Patents

Literature

1277results about How to "High filtration precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

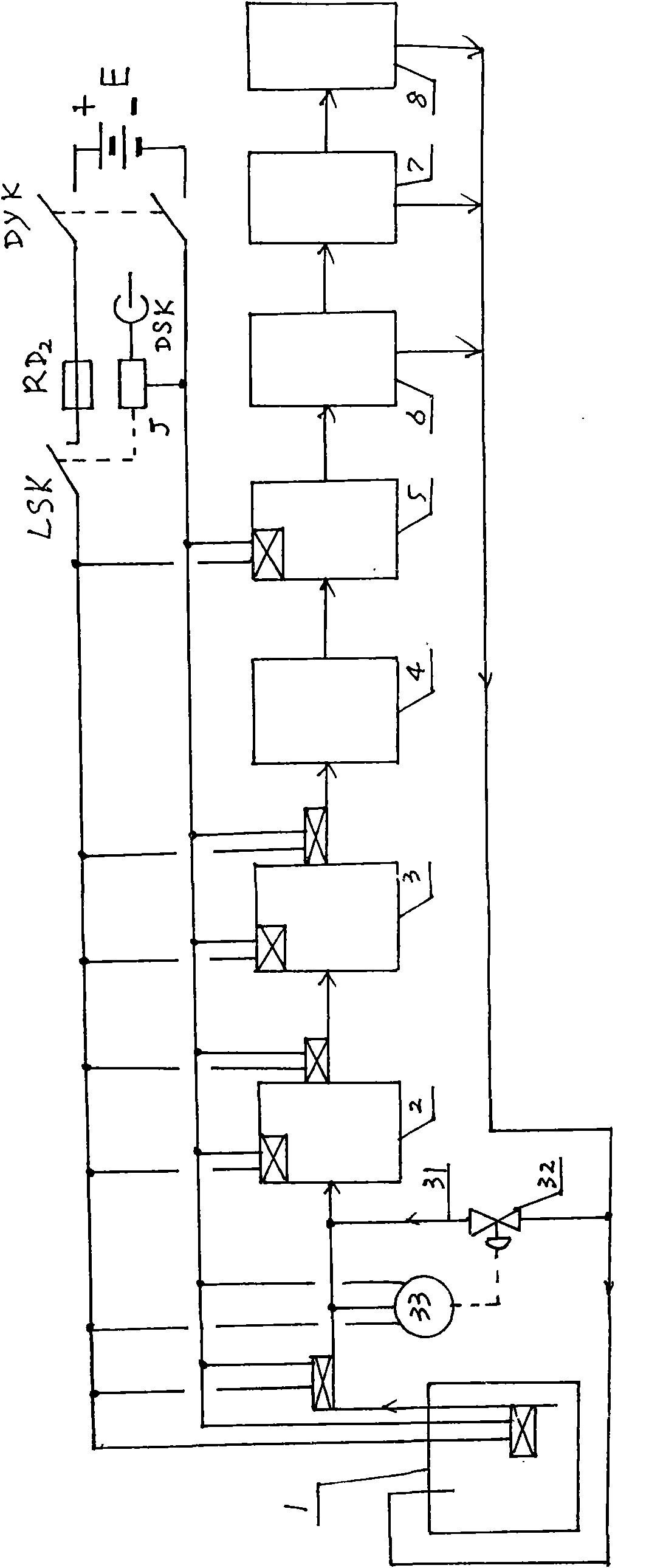

Zero-emission integrated process for treatment and reuse of high-salinity wastewater

ActiveCN104445788AHigh filtration precisionEasy to handleGeneral water supply conservationMultistage water/sewage treatmentSoftened waterEvaporation

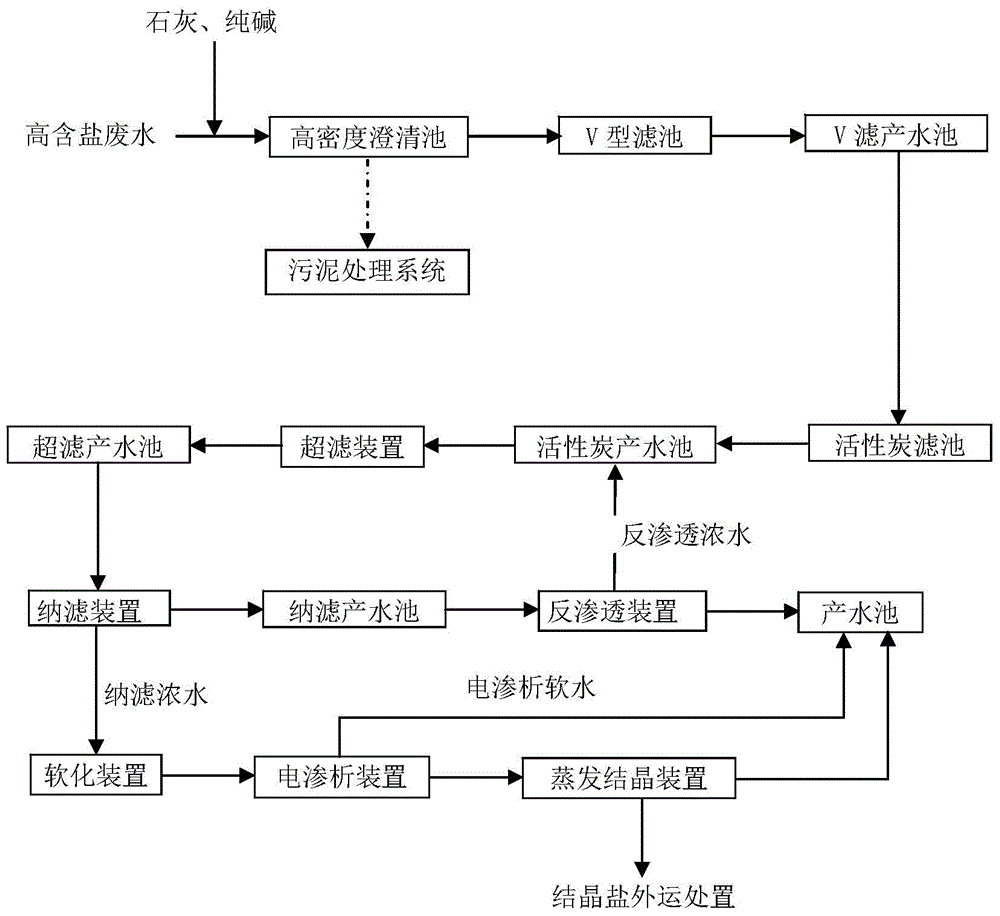

The invention discloses a zero-emission integrated process for treatment and reuse of high-salinity wastewater. The invention relates to a softening desalination treatment technology of water and particularly relates to a reuse treatment system for reverse osmosis concentrated water containing low-concentration organic matters which can achieve the requirement of 'zero emission'. The integrated process comprises the following steps: (1) firstly softening and pre-treating the high-salinity wastewater; (2) acquiring pre-treated water by virtue of activated carbon adsorption and an ultrafiltration device; (3) acquiring nanofiltration softened water and nanofiltration concentrated water by virtue of a nanofiltration device; (4) acquiring reverse osmosis softened water and reverse osmosis concentrated water by virtue of a reverse osmosis device; (5) acquiring electrodialysis softened water and electrodialysis concentrated water by virtue of an electrodialysis device; and (6) carrying out evaporation crystallization treatment on the electrodialysis concentrated water by virtue of an evaporation-crystallization device, regularly outwards transporting salts generated by the evaporation crystallization, feeding generated salt into a water-producing tank to enter a reuse system and finally completing the treatment and reuse of high-salinity wastewater. The integrated process is mainly used for the integrated treatment of the high-salinity wastewater.

