Preparation method of catalyst for synthetic gas preparation through reforming of methane and carbon dioxide

A carbon dioxide and catalyst technology, which is applied in the field of preparation of a catalyst for methane-carbon dioxide reforming to syngas, can solve the problems of complicated preparation process, high cost, easy carbon deposition of the catalyst, etc. Beneficial for industrial amplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

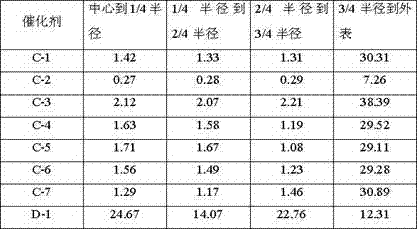

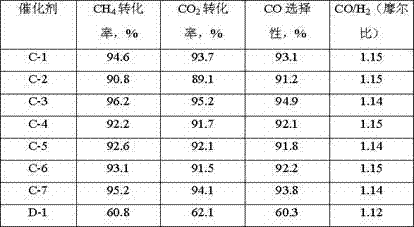

Examples

Embodiment 1

[0027] The spent hydrotreating catalyst (MoCo / Al 2 o 3), the oil on the catalyst surface was removed by petroleum ether extraction, dried at 110°C for 8 h, and the obtained catalyst was calcined at 450°C for 4 h to obtain catalyst precursor A, wherein Mo accounted for 6.1wt% by weight of catalyst precursor A in terms of elements, Co accounts for 1.8wt% of the weight of the catalyst precursor A in terms of elements, Ni accounts for 2.3wt% of the weight of the catalyst precursor A in terms of elements, and V accounts for 1.9wt% of the weight of the catalyst precursor A in terms of elements; Activation in a mixed atmosphere of hydrogen, the volume content of hydrogen in the mixed gas is 80%, the reduction conditions are 450°C, 0.2MPa (absolute pressure), and the reduction time is 4h; 2.54g of zirconium nitrate is dissolved in 16mL of deionized water to obtain solution B, And mix it with 40% furfural aqueous solution with a mass fraction of 4 times its mass, and then add it to th...

Embodiment 2

[0029] The spent hydrotreating catalyst (MoCo / Al 2 o 3 ), the oil on the catalyst surface was removed by petroleum ether extraction, dried at 110°C for 8 h, and the obtained catalyst was calcined at 450°C for 4 h to obtain catalyst precursor A, wherein Mo accounted for 5.2wt% by weight of catalyst precursor A in terms of elements, Co accounts for 1.2wt% of the weight of the catalyst precursor A in terms of elements, Ni accounts for 1.5wt% of the weight of the catalyst precursor A in terms of elements, and V accounts for 1.3wt% of the weight of the catalyst precursor A in terms of elements; Activate in a mixed atmosphere of hydrogen, the volume content of hydrogen in the mixed gas is 80%, the reduction conditions are 450°C, 0.2MPa (absolute pressure), and the reduction time is 4h; 0.99g of zirconium nitrate is dissolved in 16mL of deionized water to obtain solution B. And mix it with 40% furfural aqueous solution with a mass fraction of 4 times its mass, and then add it to the...

Embodiment 3

[0031] The spent hydrotreating catalyst (MoCo / Al 2 o 3 ), the oil on the catalyst surface was removed by petroleum ether extraction, dried at 110°C for 8 h, and the obtained catalyst was calcined at 450°C for 4 h to obtain catalyst precursor A, wherein Mo accounted for 6.1wt% by weight of catalyst precursor A in terms of elements, Co accounts for 1.8wt% of the weight of the catalyst precursor A in terms of elements, Ni accounts for 2.3wt% of the weight of the catalyst precursor A in terms of elements, and V accounts for 1.9wt% of the weight of the catalyst precursor A in terms of elements; Activate in a mixed atmosphere of hydrogen, the volume content of hydrogen in the mixed gas is 80%, the reduction conditions are 450°C, 0.2MPa (absolute pressure), and the reduction time is 4h; 7.25g of zirconium nitrate is dissolved in 20mL of deionized water to obtain solution B. And mix it with 40% furfural aqueous solution with a mass fraction of 4 times its mass, and then add it to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com