High-density small-spacing LED module with graphic hollow interlayer, display and method

A LED module and small-pitch technology, applied in static indicators, instruments, electric solid devices, etc., can solve the problems of easy crushing of metal pillars, too small bonding area, insufficient bonding strength, etc., to improve light output Efficiency, increased bonding area, and increased bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

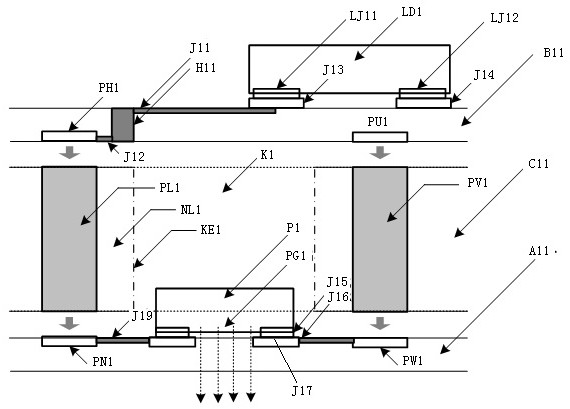

[0061] like Figure 5 As shown in the above, a method for preparing a high-density small-pitch LED module with a pattern hollowed out and connected with a sandwich layer as described above specifically includes the following steps:

[0062] S1: prepare a glass carrier, and mount the LED flip-chip light-emitting chip on the glass carrier;

[0063] S2: prepare a driver carrier board, and install the driver chip on the driver carrier board;

[0064] S3: Prepare a patterned hollow interconnection interlayer, set according to the position where the LED flip-chip light-emitting chip is mounted on the glass carrier, the position where the driver chip is mounted on the driver carrier, and the connection position relationship between the LED flip-chip light-emitting chip and the driver chip The conductive material part, the patterned hollow part and the non-conductive material part make the LED flip-chip light-emitting chip wrapped in the patterned hollow part, and the LED flip-chip l...

Embodiment 1

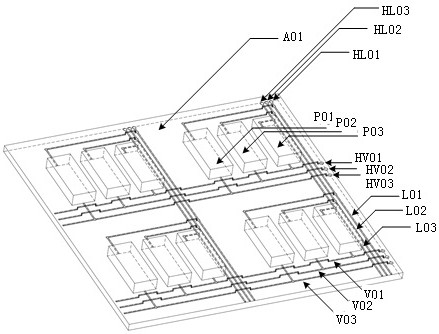

[0071] This embodiment is the production process of the high-density small-pitch LED display unit module based on the patterned hollowing and pressing of the Unicom interlayer, as shown in the appendix. Figure 6a As shown in the figure, it includes a component with a glass carrier as the main body and a component with a printed circuit carrier as the main body; A21 in the figure is a glass carrier, P21, P22, P23 are respectively the reverse side light-emitting red primary color LED flip-chip light-emitting chip, the reverse side The light-emitting green primary color LED flip-chip structure light-emitting chip and the reverse light-emitting blue primary color LED flip-chip structure light-emitting chip (see attached Figure 6a The dashed line on the back of the glass carrier A1), the light-emitting surface of the LED flip-chip light-emitting chip is on the upper part of the glass carrier A21 (as indicated by the dashed arrow); V21, V22, V23 are red, green, and blue LEDs Displ...

Embodiment 2

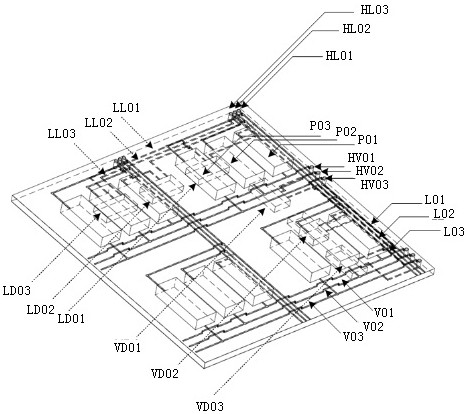

[0074] This embodiment is the production process of generating high-density small-pitch LED display unit modules based on patterned hollowing and pressing the interconnected interlayer (that is, when the patterned hollowing part is set to a large hollow space), as shown in the appendix. Figure 7a As shown, it includes a component with a glass carrier as the main body and a component with a printed circuit carrier as the main body; A31 is the glass carrier in the figure, P31, P32, P33 are the reverse light-emitting red primary color LED flip-chip structure light-emitting chip, the reverse side The light-emitting green primary color LED flip-chip structure light-emitting chip and the reverse light-emitting blue primary color LED flip-chip structure light-emitting chip (see attached Figure 7aThe dashed line on the back of the middle glass carrier A31), the light-emitting surface of the LED flip-chip light-emitting chip is on the upper part of the glass carrier A31 (as shown by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com