Non-woven fabric engine oil filter element

A technology for non-woven fabrics and oil filtration, which is applied in the fields of filtration and separation, non-woven fabrics, textiles and papermaking, etc., can solve the problems of general filtration effect and short life, and achieves high filtration effect, service life and high filtration accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

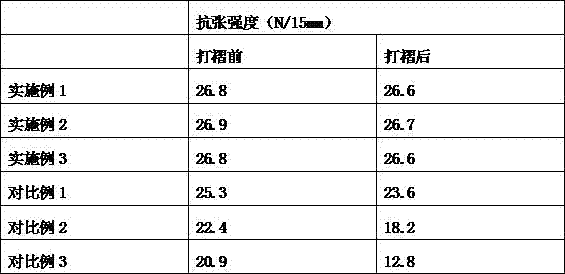

Examples

Embodiment 1

[0019] A non-woven oil filter, the preparation method of the non-woven oil filter comprises the following steps:

[0020] (1) Soak the bamboo slices in ethanol solution for 2 hours, then take them out, soak them in sodium hydroxide solution for 40 minutes, then filter them, dry them to constant weight, and carry out carbonization treatment, then use the carbonized bamboo slices with Grind with a flat jet mill until the particle size is ≤1.0um to obtain carbon powder. Mix the carbon powder and coupling agent solution at a ratio of 150g: 450mL and process for 40 minutes, then filter and dry to constant weight;

[0021] (2) In parts by weight, uniformly mix 80 parts of polypropylene, 15 parts of carbon powder, 5 parts of diatomaceous earth, 3 parts of epoxy soybean oil, and 1.2 parts of nano-silica, add them to a twin-screw extruder, and extrude out of granulation to obtain masterbatch;

[0022] (3) The master batch obtained in step (2) is made into a non-woven fabric by a melt ...

Embodiment 2

[0032] A non-woven oil filter, the preparation method of the non-woven oil filter comprises the following steps:

[0033] (1) Soak the bamboo slices in ethanol solution for 3 hours, then take them out, soak them in sodium hydroxide solution for 50 minutes, then filter them, dry them to constant weight, and carry out carbonization treatment, then use the carbonized bamboo slices with Grind with a flat jet mill until the particle size is ≤1.0um to obtain carbon powder. Mix the carbon powder and coupling agent solution at a ratio of 200g: 450mL and process for 40 minutes, then filter and dry to constant weight;

[0034] (2) In parts by weight, uniformly mix 85 parts of polypropylene, 18 parts of carbon powder, 6 parts of diatomaceous earth, 5 parts of epoxy soybean oil, and 1.8 parts of nano-silica, add them to a twin-screw extruder, and extrude out of granulation to obtain masterbatch;

[0035] (3) The master batch obtained in step (2) is made into a non-woven fabric by a melt ...

Embodiment 3

[0045] A non-woven oil filter, the preparation method of the non-woven oil filter comprises the following steps:

[0046] (1) Soak the bamboo slices in ethanol solution for 2.5 hours, then take them out, soak them in sodium hydroxide solution for 45 minutes, then filter them, dry them to constant weight, and carry out carbonization treatment, then use the carbonized bamboo slices with Grind with a flat jet mill until the particle size is ≤1.0um to obtain carbon powder. Mix the carbon powder and coupling agent solution at a ratio of 180g: 450mL and process for 40 minutes, then filter and dry to constant weight;

[0047] (2) In parts by weight, uniformly mix 82 parts of polypropylene, 16.5 parts of carbon powder, 5.5 parts of diatomaceous earth, 4 parts of epoxy soybean oil, and 1.5 parts of nano-silica, add them to a twin-screw extruder, and extrude out of granulation to obtain masterbatch;

[0048] (3) The master batch obtained in step (2) is made into a non-woven fabric by a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com