Patents

Literature

699results about How to "Achieve emission standards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Comprehensive electroplating wastewater treatment method

ActiveCN102531296AAchieve emission standardsReduce manufacturing costMultistage water/sewage treatmentChemical treatmentWater quality

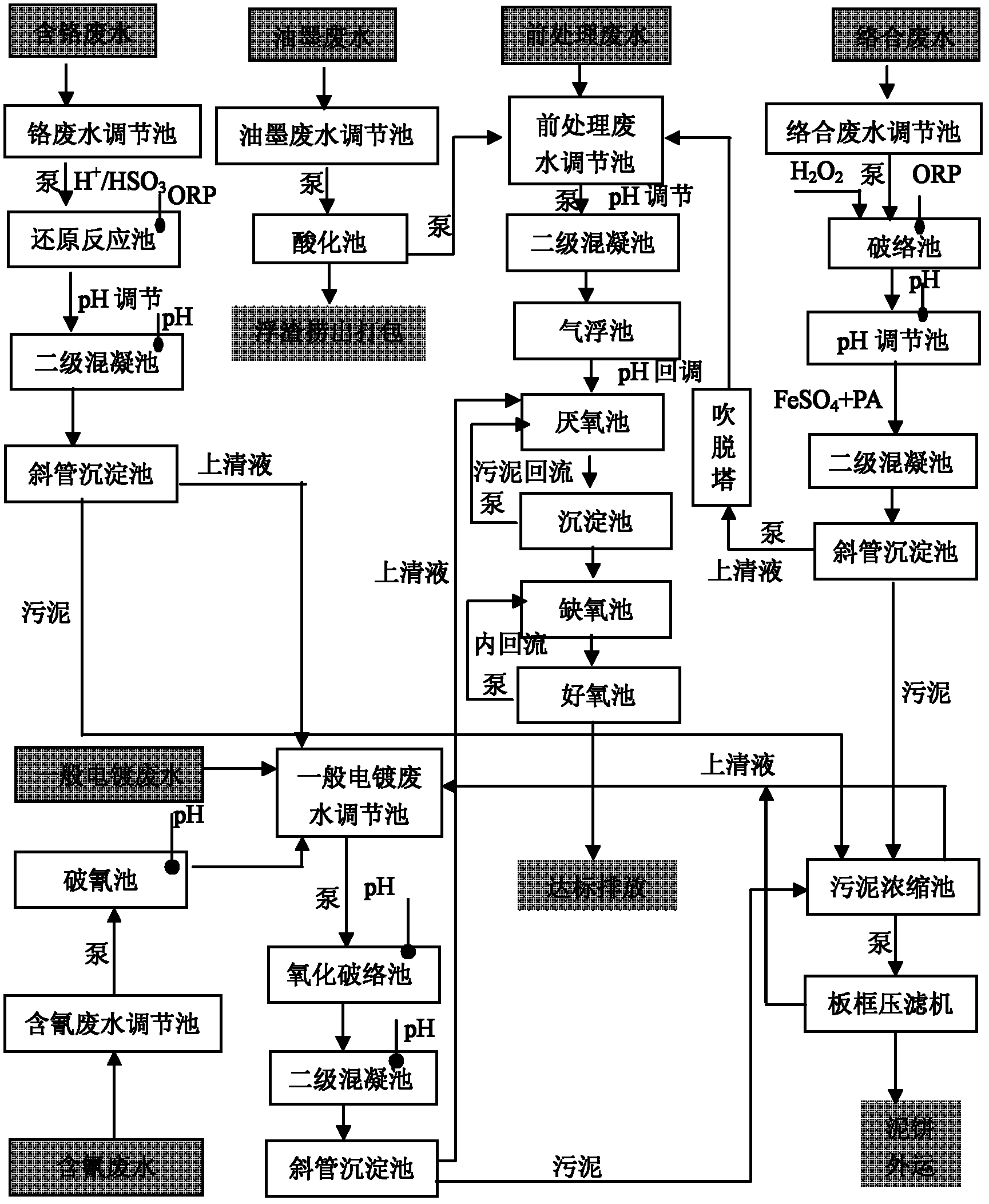

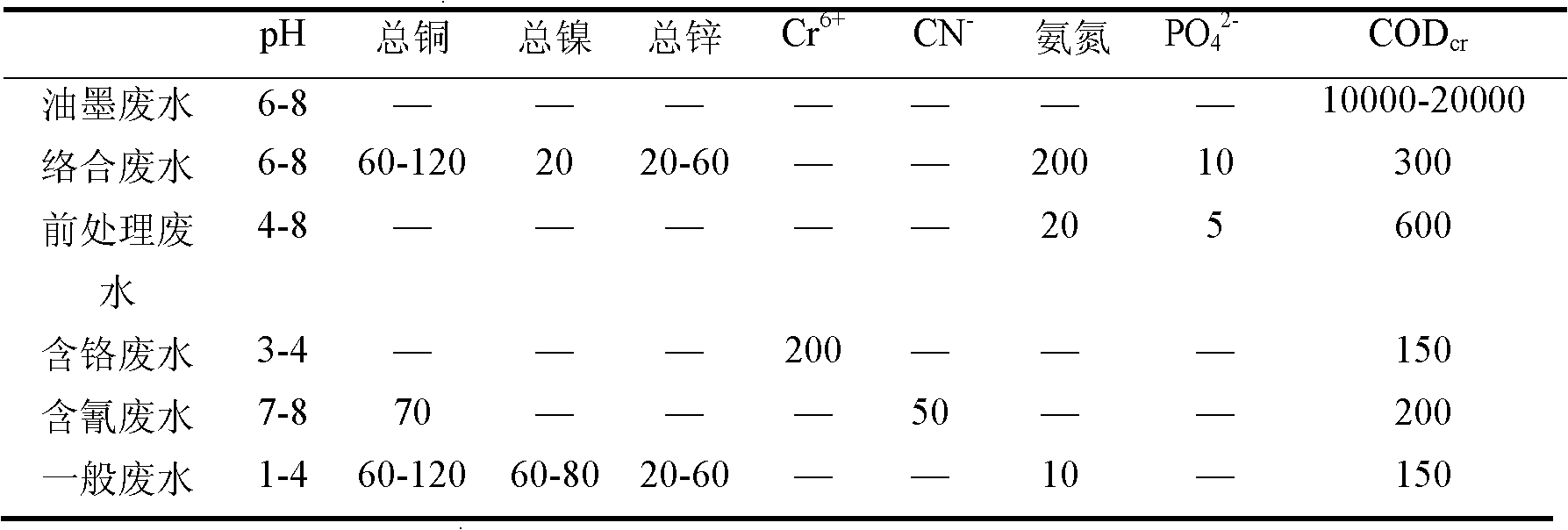

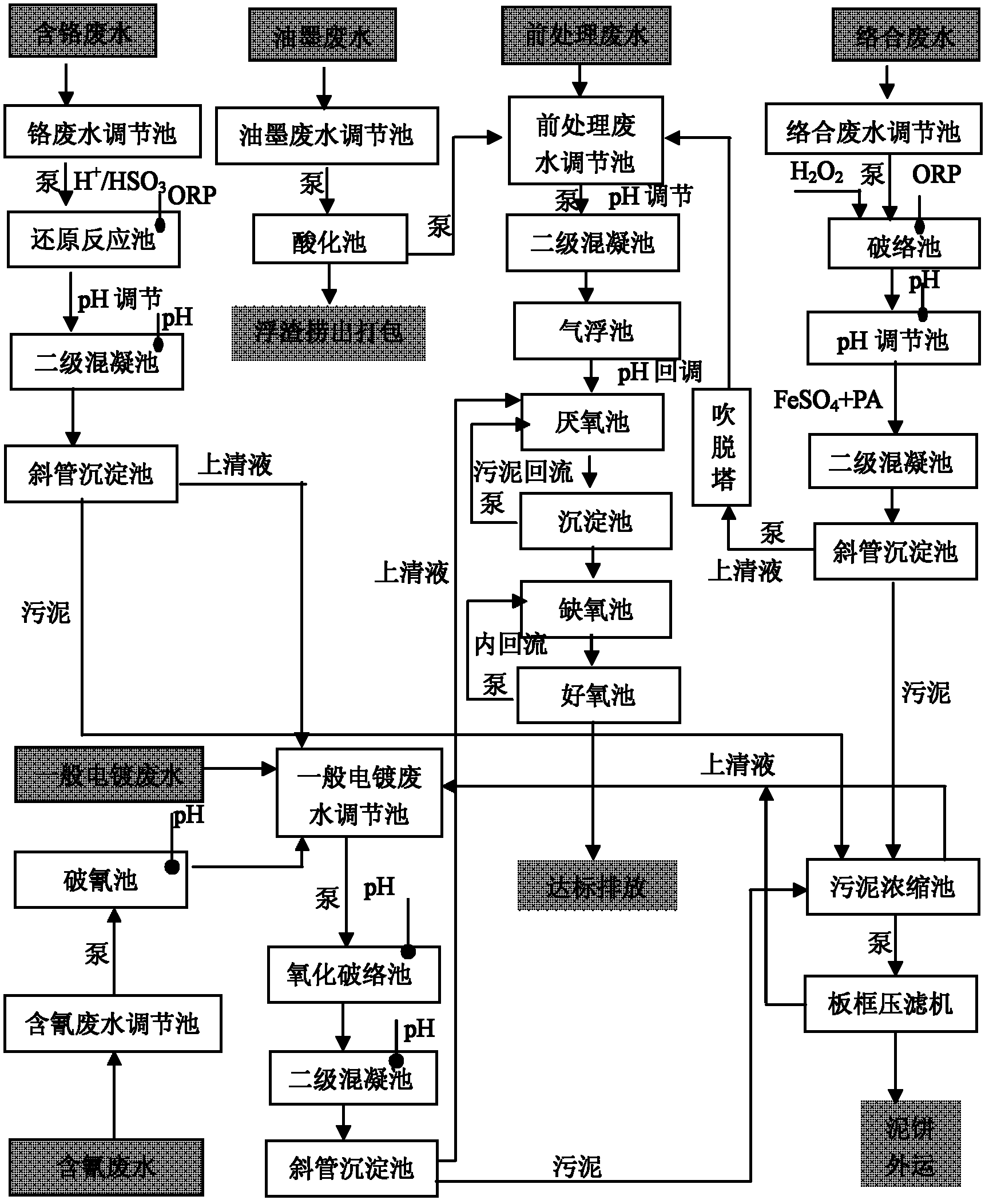

The invention relates to a comprehensive electroplating wastewater treatment method. The electroplating wastewater is divided into six brand-new classes, a chemical and biochemical combined process is adopted, a separate system drainage pipe network is adopted, the electroplating wastewater is divided into ink wastewater, complex wastewater, pretreatment wastewater, cyanogen-containing wastewater, chromium-containing wastewater and common electroplating wastewater, the six classes of wastewater respectively flows into respective underground adjusting tank through the pipe network, and is treated by respective process, and the effluent is discharged after reaching a standard. Because of the scientific water separating and stepwise pretreatment of a front-end chemical treatment part, different pollutants are respectively removed in different process sections according to characteristics, crossed enrichment and mutual reaction of the different pollutants are reduced to the greatest extent, and the pressure of microorganisms in the biochemical process is reduced. Treatment facilities for the six classes of wastewater are mutually connected and relatively dependent, and when inlet water quality fluctuates, a corresponding section is only required to be adjusted, the whole process is not influenced, the management is scientific and orderly, and operational risks are reduced.