Owner:XINJIANG DELAND

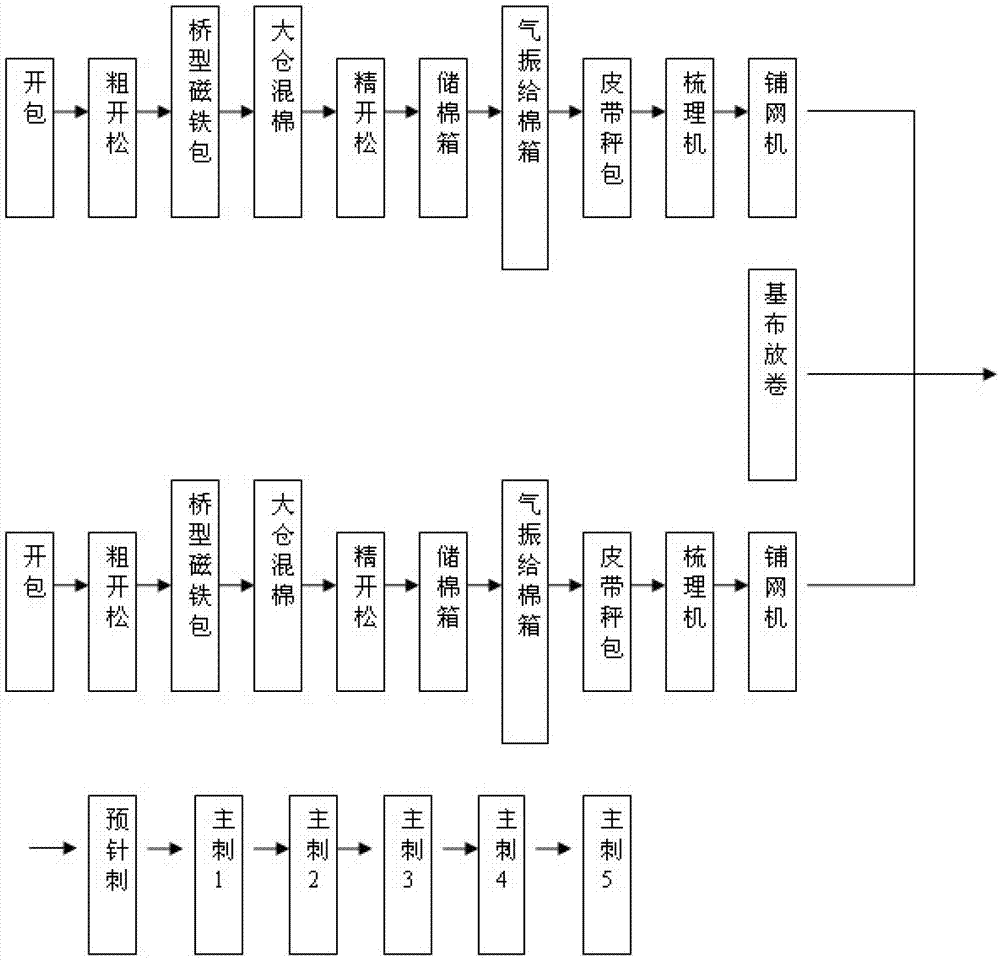

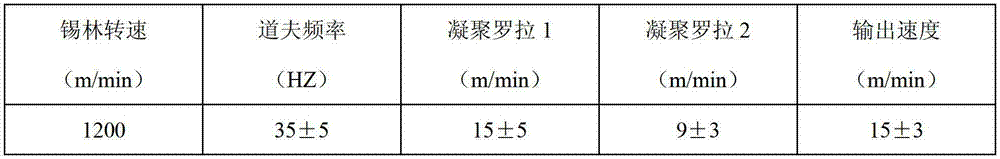

Method for producing needled and spunlaced composite nonwovens for filter materials

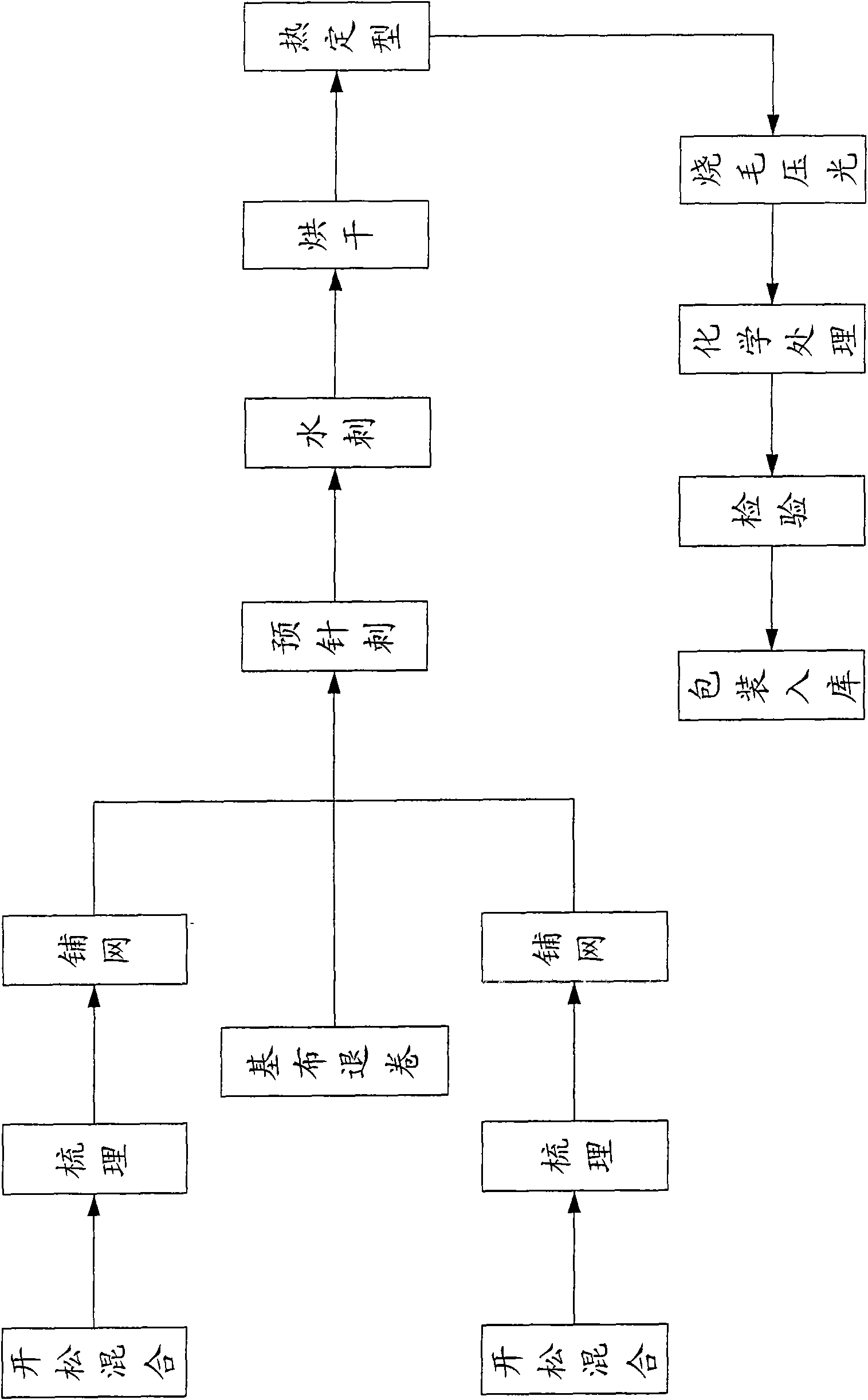

The invention discloses a method for producing needled and spunlaced composite nonwovens for filter materials. The method comprises the following steps of: (1) respectively opening, mixing, carding and lapping two same or different fibers to form fiber webs, and superposing the fiber webs; (2) pre-needling the two superposed fiber webs to form a pastel felt, and controlling the needling density to between 200 and 300 needles / cm<2>; (3) spunlacing the pastel felt in a high-speed superfine water flow, controlling the initial water pressure of the high-speed superfine water flow to be 20 bars, and controlling the subsequent water pressure to be more than or equal to 20 bars and less than or equal to 400 bars; and (4) drying at the temperature of between 100 and 250 DEG C. The nonwovens produced by the production method have the characteristics of small pores, high porosity, high strength, smooth surfaces, softness and the like and have the properties of easy ash removal, stability and low resistance in running, high filter efficiency, high filter precision and the like in use.

