Coal mining and transporting integrated machine

An all-in-one machine, coal mining and transportation technology, which is used in earth-moving drilling, slitting machinery, underground transportation, etc., can solve the problems of unsuitable coal mining in very thin coal seams, low unit yield and efficiency of working face, and low degree of coal mining mechanization. , to achieve the effect of eliminating the hidden danger of personal injury, convenient maintenance and repair, and improving the recovery rate and coal mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

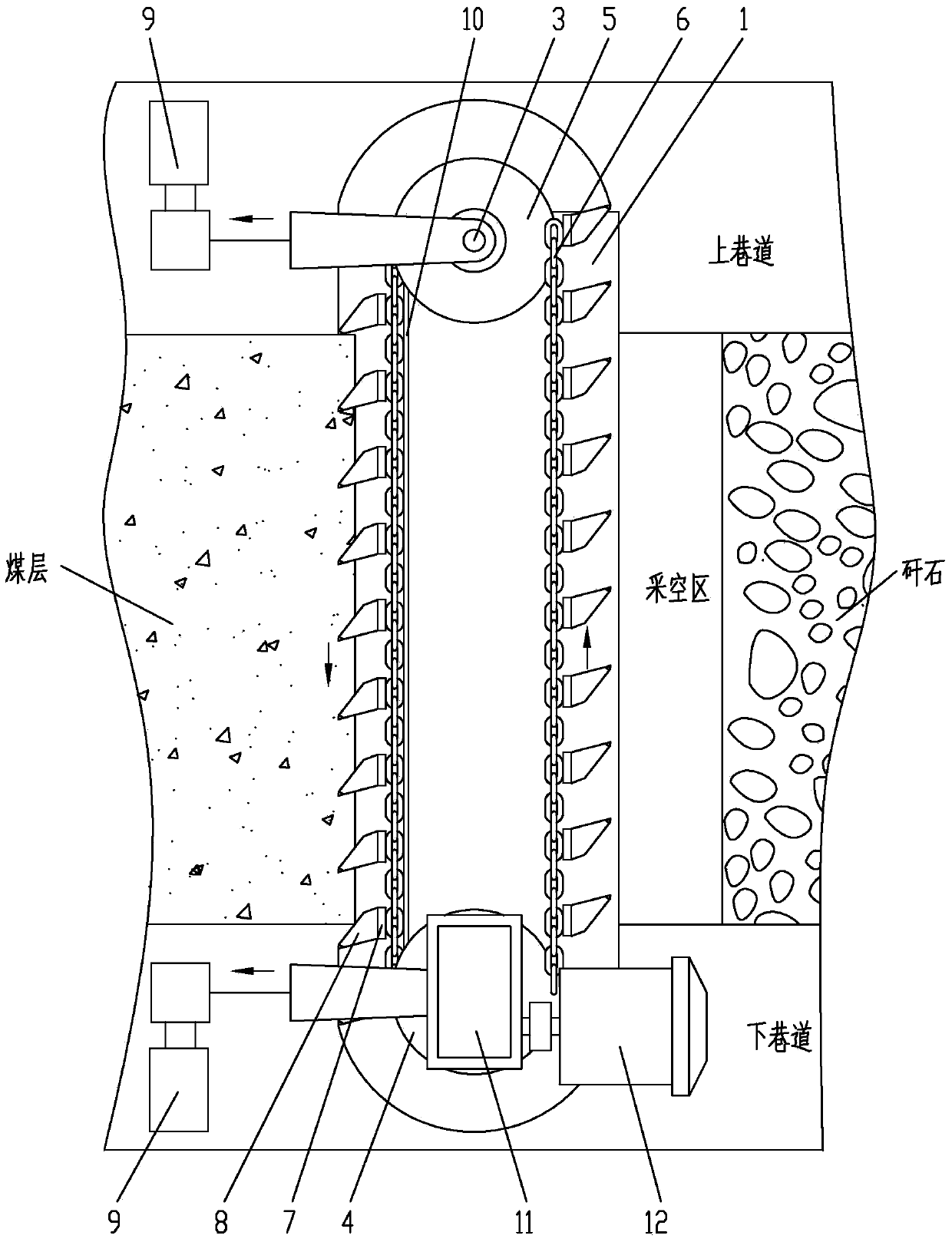

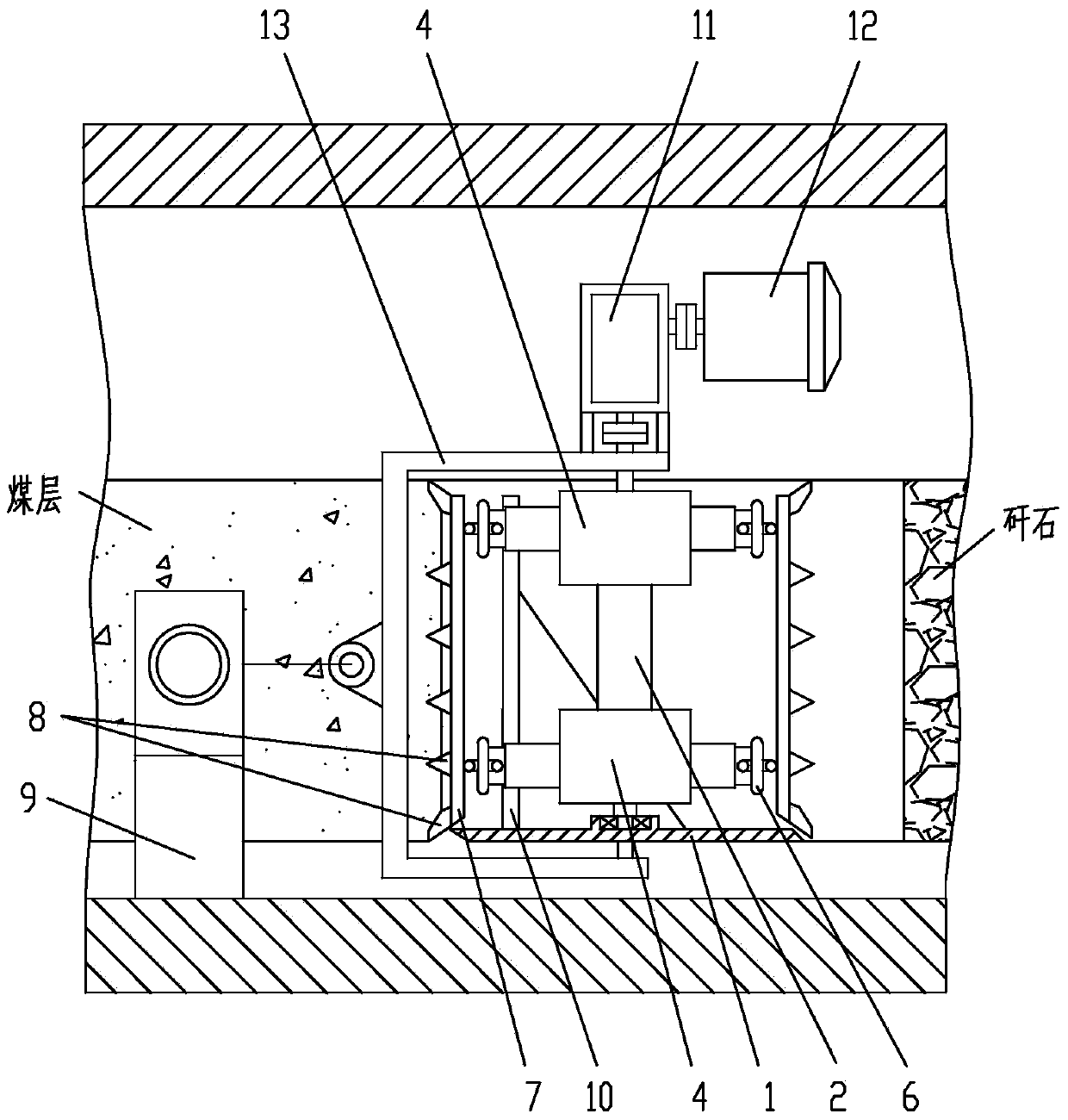

[0021] Example 1, see figure 1 , figure 2 , an integrated machine for mining and transporting coal, including a frame, the frame is connected with a hydraulic traction device 9, the frame includes a base plate 1 and a baffle plate 10 fixedly connected to each other, the base plate 1 is horizontally arranged, and the base plate 1 is provided with Vertically arranged driving sprocket shaft 2 and driven sprocket shaft 3, the driving sprocket shaft 2 is rotatably supported on the base plate 1, the driving sprocket shaft 2 is driven to rotate by the driving motor 11 through the reducer 12, and the driving sprocket shaft 2 is coaxially fixed Two identical driving sprockets 4 with overlapping vertical projections are connected; the driven sprocket shaft 3 is fixedly connected to the base plate 1, and the driven sprocket shaft 3 is coaxially connected with two identical and overlapping vertical projections. The driven sprocket 5; the driving sprocket 4 and the driven sprocket 5 are ...