Owner:SHENZHEN YINTAI ENVIRONMENTAL PROTECTION ENG TECH +2

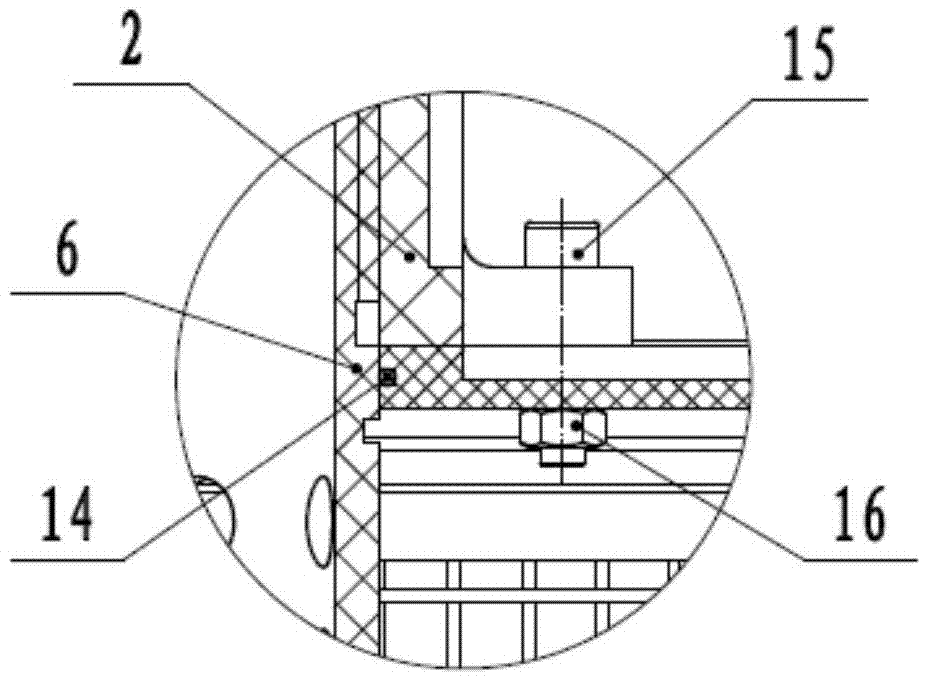

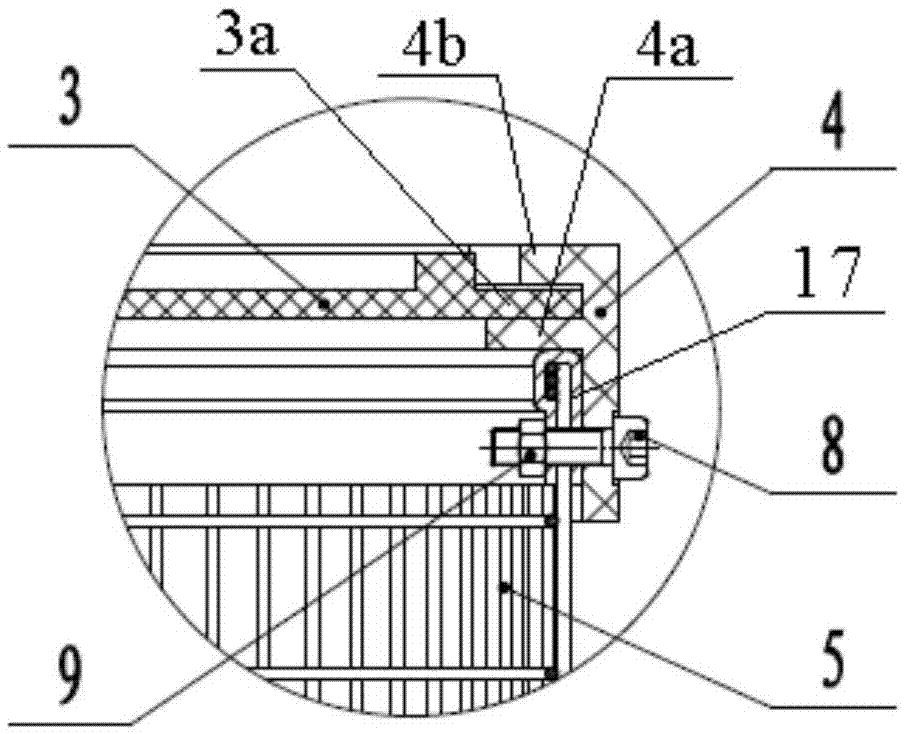

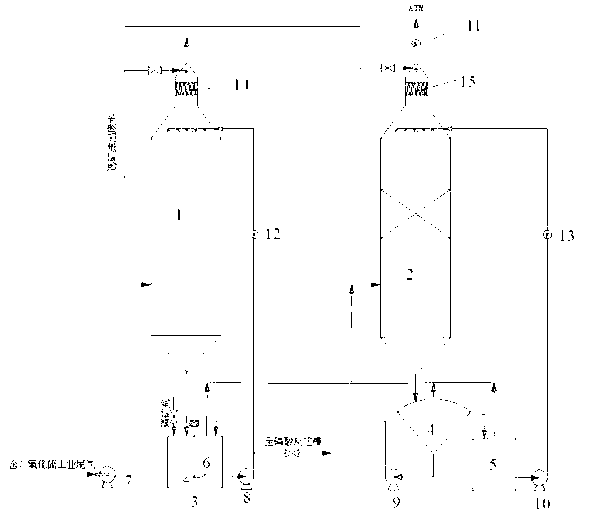

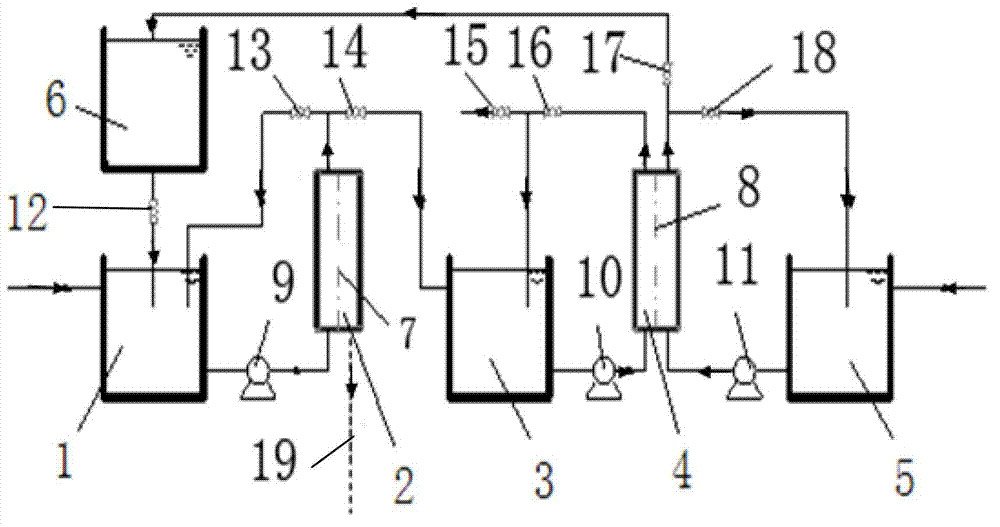

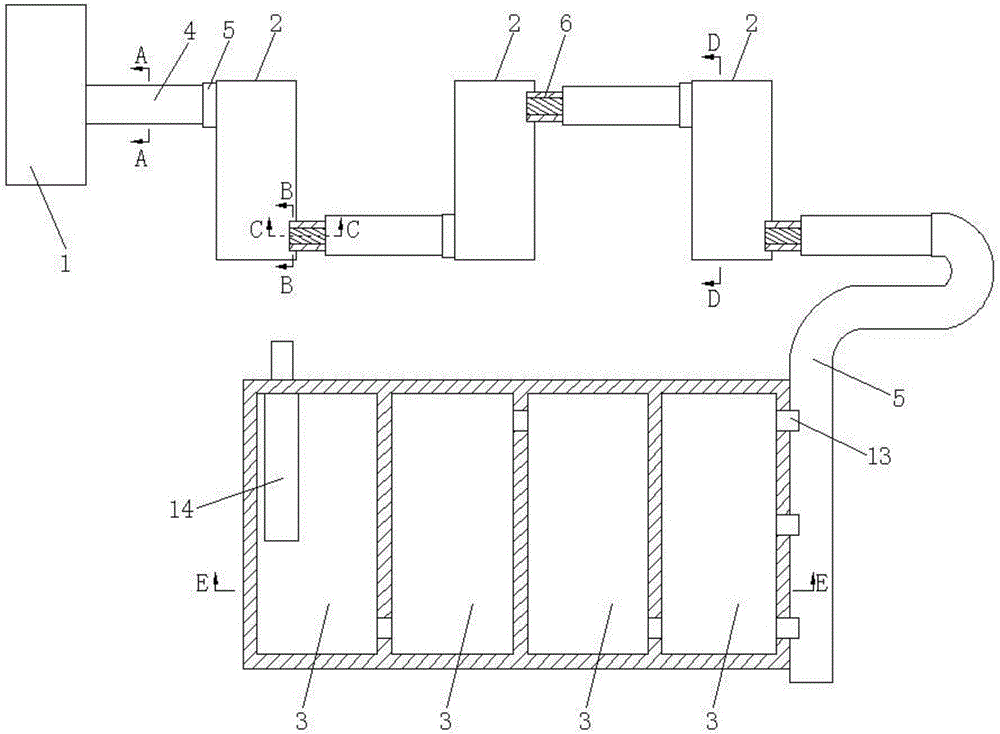

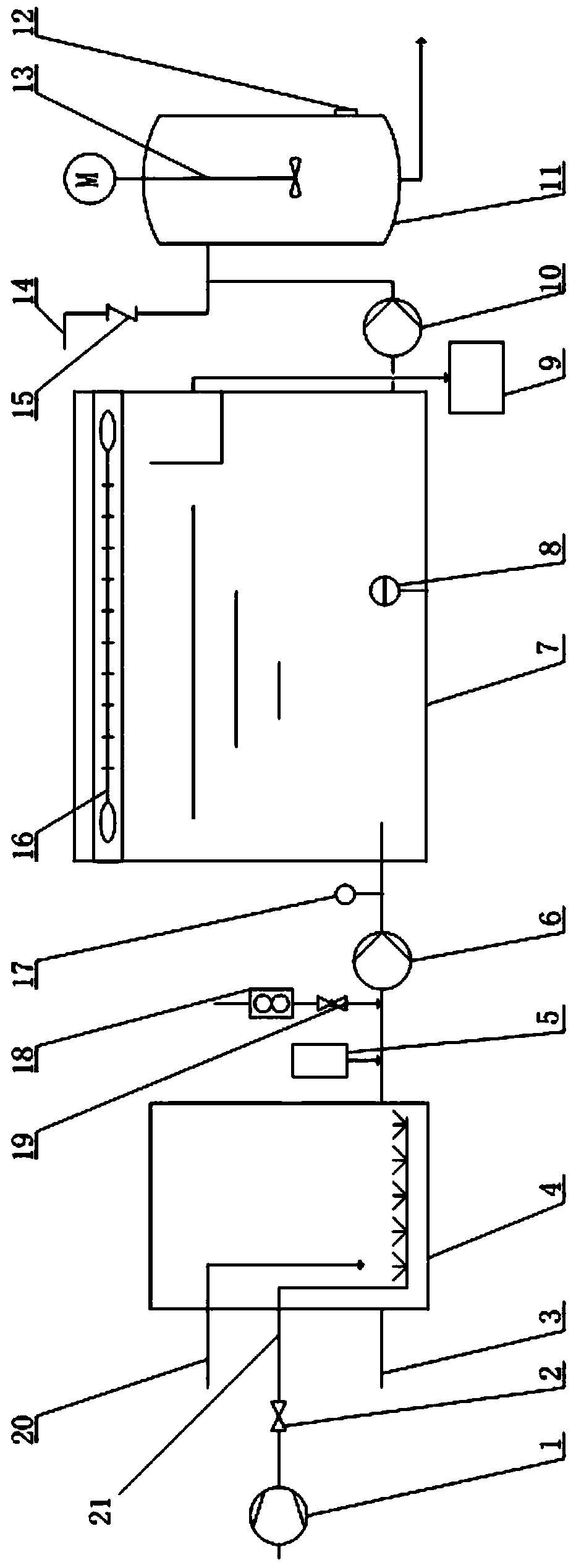

Device and method for sludge digestive juice semi-partial nitrification anaerobic ammonia oxidation denitrification and denitrifying phosphorus removal coupling system

ActiveCN103864206AReduce productionEase of compliance with emission standardsWater contaminantsTreatment with anaerobic digestion processesWater dischargeSludge

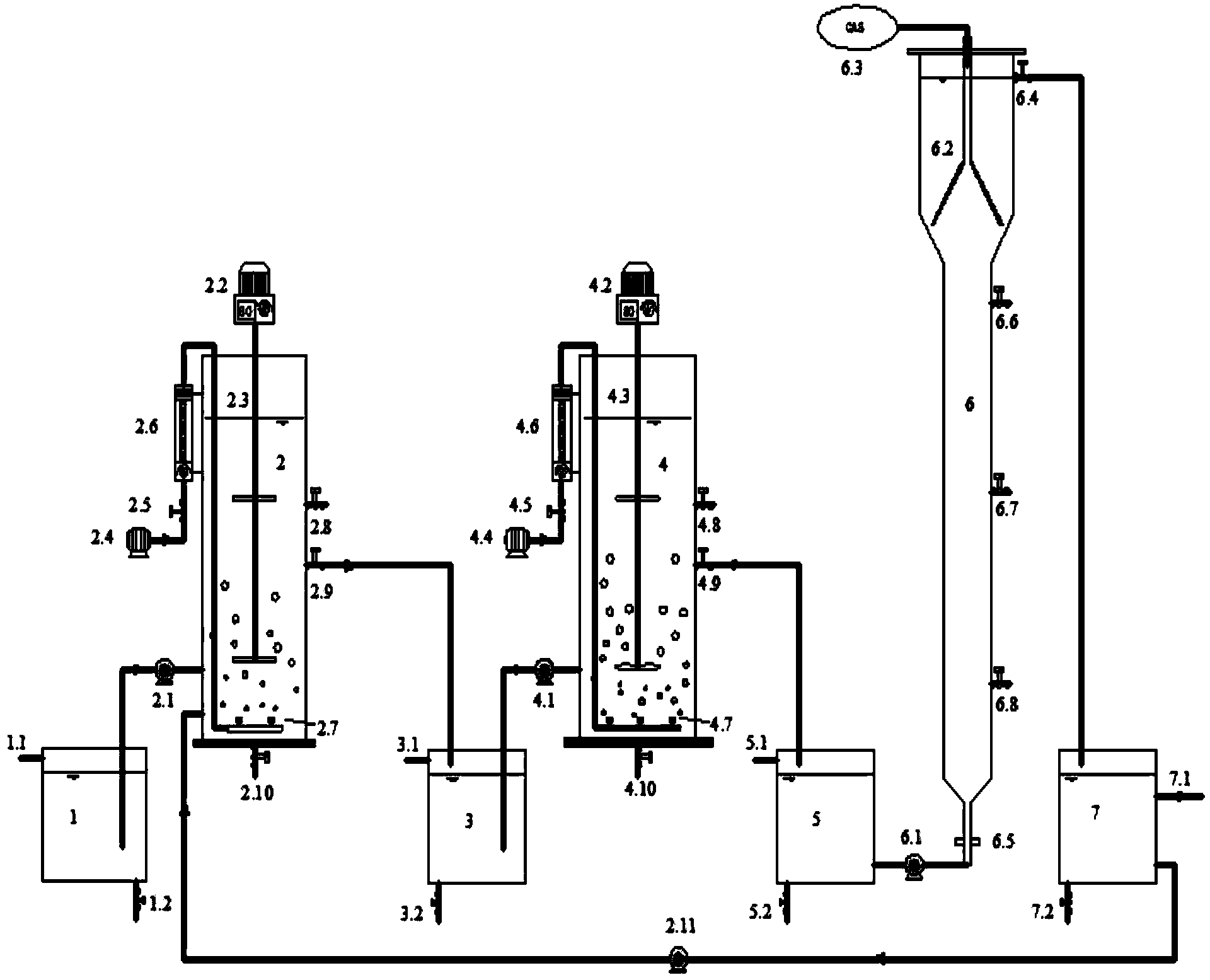

The invention relates to a device and method for a sludge digestive juice semi-partial nitrification anaerobic ammonia oxidation denitrification and denitrifying phosphorus removal coupling system and belongs to the technical field of biological sewage treatment. The device comprises a raw water tank, a denitrifying phosphorus removal reactor, a first regulating water tank, a semi-partial nitrification reactor, a second regulating water tank, an anaerobic ammonia oxidation reactor and a water discharging water tank; the method for the sludge digestive juice semi-partial nitrification anaerobic ammonia oxidation denitrification and denitrifying phosphorus removal coupling system comprises the steps that sludge digestive juice firstly enters the denitrifying phosphorus removal reactor, phosphorus-accumulating bacteria release phosphorus by utilizing a carbon source in raw water, then NO3-N in refluxed anaerobic ammonia oxidation effluent is utilized for carrying out denitrifying phosphorus removal, effluent is discharged into the semi-partial nitrification reactor and the anaerobic ammonia oxidation reactor for realizing removal of ammonia nitrogen in the raw water; one part of effluent of the anaerobic ammonia oxidation reactor is discharged, one part of the effluent of the anaerobic ammonia oxidation reactor is refluxed into the denitrifying phosphorus removal reactor for being used during denitrifying phosphorus removal. The method for the sludge digestive juice semi-partial nitrification anaerobic ammonia oxidation denitrification and denitrifying phosphorus removal coupling system can be applied to biological nitrogen and phosphorus removal of high ammonia nitrogen waste water with low CN ratio, oxygen consumption and energy consumption are reduced compared with the traditional denitrification and phosphorus removal technology, and denitrification and phosphorus removal efficiency is greatly improved.

Owner:BEIJING UNIV OF TECH

Method of recovery copper, nickel and noble metal in waste water and slag by combined technology of wet method and fire method

A process for recovering the copper, Ni and noble metals from the sewage and dregs by the combination of wet method and fire method includes the wet process including extracting, Cu-Ni separation, removing Fe, extracting, and refining nickel carbonate, and the fire process including sintering and smelting to produce nickel matte and black copper. Its advantages are high recovery rate of Ni, Cu, Au, Ag and Pd, and no secondary pollution.

Owner:孙涛 +1

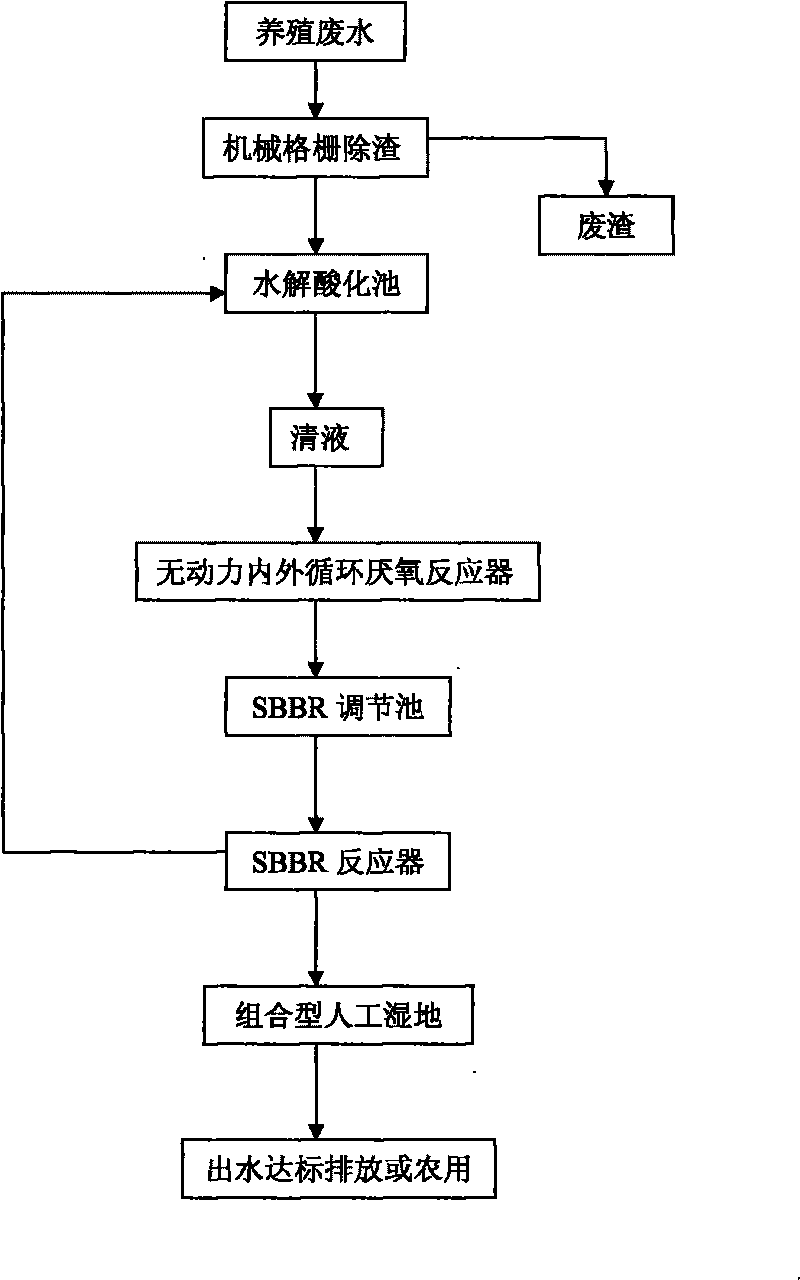

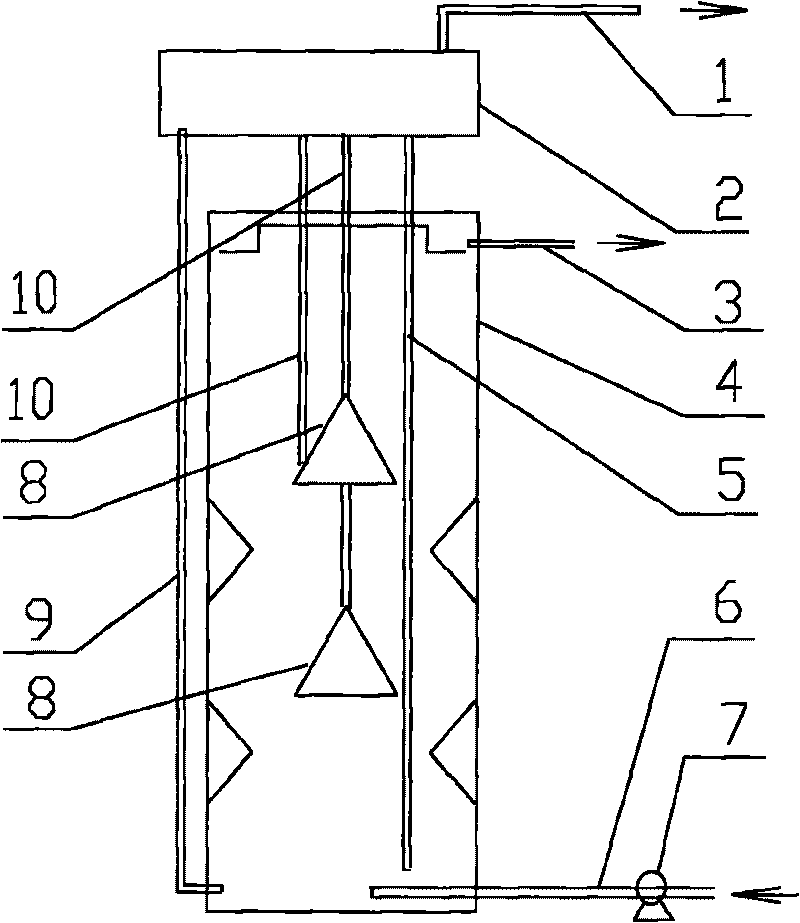

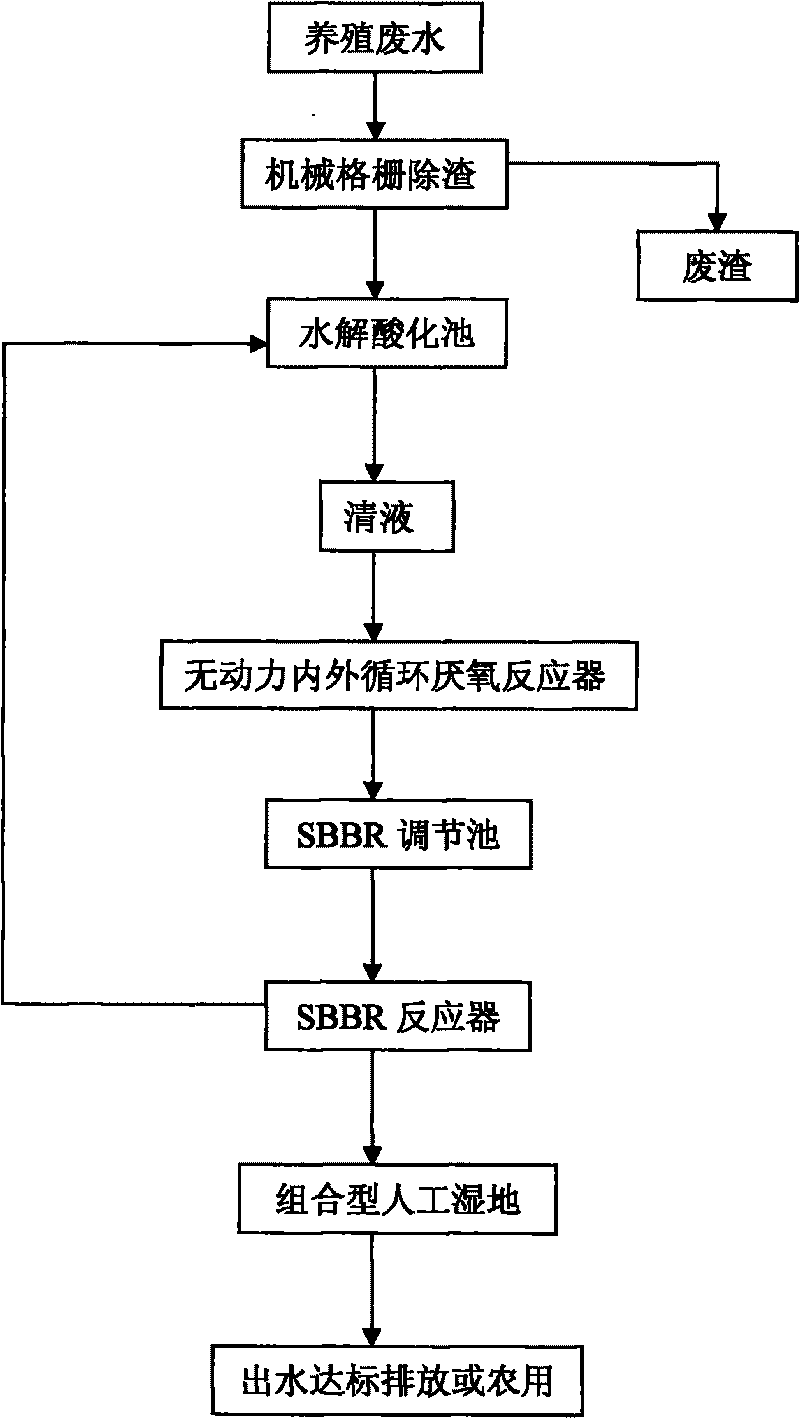

Treatment combined process for pig farm waste water with high nitrogen content

InactiveCN101759323AGood effect on treating pig farm wastewaterReduce energy consumptionWaste water treatment from animal husbandryWaste based fuelPig farmsConstructed wetland

The invention provides a treatment combined process for pig farm waste water with high nitrogen content, which is characterized in that the process adopts a combined process realized by an unpowered inside and outside circulation (IOC) anaerobic reactor, an SBBR sequencing batch type biomembrane reactor and artificial swamp. The process flow of the combined process comprises the following steps: a, removing large-grain pollutants and floaters in sewage by mechanical grids; b, carrying out hydrolysis and acidification; c, using the inside and outside circulation anaerobic reactor for high-efficient anaerobic digestion; d, using SBBR reactor for aerobic / anoxic nitration; and e, carrying out the depth treatment by the artificial swamp, and realizing the high-efficient purification on the sewage through substrate filtering, absorption, precipitation, ion exchange, plant absorption and microbiological degradation. The invention can be applicable for the treatment and the integrated utilization of the waste water in big-and-middle-sized pig farms.

