Patents

Literature

137results about How to "Reduce concentration difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quantum dot optical film of multi-layer structure, and preparation method and application thereof

InactiveCN107656330AImprove luminous brightnessImprove stabilityDiffusing elementsNon-linear opticsQuantum dotPhysics

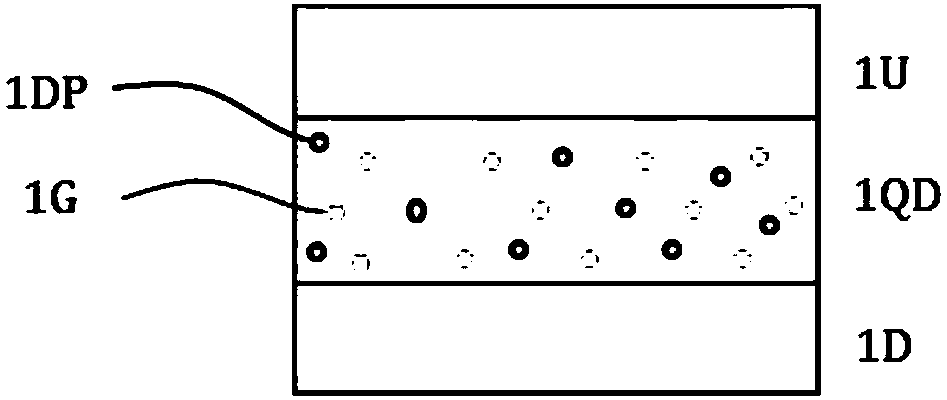

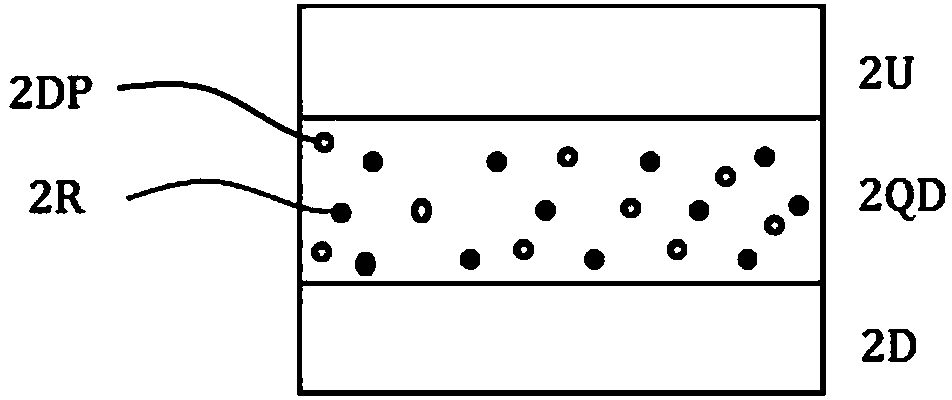

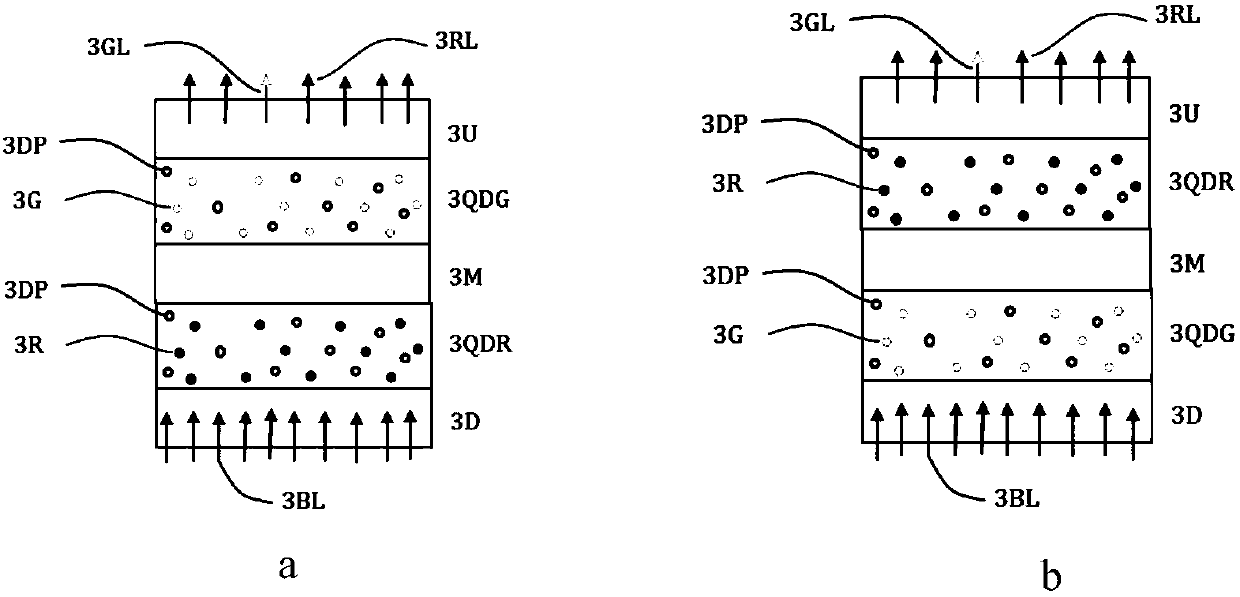

The invention relates to a quantum dot optical film of a multi-layer structure. The quantum dot optical film comprises one or more green quantum dot layers, one or more red quantum dot layers, and separating layers or dichroic mirrors, wherein the green quantum dot layers and the red quantum dot layers are alternatively arranged, and the separating layers or dichroic mirrors are arranged between the green quantum dot layers and the red quantum dot layers. The invention further relates to a preparation method and application of the quantum dot optical film.

Owner:WUHAN BAOLI LIANGCAI TECH CO LTD

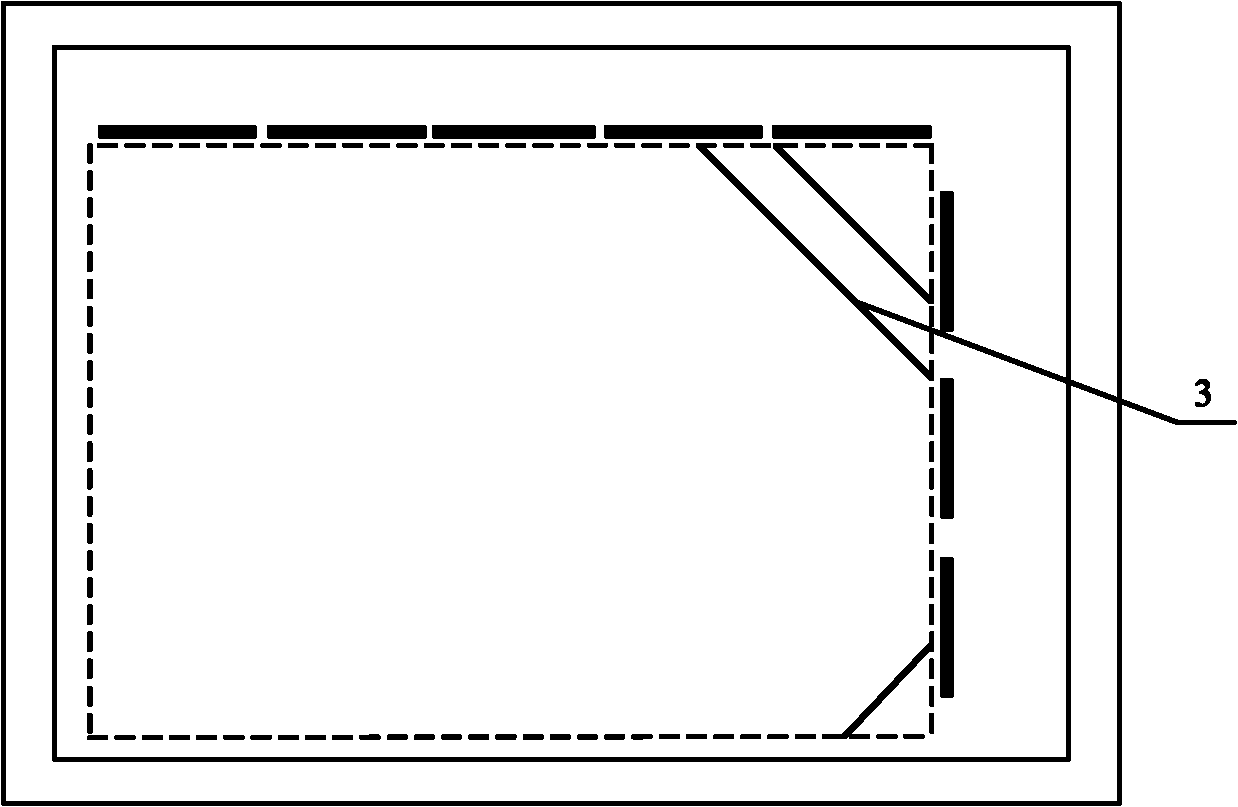

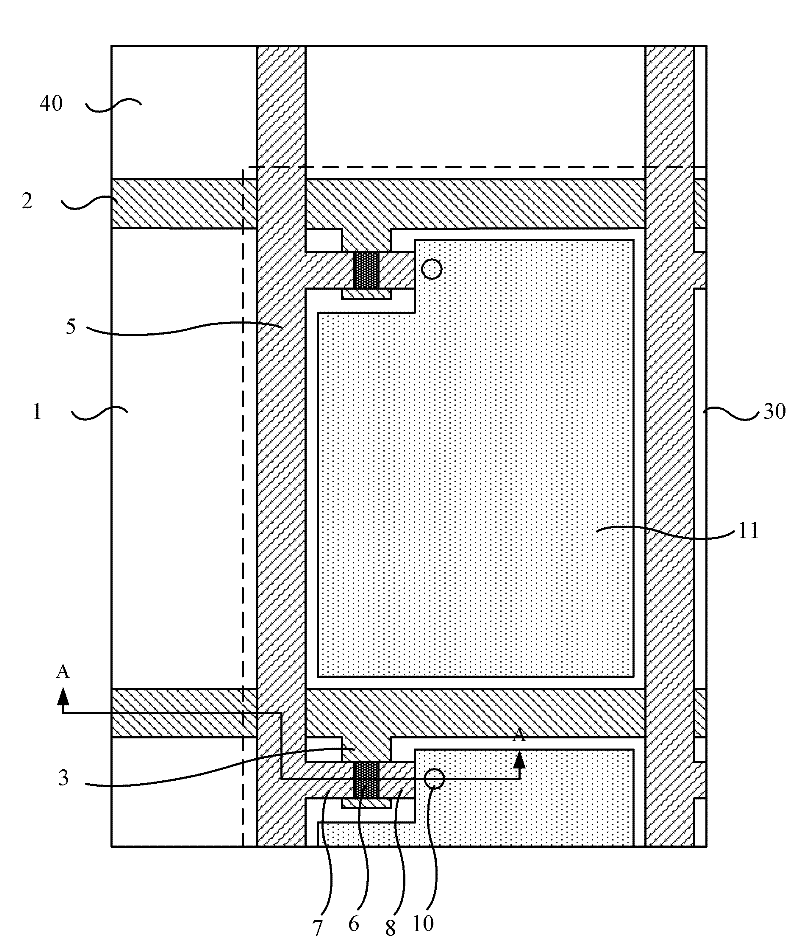

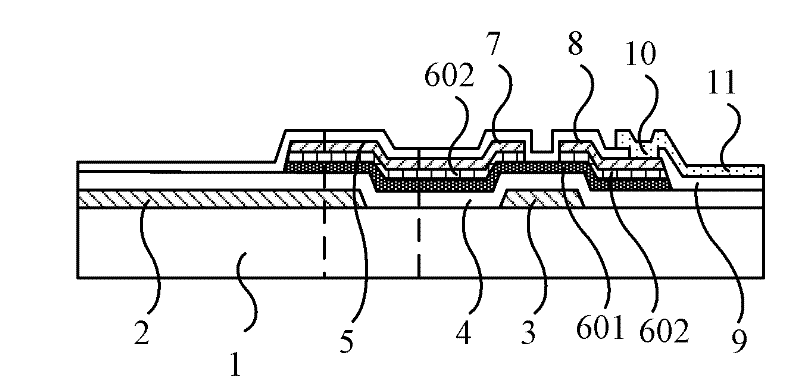

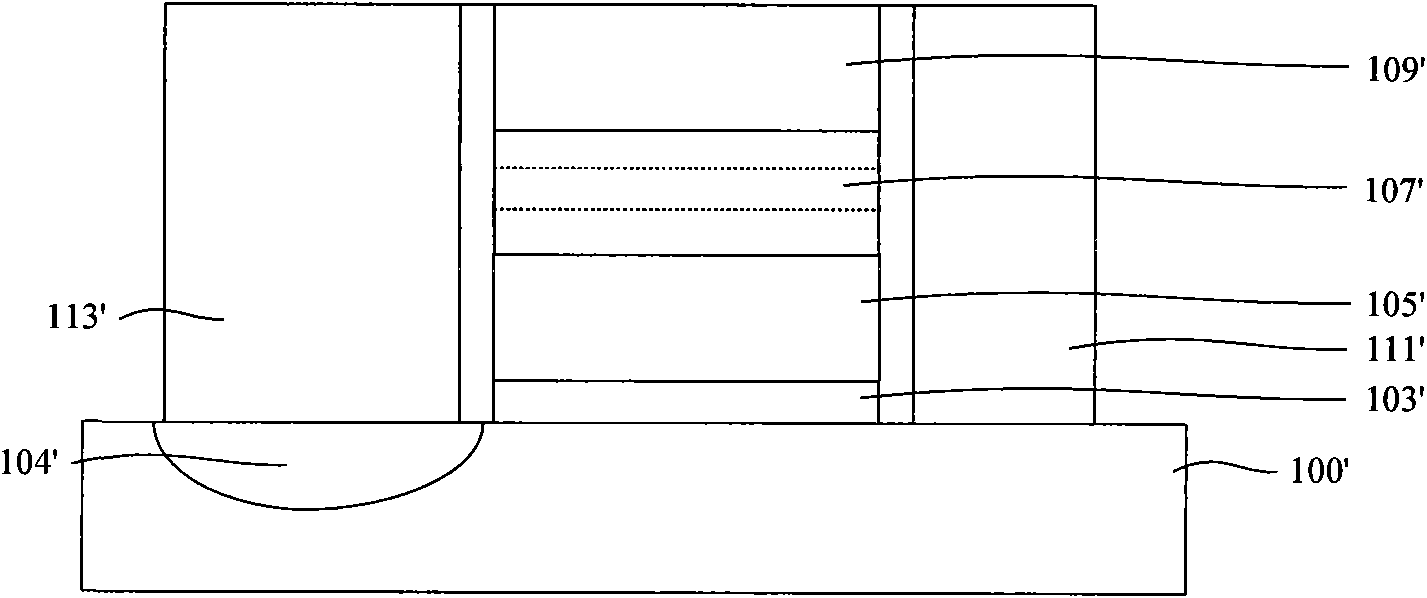

TFT-LCD (thin film transistor liquid crystal display) pixel electrode layer structure, preparation method and mask plate thereof

ActiveCN102169260AControlling CD UniformityReduce concentration differenceSolid-state devicesPhotomechanical apparatusLiquid-crystal displayThin-film-transistor liquid-crystal display

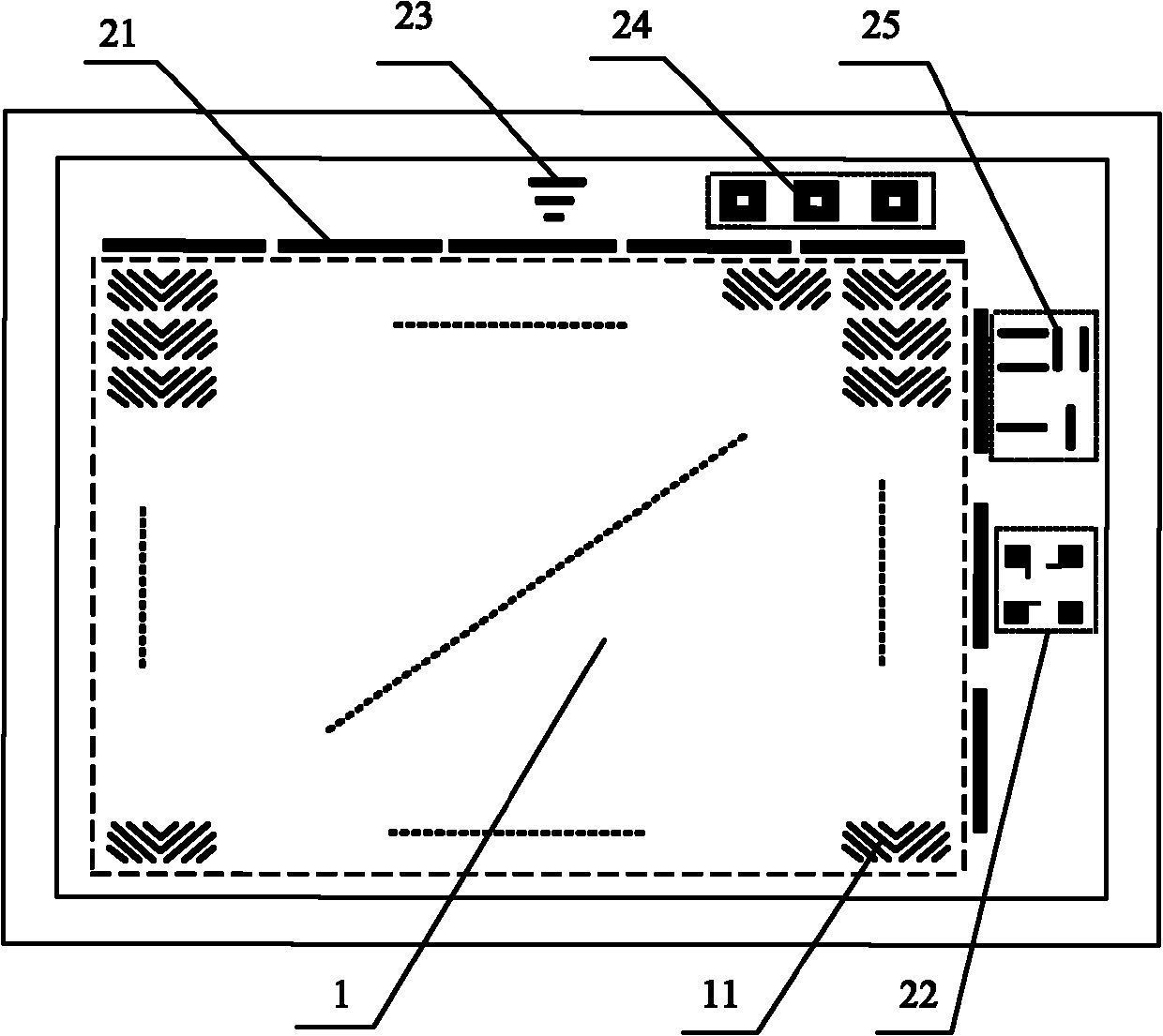

The embodiment of the invention discloses a TFT-LCD (thin film transistor liquid crystal display) pixel electrode layer structure, a preparation method and a mask plate thereof and relates to the field of liquid crystal display. By using the TFT-LCD pixel electrode layer structure provided by the invention, twilled mura caused by the difference of developer solution concentration can be reduced. The TFT-LCD pixel electrode layer structure comprises a pixel electrode pattern which corresponds to a display area of a liquid crystal panel, a peripheral area pattern which corresponds to a non-display area of the liquid crystal panel, and a peripheral filling graph which is distributed in an area without peripheral area patterns in the non-display area. The TFT-LCD pixel electrode layer structure is applied to the manufacture of the liquid crystal display.

