Patents

Literature

55 results about "Slow sand filter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

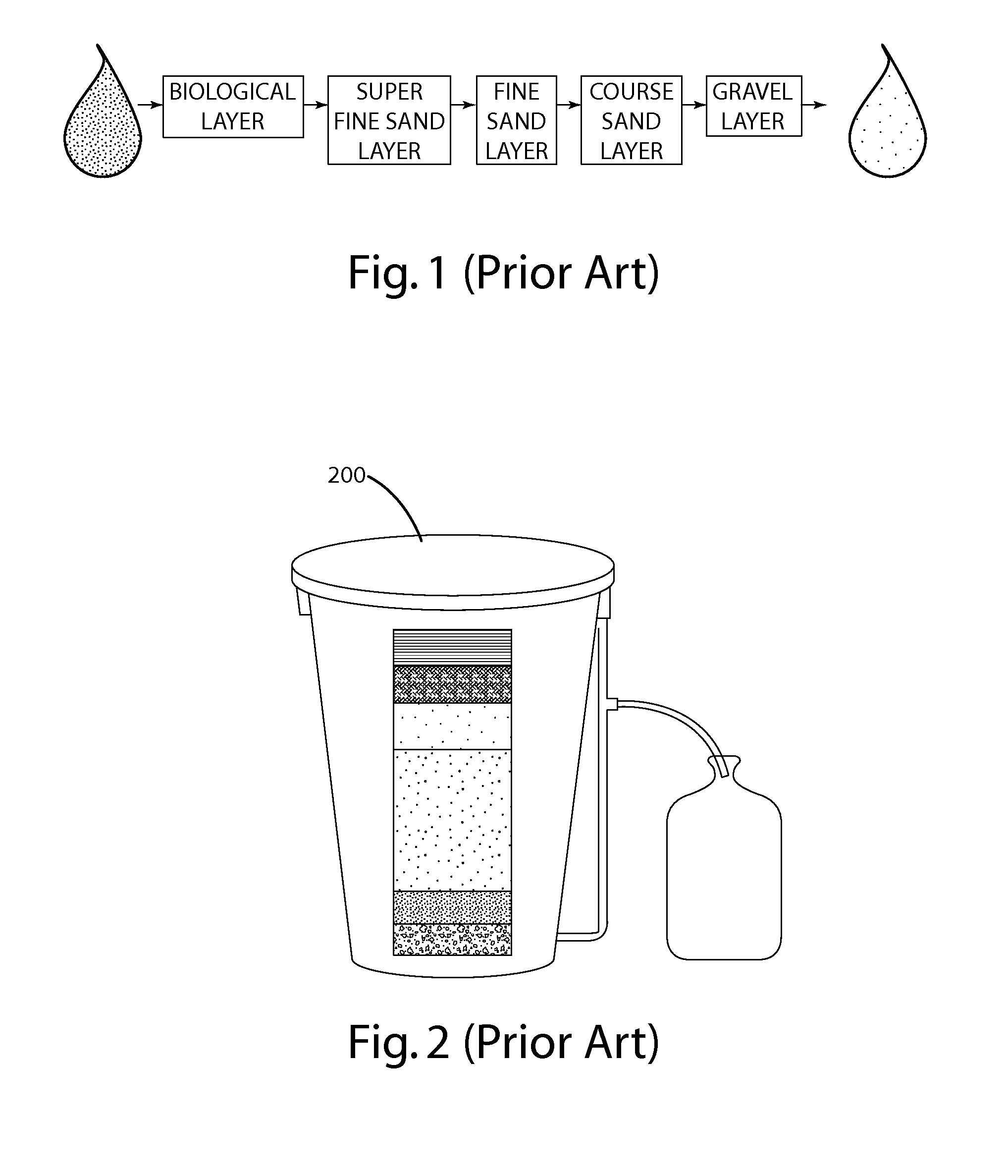

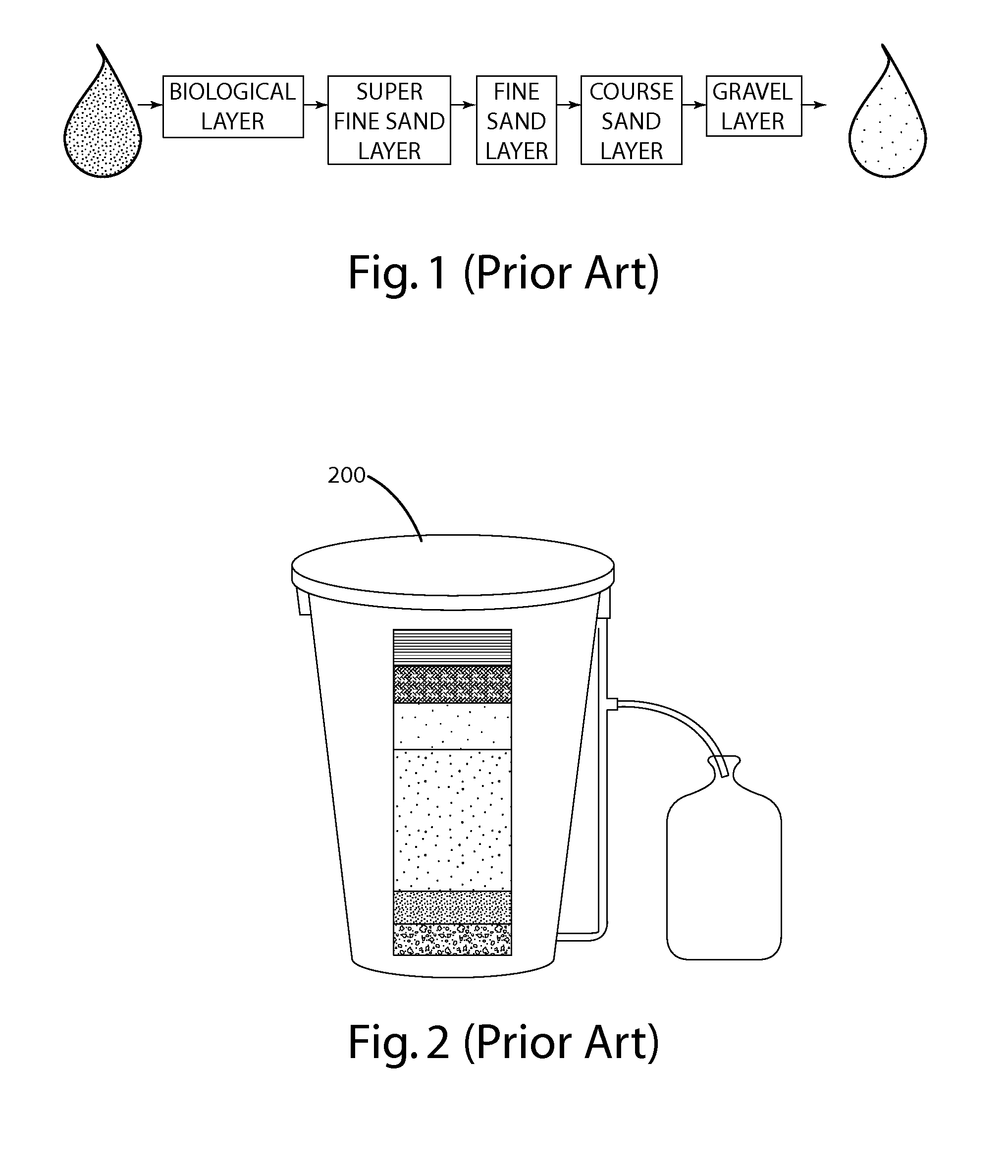

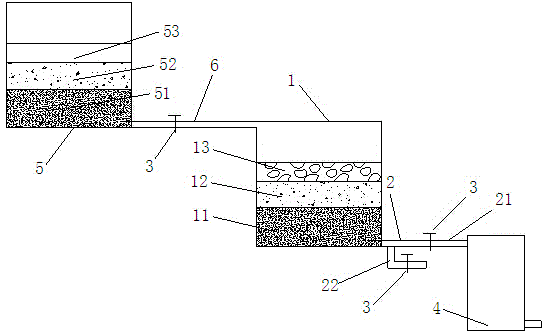

Slow sand filters are used in water purification for treating raw water to produce a potable product. They are typically 1 to 2 metres deep, can be rectangular or cylindrical in cross section and are used primarily to treat surface water. The length and breadth of the tanks are determined by the flow rate desired by the filters, which typically have a loading rate of 200 to 400 litres per hour per square metre (or 0.2 to 0.4 cubic metres per square metre per hour).

Gravity feed water treatment system

ActiveUS20110303589A1Increase flow rateHigh flow rateTreatment using aerobic processesTreatment involving filtrationFlocculationSiphon

