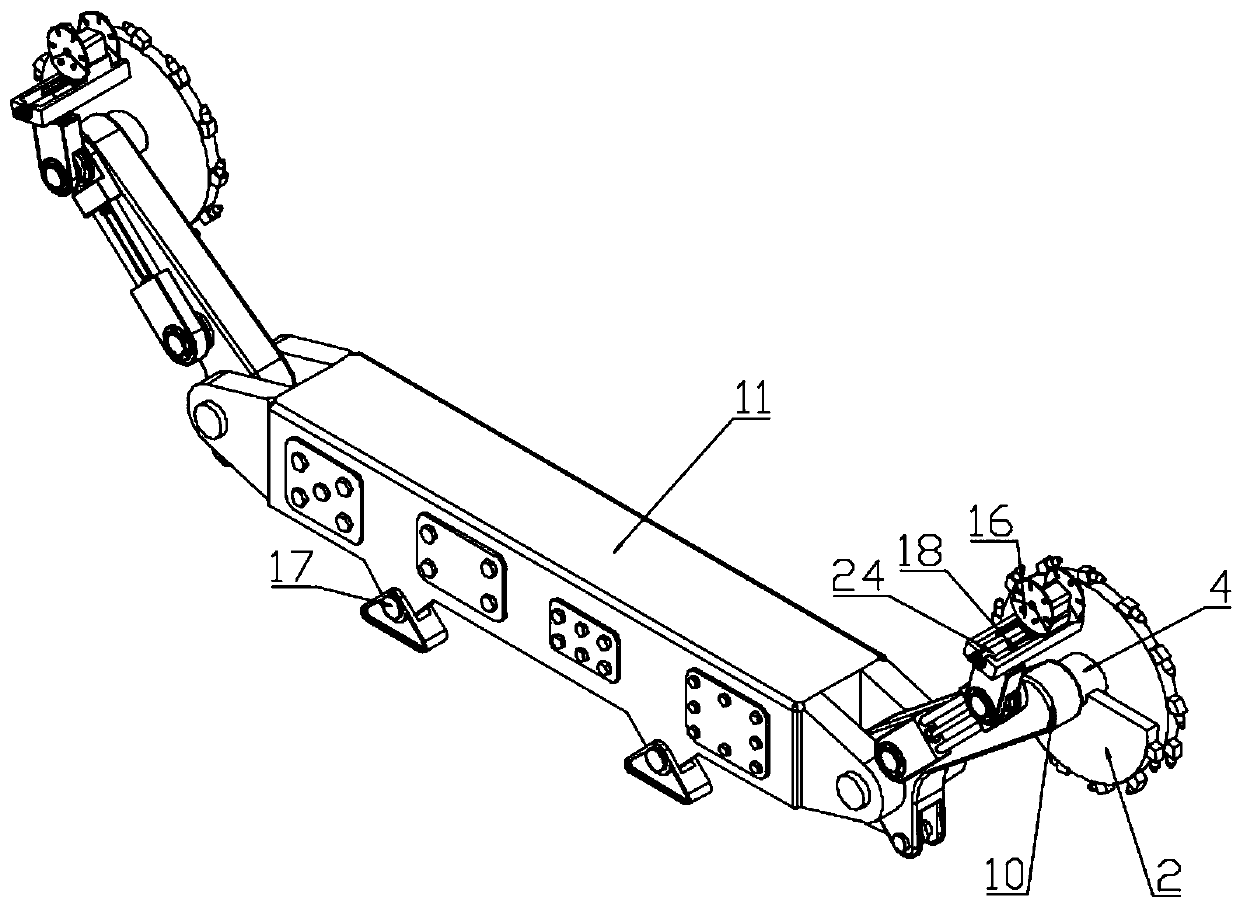

[0041] A fully automatic coal mining machine with coal rock identification function, such as figure 2 , image 3As shown, including a shearer main body 11, a cutting portion, and an auxiliary cutting device, the two ends of the shearer main body 11 are provided with a rocker arm 10, and the rocker arm 10 is connected to the shearer main body 11 through a rocker hydraulic cylinder 14, and the rocker arm 10 is connected to the shearer body 11 through a rocker hydraulic cylinder 14. The upper part of the arm 10 is provided with a cutting part, the cutting part includes a helical blade 2 and a cutting drum 4, the helical blade 2 is connected with the cutting drum 4, the helical blade 2 is connected with one end of the rocker arm 10 through the cutting drum 4, and the helical blade 2 Picks 1 are provided on the edge.

[0042] Auxiliary cutting device comprises two rotating supports, three rotating mechanical arms 6, a cutting support, a telescopic support, such as figure 2 , ...

Embodiment 2

[0045] A fully automatic coal shearer with the function of coal and rock identification, its structure is as described in Embodiment 1, the difference is that a guide rod 20 is provided on the rotating support II 19, a through hole is provided on the telescopic support 27, and the telescopic support 27 Matching connection with the guide rod 20 through the through hole. The expansion and contraction of the first telescopic hydraulic cylinder 22 drives the telescopic bracket 27 to move linearly along the guide rod 20 , and the guide rod 20 is used to provide a movement route and reduce the bearing pressure of the first telescopic hydraulic cylinder.

Embodiment 3

[0047] A fully automatic coal shearer with coal rock identification function, its structure is as described in Embodiment 1, the difference is that the cutting support 29 is provided with a second telescopic hydraulic cylinder 24 and a guide rail 5, such as Figure 5-1 , Figure 5-3 As shown, the output end of the second telescopic hydraulic cylinder 24 is connected to the identification device 33 , and the identification device 33 is arranged on the guide rail 5 . The second telescopic hydraulic cylinder controls the expansion and contraction of the identification device on the guide rail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com