Owner:BOE TECH GRP CO LTD

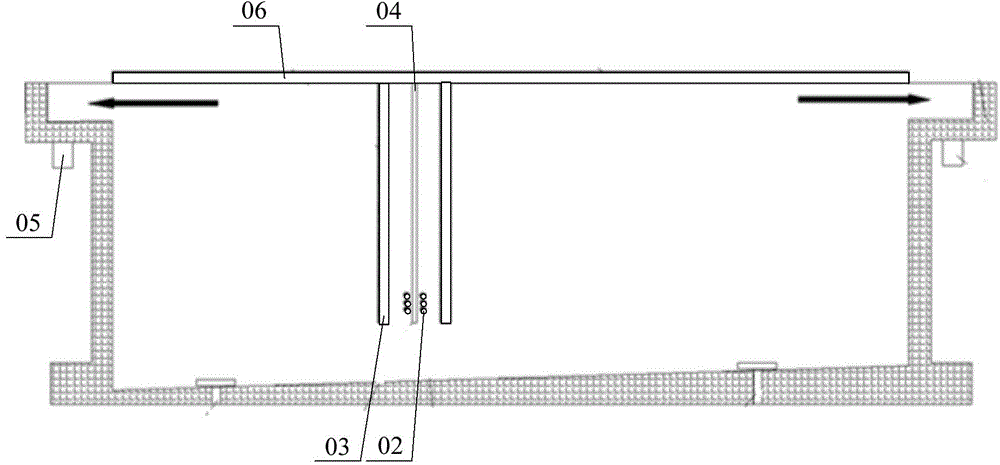

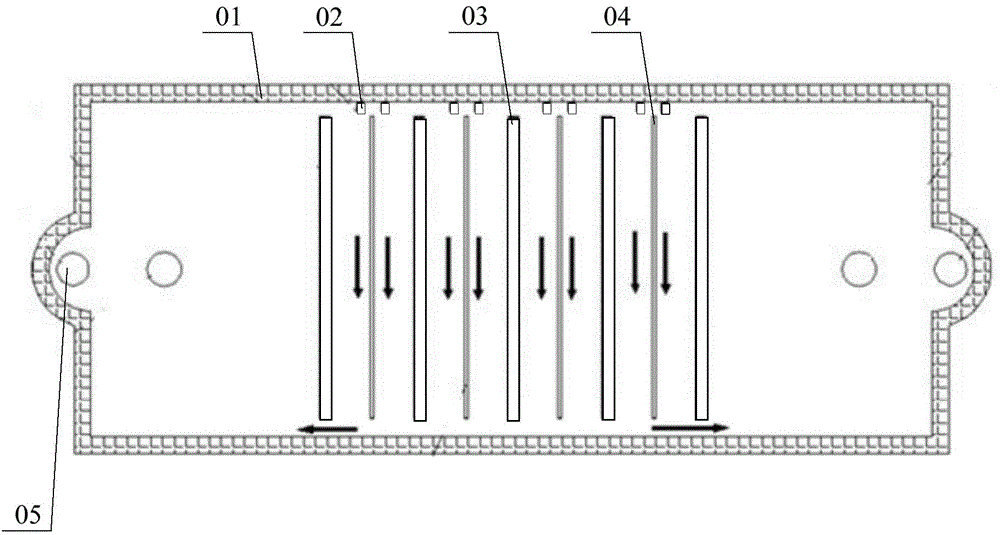

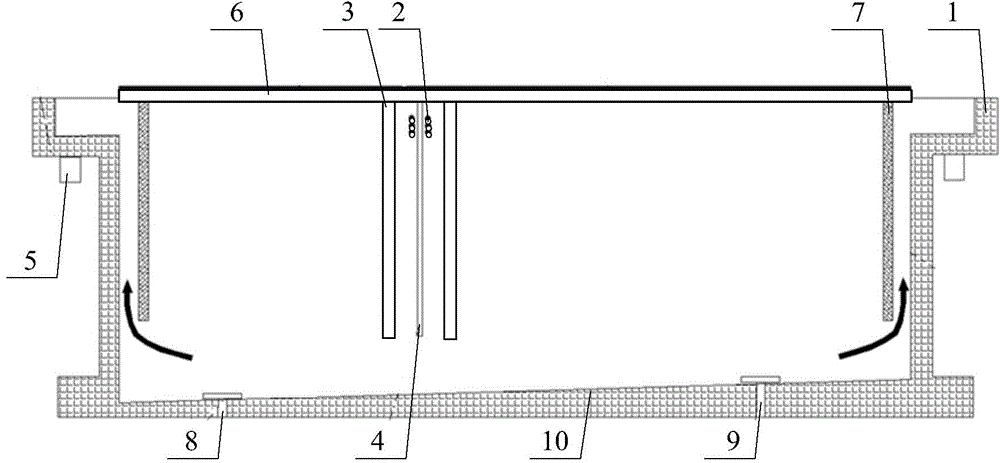

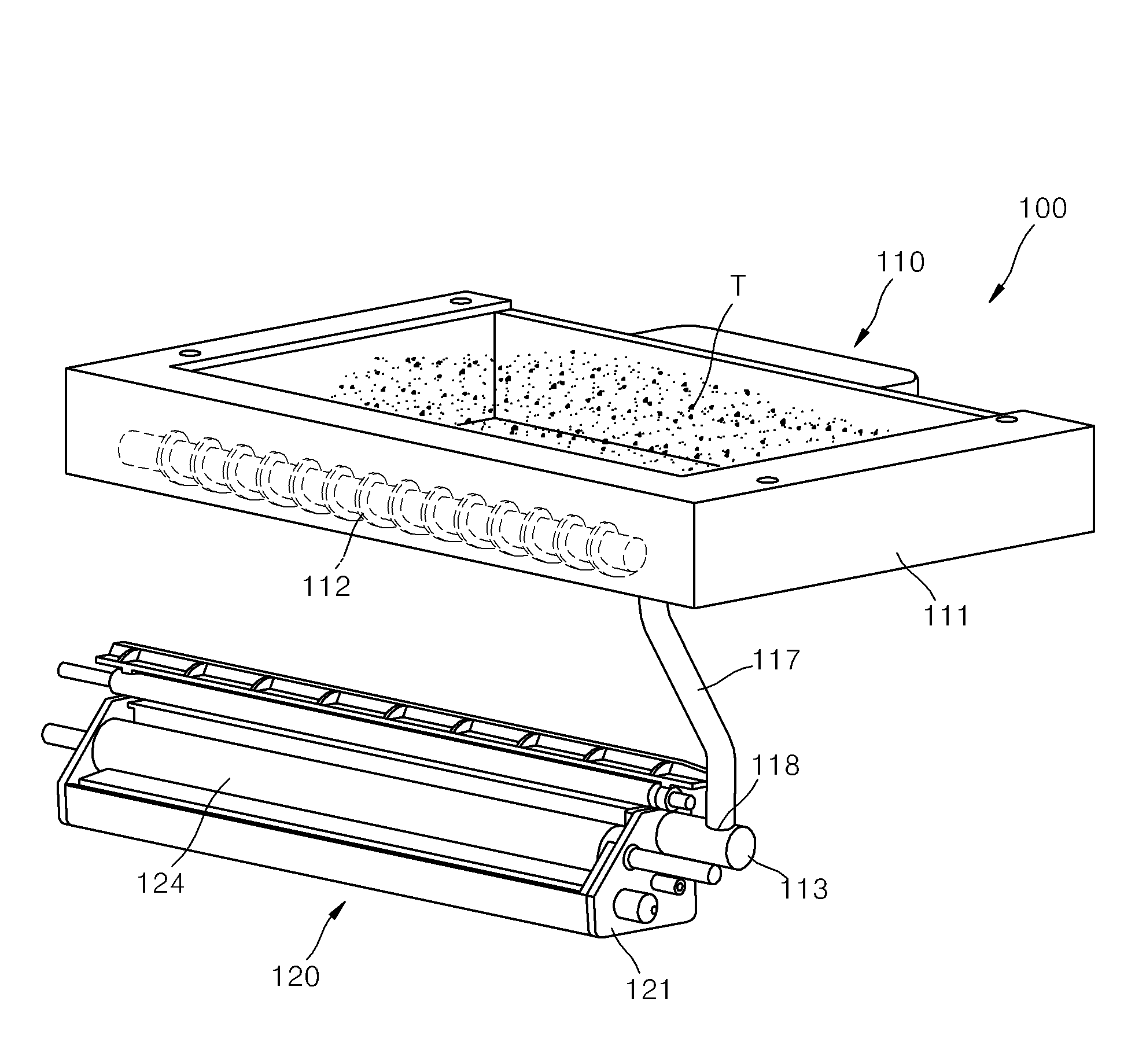

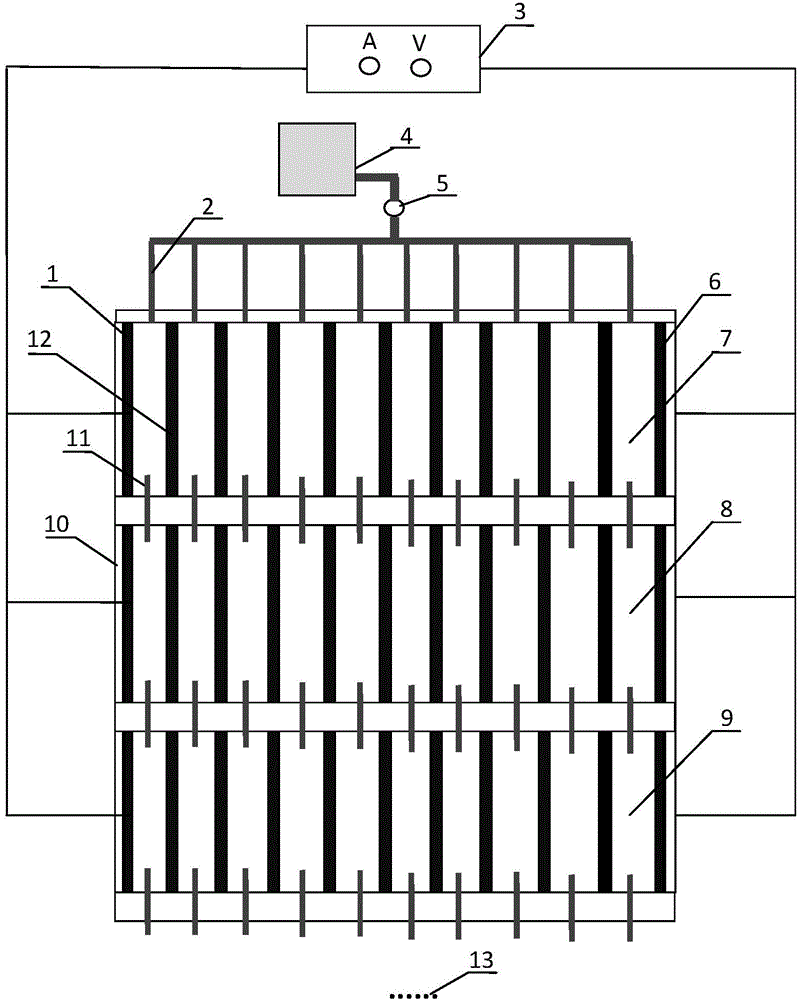

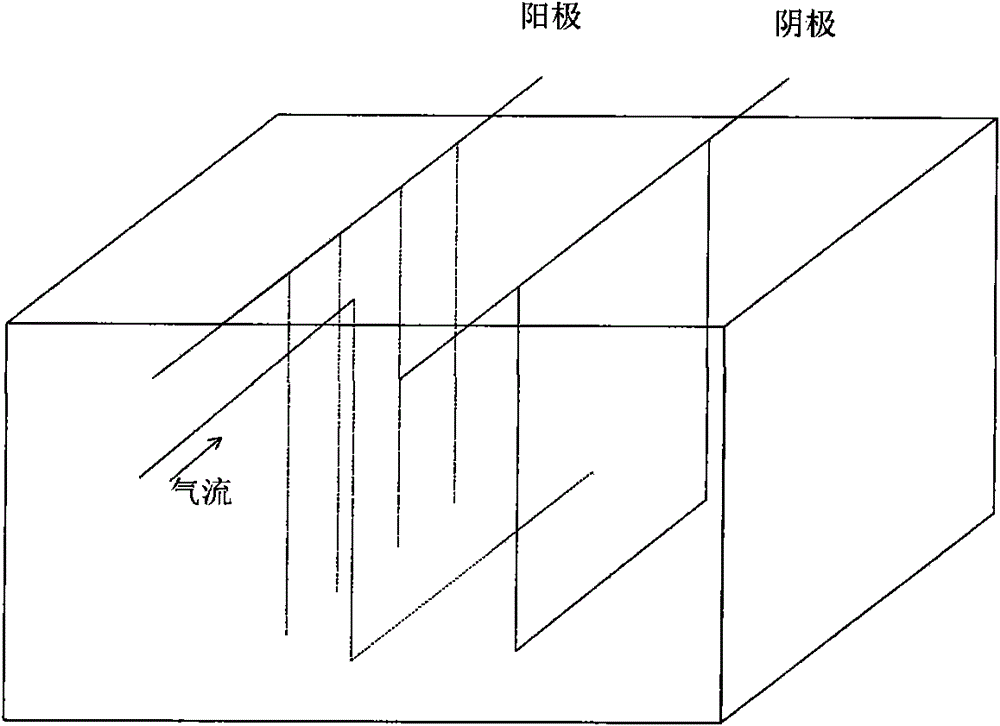

Metallic electrolytic cell and metal electrolysis process

ActiveCN104404575AReduce concentration differenceSpeed up the flowPhotography auxillary processesElectrolysis componentsConcentration polarizationMaterials science

The invention discloses a metallic electrolytic cell which comprises a cell body, anode plates, cathode plates and arc-shaped drainage bulges, wherein the arc-shaped drainage bulges are mounted at the two opposite ends of the cell body; the anode plates and the cathode plates are alternatively arranged in the cell body, and liquid inlets and overflow openings are formed in the cell body; the liquid inlets in the two sides of each cathode plate are positioned in the same end of the cathode plate, and the liquid inlets in the two sides of each anode plate are respectively positioned in the two ends of the anode plate; the two ends of each cathode plate are respectively butted with the convex ends of the arc-shaped drainage bulges, and a liquid drainage cavity is formed between the cathode plates and the arc-shaped drainage bulges. Two adjacent cathode plates and one anode plate between the cathode plates form a similar closed space, electrolyte is fast ejected to enter the space through the liquid inlets in one end of one cathode plate and the other end of the adjacent cathode plate, and then the electrolyte flows clockwise and anticlockwise. The kinetic energy of electrolyte is utilized, the concentration difference of metal ions between the two pole plates is greatly reduced, and the concentration polarization is effectively reduced. The invention further discloses a metal electrolysis process.

Owner:YANGGU XIANGGUANG COPPER

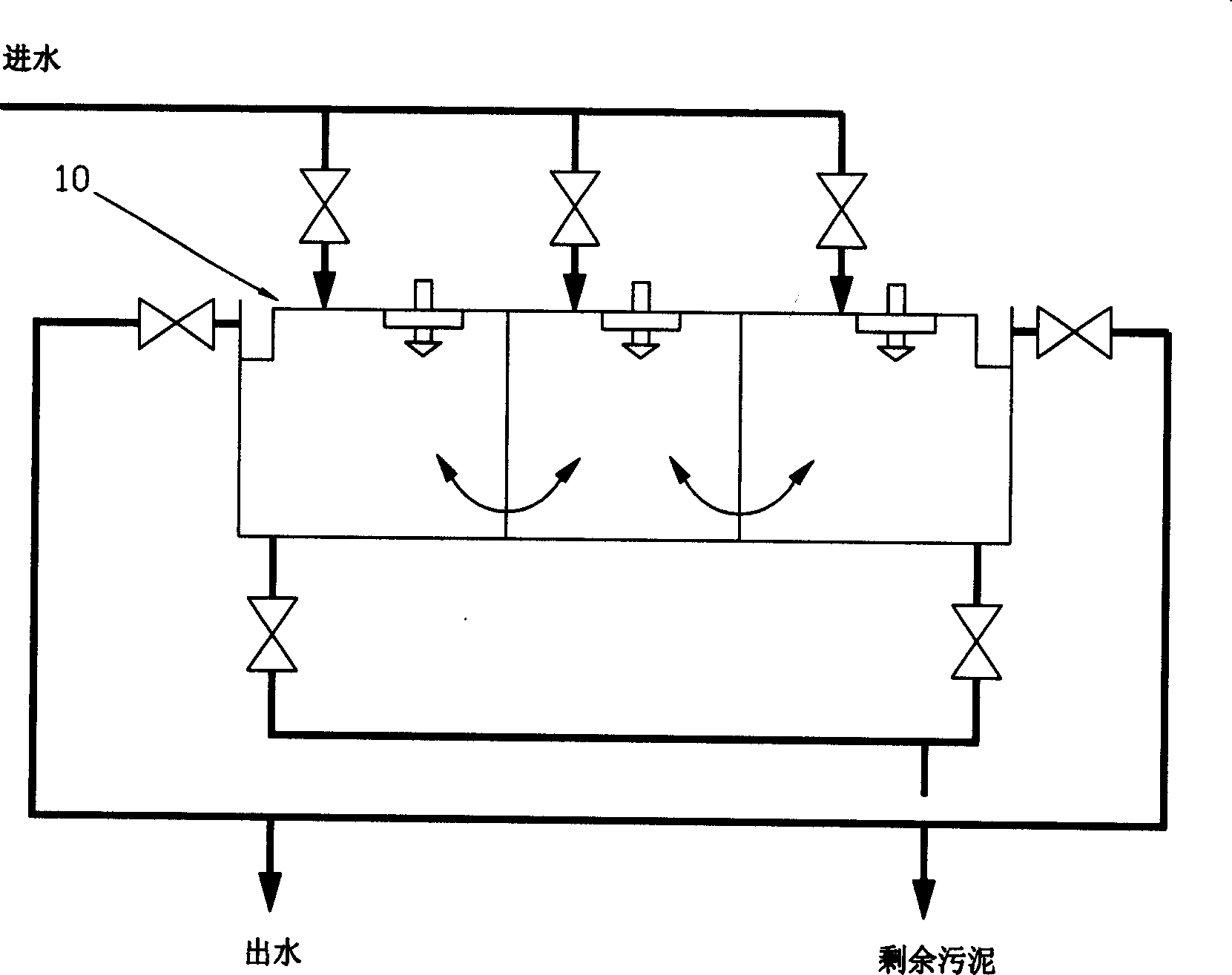

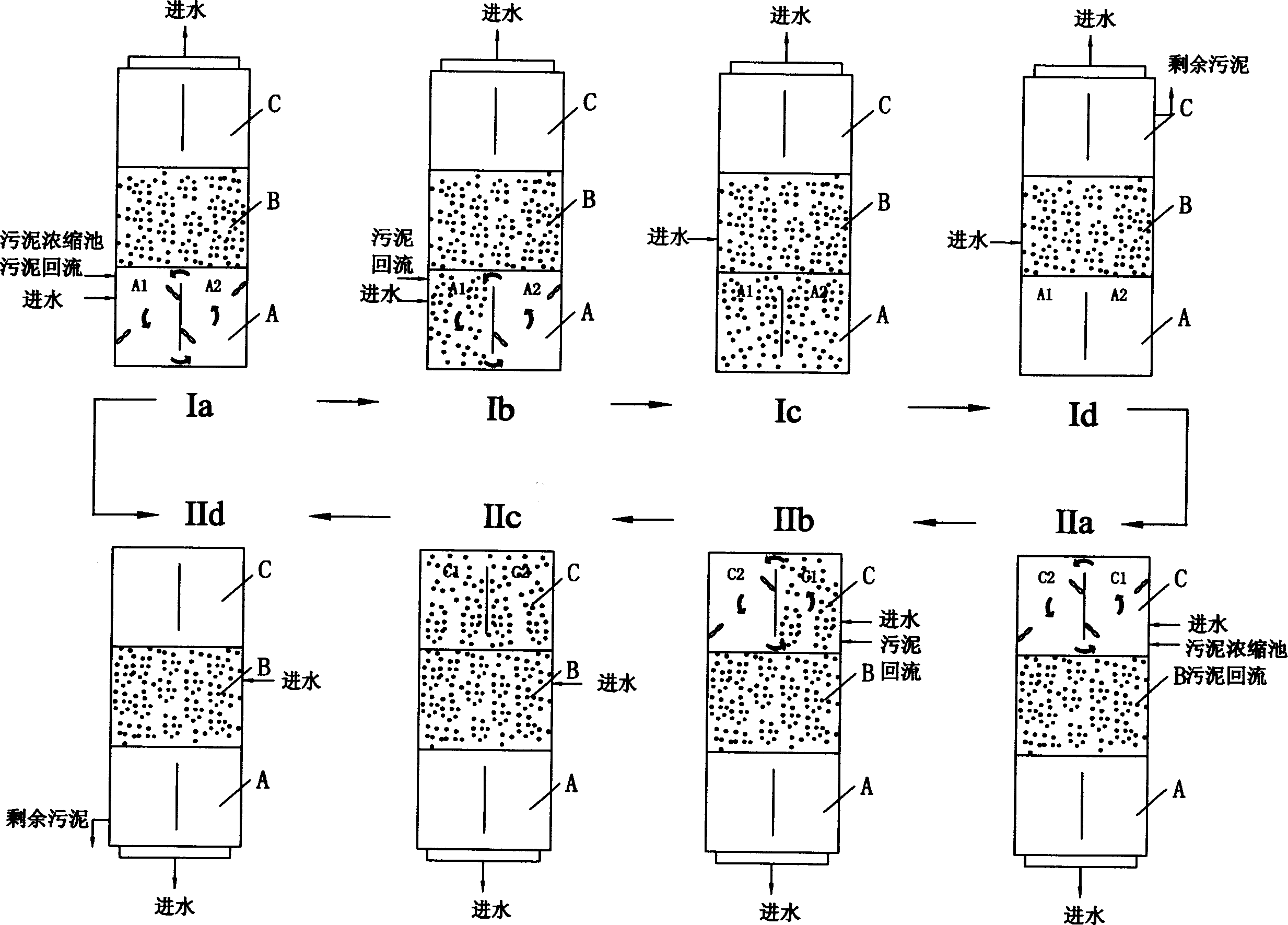

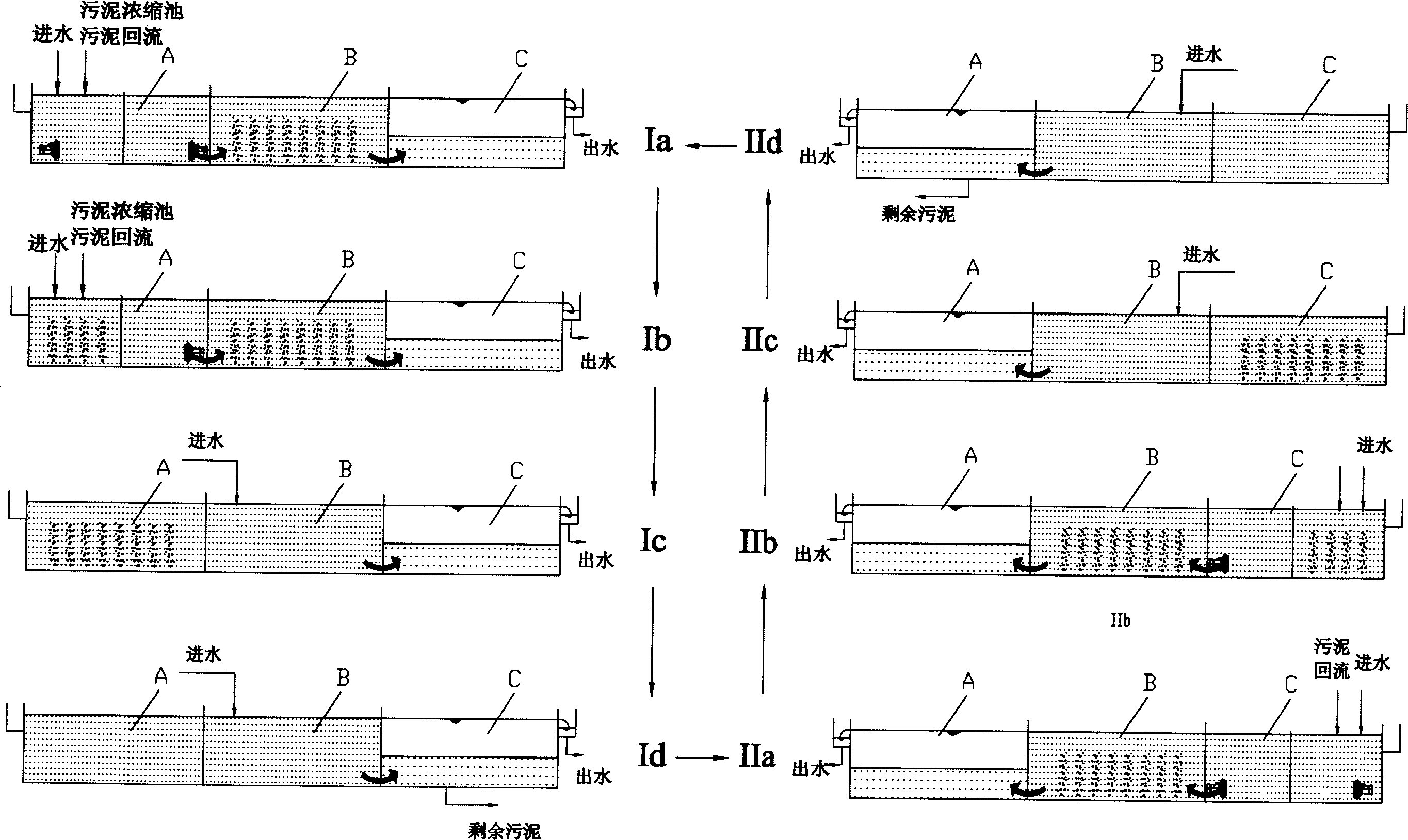

Improved type alternated technique for wastewater treatment of activated sludge process and equipment

ActiveCN1686862AIncrease water depthReduce energy consumptionTreatment with aerobic and anaerobic processesSustainable biological treatmentActivated sludgeFlocculation

The present invention relates to a sewage treatment process by adopting improved alternative type active sludge method. Said sewage treatment process utilizes the equipments of treatment tank, anaerobic chamber, anoxybiontic chamber, aeration tank and flocculation precipitation tank, etc. and alternatively adopts the process steps of stirring, aeration, concentration, sludge reflus, mixing, flocculation, precipitation and biological dephosphorization, etc. so as to attain the goal of purifying sewage.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