Owner:ENERGY RES INST OF JIANGXI ACAD OF SCI +1

Method for treating phosphorus-containing waste water

ActiveCN103121772AAchieve emission standardsRelieve stressMultistage water/sewage treatmentWater/sewage treatment by neutralisationElectrolysisEmission standard

The invention discloses a method for commprehensively treating phosphorus-containing waste water. The method mainly comprises the steps of: classifying waste water with total phosphorus concentration being 20-10000mg / L generated in a factory; for different types of phosphorus-containing waste water, carrying out different combined pre-treatment of more than two of iron-carbon micro-electrolysis, oxidation, coagulating sedimentation, lime stone neutralization and the like; and afterwards, further carrying out biochemical treatment so that the waste water reaches the emission standard with TP (Total Phosphorus) being smaller than or equal to 0.5mg / L.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

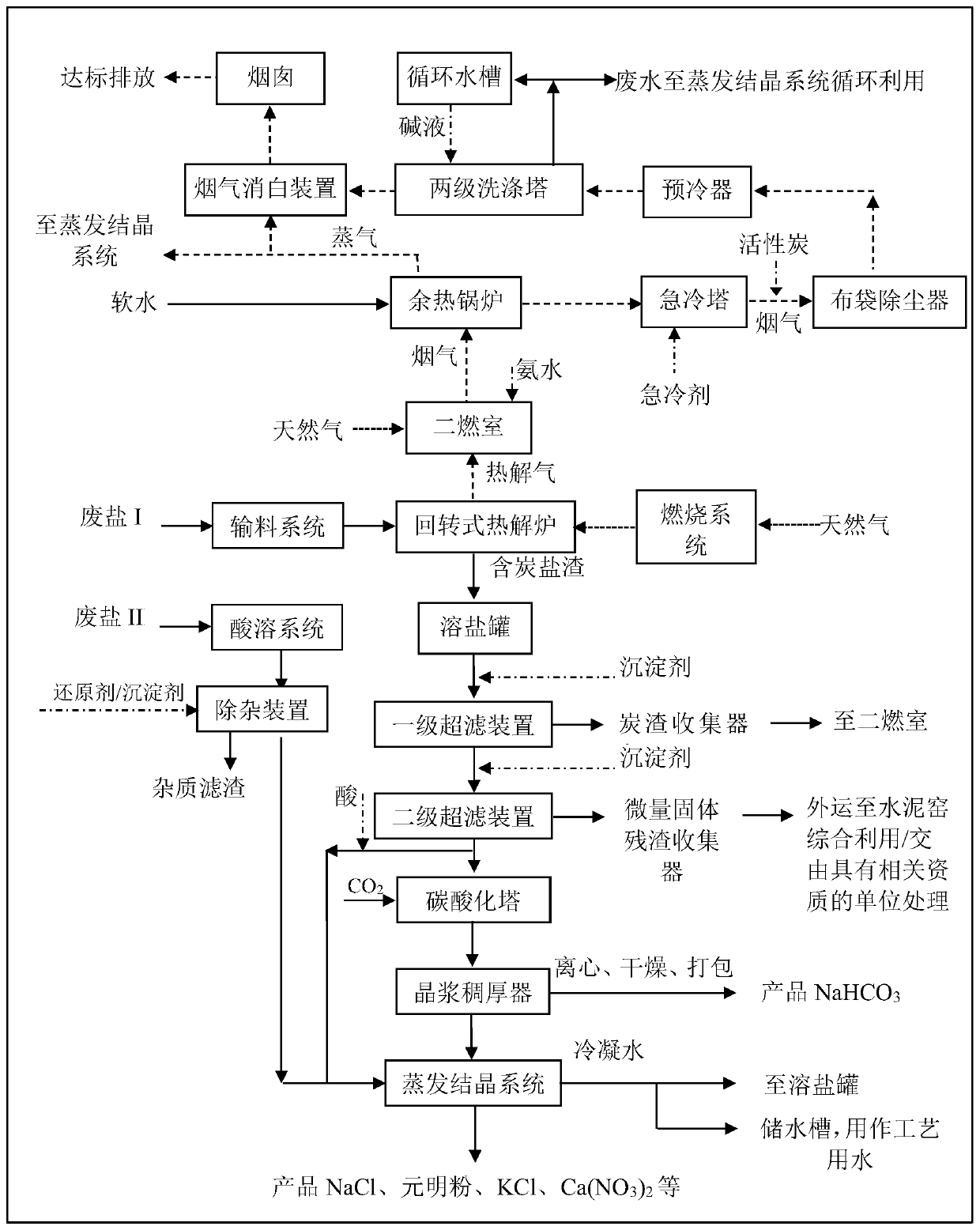

Waste salt resourceful treatment system and application

PendingCN110201975ARealize resourcesAchieve emission standardsSolid waste disposalTransportation and packagingSlagEvaporation

The invention relates to a waste salt resourceful treatment system which comprises a waste salt carbonization and pyrolysis system, a carbon-containing salt slag dissolving and filtering system and anevaporating and salt separating system in sequential connection, wherein the waste salt carbonization and pyrolysis system can carry out carbonization and pyrolysis treatment on waste salt I composedof sodium chloride, and sodium sulfate monomer salt or mixed waste salt and also can treat tail gas; the carbon-containing salt slag dissolving and filtering system can dissolve and filter the carbon-containing salt slag treated by the waste salt carbonization and pyrolysis system; and the evaporating and salt separating system can carry out evaporation and concentration, fractional crystallization and drying treatment on the strong brine treated by the carbon-containing salt slag dissolving and filtering system to obtain product salt. The waste salt resourceful treatment system takes industrial waste salt as the raw material, removes organic pollutant from waste salt and separates mixed inorganic salt to finally obtain an industrial second-grade salt product, so that recycling of waste salt is realized, and the flue gas generated during the production process is discharged after reaching the standard.

Owner:北京航天环境工程有限公司

Method for preparing manganese sulfate solution by using sulphur dioxide gas leach manganese dioxide ore

The invention discloses a method for preparing a manganese sulphate solution by leaching pyrolusite with sulfur dioxide gas. The method mainly comprises: pyrolusite and water are prepared into pyrolusite slurry with a liquid to solid ratio of between 5:1 and 1:1; the slurry, the sulfur dioxide gas and oxygen are continuously passed into a reactor provided with two stages of absorbing and leaching reaction chambers which are arranged and connected serially up and down; and absorbing and leaching reactions are carried out in the two absorbing and leaching reaction chambers sequentially at normal temperature, wherein each stage of absorbing and leaching reaction chamber is provided with a stirrer of no less than 5 kW for each cubic meter, the mass flow of the slurry is determined by the stoichiometric ratio of manganese dioxide required by the mass flow of the sulfur dioxide, and the amount of the added oxygen is determined by the pH values of reaction systems in the absorbing and leaching reaction chambers. Another invention applied by the applicant of the invention discloses a reactor for use in pyrolusite leaching. The reactor realizes stable and continuous production, achieves high sulfur and manganese resources recovery rate, meets tail gas exhaust standards and can effectively suppress the generation of MnS2O6 at the same time.

Owner:成都合众新能源科技有限公司

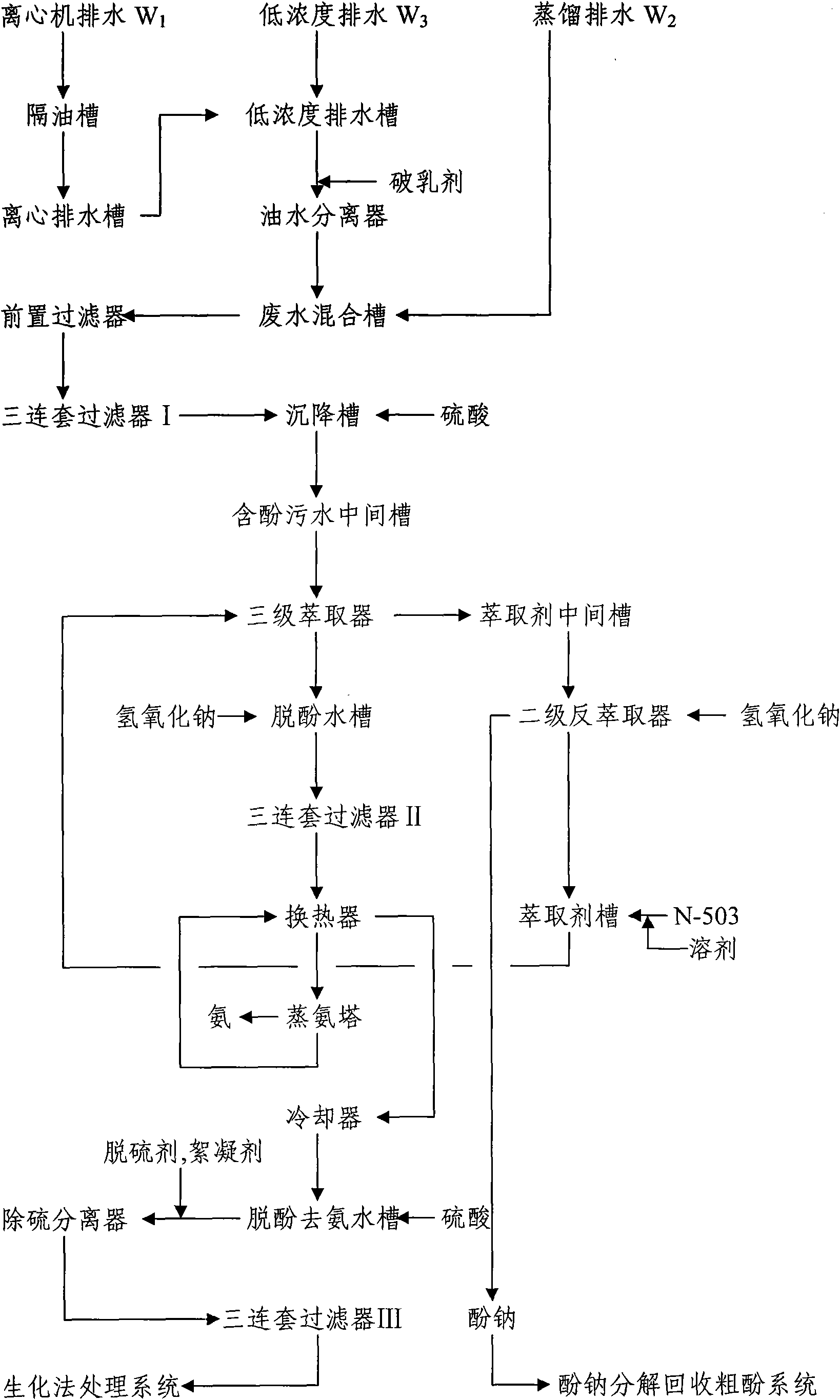

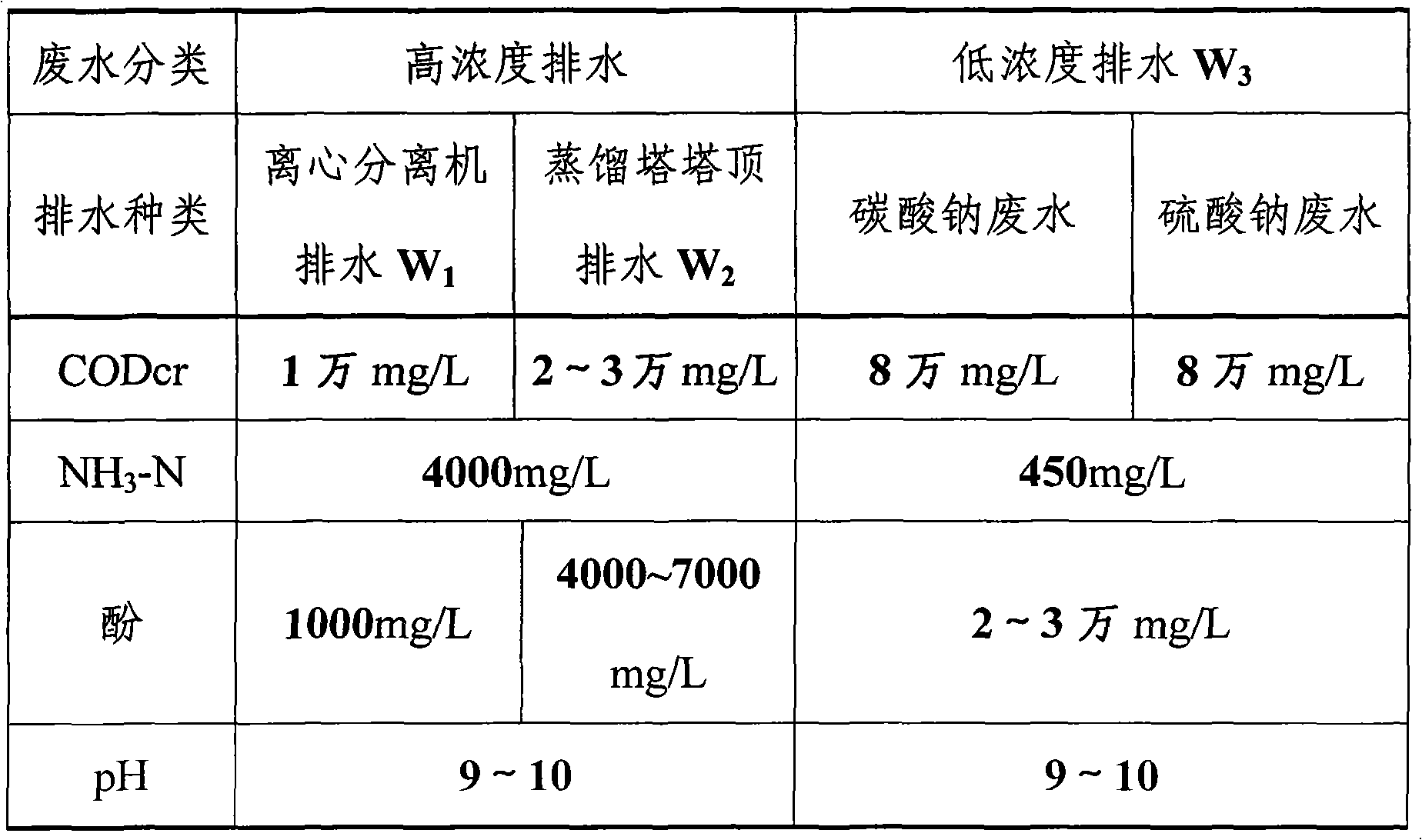

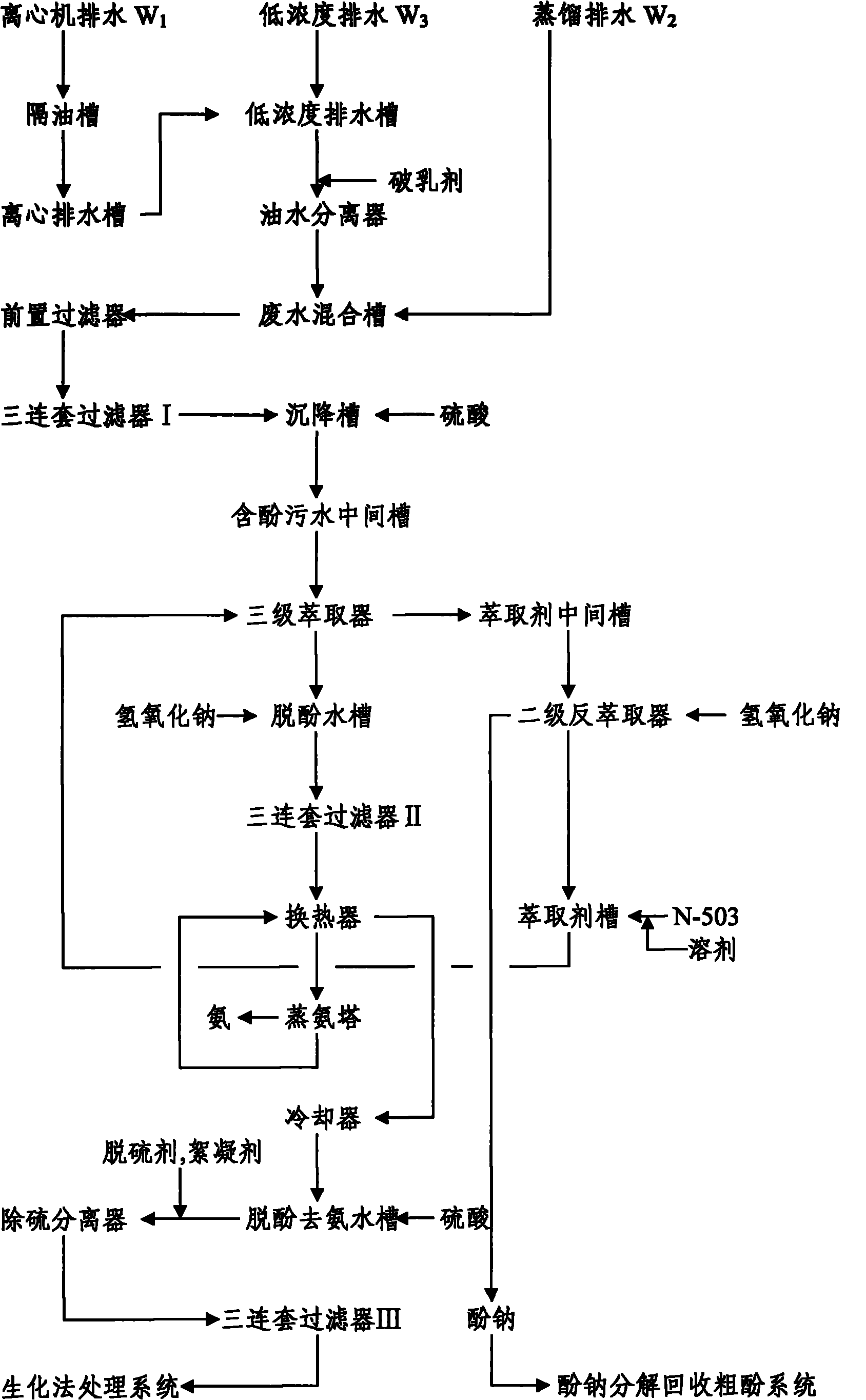

Coal tar processing wastewater treatment method and system

ActiveCN101875523AEfficient removalAchieve emission standardsFatty/oily/floating substances removal devicesMultistage water/sewage treatmentWater qualityEconomic benefits

The invention relates to coal tar processing wastewater treatment method and system. The treatment method comprises materialization treatment comprising the following steps of: (1) removing free oil and emulsified oil which are contained in wastewater, filtering, regulating the pH value of the wastewater to 3-4, and then separating out depositions; (2) extracting and dephenolizing; (3) regulatingthe pH value of the dephenolized wastewater to 9-10, filtering, then carrying out steam stripping and deaminization by using steam, and besides, carrying out reextraction on extract phase containing phenol to respectively recover an extracting agent and phenate, and then recycling the extracting agent and decomposing the phenate to obtain crude phenol; and (4) cooling the deaminized wastewater, regulating the pH value to 7-8, and then filtering after adding a desulfurizing agent to remove sulfides. The water quality of the materialized wastewater achieves the requirement of a biochemical treatment system; meanwhile, the invention can recover a given amount of useful matter comprising the phenol, ammonia and the like and make the extracting agent recycled so that the economic benefit of wastewater treatment is improved.