Owner:XIAMEN ZHONGCHUANG ENVIRONMENTAL TECH CO LTD

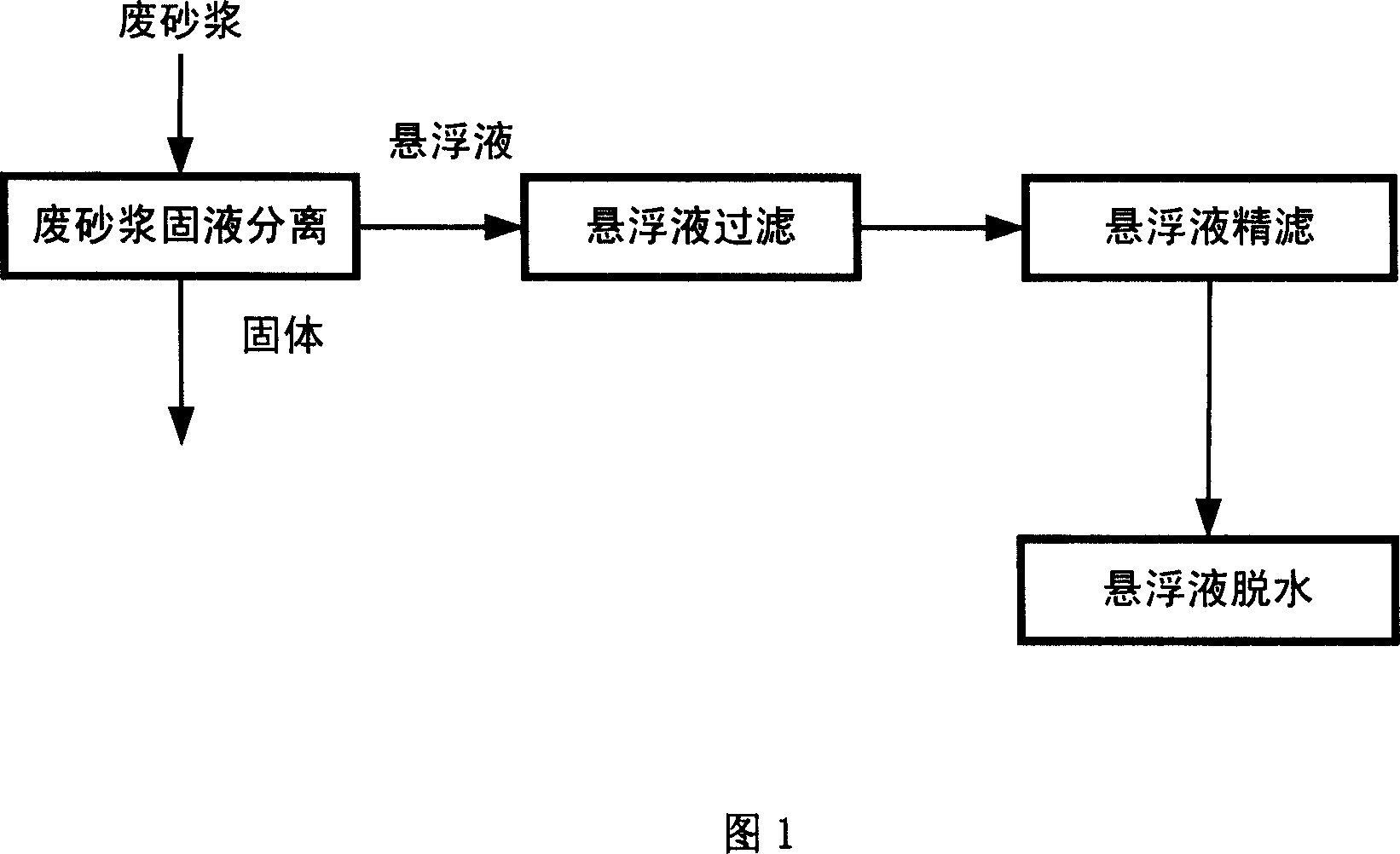

Method of recycling cutting suspension

InactiveCN101032806AGuaranteed purityAvoid adverse effects from re-useAbrasive machine appurtenancesRecovery methodPolyethylene glycol

The waste cutting suspension recovering process features that the waste linear cutting sand pulp from silicon chip processing is multiple stage treated through the steps of solid-liquid separation, initial filtering of the suspension, final filtering of the suspension, and concentrating and drying of the suspension. The process has recovered polyethylene glycol-base or oil-base suspension possess performance the same as or near that of new material and capacity of being reused. The present invention raises material using efficiency, lowers silicon chip producing cost and avoids environmental pollution caused by exhausting waste linear cutting sand pulp.