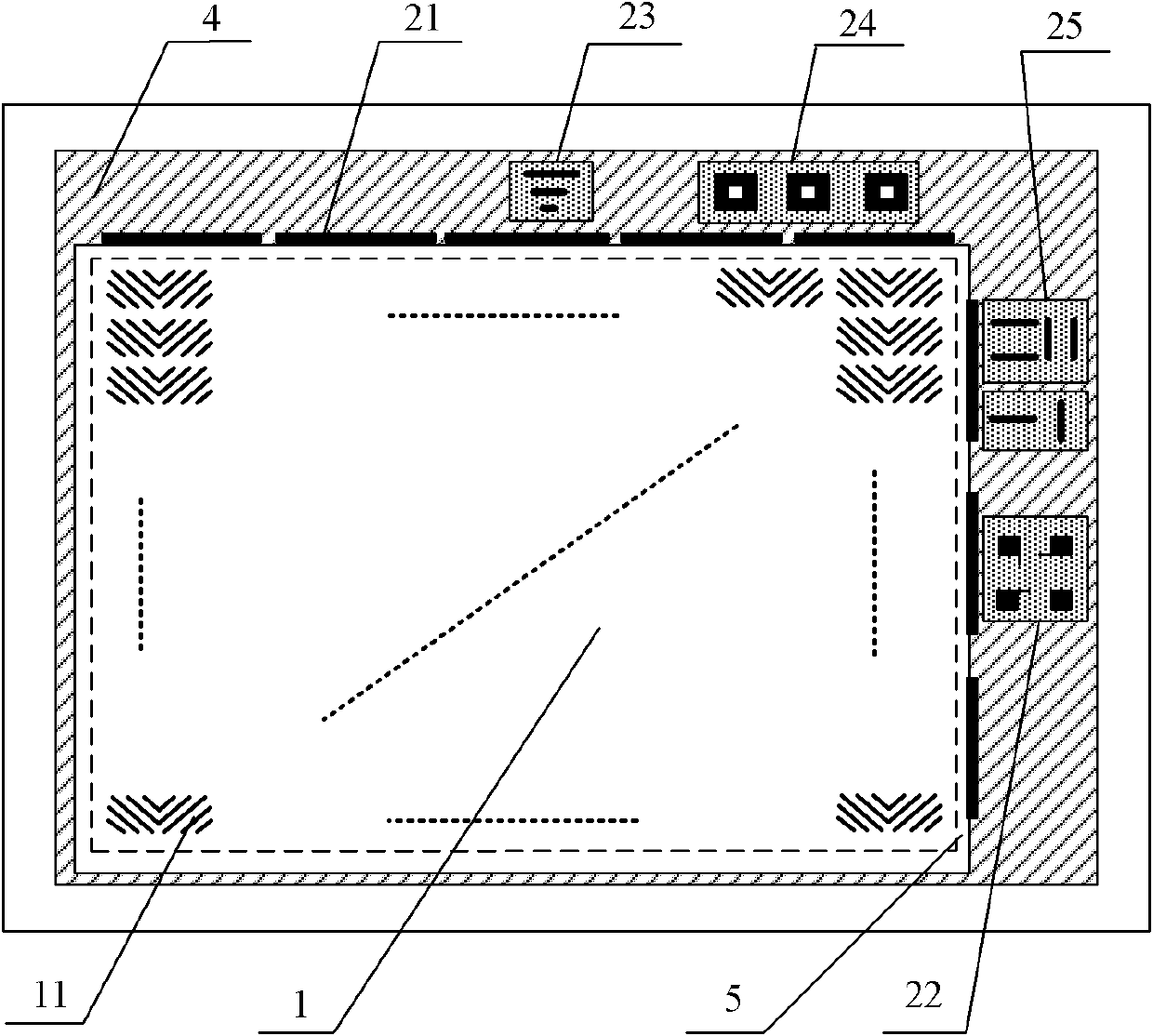

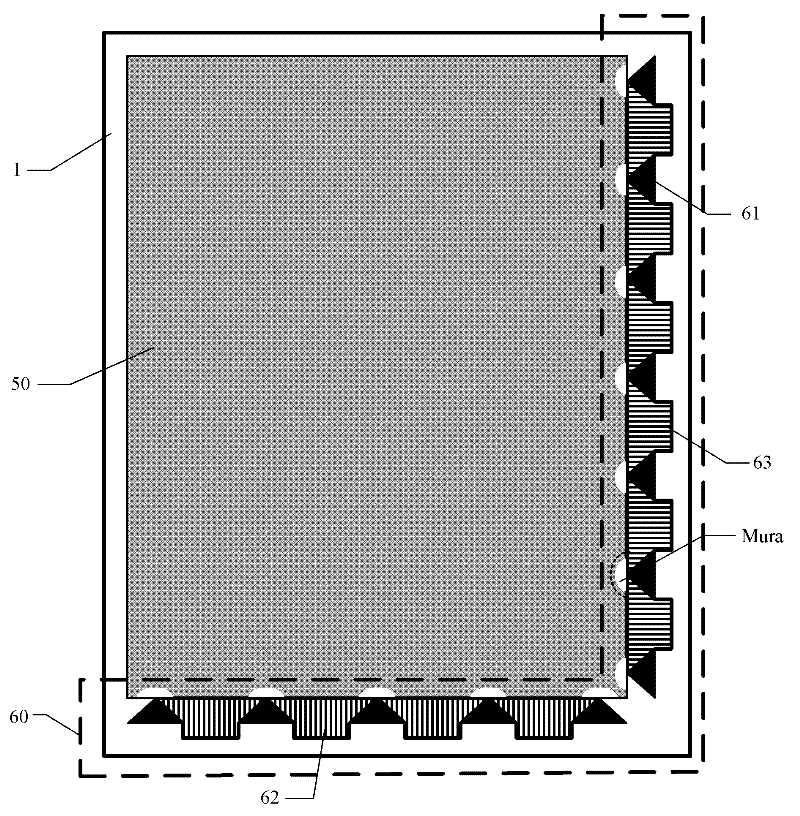

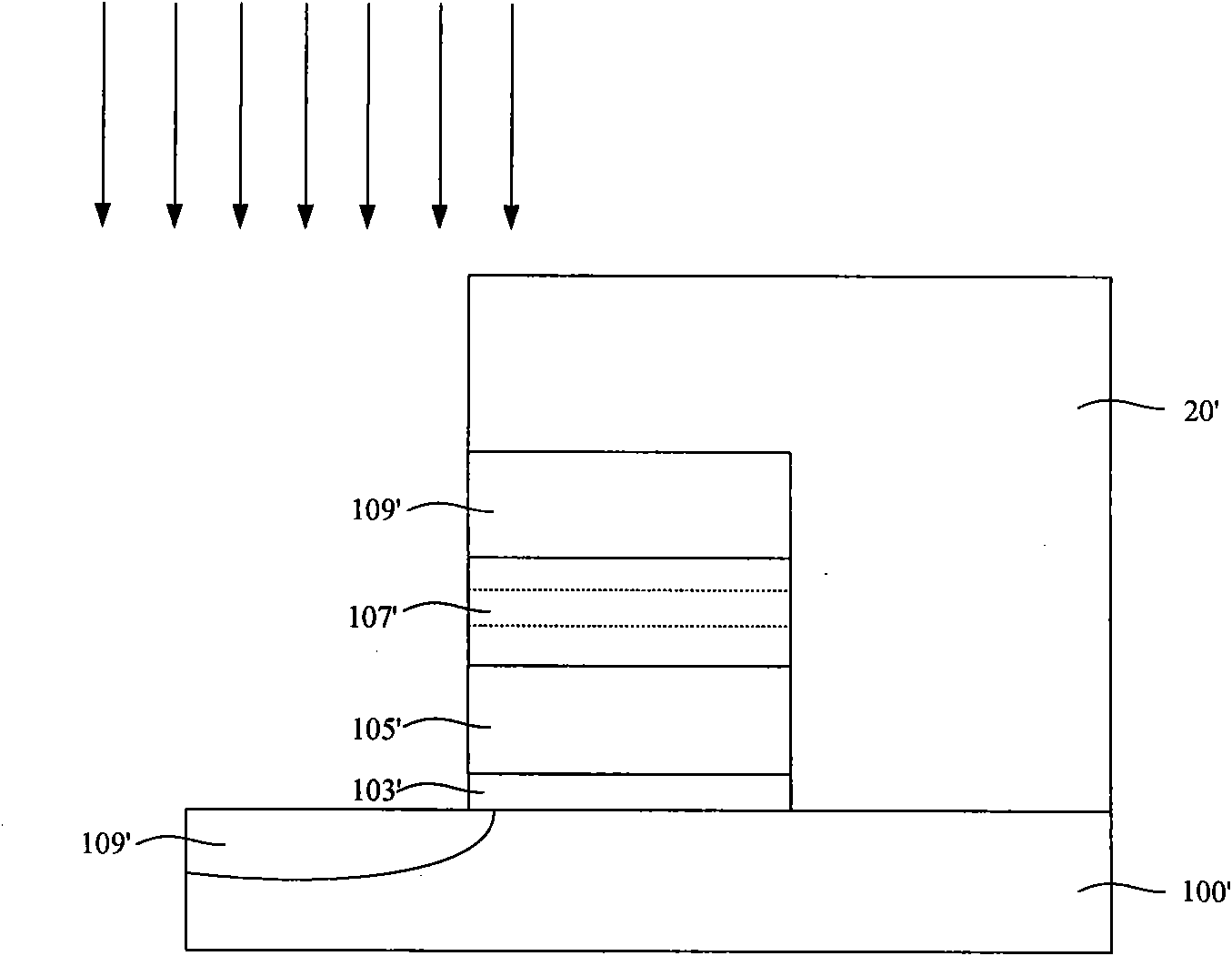

Array substrate, liquid crystal display and manufacturing method of array substrate

ActiveCN102466936AReduce manufacturing defect rateQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

The invention discloses an array substrate, liquid crystal display and manufacturing method of array substrate; the array substrate comprises a substrate; the substrate comprises a pixel area and a driving circuit area; a common electrode driver interface pattern, a grid line driver interface pattern connected with the common electrode driver interface pattern and a data line driver interface pattern are formed on the substrate positioned in the driving circuit area; a slit is formed on the common electrode driver interface pattern; and various parts of the common electrode driver interface pattern separated by the slit are mutually connected. The technical scheme of the invention consumes the developer solution while the slit is formed on the common electrode driver interface pattern, reduces the influence of the periphery driving circuit area to the concentration of the developer solution in the adjacent pixel area, and improves the manufacturing yield of the array substrate.

Owner:BOE TECH GRP CO LTD

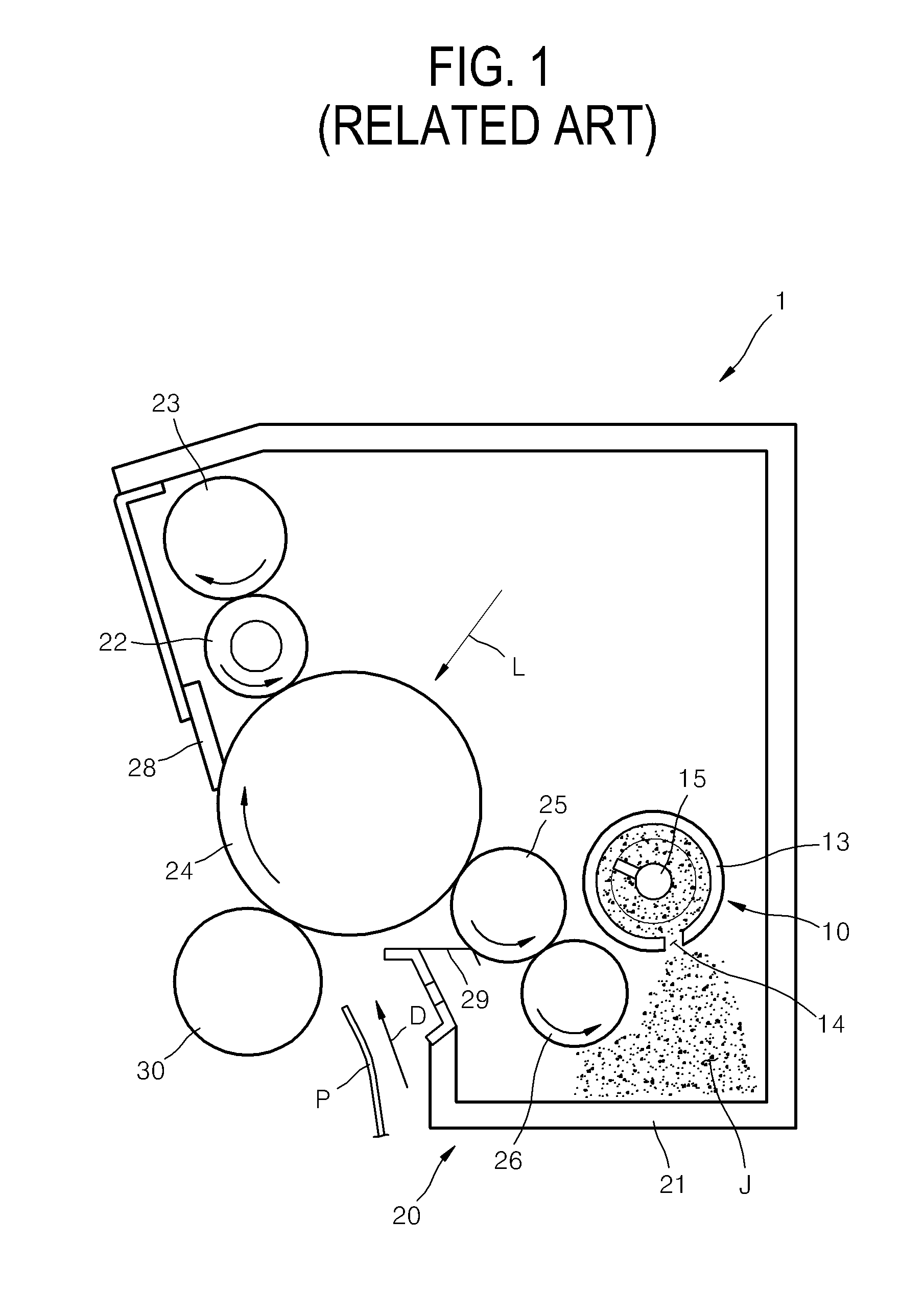

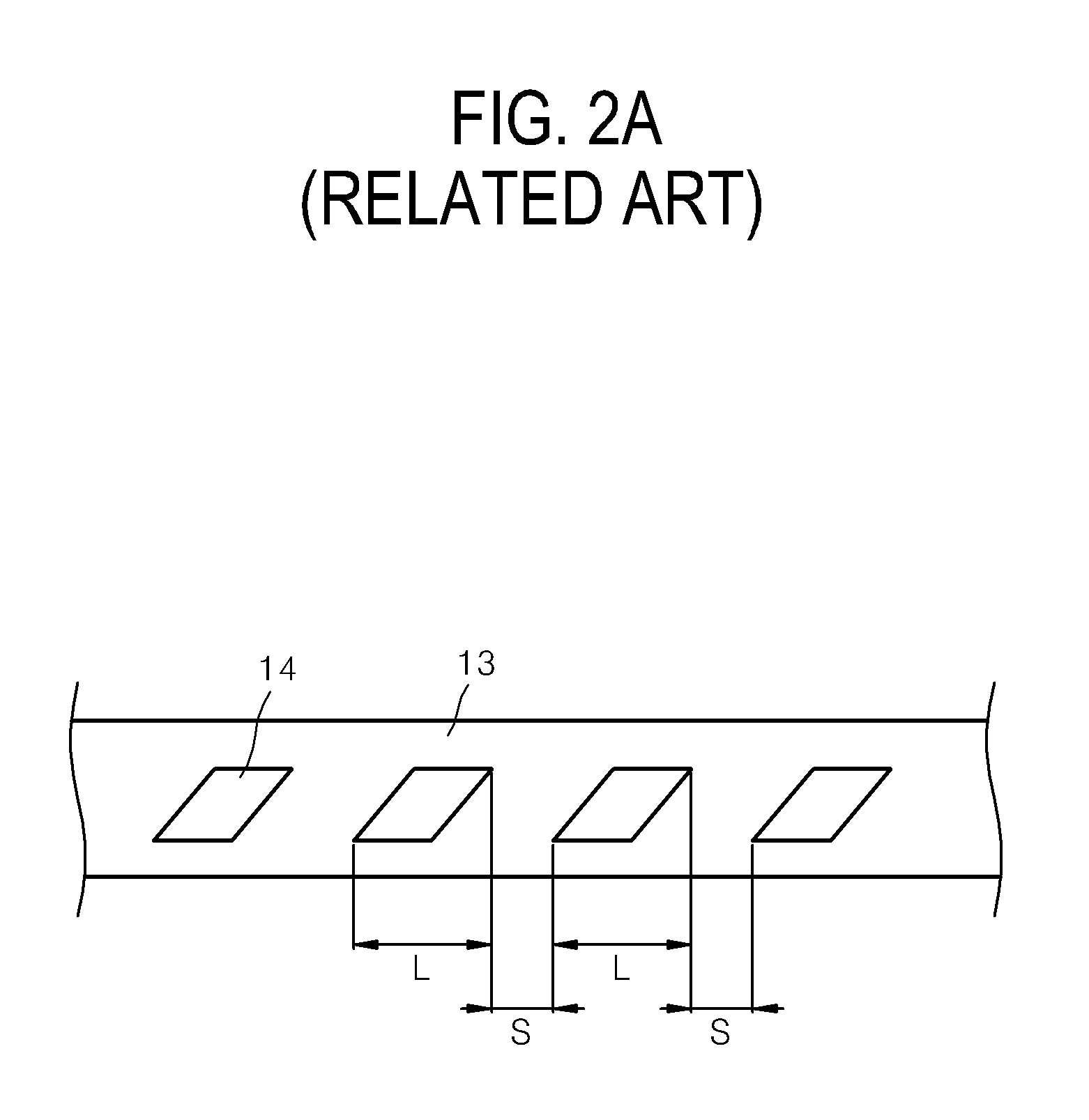

Image forming apparatus

InactiveUS20080193168A1Reduce concentration differenceElectrographic process apparatusImage formationEngineering