Owner:高科环保工程集团有限公司

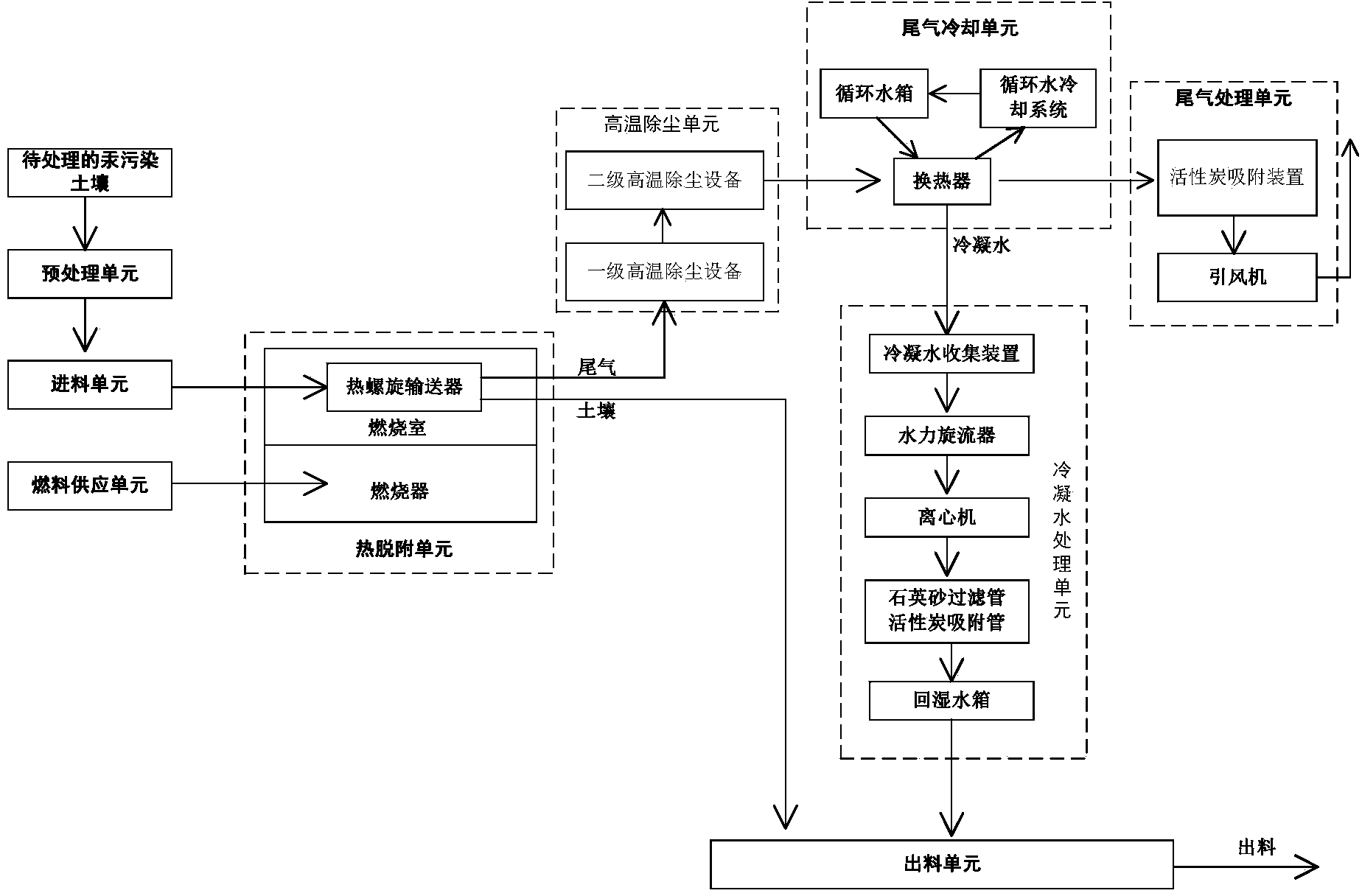

Device and method applied to thermal desorption treatment of mercury-contaminated soil

ActiveCN104289513ARealize resource utilizationQuick installationContaminated soil reclamationThermal desorptionFuel supply

The invention discloses a device and a method applied to thermal desorption treatment of mercury-contaminated soil. The device comprises a pretreatment unit, a charging unit, a fuel supply unit, a thermal desorption unit, a high-temperature dust removal unit, a condensate water treatment unit, a discharging unit, a tail gas cooling unit and a tail gas treatment unit, wherein the pretreatment unit is connected with the charging unit; the charging unit, the fuel supply unit, the discharging unit and the high-temperature dust removal unit are connected with the thermal desorption unit; the high-temperature dust removal unit is connected with the tail gas cooling unit; the tail gas cooling unit is connected with the tail gas treatment unit and the condensate water treatment unit; the condensate water treatment unit is connected with the discharging unit; the thermal desorption unit adopts a thermal screw conveyor. According to the device, the contaminants are indirectly heated, volatilized and separated out of the contaminated soil, so that the mercury in the mercury-contaminated soil can be effectively removed; meanwhile, the mercury in the tail gas can be recycled and desorbed by a hydrocyclone separation method; and the up-to-standard emission of the tail gas and the wastewater can be achieved.

Owner:中节能大地环境修复有限公司

Microbial deodorant and preparation method thereof

InactiveCN102258796AStrong fermentation and decomposition abilityGrowth inhibitionFungiBacteriaCfu - colony-forming unitSaccharomyces cerevisiae

The invention applies to provide a microbial deodorant which is a microbial colony composed of lactobacillus plantarum, bacillus subtilis, saccharomyces cerevisiae and rhodopseudomonas palustris, wherein counted by 108CFU (colony-forming unit) / ml as a unit, the total viable count is not less than 10, the lactobacillus plantarum count is not less than 3, the saccharomyces cerevisiae count is not less than 3, the rhodopseudomonas palustris count is not less than 2 and the bacillus subtilis count is not less than 2. The microbial deodorant applied by the invention has stronger zymolysis ability under both aerobic and anaerobic conditions, and the beneficial bacteria mutually play a role in inhibiting the growth of putrefactive bacteria and interrupting the putrefactive process, secrete organic acid while reproducing quickly, and generate antioxidation substances, thus converting odorous substances such as NH3, H2S, indoles and the like into non-odorous substances.

Owner:黄小娃

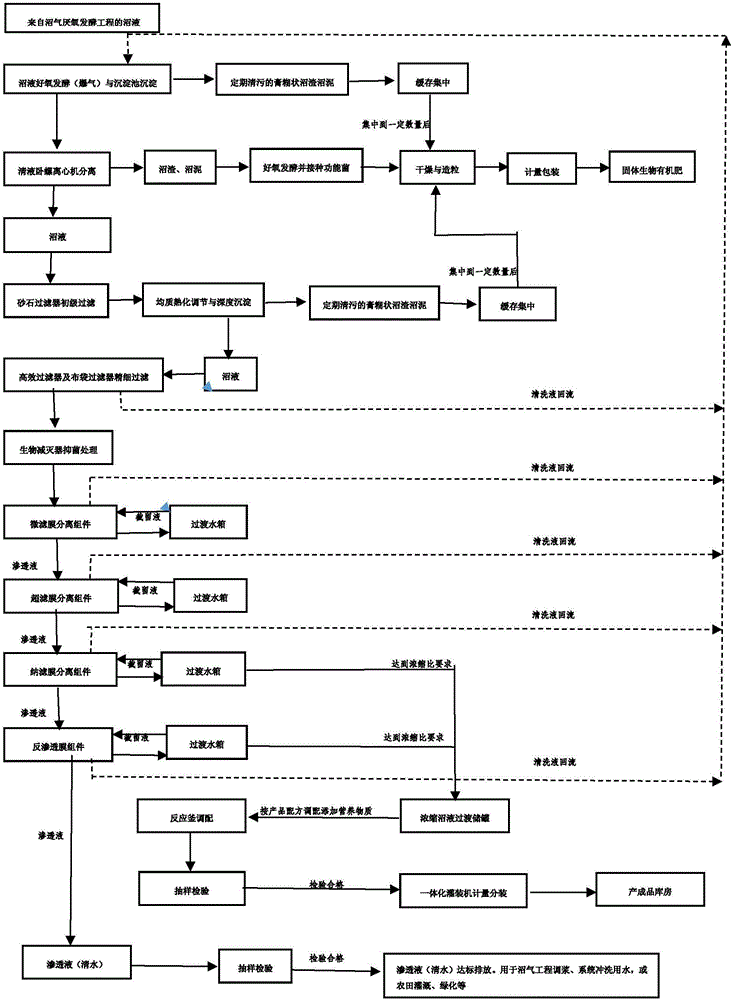

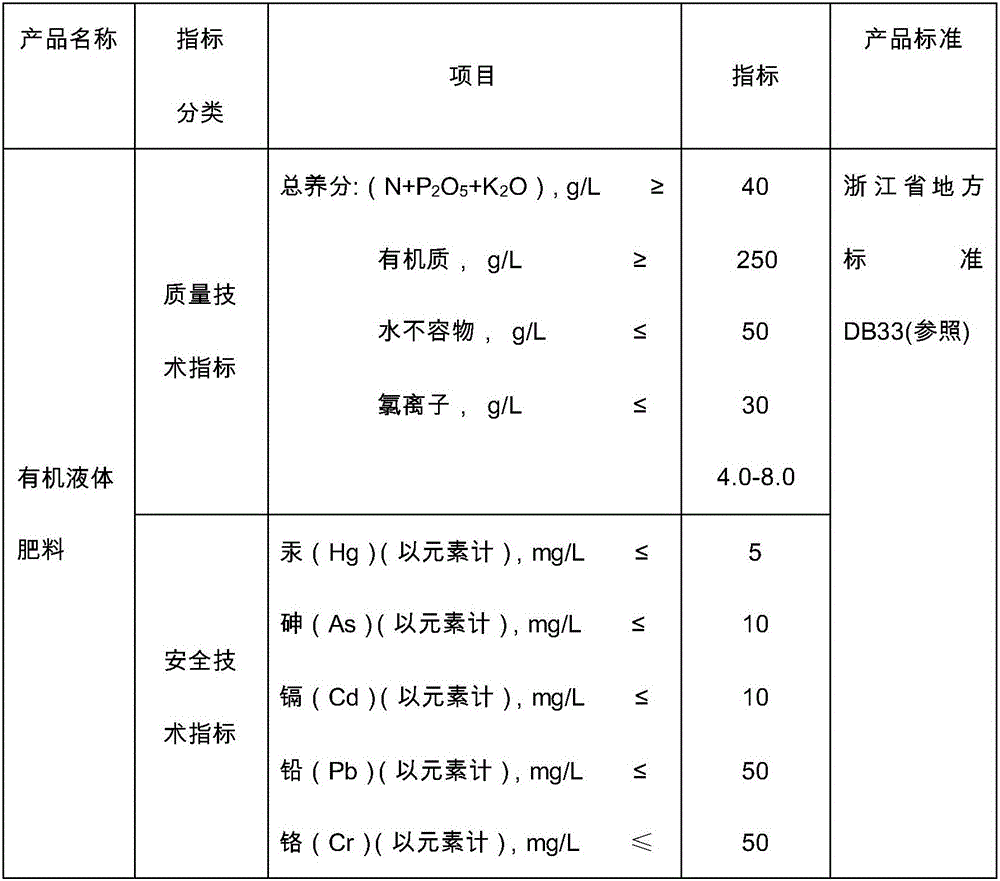

Production process for producing organic fertilizer through concentrating biogas slurry by using multistage membrane separation technology

InactiveCN106336253AFully removedReduce pollutionBio-organic fraction processingClimate change adaptationUltrafiltrationSeparation technology

The invention discloses a production process for producing an organic fertilizer through concentrating biogas slurry by using a multistage membrane separation technology; the production process comprises the following steps: a, pretreatment: carrying out pretreatment of biogas slurry after anaerobic fermentation through precipitation, aerobic fermentation, solid-liquid separation, primary filtration, homogeneous curing adjustment, deep precipitation, fine filtration and biological bacteria inhibition; b, multistage membrane separation before concentration: carrying out microfiltration membrane separation and ultrafiltration membrane separation of the biogas slurry after fine filtration and biological bacteria inhibition; c, multistage membrane concentration: carrying out multistage membrane concentration of the biogas slurry penetrated fluid obtained by ultrafiltration membrane separation through nanofiltration membrane concentration, reverse osmosis membrane concentration and concentration membrane protection; d, blending: adding large, medium and trace elements and other nutritional ingredients and functional components into the intercepted concentrate obtained by nanofiltration and reverse osmosis membrane separation, blending to obtain a liquid organic fertilizer, and sub-packaging; and e, product packaging. The production process has the advantages of flexible structure, advanced equipment and scientific process layout, can meet resource comprehensive utilization development of biogas slurry of all large and medium sized biogas projects.

Owner:NINGXIA SHUNBAO MODERN AGRI CO LTD

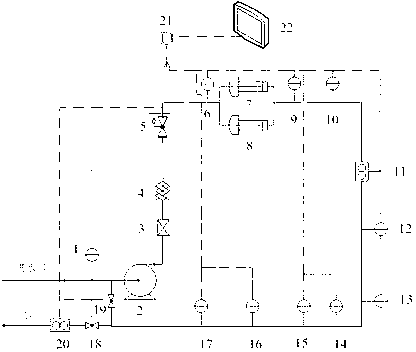

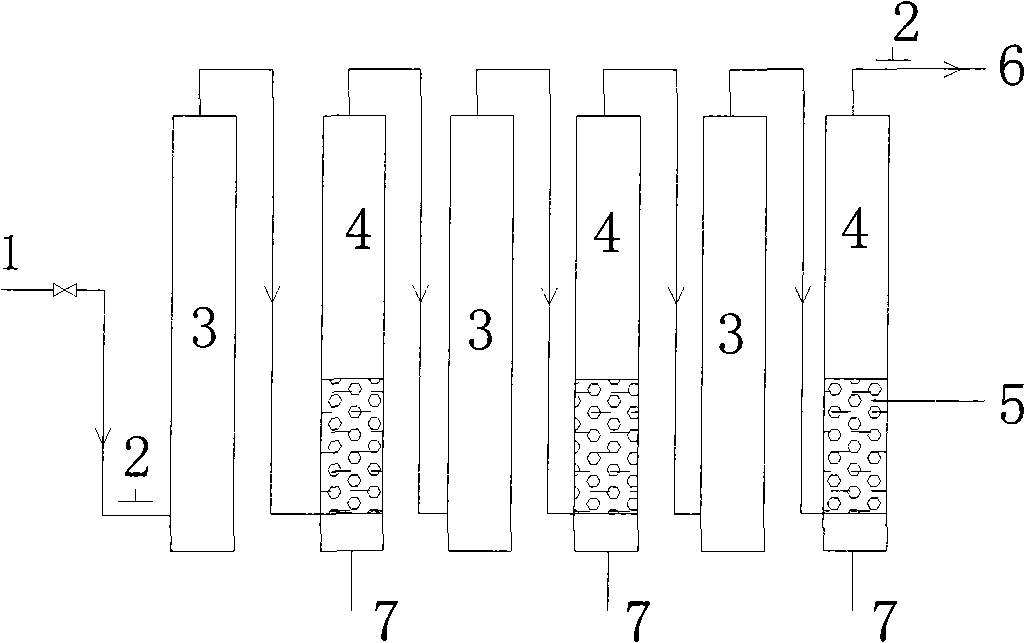

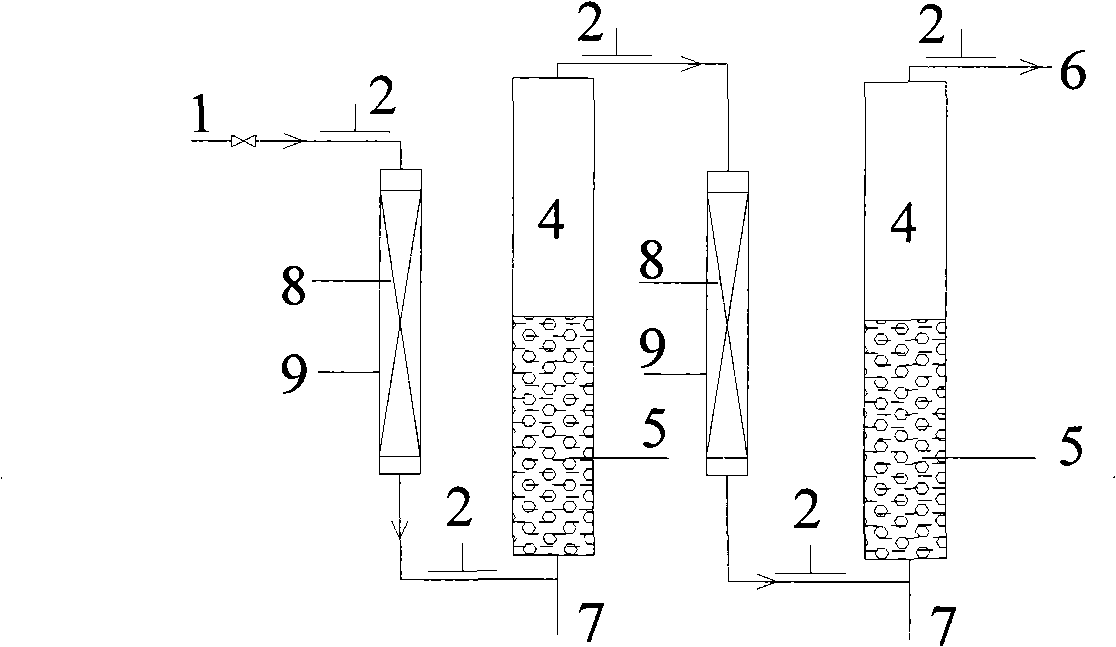

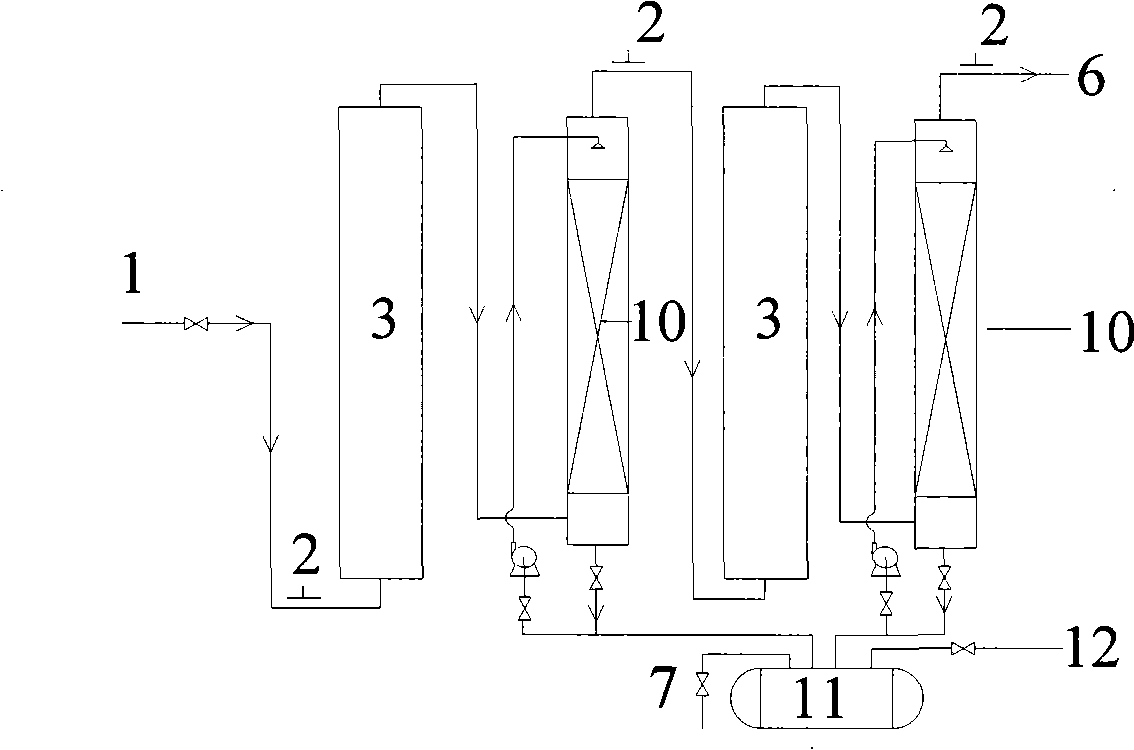

Hydrodynamic-cavitation enhanced water treating apparatus

InactiveCN102795727AImprove processing efficiencyRealize the display effectMultistage water/sewage treatmentWater/sewage treatment using germicide/oligodynamic-processChemical oxygen demandAutomatic control