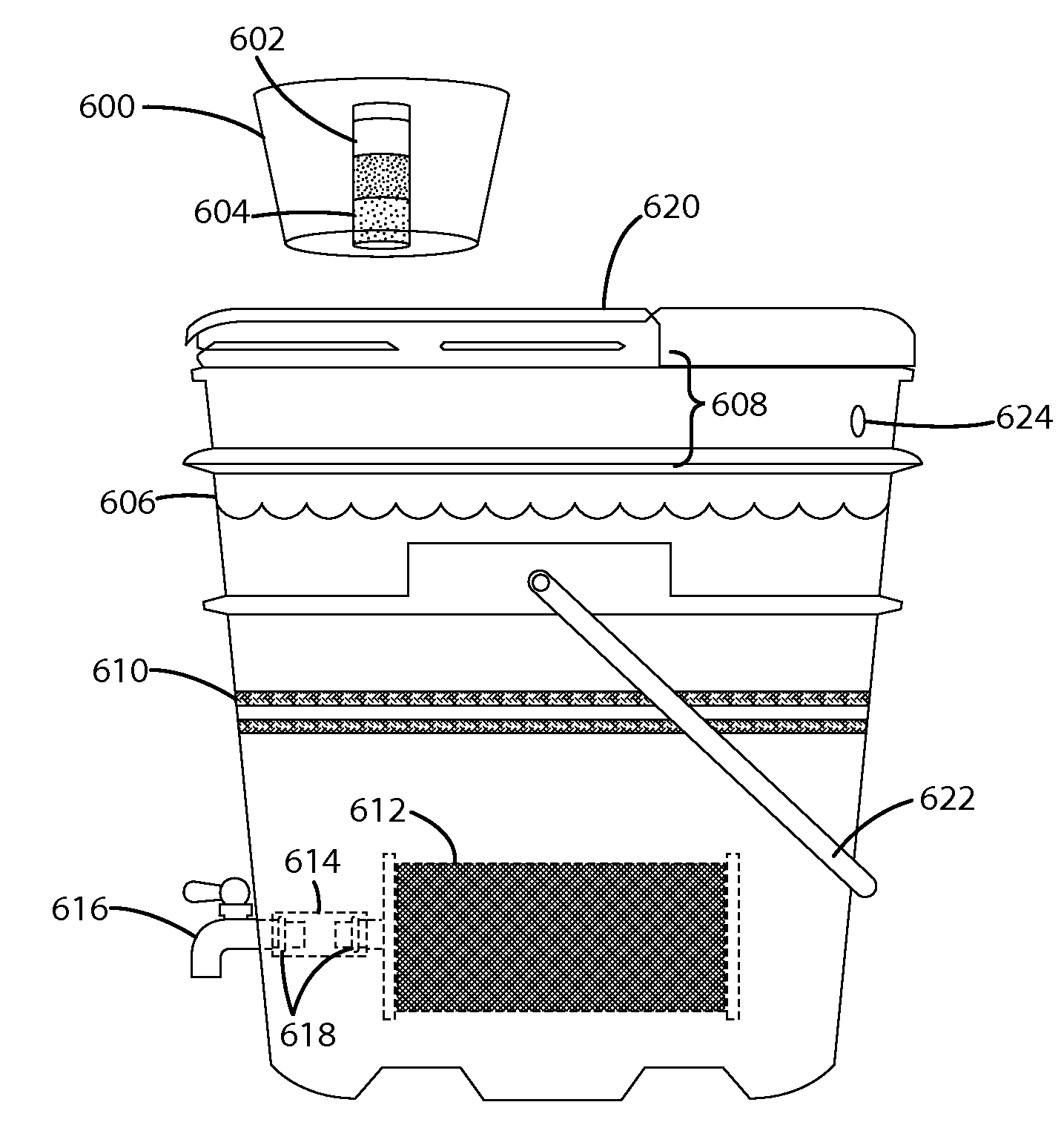

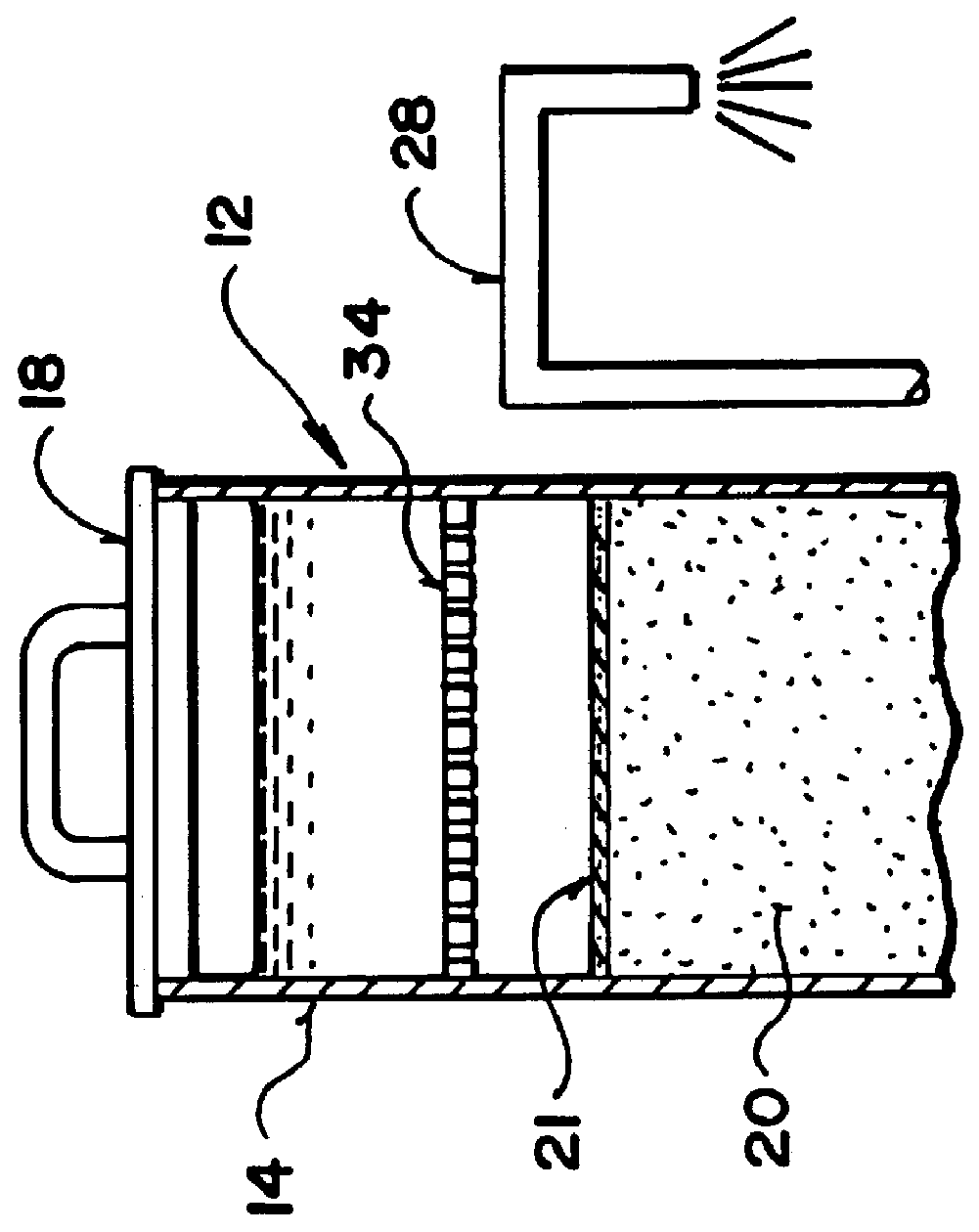

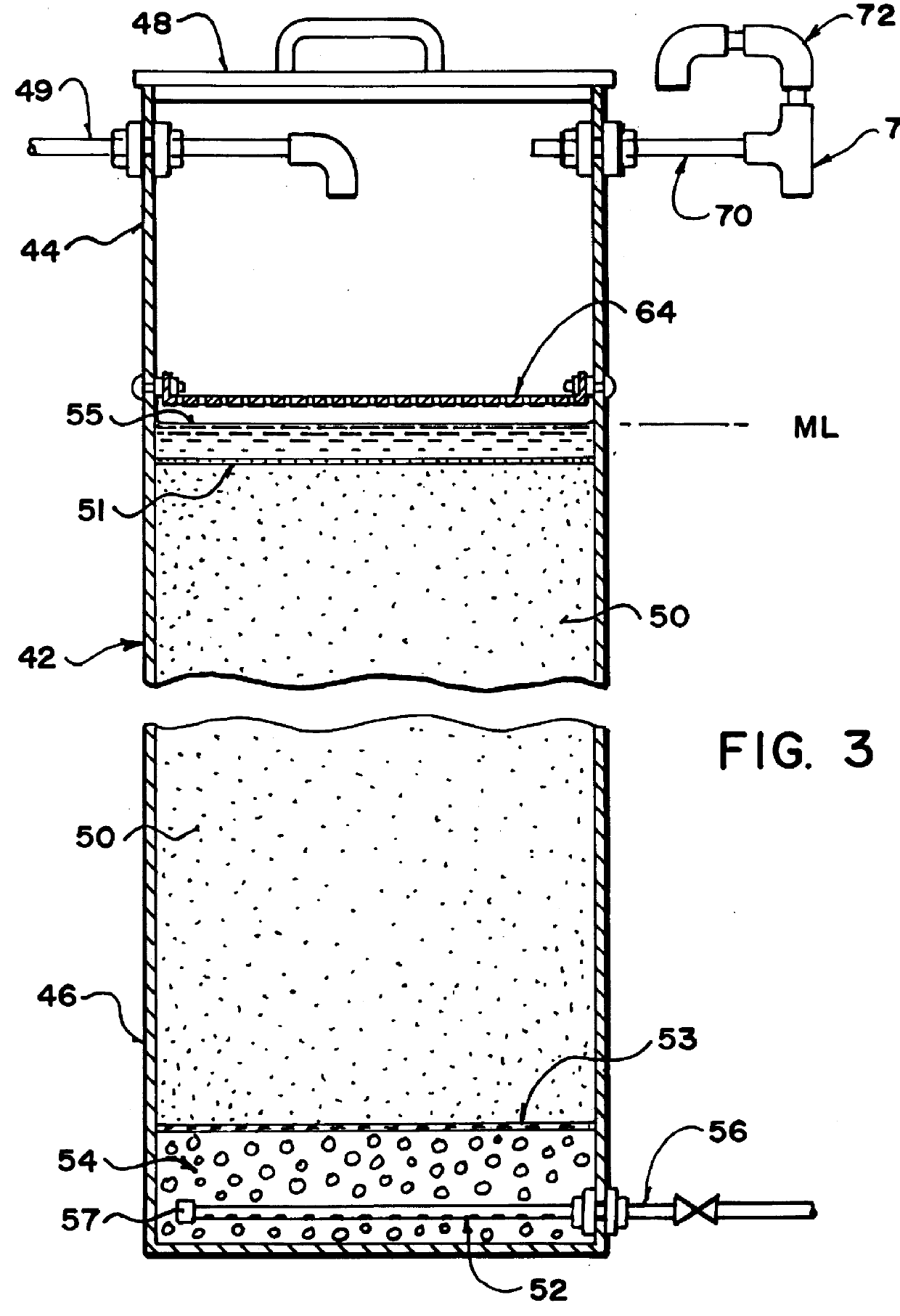

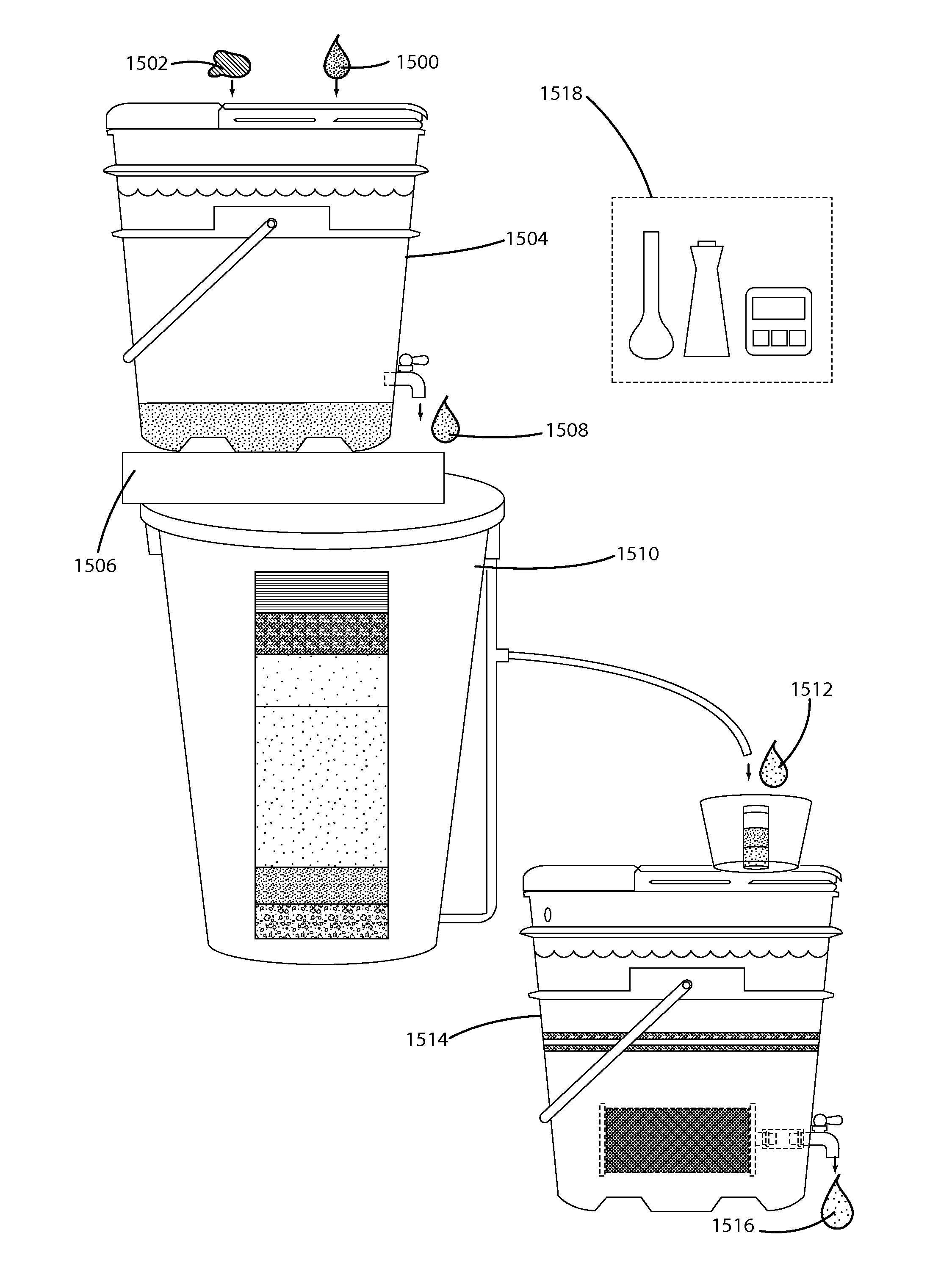

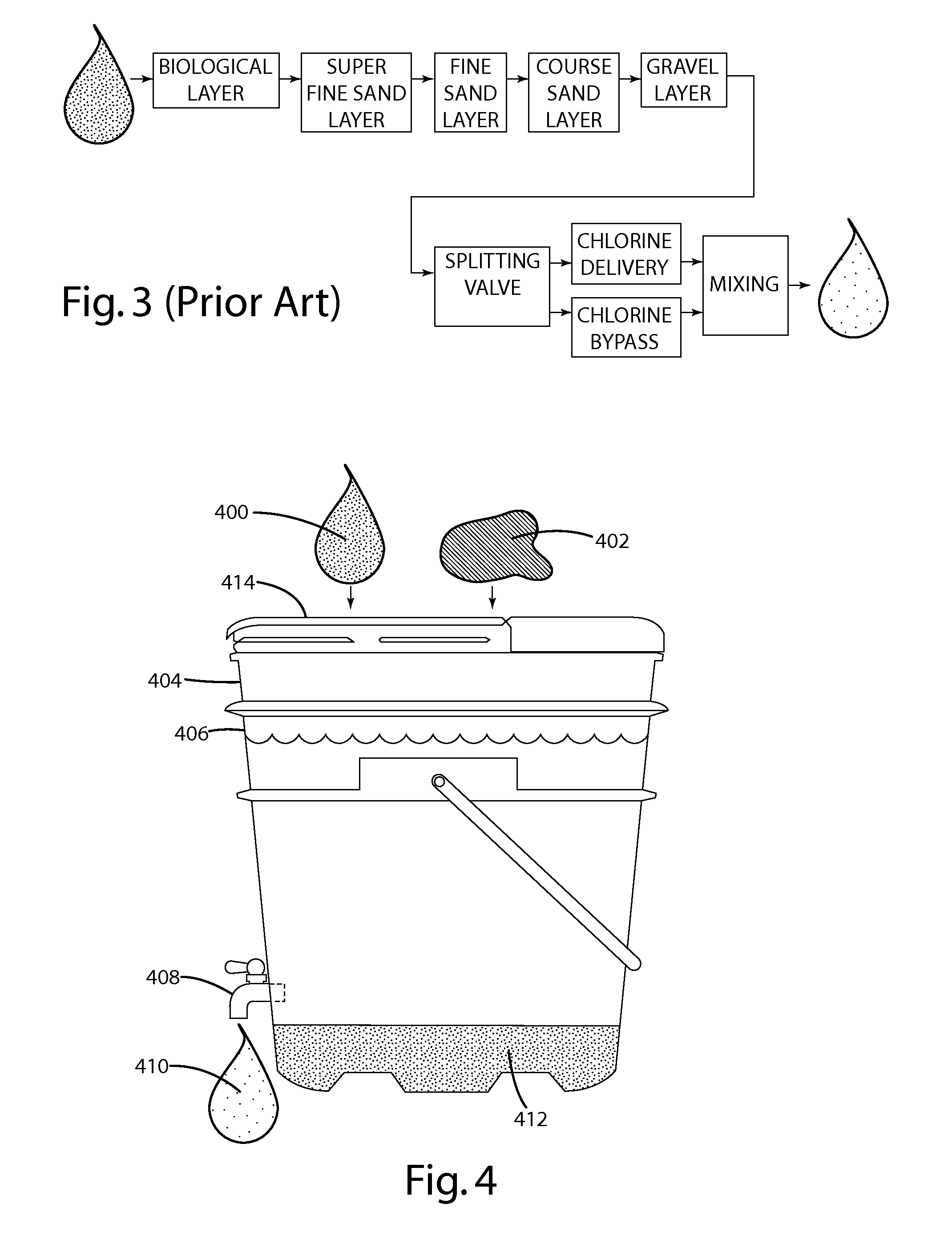

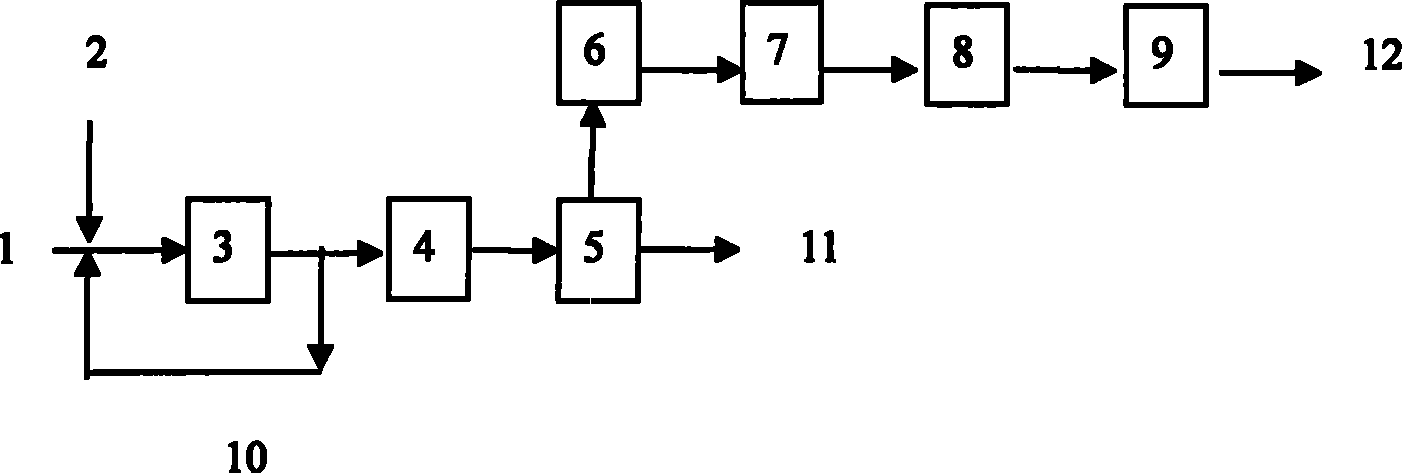

A portable water treatment system includes at least one sub-system to treat water including a flocculation system, a chlorination system, and a bio-sand filter system. The water treatment system may include multiple sub-systems for treating water that feed into one another. The sand filter system may include a mini bio-sand filter, a foam filter, or a pressed block filter. The flocculation system may include a tank bottom that urges settling particles toward a sump and a ladle that removes settled particles. A manual pump or siphon may be included in the water treatment system.

Owner:ACCESS BUSINESS GRP INT LLC

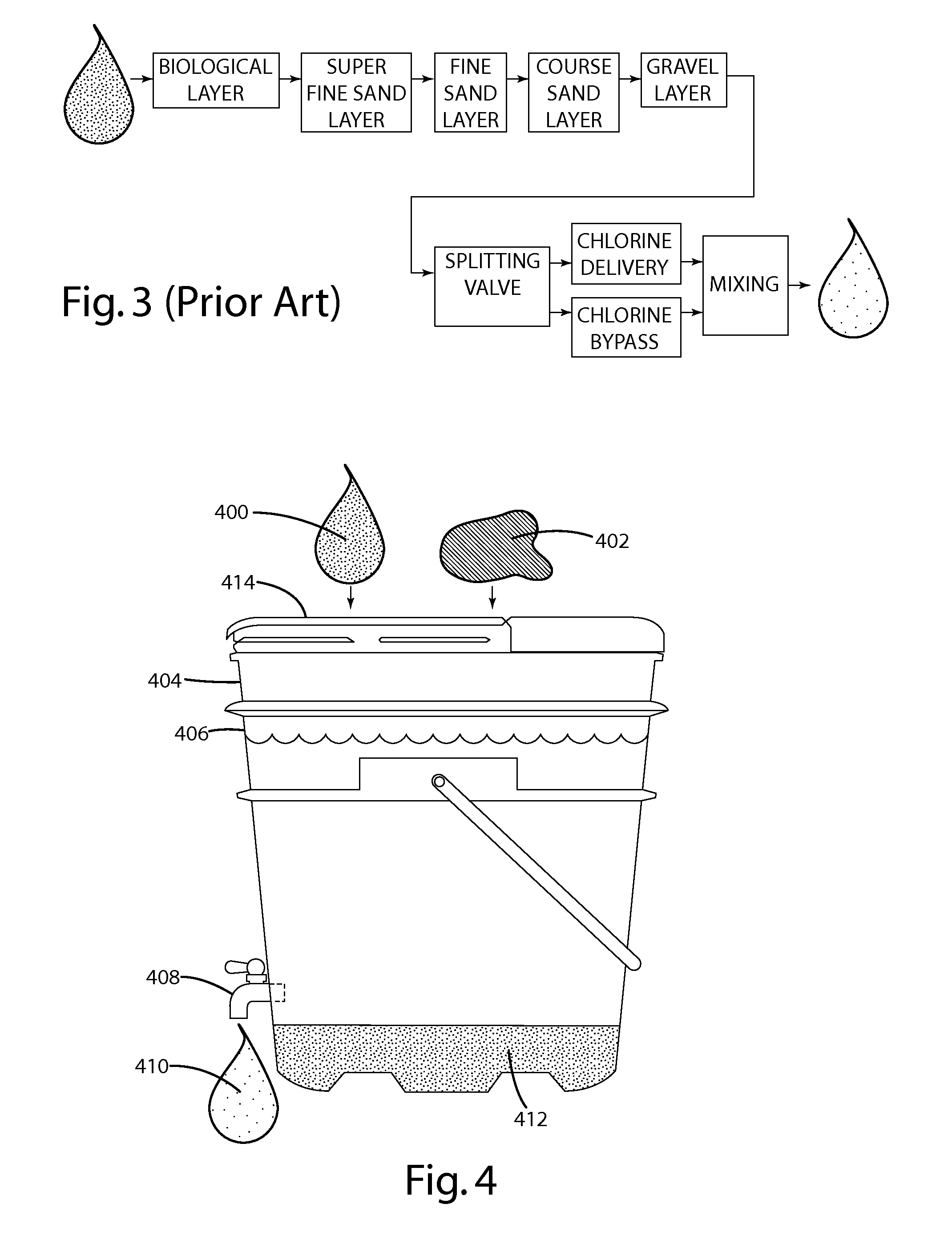

Slow sand filter for use with intermittently flowing water supply and method of use thereof

InactiveUS6123858ATreatment using aerobic processesSettling tanks feed/dischargeWater sourceWater flow

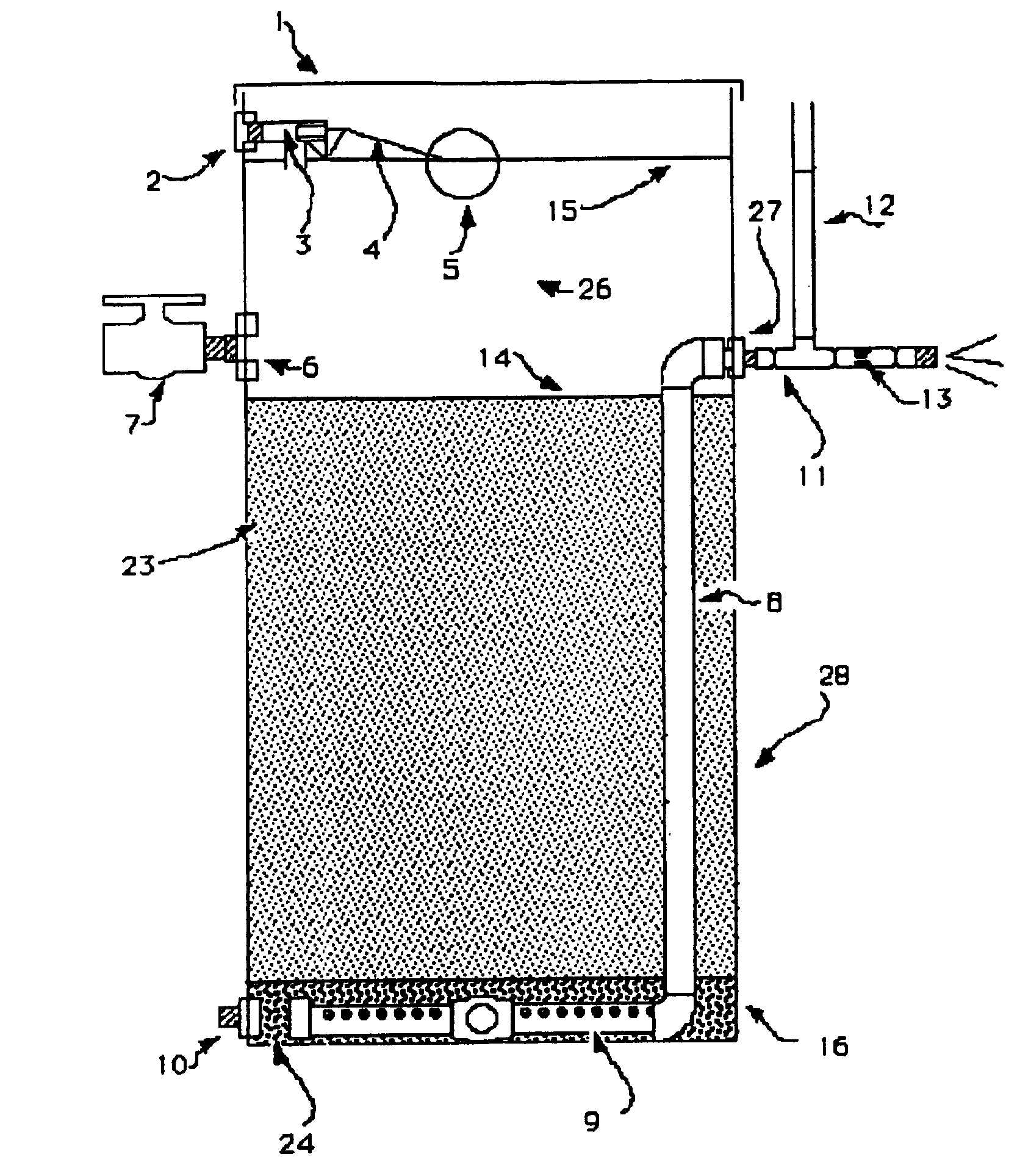

This invention relates to a novel intermittent slow sand filter and a method of using the intermittent filter. More particularly, this invention pertains to a novel slow sand filter which remains effective, even when intermittently operated, and which can be periodically cleaned without disturbing the action of the intermittent filter. A slow sand filter apparatus comprising: a container having an upper portion and a lower portion; a water inlet in the upper portion of the container, the water inlet being connected to a supply of water; a filter material filling at least the lower portion of the container, the filter material having a top surface below the water inlet; a schmutzdeuke layer on the top surface of the filter material; a water outlet in the lower portion of the container below the top surface of the filter material; and a water level maintenance device in the upper portion which maintains water in the upper portion of the container at a maintenance level above the top surface of the filter material, the maintenance level being a balance between (1) a water maintenance level that is sufficiently deep that water falling from the water inlet onto the top of the water in the container does not significantly disturb the schmutzdeuke layer; and (2) a water maintenance level that is sufficiently shallow that oxygen from the air above the water level can diffuse through the water and reach the schmutzdeuke layer so that the schmutzdeuke layer is maintained in living condition even when there is no flow of water through the water inlet.

Owner:UNIV TECH INT +1

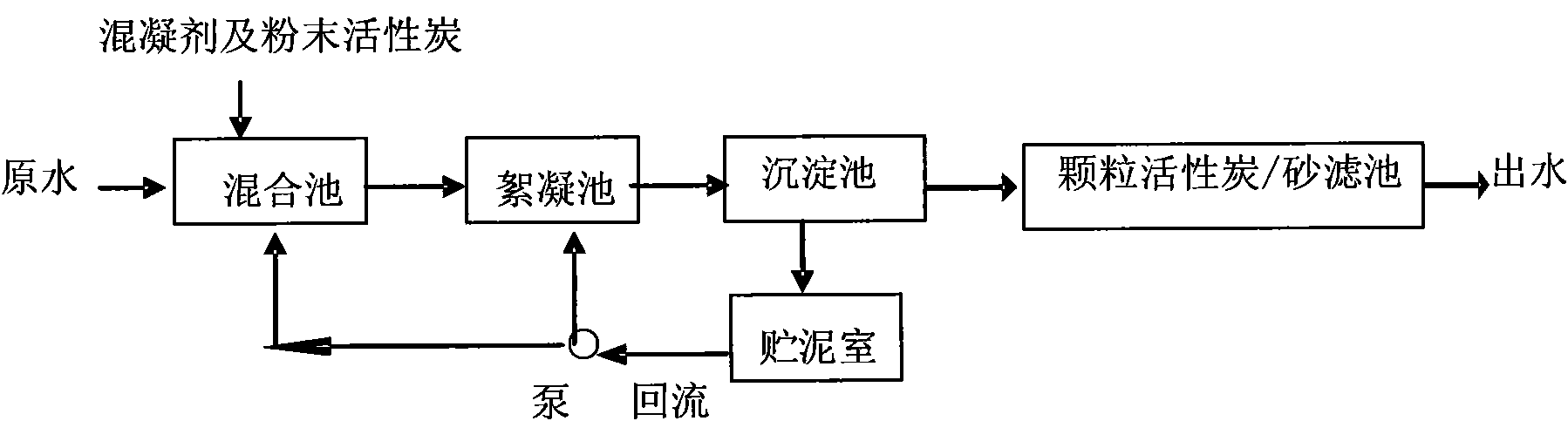

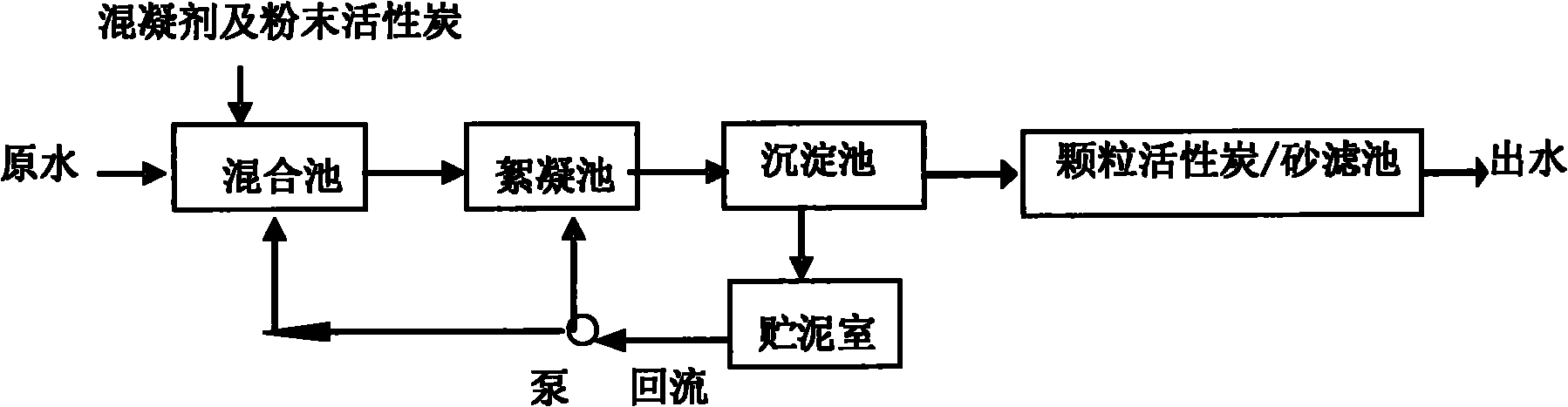

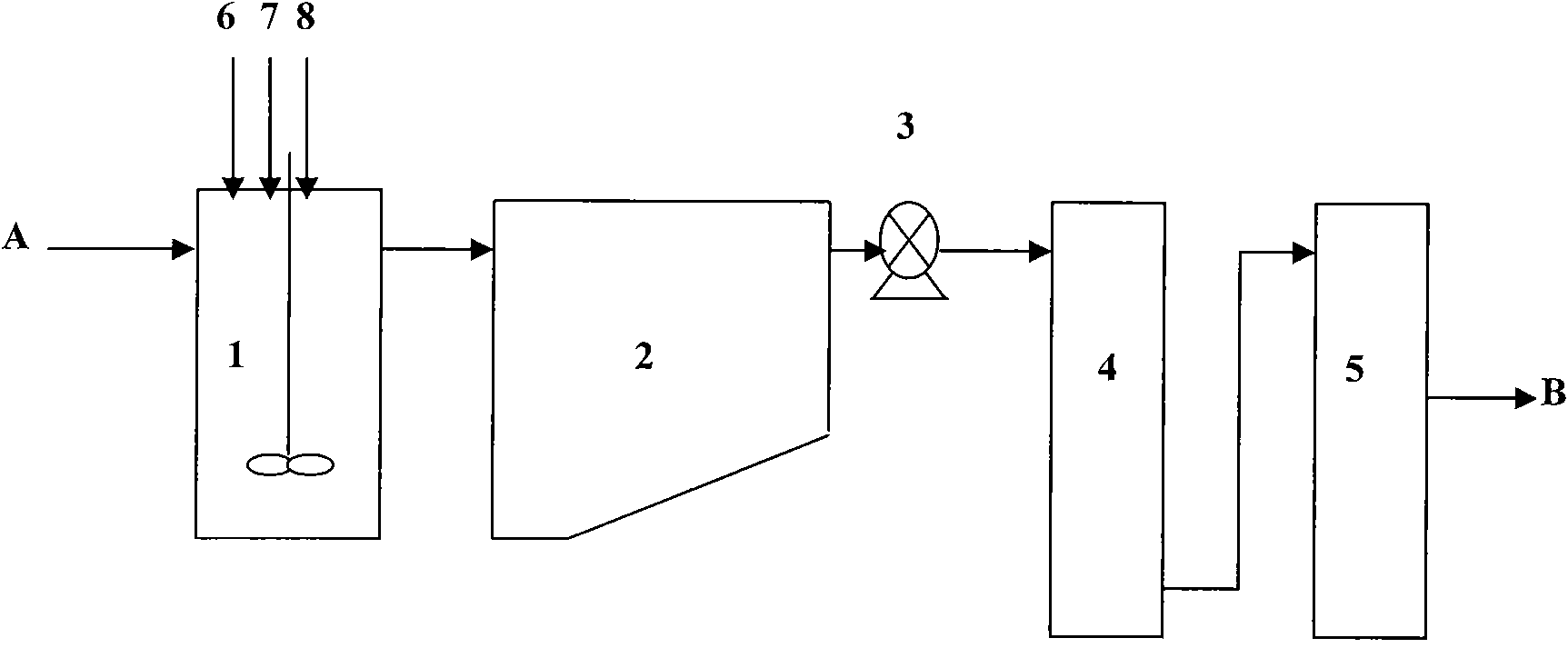

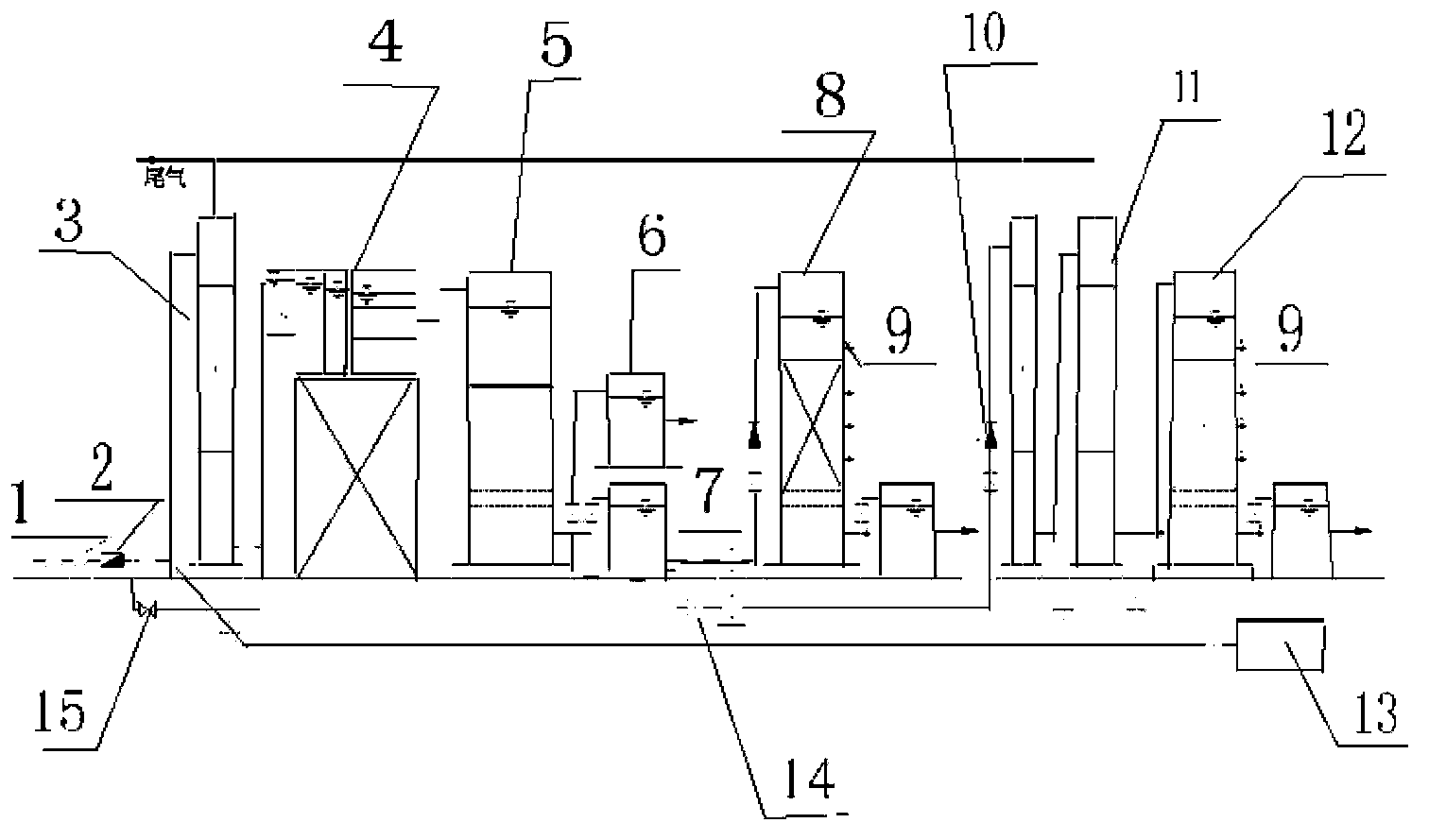

Powdered carbon backflow and carbon/sand filter combined process for treating polluted water

InactiveCN101962251AMake full use of the adsorption capacityEfficient removalMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFlocculationSand filter

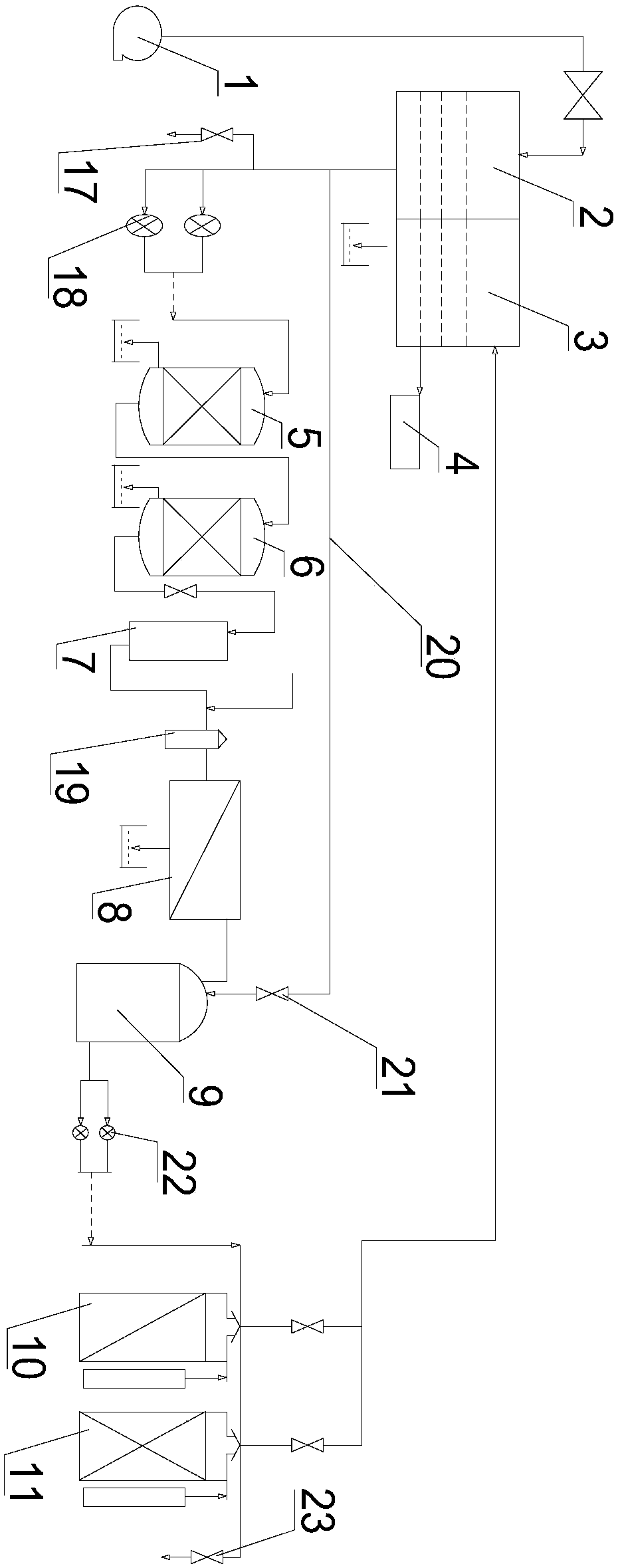

The invention discloses a powdered carbon backflow and carbon / sand filter combined process for treating polluted water, which belongs to the field of water treatment. A device comprises a mixing tank, a flocculating tank, a settling pond and a carbon / sand filter which are connected in series in turn, wherein powdered active carbon and a coagulant are added in raw water to be treated, and the raw water is mixed with the coagulant in the mixing tank; the mixed raw water enters the flocculating tank to undergo a flocculation reaction and then enters the settling pond to undergo solid-liquid separation, active carbon mud settled in the settling pond is concentrated in a mud storage chamber and flows back to the mixing tank or flocculating tank by a reflux pump, the concentrated active carbon mud flows back to the mixing tank when the coagulant is added and flows back to the flocculating tank when the coagulant is not added; and water after the settlement enters the carbon / sand filter, the granular active carbon is filled on the upper layer of the carbon / sand filter, and quartz sand is filled in the lower layer. In the invention, a powdered carbon backflow process is adopted, so that over 50 percent of medicinal preparation can be saved; and the physical absorption effect, biological degradation effect and strengthening coagulation effect of the active carbon act in coordination, and the carbon / sand dual-layer filter has the physical absorption and biological degradation effects at the same time.