Owner:HEWLETT PACKARD DEV CO LP

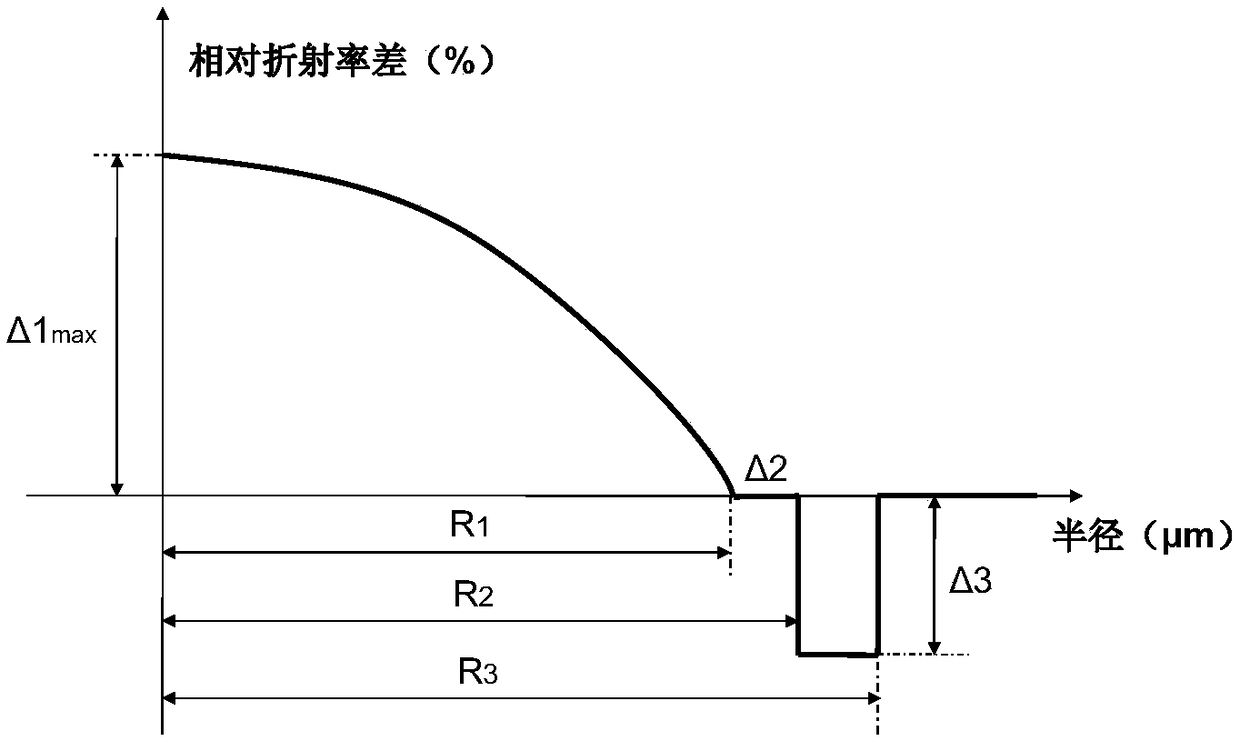

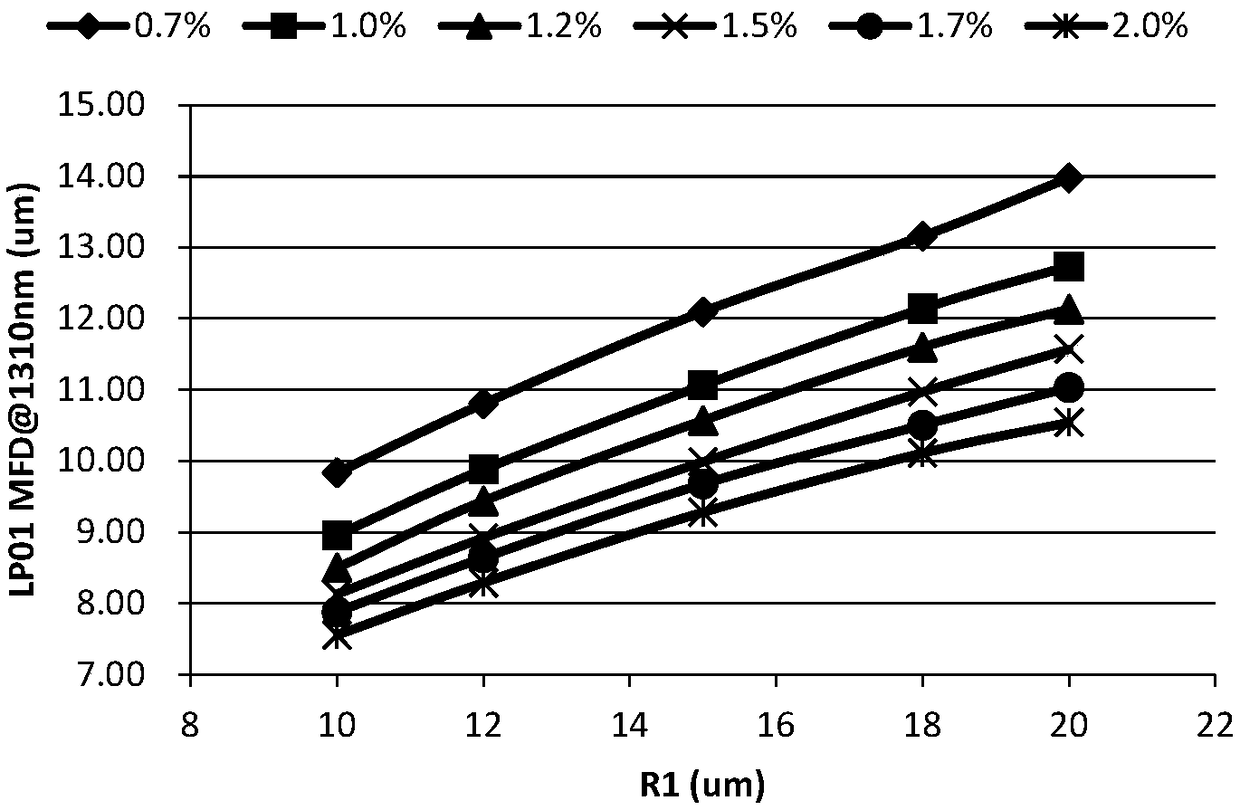

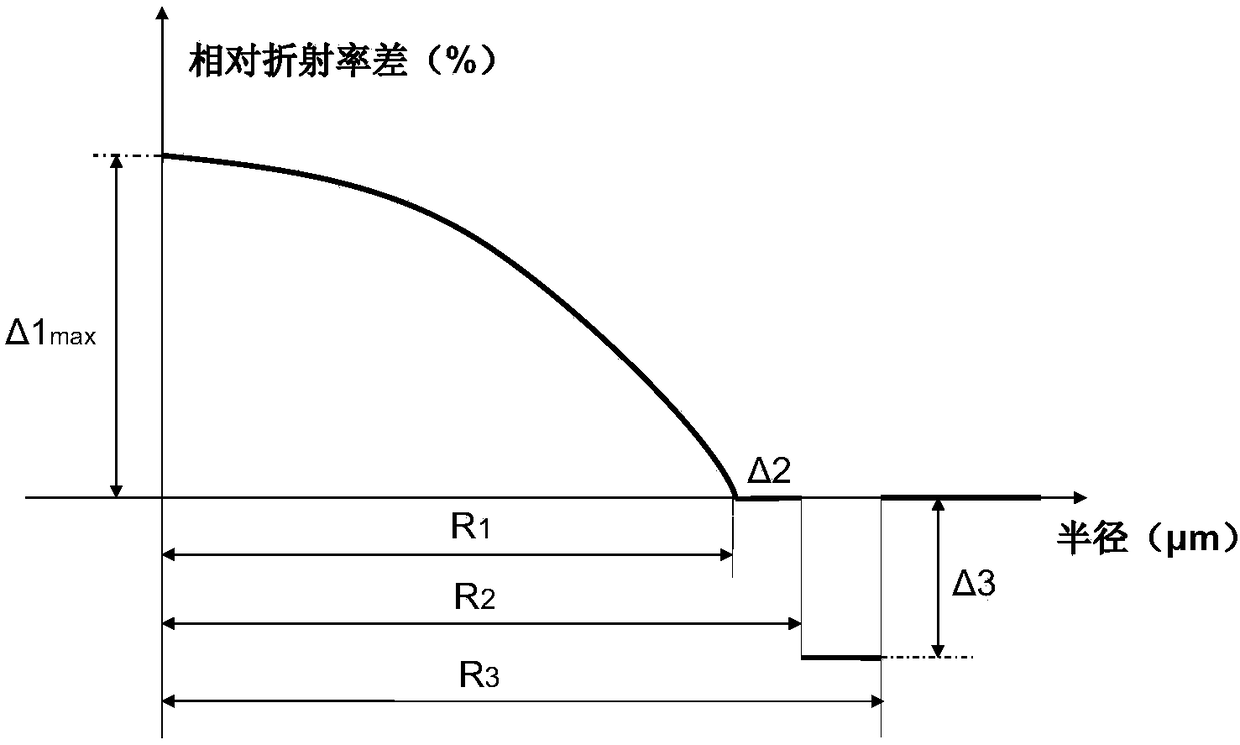

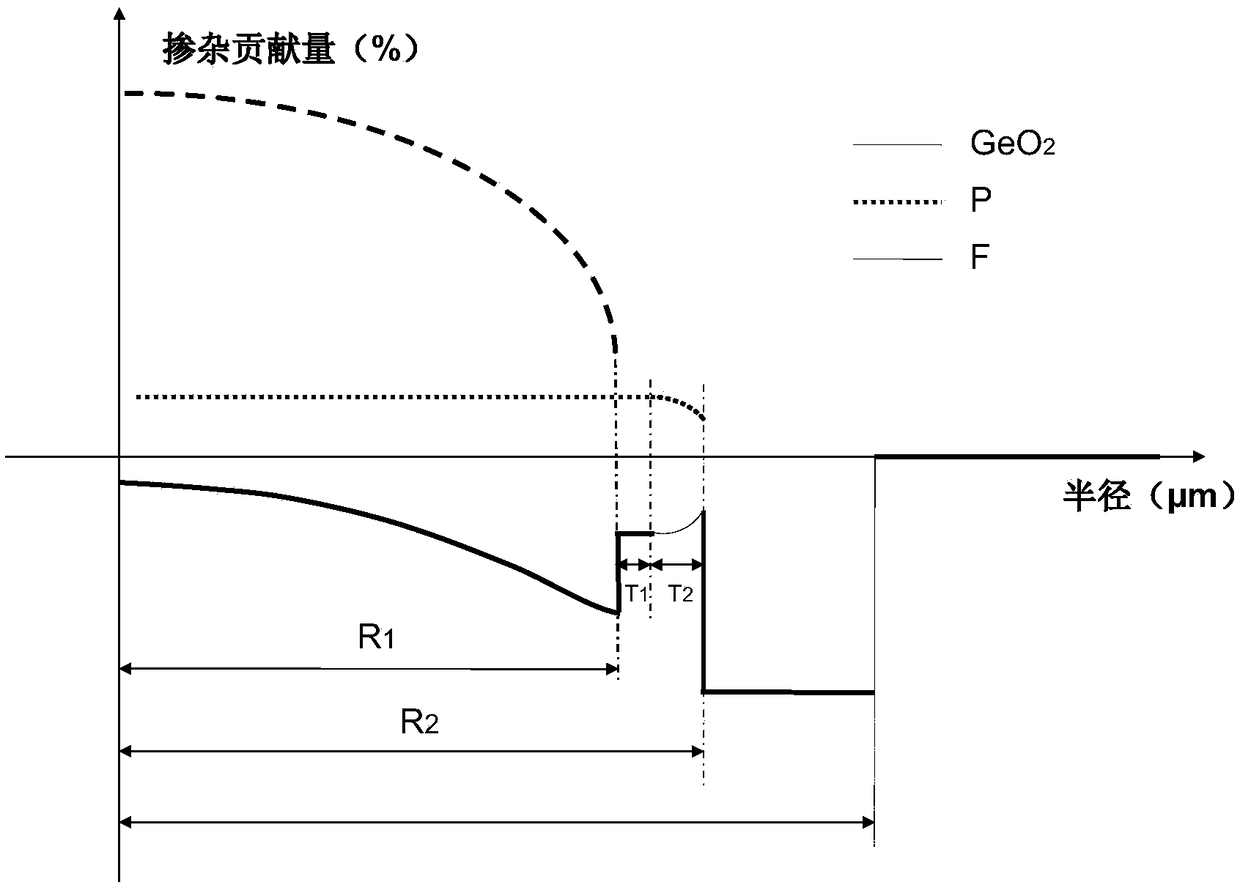

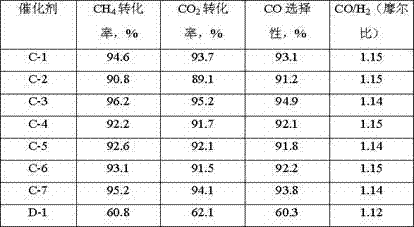

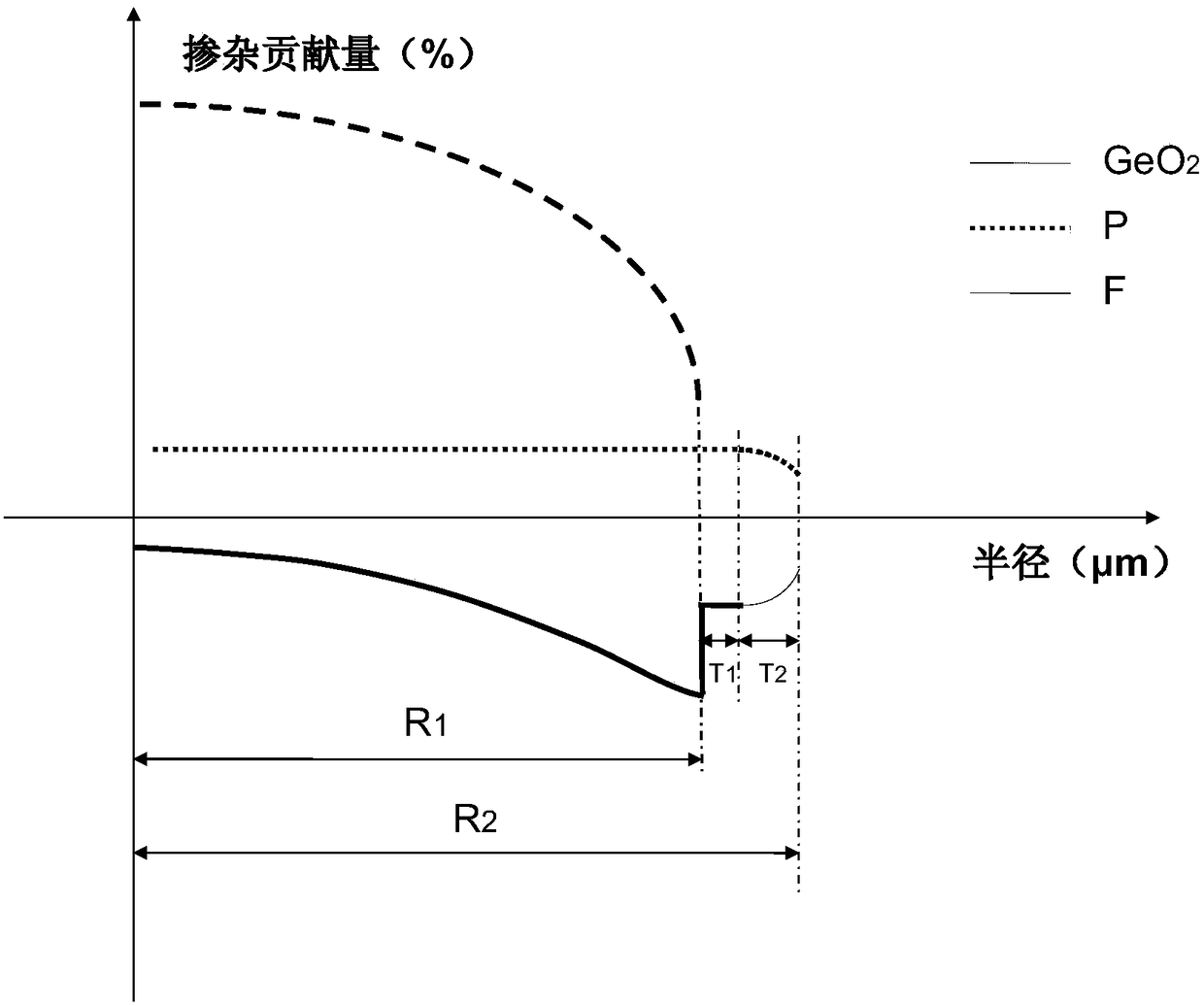

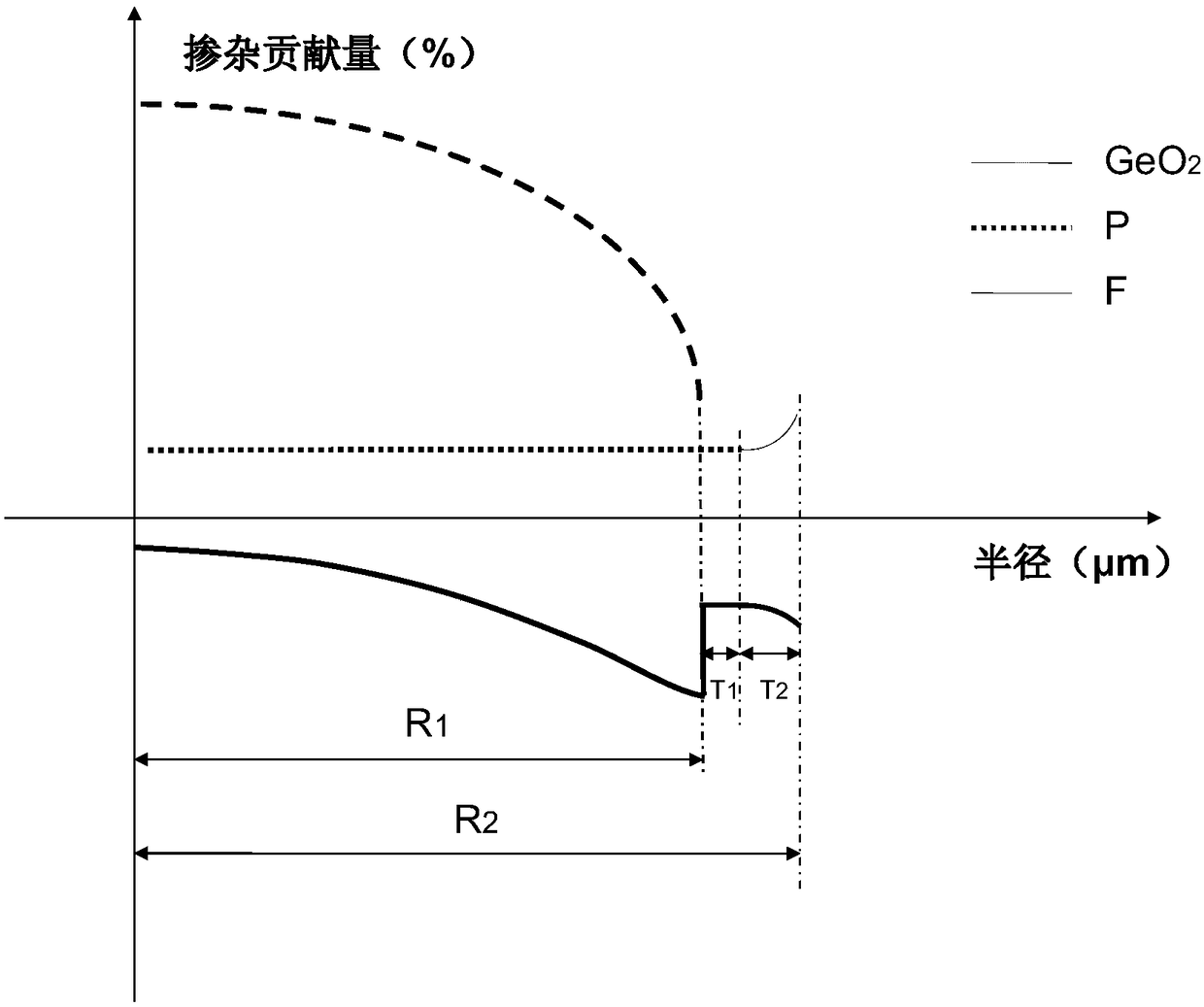

Small-core-diameter graded index fiber

ActiveCN109188603AImprove bend insensitive performanceImprove bending resistanceOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingAccess networkRelative refractive index

The invention relates to a small-core-diameter graded index fiber. The small-core-diameter graded index fiber comprises a core layer and claddings; the claddings are an inner cladding, a sunken cladding and an outer cladding in sequence from inside to outside; the small-core-diameter graded index fiber is characterized in that the refractivity profile of the core layer is parabolic, a distributionindex alpha is 1.9-2.1, the radius R1 of the core layer is 10-21 [mu]m, and the maximum relative refractive index difference delta 1max of the center of the core layer is 0.7-1.7%; the core layer isa Ge, P and F-coped silicon dioxide glass layer, the inner cladding is a pure silicon dioxide layer or an F-doped silicon dioxide glass layer, the one-sided width of the inner cladding is 0.5-5 [mu]m,delta 2 is -0.4-0%, and the one-sided width of the sunken cladding is 2-10 [mu]m, delta 3 is -0.8-0.2%; and the outer cladding is a pure silicon dioxide glass layer. The small-core-diameter graded index fiber can be compatible with an existing OM3 / OM4 multimode fiber, and also can support a wavelength division multiplexing technology in a wavelength range of 850-950nm; the small-core-diameter graded index fiber can be compatible with a single mode fiber, and supports single mode transmission of 1,310nm and 1,550nm; and the small-core-diameter graded index fiber has excellent bending-resistantperformance and can be suitable for access networks and miniaturized optical devices.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

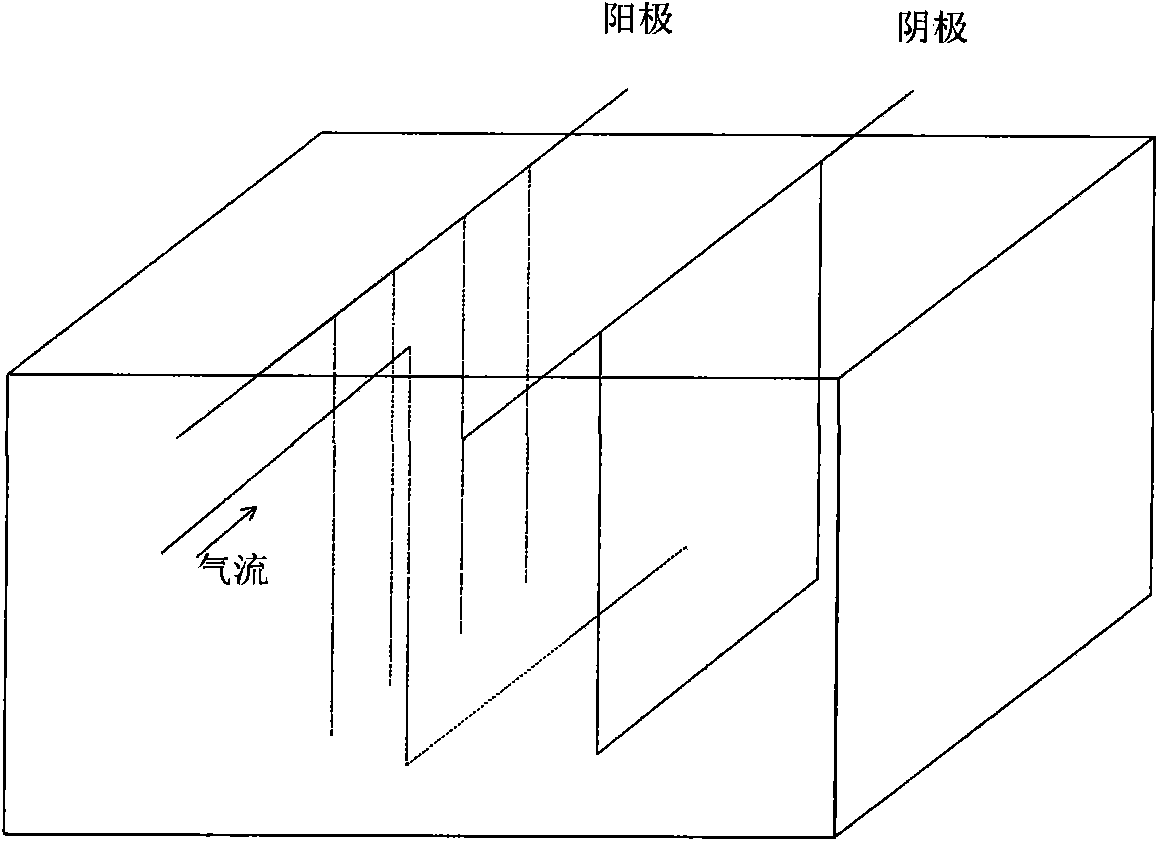

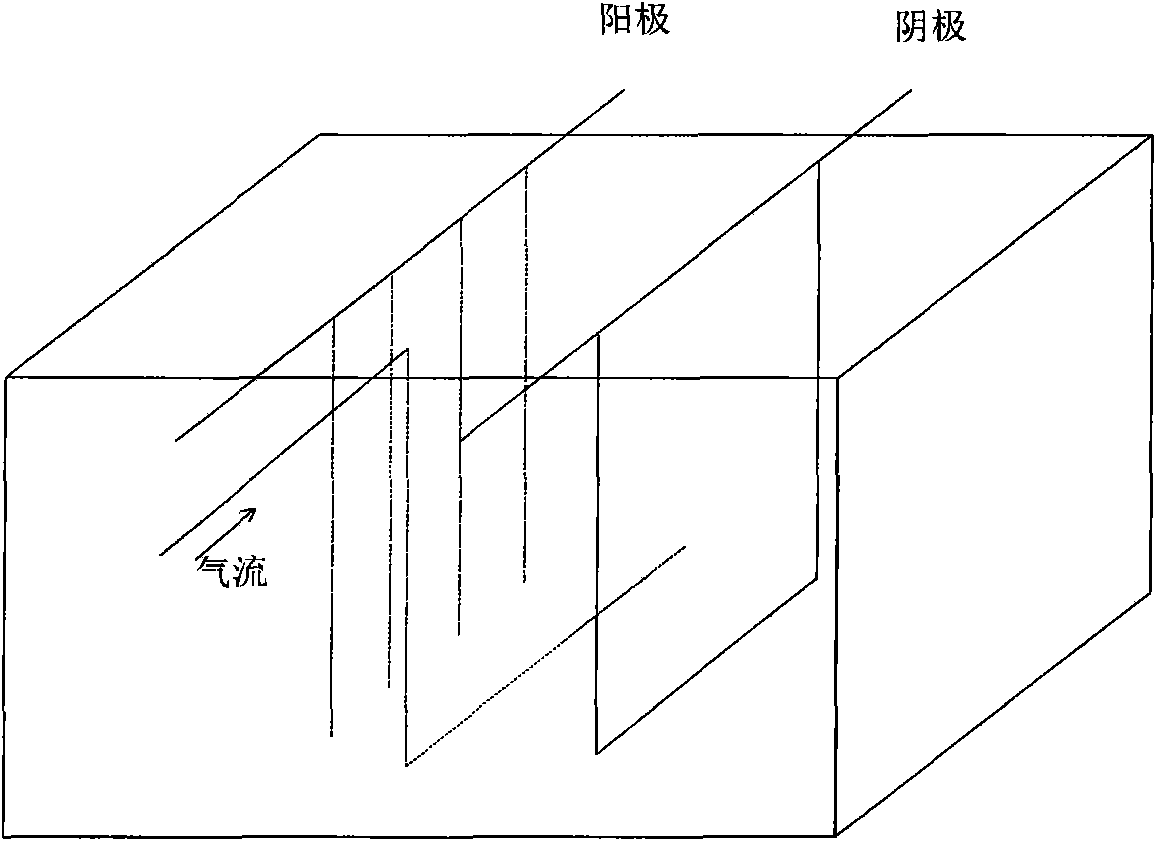

Electro-adsorption desalination method for saline wastewater

InactiveCN104909439AReduce concentration differenceEvenly distributedDispersed particle separationSaline waterDesalination

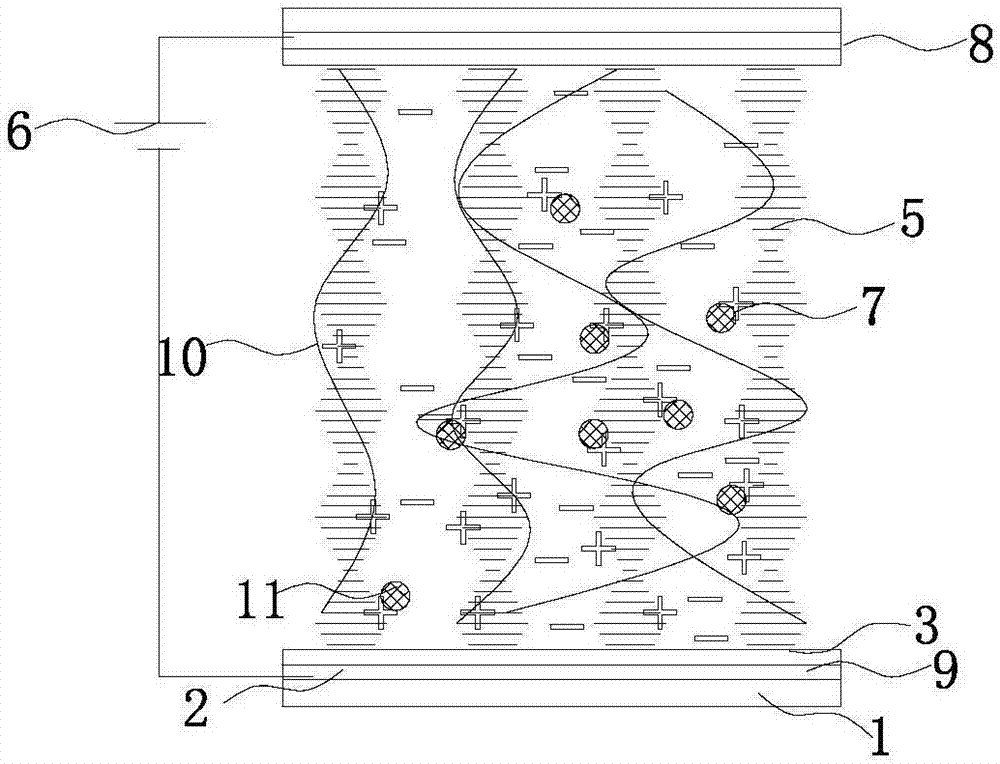

The invention discloses an electro-adsorption desalination method for saline wastewater. According to the method, an electro-adsorption device is constructed at first, and the electro-adsorption device is composed of a saline water distribution pool, stable adsorption pool groups, a constant-flow pump, an insulation water inlet tube, an insulation outer frame, a single-sided anode electrode plate, a single-sided cathode electrode plate, a double-sided electrode plate, an insulation channel and a voltage-stabilizing direct-current power supply; saline water longitudinally flows among the electrode plats, and flows to the low-concentration saline water stable adsorption pool group from the high-concentration saline water stable adsorption pool group; electro-adsorption desalination for saline wastewater is carried out after the device is constructed; the electro-adsorption device is operated, the saline water in the saline water distribution pool enters stable adsorption pools through the constant-flow pump, and during an electro-adsorption process, anions and cations in the stable adsorption pools are directionally migrated to a double-sided electrode with opposite electrical properties, one surface of the double-sided electrode adsorbs the anions, and the other surface of the double-sided electrode adsorbs the cations. The method disclosed by the invention reduces the balanced adsorption time, saves electrode materials, and is suitable for electro-adsorption desalination for mixed saline water with a single component or a relatively consistent ion migration speed.

