Pick having bimetal structure and preparation method thereof

A bimetallic and pick technology, applied in cutting machinery and other directions, can solve the problems of long service life, peeling, falling off, etc., and achieve the effect of improving wear resistance and impact resistance, good hardness and toughness, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0035] I. According to the weight percentage of the chemical composition of the deposited metal C: 0.46, Cr: 4.0, W: 6.0, Mo: 2.3, V: 0.6, Si: 0.18, Mn: 0.17, Ni: 0.50, S: 0.030, P: 0.028 Special alloy steel electrode, dried at 240°C for 2.5 hours;

[0036] II. The tooth body is machined into a cylindrical tooth shank 2 and a conical tooth head 4 by using medium carbon alloy steel;

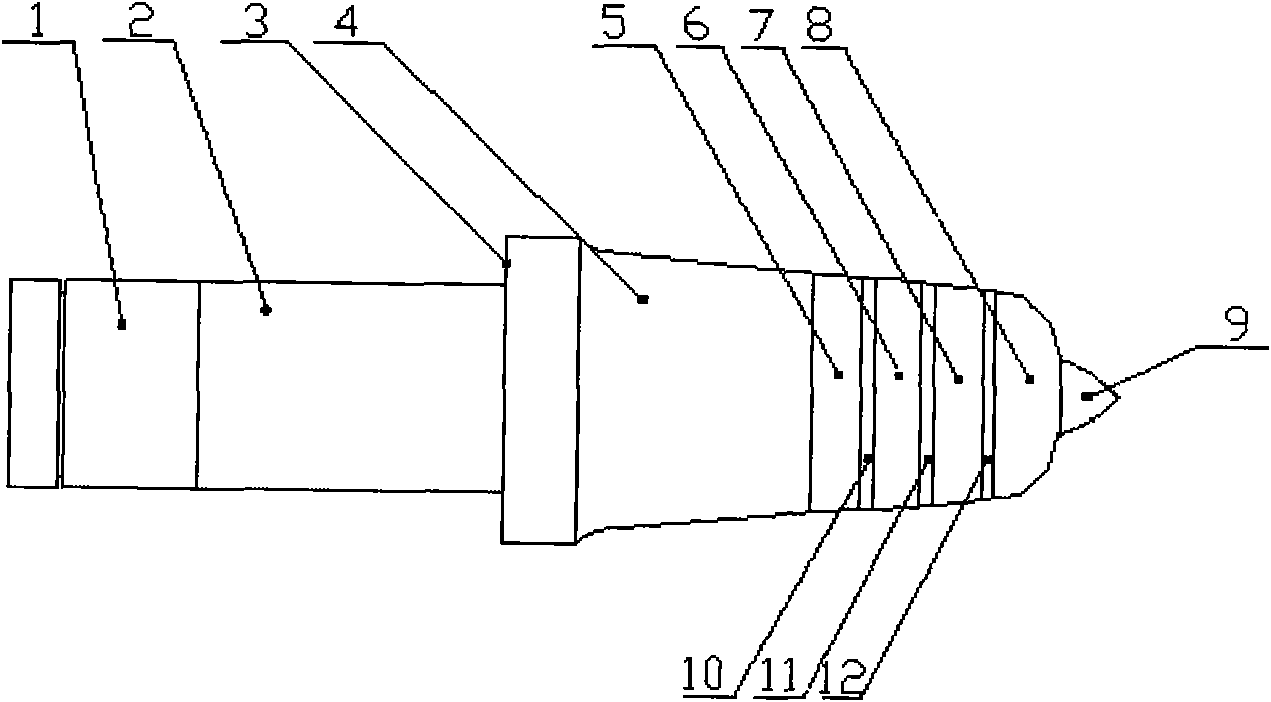

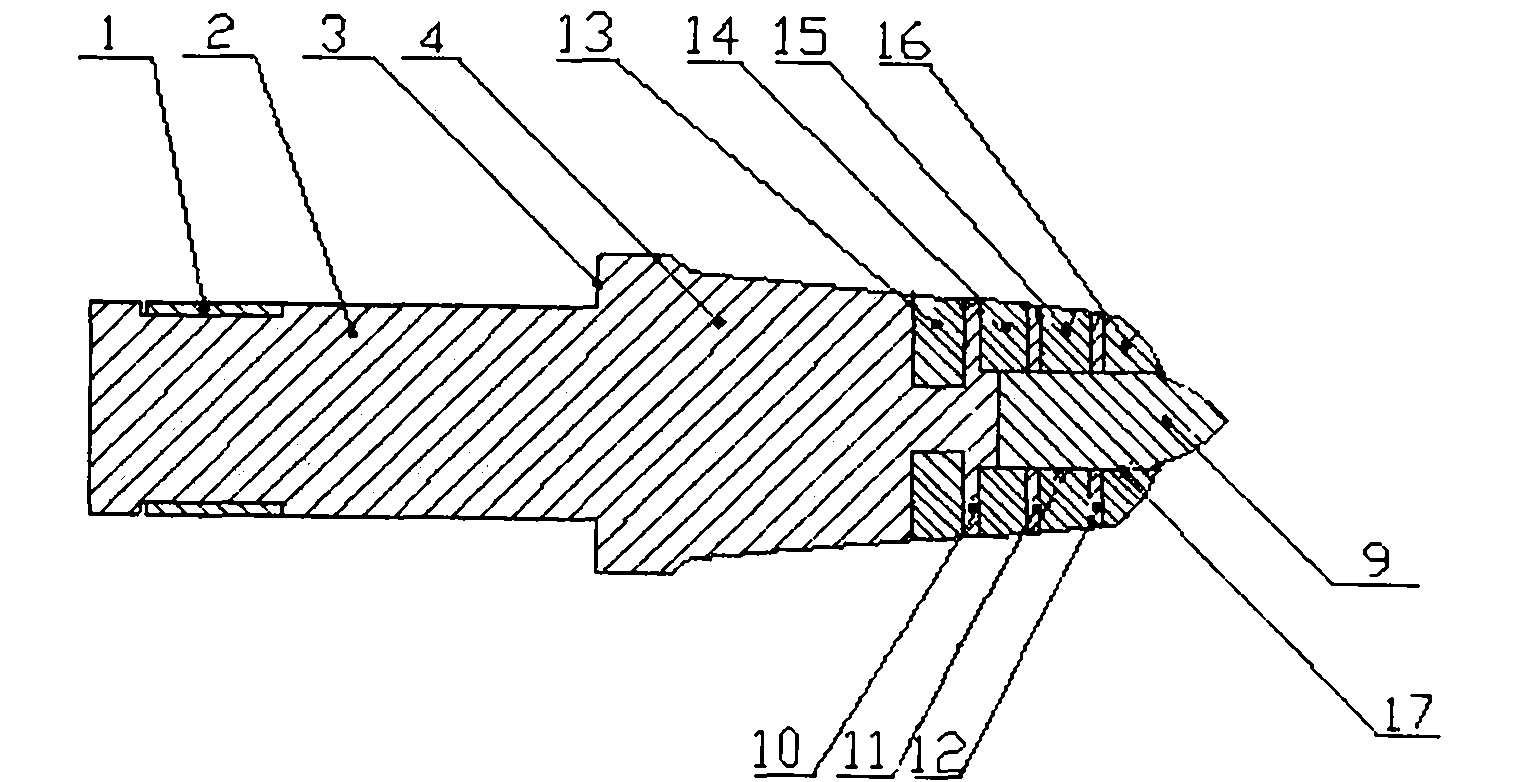

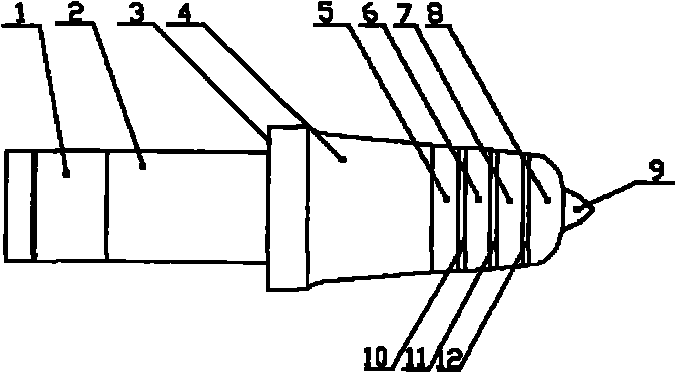

[0037] III. Open 3 annular grooves downwards at the top of the conical tooth head 4 of the tooth body obtained in the above II. The net width of the annular grooves is 7 millimeters, and the interlayer between two adjacent annular grooves is 1.5 millimeters. The conical teeth The depth of the first annular groove downwards from the top of the head 4 is 5.5 mm, and the depth of the remaining annular grooves is deepened to 8 mm as the conical shape of the tooth head increases. The range of the annular grooves is larger than the bottom surface of the carbide head 9. The distance between the top of t...

Embodiment approach 2

[0043] I. According to the weight percentage of the chemical composition of the deposited metal C: 0.52, Cr: 5.0, W: 8.5, Mo: 2.65, V: 0.95, Si: 0.19, Mn: 0.18, Ni: 0.55, S: 0.0325, P: 0.029 Special alloy steel electrode, dried at 250°C for 2.25 hours;

