Circulating stirring device

A technology of circulating stirring and stirring device, applied in the field of liquid stirring machinery, can solve the problems of uneven concentration difference between upper and lower layers, and achieve the effect of narrowing the width range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

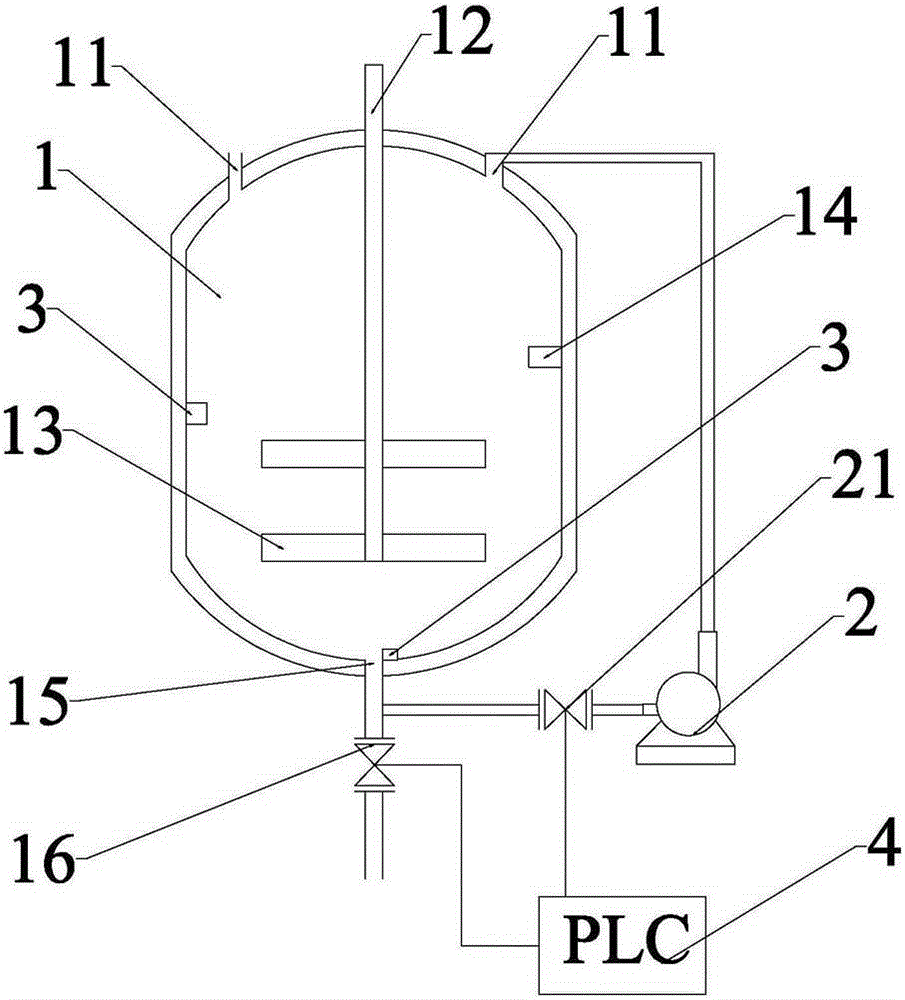

[0014] Have figure 1 It can be seen that the present invention includes a reactor 1, a circulating pump 2, a sensor 3, and a PLC controller 4. The top of the reactor 1 is provided with a feed port 11 and a power drive shaft 12. In the inner cavity of the reactor 1, A stirring device 13 connected to the power drive shaft 12, a liquid level gauge 14, and at least two concentration sensors 3 are provided, and a discharge port 15 is provided at the bottom of the reaction kettle 1;

[0015] One end of the circulating pump 2 is connected to the discharge port 15, and the other end of the circulating pump 2 is connected to the feed port 11 of the reactor 1;

[0016] The PLC controller 4 is connected with the liquid level gauge 14 , the circulating pump 2 , the sensor 3 and the stirring device 13 .

[0017] Preferably, the discharge port 15 is provided with a discharge valve 16 , and the discharge valve 16 is connected to the PLC controller 4 .

[0018] Preferably, a circulation val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com