Preparation method of compression molded board

A technology of molding and forming boards, which is applied in the field of preparation of molding boards, can solve problems such as long drying time, unfavorable environmental protection of wood, efficiency, scale, and automation that cannot reach industrial production, so as to save wood resources and benefit The effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

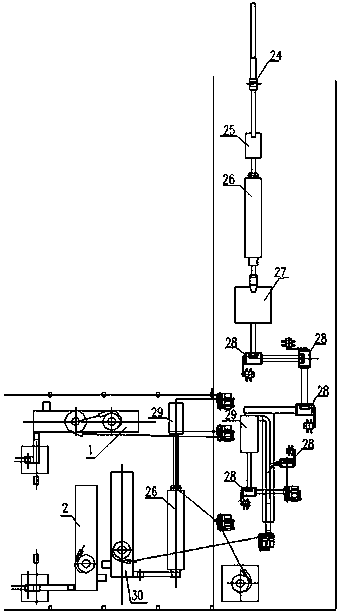

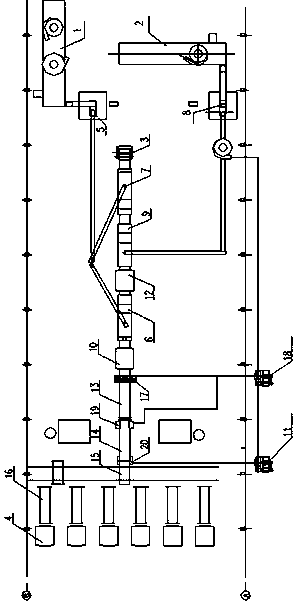

Method used

Image

Examples

Embodiment 1

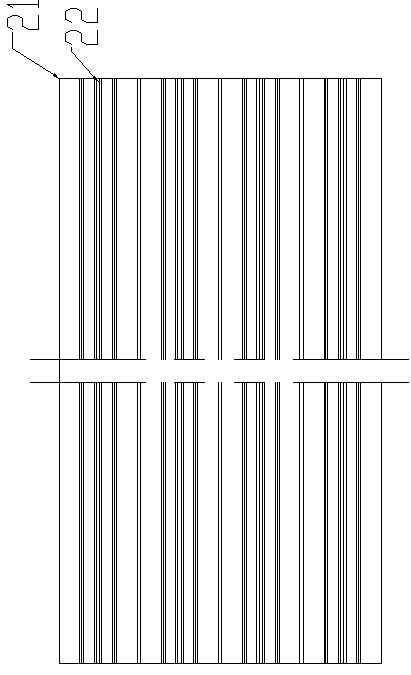

[0062] A method for preparing a molded molded board, comprising: sequentially processing a molded board through a raw material preparation process and a molding hot-pressing process, forming a plurality of products to be processed on the molded board, and leaving a gap between two adjacent products Cutting seam, after cutting by a cutting machine, multiple products are obtained through a forming board.

[0063] The raw material preparation process specifically includes the following steps:

[0064] a. Chip the raw material to a length of 20-30mm;

[0065] b. Pre-dry the raw materials to a moisture content below 25%;

[0066] c. Crushing the raw materials to the required thickness;

[0067] d. Dry the crushed raw materials to a moisture content of 4-5%;

[0068] e, sieve the dried raw material into surface layer material and core layer material;

[0069] f. Add glue to the surface material and the core material respectively and mix them evenly;

[0070] g. Send the mixed g...

Embodiment 2

[0096] In this embodiment, the molded photo frame strip is taken as an example to further illustrate the present invention.

[0097] A preparation method for mass-producing molded photo frame strip forming boards in an industrialized, automated and large-scale manner, including two major steps: a raw material preparation process and a forming hot-pressing process:

[0098] 1. Raw material preparation process

[0099] 1. Use a chipper to chip the raw material (bamboo or wood) to a length of 20mm;

[0100] 2. Use a dryer to pre-dry the raw materials to a moisture content of about 20%.

[0101] 3. Send the raw materials to the chip silo, and then evenly send them to the crushing equipment.

[0102] 4. Arrange multiple crushers in series. Each crusher has different sieve holes, which are distributed from large to small, and crushed step by step. The raw materials are crushed to the same thickness as that required by ordinary homogeneous particleboard for surface materials and co...

Embodiment 3

[0130] In this embodiment, the height difference on one surface of finished products such as molded dinner plates and cabinet doors does not exceed 5mm as an example to further illustrate the present invention.

[0131] A method for preparing a molded molded board, comprising: sequentially processing a molded board through a raw material preparation process and a molding hot-pressing process, forming a plurality of products to be processed on the molded board, with a cut space reserved between two adjacent products seam.

[0132] The raw material preparation process specifically includes the following steps:

[0133] a. Chip the raw material to a length of 30mm;

[0134] b. Pre-dry the raw materials to a moisture content below 25%;

[0135] c. Crushing the raw materials to the required thickness;

[0136] d. Dry the crushed raw materials to a moisture content of 5%;

[0137] e, sieve the dried raw material into surface layer material and core layer material;

[0138] f. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com