Deep sand filter

A sand filter and depth-type technology, which is applied in the direction of gravity filter, loose filter material filter, filter separation, etc., can solve the problems of energy input and cost increase, operation efficiency decrease, environmental pollution increase, etc., and achieve simple structure, The effect of small equipment investment and increased filtration area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

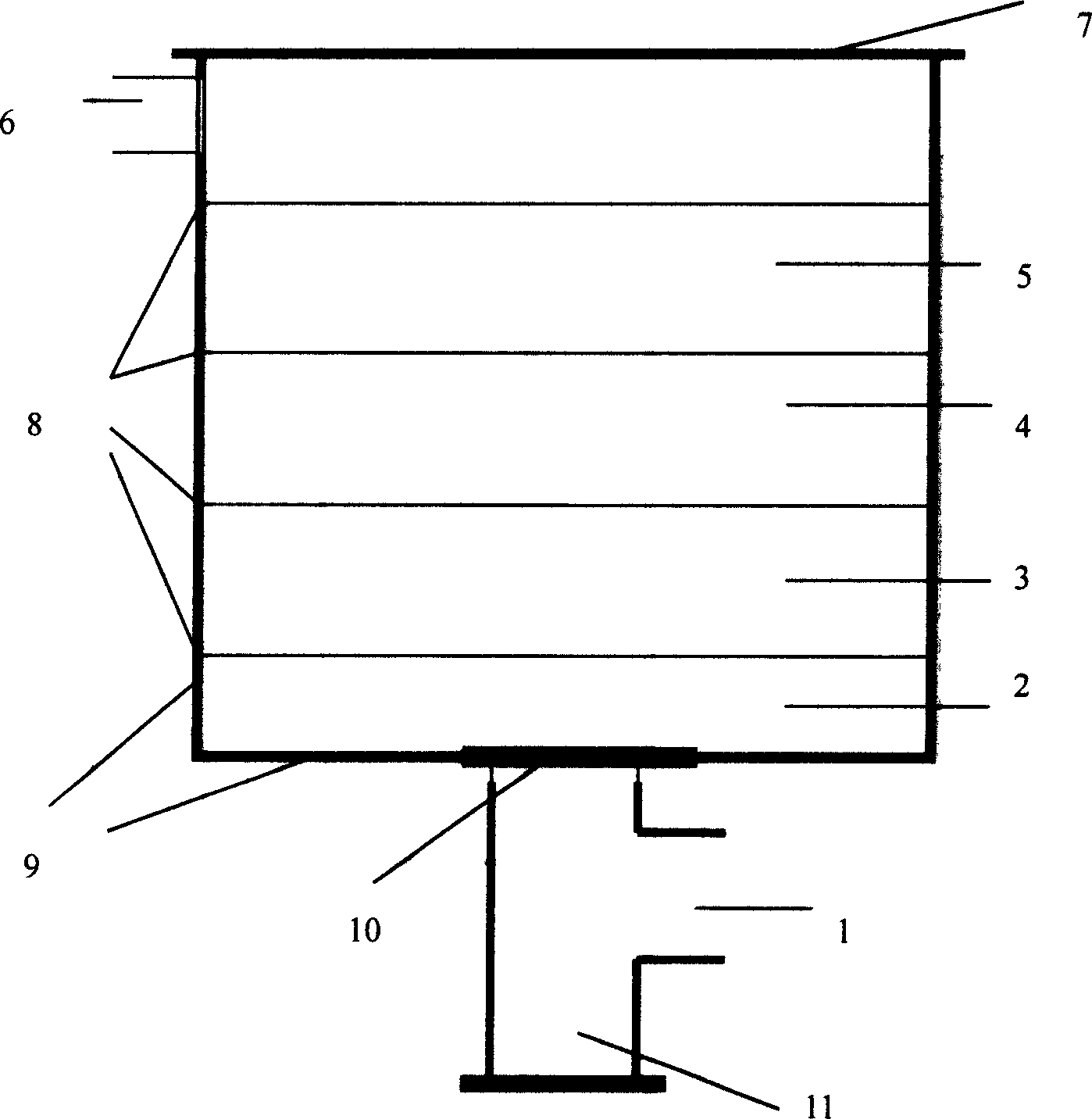

[0051] A cylindrical upflow depth type sand filter made of ABS material, such as figure 1 Shown, body of wall 9 wall thicknesses 3 millimeters, internal diameter 200 millimeters, height 500 millimeters, water inlet pipe 1 and outlet pipe 6 internal diameters 30 millimeters, top is provided with seal cover 7. There are three layers of sand inside, and a partition 8 is arranged between each layer of sand. The coarse sand area 3 in the bottom layer has a grain size of 20-2 mm and a thickness of 100 mm. The sand grain size of the middle sand area 4 in the middle layer is 2-0.3 mm. , thickness 50, the sand particle size of the upper fine sand area 5 is 0.3-0.01 mm, and the thickness is 200 mm. There is a 100mm height difference between the upper part of the sand layer and the outlet pipe to prevent the fine sand from flowing out together with the filtered water. Take 300 liters of rainwater flowing down from the roof, suspended matter SS 150ppm, sludge index SDI 30, and filter it ...