Owner:PRECISION RECYCLING TECH CO LTD

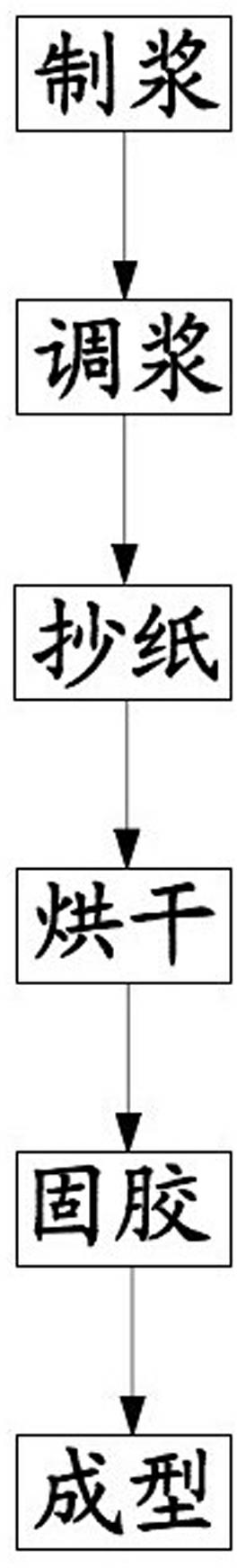

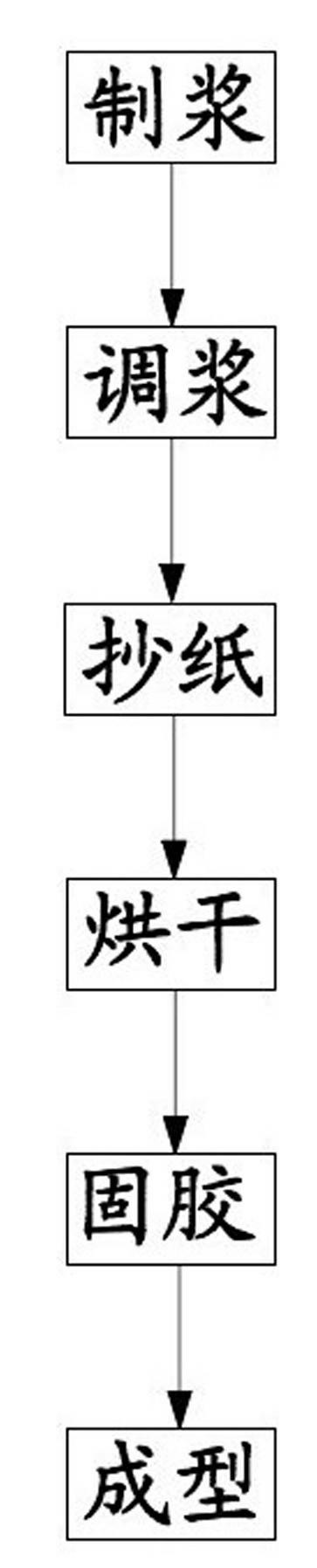

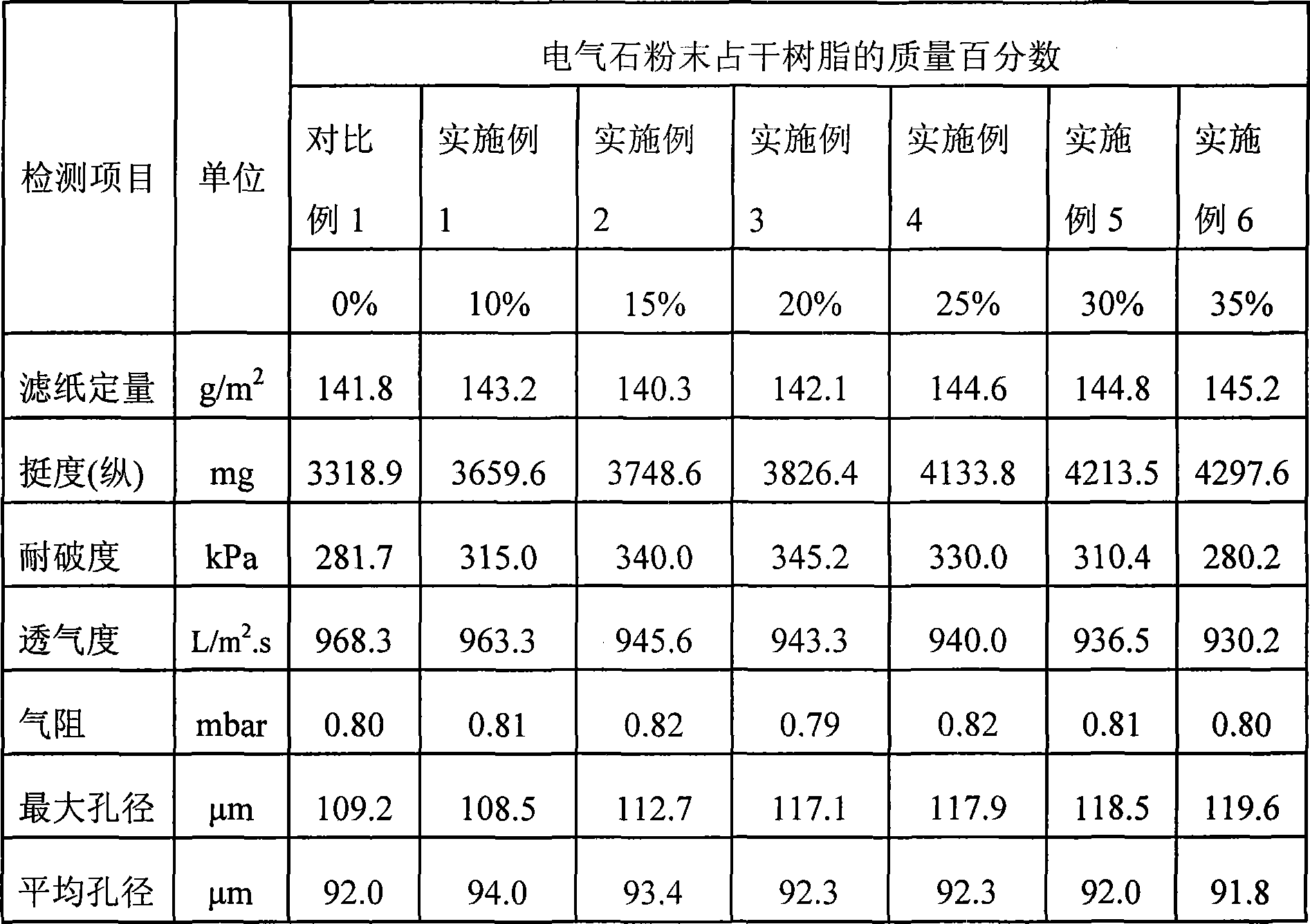

Filter paper for cooling system in wire electrical discharge machining (WEDM) and production method of filter paper

InactiveCN102444054AReduce the maximum apertureReduce the average pore sizeNon-fibrous pulp additionPaper/cardboardPolyesterGlass fiber

The invention relates to filter paper for a cooling system in wire electrical discharge machining (WEDM), which comprises the following components in percent by weight: 18-25 percent of phenolic resin, 0.5-5 percent of glass fiber, 0.5-5 percent of polyester fiber and 65-82 percent of wood pulp fiber. A production method of the filter paper comprises the steps of pulping, pulp mixing, paper making, drying, glue setting and forming. The filter paper adopts the wood pulp fiber as the main material which is matched with a proportion of glass fiber and polyester fiber, so that the bore diameter of the filter paper can be reduced, and the filtering accuracy can be improved; and in addition, since the polyester is chemically-synthesized fiber and has high strength, the bursting strength of the filter paper is improved, and the service life of the filter paper is prolonged. In the production process of the filter paper, thermosetting phenolic resin is introduced by dipping setting glue, and the size stability, the high temperature resistance and the water resistance of the filter paper are further improved. When being applied to a cooling liquid circulating system in WEDM, the filter paper is not deformed or expanded and has good strength in water, and the phenomena of water jetting and black water generating due to bursting are avoided.