Owner:BEIJING UNIV OF TECH +1

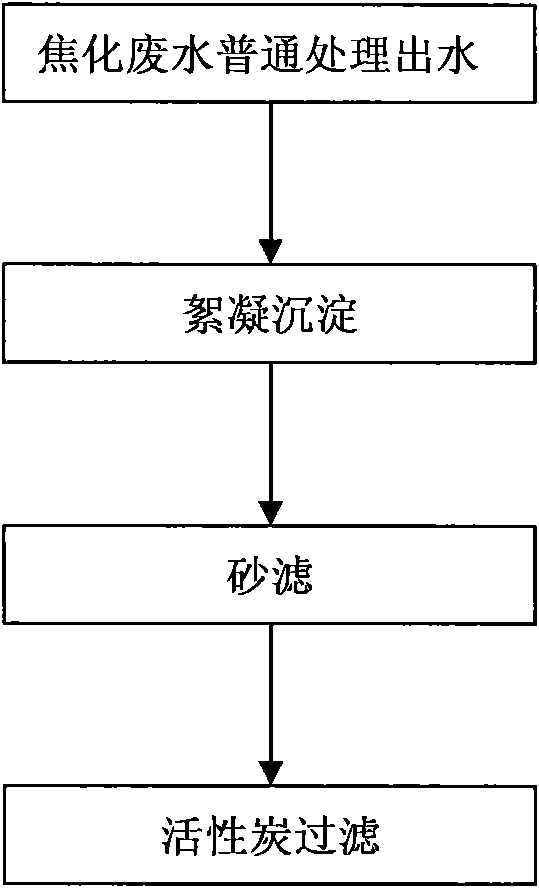

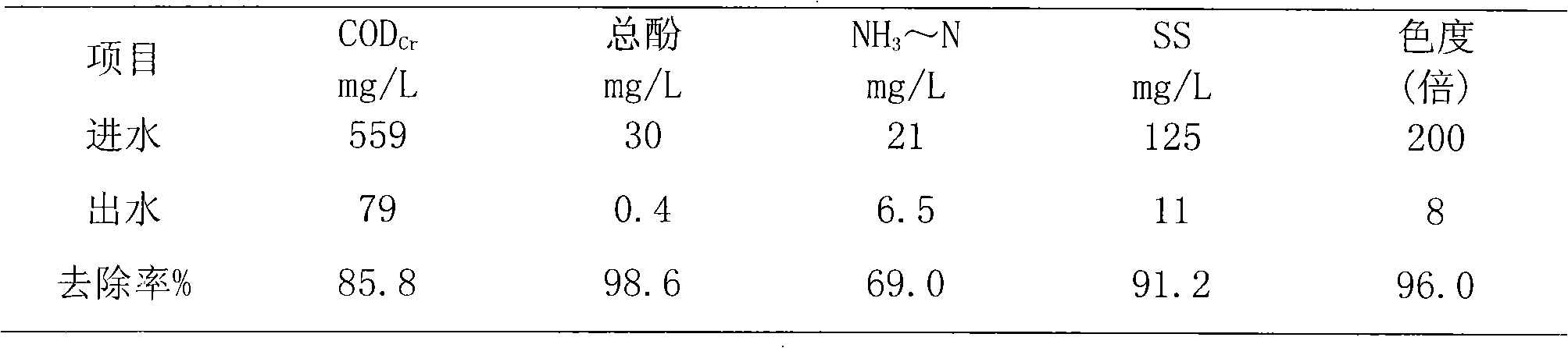

Coking wastewater treatment device and coking wastewater posttreatment method

InactiveCN101987762AReduce CODAchieve emission standardsMultistage water/sewage treatmentWater/sewage treatment by neutralisationChemical oxygen demandActivated carbon filtration

The invention relates to a coking wastewater treatment device which comprises a flocculation reaction tank, wherein the flocculation reaction tank is connected with a flocculation settling pond, the flocculation settling tank is connected with a sand filter, and the sand filter is connected with an active carbon filter. A coking wastewater posttreatment method comprises the steps of: adding an efficient composite flocculating agent, a polymer coagulant aid and a mineral powder absorbing agent into the coking wastewater subjected to common treatment; regulating the pH value to be 8-9 with alkali, wherein the flocculation reaction settling time is 1-2.5h; and then carrying out sand leaching and active carbon filtration, wherein the effluent quality fully reaches the standard for emission or recycling. The COD (Chemical Oxygen Demand), the total phenol, the ammonia nitrogen, SS (Suspended Substances) and the chromaticity in the coking wastewater subjected to the treatment with the method are respectively reduced by above 80 percent, 90 percent, 60 percent, 90 percent and 95 percent; and by treating the coking wastewater according to the invention, the purposes of good effect, simple operation and convenience in management are achieved.

