Separating method and device for organic matter-inorganic salt in high-salt high-COD wastewater

A separation method and technology of separation device, which are applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of unsuitable treatment of small flow wastewater, large demand for circulating water, increased economic costs and equipment occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

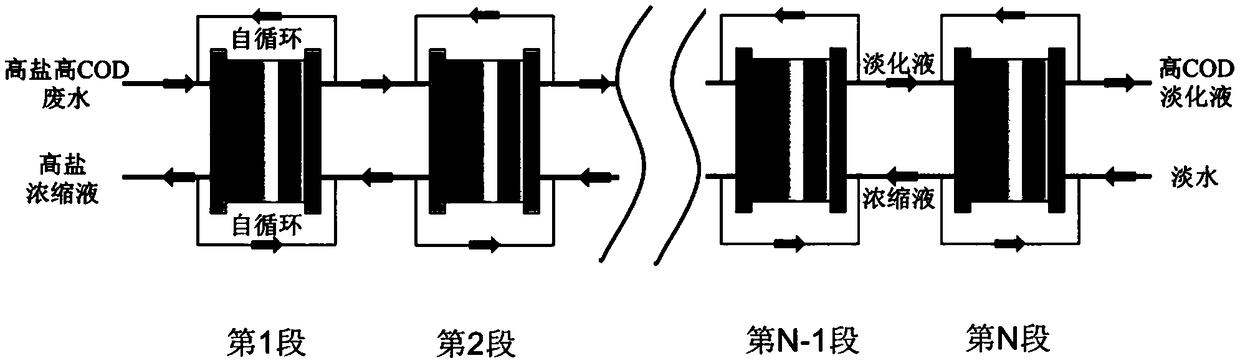

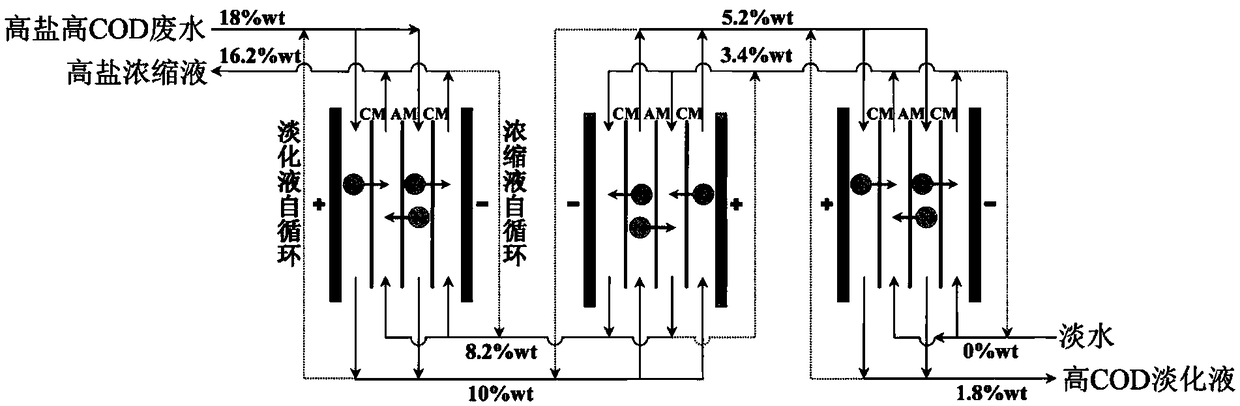

[0029] refer to figure 1 , a separation device for organic matter-inorganic salts in high-salt and high-COD wastewater, including: at least one section of special electric-driven membrane device, the entrance of the desalination chamber and the entrance of the concentration chamber of the special electric-driven membrane device are respectively arranged in the special electric-driven membrane device The flow direction of high-salt and high-COD wastewater is opposite to the flow direction of fresh water, and two adjacent sections of special electric-driven membrane devices are connected in series.

[0030] A self-circulation pipeline connecting the outlet of the desalination chamber and the inlet of the desalination chamber is arranged between the outlet of the desalination chamber and the inlet of the desalination chamber of each section of the special electric-driven membrane device.

[0031] A self-circulation pipeline connecting the outlet of the concentration chamber and t...

Embodiment 2

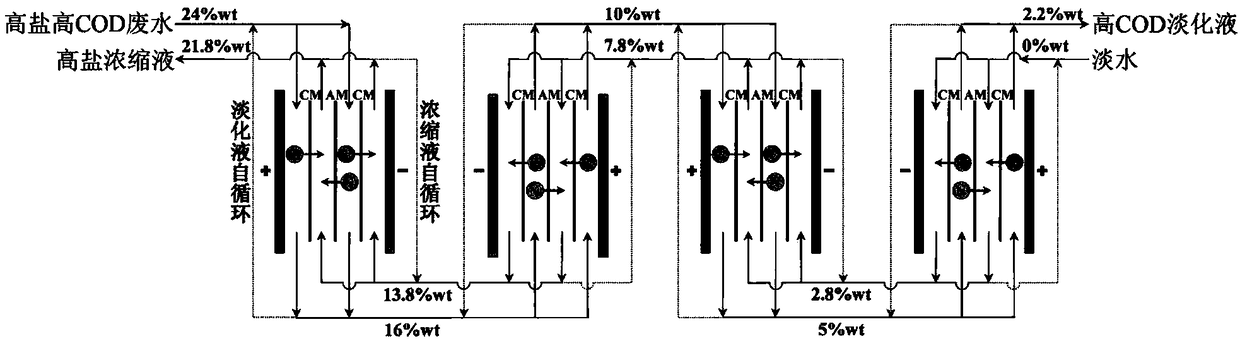

[0037] The raw material is amine waste water with a salt content of 24%wt, a pH of 13.4, and a COD of 15.2 g / L. image 3 As shown, the current density is 280 A / m 2 , the operating power is 21 Kw, and the cycle runs for 10 minutes to obtain a desalinated solution with a salt content of 16%wt and a COD of 13.4 g / L. m 2 , the operating power is 12 Kw, and the cycle runs for 10 minutes to obtain a desalinated solution with a salt content of 10% wt and a COD of 12.2 g / L. m 2 , the operating power is 10 Kw, and the cycle runs for 10 minutes to obtain a desalinated solution with a salt content of 5%wt and a COD of 11.2 g / L. m 2 , operating power 8 Kw, cycled for 10 minutes to obtain a desalinated solution with a salt content of 2.2%wt and a COD of 10.4 g / L, and passed the fresh water into the concentration chamber of the fourth special electric-driven membrane device with a current density of 100A / m 2 , operating power 8 Kw, cycled for 10 minutes to obtain a concentrated solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com