Coking wastewater treatment device and coking wastewater posttreatment method

A technology of coking wastewater and treatment equipment, which is applied in the field of water treatment and wastewater treatment, can solve problems such as excessive chromaticity indicators, and achieve the effects of protecting the water environment and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

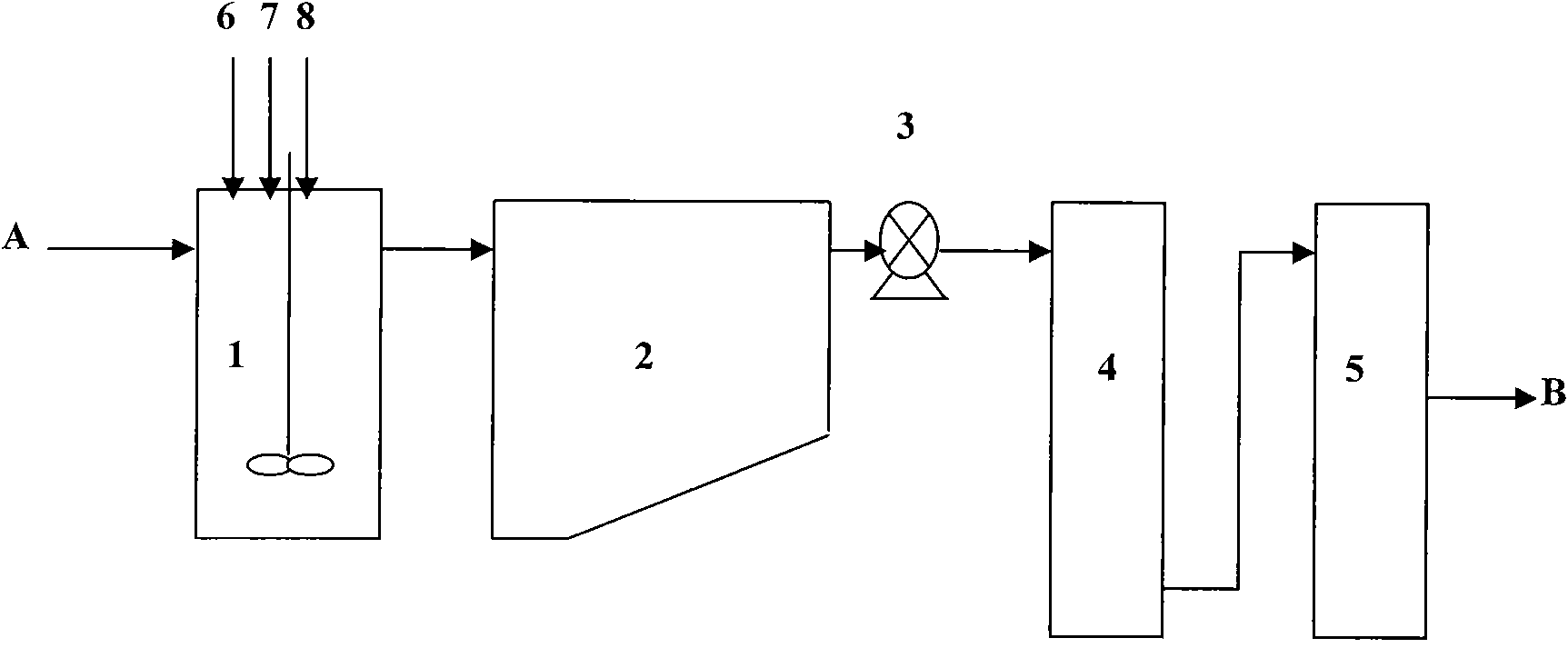

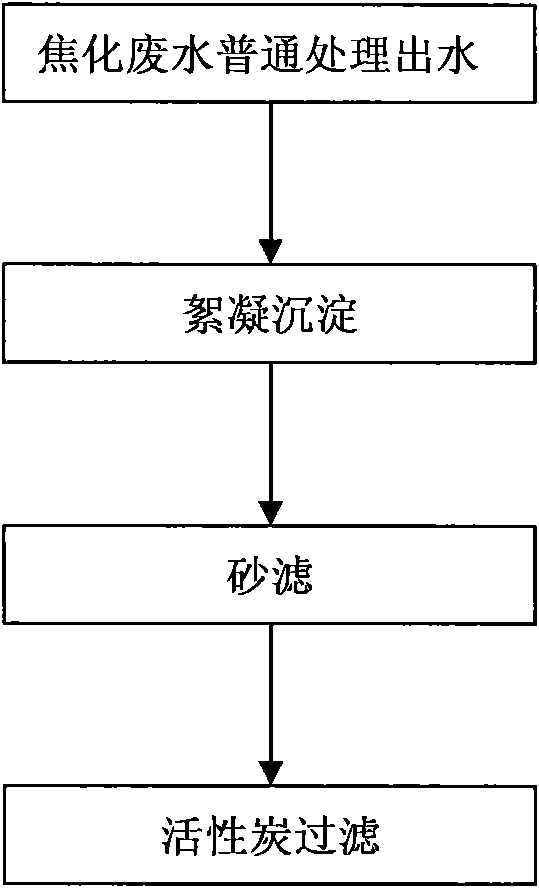

[0036] like figure 1 , figure 2 As shown, (1) Put the coking wastewater A after ordinary biochemical treatment in the coking plant into the flocculation reaction tank 1, add 1000mg / L high-efficiency composite flocculant 6, and the aluminum sulfate and ferrous sulfate in the composite flocculant 6 are based on the ratio of 1: Prepare at a ratio of 1.5, then add 5mg / L coagulant 7 cationic polyacrylamide and 5g / L mineral adsorbent 8 fly ash, and mix for 15 minutes;

[0037] (2) The coking wastewater after the mixed reaction is connected to the flocculation sedimentation tank 2, and the sedimentation residence time is 1.5h;

[0038](3) The water outlet of the flocculation sedimentation tank 2 is pumped into the sand filter 4 by the booster pump 3;

[0039] (4) the sand filter 4 outlet is connected to the active carbon filter 5;