Owner:SHANGHAI WEILAI ENTERPRISE

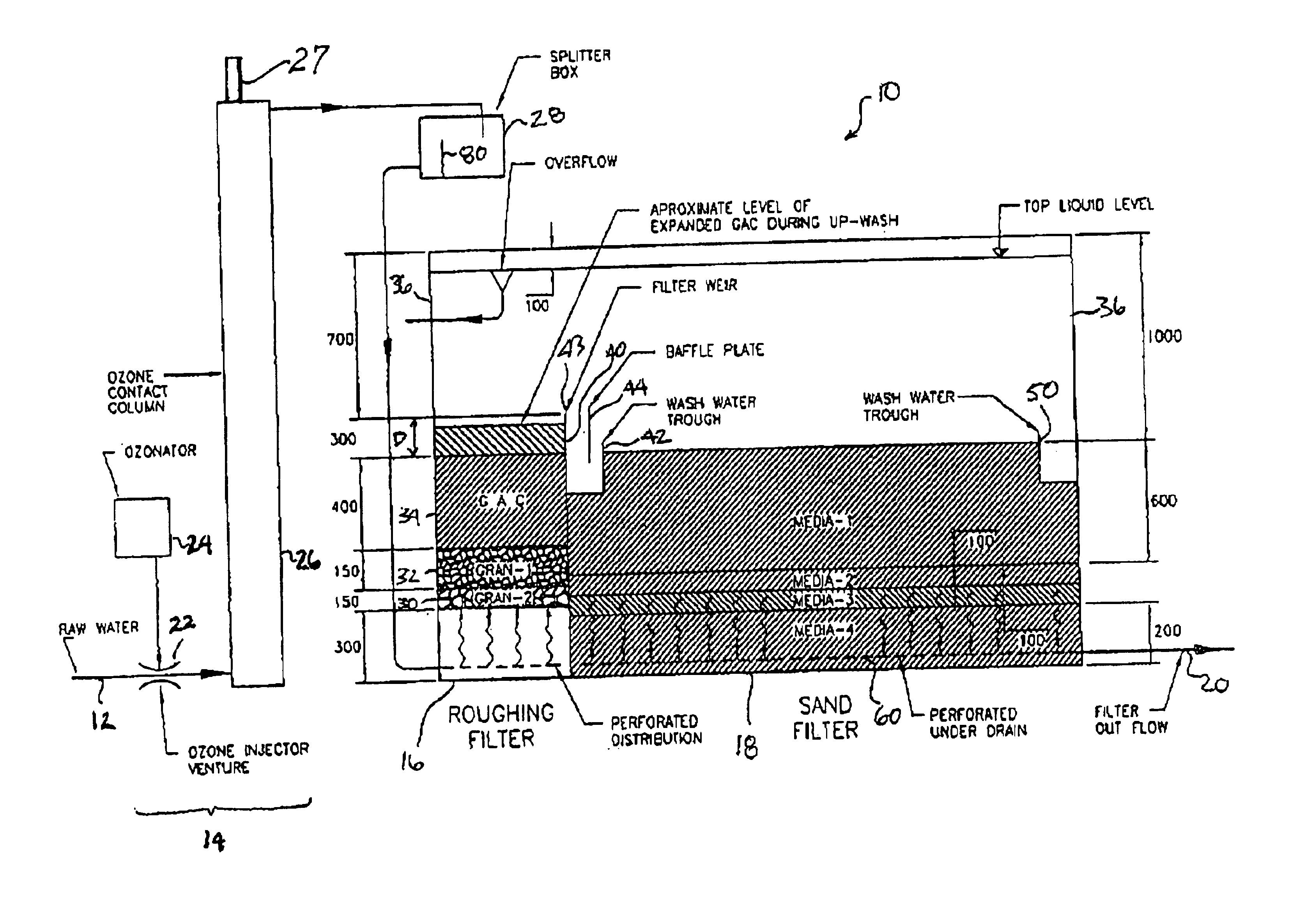

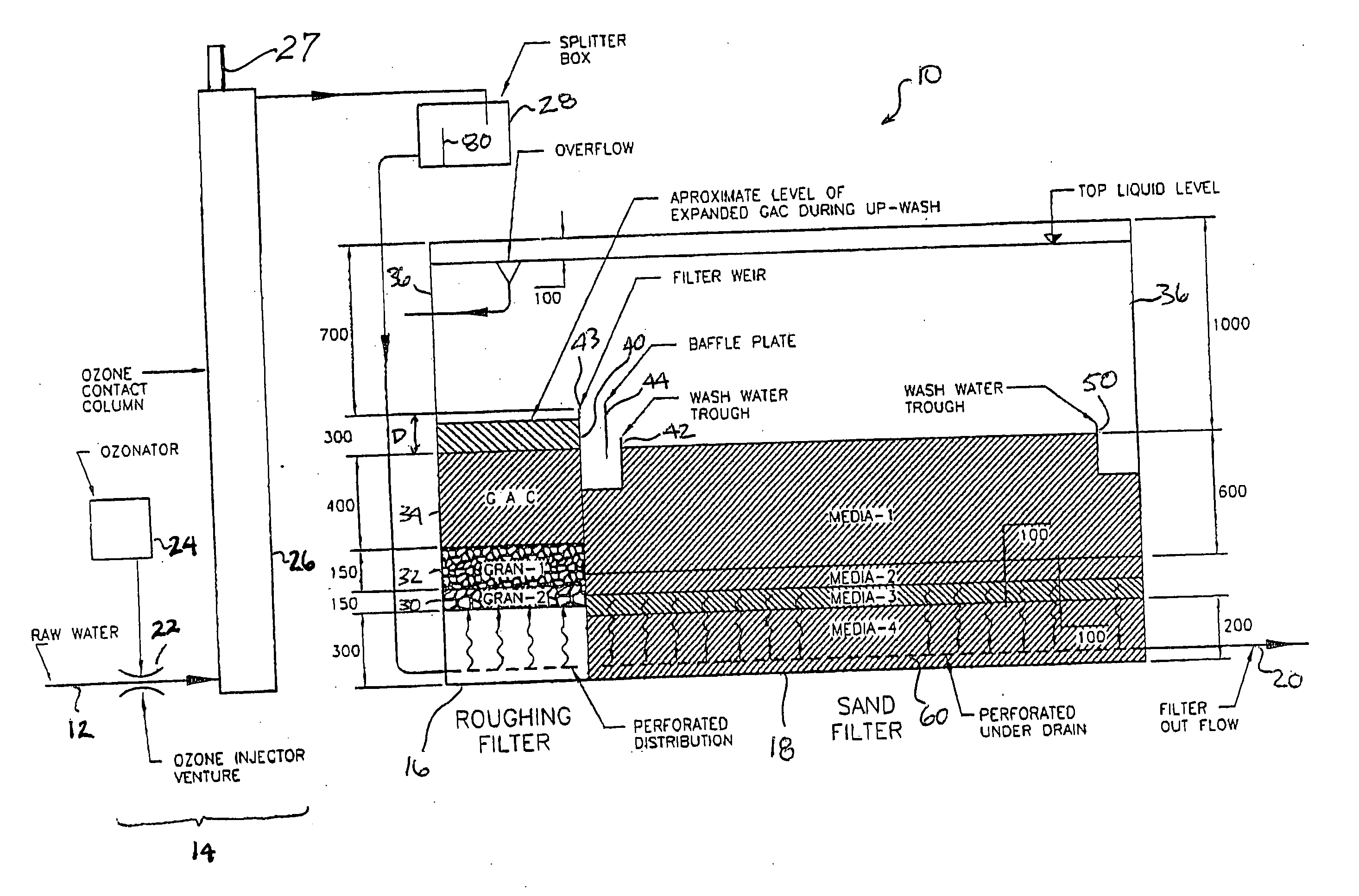

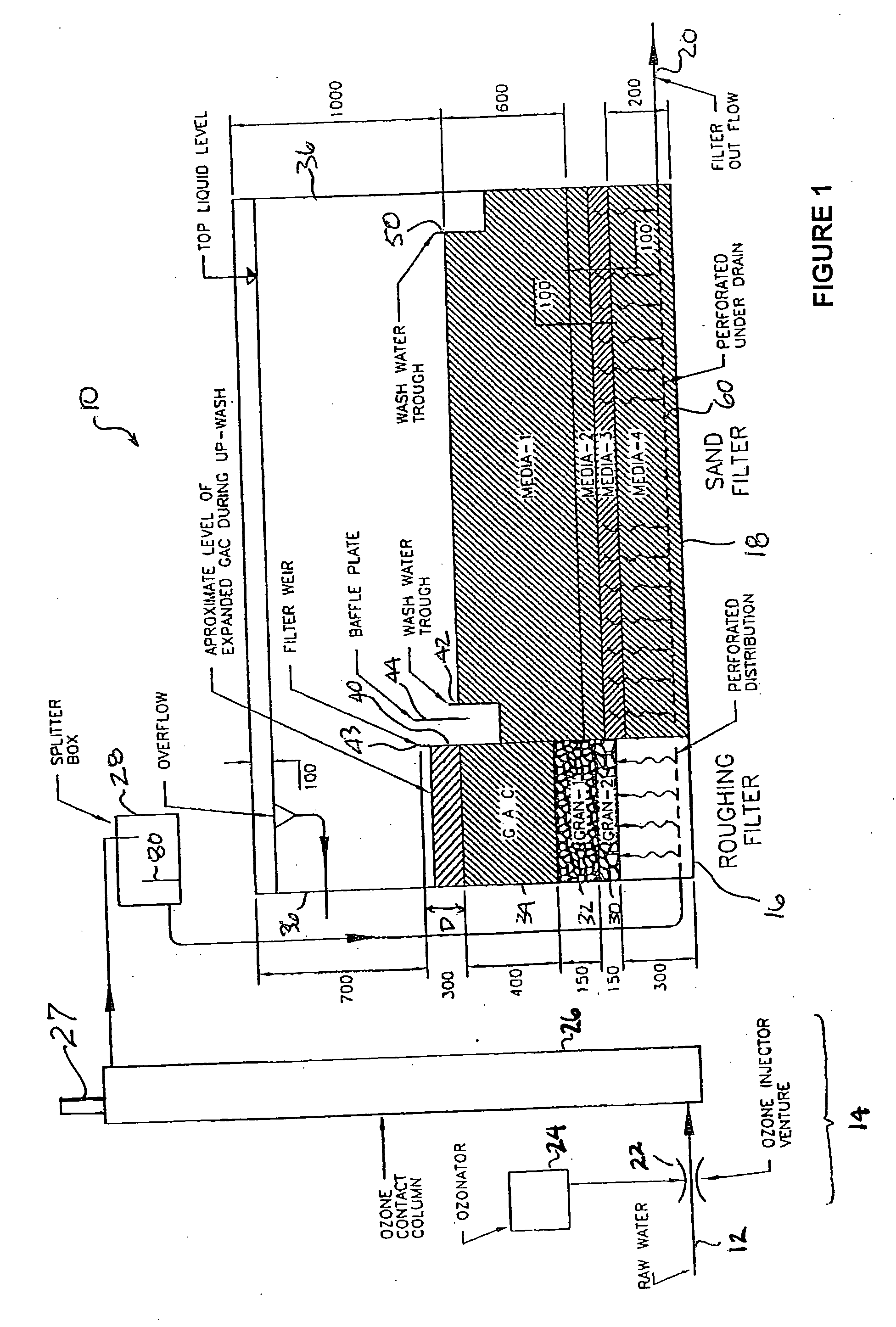

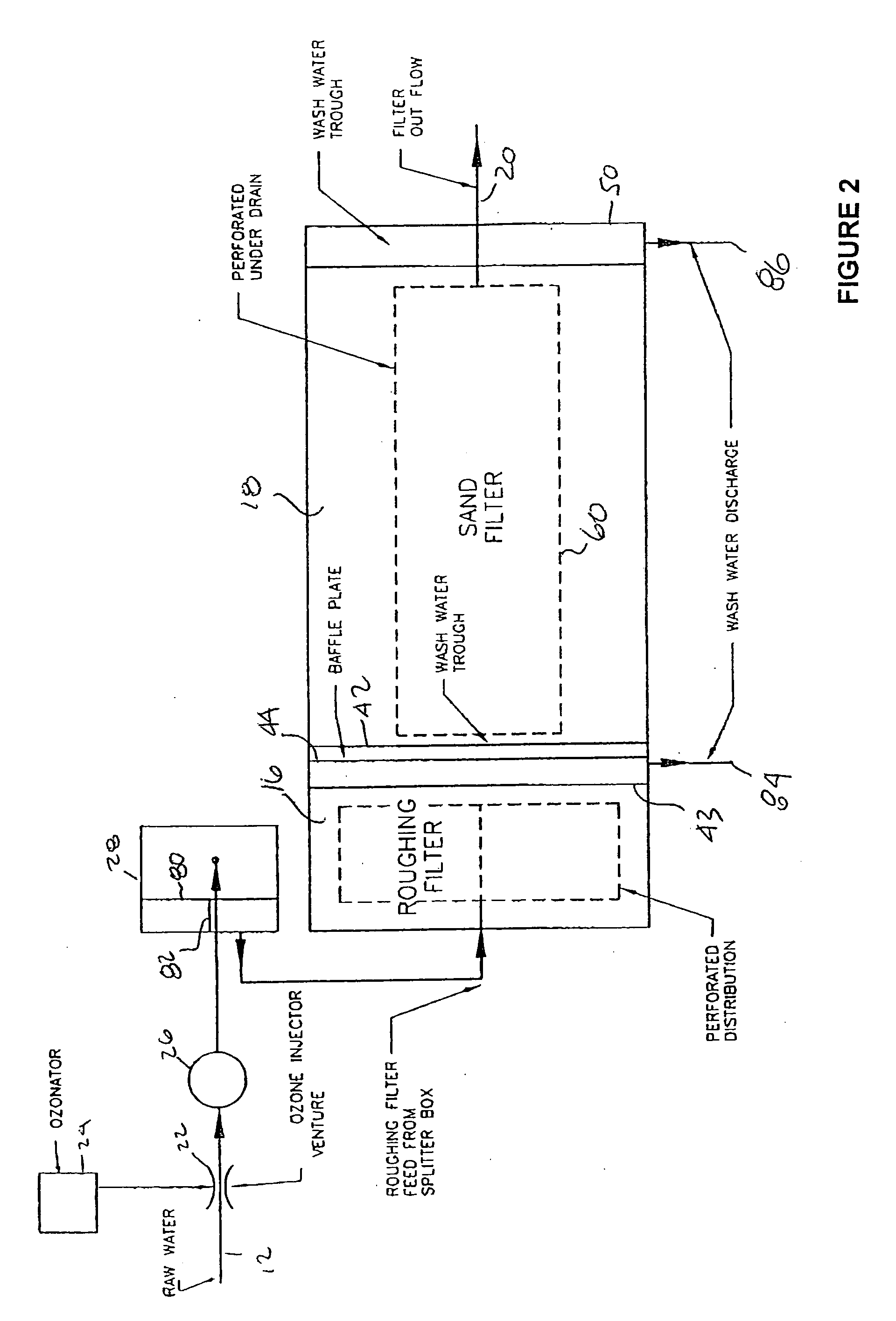

Potable water treatment plant and method of maintaining same

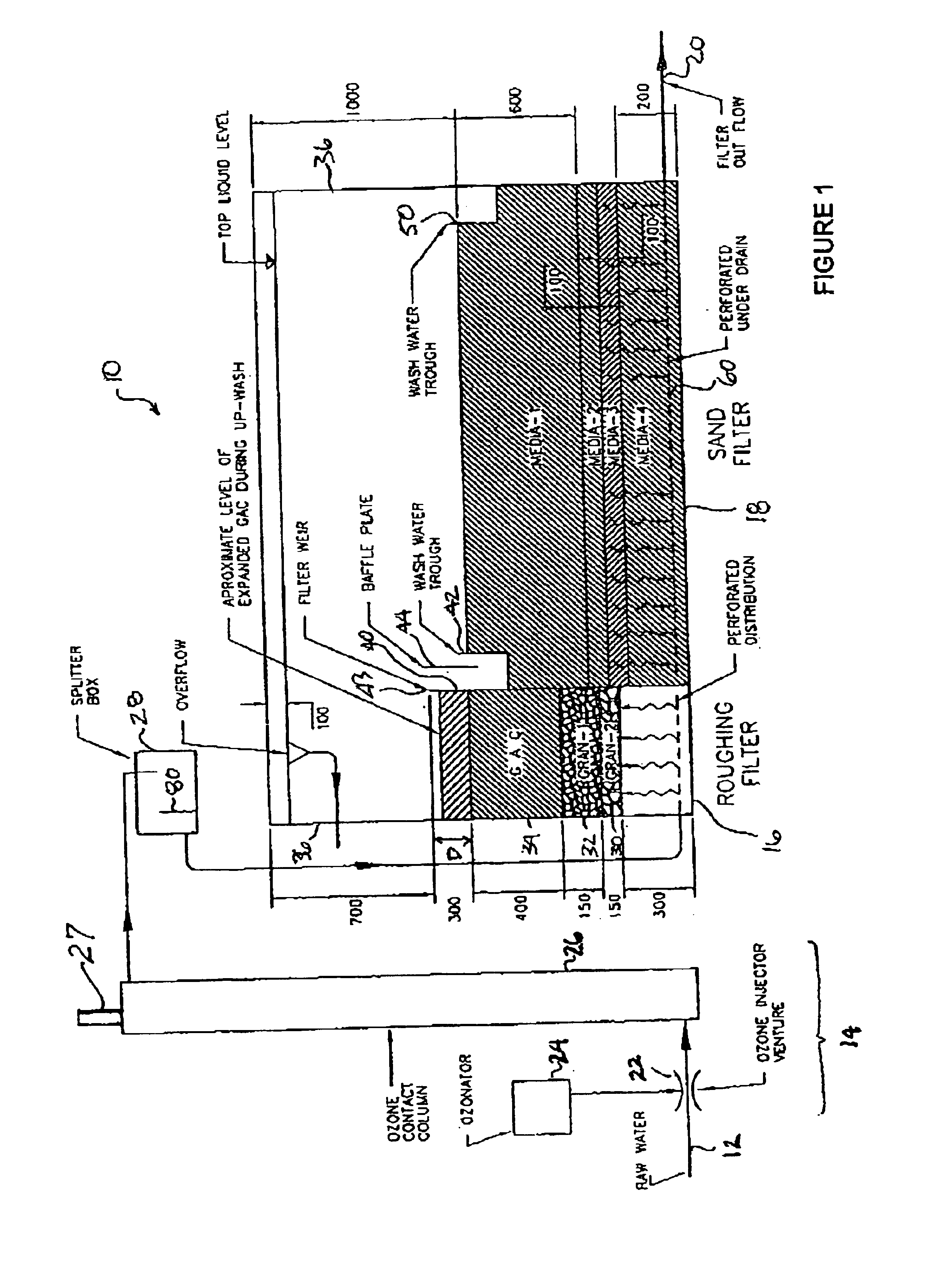

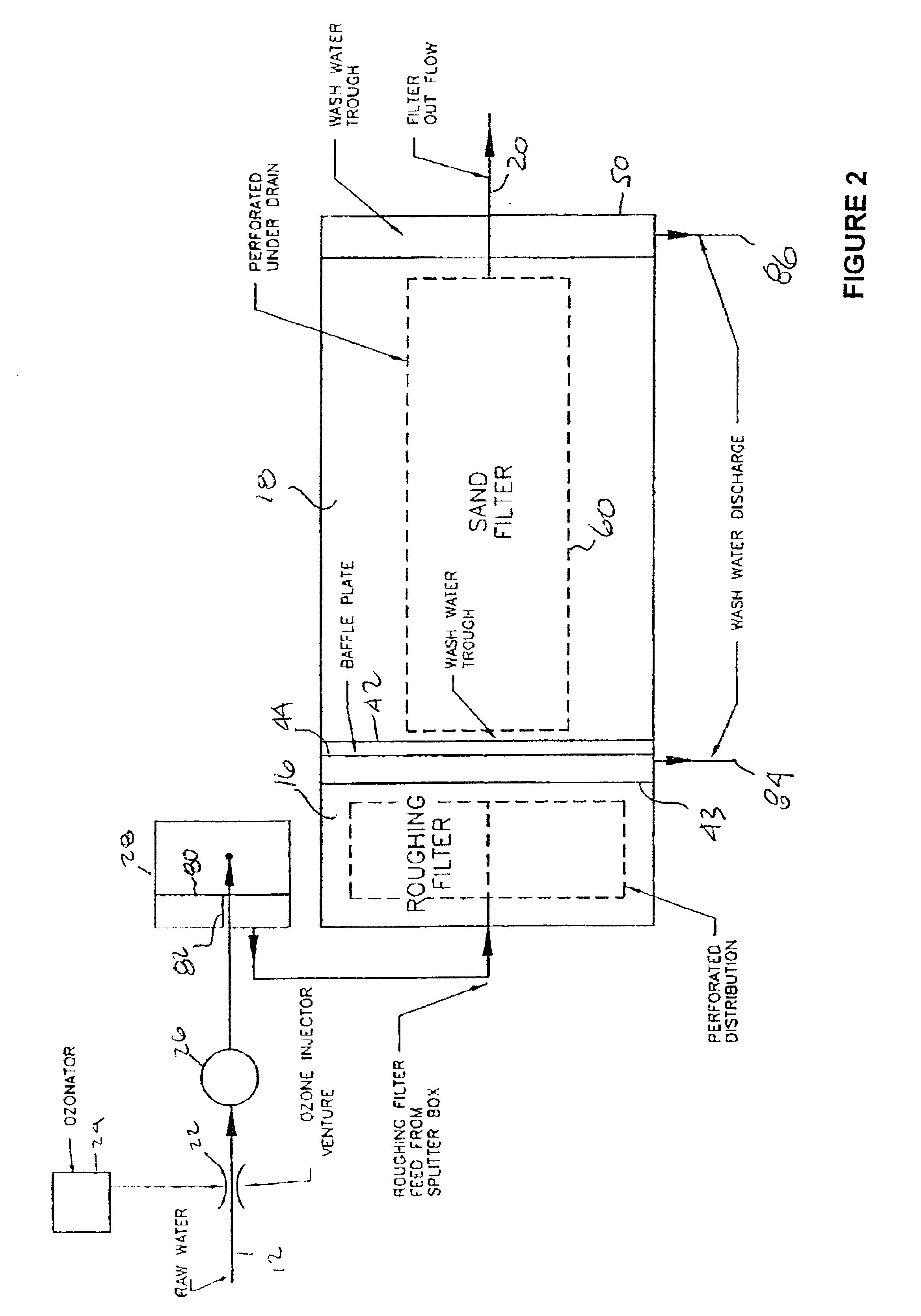

InactiveUS6953525B2Easy to useEasy maintenanceTreatment involving filtrationSolid sorbent liquid separationParticulatesPotable water

A package plant for treating raw water to yield potable water. The package plant includes an inlet for raw water, followed by an ozonator for disinfecting the water. Next is provided an up flow roughing filter including a chemically active layer, on top. A slow sand filter follows, which is sized and shaped to promote growth of a biomass for water purification. The up flow roughing filter removes particulates, contributes to the removal of dissolved organics, and protects the slow sand biomass by removing disinfection residuals. In another aspect a method of maintaining the plant is provided, including washing the up flow roughing filter by draining water down through it, providing a vigorous up flow to agitate the top layer, and then washing the slow sand filter.

Owner:MS FILTER SYST

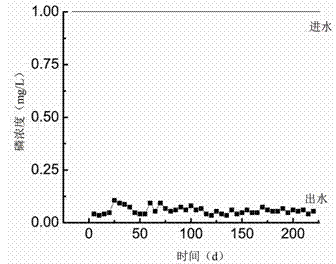

Siderite active sand dephosphorization method

The invention discloses a method for deep dephosphorization of wastewater by using siderite as a sand filter filtering material. The method is characterized by comprising the steps of crushing and screening natural siderite ore to obtain 0.25-0.5mm particles, filling a sand filter by using the particles as filler, and carrying out deep dephosphorization on low-concentration phosphorus wastewater via a filter manner. The principle is that the siderite is slowly oxidized by the dissolved oxygen in the water to form newly born ferrihydrite (iron hydroxide) and the newly born ferrihydrite adsorbs to remove the phosphor in the water. Through regular back washing, the ferrihydrite membranes on the surfaces of the particles fall off, so that the oxidization dephosphorization of the siderite is restored. The method provided by the invention is suitable for the deep dephosphorization of domestic wastewater, landscape water and polluted river water.

Owner:HEFEI UNIV OF TECH

Potable water treatment plant and method of maintaining same

InactiveUS20060021953A1Easy to useEasy maintenanceOther chemical processesSpecific water treatment objectivesParticulatesPotable water

A package plant for treating raw water to yield potable water. The package plant includes an inlet for raw water, followed by an ozonator for disinfecting the water. Next is provided an up flow roughing filter including a chemically active layer, on top. A slow sand filter follows, which is sized and shaped to promote growth of a biomass for water purification. The up flow roughing filter removes particulates, contributes to the removal of dissolved organics, and protects the slow sand biomass by removing disinfection residuals. In another aspect a method of maintaining the plant is provided, including washing the up flow roughing filter by draining water down through it, providing a vigorous up flow to agitate the top layer, and then washing the slow sand filter.

Owner:MS FILTER SYST

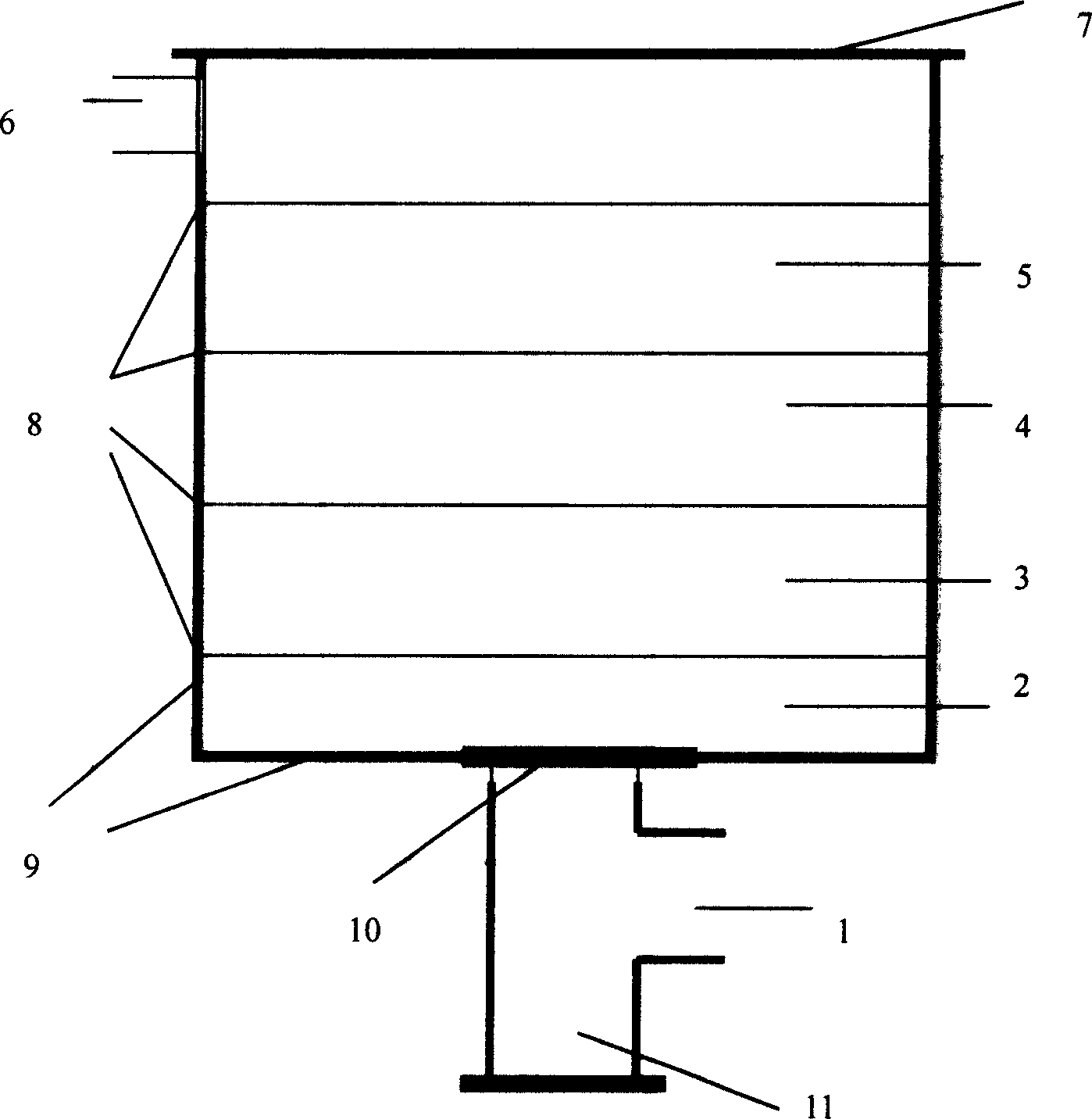

Deep sand filter

InactiveCN1528489ALarge dirt holding capacityAct as a coarse sand filterLoose filtering material filtersGravity filtersNormal filterEngineering

The invention is a depth-type sand filter, the size of sand gradually diminishing with the flow direction of the normal filtering fluid. It leads the fluid to the inlet of the sand filter through the pipeline, firstly holds back big suspension through big sand area, then holds back medium suspension through medium sand area, finally eliminates most fine suspension through fine sand area, and then makes the fluid flow out from the outlet. It is composed of wall body, filtering sand and ground leak; the wall body is set with inlet and outlet, the ground leak is set under the wall body, the filtering sand is spread in the liquid flow direction in turn according to the size. It can adopt upflow and downflow modes. It can stably and economically run in a wide range. It is applied to economical sand filtering field, especially the field where the sand filter is used infrequently or discontinuously.

Owner:安逢龙

SSF/x slow sand filter

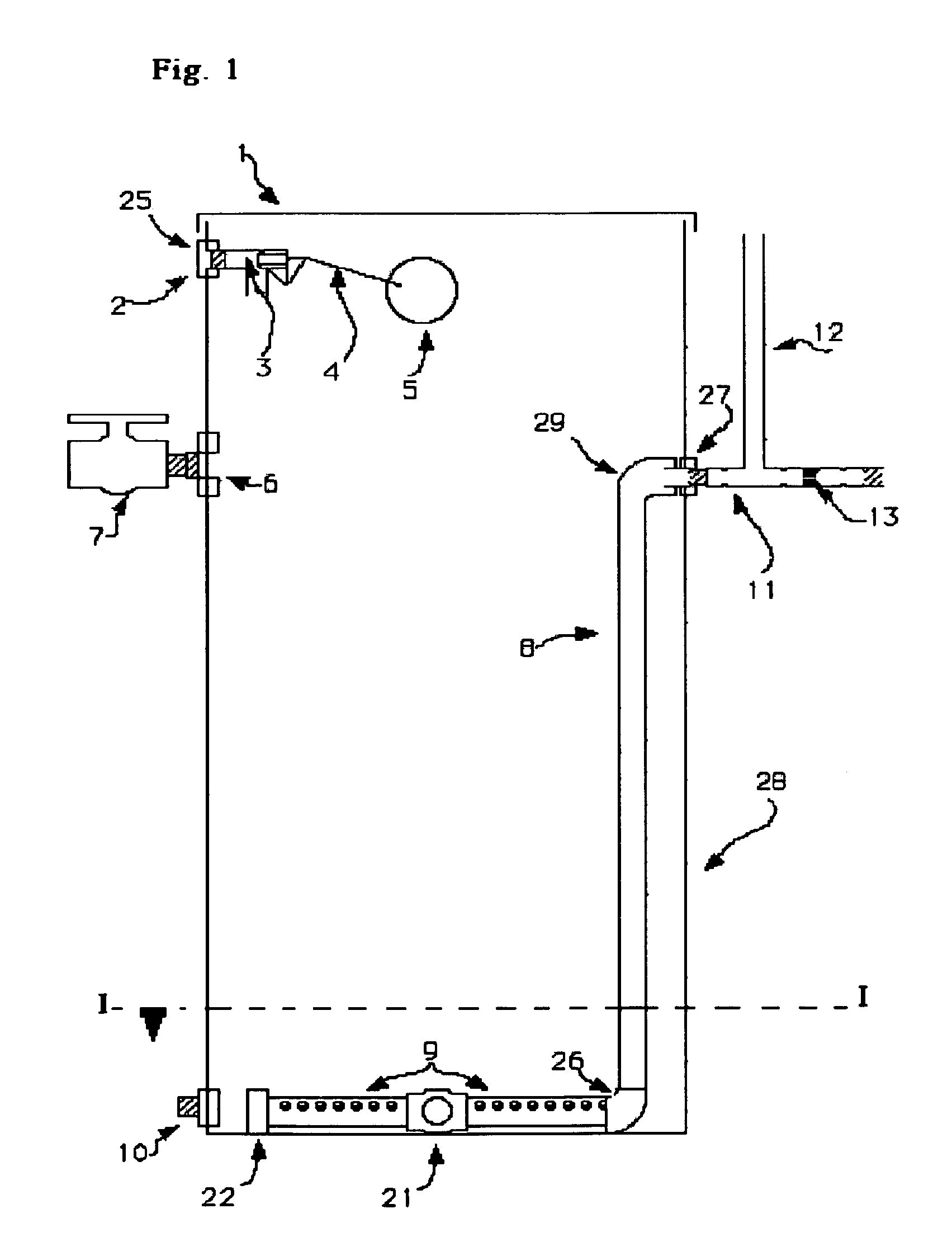

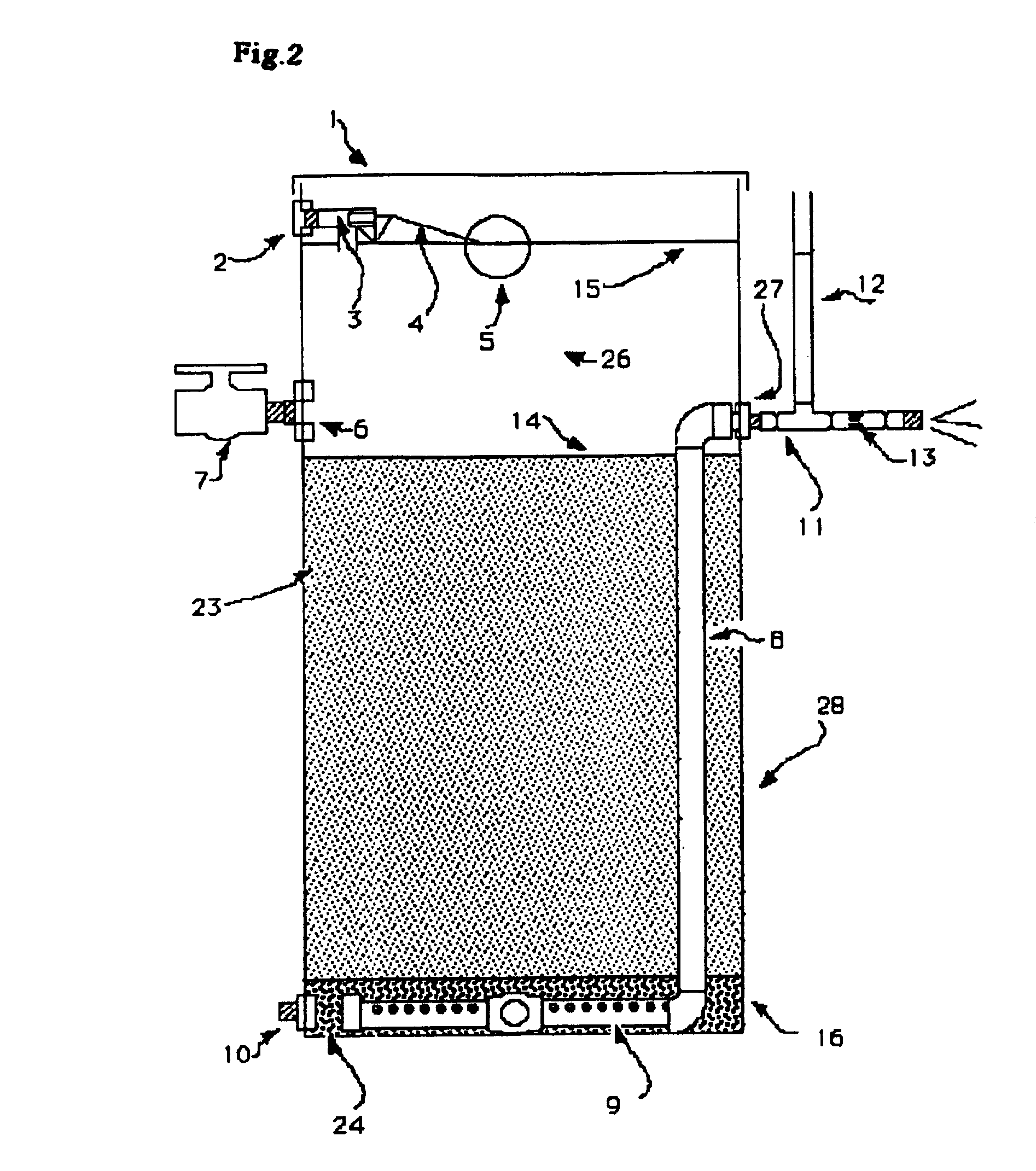

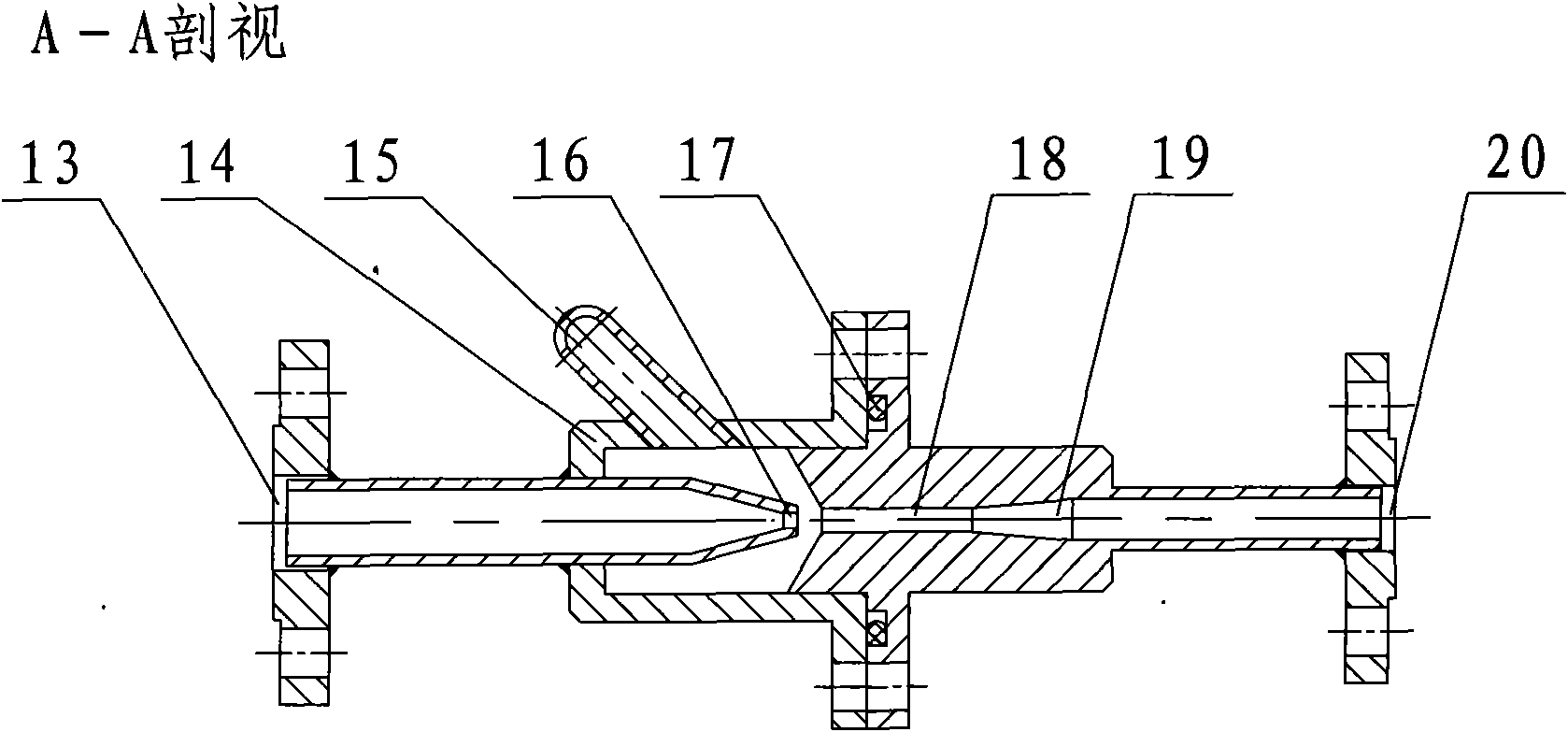

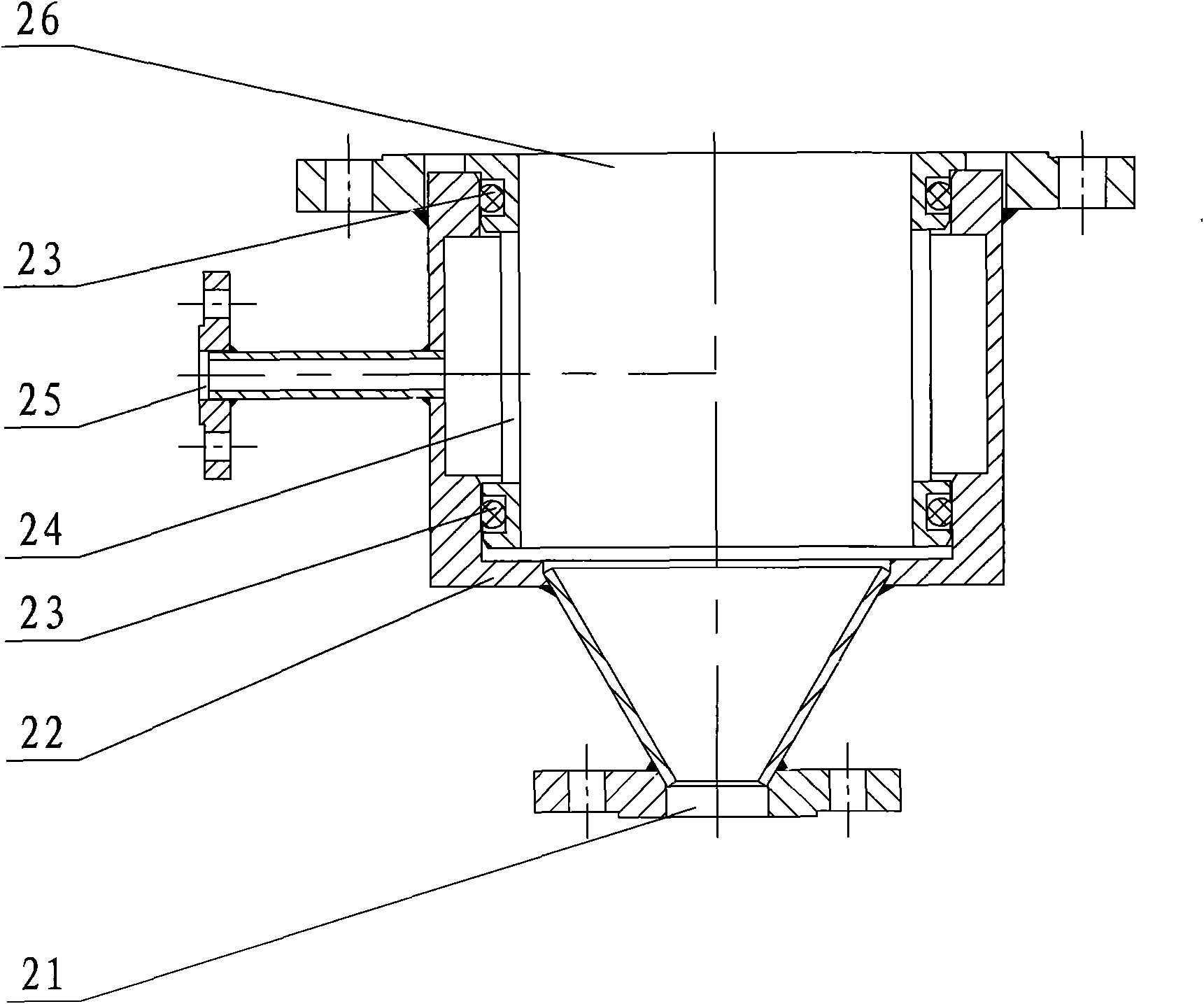

InactiveUS6966980B2Less head pressureLarge apertureSettling tanks feed/dischargeLoose filtering material filtersSiphonRural location

The SSF / x slow sand filter for use in treating drinking water for homes or rural villages with features providing simpler on-site assembly, preset maximum flow, easy monitoring of pressure head loss, protection of piping, and a harrowing system for cleaning. The filter employs a novel hydraulic scheme which places most pipe and plumbing within the filter vessel. The filter employs a novel device that combines flow control, pressure measurement, freeze protection, and anti-siphon features. This in combination with a relatively shallow supernatant level provides for consistent reliable operation, easy maintenance, and reasonably long filter runs as deemed very desirable in remote rural locations.

