Secondary-adsorption organic waste gas recovering method

A secondary adsorption and organic waste gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as solvent decomposition and deterioration, and achieve the effect of improving solvent recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

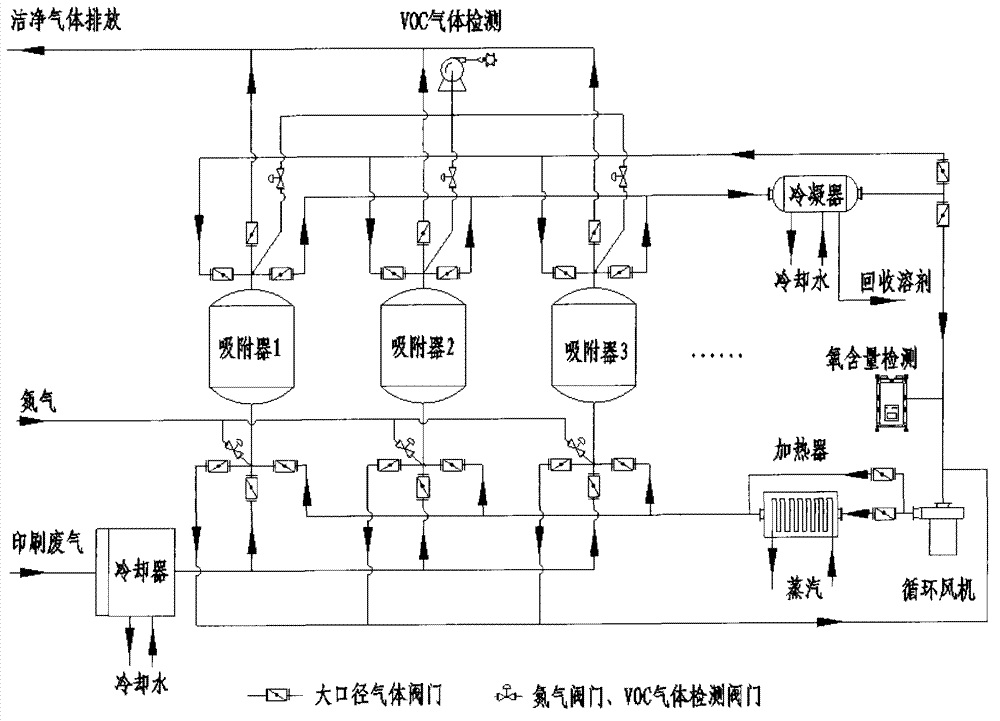

[0069] This embodiment takes three adsorbers as an example to illustrate the technical solution.

[0070] Since the three adsorbers work in different working conditions, the initial state of the specified cycle recovery step is: adsorber 3 has completed regeneration and desorption and is ready to start exhaust gas adsorption, adsorber 1 has completed desorption solvent condensation recovery, and adsorber 2 The exhaust gas adsorption is almost complete. The following begins the introduction of recycling steps:

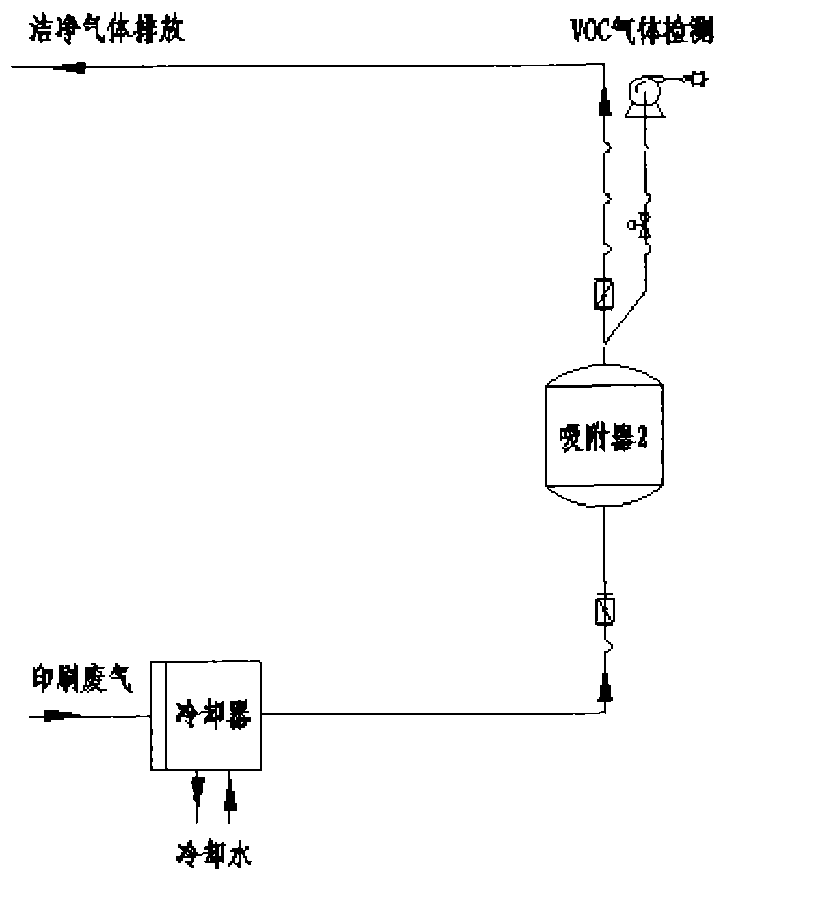

[0071] ①Exhaust gas adsorption: (see figure 2 ) The adsorber 2 stops working after the adsorption is completed, and the adsorber 3 starts to adsorb;

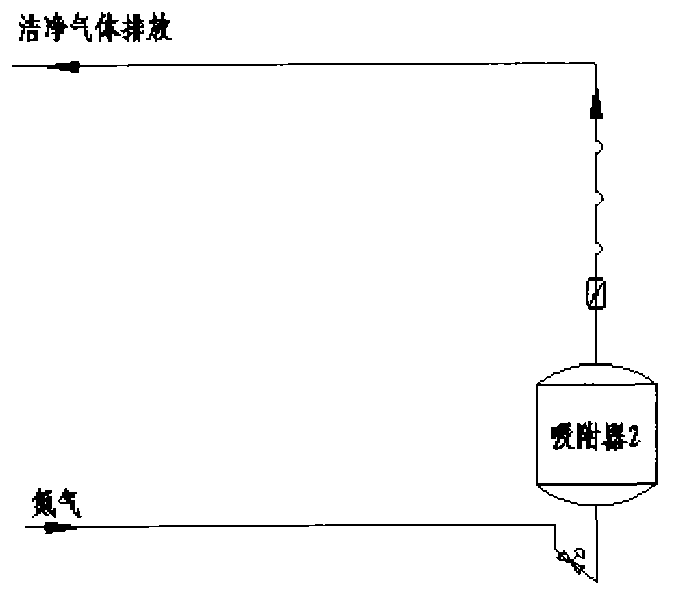

[0072] ② Flame retardant gas replacement: (see image 3 ) The air in the adsorber 2 is replaced by a flame retardant gas;

[0073] ③ regeneration desorption and secondary adsorption: (see Figure 4 ) Adsorber 1, condenser, adsorber 2, circulation fan, and heater form a regenerative desorption and secondary adsorptio...

Embodiment 2

[0085]A recovery system equipped with 5 absorbers of the present invention has been actually applied to the waste gas treatment project of a color flexible packaging printing enterprise.

[0086] Since each adsorber works in different working conditions, the initial state of the specified cycle recovery step is: adsorber 3 and adsorber 4 are in the process of exhaust gas adsorption, and adsorber 5 has completed regeneration and desorption and is waiting to start exhaust gas adsorption. Adsorber 1 has completed the heating and desorption solvent condensation recovery, and the exhaust gas adsorption of adsorber 2 is nearly completed. The introduction of the recycling procedure begins below.

[0087] ①Exhaust gas adsorption: (see figure 2 ) The adsorber 2 stops working after exhaust gas adsorption is saturated, and the adsorber 5 starts exhaust gas adsorption. The exhaust gas enters the adsorber after being cooled by the cooler. The VOC gas detection equipment monitors the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com