Integral intermediate groove of isothermal quenching ductile iron conveyor and preparation method

A technology of isothermal quenching ductile iron and isothermal quenching, which is applied to conveyors, transportation and packaging, etc., can solve the problems of reducing fully mechanized mining efficiency, many times of downtime for maintenance, poor wear resistance, etc., to reduce downtime and improve coal mining. Efficiency and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

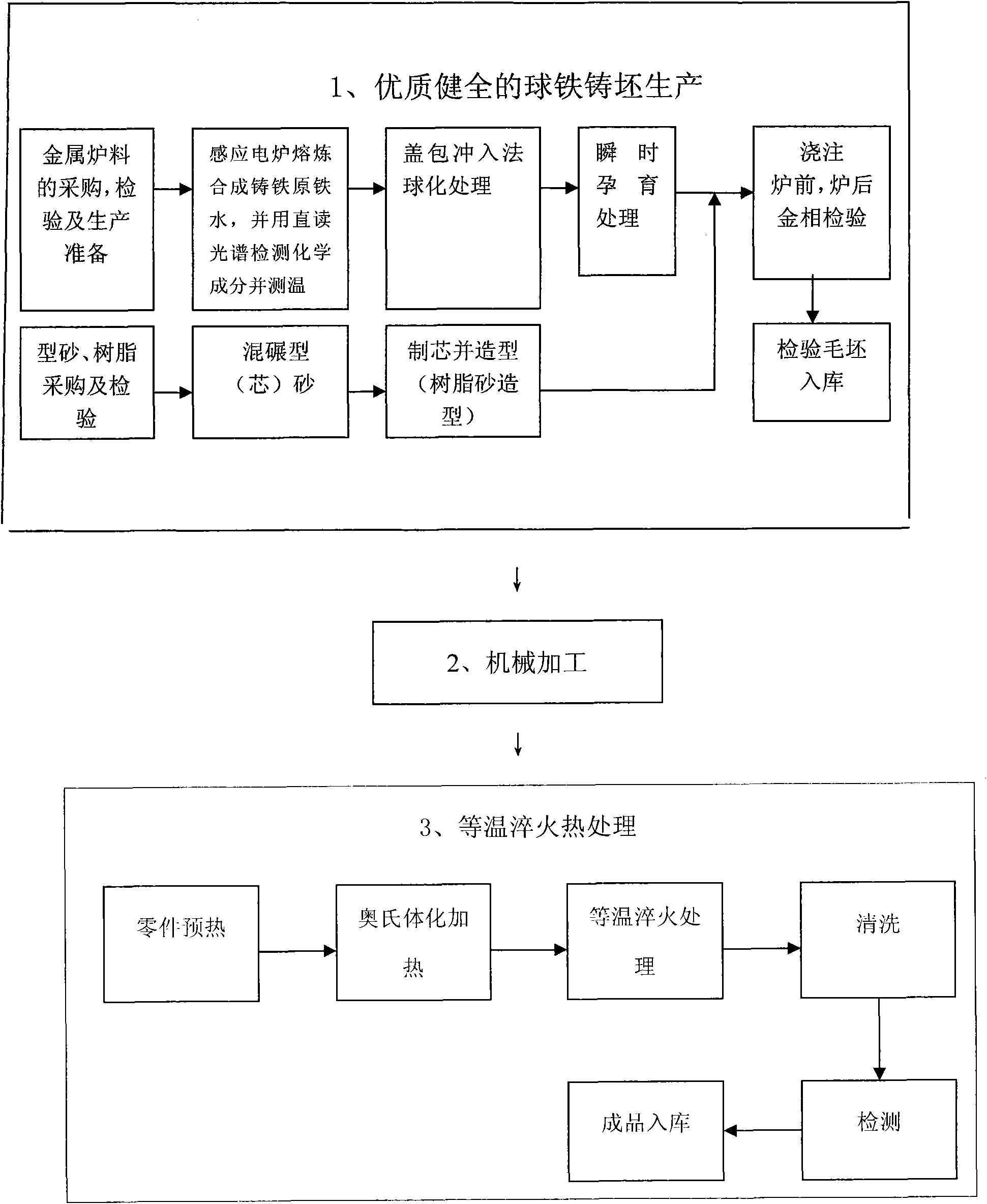

Method used

Image

Examples

Embodiment 1

[0034] An integral intermediate trough of an isothermally quenched nodular cast iron scraper conveyor with high strength and good wear resistance. The raw material of the integral intermediate trough is isothermally quenched nodular cast iron. The nodular cast iron includes the following chemical components in weight percentages:

[0035] C 3.40, Si 2.00, Mn<0.3, P<0.03, S<0.02, Mg 0.04,

[0036] Re 0.01, Cu 0.60, Mo 0.20, and the rest are iron.

[0037] The metallographic matrix structure of graphite in the austempered ductile iron is acicular ferrite+austenite;

[0038] The nodularization rate of the ductile iron is above grade two, and the number of graphite nodules is ≥100 / mm 2 .

[0039] The aforementioned method for preparing an integral middle tank of a high-strength, good-wear-resistant isothermally quenched nodular cast iron scraper conveyor comprises the following steps:

[0040] 1) Production of nodular cast iron: use low-carbon scrap steel to add carburant charg...

Embodiment 2

[0058] An integral intermediate trough of an isothermally quenched nodular cast iron scraper conveyor with high strength and good wear resistance. The raw material of the integral intermediate trough is austempered nodular cast iron. The nodular cast iron includes the following chemical components in weight percentage:

[0059] C 3.60, Si 2.40, Mn<0.3, P<0.03, S<0.02, Mg 0.05,

[0060] Re 0.02, Cu 0.80, Mo 0.30, and the rest are iron.

[0061] The metallographic matrix structure of graphite in the austempered ductile iron is acicular ferrite+austenite;

[0062] The nodularization rate of the ductile iron is above grade two, and the number of graphite nodules is ≥100 / mm 2 .

[0063] The aforementioned method for preparing an integral middle tank of a high-strength, good-wear-resistant isothermally quenched nodular cast iron scraper conveyor comprises the following steps:

[0064] 1) Production of nodular cast iron: use low-carbon scrap steel to add carburant charge, and melt n...

Embodiment 3

[0082] An integral intermediate trough of an isothermally quenched nodular cast iron scraper conveyor with high strength and good wear resistance. The raw material of the integral intermediate trough is austempered nodular cast iron. The nodular cast iron includes the following chemical components in weight percentage:

[0083] C 3.43, Si 2.25, Mn 0.22, P 0.021, S 0.012, Mg 0.055,

[0084] Re 0.019, Cu 0.74, Mo 0.25, and the rest are iron.

[0085] The metallographic matrix structure of graphite in the austempered ductile iron is acicular ferrite+austenite;

[0086] The nodularization rate of the ductile iron is above grade two, and the number of graphite nodules is ≥100 / mm 2 .

[0087] The aforementioned method for preparing an integral middle tank of a high-strength, good-wear-resistant isothermally quenched nodular cast iron scraper conveyor comprises the following steps:

[0088] 1) Production of nodular cast iron: use low-carbon scrap steel to add carburant charge, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com