Owner:BLACKBURN HUMPHREY

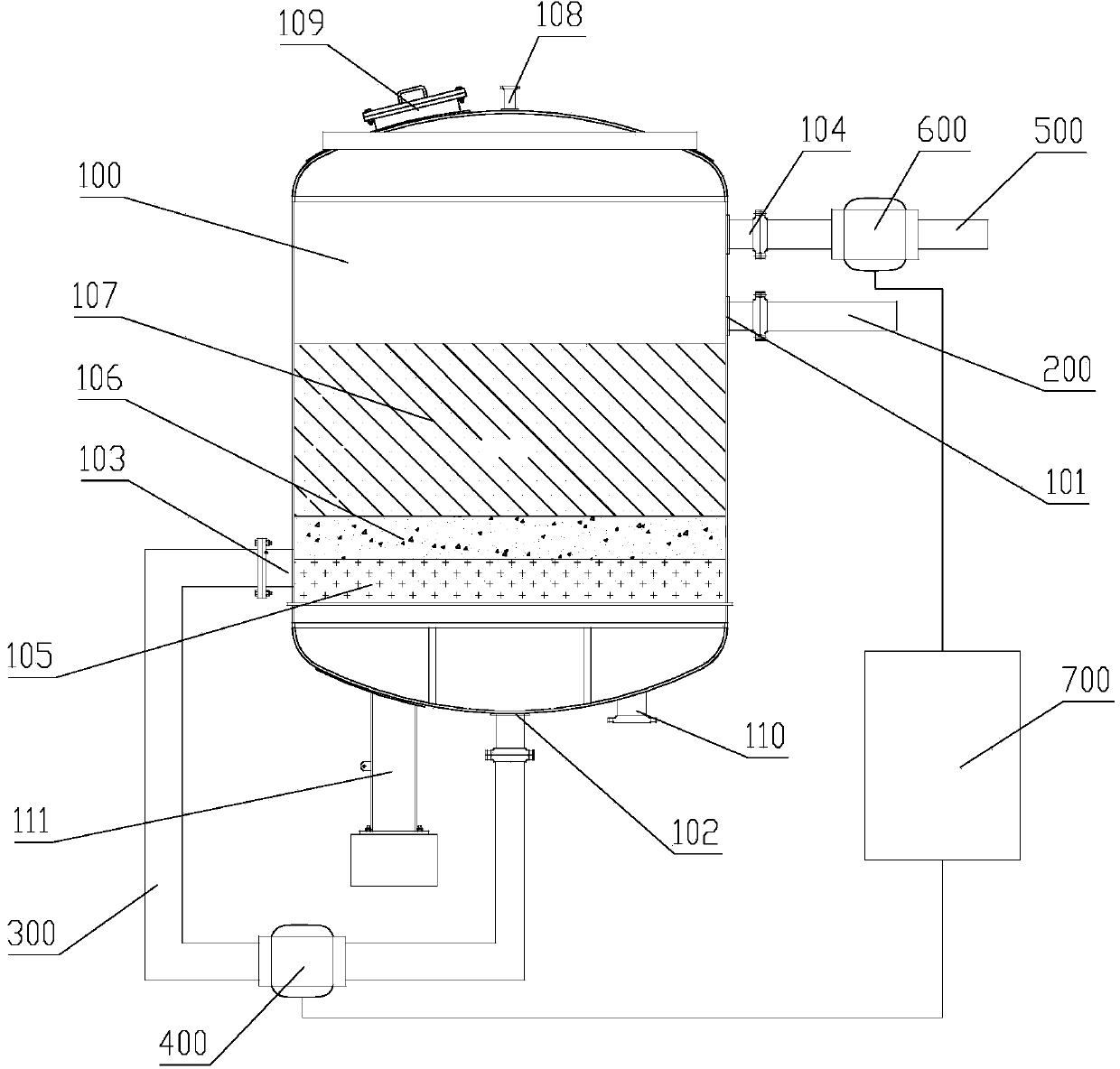

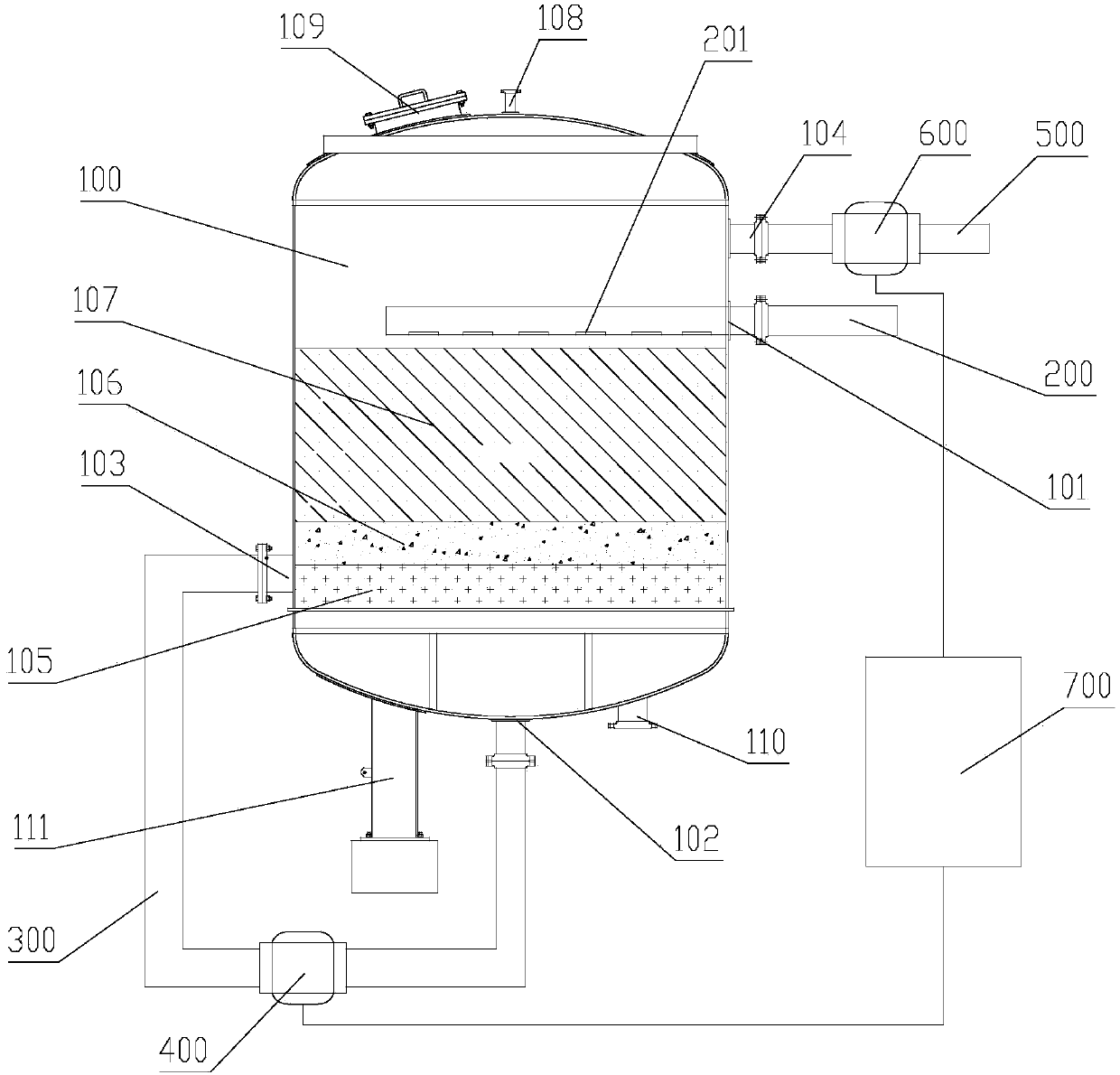

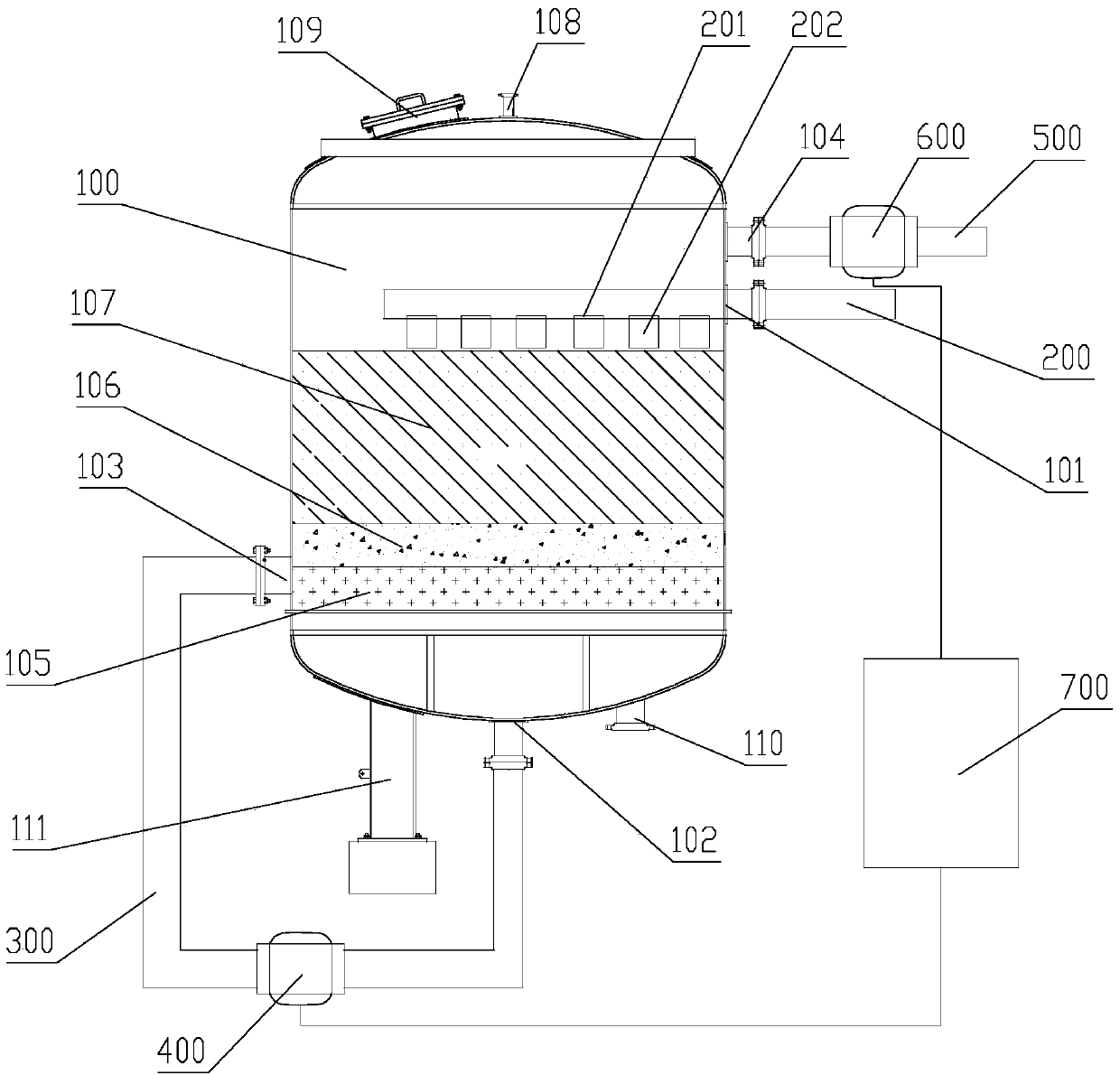

Sand filter system

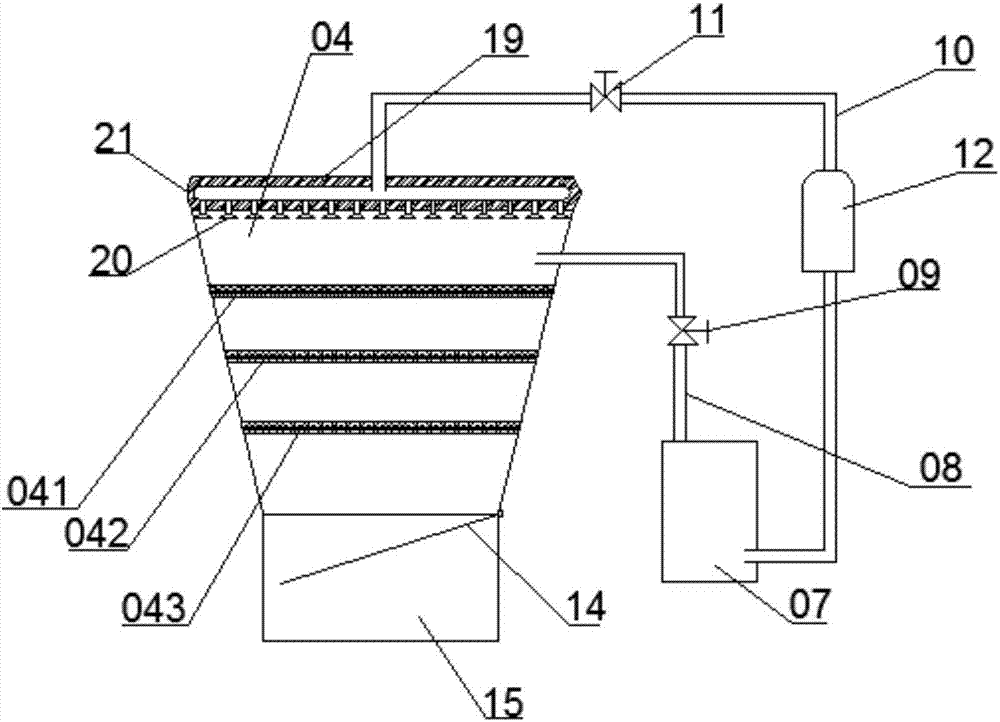

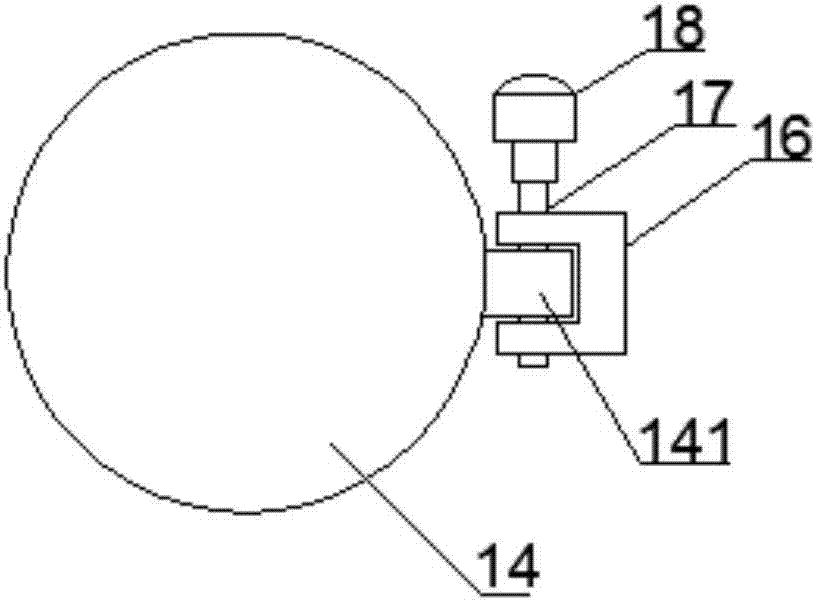

InactiveCN103505920AImprove filtering effectRealize automatic controlLoose filtering material filtersGravity filtersEngineeringSand filter

The invention discloses a sand filter system which is designed for solving the problems about poor filtering effect of a conventional sand filter device and the like, and comprises a sand filter tank, wherein a conventional flushing inlet and a back flushing outlet are formed in the upper part of the sand filter tank; a conventional flushing outlet and a back flushing inlet are formed in the lower part of the sand filter tank; the conventional flushing inlet is connected with a water inlet pipe; the conventional flushing outlet is connected with the back flushing inlet through a transition pipe; a first valve is arranged on the transition pipe; the back flushing outlet is connected with a water outlet pipe; a second valve is arranged on the water outlet pipe. Since the sand filter system filters water for two times through conventional flushing and back flushing, the filtering effect is good.

Owner:KUNSHAN SHENGXING EQUIP INSTALLATION

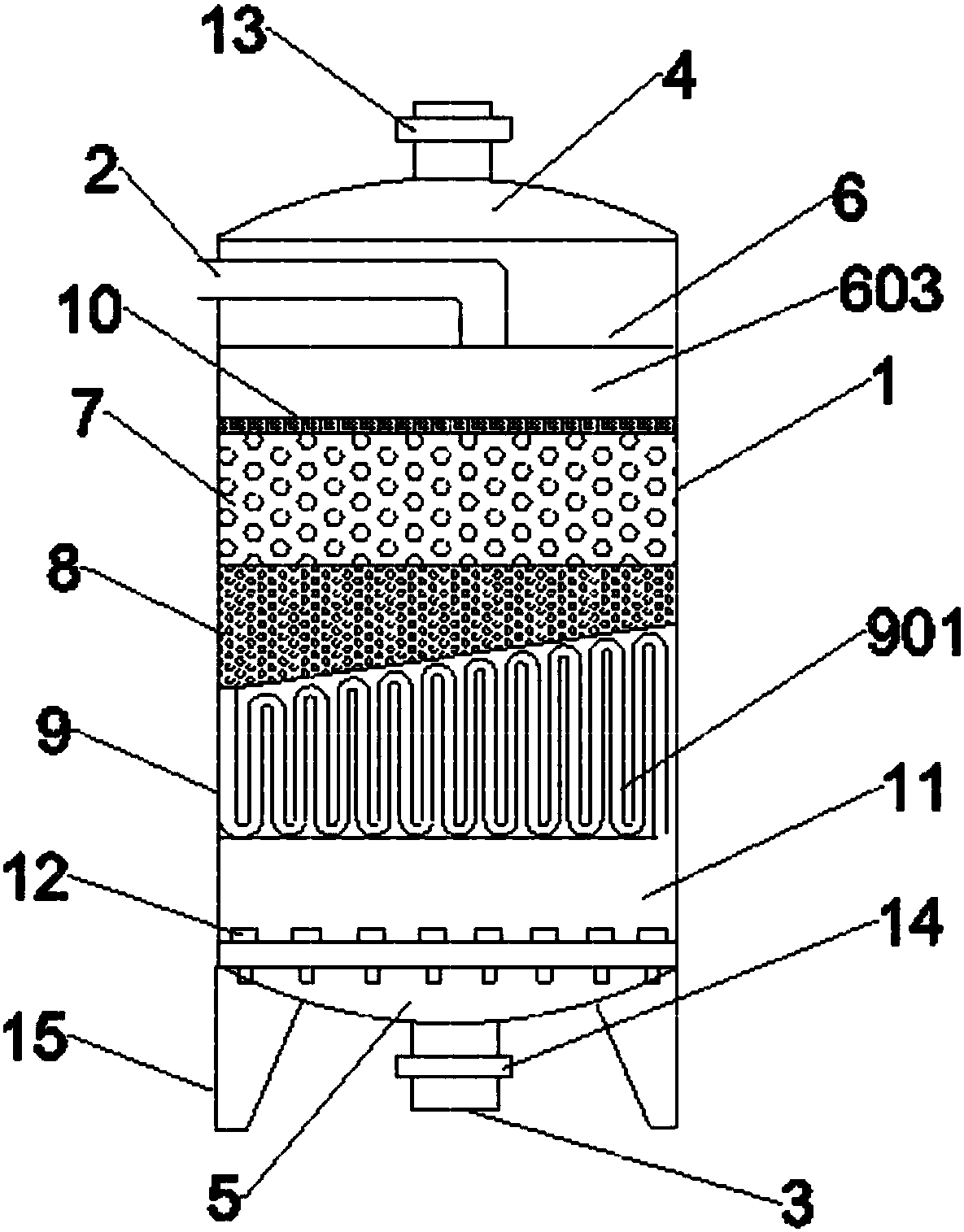

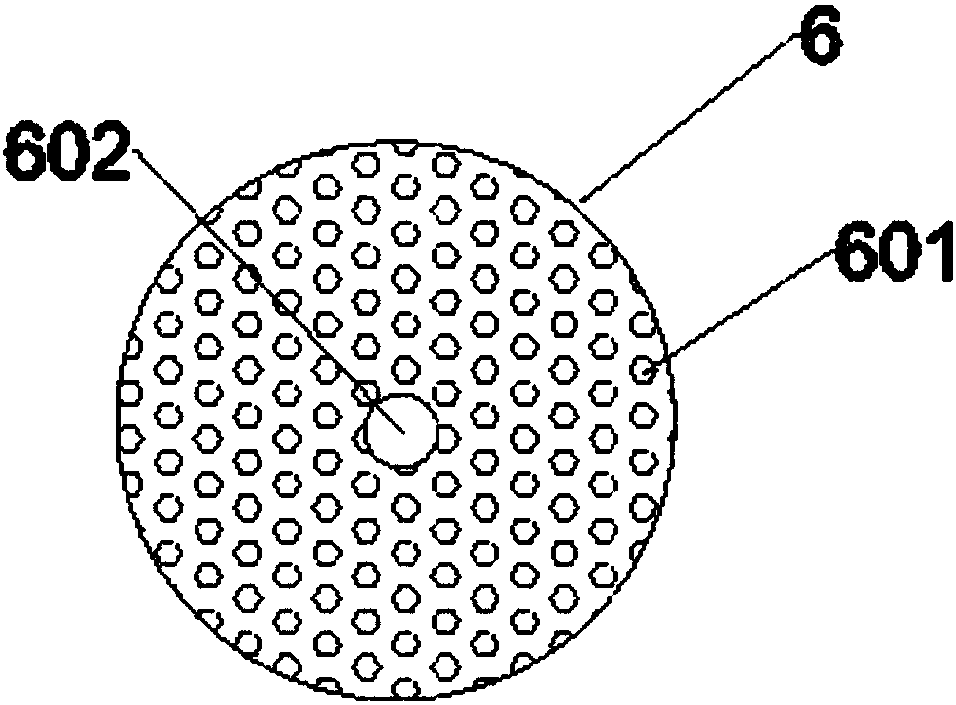

Silica sand filter for water treatment

InactiveCN108714323AAvoid enteringReduce entryLoose filtering material filtersGravity filtersSand filterSlow sand filter

The invention discloses a silica sand filter for water treatment. The middle of a filter tank is of a cylindrical structure. End enclosures are fixed to the upper end and the lower end of the filter tank respectively. An overflow tube of an L-shaped structure is fixed to the side portion of the filter tank. A lower inlet of the overflow tube is communicated with an inner cavity of the lower portion of the filter tank. The upper end of the overflow tube is communicated with an annular water outlet tube. The annular water outlet tube is arranged on the outer side of the upper portion of the filter tank, and is supported and fastened through an annular tube. An effluent stop plate is arranged at the lower inlet of the overflow tube. A 4-8cm gap is formed between the effluent stop plate and the lower inlet of the overflow tube. The effluent stop plate is fixed to the inner wall of the filter tank through a stop plate support. A water inlet tube is mounted at the top of the filter tank. Aninflow stop plate is arranged under the water inlet tube, and is fixed to the inner wall of the filter tank through a support rod. The silica sand filter has the advantages of high stability, good filtration effect and convenience in use.