Owner:SUZHOU XINYE PAPER - MAKING

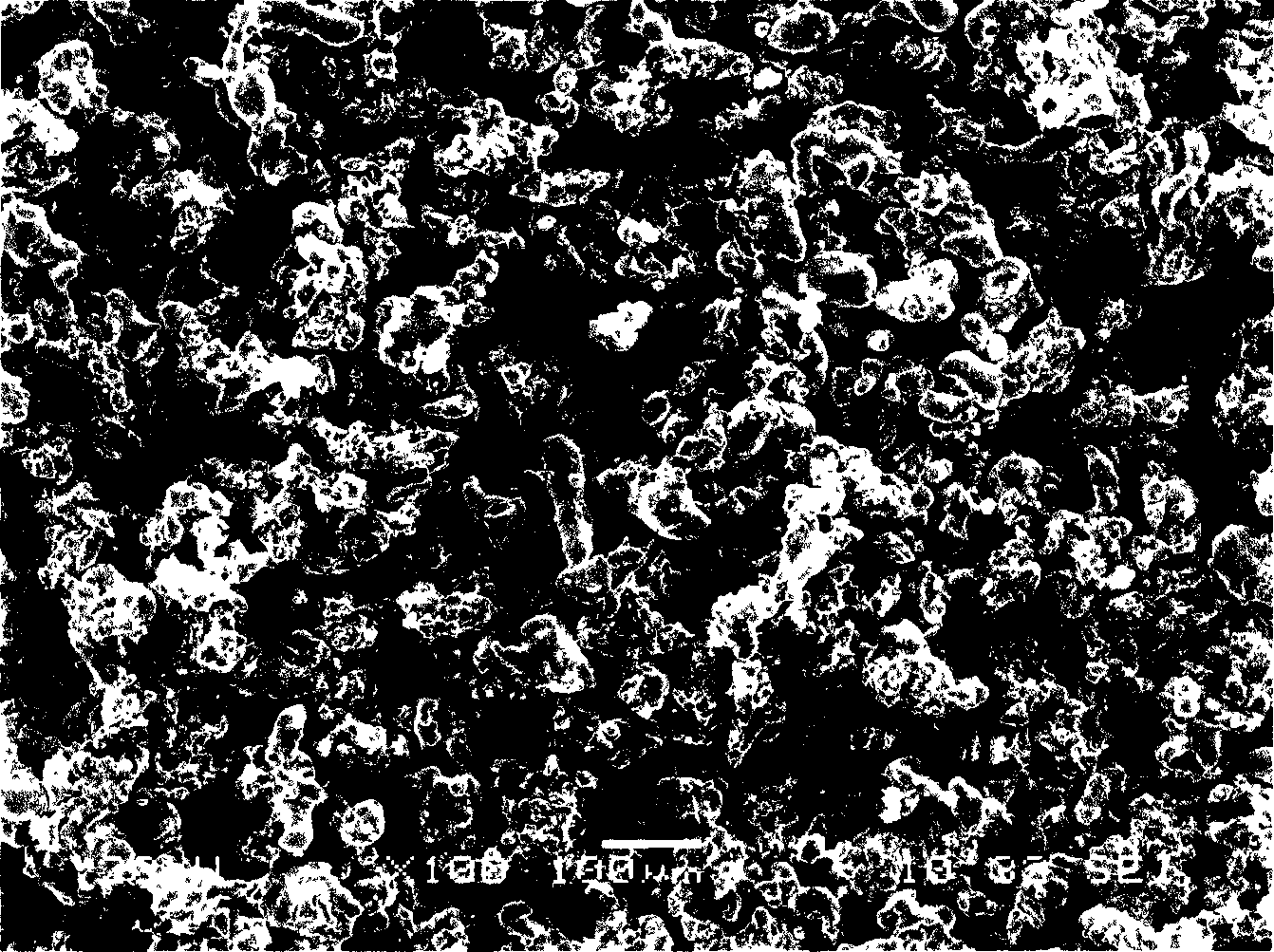

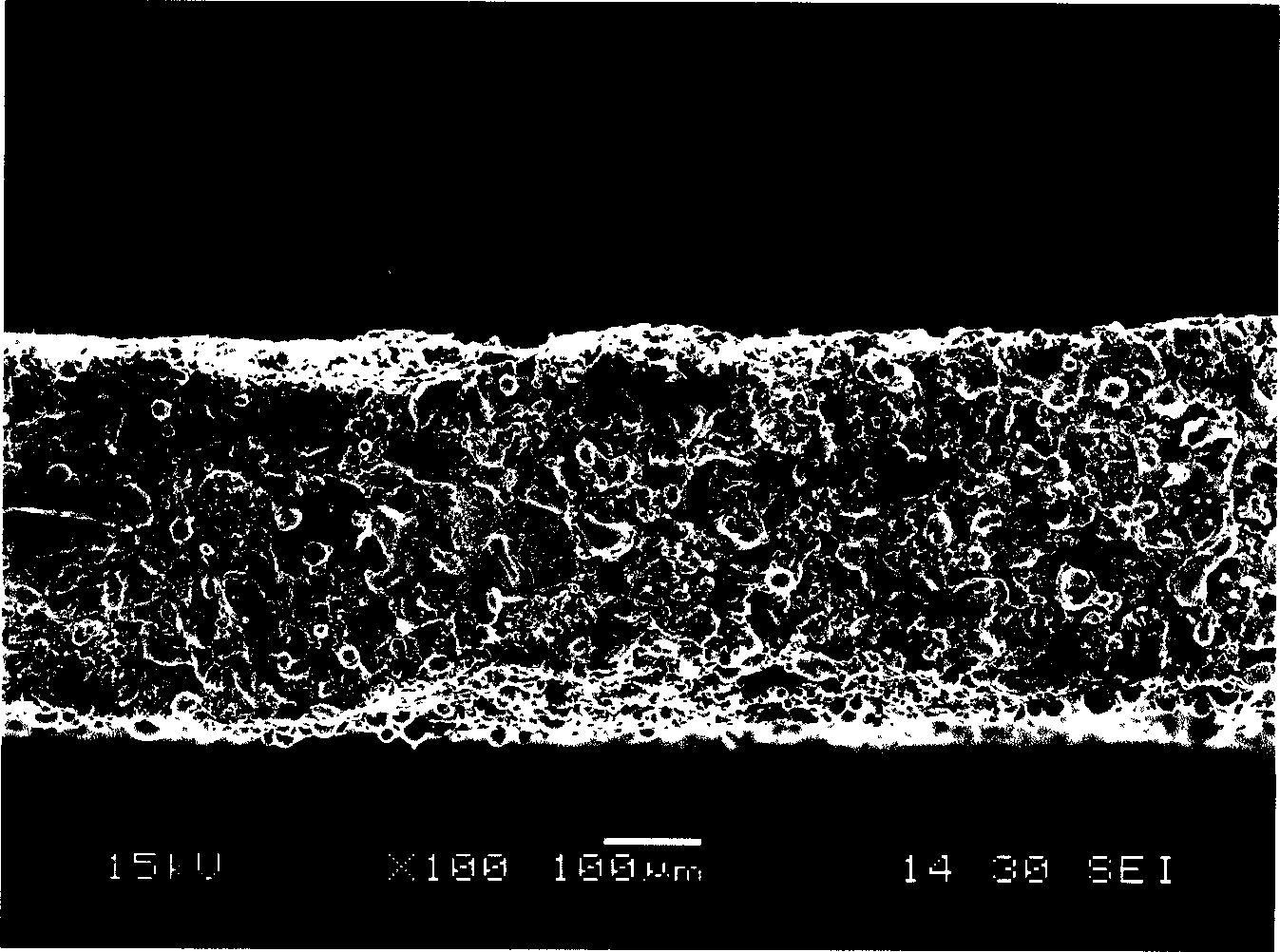

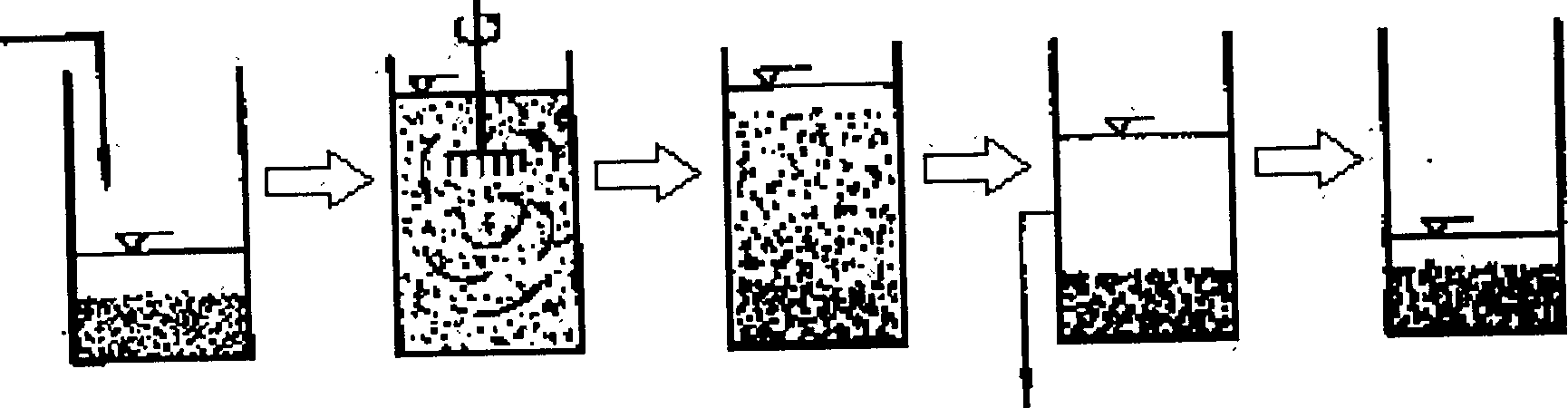

Prepn process of porous metal materrial

The present invention is preparation process of porous metal material, and features that metal powder and water soluble adhesive are mixed into slurry; the slurry is painted onto metal net, stoved and sintered in vacuum or reducing atmosphere; and the sintered metal net is rolled and flattened to obtain the said porous metal material. The present invention provides the preparation process of sintered porous metal material with high filtering precision, excellent permeating performance and excellent mechanical and physical performance. The porous metal material is used mainly in filtering and separating in industry, and may be also used in fluid distributing and control, catalyst carrier, energy exchange, electrode material, etc.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