[0040] (5) After the activated carbon filter 5 is tested, discharge it up to the standard or connect it to a reuse pool for reuse.

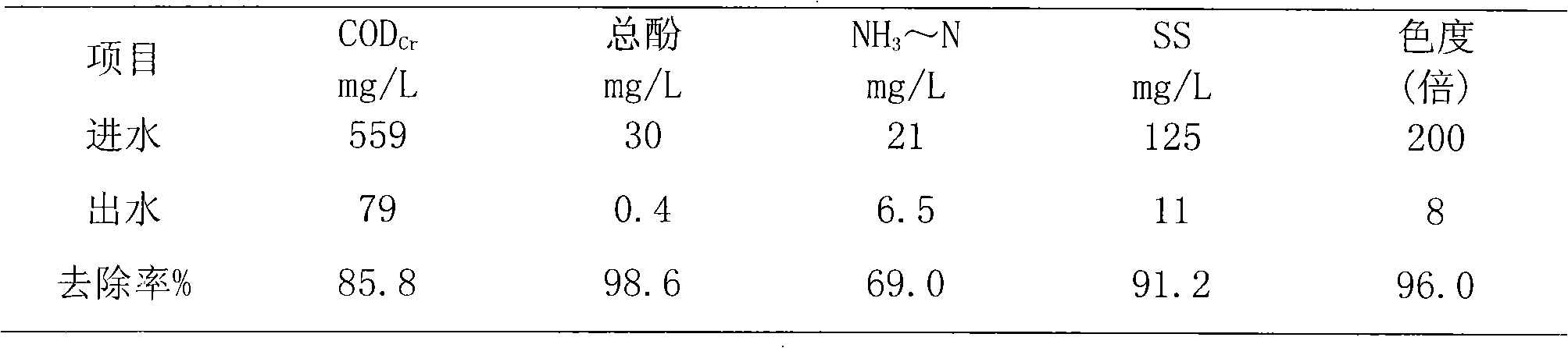

[0041] Coking w...

Embodiment 2

[0045] like figure 1 , figure 2 As shown, (1) Put the coking wastewater A of a coking plant after ordinary biochemical treatment into the flocculation reaction tank 1, and add 1500 mg / L high-efficiency composite flocculant 6, and the aluminum sulfate and ferrous sulfate in the composite flocculant 6 are based on 1 : 4 ratio preparation, then add 7mg / L coagulation aid 7 cationic polyacrylamide and 5g / L mineral powder adsorbent 8 fly ash, mixed reaction 20min;

[0046] (2) The coking wastewater after the mixed reaction is connected to the flocculation sedimentation tank 2, and the settlement residence time is 2h;

[0047] (3) The water outlet of the flocculation sedimentation tank 2 is pumped into the sand filter 4 by the booster pump 3;

[0048] (4) the sand filter 4 outlet is connected to the active carbon filter 5;

[0049] (5) After the activated carbon filter 5 is tested, discharge it up to the standard or connect it to a reuse pool for reuse.

[0050] Coking wastewate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com