Owner:安徽海沃特水务股份有限公司

Gravity feed water treatment system

ActiveUS9352979B2Increase flow rateImprove pressure resistanceTreatment using aerobic processesTreatment involving filtrationFlocculationSiphon

Owner:ACCESS BUSINESS GRP INT LLC

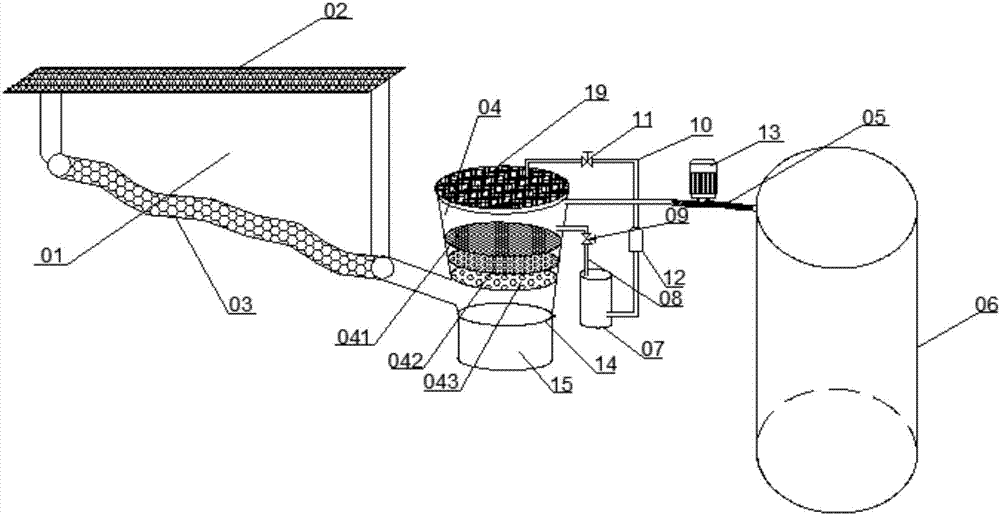

Expressway rainwater sustainable collection and purification device

InactiveCN107542156AAvoid easy cloggingAvoid the problem of not being able to collect in the sand treatment wellFatty/oily/floating substances removal devicesSewerage structuresCircular discEngineering

The invention discloses a rainwater sustainable collection and purification equipment for highways, which relates to the technical field of rainwater collection, and comprises water collecting ditches arranged on one or both sides of the expressway, and the top of the water collecting ditches is covered with a water ditch cover with filter holes A water collection pipe is laid on the bottom of the inner ditch of the water collection ditch, and several filter holes are evenly arranged on the surface of the water collection pipe. It also includes a sand filter treatment well, multiple grass planting ecological side ditches, and a reservoir. There are three layers of discs with holes in sequence, and the water collection pipes are connected downwards in a stepped manner to the bottom of the discs with holes in the lowest layer. There is a reserved water storage pool outside the sand filter treatment well, which is collected through the water storage pipes to the reserved storage. The rainwater in the pool is sprayed from top to bottom into the sand filter treatment well through the spray pipe and circulation pump. Through the implementation of the technical solution, the problem that the three-layer disc with holes will be blocked due to the self-settling effect of sand and mud for a long time will still cause rainwater to be unable to be discharged or cause secondary pollution to collected rainwater.

Owner:弘毅天承知识产权股份有限公司

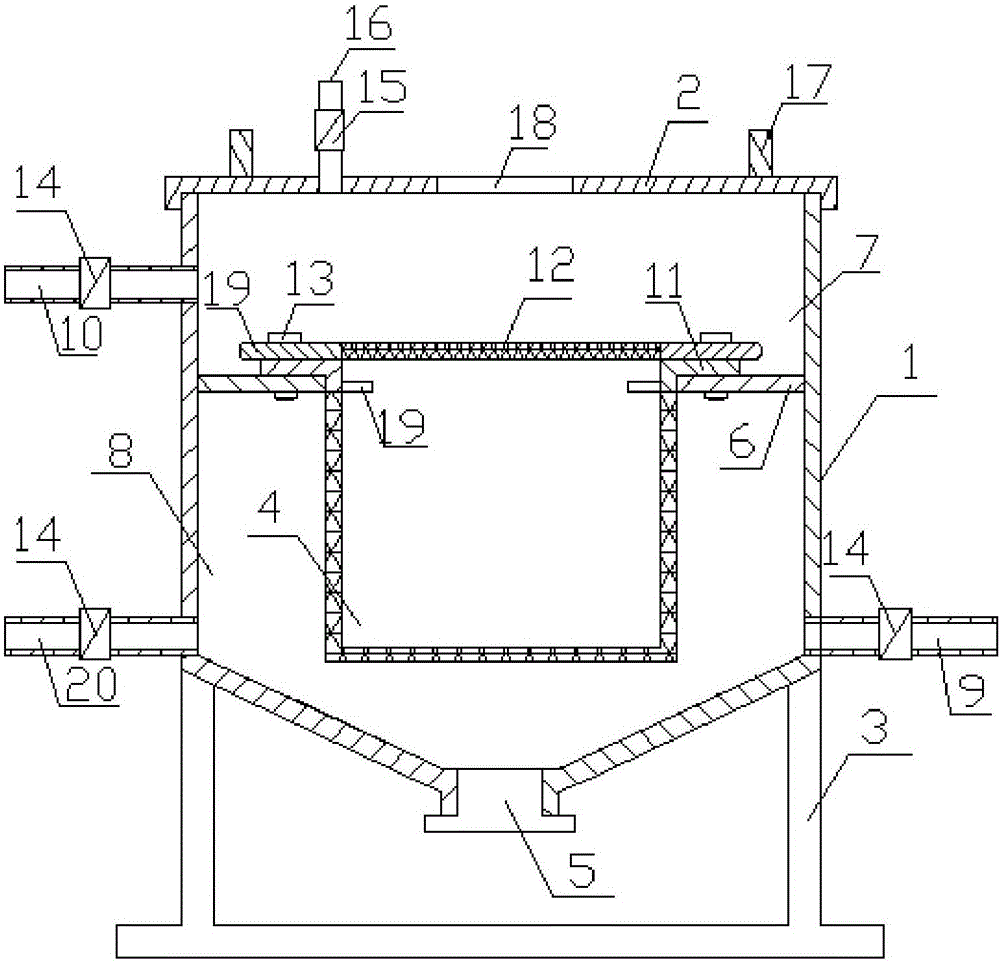

Novel water collection and backwashing sand filter

InactiveCN103239908AEffective interceptionIncrease the circulation areaLoose filtering material filtersGravity filtersLife timeFilter material

The invention relates to a novel water collection and backwashing sand filter. The sand filter comprises a tank body, wherein the upper part and the lower part of the tank body are respectively provided with a water inlet, a vent port, a water outlet and an air inlet, the middle part inside the tank body is a filter material layer, a screen plate is arranged inside the filter material layer, the screen plate is provided with a plurality of filter caps and a homogenizing filter material, a collection chamber is arranged below the screen plate, a water collection air distribution pipe is arranged inside the collection chamber, and the water collection air distribution pipe is communicated with the water outlet and the air inlet. The novel water collection and backwashing filter can thoroughly filter the sand and effectively intercept the fine organic particles, and the filtering efficiency is high; thoroughness in backwashing can be realized, the washing water can be saved, and the processing capacity can be increased; and the flow area of the filter cap is large, and the filter cap is anti-aging, has good pressure resistance and long service life, is hardly damaged, is safe and reliable and has low comprehensive cost; and the floor occupied area is small, rapidness in installation can be achieved, the investment can be saved, and convenience for operation and maintenance can be realized; and the tank bodies are connected in parallel for use, so that convenience for backwashing can be achieved.

Owner:扬州绿都环境工程设备有限公司

Ammonia nitrogen wastewater denitrification treatment method

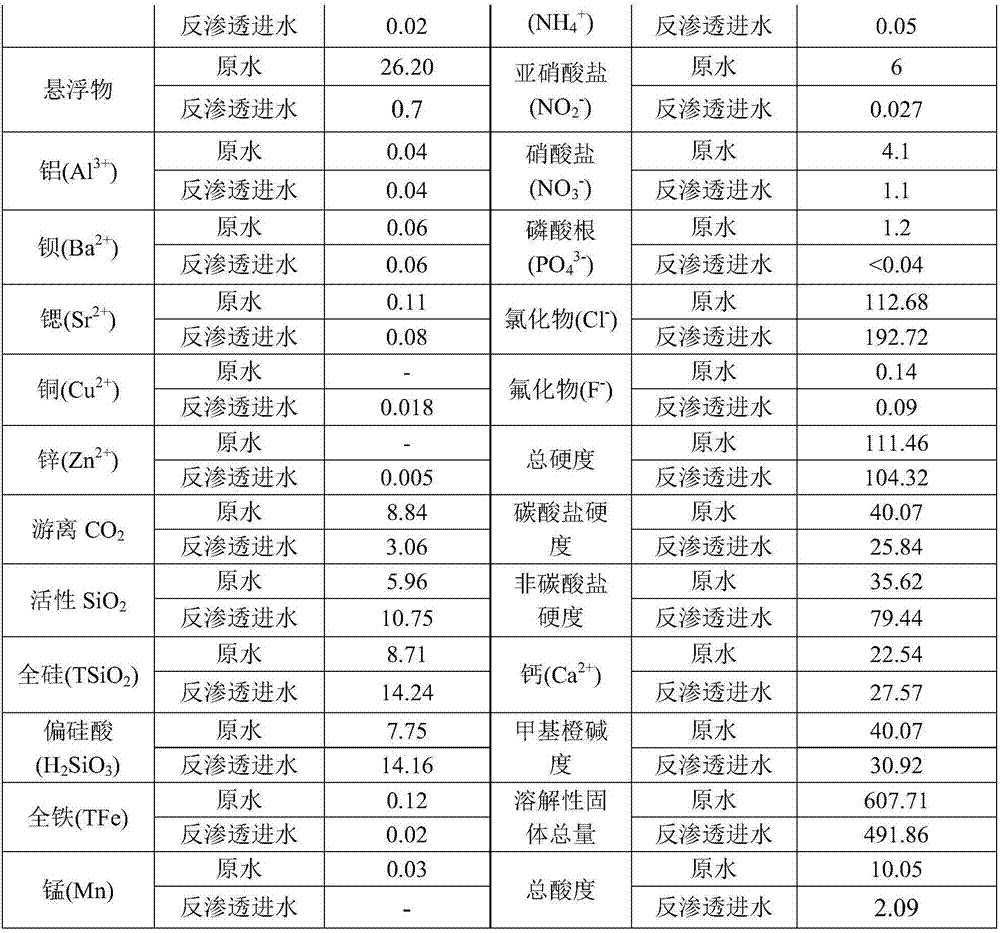

ActiveCN107973488ASolve the problem of reuse of boiler water in power plantsReduce aeration energy consumptionWater treatment compoundsTreatment involving filtrationUltrafiltrationBiological filter

The invention discloses an ammonia nitrogen wastewater denitrification treatment method, and solves the troubled problem of incomplete removal of nutrient elements of N, P, etc. in city tail water according to the characteristics of the city tail water. The method is characterized by that ammonia nitrogen wastewater is subjected to a series process of an anoxic denitrification biological filter and an aerobic nitrification biological filter, then is subjected to sedimentation treatment in a mechanical stirring clarification pool, and then is filtered in a sand filter to remove suspended solidsand some bacteria and microorganisms in the water, and the obtained filtrated water is subjected to ultrafiltration reverse osmosis system treatment. According to the method, a combined technology ofdenitrification and dephosphorization of the denitrification-nitrification biological filters, coagulation, disinfection, filtration, ultrafiltration and reverse osmosis is used, and the nitrification process is controlled at a short-term stage through addition of a nitrifying bacteria inhibitor into the nitrification filter, so that the problems that power plant aeration energy consumption is large, carbon source is in insufficient, service life of ultrafiltration membranes and reverse osmosis membranes is short, and the likes are solved, thereby providing a technical support for the economical use of the city tail water by the power plants.

Owner:SOUTH CHINA UNIV OF TECH +1

Automatically-cleaning and convenient-to-disassemble filtration method

InactiveCN107551670AEliminate cumbersome cleaning proceduresStructure does not affectLoose filtering material filtersGravity filtersWater detectorMicrocomputer

The invention discloses an automatically-cleaning and convenient-to-disassemble filtration method, in which a base is arranged, a filtering sand tank body is mounted above the base, a rotation cover is mounted on one side of the filtering sand tank body, a waterproof sealing pad is arranged on the inner side of the rotation cover, one end of the rotation cover is rotatably connected with the filtering sand tank body through a rotation shaft of the rotation cover, and the other end of the rotation cover is fixedly connected with the filtering sand tank body by a handed screwing bolt of the rotation cover; a quartz sand filtering layer, an activated carbon filtering layer, an anthracite filtering layer and a special filtering sand filtering layer are mounted in the filtering sand tank body,sliding grooves are formed in both sides of the inner wall of the filtering sand tank body; and a water flow detector is arranged and can be used for detecting water flow, so as to control switching on and off of a solenoid valve by data analysis and processing through a KS02Y microcomputer controller; the filtering sand tank body is cleaned through reverse flowing of water, so as to omit a tedious procedure of regular manual cleaning of the filtering sand tank body.

Owner:俞鉴卿

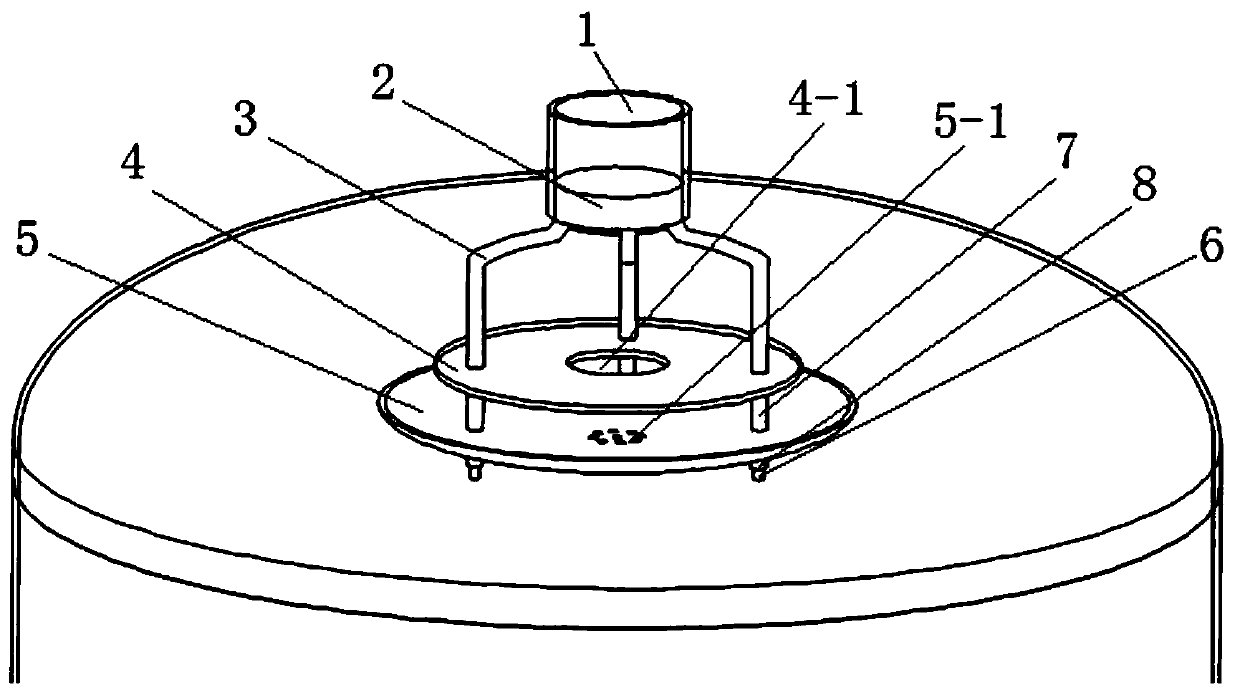

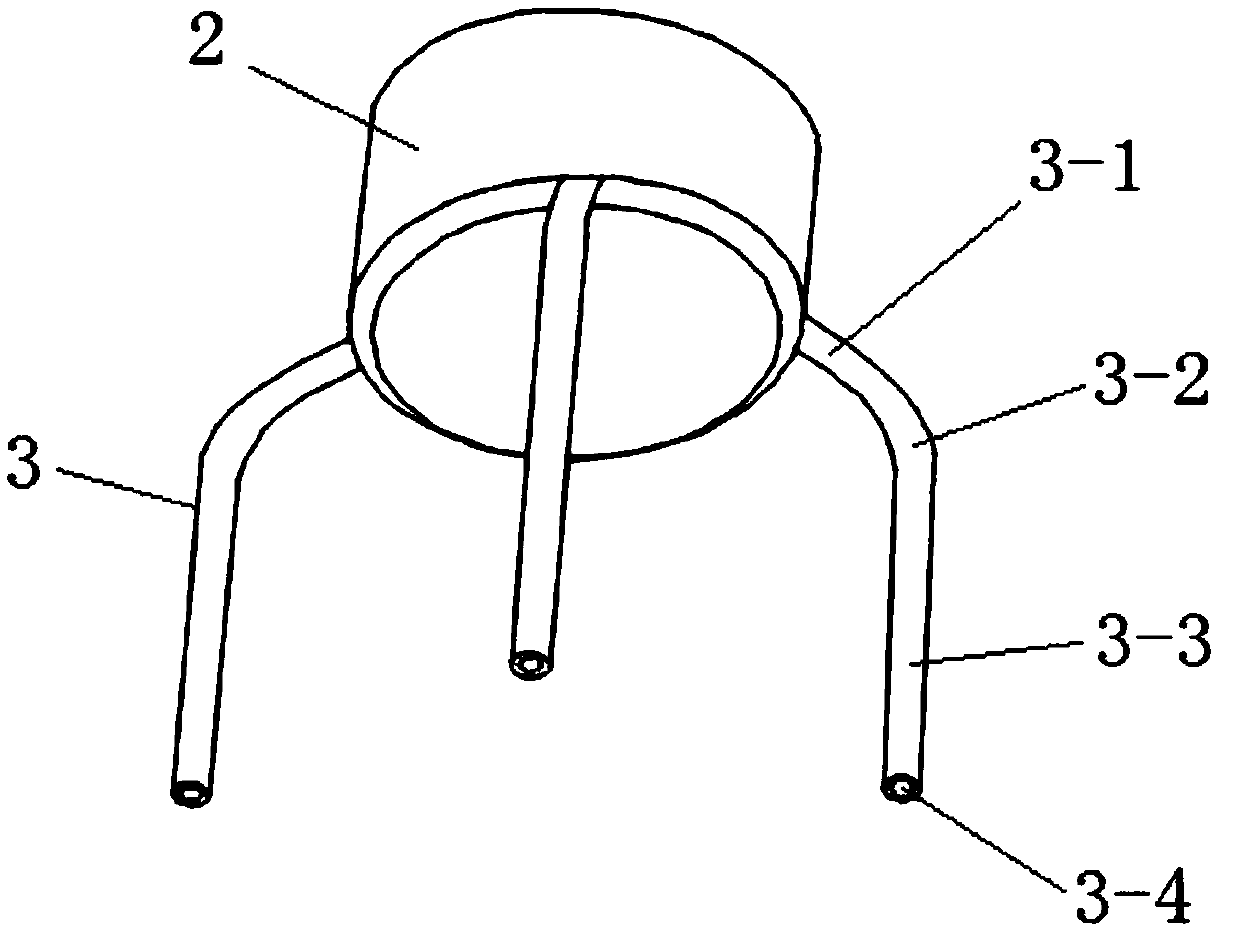

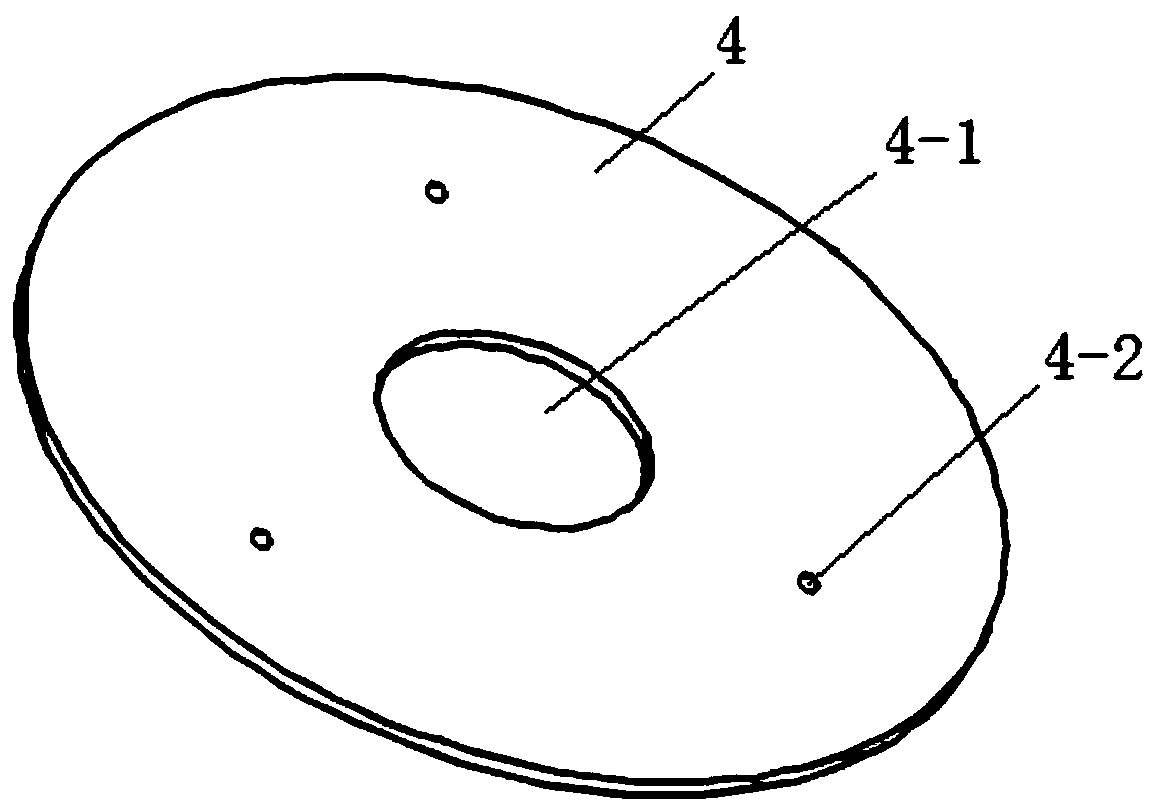

Water distributor for sand filter

PendingCN109529422AImprove uniformityExpand the scope ofLoose filtering material filtersGravity filtersEngineeringSewage treatment

The invention discloses a water distributor for a sand filter and relates to the technical field of sewage disposal. The water distributor comprises a cylindrical water inlet, a connecting bracket, anupper disc, a water distribution tray and a plurality of connecting parts; an internal thread is arranged on an inner wall of the water inlet; the water inlet is connected with the connecting bracketthrough a thread; the connecting bracket is placed on the upper disc; the water distribution tray is arranged under the upper disc; the upper disc is connected with the water distribution tray through the connecting parts; a circular hole is formed on the upper disc; a plurality of circular water-dispersing holes are formed on the water distribution tray. The water distributor for the sand filterdisclosed by the invention has a simple structure, will not be blocked and is capable of flexibly uniform distributing water at different flow rates. All the components are detachably connected and can be conveniently detached and stored.

Owner:FLT FILITERING SYST CO LTD

Boiler water treatment system

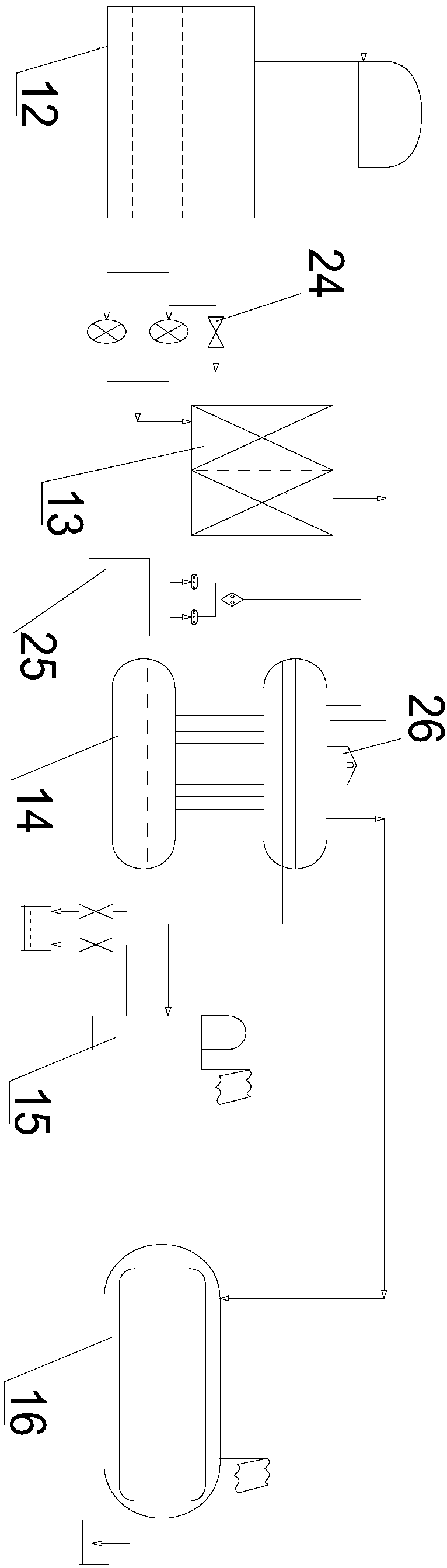

PendingCN108101269AAvoid corrosionPrevent scalingSpecific water treatment objectivesTreatment involving filtrationReverse osmosisWater quality

The invention discloses a boiler water treatment system. The boiler water treatment system comprises a deep well pump, a raw water tank, a soft water tank, a deaerator, a sand filter, a carbon filter,a security filter, a reverse osmosis device, a reverse osmosis water production tank, a first salt tank, a second salt tank, a deaerator, a coal economizer, a boiler steam pocket, a tandem expansionvessel and a reactor. The boiler water treatment system has a reasonable structure, comprehensive functions, remarkable water purification effects and a perfect system.