[0044] II adopts medium-carbon alloy steel to be machined into a tooth body consisting of a cylindrical tooth shank 2 and a conical tooth head 4;

[0045] III. Open 4 annular grooves downwards at the top of the conical tooth head 4 of the tooth body obtained in the above II. The net width of the annular grooves is 8 millimeters, and the interlayer between two adjacent annular grooves is 1.75 millimeters. The conical teeth The depth of the first annular groove downwards from the top of the head 4 is 5.75 mm, and the depth of the remaining annular grooves is deepened to 8.5 mm as the conical shape of the tooth head increases. The distance between the top of the tooth head 4 and the last annular groove A 5 from the bottom 3 of t...

Embodiment approach 3

[0051] I. According to the weight percentage of the chemical composition of the deposited metal C: 0.58, Cr: 6.0, W: 11.0, Mo: 3.0, V: 1.3, Si: 0.20, Mn: 0.19, Ni: 0.60, S: 0.035, P: 0.030 Special alloy steel electrode, dried at 260°C for 2.0 hours;

[0052] II. The tooth body is machined into a cylindrical tooth shank 2 and a conical tooth head 4 by using medium carbon alloy steel;

[0053] III. Five annular grooves are opened downward on the top of the conical tooth head 4 of the tooth body obtained in the above II. The net width of the annular groove is 9 mm, and the interlayer between two adjacent annular grooves is 2.0 mm. The conical tooth The depth of the first annular groove downwards from the top of the head 4 is 6.0 mm, and the depth of the remaining annular grooves is deepened to 9 mm as the conical shape of the tooth head increases. The distance between the top of the tooth head 4 and the last annular groove A 5 from the bottom 3 of the conical tooth head is not g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com