Owner:UNIV OF SCI & TECH LIAONING

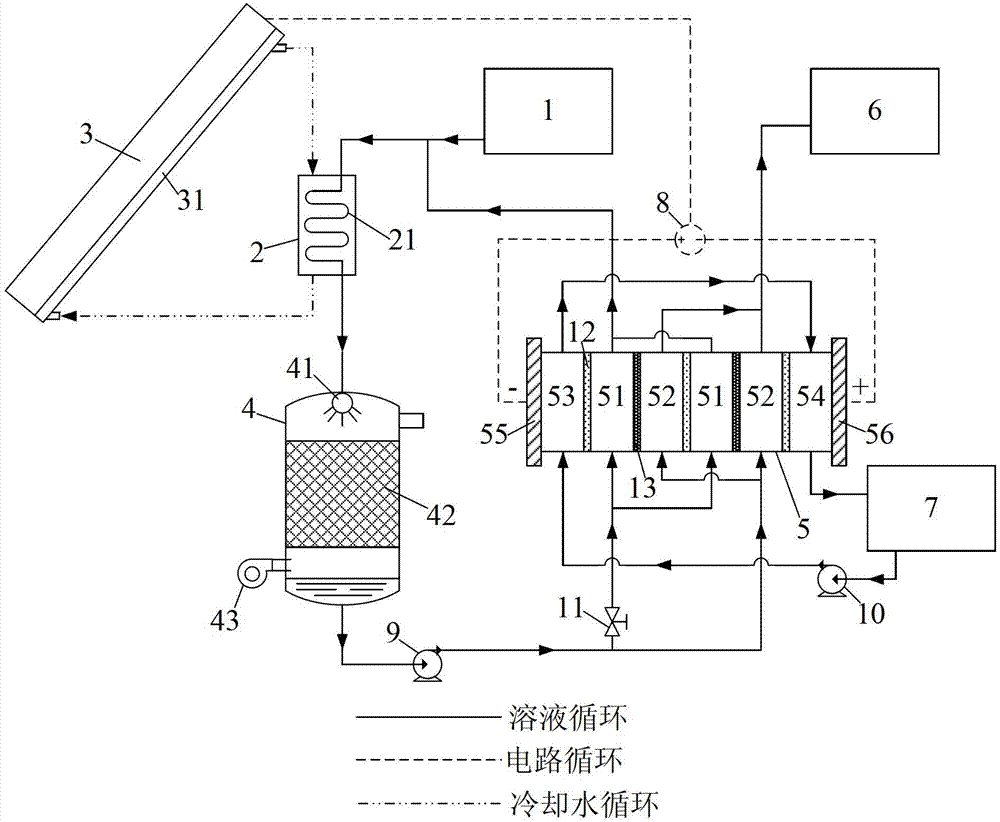

Solution regeneration apparatus for solution deep dehumidifying system

InactiveCN103041675AImprove power generation efficiencyReduce the temperatureDispersed particle separationElectricityHigh concentration

The invention discloses a solution regeneration apparatus for a solution deep dehumidifying system, comprising a first solution tank, a heat exchanger, a solar photovoltaic cell, a solution preprocessor, a membrane regenerator, a second solution tank, a third solution tank, a storage battery, a first anticorrosion solution pump, a second anticorrosion solution pump and a regulating valve. The apparatus of the invention heats the dehumidifying solution by the heat exchanger, and then primarily regenerates the dehumidifying solution by the solution preprocessor, which increase the concentration of the inlet solution of a regeneration chamber and a desalination chamber of the membrane regenerator, thereby raising the regeneration effect of the membrane regenerator. Finally, high-concentration dehumidifying solution for the solution deep dehumidifying system is obtained. The apparatus of the invention effectively utilizes the complementarity of solar photovoltaic and photo-heat, thereby raising the running stability of the solar solution deep dehumidifying system, and simultaneously, the apparatus stores energy by the night low-ebb and low-price electric energy, thereby alleviating the peak-valley difference of the electrical loads, and raising the economy of the system.

Owner:东南大学常州研究院

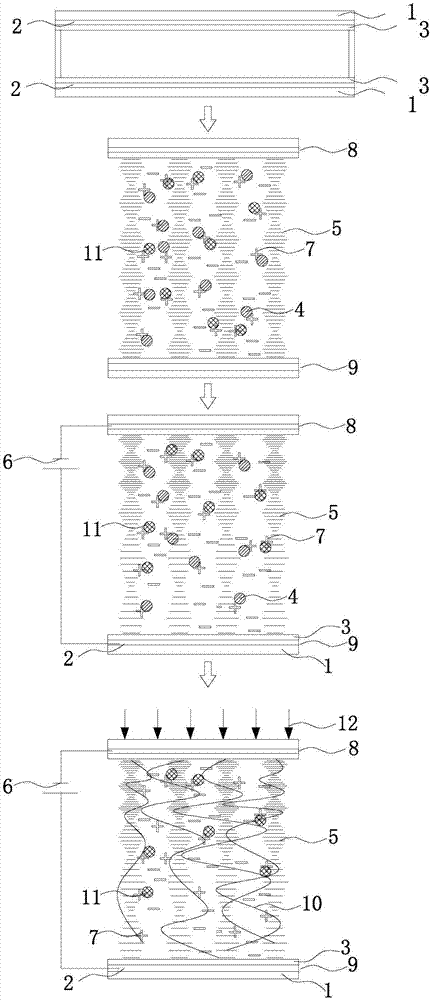

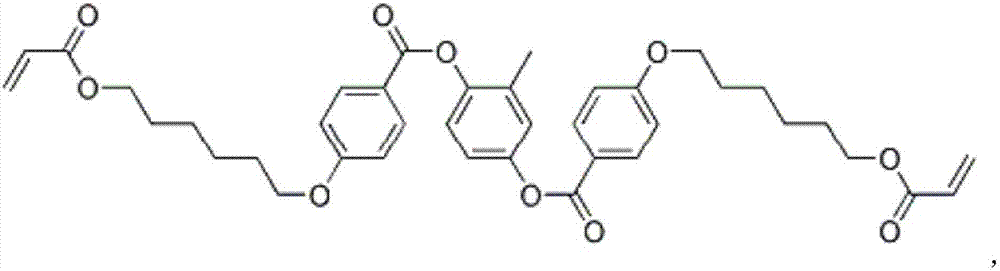

Manufacturing method of infrared reflecting device

InactiveCN106997133AReduce concentration differenceDecrease the concentration gradientLiquid crystal compositionsLight protection screensDopantPolymer network

The invention discloses a manufacturing method of an infrared reflecting device. The manufacturing method of the infrared reflecting device comprises the following steps: making a first conductive light transmitting substrate and a second conductive light transmitting substrate at first, and enabling the two conductive light transmitting substrate to opposite to each other; manufacturing parallel orientation layers on the opposite surfaces of the two conductive light transmitting substrates; manufacturing a liquid crystal box by using the two conductive light transmitting substrates; mixing negative liquid crystal, a chiral dopant, liquid crystal monomers and a photoinitiator to obtain a liquid crystal mixture; injecting the liquid crystal mixture in the liquid crystal box; connecting the first conductive light transmitting substrate with a negative pole of a power supply assembly, connecting the second conductive light transmitting substrate with a positive pole of the power supply assembly, capturing impurity positive ions by using the liquid crystal monomers and / or the chiral dopant so that the liquid crystal monomers and / or the chiral dopant have positive charge, and enabling the liquid crystal monomers and / or the chiral dopant to continue moving towards the negative pole direction; and carrying out ultraviolet irradiation to polymerize the liquid crystal monomers so as to form a polymer network, and enabling the densities of the polymer network to be distributed in a gradient manner in the direction perpendicular to the conductive light transmitting substrate to obtain the infrared reflecting device with wide reflection bandwidth. By change of the direction of an electric field, infrared reflection waveband can be adjusted.

Owner:SOUTH CHINA NORMAL UNIVERSITY +2

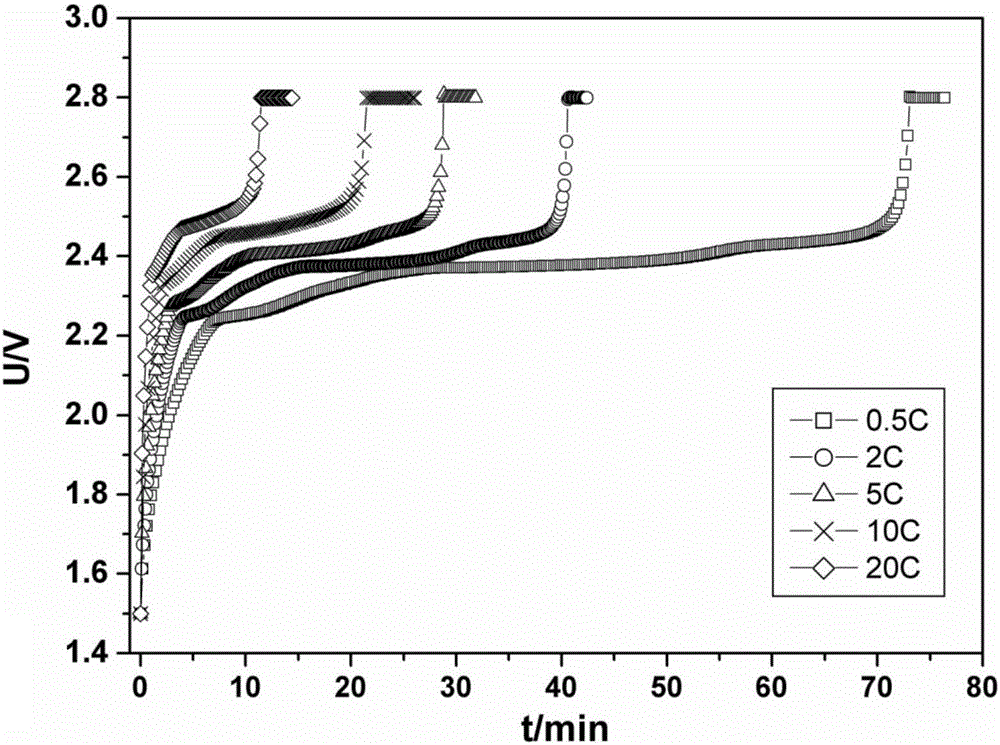

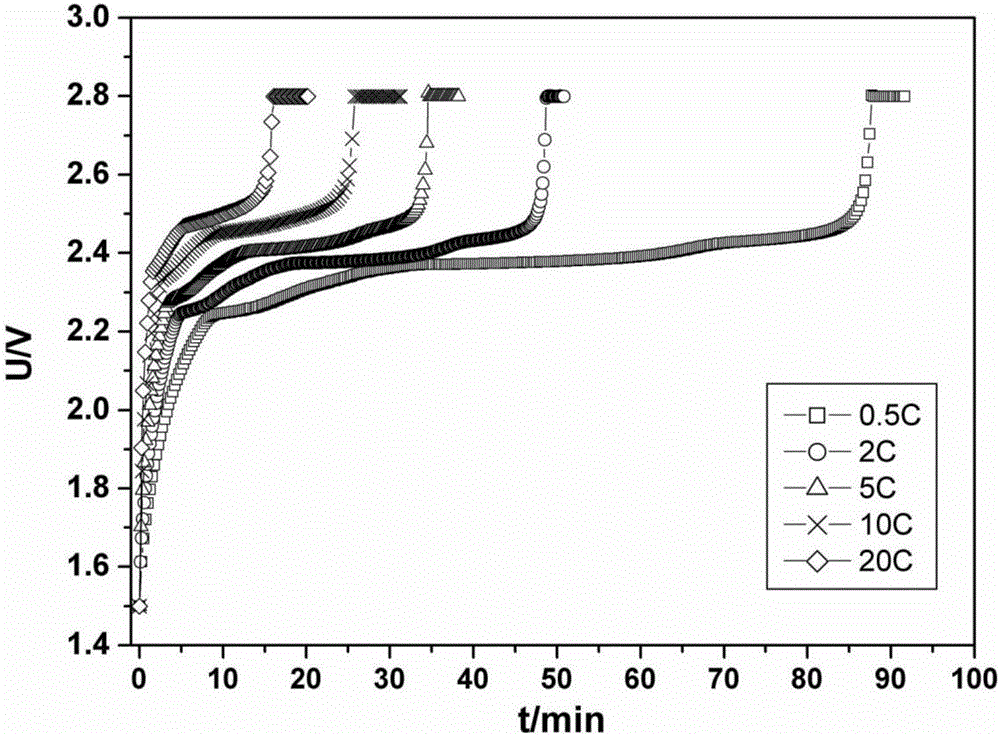

Fast charging lithium titanate composite negative electrode piece and lithium ion battery

InactiveCN106159236AImprove conductivityLarge current carryingElectrode carriers/collectorsSecondary cellsElectrical batteryCarbon nanotube

The invention discloses a fast charging lithium titanate composite negativeelectrode piece and a lithium ion battery. The lithium titanate composite negative electrode piece comprises a negative electrode current collector, wherein one or both sides of the negative electrode current collector are sequentially provided with a lithium titanate composite layer and a lithium-supplementing layer in a direction away from the negative electrode current collector, and the lithium titanate composite layer comprises lithium titanate, graphene and carbon nanotubes according to a mass ratio of (90 to 94) : (1 to 3): (1 to 3); the lithium-supplementing layer comprises organic lithium. The composite negative electrode piece is in a layered structure, the carbon nanotubes and graphene doped in the lithium titanate composite layer have the characteristics of high conductivity and large current carrying capacity, and the lithium titanate has small particles and small transmission distance, so that the lithium ion transmission time is shortened; the lithium-supplementing layer supplies sufficient lithium ions in the charging and discharging process of the battery, and the transmission rate of the lithium ions in the battery is improved, thereby the cycling performance and the rate performance of the battery are improved, and the fast charging effect is good.

Owner:深圳博磊达新能源科技有限公司

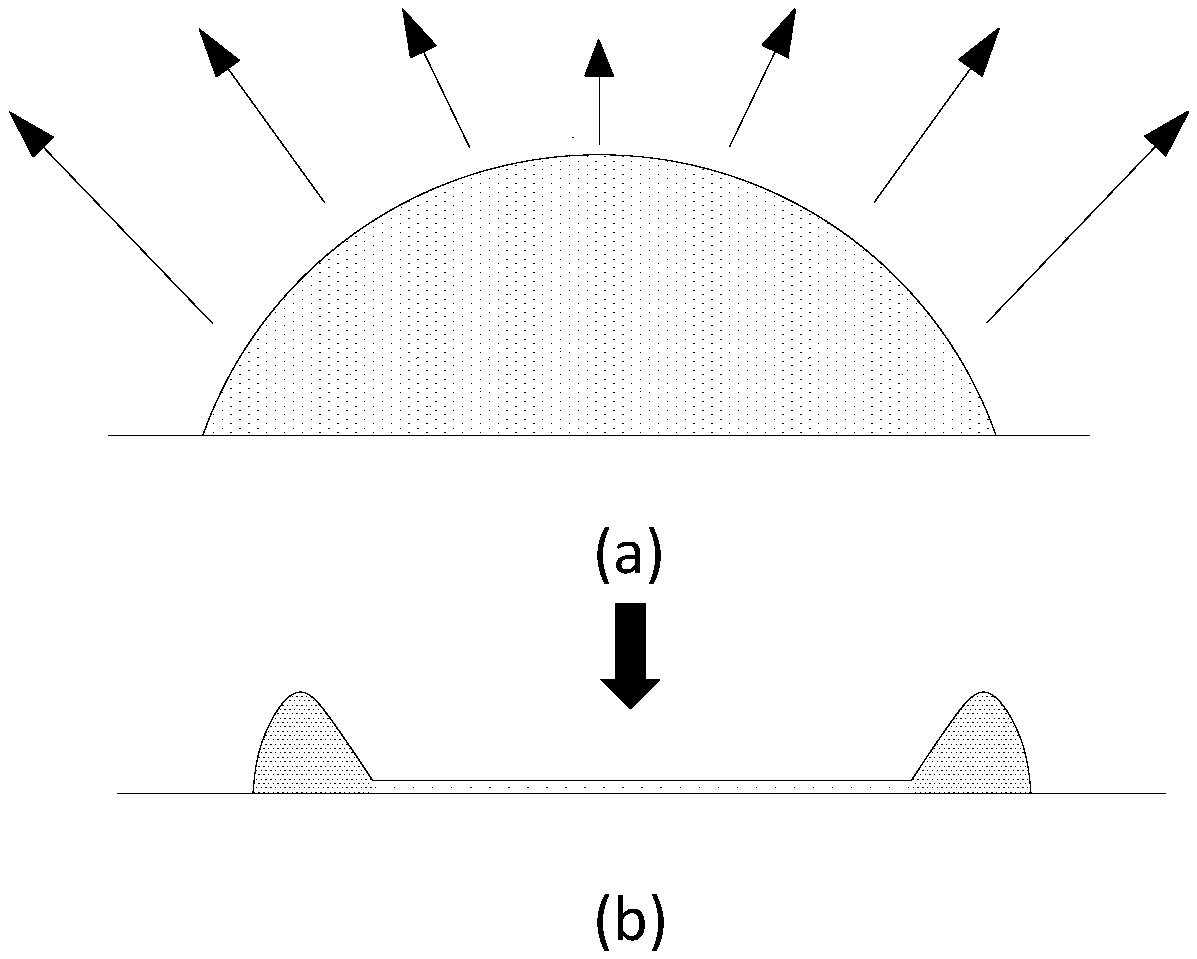

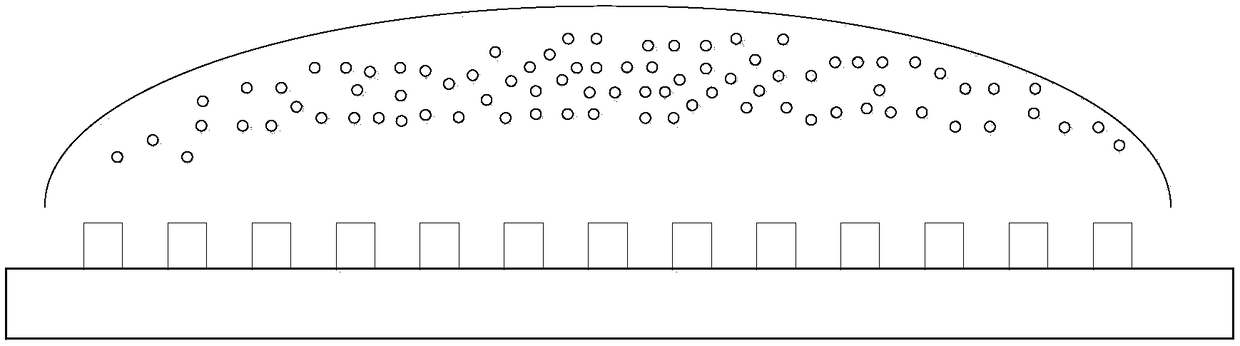

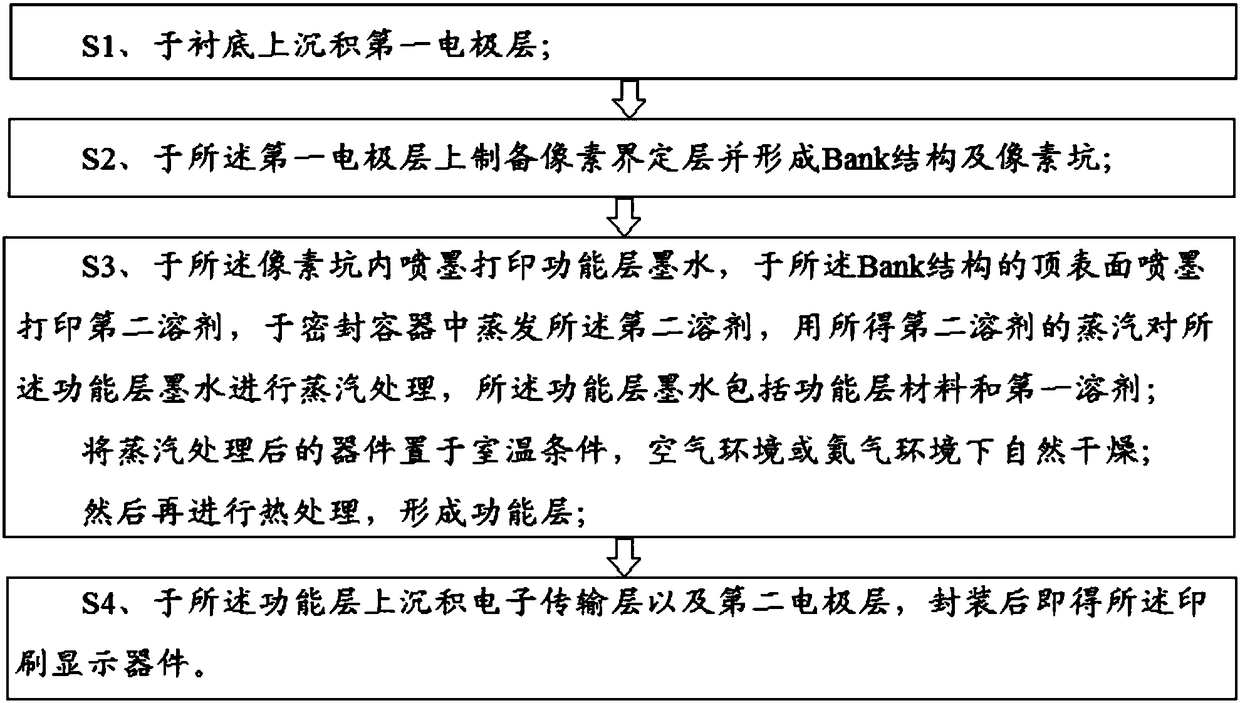

Preparation method of printed display device

ActiveCN108346679AReduce surface tensionGood spreadabilitySolid-state devicesSemiconductor/solid-state device manufacturingNitrogenDisplay device