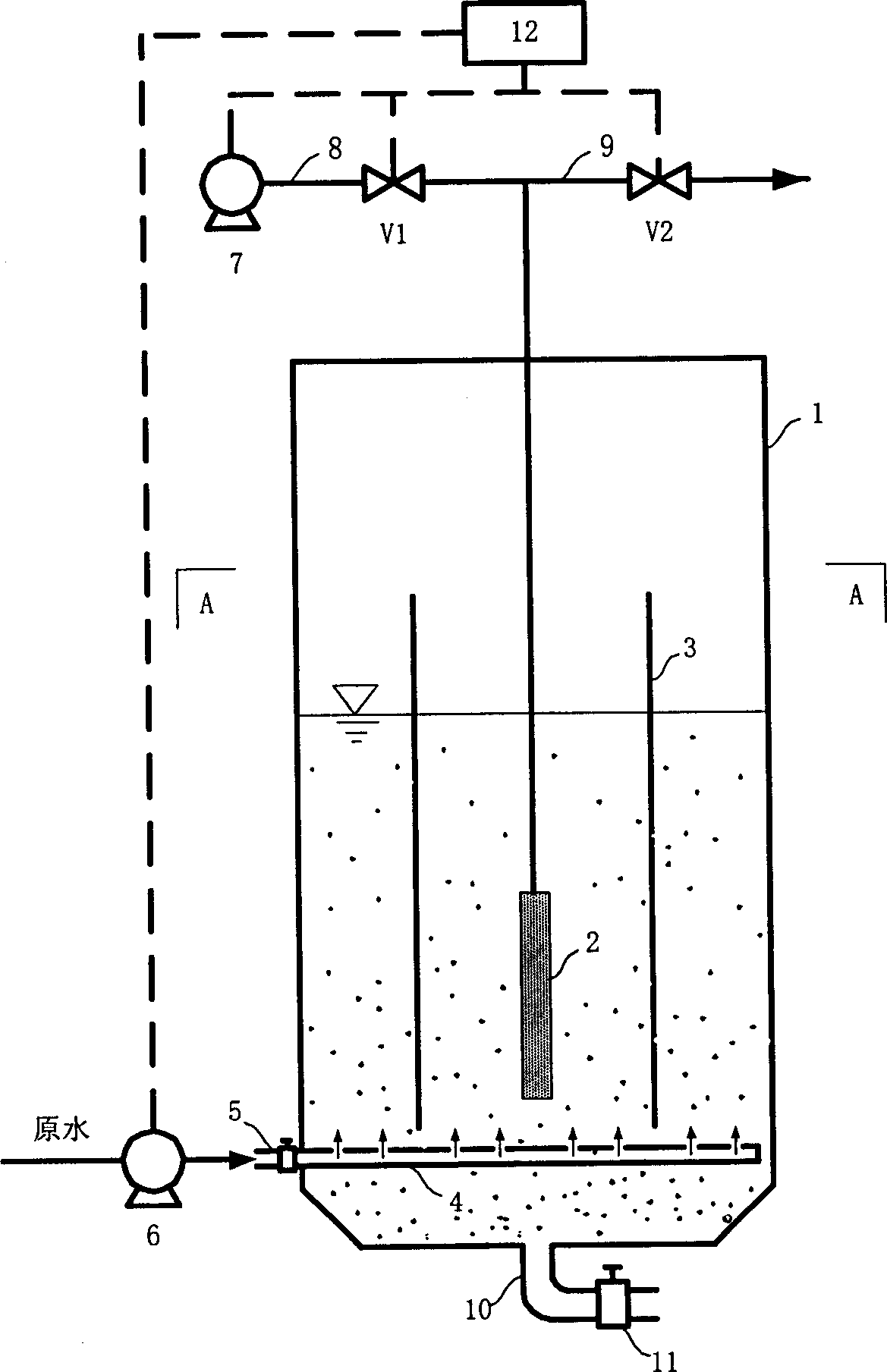

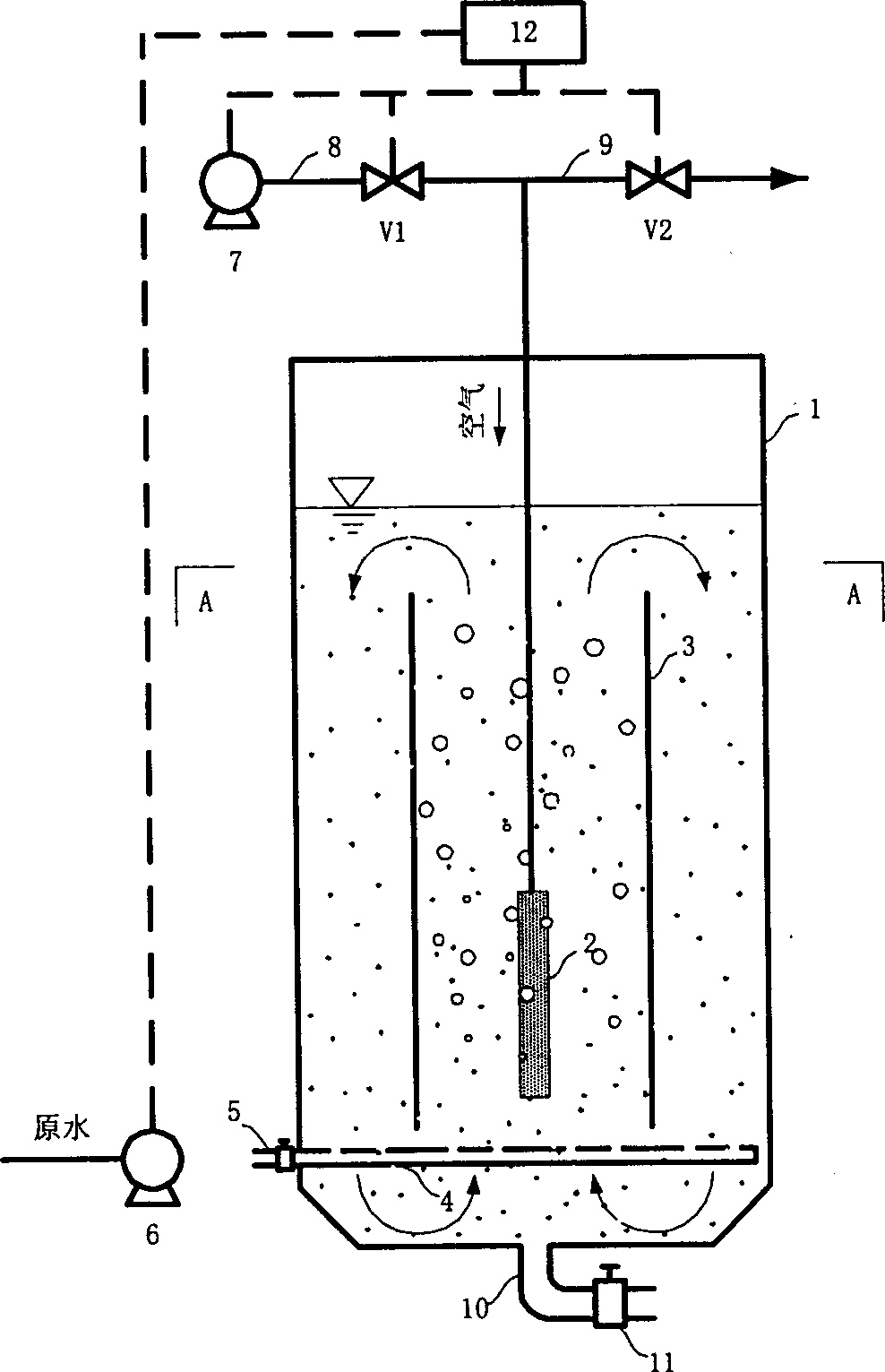

Process and apparatus for wastewater by batched membrane-bioreactor

InactiveCN1424265AGood water qualitySimple device structureWater/sewage treatment bu osmosis/dialysisTreatment with aerobic and anaerobic processesAutomatic controlPollutant

A process for treating sewage by integrating sequential active sludge method with membrane-bioreactor features that the membrane assembly is put in bioreacting pool, its outlet is respectively connected to air inlet pipe and water outlet pipe via two control valves, the whole system sequentially passes through flow-in, reaction, discharge and idle steps, that is, anaerobic, aerobic and anoxic states, and said membrane assembly plays the roles of aerating unit in reaction step or separator in discharge step. Its advantages are simple structure and high effect.

Owner:TSINGHUA UNIV

Silicon carbide porous ceramic filter and manufacturing method thereof

The invention relates to a silicon carbide porous ceramic filter and a manufacturing method thereof, in particular to a filter material for high-temperature liquid or gaseous fluid. The ideal silicon carbide porous ceramic filter has the advantages of gradient pore structure, low sintering temperature, high use temperature, high porosity factor, low pressure drop, large geometric surface area, zigzag flow path, high intensity, long service life, low production cost, easy regeneration and repeated use. Moreover, the filter is formed by compounding and sintering a plurality of layers of ceramic materials of different pore structures, and comprises a main body billet layer, a transition compound film layer and a surface compound film layer. Therefore, the filter is suitable for filtration and purification of various high-temperature and low-temperature fluids such as molten metal, high-temperature flue gas, coking gas and automobile exhaust.