Owner:SUZHOU DISEN BIOLOGICAL ENERGY +1

Technique for biological treatment of mine acidic wastewater

InactiveCN101219844BIncrease concentrationReduce organic contentWaste water treatment from quariesTreatment with aerobic and anaerobic processesResource utilizationColorless Sulfur Bacteria

Owner:TAIYUAN UNIV OF TECH

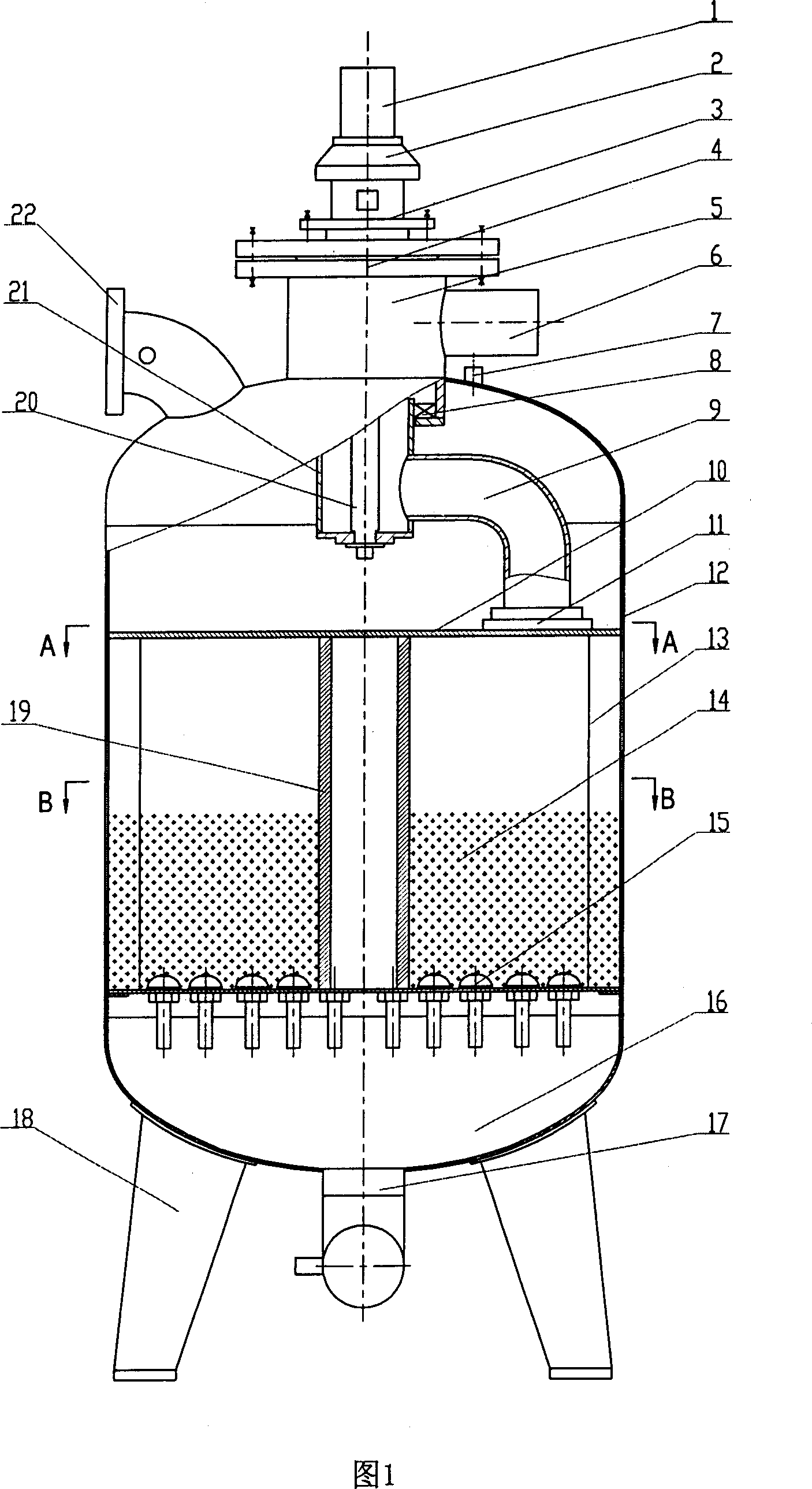

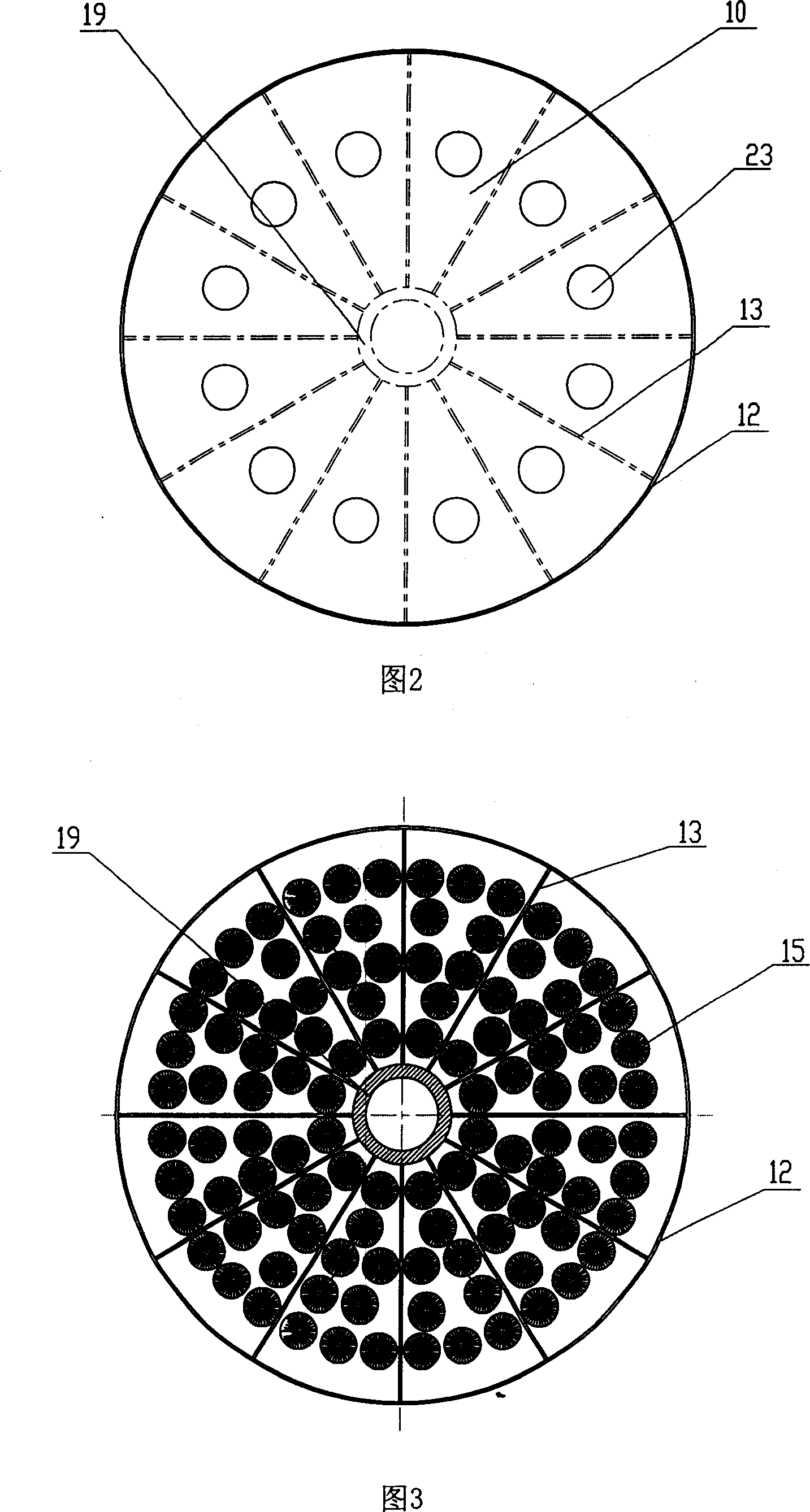

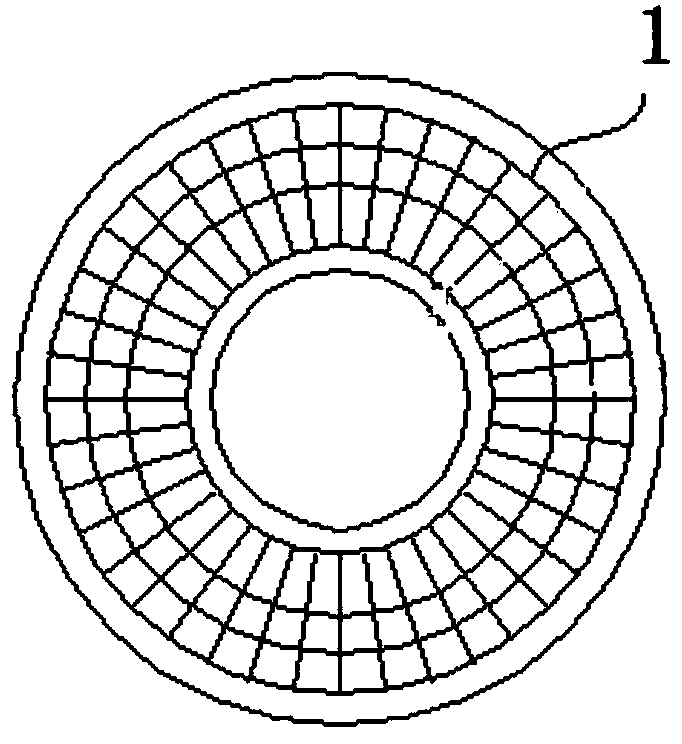

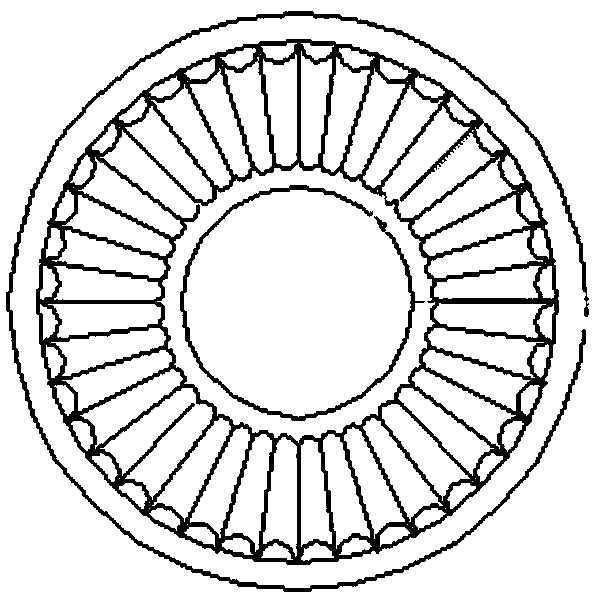

On-line back flushing sand filter

InactiveCN100363081CImprove work efficiencyHigh backwash pressureLoose filtering material filtersGravity filtersEngineeringFilter material

The on-line back flushing sand filter includes barrel, water inlet and blow-down port in the upper part of the barrel, water outlet in the lower part of the barrel, filtering material layer in the middle part and water collecting cavity below the filtering material layer. The present invention features that the middle part of the barrel has several partition boards to separate the filtering material layer into several independent filtering sectors, horizontal separating board with holes to the corresponding filtering sectors on the partition boards, hollow connecting arm over the separating board and set on one turntable, and driver for the turntable outside the barrel. The said structure makes it possible to back flush the filtering sectors one by one, so that the sand filter has greatly raised work efficiency, simple structure, small size, great back flushing pressure and good back flushing effect.

Owner:ZHEJIANG DEAN TECH

Water purification system for karst region

ActiveCN104445826AImprove purification effectEliminate health hazardsMultistage water/sewage treatmentWater treatment multistage treatmentsPurification methodsKarst

The invention provides a water purification system for a karst region. A purification layer at the bottom of a water purification pond sequentially consists of an upper purification layer, a middle purification layer and a lower purification layer from top to bottom, wherein the upper purification layer is formed by fillingcoarse sandwith grain size being 0.5m-5mm, the middle purification layer is formed by mixing and fillingmedium sandwith grain size being0.25mm-2mm and coarse sand,and the lower purification layer is formed by mixingfine sand with grain size being0.05mm-0.5mm and medium sand. A water outlet pipe is guided out from the bottom of the lower purification layer, the water outlet pipe which is guided out is divided into a first water pipe and a second water pipe, the first and second water pipes are respectively provided with stop valves, and the first water pipe extends into a water inlet of a slow sand filter. The system is used for solving the problem that water resources in stony desertification regions such as karst region are relatively deficient, the water quality of multipleplaces is relatively poor and huge healthy hidden trouble exists after the water is drunk for a long time, and existing conventional water purification method is not suitable for karst region. The system provided by the invention belongs to the field of water purification of the karst region.

Owner:GUIZHOU NORMAL UNIVERSITY

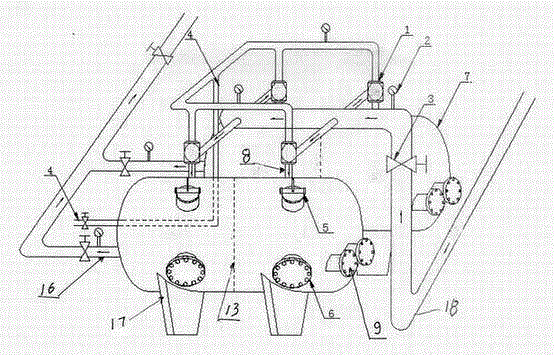

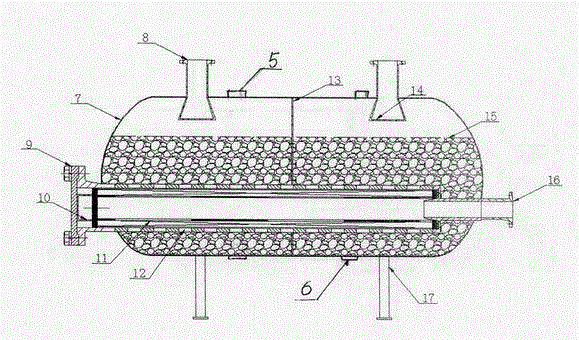

Micro-irrigation full-automatic back-wash sand filter

InactiveCN102716613AGood backwashing automationGood degree of automationFiltration circuitsEngineeringControl valves

Provided is a micro-irrigation full-automatic back-wash sand filter. Two sand filtering tanks are respectively and parallely mounted on a pair of supports, two filter drums are respectively, longitudinally and parallely arranged in the sand filtering tanks, the other end of each sand filtering tank respectively leads out of the tanks to form a water outlet, a stop valve and a pressure gage are respectively installed on a pipeline of each water outlet, a pulling handle is respectively installed on a filter element at one end of each flange cover, a separation plate is respectively and transversely arranged on the middle portion in each filtering tank, the top portions of the filtering tanks on two sides of the separation plate are respectively led out upwards to form a water inlet and a sand containing port, a back-wash control valve is respectively installed at each water inlet through a branch pipe, the other end of the branch pipe of the back-wash control valve is respectively in parallel connection with a water inlet pipe, a water adding pipe is respectively connected with each back-wash control valve towards the inside of the water inlet, the upper end of each back-wash control valve is respectively connected onto a blow-off pipe, a stop valve is respectively arranged on the blow-off pipe and the water inlet pipe, and two sand discharge ports are respectively arranged on the bottom side of each filtering tank.

Owner:FARMLAND IRRIGATION RES INST CHINESE ACAD OF AGRI SCI

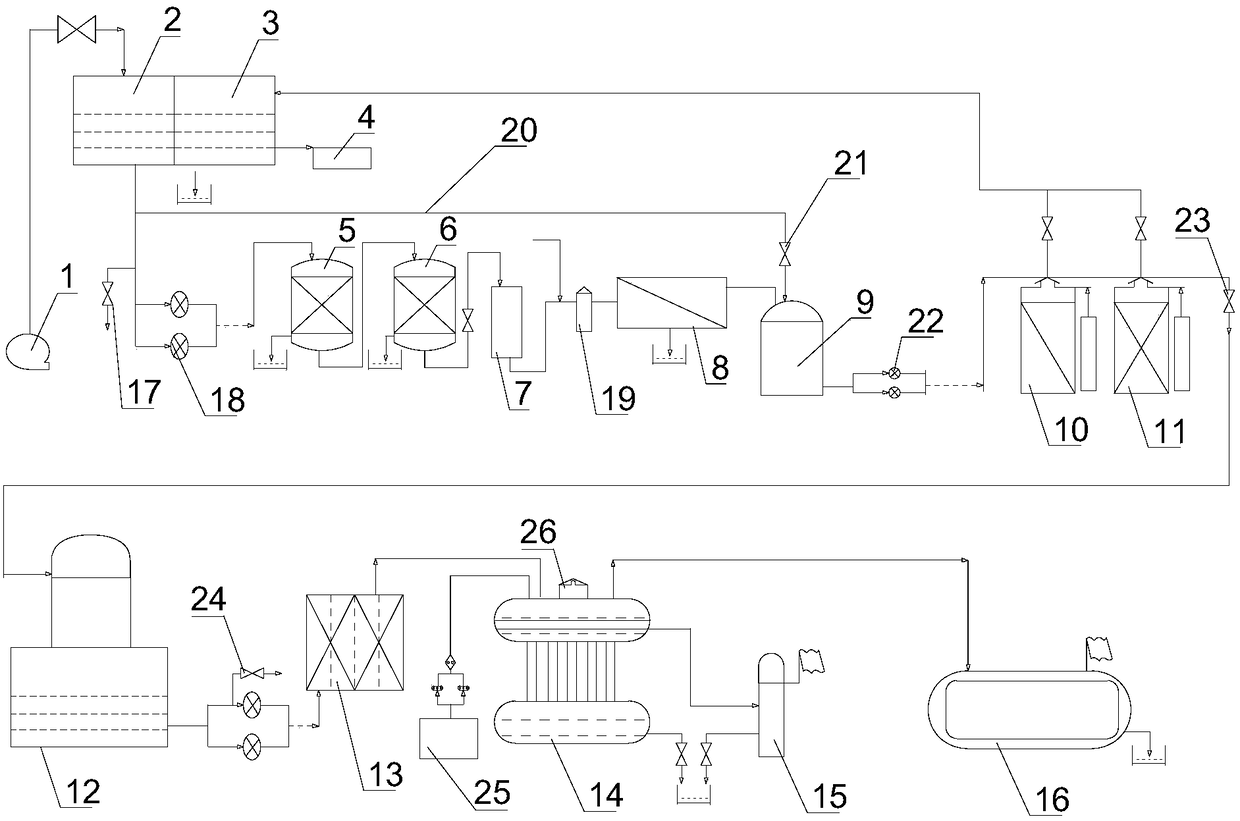

Drinking water treatment system

InactiveCN103435179AGood removal effectLow costMultistage water/sewage treatmentFlocculationWater treatment system

The invention relates to a drinking water treatment system, which comprises a water inlet lift pump, wherein the water inlet lift pump is connected with an electromagnetic flowmeter; the electromagnetic flowmeter is connected with a pre-ozonation contact tower; the pre-ozonation contact tower is connected with a mixing flocculation settling pond; the mixing flocculation settling pond is connected with a sand filter; the sand filter is connected with a disinfection pond; a sand filter water lift pond is mounted below the disinfection pond. The drinking water treatment system has the benefits that the cost is low, and the effect of removal of organic substances and particles is excellent.

Owner:LIUZHOU BOZE SCI & TECH

Oil sand filter easy to clean

InactiveCN106178649AEasy to cleanAvoid cloggingRefining by filtrationStationary filtering element filtersEngineeringSand filter

The invention provides an oil sand filter easy to clean. The oil sand filter comprises a barrel, a head cover and a filter cylinder arranged in the barrel; a cleaning opening with a bottom cover is formed in the bottom of the barrel, an annular lapping plate is fixedly arranged on the inner side wall of the barrel, the filter cylinder is connected to the lapping plate in a lapping mode, a filter cylinder cover is arranged at the top end of the filter cylinder, the side wall, the bottom and the filter cylinder cover of the filter cylinder are made of filter screens with filtration pores, and the filtration pores of the filter cylinder cover is smaller than those of the filter cylinder. The oil sand filter easy to clean has the advantages of being simple in structure, good in sand filtering effect, not prone to block the filter screens and capable of cleaning the filter screens.

Owner:天津帅通科技发展有限公司

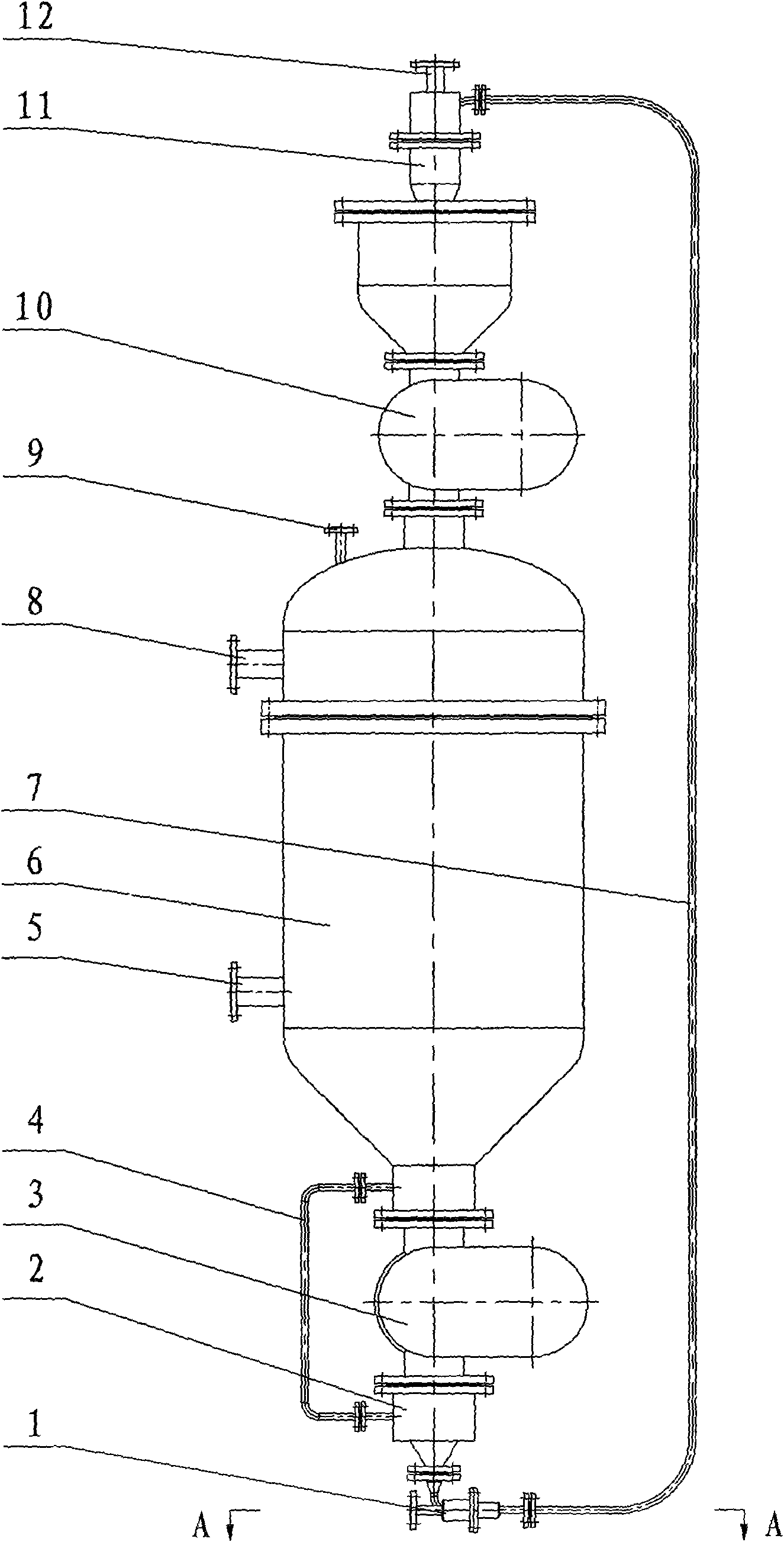

Pressure type dynamic sand filter

InactiveCN101564617AOvercome the defect of not being able to work continuouslyFiltration circuitsEngineeringFilter material

The present invention provides a pressure type dynamic sand filter. The invention relates to a sand filter applied for liquid filtering, and especially to a pressure type dynamic sand filter which can continuously wash the filter material. The aim of the invention is to overcome a defect that the common pressure type sand filter can not operate continuously, and provide the pressure type dynamic sand filter which can clean the filter material and operate continuously. The invention is mainly characterized in that the pressure type dynamic sand filter is composed of a sand filter tank body, a sand distribution valve, a sand-water separator, a bypass pipe, a sand conveyor, a sand conveying pipe and a sand washer. The sand filter tank body is internally installed with a water distribution ring, a flow guiding sand cone, a sand outlet filter element, a water outlet filter element, a sand dropping pipe and a sand distribution cone. When the pressure type dynamic sand filter operates normally, the raw water passes through a water inlet, the water distribution ring and the filter material layer, and is discharged from the water outlet filter element and the water outlet after filtering. Simultaneously the filter material is washed continuously through the sand distribution valve, the sand conveyor, the sand conveying pipe and the sand washer, and then drops into the sand filter tank body and forms a circulation.