The invention discloses a preparation method of a printed display device, which comprises the steps of depositing a first electrode layer on a substrate; preparing a pixel defining layer on the firstelectrode layer, and forming a Bank structure and pixel pits; ink-jet printing functional layer ink in the pixel pits, ink-jet printing a second solvent on the top surface of the Bank structure, evaporating the second solvent in a sealed container, and performing steam treatment on the functional layer ink by the obtained steam of the second solvent, wherein the functional layer ink comprises a functional layer material and a first solvent; placing the device subjected to steam treatment in a room temperature condition, namely, an air environment or a nitrogen environment, for natural drying;then performing thermal treatment to form a functional layer; depositing an electron transport layer and a second electrode layer on the functional layer, and packaging to obtain the printed display device. The preparation method improves the uniformity of a thin film and the wettability of the functional ink and the pixel defining layer, ensures uniform spreading of the ink so as to play an effect of suppressing the leakage current, is simple and easy to implement and can substantially reduce the manufacturing difficulty and the manufacturing cost.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

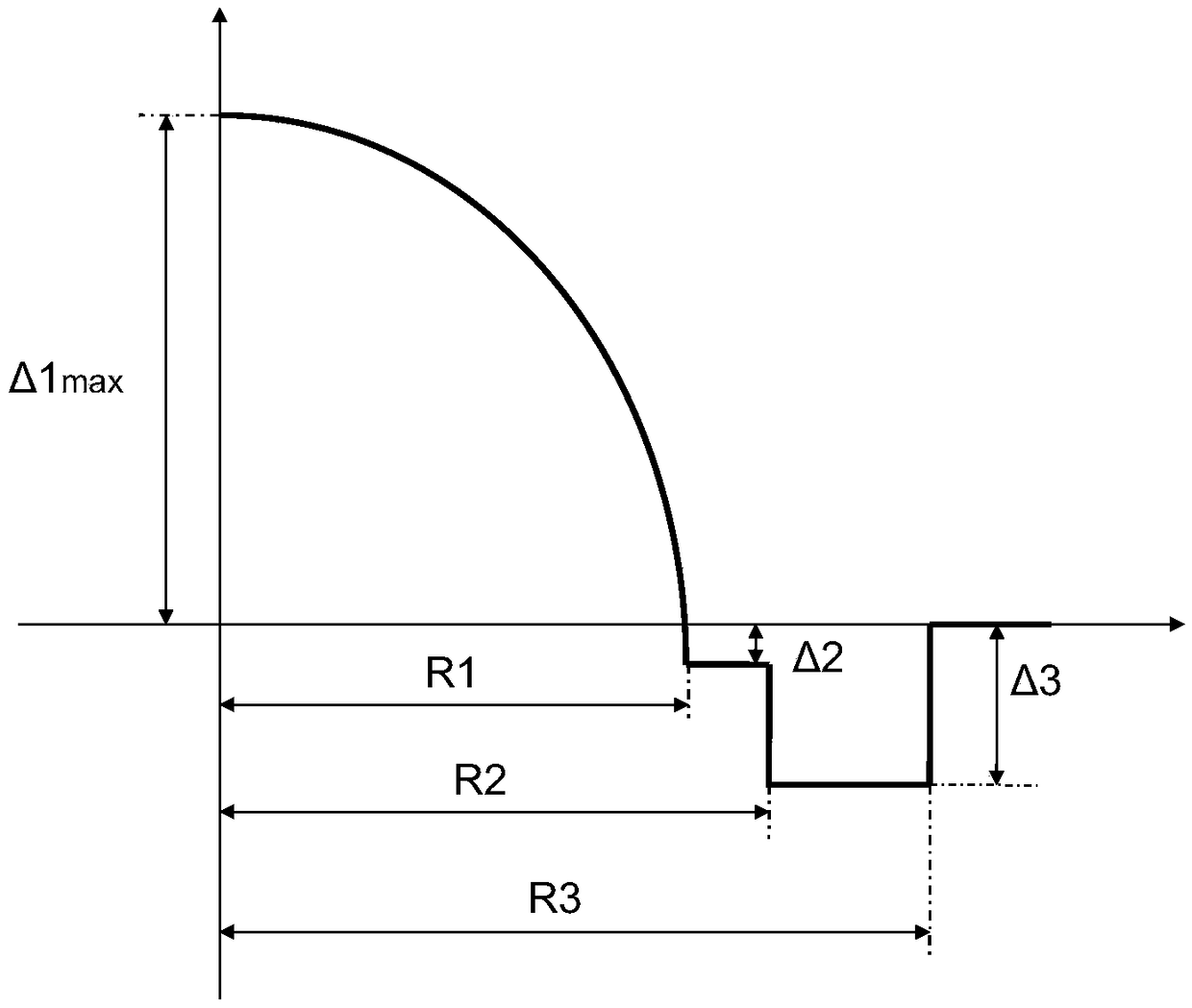

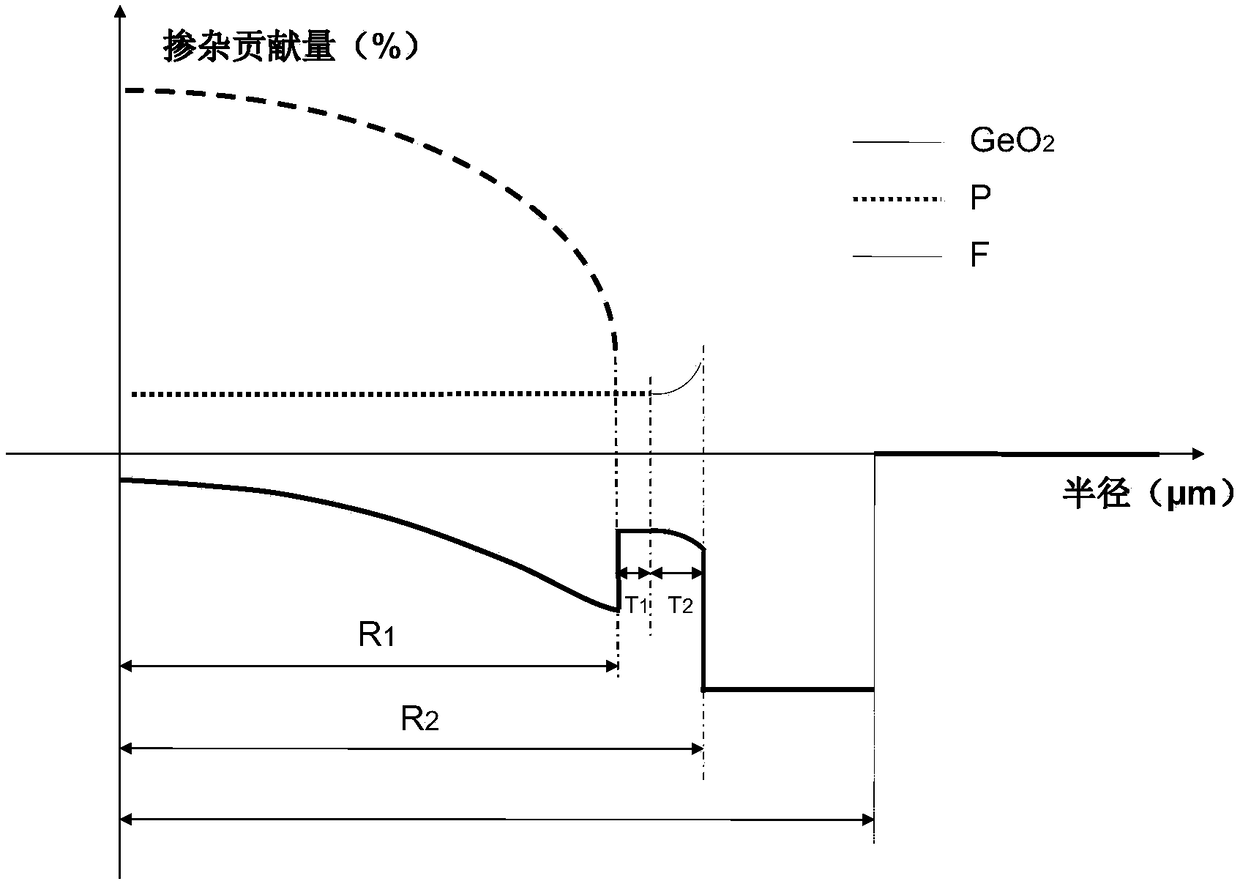

High-bandwidth bending-insensitive multimode optical fiber

ActiveCN108375815AIncrease concentrationImproved material dispersionOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingRelative refractive indexSilicon dioxide

The present invention relates to a high-bandwidth bending-insensitive multimode optical fiber. The optical fiber comprises a core layer and a cladding layer, wherein the cladding layer includes an inner cladding layer, a depressed cladding layer and an outer cladding layer which are distributed from inside to outside. The optical fiber is characterized in that the refractive index profile of the core layer is of a parabola shape; the distribution index alpha of the core layer ranges from 2.0 to 2.3; the radius R1 of the core layer ranges from 23 to 27 micrometers; the maximal relative refractive index difference delta1max of the center of the core layer ranges from 0.9% to 1.2%; the core layer is a germanium (G), phosphorus (P) and fluorine (F) co-doped silica glass layer; the contributionamount deltaP0 of phosphorus (P) at the center of the core layer ranges from 0.01% to 0.30%; the contribution amount deltaP1 of phosphorus (P) at the interface of the core layer and the inner cladding layer ranges from 0.01% to 0.30%; the content of phosphorus (P) at the center of the cover layer is consistent with the content of phosphorus (P) at the edge of the core layer; the doping amount offluorine (F) is gradually increased from the center of the core layer to the edge of the core layer; the contribution amount deltaF0 of fluorine (F) at the center of the core layer ranges from 0.0% to-0.1%; and the contribution amount deltaF1 of fluorine (F) at the edge of the core layer ranges from -0.4% to -0.20%;. The material compositions of the high-bandwidth bending-insensitive multimode optical fiber and the structural design of the core layer and cladding layer of the high-bandwidth bending-insensitive multimode optical fiber are reasonable; the chromatic dispersion of the optical fiber is reduced; the bandwidth performance of the optical fiber is improved; and the attenuation of the optical fiber is reduced.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

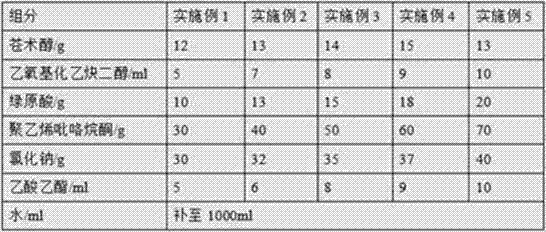

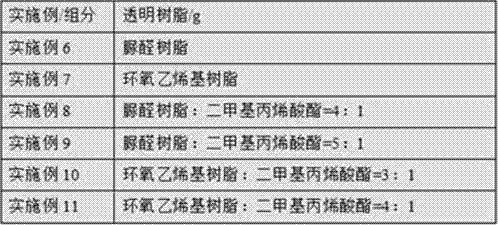

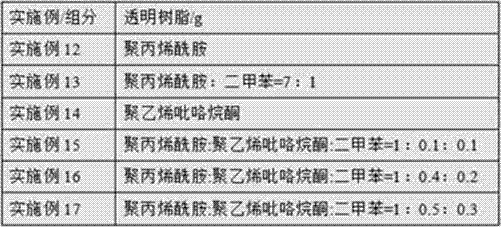

Pathological specimen processing method

InactiveCN106908294ABroad antimicrobial effectAntioxidantPreparing sample for investigationChlorogenic acidSpecimen Handling

The invention discloses a pathological specimen processing method and belongs to the field of specimen processing technology. According to the processing method, sampled pathological tissues successively undergo fixation, dehydration, transparency, wax impregnation, embedding, slicing, staining and mounting so as to obtain a pathological specimen. The fixation is to fix the pathological tissues by the use of a fixative for 4-15 h. The fixative is composed of atractylol, ethoxylated acetylenediol, chlorogenic acid, polyvinylpyrrolidone, sodium chloride, ethyl acetate and pure water. The mounting is to carry out mounting on the stained pathological tissues by the use of a mixture of polyacrylamide, polyvinylpyrrolidone and xylene. According to the invention, toxicity of reagents used in the invention is obviously reduced, the fixation effect is good, degradation and transparency degree are easy to control. Then, the tissues are not easy to deform, embrittle or harden, and mounting is complete and staining is remarkable.

Owner:LUOHE MEDICAL COLLEGE

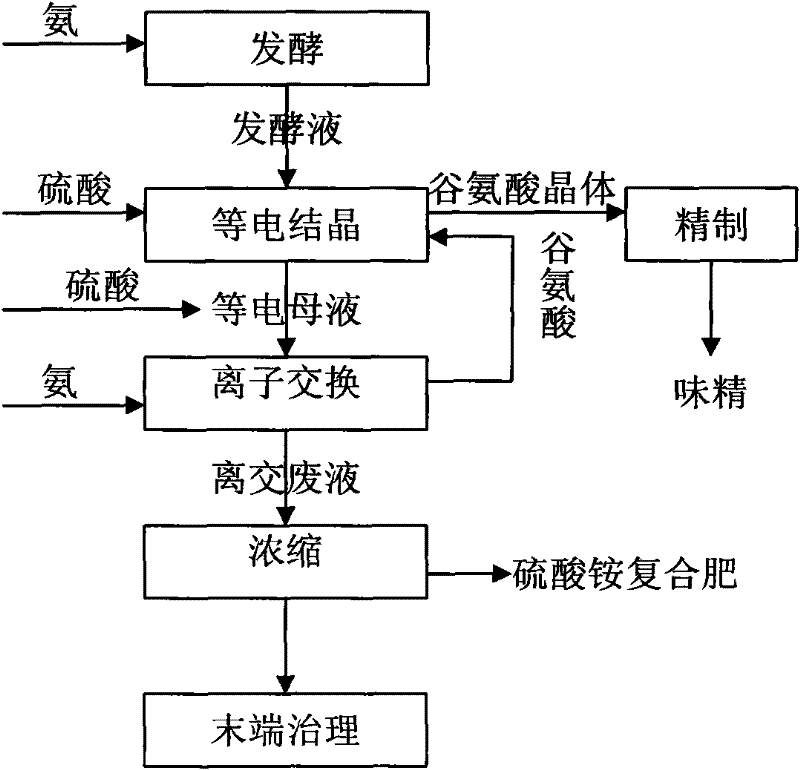

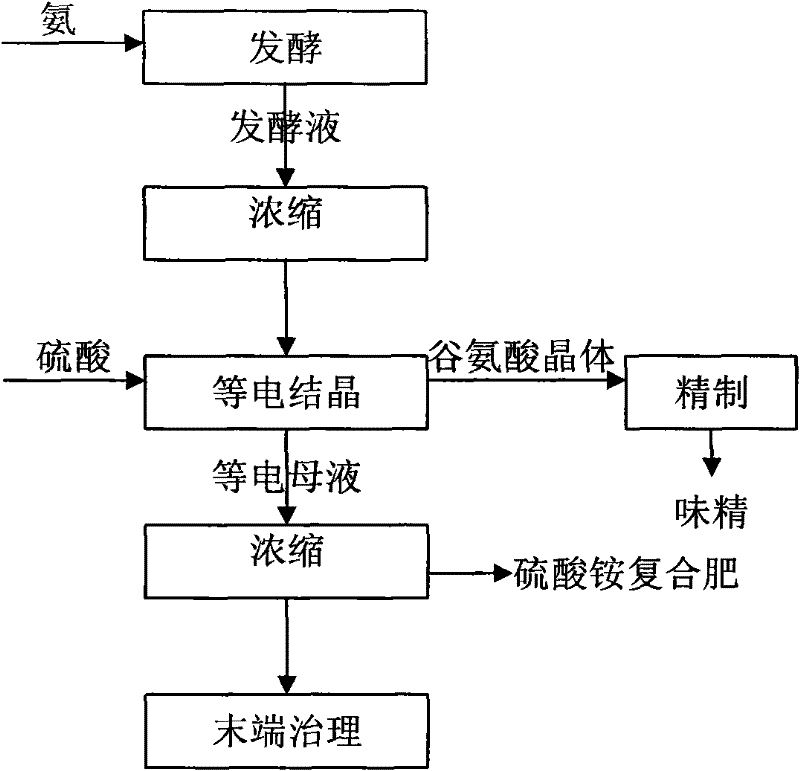

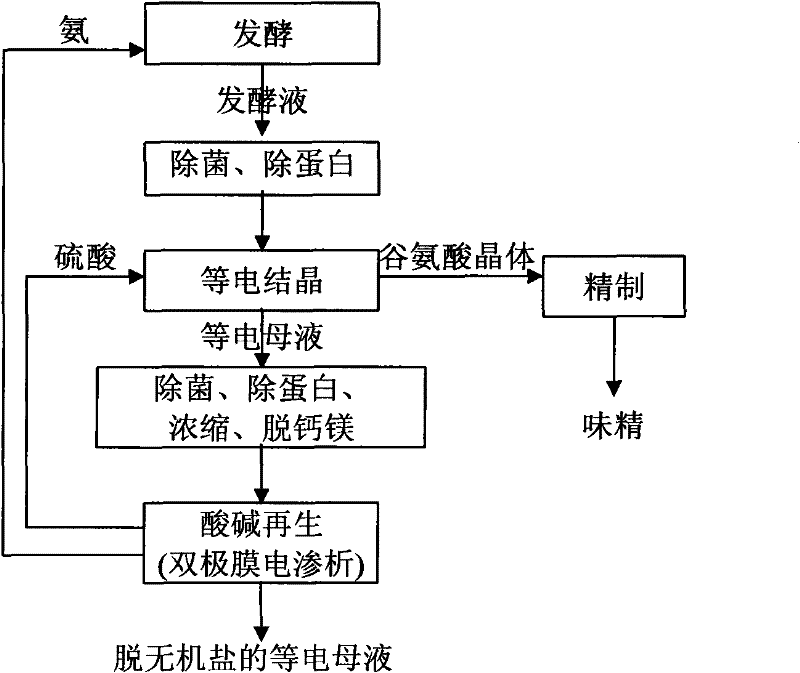

Multilevel processing method for regenerating acid base from glutamic acid isoelectric mother liquor

ActiveCN102125252AReduce energy consumptionReduce leakageElectrodialysisFood preparationAmmonium nitrateInorganic acids

The invention relates to a multilevel processing method for regenerating acid base from glutamic acid isoelectric mother liquor. In the method, a multilevel bipolar membrane electroosmosis method is adopted; the flow direction of salt room liquid and acid room liquid in a bipolar membrane electrodialyzer is changed; and regenerating ammonium sulfate, ammonium chloride or ammonium nitrate in the glutamic acid isoelectric mother liquor comprising the ammonium sulfate, the ammonium chloride or the ammonium nitrate into corresponding sulfuric acid, hydrochloric acid or nitric acid and ammonia (NH3). By the multilevel processing method, concentration difference of inorganic acid radical ions between the acid room and the salt room is totally reduced; the migration rate of the inorganic acid radical is increased by 29 percent; migration energy consumption is reduced by 24 percent; H<+> leakage from the acid room to the salt room is remitted; and concentration of acid liquor recovered by theacid room is increased.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for recycling copper from copper nitrate waste water

ActiveCN101906644AHigh recovery rateSimple production processPhotography auxillary processesProcess efficiency improvementCopper nitrateWastewater

The invention discloses a method for recycling copper from copper nitrate waste water. The technical key points of the invention are that: an iron rod is taken as an insoluble anode; a copper plate is taken as a cathode; and gas stirring is performed on the copper nitrate waste water in an electrolytic bath, so that an electrolytic process can be operated continuously. The purity of the copper recycled by the method is over 99.97 percent, and the recovery rate of the copper is over 99.5 percent. The method has the advantages of short process flow, simple operation, simple equipment, low equipment requirement, low investment and particular suitability for the realization of the recycling of the copper from the copper nitrate waste water in small and medium-sized enterprises.

Owner:温州伟达贵金属粉体材料有限公司

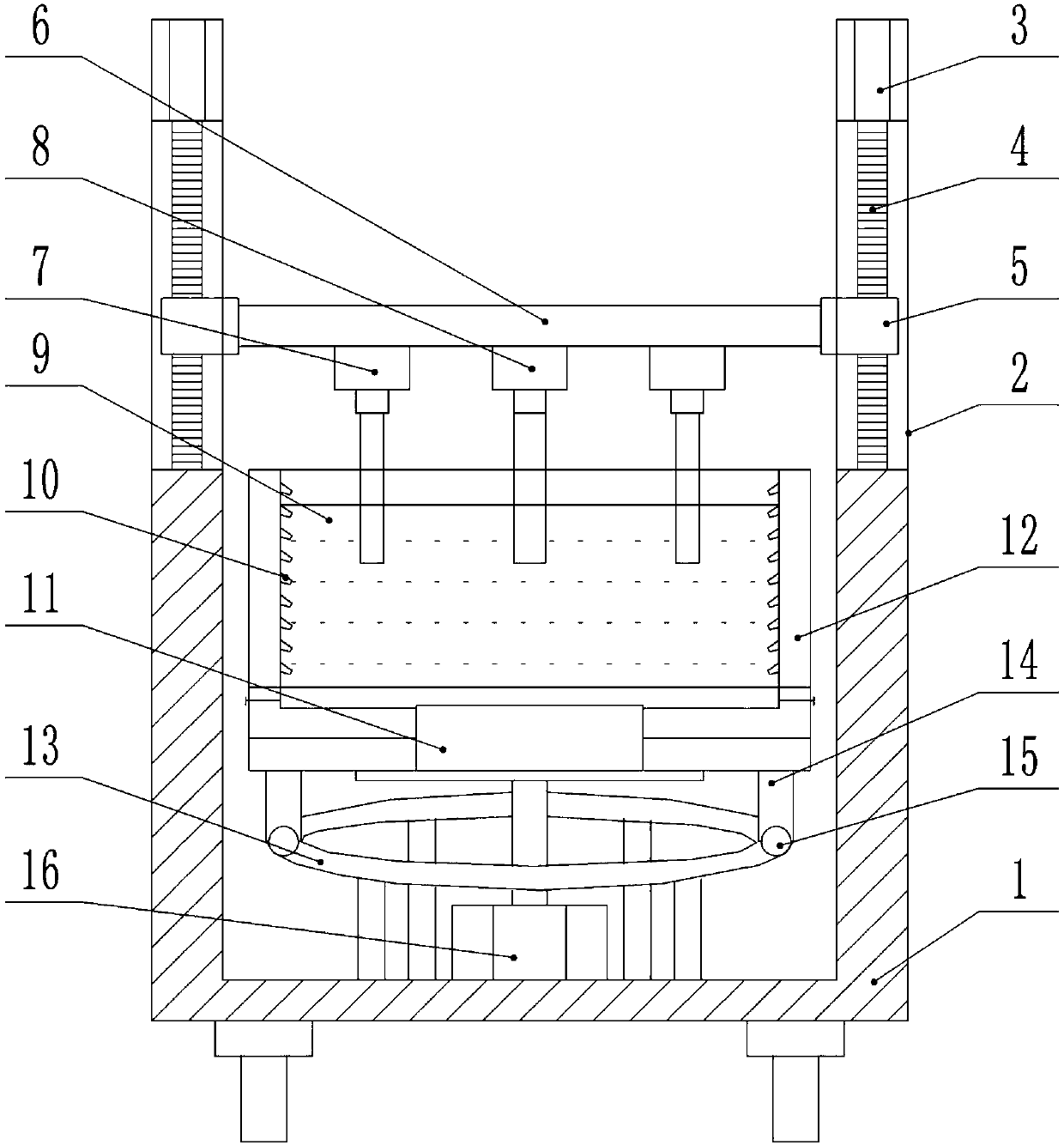

Efficient electroplating device capable of achieving complete plating layer

The invention provides an efficient electroplating device capable of achieving a complete plating layer. The efficient electroplating device capable of achieving the complete plating layer comprises aframe, and is characterized in that an annular track is horizontally arranged at the bottom of the interior of the frame, electrolytes are detachably connected to the bottom of an electroplating anode, and an electroplated workpiece is detachably connected to the bottoms of electroplating cathodes. The efficient electroplating device capable of achieving the complete plating layer is simple in structure and convenient to operate. Air outlet pipes with inclined and downward air nozzles are arranged on the inner wall of an electroplating bath, a rotating motor is matched with the electroplatingbath and drives the electroplating bath to rotate in the annular track, and therefore the difference, caused by the different distances between the surface of the metal workpiece and the electrolytes, of the concentrations of the electrolytes is reduced in the electroplating process, the plating layer can be uniform, and the electroplating effect is improved. Lifting tracks and a lifting plate are arranged, and therefore the movement of the metal workpiece in the electroplating process is achieved, electroplating of the metal workpiece can be complete, the situation that electroplating omission exists on the surface of the metal workpiece is avoided, and the electroplating quality of the metal workpiece is improved.