The invention discloses a hydrodynamic-cavitation enhanced water treating apparatus, comprising a pretreatment unit, an enhanced cavitation formation device, a water feedback cycle treatment loop, a multi-parameter water quality detection / display system and a smart automatic control system, wherein the multi-parameter water quality detection / display system is composed of a pressure sensor, a redox potential sensor, a flowmeter, a pH sensor, a conductivity sensor, a dissolved oxygen sensor, a chemical oxygen demand sensor, a total organic carbon sensor, a temperature sensor and an LED (Light-Emitting Diode) touch display screen, all of which are orderly mounted in a water outlet pipeline; the two ends of the water feedback cycle treatment loop are connected to the front section of a water outlet electromagnetic valve and the front end of a water pump of a water inlet pipeline, respectively; and the water outlet electromagnetic valve and a cycle-treatment electromagnetic valve are connected to a programmable controller, respectively. The hydrodynamic-cavitation enhanced water treating apparatus is used for water treatment and purification, and realizes online detection and display of a plurality of water quality parameters and operating parameters therein and automatic control on the operation thereof by means of a plurality of sensors.

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA

Gas phase oxidation-liquid phase reduction method for absorbing and removing nitrous oxides in exhaust air

InactiveCN101279185AAchieve emission standardsSimple processDispersed particle separationGas phaseEmission standard

The invention provides a gas-phase oxidation / liquid-phase reduction method for absorbing and removing NOx. The method utilizes O2 in waste gases as an oxidizer; after be processed by non-catalyst oxidization or catalyzed oxidation by modified active carbon materials, NOx waste gas with low oxidization degree reacts with an alkaline reducing solution fully to remove NOx. After going through multi-grade oxidization, reduction and absorption, the NOx in waste gases can fully meet the emission standard. The method of the invention has the advantages of being able to realize up-to-standard emission of NOx waste gas with low oxidization degree, simple technique, small cost and high removing efficiency.

Owner:ZHEJIANG UNIV OF TECH

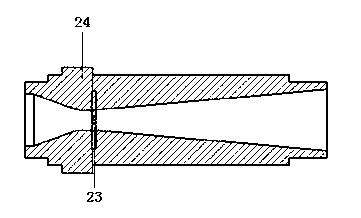

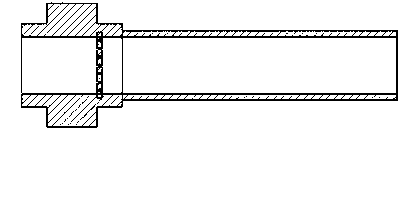

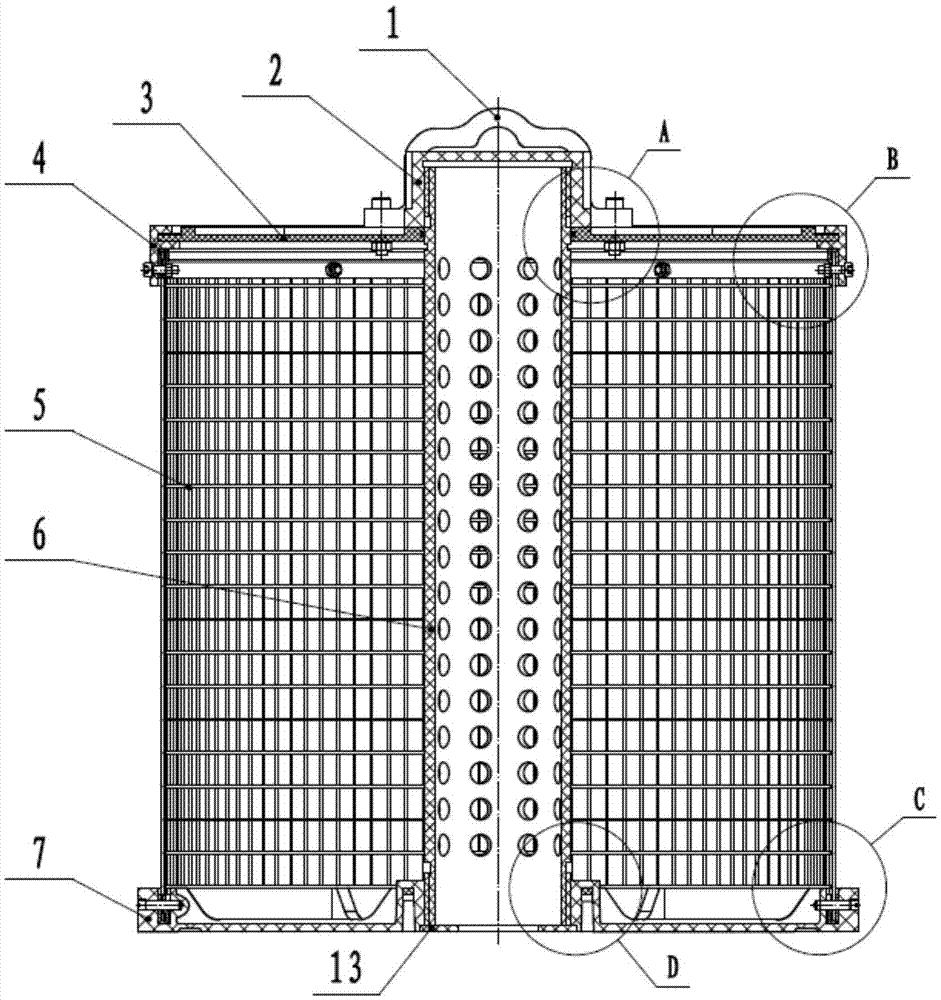

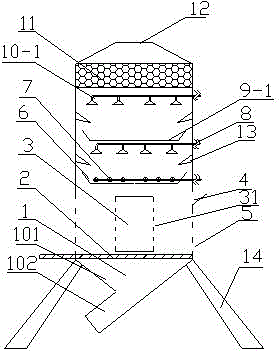

Cylinder filter

ActiveCN105435508AStable structureEasy to installStationary filtering element filtersFilter mediaEngineering

The invention discloses a cylinder filter, and belongs to the technical field of rainwater treatment devices. The cylinder filter comprises an outer cylinder with water passing holes and a collecting pipe with water passing holes, wherein the outer cylinder and the collectingpipe are coaxially arranged. The bottom end of the outer cylinder and the bottom end of the collecting pipe are detachably connected to the base. A cover plate is detachably connected to the top end of the outer cylinder. A handle is fixedly connected to the cover plate. The space between the outer cylinder and the collecting pipe is filled with a filtering medium for filtering rainwater. The diameter of the water passing holes in the outer cylinder and the diameter of the water passing holes in the collecting pipe are both smaller than the grain diameter of the filtering medium. The cylinder filter is stable and reliable in structure and can be conveniently mounted and dismounted on site, meanwhile the filtering medium can be conveniently replaced, the workload is reduced, and the efficiency is improved.

Owner:WUHAN MEIHUA YUSHUI ENVIRONMENT CO LTD

Industrial exhaust gas desulfurizer

InactiveCN103191637AReduce consumptionReduce pollutionDispersed particle separationWastewaterPulp and paper industry

The invention discloses an industrial exhaust gas desulfurizer. The device comprises a desulfurizing tower, a phosphoric ore pulp circulating tank, a washing tower, a setting tank and a clear liquid tank, wherein an inlet of the desulfurizing tower is provided with an induced draft fan, a spraying system of the desulfurizing tower is connected with the phosphoric ore pulp circulating tank through a phosphoric ore pulp circulating pump, and the bottom of the desulfurizing tower is provided with an outlet which is communicated with the phosphoric ore pulp circulating tank; an outlet of the top of the desulfurizing tower is communicated with the washing tower by a pipeline, the spraying system of the washing tower is connected with the clear liquid tank through a washing tower circulating pump, the bottom of the washing tower is provided with an outlet which is communicated with the setting tank, an outlet of the bottom of the setting tank is communicated with the phosphoric ore pulp circulating tank through a slush pump, and a clear liquid outlet of the setting tank is connected with the clear liquid tank. The sulfuric acid tail gas which is subjected to desulfurization by the device contains dioxo sulphur content being smaller than 100ppm, and can meet the new standard in China. In addition, due to the adoption of the device, the three wastes can not be generated in the whole process, a sulphur resource is fully utilized, a phosphorus resource is not damaged, and the part industrial wastewater is also consumed.

Owner:WENGFU (GRP) CO LTD

Integrated device for remediation on volatile pollution soil

ActiveCN104056851AIncrease contact areaImprove absorption rate and absorption effectDispersed particle separationContaminated soil reclamationWater storage tankIntegrated devices

The invention discloses an integrated device for remediation on volatile pollution soil. The integrated device comprises a soil adding and discharging system, an oxidation system, a neutralization system, an adsorption system and an air discharging system in sequence from bottom to top, wherein an inclined soil discharging bucket is positioned at the bottommost part of a tank body; an upper end opening in the inclined soil discharging bucket is provided with a baffle plate for sealing the inclined soil discharging bucket; two ends of a gas collecting tube are opened, the gas collecting tube is fixed in the tank body through a bracket and a plurality of gas collecting holes are formed in the wall of the gas collecting tube; a soil adding hole is formed in the tank body; a gas feed hole is formed in the tank body between the soil adding hole and the baffle plate; the oxidation system comprises an ozone oxidation water storage tank, an aeration disk in the water storage tank, an ozone generation device communicated with the aeration disk, and an ozone oxidation water spraying device communicated with the ozone oxidation water storage tank through a circulating pump I; the neutralization system comprises a neutralization solution tank, and a neutralization solution spraying device communicated with the neutralization solution tank through a circulating pump II; the air discharging system comprises an opening in the top of the tank body and an exhaust fan in the opening.

Owner:邳州市博睿投资管理有限公司

Method for treating 2,4,6-trinitrotoluene waste water and application thereof

ActiveCN101830606AAvoid inhibitionAvoid side effectsWater contaminantsMultistage water/sewage treatmentBiotechnologyHazardous substance

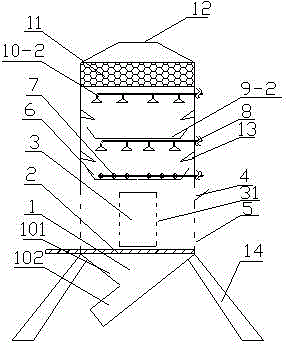

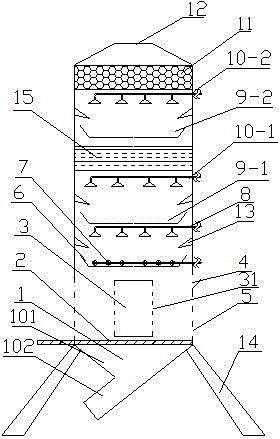

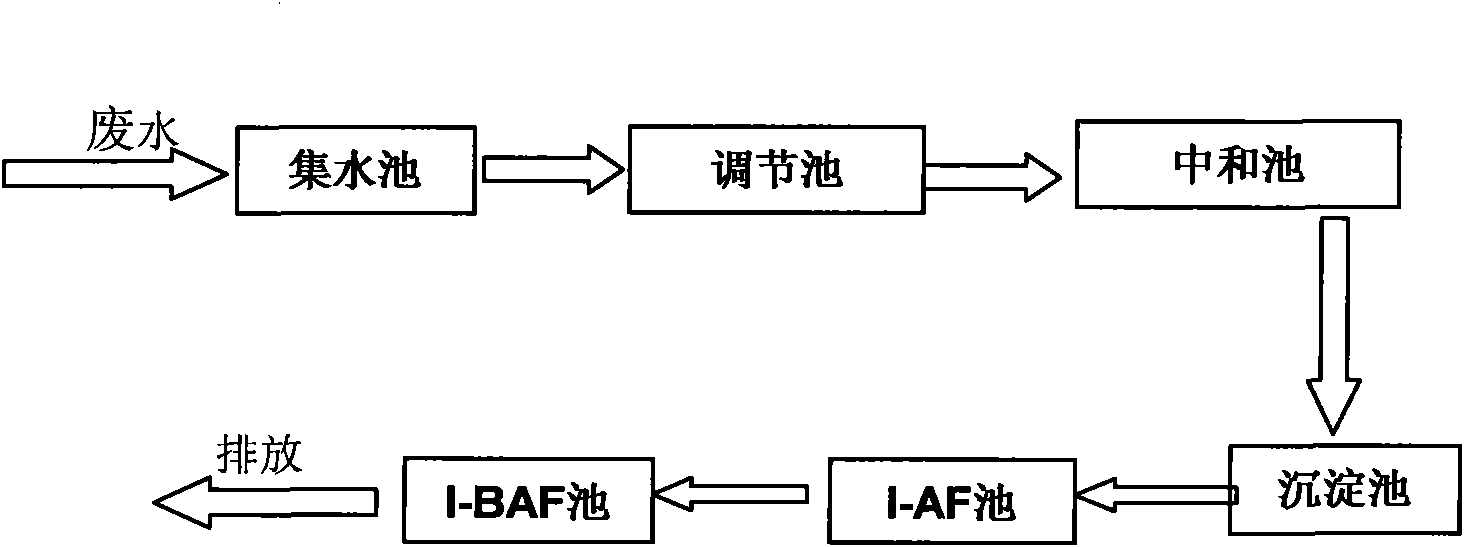

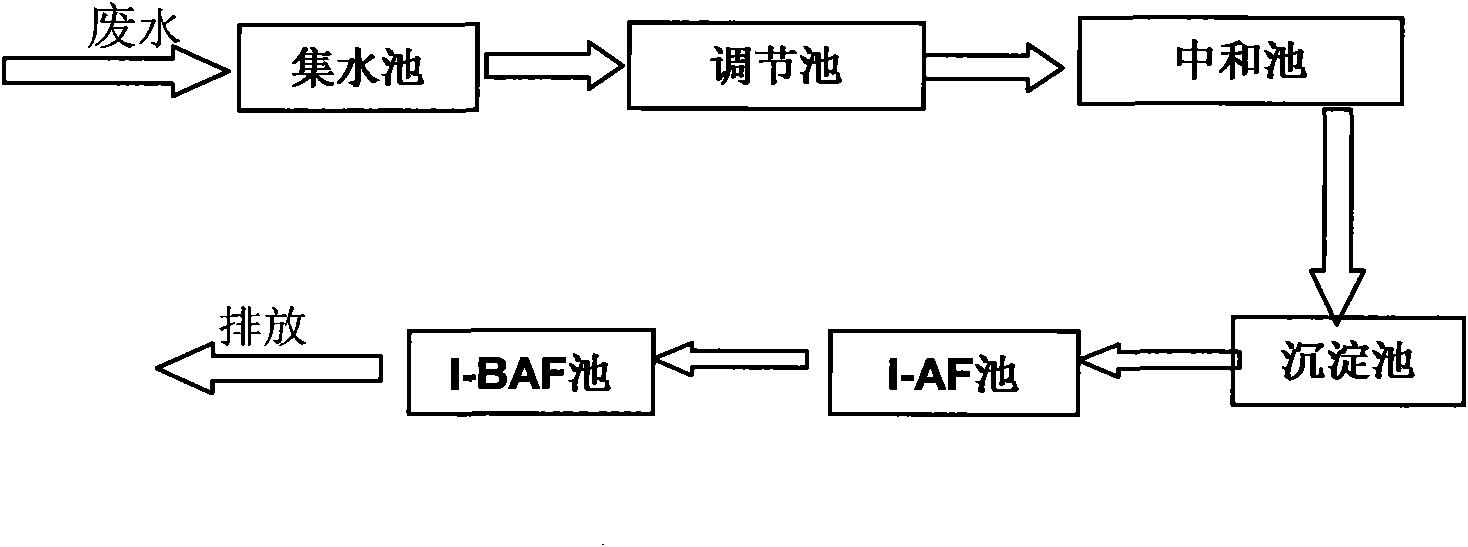

The invention provides a method for treating 2,4,6-trinitrotoluene (TNT for short) waste water. In the invention, waste water is mainly treated by immobilized microorganisms, an anaerobic biological filter (I-AF) and immobilized microorganisms and a biological aerated filter (I-BAF), wherein the waste water enters a collecting tank, is lifted by a pump to enter a regulating tank and enters a setting tank after being homogenized and neutralized by the regulating tank so as to remove suspended substances (SS) in the waste water; the effluent is discharged after reaching standards after enteringthree-stage I-AF and five-stage I-BAF for further treatment. The specific steps of the method are shown in the specification. The invention has the advantages that biological treatment adopts an immobilized microorganism technology, which improves the poison resistance of the microorganisms, realizes the high-efficiency removal on toxic and harmful substances of nitrobenzene and the like, reducesthe treatment cost and realizes the standard-reaching discharge of the waste water. The application of the invention is not only suitable for treating the TNT waste water but also is applied to treating nitrobenzene and aniline contained pollutants and organic waste water thereof.