Embodiment 2

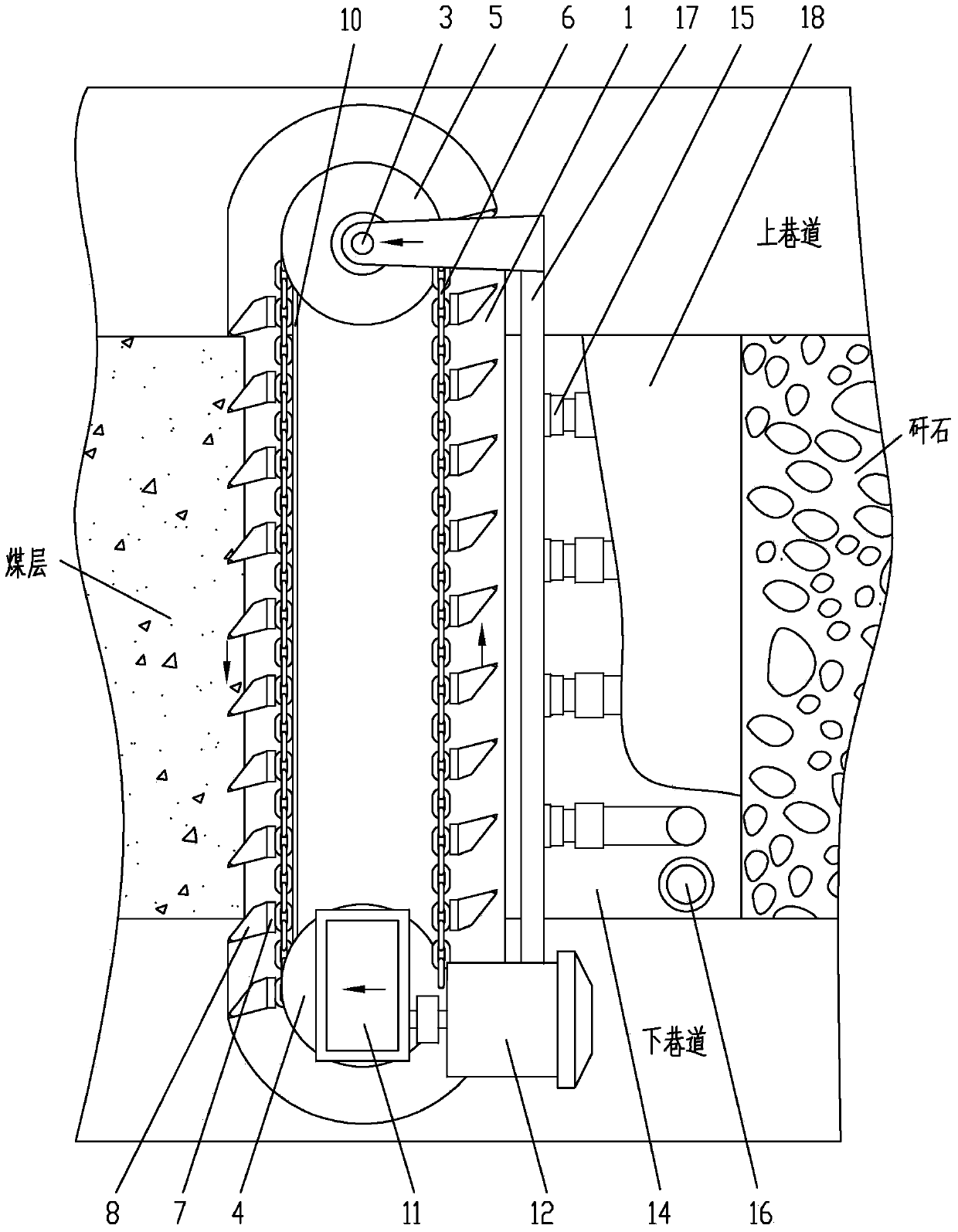

[0022] Example 2, see image 3 , Figure 4 , the power unit is a hydraulic propulsion device, the hydraulic propulsion device is located in the coal seam goaf, the hydraulic propulsion device includes a base 14, the base 14 is provided with a horizontal propulsion cylinder 15 and a jacking cylinder 16, and the other end of the horizontal propulsion cylinder 15 Be connected with propelling arm 17, and this propelling arm 17 forms the part of described frame, and this propelling arm 17 is the stool structure of four legs, and propelling arm 17 is connected with horizontal propelling oil cylinder 15 by its stool surface end; Described jacking oil cylinder 16 The top beam plate 18 is connected to the upper end.

[0023] The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

[0024] The driving sprocket 4 in the aforementioned embodiment, the driven sprocket 5 and the chain 6 all can be set to one, perhaps, be set to thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com