Owner:TIANJIN KAIXIN METAL PRODN

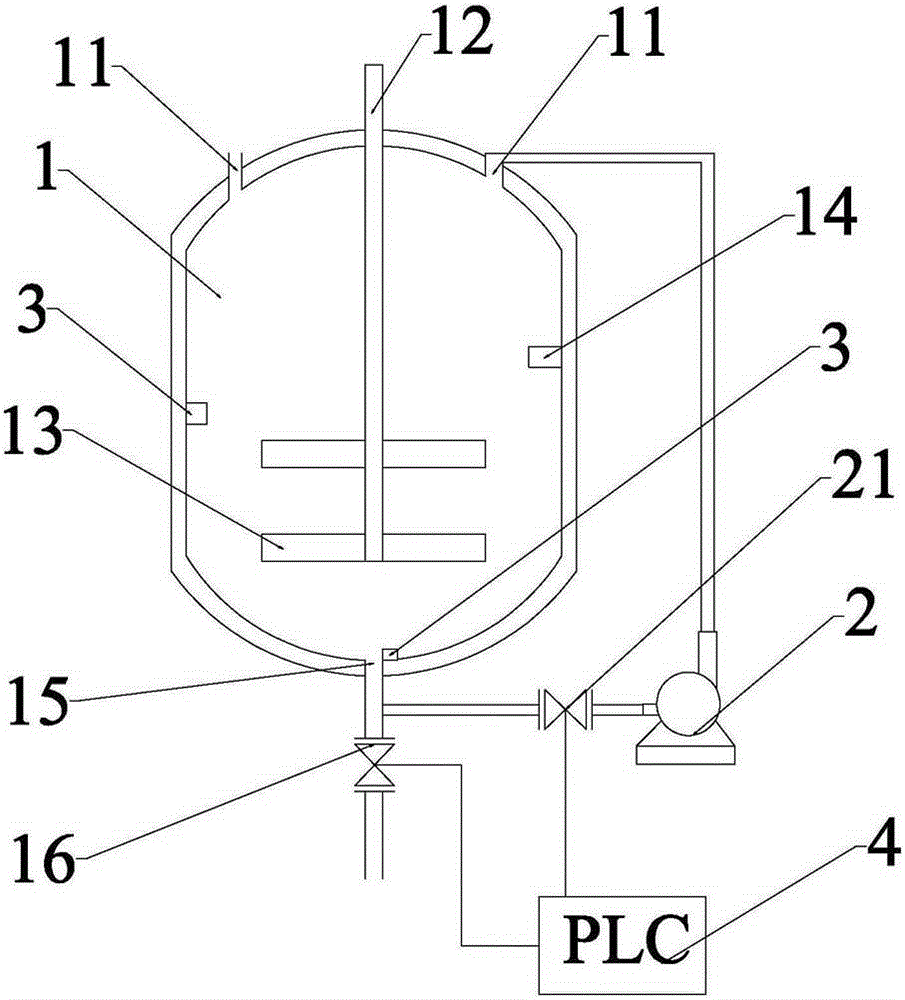

Circulating stirring device

InactiveCN105195075AReduce concentration differenceNarrow down the width rangeChemical/physical/physico-chemical stationary reactorsDrive shaftProgrammable logic controller

The invention provides a circulating stirring device which comprises a reaction kettle, a circulating pump, a sensor and a PLC (Programmable Logic Controller), wherein a feed port and a power driving shaft are arranged on the top of the reaction kettle, a stirring device, a liquid level meter and at least two concentration sensors which are connected with the power driving shaft are arranged in a cavity in the reaction kettle, and a discharge port is formed in the bottom of the reaction kettle; one end of the circulating pump is connected with the discharge port, and the other end of the circulating pump is connected with the feed port of the reaction kettle; the PLC is connected with the liquid level meter, the circulating pump, the sensor and the stirring device. According to the circulating stirring device, the circulating pump is connected between the feed port and the discharge port of the reaction kettle, the circulating pump is controlled to operate according to the concentration or density value measured by the control end of the PLC and the concentration sensors in the reaction kettle, so that materials at the bottom of the reaction kettle are returned to the top of the reaction kettle, a quick up-and-down stirring passage is created for the reaction kettle, and the concentration difference between upper and lower layers of materials is greatly reduced and can be completely ignored, so that the width range of a molecular weight is synchronously narrowed.

Owner:西达(无锡)生物科技有限公司

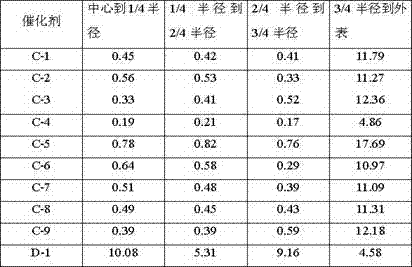

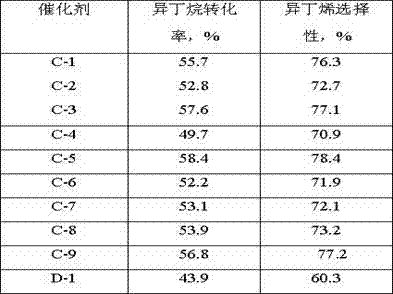

Preparation method of catalyst for propylene preparation through oxidative dehydrogenation of propane

ActiveCN106944081ASlow down the spreadReduce dosageHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsActive componentDehydrogenation

The present invention relates to a preparation method of a catalyst for propylene preparation through oxidative dehydrogenation of propane, wherein the catalyst comprises an active component, an auxiliary agent, and a carrier. The preparation method comprises: preparing a catalyst precursor A, and reducing the catalyst precursor A; dissolving an auxiliary agent precursor in water, and uniformly mixing with a furfural aqueous solution; adding the obtained mixture and the catalyst precursor A to a high pressure reaction kettle, adding a solution C, and carrying out a reaction; and treating and separating the obtained solid-liquid mixture, filtering the obtained solid sample, drying, and calcining to obtain the catalyst. According to the present invention, the waste residue oil hydrotreating catalyst is completely utilized so as to save the cost; and the prepared catalyst has characteristics of high reaction activity, metal consumption reducing, and propylene selectivity improving.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for manufacturing split gate flash by reducing writing interference

ActiveCN102376652AReduce doping concentrationReduce concentration differenceSemiconductor/solid-state device manufacturingIon beamEngineering

The invention discloses a method for manufacturing a split gate flash by reducing writing interference. After a control gate, a floating gate, an erasing gate and a word line are formed on a semiconductor substrate, lightly-doped ions are implanted; and the iron implantation comprises a vertically lightly doping step and a pocket ion implantation step, wherein in the pocket ion implantation step, an ion beam is injected into the semiconductor substrate below the word line at an inclined angle. By the method for manufacturing the split gate flash, an ion implantation step which is used for defining threshold value voltage of a flash unit in the prior art is eliminated; after a step of forming the word line, the pocket ion implantation step is added to reduce the doping concentration of a substrate area below a clearance between the word line and the floating gate, so that the difference of the doping concentration of the substrate area below the clearance between the word line and the floating gate and the doping concentration between the concentrations of channels below the floating gate is reduced; therefore, a writing unit which is not ought to have a writing change is prevented from having the writing change, and the writing interference is effectively avoided.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP +1

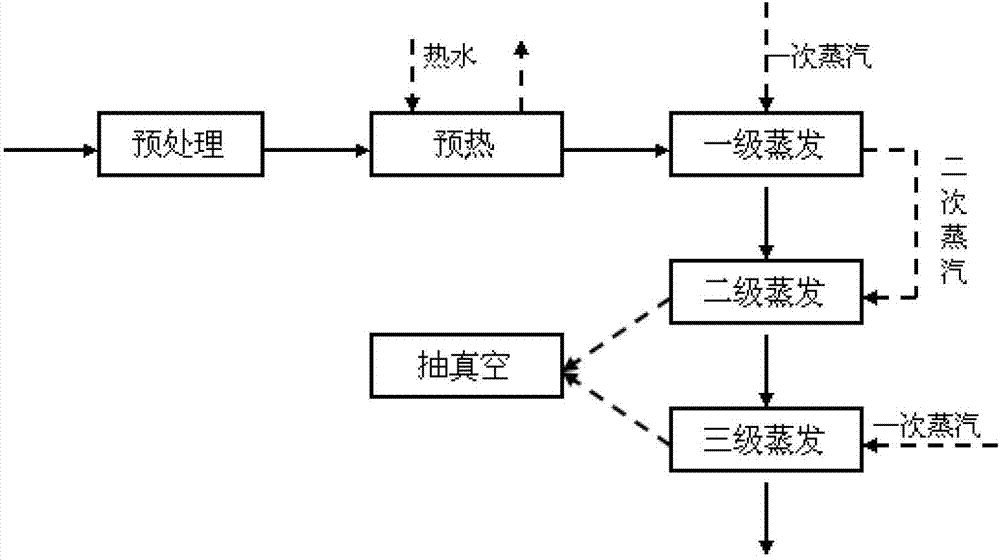

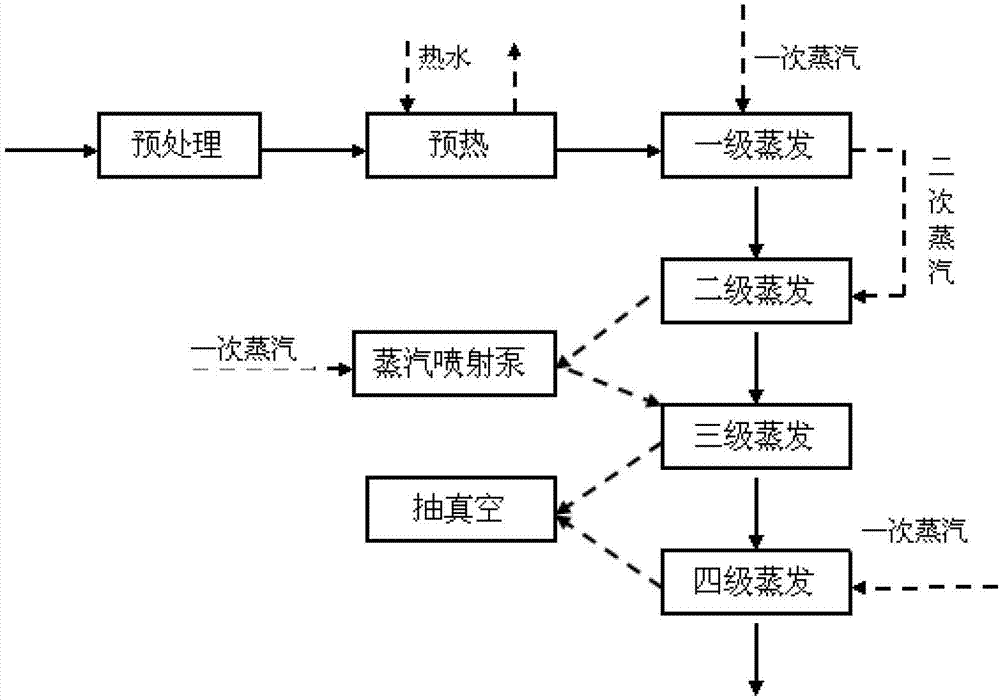

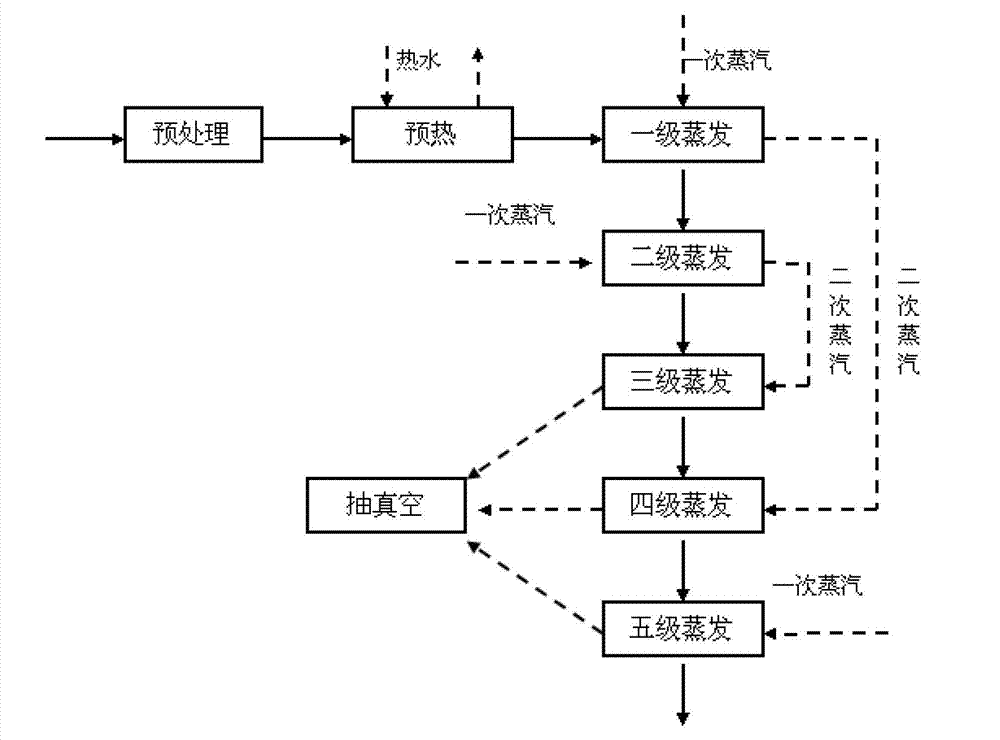

Evaporation and dehydration method for N-methylmorpholine-N-oxide solvent in cellulosic fiber production through solvent method

ActiveCN103046167AImprove stabilityRaise the evaporation temperatureArtificial filament recoveryTextile/flexible product manufactureHigh concentrationThree level

The invention provides an evaporation and dehydration method for an N-methylmorpholine-N-oxide (NMMO) solvent in cellulosic fiber production through a solvent method, and the method comprises the following steps of: regulating the pH value of solvent NMMO between 5-9, adding 20-1000ppm of stabilizer, then preheating, putting the solvent of NMMO into an evaporation system above three-level for evaporation above three-level, and finally concentrating till the requirement of the technology. And in the process of evaporation above three-level, water vapor evaporated from solvent of low concentration can be used as heat source for evaporation of solvent of high concentration. According to the method, the evaporation temperature of the solvent of NMMO is increased by improving the stability of the solvent, so that the steam can be reutilized, energy consumption for evaporation of solvent of NMMO is lowered remarkably, and the purpose of energy conservation is achieved.

Owner:SHANGHAI JUYOU CHEM ENG

Preparation method of catalyst for isobutylene preparation through oxidative dehydrogenation of isobutane

ActiveCN106944087ASlow down the spreadReduce dosageMolecular sieve catalystsMolecular sieve catalystActive componentDehydrogenation

The present invention relates to a preparation method of a catalyst for isobutylene preparation through oxidative dehydrogenation of isobutane, wherein the catalyst comprises a first active component, a second active component, a first auxiliary agent, a second auxiliary agent and a carrier. The preparation method comprises: preparing a catalyst precursor A, and reducing the catalyst precursor A; dissolving an auxiliary agent precursor in water, and uniformly mixing with a furfural aqueous solution; adding the obtained mixture and the catalyst precursor A to a high pressure reaction kettle, adding a solution C, and carrying out a reaction; and treating and separating the obtained solid-liquid mixture, filtering the obtained solid sample, drying, and calcining to obtain the catalyst. According to the present invention, the waste residue oil hydrotreating catalyst is completely utilized so as to save the cost; and the prepared catalyst has characteristics of high reaction activity, metal consumption reducing, and isobutylene selectivity improving.

Owner:CHINA PETROLEUM & CHEM CORP +1

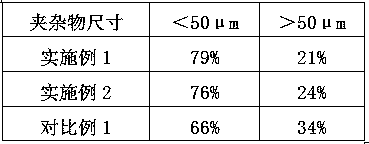

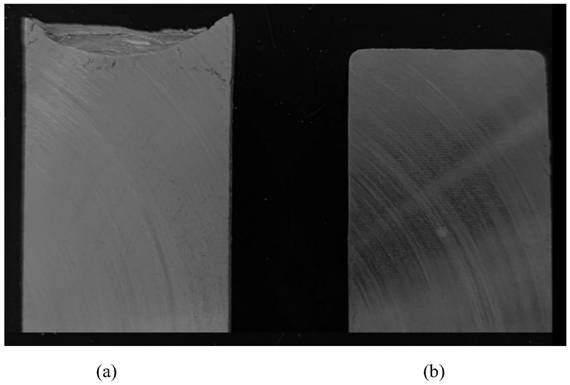

Refining method for reducing steel ladle lining erosion

The invention discloses a refining method for reducing steel ladle lining erosion. The refining method comprises LF refining and VD refining. In the later stage of LF refining, a magnesium raw material is added in a steel ladle. According to the method, the magnesium fireproof raw material is used for adjusting the content of magnesium in refining slag so that the concentration difference of the magnesium content between magnesium-carbon bricks and the refining slag can be reduced; in the VD furnace vacuum treatment process, erosion of the refining slag to the steel ladle lining magnesium-carbon bricks is restrained; and the purposes of reducing the steel ladle lining erosion and reducing the content of foreign inclusions in molten steel are achieved. By means of the method, erosion of furnace slag to a steel ladle lining in the VD processing process is reduced, the service life of the steel ladle is prolonged, and meanwhile, the molten steel inclusions are reduced.

Owner:HEBEI IRON AND STEEL

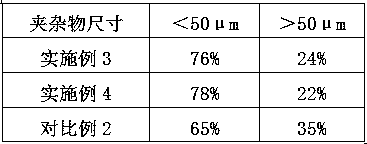

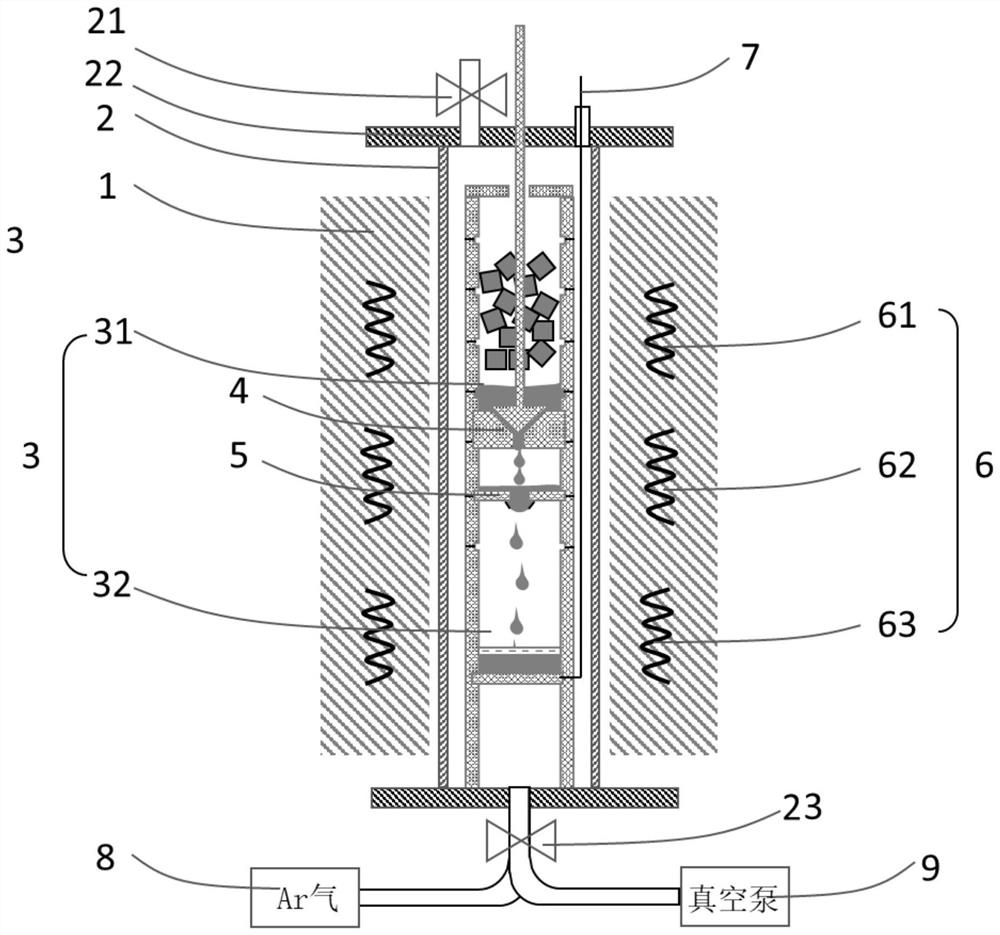

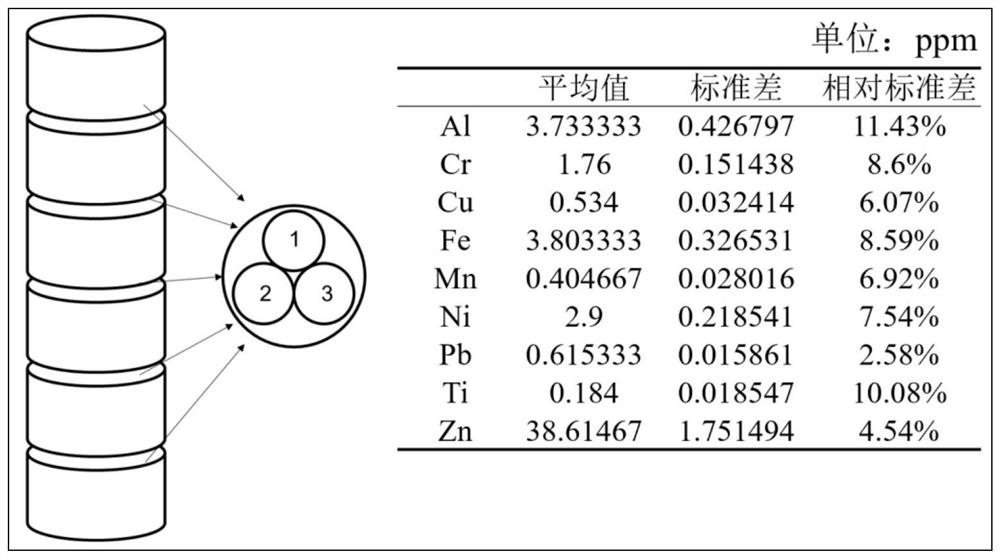

Magnesium and magnesium alloy casting device and method based on melt speed-controlled drop casting

ActiveCN114247857AAchieve layer-by-layer solidificationFacilitate liquid flowMolten metal pouring equipmentsIngot casting plantsExhaust valveDrop casting

The invention discloses a magnesium and magnesium alloy casting device and method based on melt speed-controlled drop casting. The casting device comprises an electric furnace body, a sealed cabin and a multi-section temperature control assembly are arranged in the electric furnace body, a flange end cover and an exhaust valve are arranged on the upper portion of the sealed cabin, and a bottom air inlet valve is communicated with an argon supply mechanism and a vacuum mechanism; a top pouring type integrated crucible is arranged in the sealed cabin body, a flow rate adjusting mechanism and a filtering mechanism are nested between a smelting area and an ingot casting area of the top pouring type integrated crucible, and a thermocouple is arranged at the bottom of the outer wall of the top pouring type integrated crucible; the casting method comprises the following steps: placing magnesium and magnesium alloy raw materials in a smelting area; vacuumizing to enable the whole cavity to be filled with argon; the temperature of the multi-section temperature control assembly is set, and magnesium and magnesium alloy raw materials are melted in the full argon protection atmosphere; meanwhile, the flow velocity adjusting mechanism is adjusted to control the flow velocity of the melt; the liquid drops drop into an ingot casting area in a continuous and clean liquid drop form; the device and the process are simple, the effect is excellent, and the formed casting product has high homogeneity, high compactness and high cleanliness at the same time.