Owner:PEKING UNIV +1

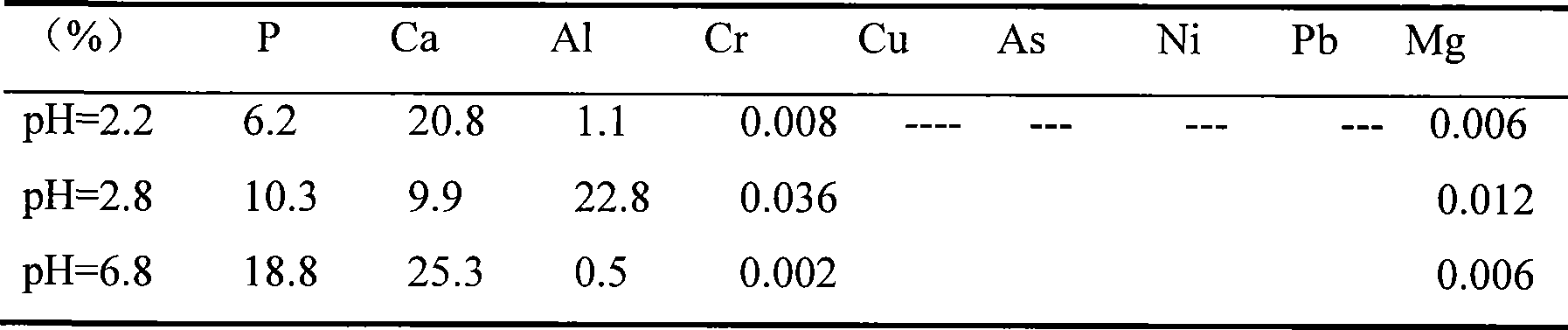

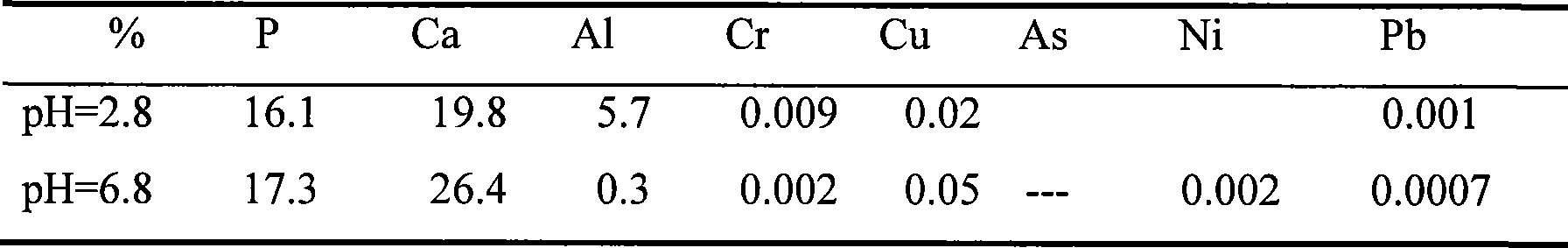

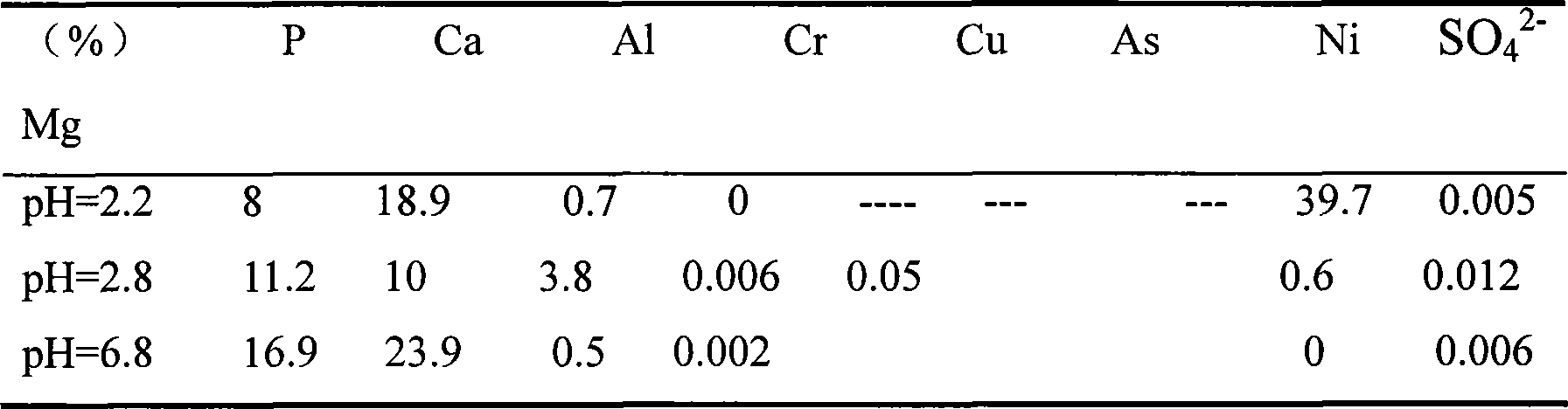

Comprehensive utilization method of chemical polishing waste phosphoric acid

ActiveCN101456547AIncrease profitAchieve emission standardsPhosphorus compoundsSludgePhosphoric acid

The invention relates to a method for comprehensively utilizing chemically polished waste phosphoric acid, which comprises the following steps: firstly, diluting the chemically polished waste phosphoric acid until the relative density is between 1.1 and 1.2, slowly adding lime cream, controlling the reaction temperature to be between 50 and 80 DEG C, adjusting the pH value to be between 2.8 and 3.0, and filtering to obtain deposit, namely fertilizer calcium hydrophosphate; and secondly, continuously adding the lime cream into filtrate obtained in the first step, controlling the reaction temperature to be between 50 and 60 DEG C and the pH value of the reaction endpoint to be between 6.5 and 6.8, and filtering to obtain deposit, namely feed-grade calcium hydrophosphate. The method mainly produces phosphorus-containing products in a form of calcium hydrophosphate, generates a small quantity of sludge during reaction and even does not generate the slurry, reduces the landfill cost, achieves secondary economic benefit, has simple production process, low cost and high utilization rate of phosphorus, simultaneously realizes emission meeting the standard of TP, and is easy to realize mass production.

Owner:SHENZHEN SHENTOU ENVIRONMENT TECH CO LTD

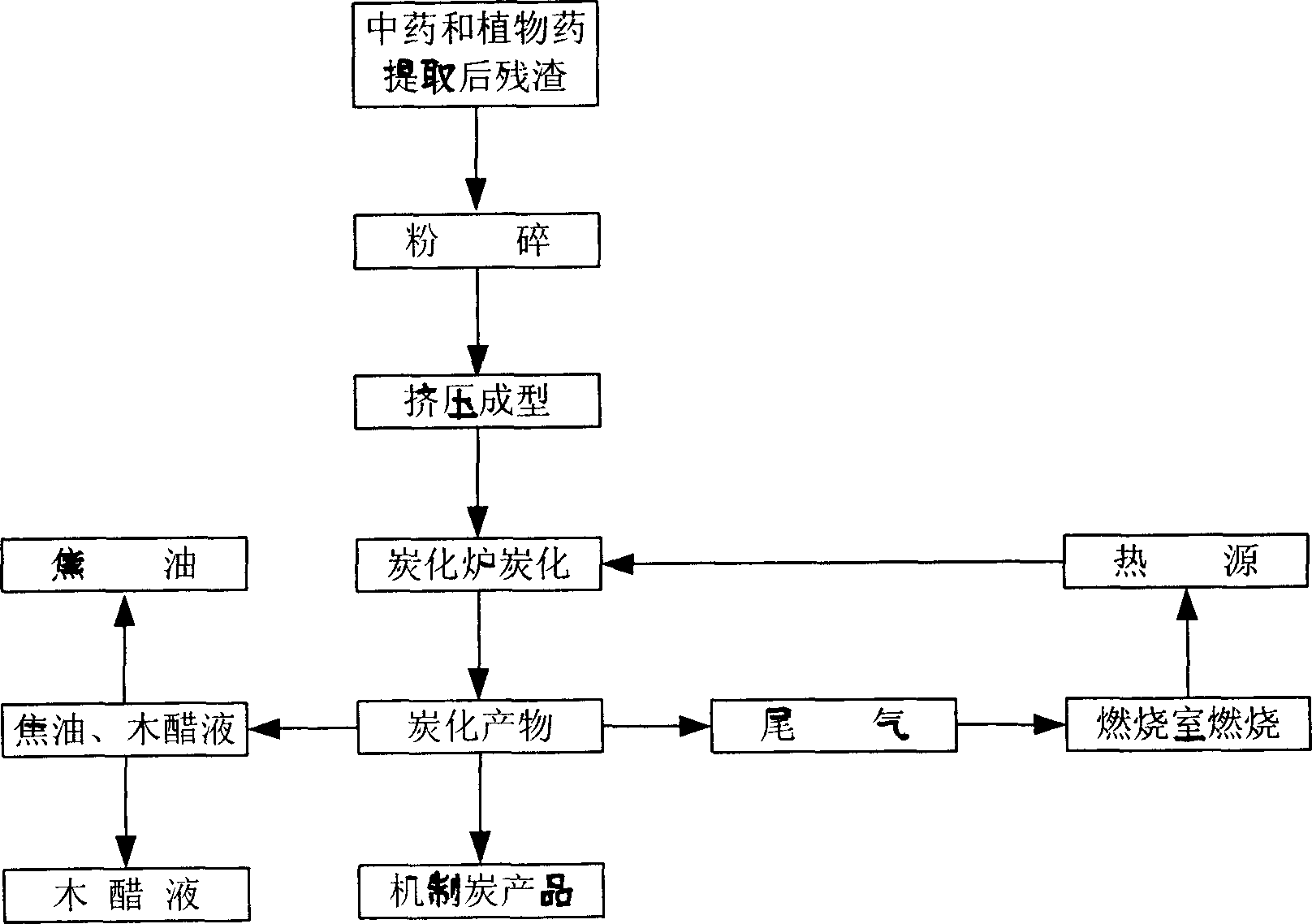

Method for manufacturing machine processed charcoal by utilizing Chinese medicinal or herbal drug to extract solid waste

InactiveCN1803981AReduce energy consumptionReduce manufacturing costBiofuelsSpecial form destructive distillationCombustion chamberThree stage

The disclosed preparation method for charcoal comprising: crushing the solid waste from extracted traditional drug or plant to extrude into bar-form; loading the product into retort for charring reaction with three stages for 10-30min at 120Deg, 200-400min at 120-350Deg and 100-300min at 350-450Deg, respectively. Wherein, firing the exhaust gas in combustion chamber to provide heat source. This invention has yield rate as 40-55% with low energy consumption and little pollution.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

Treatment method of heavy metals in desulfurization waste water

InactiveCN103332810AAvoid secondary pollutionAvoid leachingMultistage water/sewage treatmentFerrous saltsSorbent

The invention discloses a treatment method of heavy metals in desulfurization waste water, and belongs to the technical field of waste water treatment. A combination method of chemical precipitation and physical adsorption treatment is adopted to remove the heavy metals in the desulfurization waste water. The chemical precipitation method uses a ferrite precipitation method that a process condition is controlled by adding ferric and ferrous salts into desulfurization slurry, so that various metal ions such as Cd, Pb, Hg, Cu, Zn, Cr and Ni in the waste water form an insoluble composite ferrite; after aging for a period of time, a solid-liquid separation means is used to achieve the object of removing the heavy metal ions; a natural adsorbent is used for adsorbing the residual heavy metals in the desulfurization waste water, therefore the discharge standard of the heavy metal ions in the desulfurization waste water is achieved. The method has the advantages of simple process, good sediment stability, high removal efficiency of heavy metals and good environmental benefits, and effectively solves the secondary pollution problem of heavy metals.

Owner:WUHAN UNIV

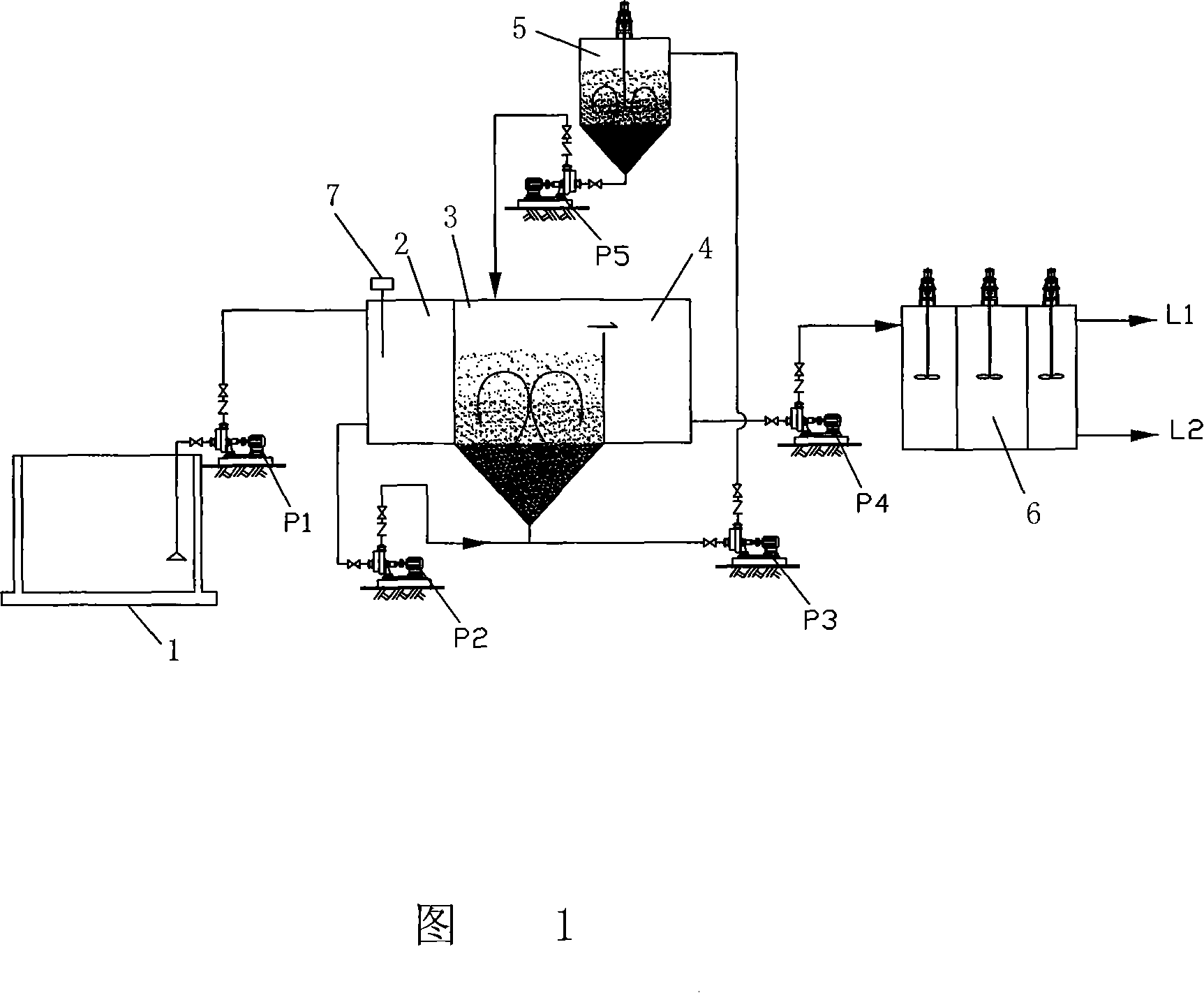

Process and apparatus for treating waste water containing metal complex

InactiveCN101088936AEasy to handleLow costWaste water treatment from metallurgical processMultistage water/sewage treatmentIron powderFluidized bed

The process of treating waste water containing metal complex includes: regulating pH value to 2-4 and adding H2O2, contacting with iron powder in a fluidized bed reactor to produce displacement reaction and complex eliminating reaction, adding alkali in a deposition tank one deposit metal ion, and separating supernatant and the lower precipitate. The process can prevent the aggregation and deactivation of iron powder in the reaction, and has greatly raised reaction efficiency, low cost and high waste water treating effect.

Owner:ZHEJIANG UNIV

Ammonia removal method by ammonia nitrogen wastewater membrane integration

ActiveCN103086453AAchieve emission standardsSolve the reuse problemWater contaminantsWater/sewage treatment bu osmosis/dialysisResource utilizationTwo step

The invention belongs to the technical field of wastewater ammonia removal, and particularly relates to a technical method for efficient membrane ammonia removal treatment on industrial high-ammonia containing wastewater by applying an integration membrane. According to the integration membrane ammonia removal method, a vacuum membrane ammonia removal and membrane absorption ammonia removal combined two-step ammonia removal method is used for realizing efficiently low-consumption ammonia removal of wastewater. The technical method comprises the steps of: firstly removing about 80% of ammonia nitrogen in the wastewater by using a vacuum membrane ammonia removal method, and then removing about 99% of remained ammonia nitrogen in the wastewater by adopting a membrane absorption ammonia removal method, thus the total ammonia removal efficiency exceeds 99%. Ammonia removed by the vacuum membrane ammonia removal method is used for preparing about 15% ammonia water by adopting an absorption method and is recycled for production. An acidic ammonia containing waste absorption liquid generated by adopting the membrane absorption ammonia removal method returns to a vacuum membrane ammonia removal unit and is mixed with a raw material, and then vacuum ammonia removal is carried out. The method has the advantages of having high ammonia nitrogen removal rate, realizing resource utilization, solving the problem of recycling the acidic ammonium containing waste liquid existing in a membrane absorption ammonia removal method, and avoiding secondary pollution.

Owner:湖南海铭特种膜有限公司

Resource recycle method for waste tubes

InactiveCN101604606AEfficient recyclingLow costGlass recyclingSolid waste disposalRecovery methodReverse current

The invention relates to a resource recycle method for waste tubes, and the technique method is as follows: pouring the waste tubes into a crusher for crushing under the negative pressure; delivering the mixture after crushing into a material receiving box; sucking the waste gas into a condensing system by an exhaust fan arranged on the top of the material receiving box for separating mercury and fluorescent powder; wherein, mercury can be recycled by a vacuum heater; the glass after crushing and the metal materials are sent to a magnetic separator for separating the glass from the metal; the separated metal is sent to a washing machine for recycling the metal by third-stage reverse current spraying washing. The invention can effectively recycle the fluorescent powder, mercury and metal, thus realizing up-to-standard discharge of waste water, waste liquid and waste gas.

Owner:HUIZHOU DINGCHEN IND DEV

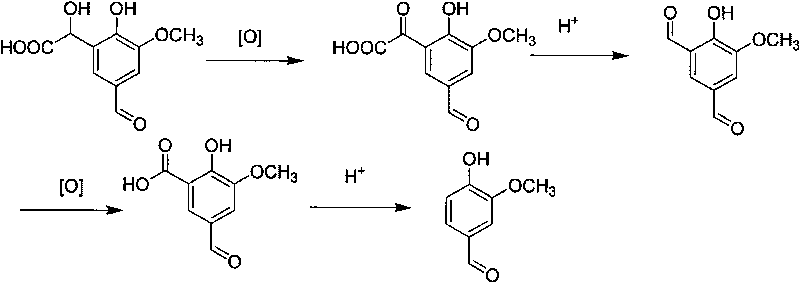

Method for converting 2-hydroxyl-3-methoxy-5-aldehyde mandelic acid into vanillin

InactiveCN101712605AAchieve emission standardsOrganic compound preparationWater/sewage treatment by ion-exchangeGlyoxylic acidEconomic benefits

The invention relates to a method for converting 2-hydroxyl-3-methoxy-5-aldehyde mandelic acid into vanillin, which sequentially comprises the steps of adsorbing by macroporous resin, oxidizing, acidizing, reoxidizing, reacidizing, and the like. The method integrates wastewater treatment and reactant recycling and realizes the wastewater treatment by the macroporous resin. Aromatic compounds in the wastewater are recycled by combining an oxidizing and acidizing process to produce a target product-vanillin. The invention realizes the standard discharge of the wastewater, realizes the recycling of the wastewater generated during producing the vanillin by a glyoxylic acid method, and improves economic benefits.