Embodiment 2

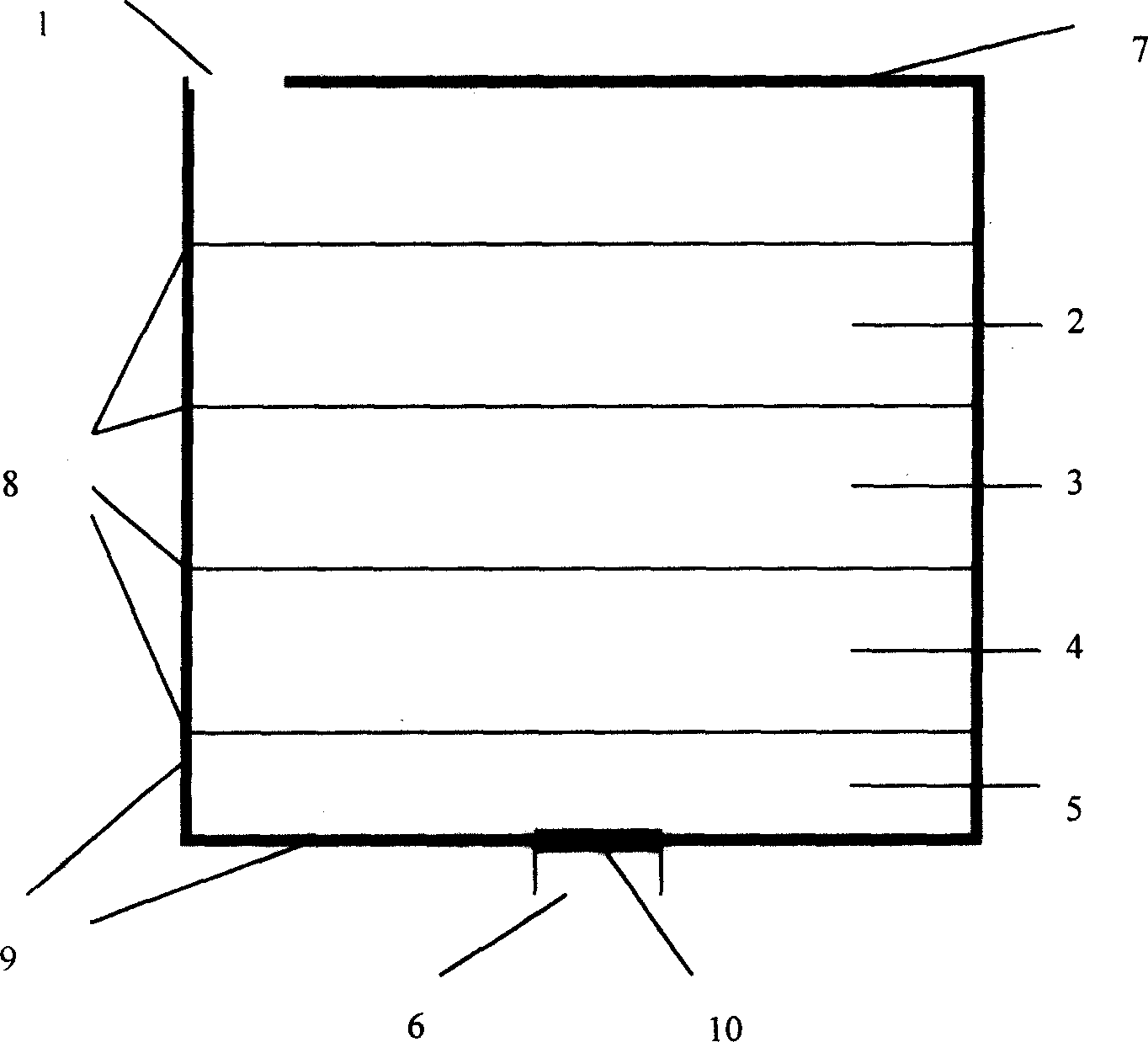

[0053] Square column type downflow depth type sand filter, such as figure 2 As shown, the wall body 9 and the water outlet pipe 6 are made of glass, the wall thickness is 1 mm, the upper cover 7 is arranged on it, the side length is 10 mm, and the height is 35 mm. There are three layers of sand inside, and the size of the upper layer 2 sand grains is 2-0.3 mm. , 5 mm thick, the middle layer 3 sand grain size is 0.3-0.1 mm, 5 mm thick, the lower layer 4 sand grain size is 0.1-0.01 mm, 15 mm thick, the bottom, middle and upper parts use apertures of 0.01 mm, 0.01 mm, 0.1 mm And 0.3 mm of 1 mm thick polyester sheet separator 8 with a porosity of 20%. Collect 200ml of clean rainwater flowing down from the roof, suspended solids SS100ppm, sludge index SDI 20, rainwater enters the deep sand filter from inlet 1, and as the rainwater flows down from the bottom, large suspended solids are mainly trapped in the upper layer of large and medium sand particles , fine suspended solids are...

Embodiment 3

[0055] Next to a highway, there is a water injection well with an inner diameter of 200 mm and a depth of 10 meters. In order to effectively utilize rainwater resources, configure the rectangular cylindrical upflow type depth sand filter of the present invention to the water injection well, which is 4 meters long, 2 meters wide and 1 meter high, because the rainwater surface below cannot reach the top of the depth sand filter. Therefore, only cover the upper part of the filter with a soft plastic cloth to prevent rainwater and dust from entering the water injection well without being filtered by the deep sand filter without sealing. There is a height difference of 1 meter between the upper parts of the filters for faster filtration. There are 5 layers of sand inside the filter, the particle size and thickness are different from bottom to top, the first layer is 200-20 mm, 400 mm, the second layer is 20-2 mm, 200 mm, the third layer is 2-0.6 mm, 150 mm, the fourth layer, 0.6-0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com