Owner:福建省江南冷却科技有限公司

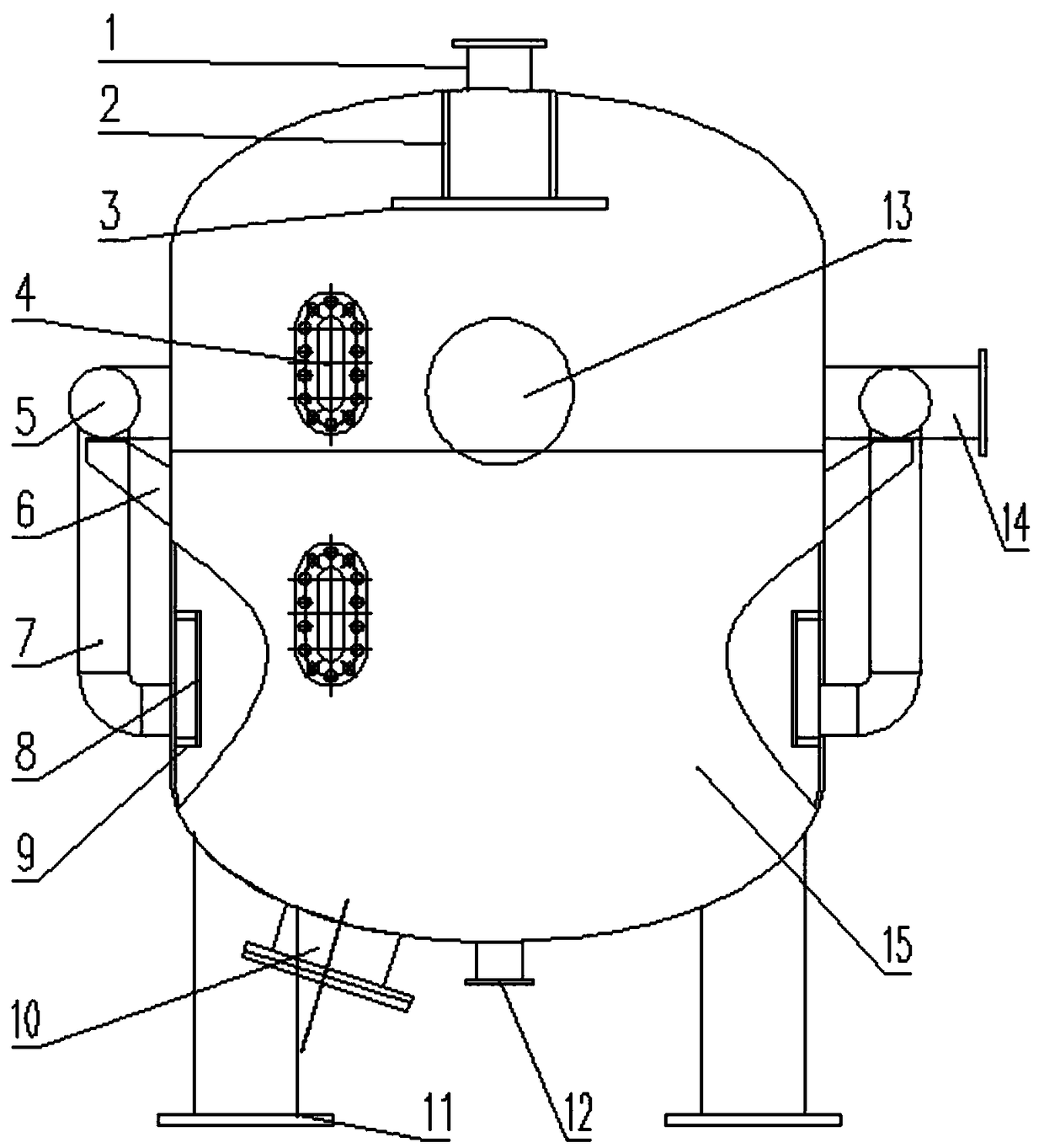

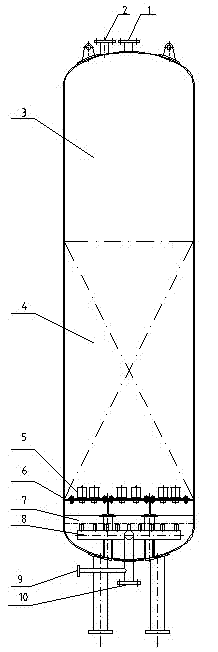

Quartz-sand filter for deep treatment of sewage

InactiveCN108273294ARelieve filter pressureExtended cleaning cycleLoose filtering material filtersGravity filtersWater leakSewage

The invention discloses a quartz-sand filter for deep treatment of sewage. The quartz-sand filter comprises a filter body, an upper sealing head, a lower sealing head, an upper manhole and a lower manhole, a water inlet and a water outlet, wherein the upper sealing head and the lower sealing head are arranged at the top part and the bottom part of the filter body in sequence; the upper manhole andthe lower manhole are respectively arranged at the top parts of the upper sealing head and the lower sealing head; the water inlet is arranged in the top part of the left side of the filter body andthe water outlet is arranged in the bottom part of the lower manhole; a water distributor is connected at the right side of the water inlet; a plurality of water leaking holes are uniformly opened inthe bottom part of the water distributor, and a coarse filtering net is arranged at the bottom part of the water distributor; a quartz-sand layer is arranged under the water distributor and comprisesa first-stage quartz-sand layer, a second-stage quartz-sand layer and a third-stage quartz-sand layer which are arranged in sequence from top to bottom; the particle diameters of the quartz sand of the first-stage quartz-sand layer, the second-stage quartz-sand layer and the third-stage quartz-sand layer are reduced in sequence; the bottom part of the second-stage quartz-sand layer is arranged obliquely; the third-stage quartz-sand layer consists of a plurality of snake-shaped pipes which are arranged in a side-by-side manner; the upper ends of the snake-shaped pipes are provided with openingswhich are communicated with the oblique bottom parts of the second-stage quartz-sand layer.

Owner:SICHUAN STONG EURO & AMERICA ENVIRONMENT ENG

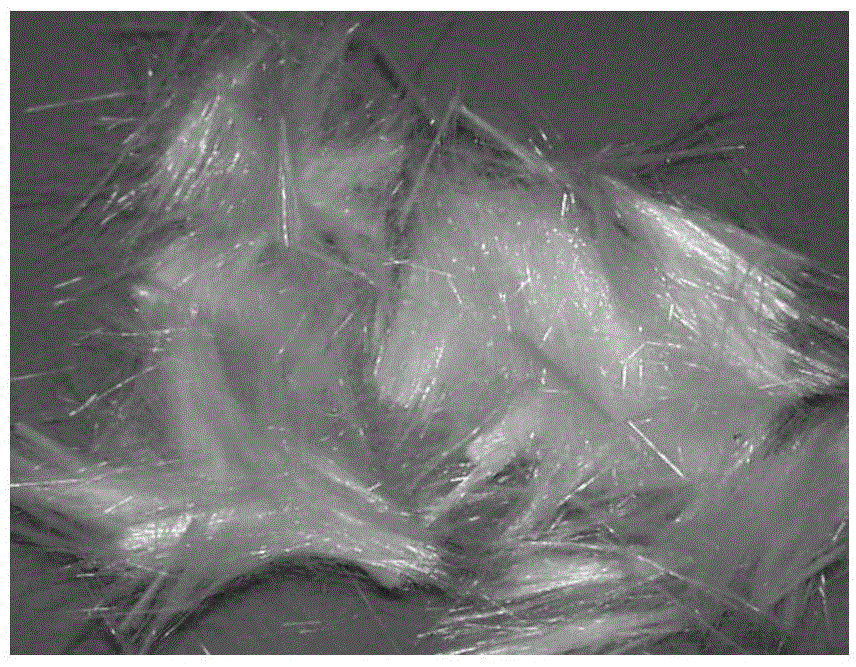

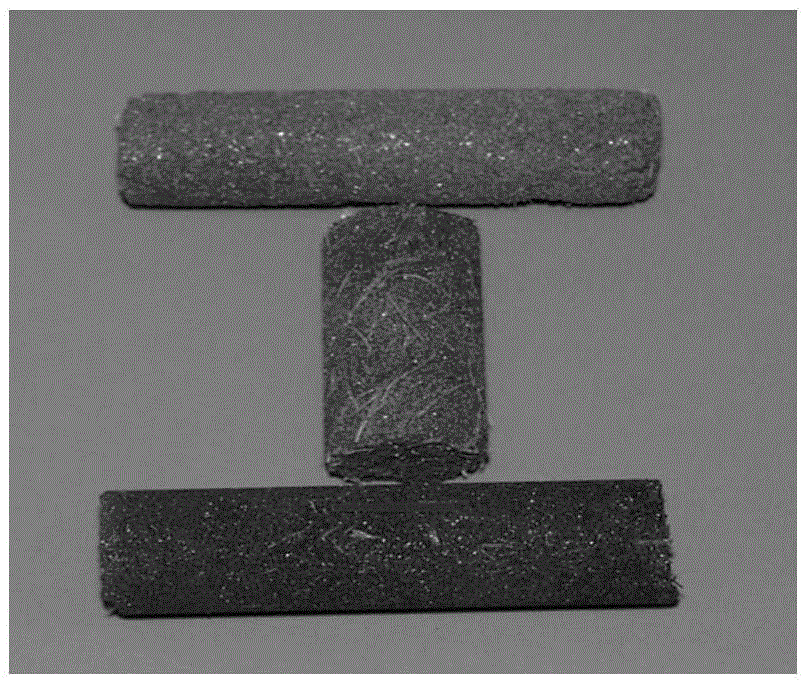

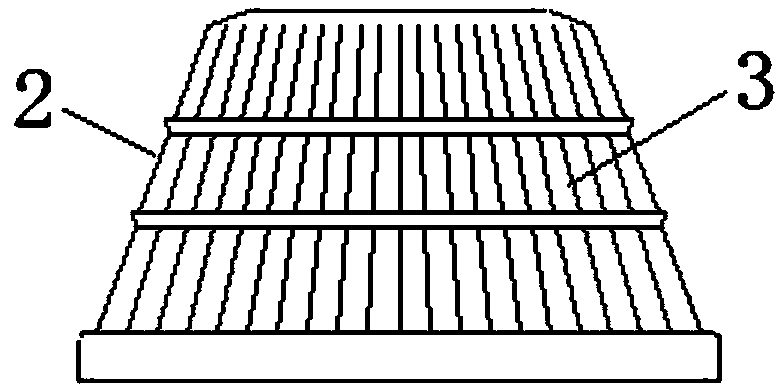

Fiber composite filter body for sand control, sand filter tube and preparation method

The invention provides a sand-proof fiber composite filter body, a sand-proof sand-filtering tube and a preparation method. The sand-proof fiber composite filter body is prepared from a propping agent coated with a coating and a fiber which is surface-processed by a silane coupling agent through die-filling thermal moulding. The sand-proof sand-filtering tube is composed of a central tube provided with an overflow hole and the fiber composite filter body sleeving the central tube. The fiber composite filter body is fixed on an overflow hole part on the central tube. The invention also provides the preparation method of the fiber composite filter body and an assembling method of the sand-proof sand-filtering tube. The fiber composite filter body is high in strength, is good in flexibility, is good in medium resistance, is uniform in pore distribution, is good in permeability and is good in sand-proof effect.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Self-healing filter cap of sand filter and mounting and using method of filter cap

ActiveCN107823927AAffect the replacement cycleExtended replacement cycleLoose filtering material filtersGravity filtersSelf-healingFilter material

The invention discloses a self-healing filter cap of a sand filter and a mounting and using method of the filter cap. The filter cap comprises a filter bearing assembly, a water and air part and a self-healing fastening part, wherein the filter bearing assembly is used for bearing granular filter materials and allowing clear water to pass; the water and air part is used for guiding filtered waterto a filter plate and allowing backwash water and compressed air to pass; the self-healing fastening part is used for fastening and connecting the filter plate and filtering the filter materials secondarily; the filter bearing assembly is connected with the self-healing fastening part through the water and air part. With application of the self-healing filter cap of the sand filter, damage to mainline equipment by the fact that the granular filter materials in the sand filter enter a circulating water system can be avoided to the greatest extent, and influence on product quality is avoided.

Owner:MAANSHAN IRON & STEEL CO LTD

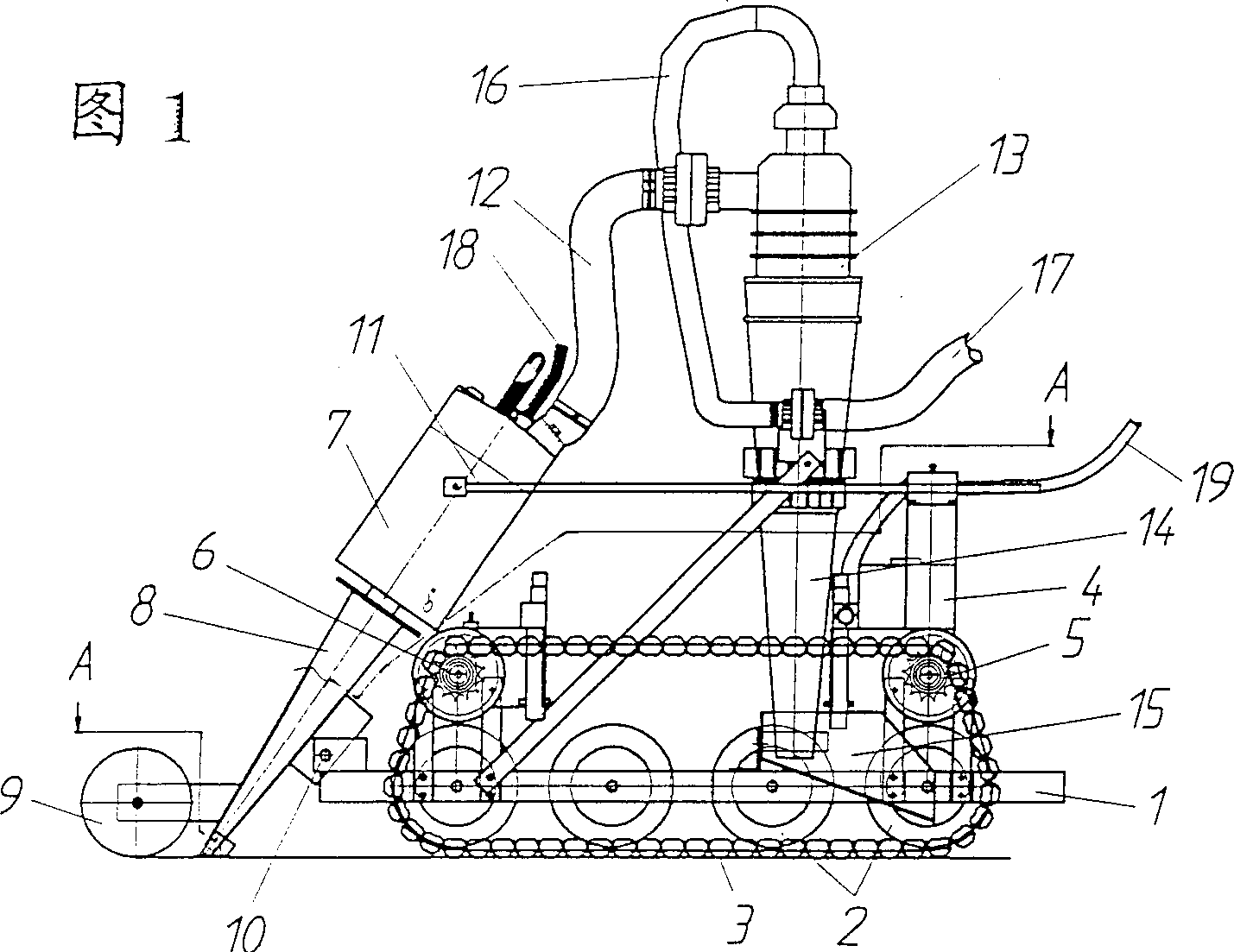

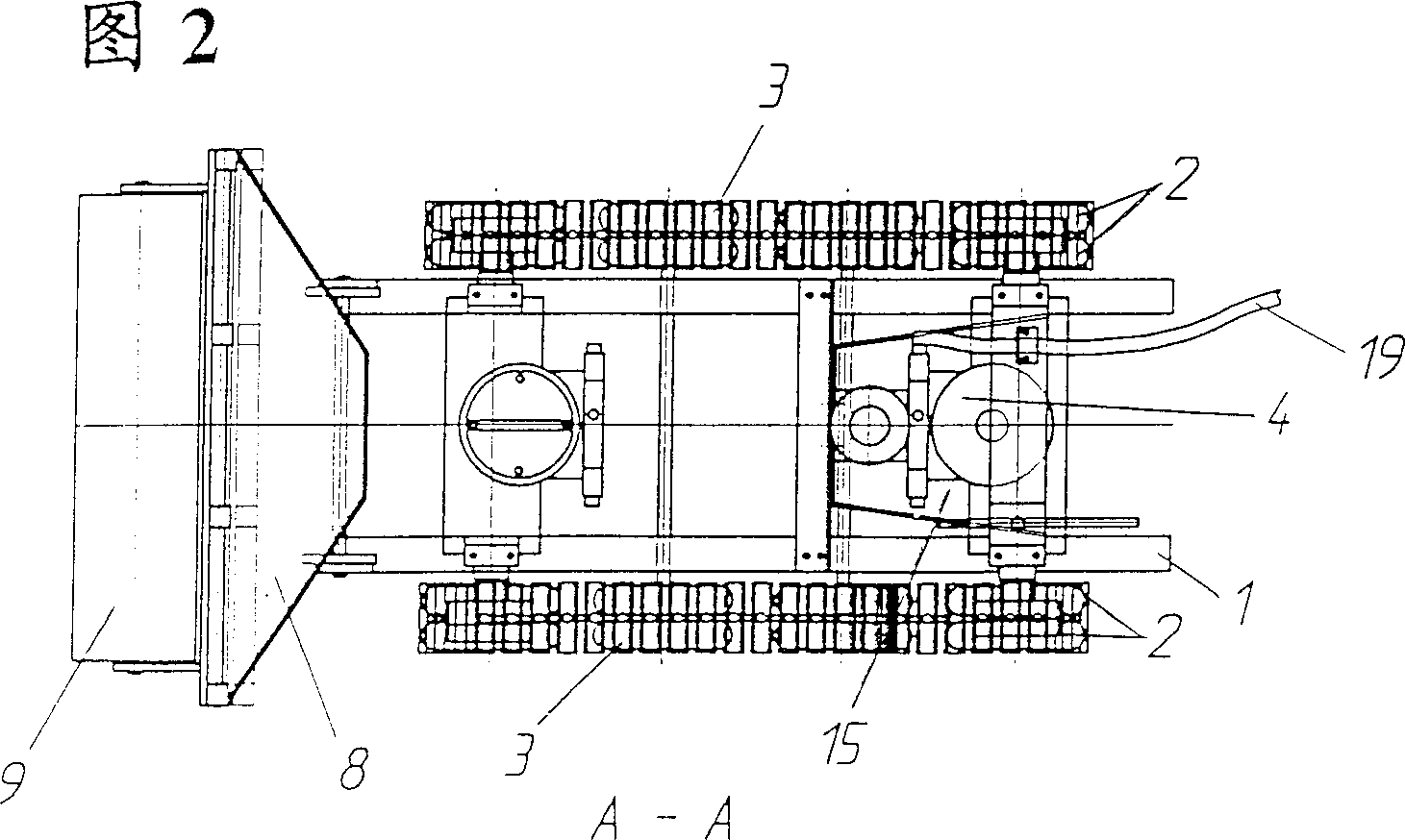

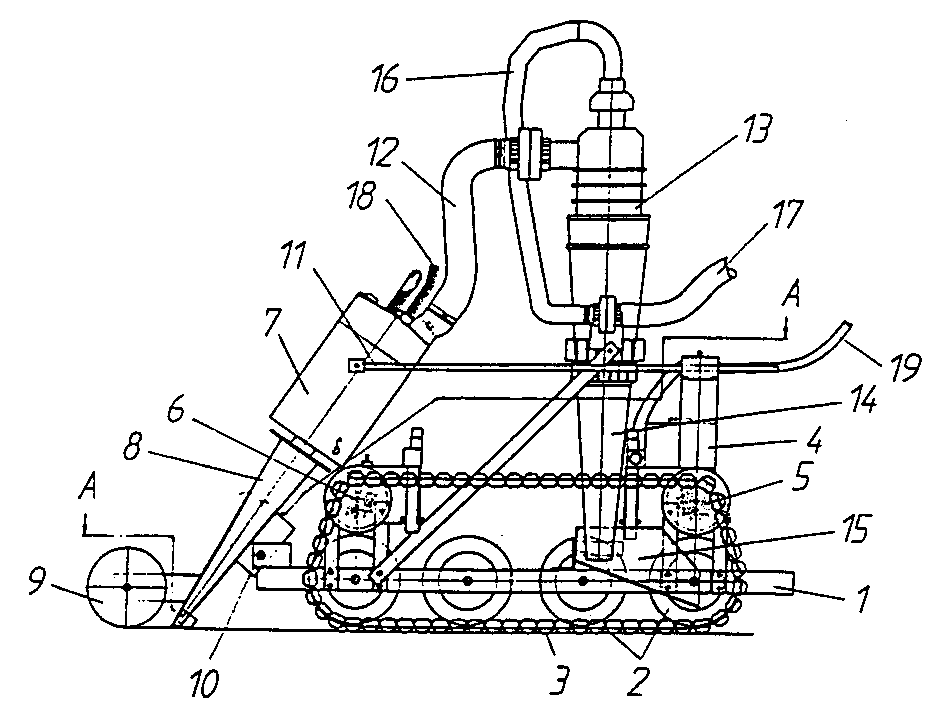

Method and device for cleaning bottoms of pools with sand beds

The invention relates to a method and an apparatus for cleaning the sand beds of slow sand filters, infiltration basins and pools of other types having sand beds in water treatment works and similar plants, while the filter is in service, by removing a few centimeters of the bed surface, cleaning the sand of the sludge or filter film formed on the bed surface, and discharging the separated sludge, or to a suitable disposal site. This is achieved using a tracked cleaning machine equipped with a submersible pump (7) and nozzle (8) to remove the top layer of sludge-bearing sand from the bed, cleaning the sludge from the sand thus removed in a hydrocyclone (13), returning the cleaned sand to the bed via a spreader plate (15) and discharging the water-suspended sludge to a drain or to a suitable disposal site through a hose (17).

Owner:WEDA POOLCLEANER

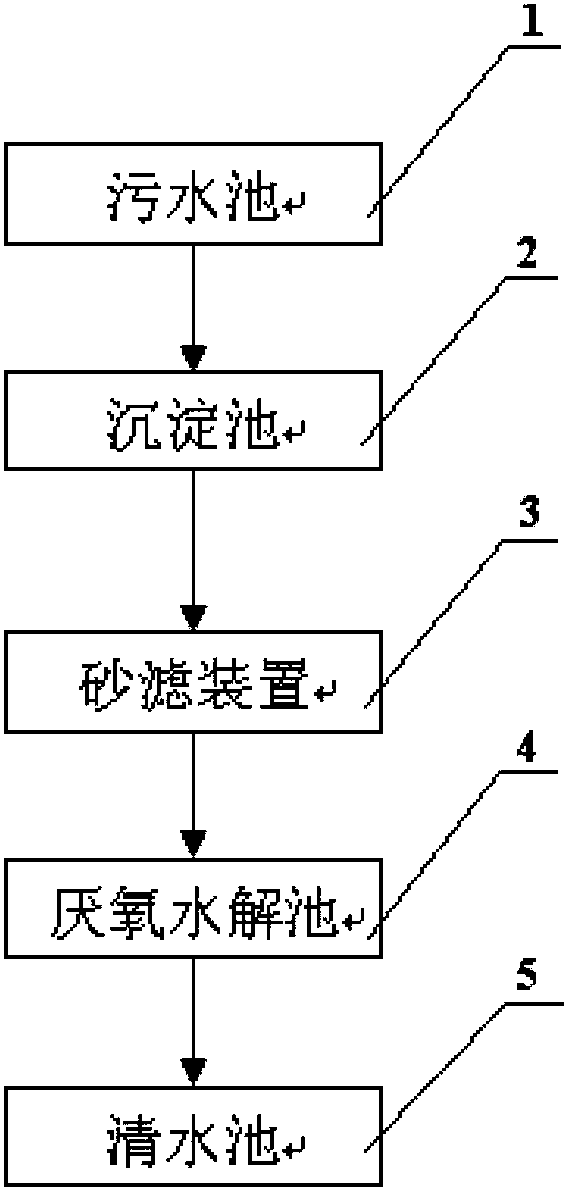

Sewage treatment system used in precision-investment casting technique

InactiveCN103351079AEffectively filter outLow running costMultistage water/sewage treatmentDental Casting TechniqueFilter effect

The invention discloses a sewage treatment system used in a precision-investment casting technique. The sewage treatment system comprises a sewage tank for collecting sewage in a workshop, and a sedimentation tank, a sand filter, an anaerobic hydrolysis pond and a clean water tank which are communicated with the sewage tank in sequence, wherein the sand filter comprises a one-stage sand filter and a two-stage sand filter; the sand filter consists of a converse-trapezoid opening container and filter sand paved in the opening container; the anaerobic hydrolysis pond consists of a one-stage anaerobic hydrolysis pond, a two-stage anaerobic hydrolysis pond, a three-stage anaerobic hydrolysis pond and a four-stage anaerobic hydrolysis pond. The sand filter comprises the one-stage sand filter and the two-stage sand filter, so that toxic impurities such as ammonia and chlorine in the sewage can be effectively filtered, the filter effect is good, the sewage after treatment can meet the standard of industrial water, and the sewage treatment system is low in cost during running.

Owner:TIANCHANG TIANXIANG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com