Owner:JIAXING ZHONGHUA CHEM

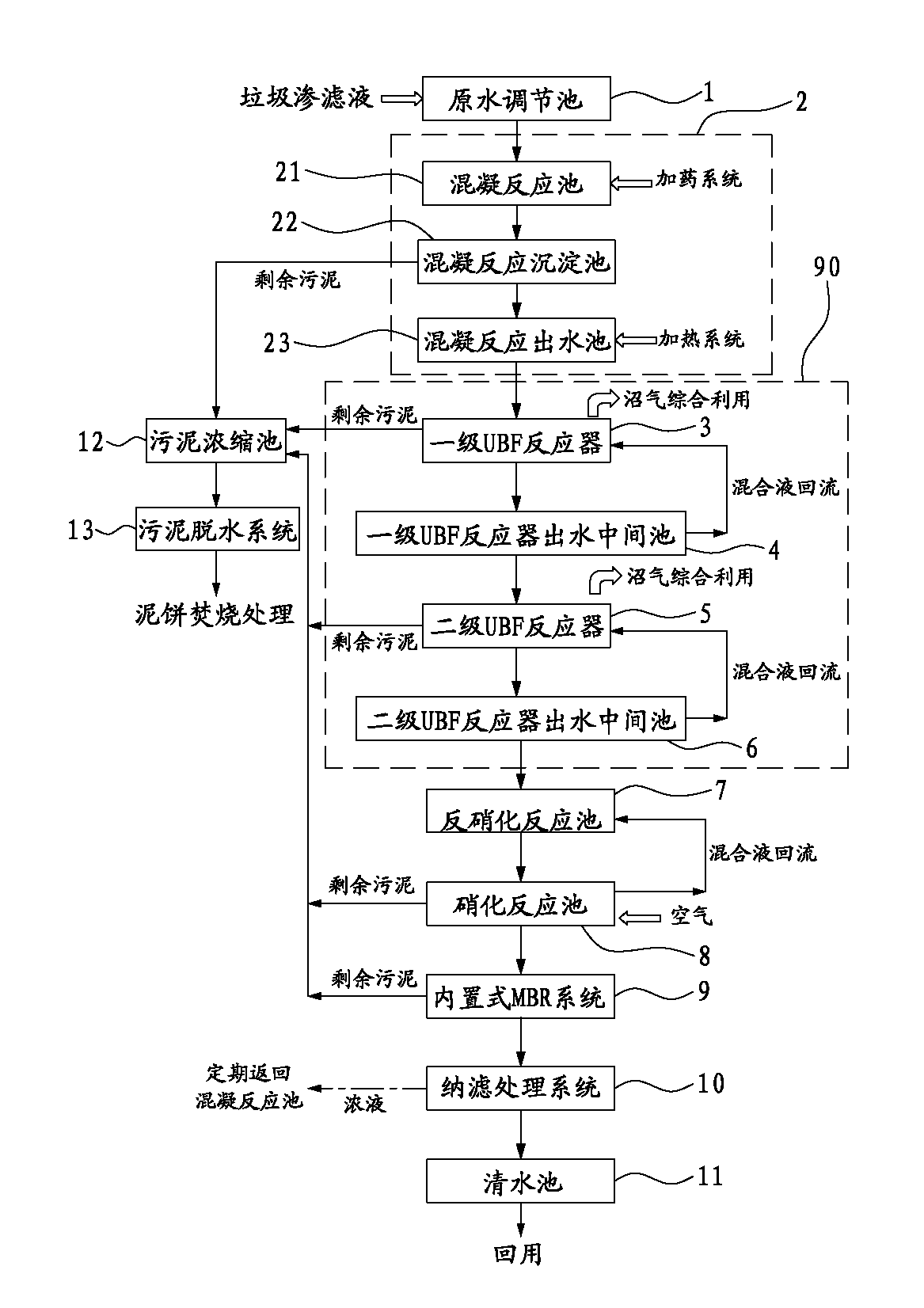

Treatment method for waste incineration power plant leachate and device thereof

ActiveCN102795746AGuaranteed concentrationGuaranteed processing efficiencyTreatment with anaerobic digestion processesTreatment with aerobic and anaerobic processesSludgeFiltration

The invention discloses a treatment method for waste incineration power plant leachate and a device thereof. The waste leachate is put into a raw water regulation pool, a coagulation reaction system, a first-stage UBF reactor, a first-stage UBF reactor effluent middle pool, a second-stage UBF reactor, a second-stage UBF reactor effluent middle pool, a denitrification pool, a nitration pool, a built-in MBR system, and a nanofiltration system for processing. According to the invention, the UBF reactor effluent middle pools are arranged behind the UBF reactors for mud-water separation and backflow after the UBF reactor effluent, guaranteeing the mud concentration in the UBF reactors and treatment effeciency. Using a built-in MBR membrane module placed in a biochemical pool helps to reduce floor space and lower energy consumption. The use of physical and chemical, biochemical, and membrane filtration technology association for the direct treatment of waste leachate can reach recycling with zero emission.

Owner:NEWSKY CHINA ENVIRONMENT & TECH

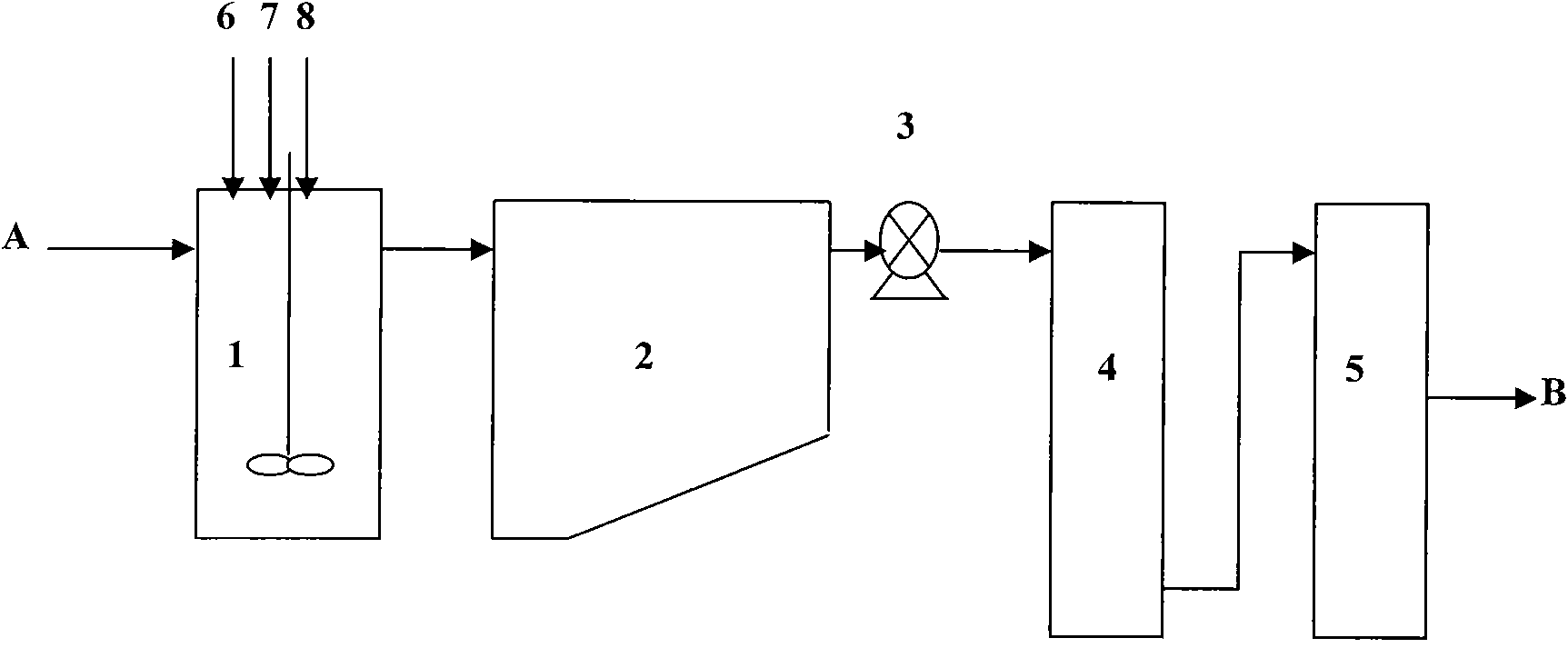

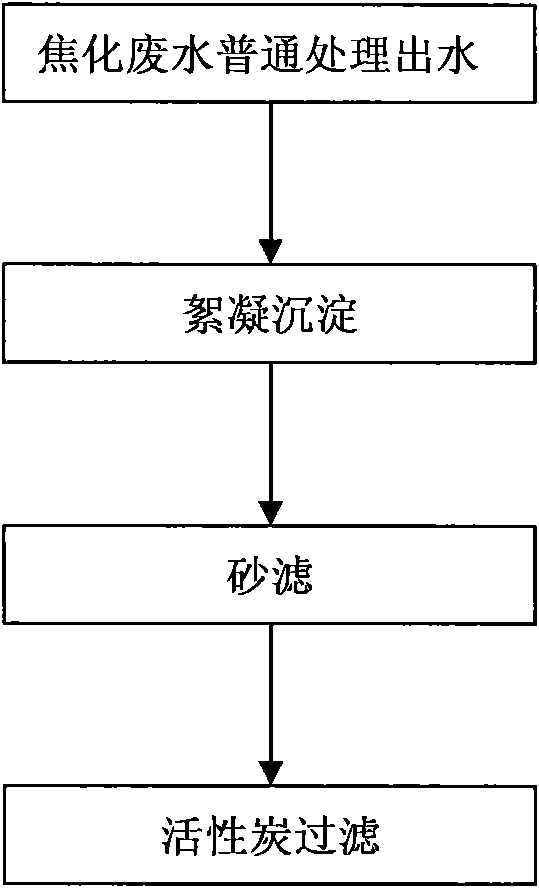

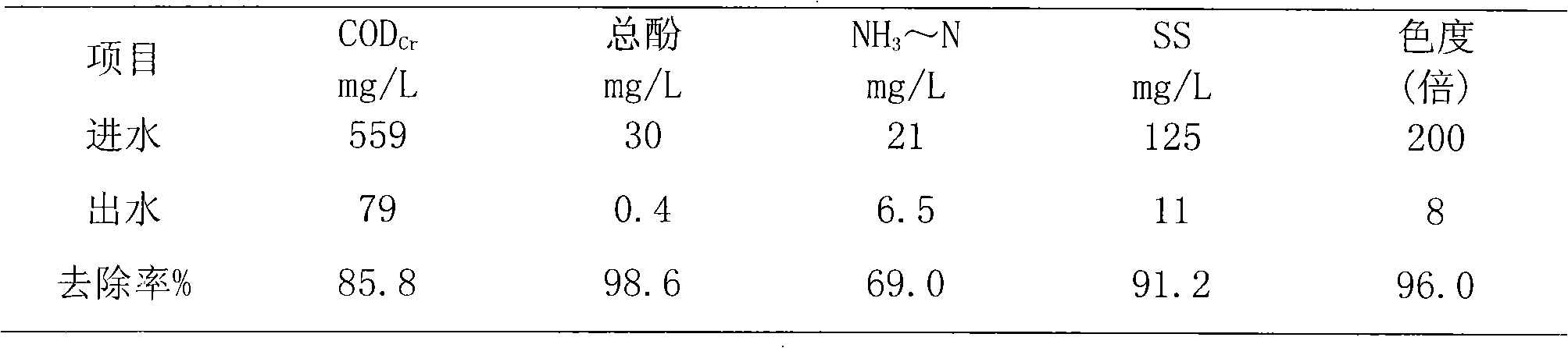

Coking wastewater treatment device and coking wastewater posttreatment method

InactiveCN101987762AReduce CODAchieve emission standardsMultistage water/sewage treatmentWater/sewage treatment by neutralisationChemical oxygen demandActivated carbon filtration

The invention relates to a coking wastewater treatment device which comprises a flocculation reaction tank, wherein the flocculation reaction tank is connected with a flocculation settling pond, the flocculation settling tank is connected with a sand filter, and the sand filter is connected with an active carbon filter. A coking wastewater posttreatment method comprises the steps of: adding an efficient composite flocculating agent, a polymer coagulant aid and a mineral powder absorbing agent into the coking wastewater subjected to common treatment; regulating the pH value to be 8-9 with alkali, wherein the flocculation reaction settling time is 1-2.5h; and then carrying out sand leaching and active carbon filtration, wherein the effluent quality fully reaches the standard for emission or recycling. The COD (Chemical Oxygen Demand), the total phenol, the ammonia nitrogen, SS (Suspended Substances) and the chromaticity in the coking wastewater subjected to the treatment with the method are respectively reduced by above 80 percent, 90 percent, 60 percent, 90 percent and 95 percent; and by treating the coking wastewater according to the invention, the purposes of good effect, simple operation and convenience in management are achieved.

Owner:SHANGHAI WEILAI ENTERPRISE

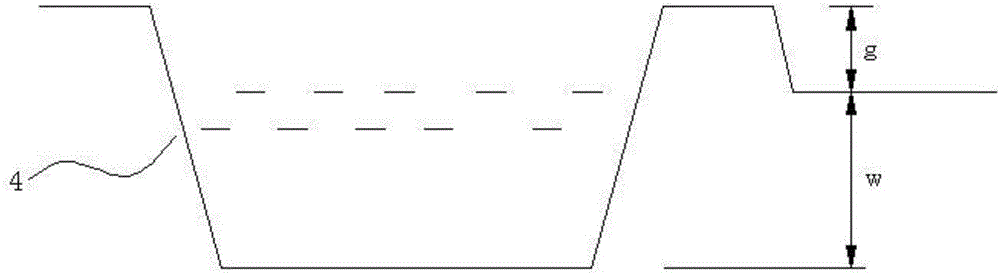

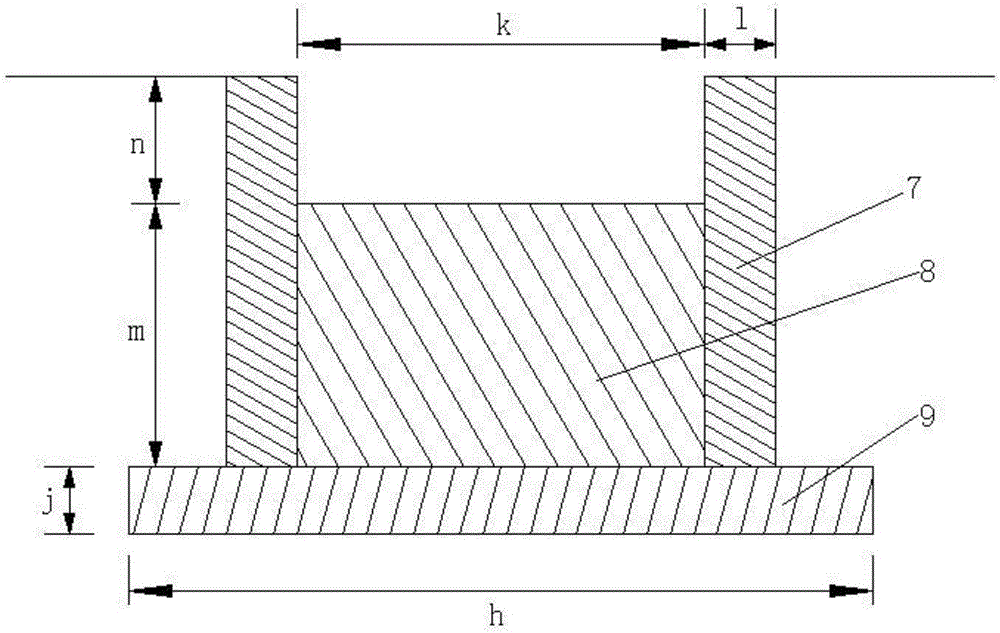

Method for treating artificial wetland breeding wastewater by integration of straw, biochar and organism

InactiveCN105967328ASolve the problem of environmental pollutionPromote emission standardsTreatment with anaerobic digestion processesSustainable biological treatmentBiologyMyriophyllum verticillatum

The invention discloses a method for treating artificial wetland breeding wastewater by integration of straw, biochar and organism. According to the method, breeding wastewater passes an anaerobic fermentation tank, three substrate tanks and four wetland tanks in sequence; a substrate channel is arranged between the anaerobic fermentation tank and the first substrate tank, between two adjacent substrate tanks, as well as between the third substrate tank and the first wetland tank; straw is laid in the substrate channels and the substrate tanks; wild plants are added onto the straw; a water blocking drop water dam is arranged at the water outlet of each substrate tank; the wetland tanks are surrounded by ridges; two adjacent wetland tanks are separated through one ridge; overflow openings of which the cross sections are in the shape of an inverted trapezoid are formed in the upper end surfaces of two ridges of each wetland tank; myriophyllum verticillatum is added into each wetland tank; a biochar layer is arranged in front of the overflow opening, near discharged water, of the last wetland tank. According to the method for treating artificial wetland breeding wastewater by integration of straw, biochar and organism, the water quality of the end discharged water is greatly superior to the water pollutant discharge standard of the national breeding industry.

