Automatic temperature control heating device of diesel vehicle fuel system

An automatic temperature control and fuel system technology, which is applied to fuel heat treatment devices, charging systems, engine components, etc., can solve problems such as failure to consider the entire fuel system, engine failure, and fuel pipeline system blockage, etc., to achieve Reliable automatic safety protection function, fast heating speed, and the effect of reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further explain in detail in conjunction with accompanying drawings;

[0016] In the figure, the arrow shows the flow direction of fuel;

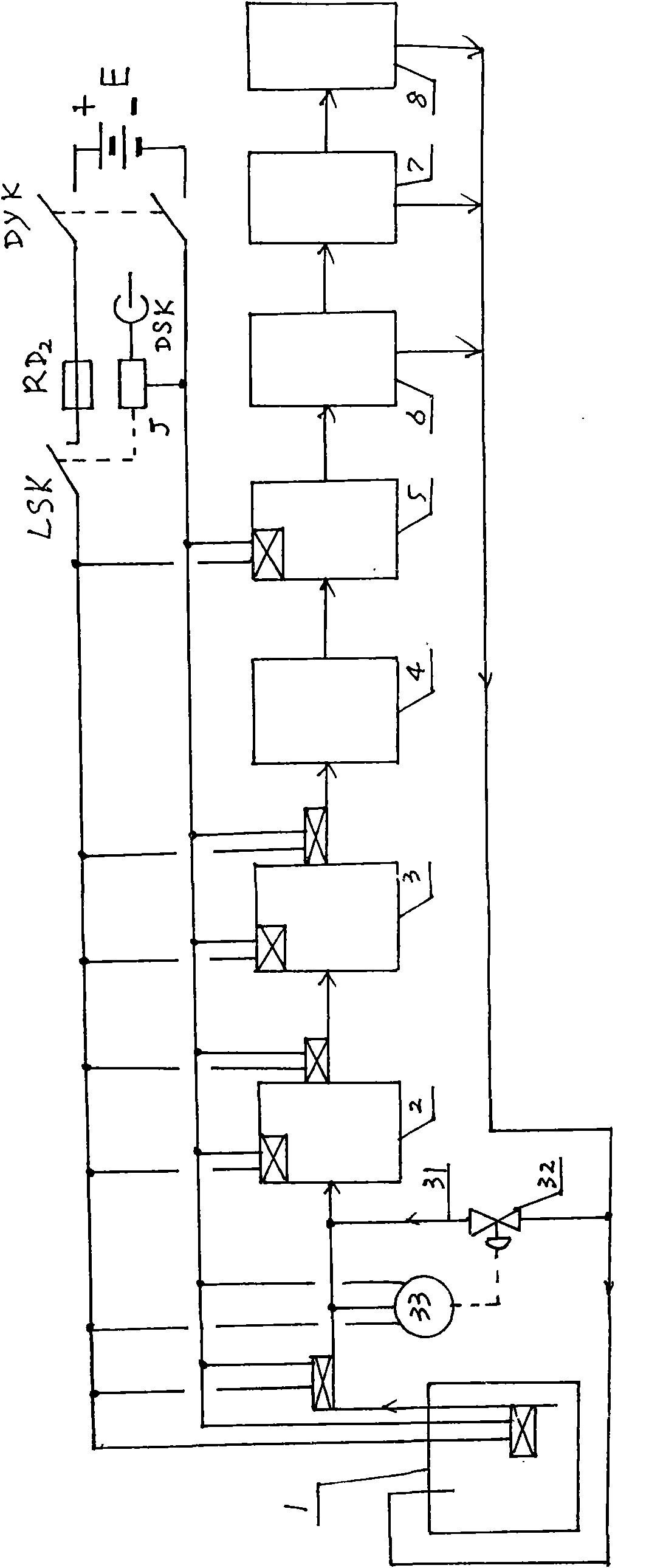

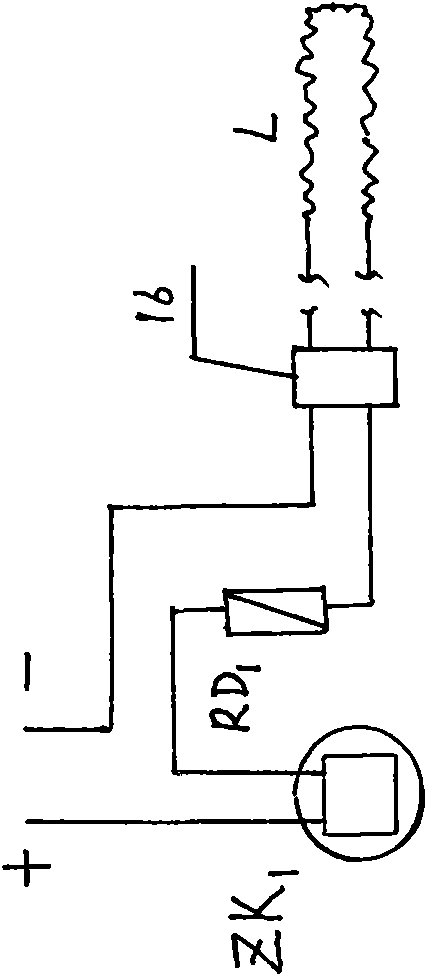

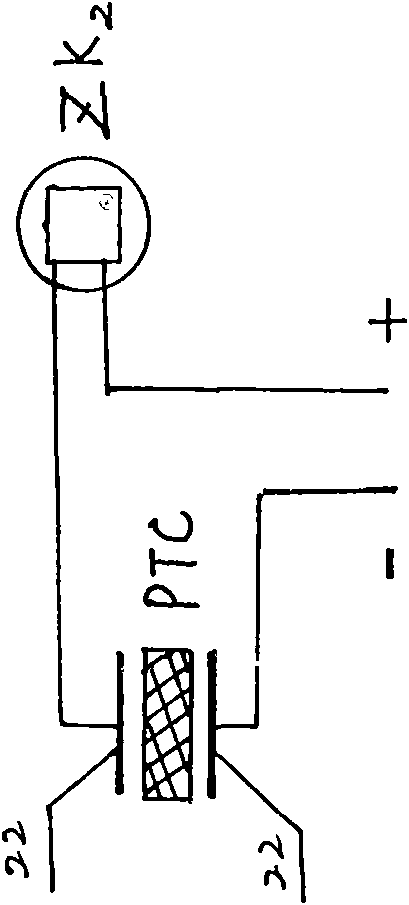

[0017] Such as figure 1 As shown, the fuel system of diesel vehicles is as follows according to the direction of fuel flow: Fuel tank 1 → 30 micron filter - that is, sedimentator 2 → 10 micron filter - that is, oil-water separator 3 → fuel pump 4 → 2 micron filter - That is, the fine filter 5 → high-pressure fuel pump 6 → high-pressure rail 7 → fuel injector 8, and also has a fuel return line from the high-pressure fuel pump 6, high-pressure rail 7 and fuel injector 8 back to the fuel tank 1; the corresponding parts of the fuel system are equipped with There are electric heaters with independent automatic temperature control and automatic safety protection functions; between the oil tank 1 to the settler 2, the settler 2 to the oil-water separator 3, and the oil-water separator 3 to the oil delivery pump 4 The fuel pipes are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com