Owner:淄博鑫拓耐火材料有限公司

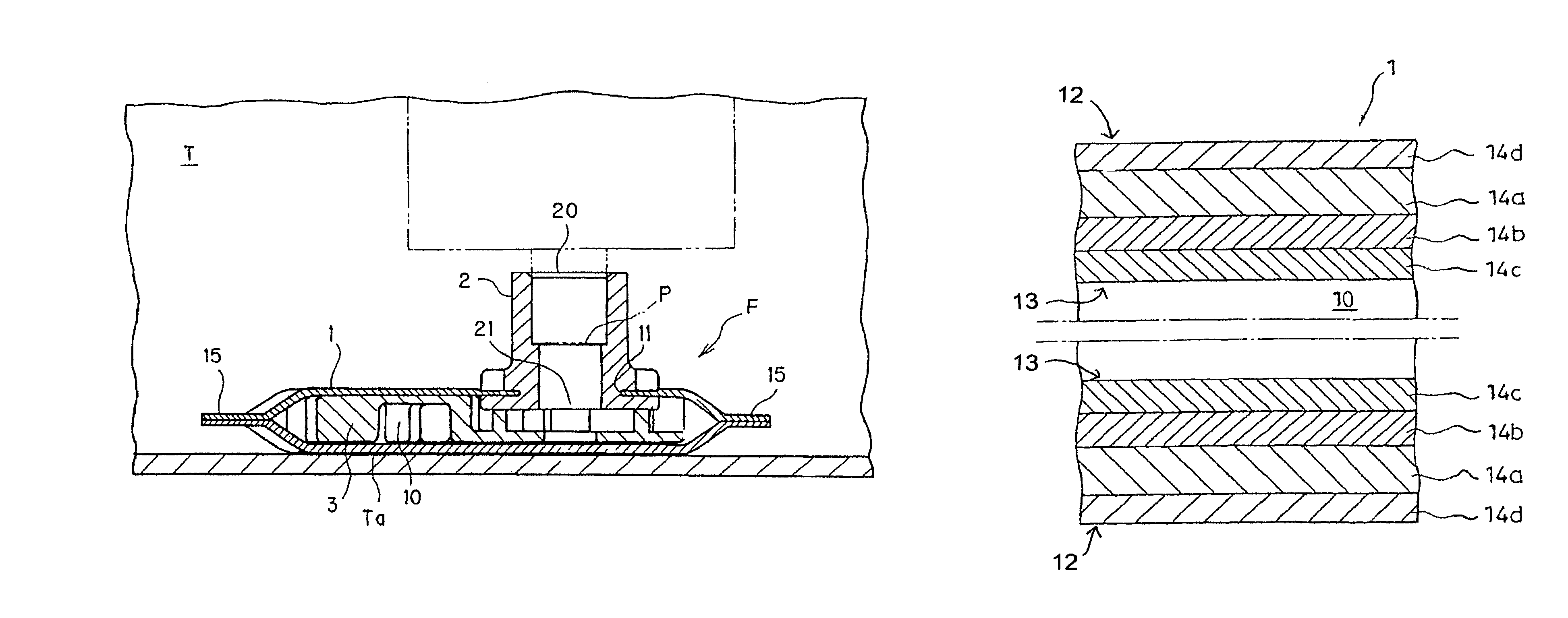

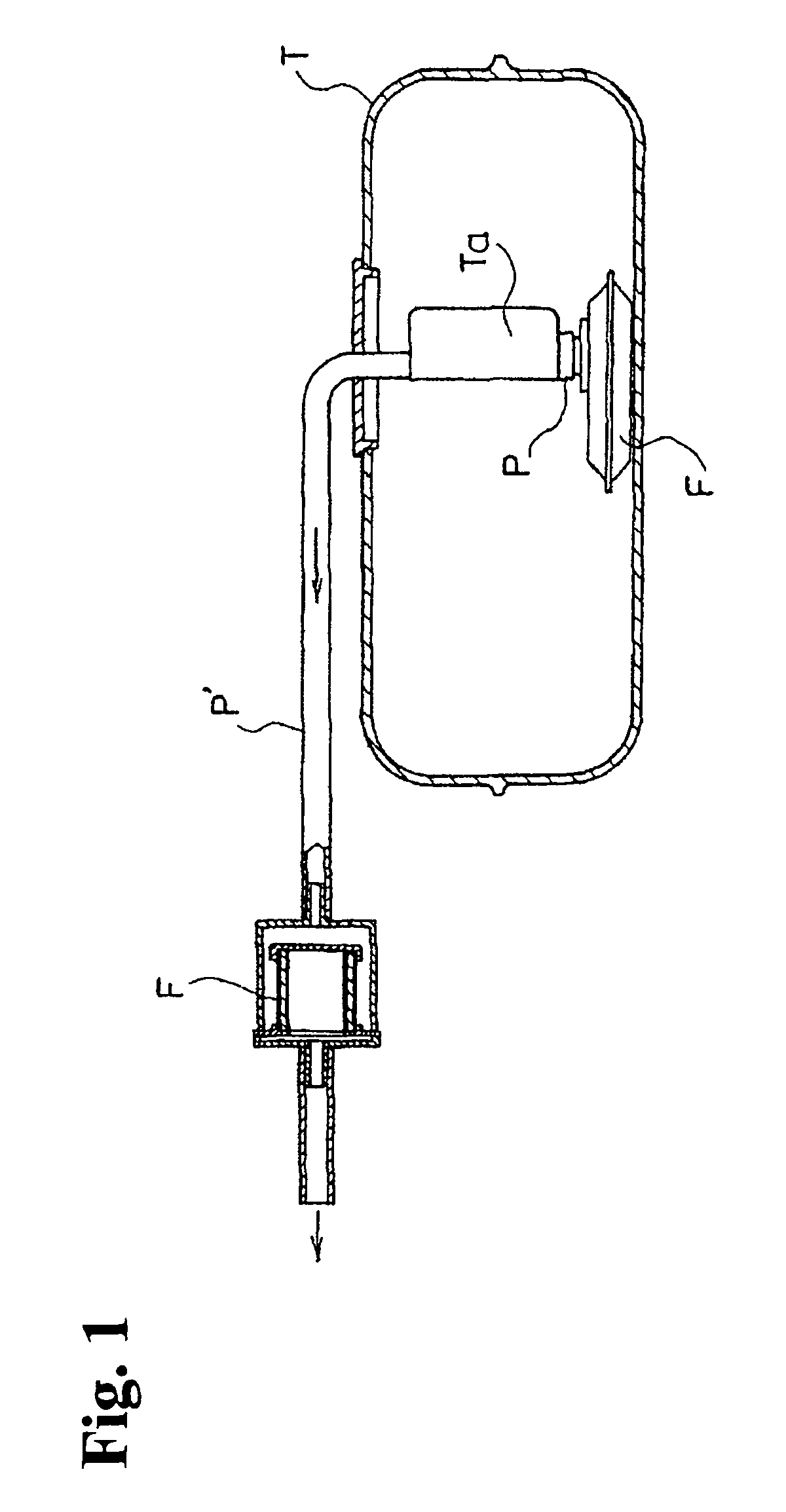

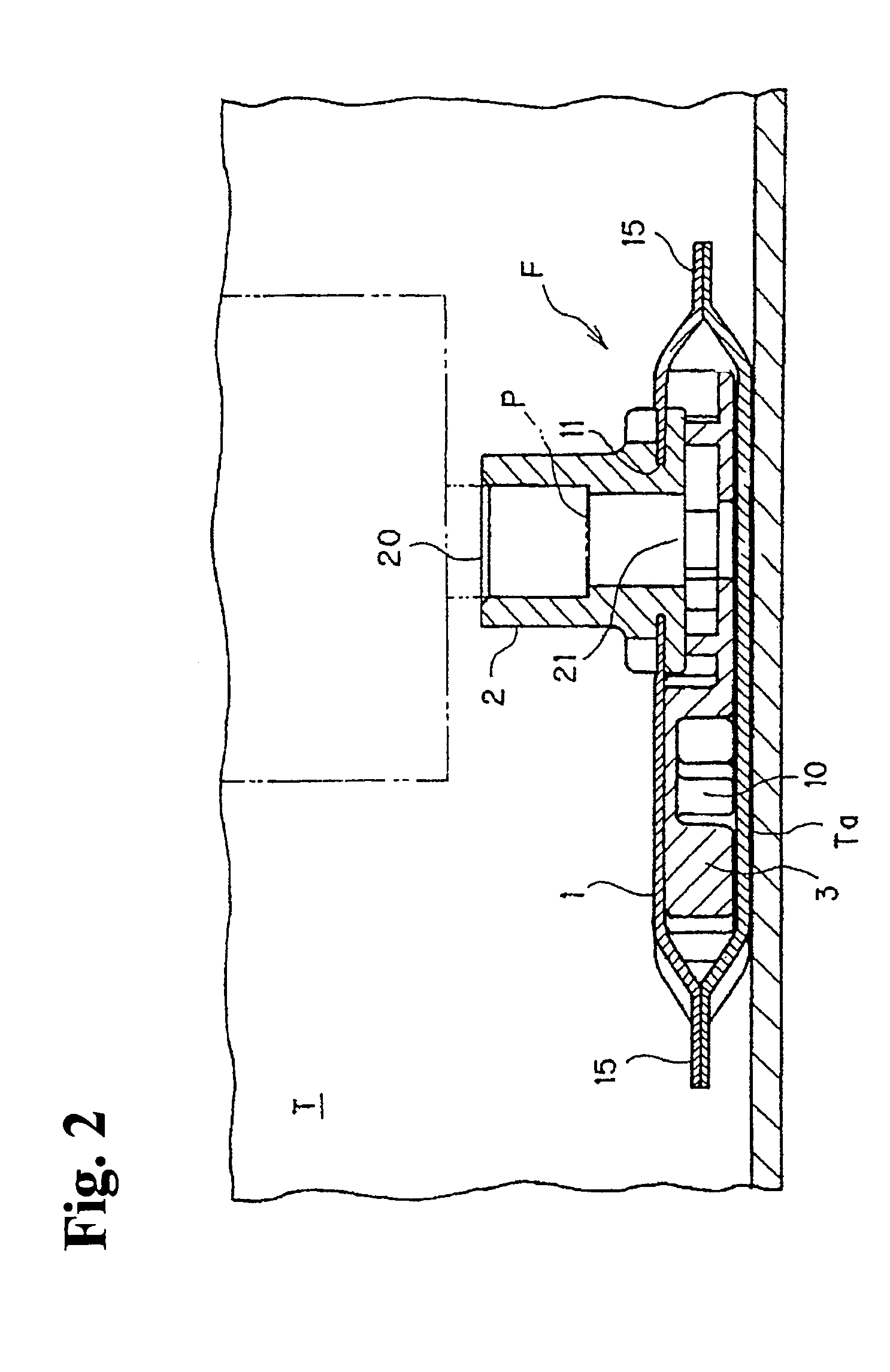

Fuel filter

ActiveUS8173013B2High filtration precisionLow priceWater/sewage treatmentMembrane filtersFuel tankFuel filter

Disclosed is a fuel filter in which is disposed in a fuel suction port of a fuel tank or in a fuel line and used to filter the fuel. At least one of filter materials constituting the fuel filter is made into a multifunctional filter material having a function of trapping dust of different particle diameters in stages, by differing the diameter of the pores in the filter material from the primary side to the secondary side of the filter material so that the size of the pores decreases toward the secondary side.