Owner:SHAOXING UNIVERSITY

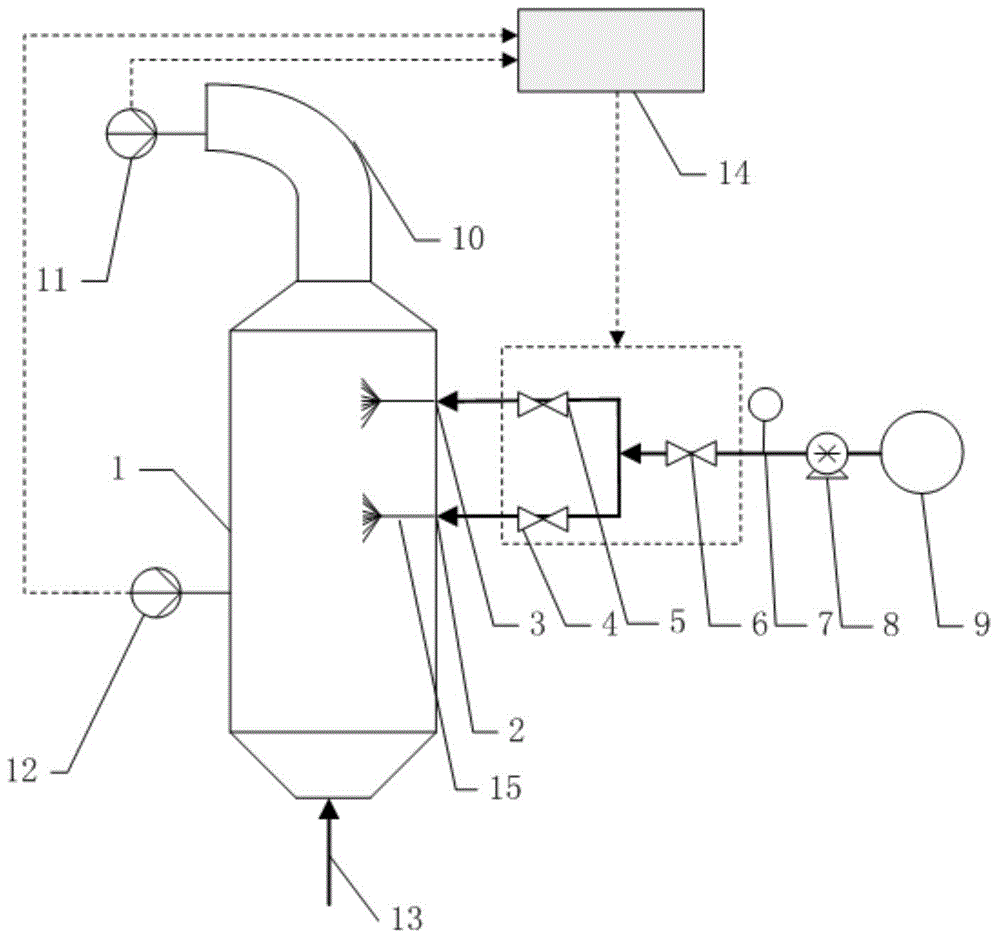

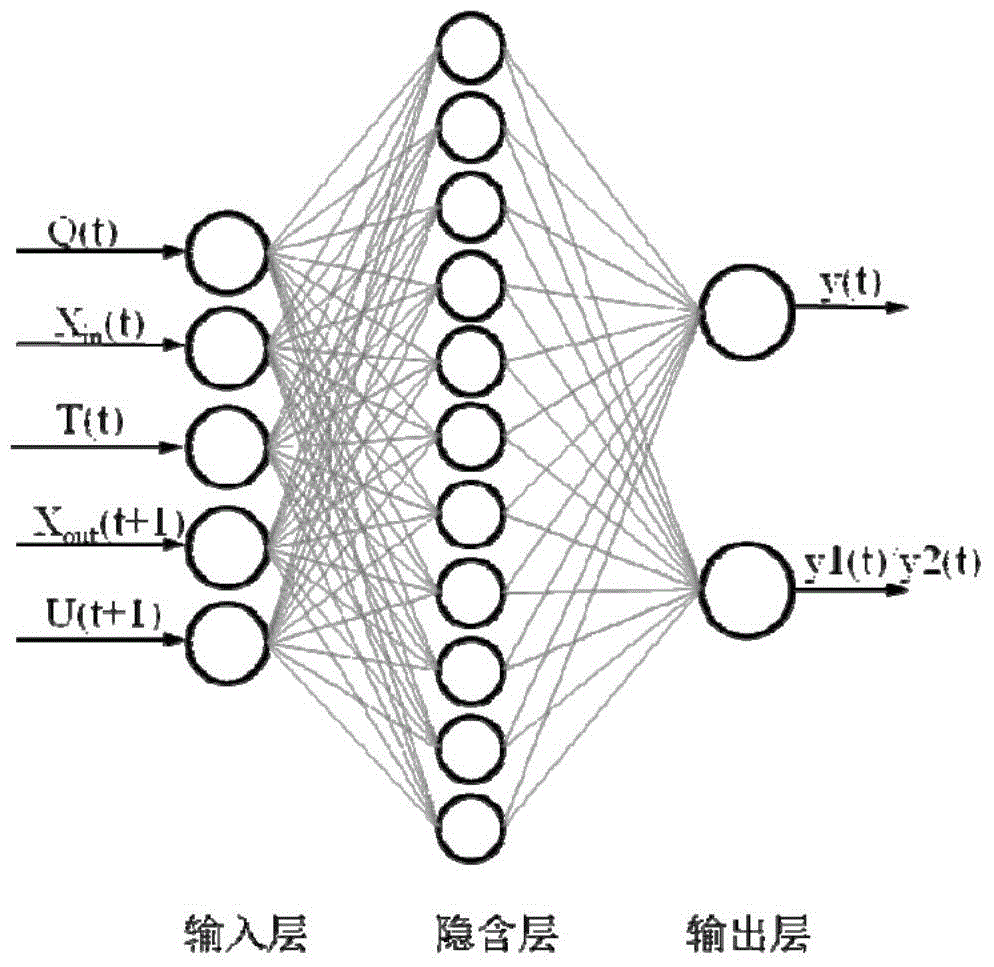

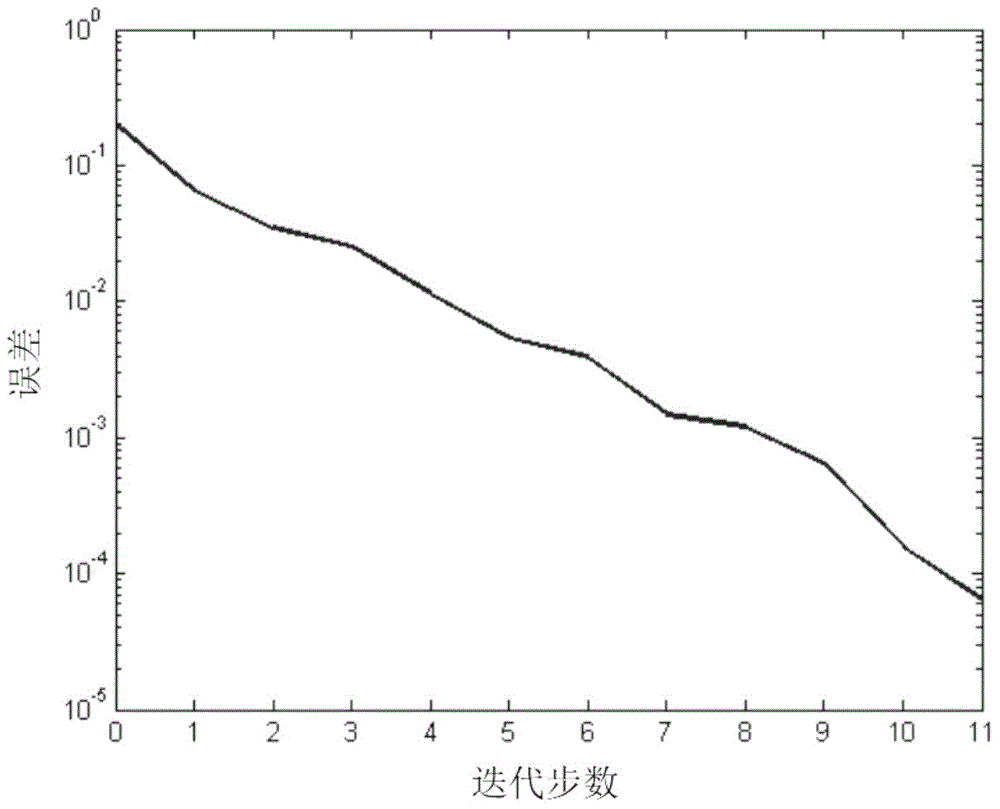

Ammonia spraying amount controlling method for SNCR (selective no catalytic reduction) flue gas denitrating system for cement manufacturing

InactiveCN104793651AReduce escapeAchieve emission standardsFlow control using electric meansProportional controlFlue gas

An ammonia spraying amount controlling method for an SNCR (selective no catalytic reduction) flue gas denitrating system for cement manufacturing includes the steps of firstly, arranging at least two layers of ammonia spraying areas in a cement kiln decomposing furnace; secondly, arranging a temperature sensor, a glue gas flow detecting sensor and a first NOx concentration detecting sensor at an entrance of the ammonia spraying areas, and arranging a second NOx concentration detecting sensor and an NH3 concentration detecting sensor at an exit of the cement kiln decomposing furnace; thirdly, by the aid of an ammonia spraying amount controlling system which is provided with an ammonia spraying amount BP (back propagation) neural-network predicting model, giving a total ammonia spraying amount and an ammonia spraying amount proportion between each two layers of the ammonia spraying areas via the ammonia spraying amount BP neural-network predicting model according to received flue gas temperature information, flue gas flow information and concentration information of NOx in flue gas at an entrance of the cement kiln decomposing furnace and concentration information of the NOx in the flue gas and NH3 concentration information at the exit of the cement kiln decomposing furnace, and controlling states of a total ammonia flow adjusting valve and branch ammonia flow adjusting valves according to the total ammonia spraying amount and the ammonia spraying amount proportions among the layers of the ammonia spraying areas to achieve real-time controlling of the ammonia spraying amount.

Owner:SICHUAN UNIV

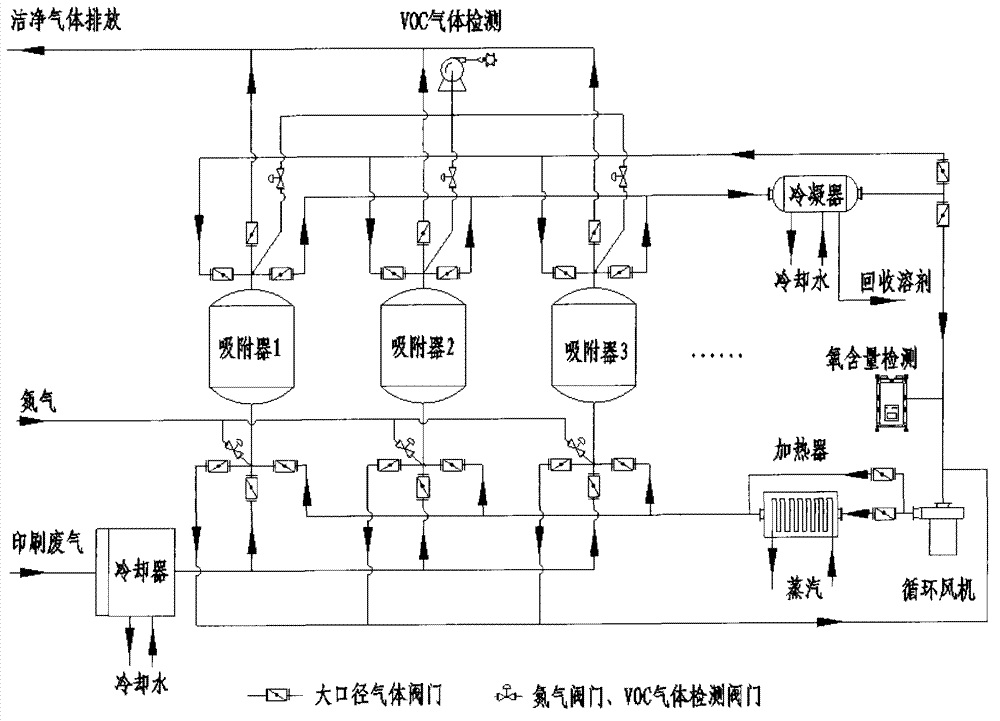

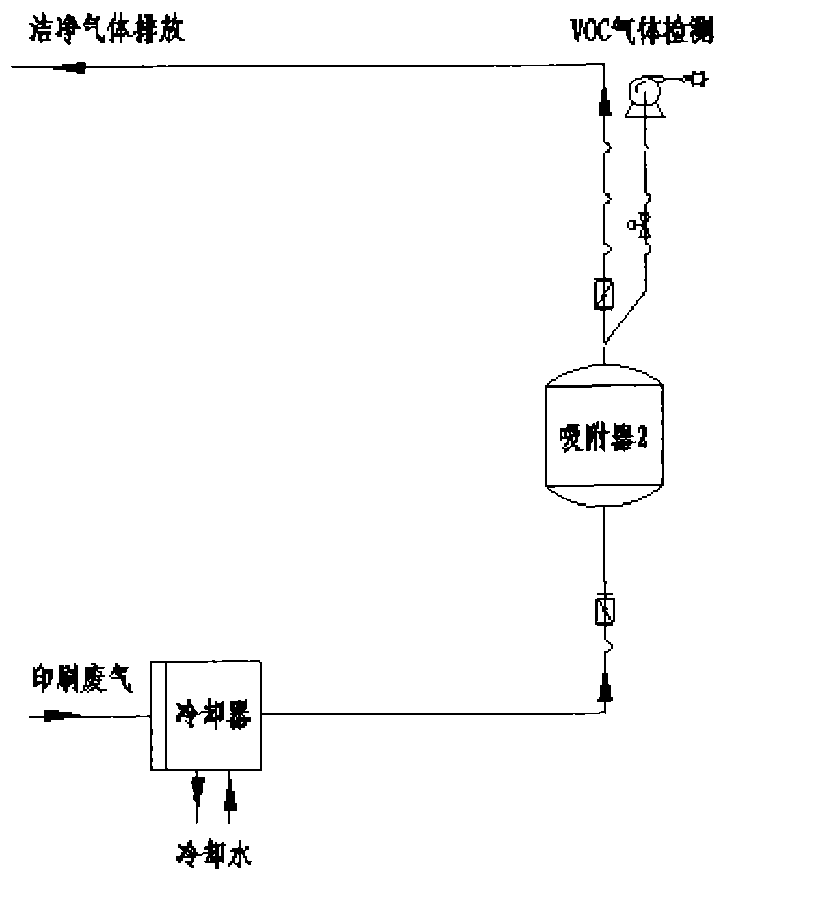

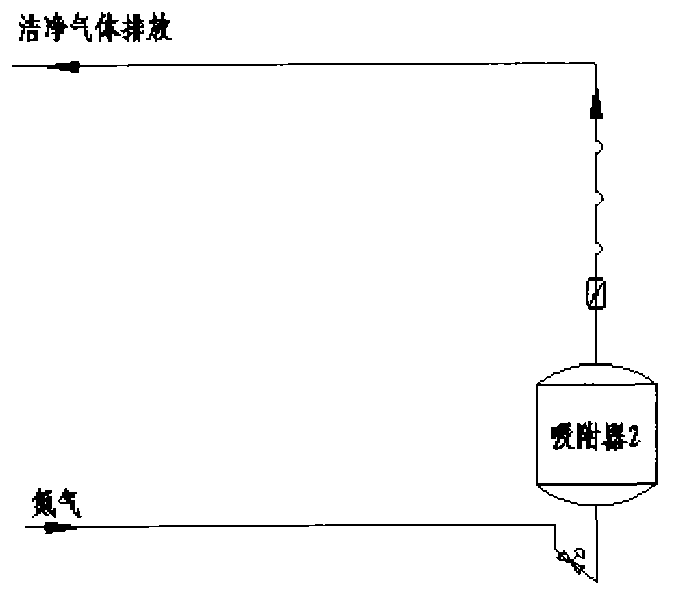

Secondary-adsorption organic waste gas recovering method

ActiveCN102805987AHigh recovery rateSolve the problem of decomposition and deteriorationDispersed particle separationDecompositionDesorption

The invention provides a secondary-adsorption organic waste gas recovering method, which is characterized in that two or more than two adsorbers sequentially and alternately carry out the processes of waste gas adsorption, secondary adsorption, desorption condense recovery, desorption regeneration and the like, desorption gas is not externally exhausted, the solvent recovery rate is improved, the standard reaching discharge of the tail gas treatment in the whole process is realized, and the problems of solvent decomposition and degeneration caused by repeated heating are solved.

Owner:洛阳印通环保科技有限公司 +1

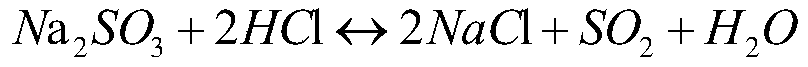

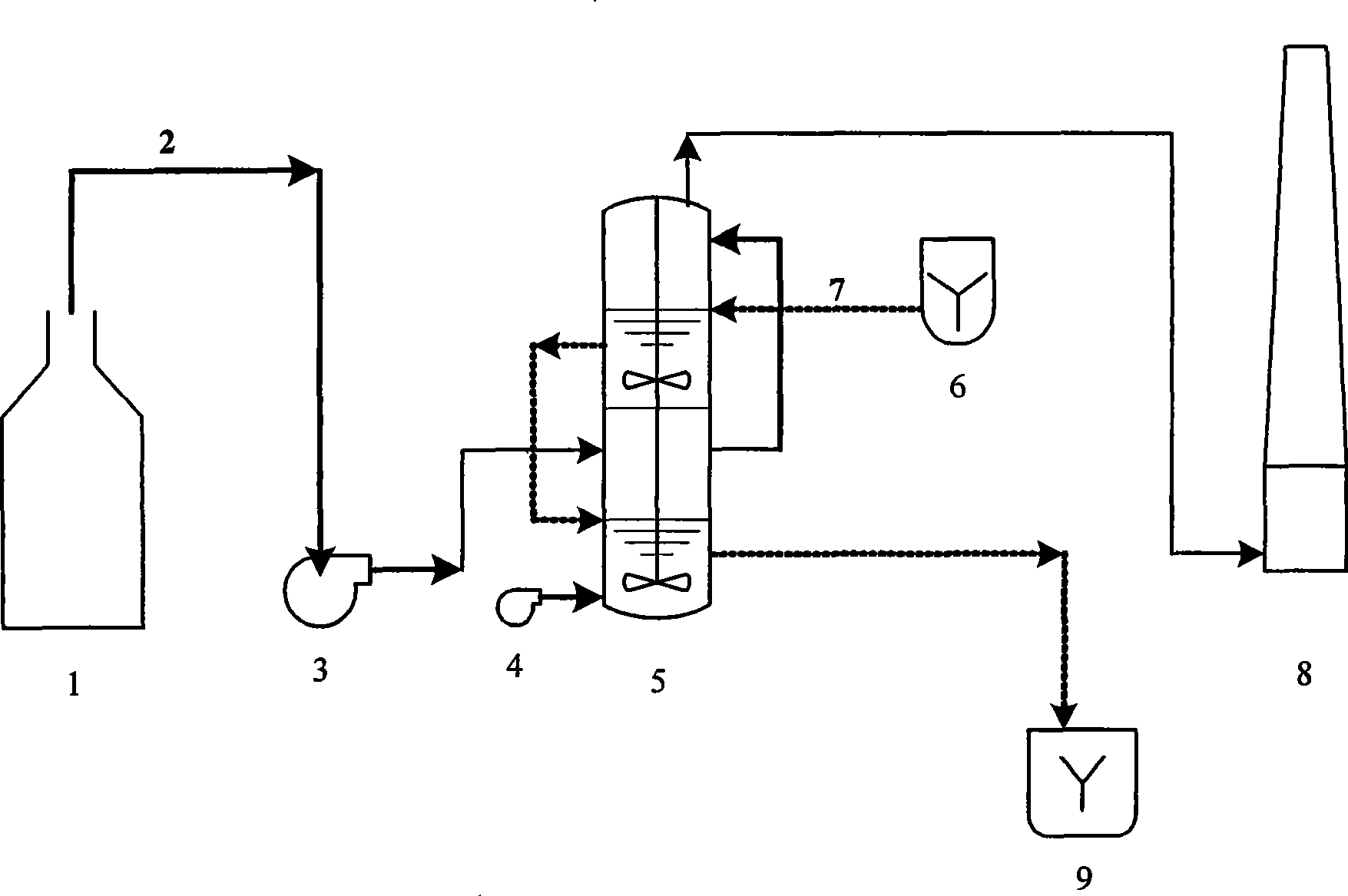

Ship exhaust gas desulfurization wash water treatment process and treatment system based on sodium alkali method

ActiveCN104326604AAchieve emission standardsSave spaceFatty/oily/floating substances removal devicesWater contaminantsFlocculationWater treatment system

The invention discloses a ship exhaust gas desulfurization wash water treatment process based on a sodium alkali method. The process comprises steps of neutralization-oxidization-conditioning, air flotation-flotation selection solid and liquid separation, filtration purification and the like. The invention also discloses a ship exhaust gas desulfurization wash water treatment system based on the sodium alkali method. By the abovementioned processing steps, the process and the system can be used for implementing oxidization of sulfite in wash water, regulation of the pH value, flocculation and air flotation of particles and impurities and adsorption of fine-dispersed emulsified oil taken by the wash water so that the quality of the discharged ship wash water is ensured to satisfy the requirements of IMO on indexes such as emission pH, PAH, turbidity, temperature and the like of the wash water of a ship exhaust gas cleaning system.

Owner:中国船舶集团有限公司第七一一研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com