Owner:XI AN JIAOTONG UNIV

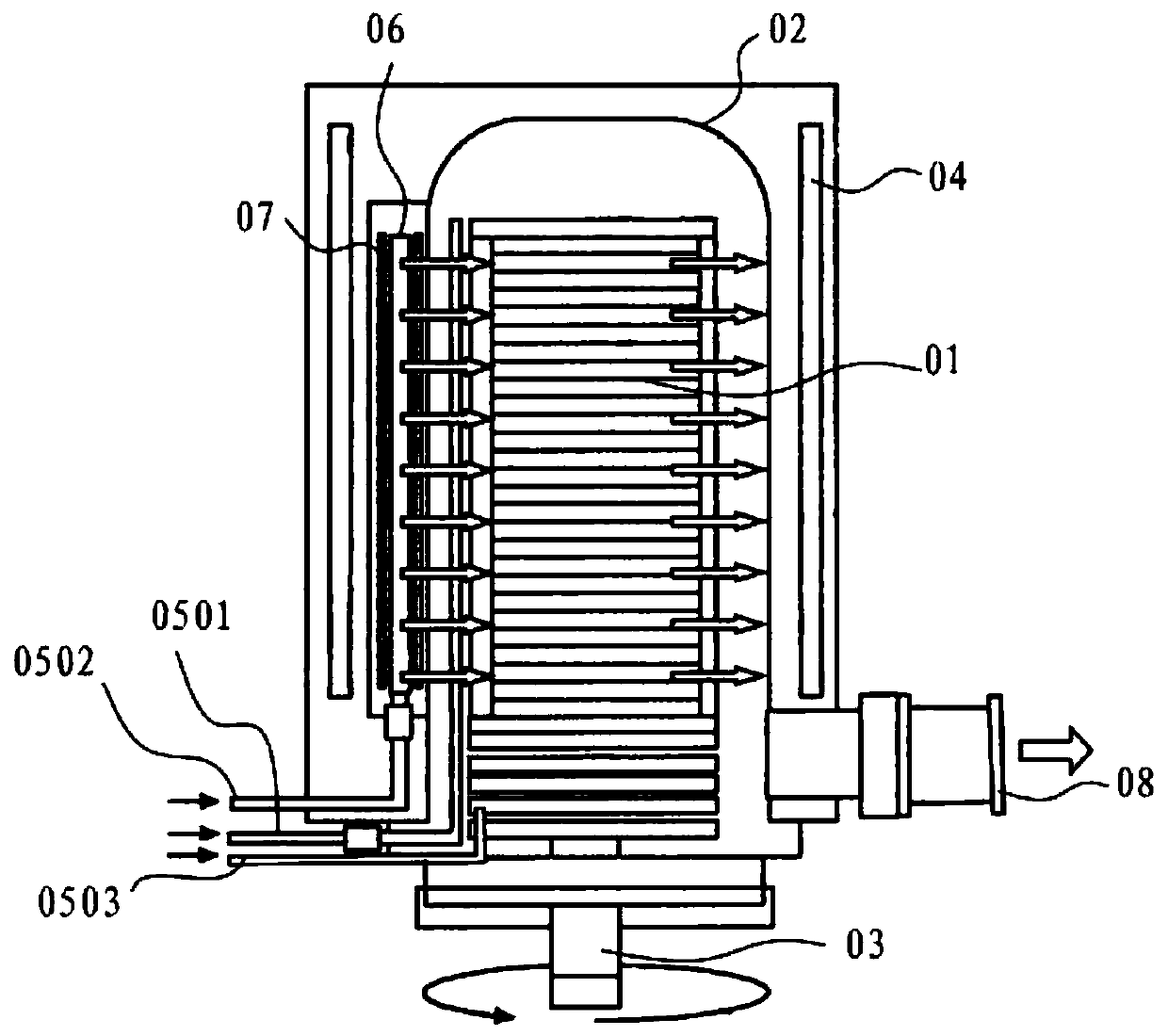

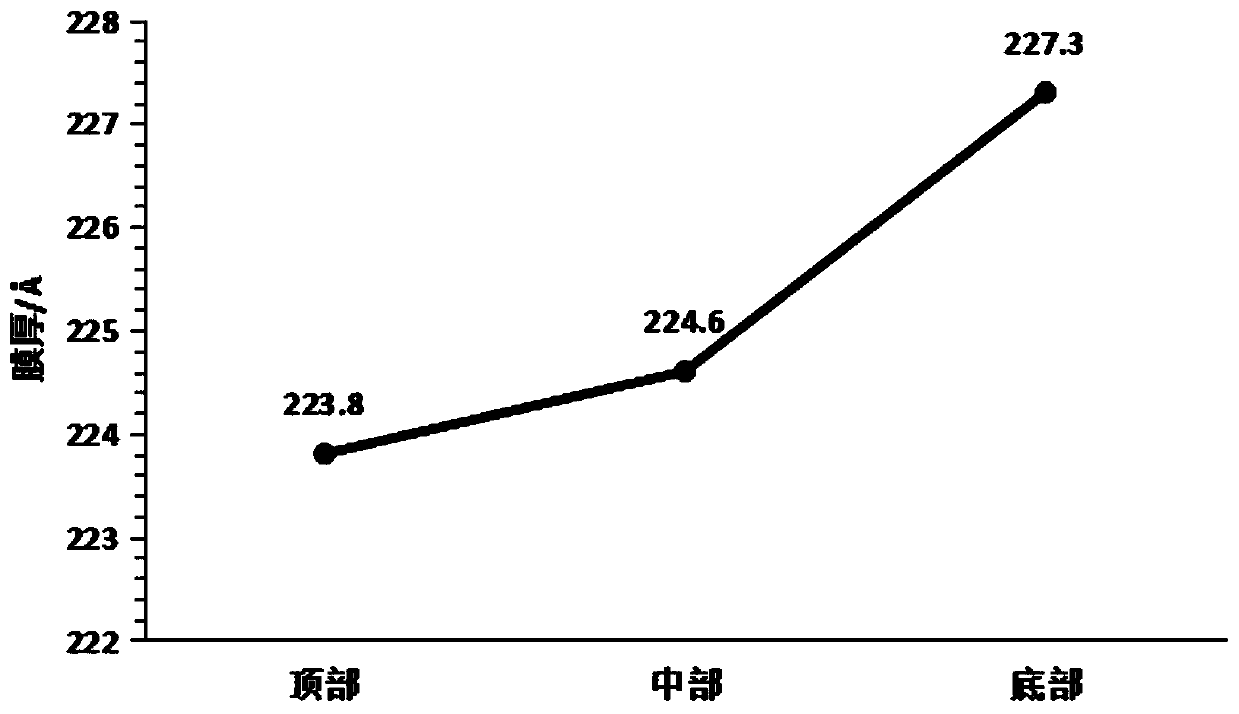

Method for forming nitride films through atomic layer deposition method

ActiveCN110468388AImprove film thickness uniformityReduce gas concentration differencesChemical vapor deposition coatingAtomic layer depositionNitride

The invention provides a method for forming nitride films through an atomic layer deposition method. The method for forming the nitride films comprises the following steps that S1, first source gas isintroduced into a reaction chamber and is adsorbed to the surface of each substrate at different height in the reaction chamber; S2, the first source gas which is not adsorbed is removed; and S3, second source gas is introduced into the reaction chamber and reacts with the first source gas adsorbed on the surface of each substrate so as to form one nitride film on the surface of each substrate, wherein third gas is introduced into the reaction chamber in each step, and the flow rate of the third gas in the step S1 and the step S3 is greater than the flow rate of the third gas in other steps.The method for forming nitride films has the advantages that through a method for increasing the flow rate of the third gas when the first source gas and the second source gas are introduced, the concentration of the reaction source gas at different positions in the reaction chamber is changed, and the uniformity of the nitride films in a furnace is improved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Treatment system and method for separating uranyl ions in concentrated nitric acid system by adopting membrane technology

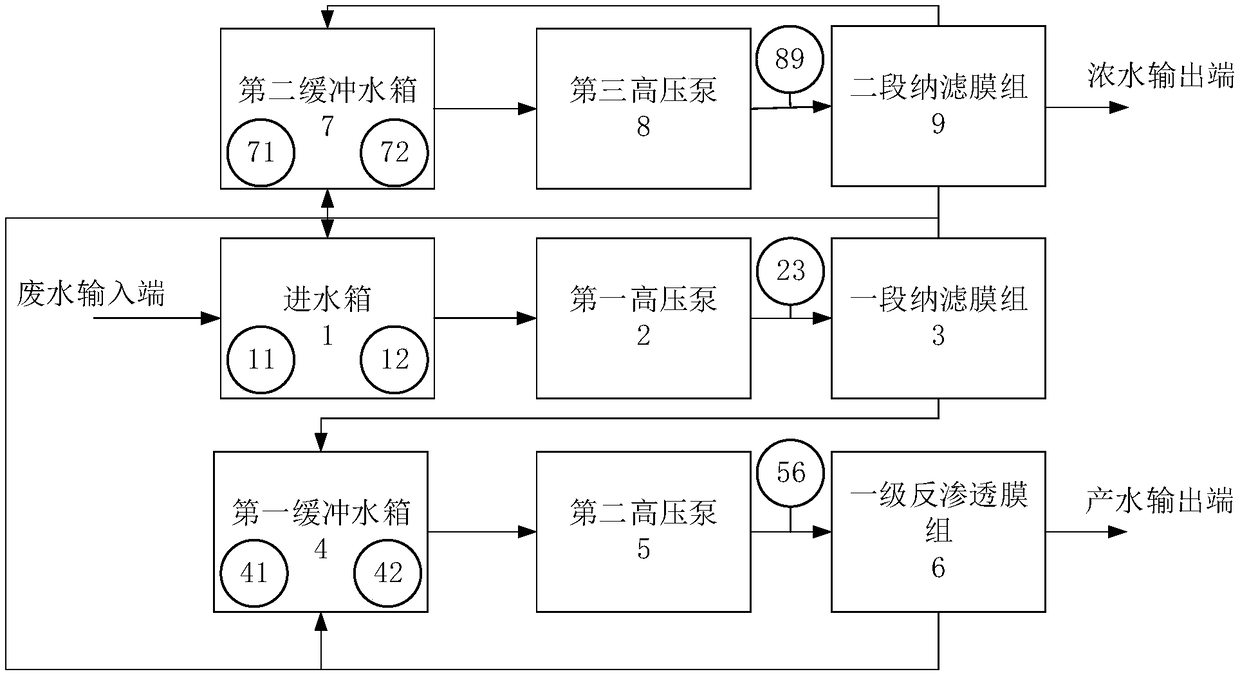

PendingCN109264828AReduce osmotic pressure differenceImprove removal efficiencyWaste water treatment from quariesWater contaminantsMembrane technologyWater production

The invention provides a treatment system and method for separating uranyl ions in a concentrated nitric acid system by adopting a membrane technology. The system comprises a water inlet tank 1, a first high-pressure pump 2, a first-section nanofiltration membrane group 3, a first buffer water tank 4, a second high-pressure pump 5, a primary reverse osmosis membrane group 6, a second buffer watertank 7, a third high-pressure pump 8 and a second-section nanofiltration membrane group 9. By adopting the treatment system and method for separating uranyl ions in the concentrated nitric acid systemby adopting the membrane technology, the lower entrapment efficiency of nanofiltration membranes is utilized to make part of uranyl ions to penetrate through a membrane material, the concentration ona water production side is increased, the concentration difference of the water inlet side and the water production side of the separating membranes is reduced, thus the osmotic pressure difference of two sides of the membranes is reduced, and the purpose of reducing operation pressure is achieved; then, the higher entrapment efficiency of reverse osmosis membranes is utilized to improve the removal efficiency of uranyl ions in uranium-bearing waste liquid and make the uranium-bearing waste liquid to meet the treatment requirements.

Owner:北京清核朝华科技有限公司

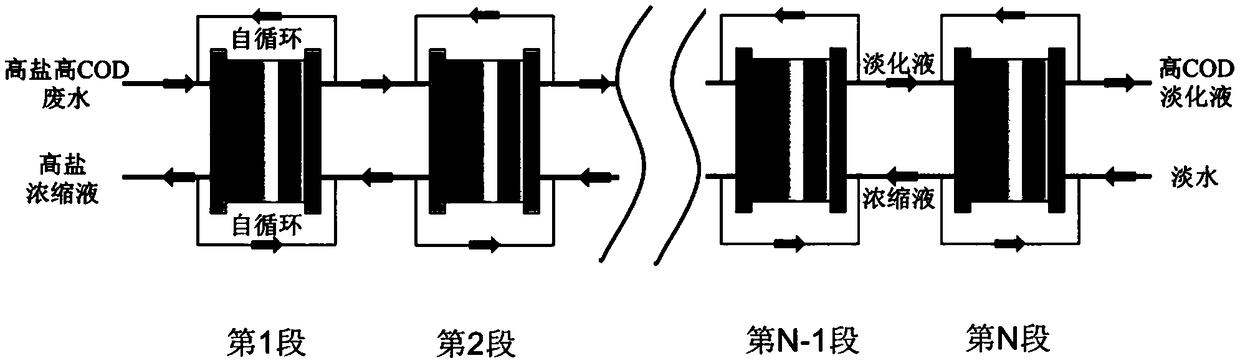

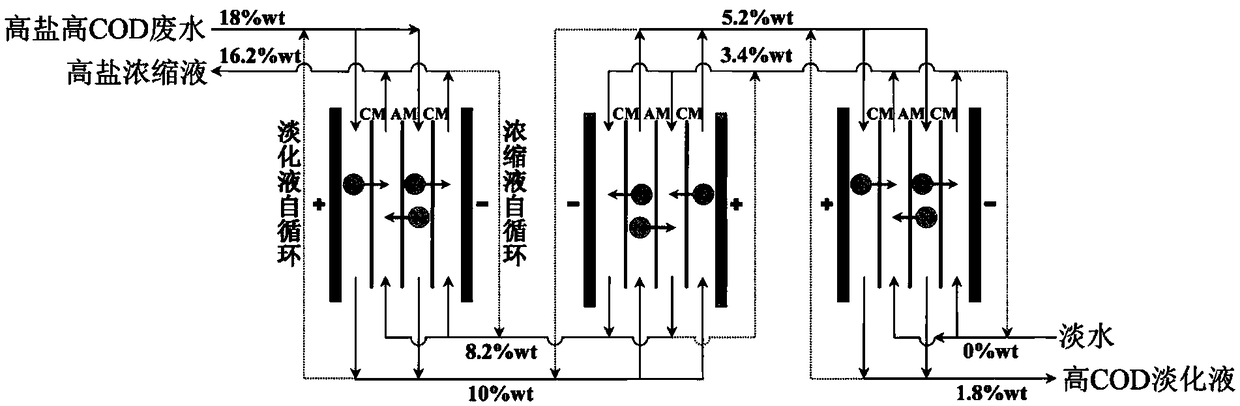

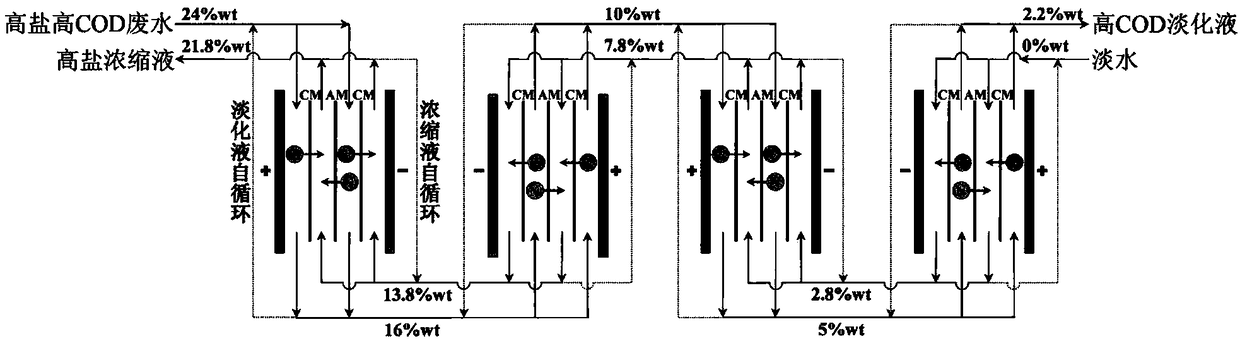

Separating method and device for organic matter-inorganic salt in high-salt high-COD wastewater

PendingCN108689461AEfficient separationReduce concentration differenceDispersed particle separationWater/sewage treatmentElectric driveTraffic volume

The invention provides a separating method and device for organic matter-inorganic salt in high-salt high-COD wastewater. A multi-section special electric driving film device is used; through cross flow feeding of a desalting chamber and a concentrating chamber, a concentration difference of each section of the special electric driving film device is reduced, and the efficient separation of organic matters and inorganic salt is realized; desalting liquid and concentrating liquid of each section of the special electric driving film device are directly refluxed to realize film stack self-circulation, the usage amounts of a multi-way valve and a water tank are reduced, and water inlet flows of the desalting chamber and the concentrating chamber of each section of special electric driving filmdevice are controlled to be consistent through the valve, so the demanded quantity of circulating water of a system and the film stack stability are greatly reduced. In addition, the device is capable of performing crystallization processing on the concentrating liquid obtained by the first section of special electric driving film device, acquiring the high-purity inorganic salt, and performing follow-up deep processing on the desalting liquid obtained by the last section of special electric driving film device; the up-to-standard discharge is realized, and the device has better social and economic benefits.

Owner:浙江迪萧科技有限公司

Method for recycling copper from copper nitrate waste water

ActiveCN101906644BAchieve electrolysisLow pricePhotography auxillary processesProcess efficiency improvementCopper nitrateWastewater

The invention discloses a method for recycling copper from copper nitrate waste water. The technical key points of the invention are that: an iron rod is taken as an insoluble anode; a copper plate is taken as a cathode; and gas stirring is performed on the copper nitrate waste water in an electrolytic bath, so that an electrolytic process can be operated continuously. The purity of the copper recycled by the method is over 99.97 percent, and the recovery rate of the copper is over 99.5 percent. The method has the advantages of short process flow, simple operation, simple equipment, low equipment requirement, low investment and particular suitability for the realization of the recycling of the copper from the copper nitrate waste water in small and medium-sized enterprises.

Owner:温州伟达贵金属粉体材料有限公司

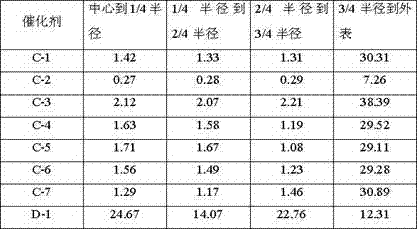

Preparation method of catalyst for synthetic gas preparation through reforming of methane and carbon dioxide

ActiveCN106944082AReduce concentration differenceSlow down the spreadHydrogenHydrogen/synthetic gas productionCarbon dioxideAqueous solution

The present invention relates to a preparation method of a catalyst for synthetic gas preparation through reforming of methane and carbon dioxide, wherein the catalyst comprises an active component, an auxiliary agent, and a carrier. The preparation method comprises: preparing a catalyst precursor A, and reducing the catalyst precursor A; dissolving an auxiliary agent precursor in water, and uniformly mixing with a furfural aqueous solution; adding the obtained mixture and the catalyst precursor A to a high pressure reaction kettle, adding a solution C, and carrying out a reaction; and treating and separating the obtained solid-liquid mixture, filtering the obtained solid sample, drying, and calcining to obtain the catalyst. According to the present invention, the waste residue oil hydrotreating catalyst is completely utilized so as to save the cost; and the prepared catalyst has characteristics of high reaction activity, metal consumption reducing, and product selectivity improving.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-bandwidth multi-mode fiber

ActiveCN108594361AReduce attenuationIncrease concentrationOptical fibre with multilayer core/claddingDopantUltrasound attenuation

The invention relates to a high-bandwidth multi-mode fiber which comprises a core layer and a wrapping layer, and is characterized in that the refractive index profile of the core layer is of a parabola shape, the distribution index alpha is 2.0-2.3, the radius R1 of the core layer is 23-37 [mu]m, the maximal relative refractive index difference [delta]1max of a core layer center is 0.9%-1.2%, thecore layer is a silica glass layer wherein Ge, P and F are jointly doped, the contribution [delta]P0 of P of the core layer center is 0.01% to 0.30%, the contribution [delta]P1 of P at the junction of the core layer and the inner wrapping layer is 0.01%-0.30%, the content of P in the core layer center is consistent with that of a core layer edge, the core layer F is used as the negative dopant, the doping amount of F is gradually increased in the direction from the core layer center to the core layer edge, the contribution [delta]F0 of F of the core layer center is 0.0% to -0.1%, and the contribution amount [delta]F1 of F of the core layer edge is -0.40% to -0.20%. The material composition and the core cladding structure of the invention are rationally designed, the chromatic dispersion is reduced, the bandwidth performance is improved, and the fiber attenuation is reduced.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com