Owner:NIFCO INC

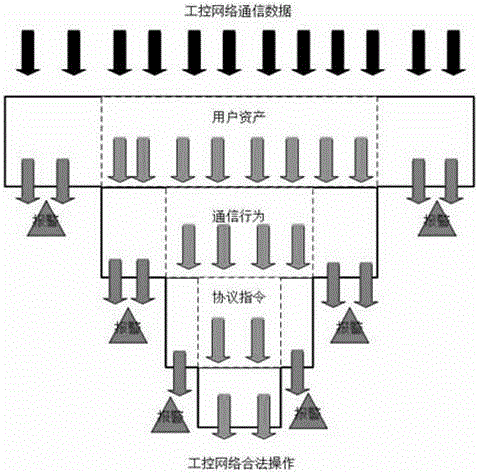

Industrial control network information security monitoring method based on funnel type white list

ActiveCN105208018AResolve identifiabilityResolve analysisTransmissionMonitoring systemPattern perception

The invention relates to an industrial control network information security monitoring method based on a funnel type white list. The industrial control network information security monitoring method comprises the following steps that (1) industrial communication data are deeply parsed; (2) a credible framework is established for legal operation in an industrial control network; and (3) a white list funnel is established based on the credible framework. The beneficial effects of the industrial control network information security monitoring method are that reductive analysis is performed on multiple industrial communication protocols so that abnormal monitoring of the production control behavior can be realized; and the credible framework is established through combination of the industrial control network environment so that the white list funnel with the industrial characteristics is generated, filtering precision is high and the communication behavior in the industrial control network is monitored in real time, early warning time for perception of the unknown threat is enhanced, and thus the industrial control information system environment is stabilized as the core guiding thought and a monitoring system is constructed.

Owner:上海三零卫士信息安全有限公司

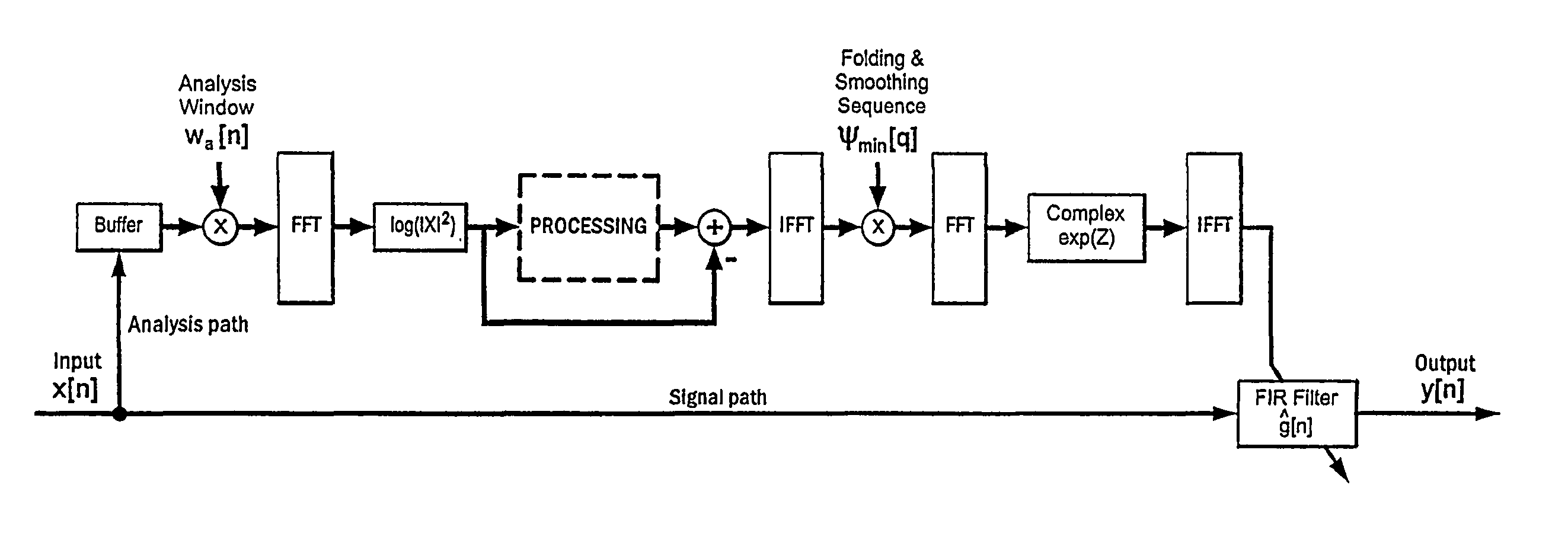

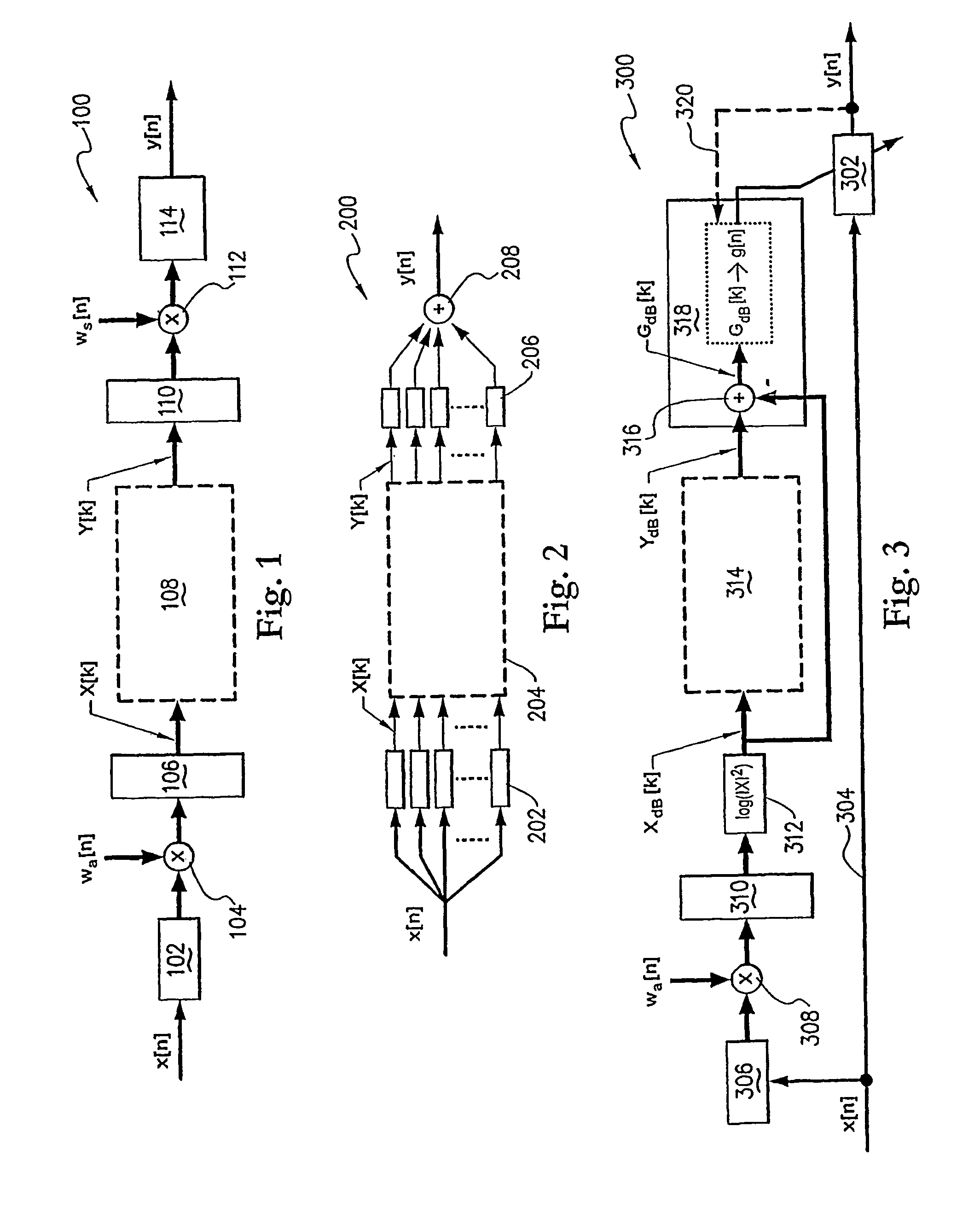

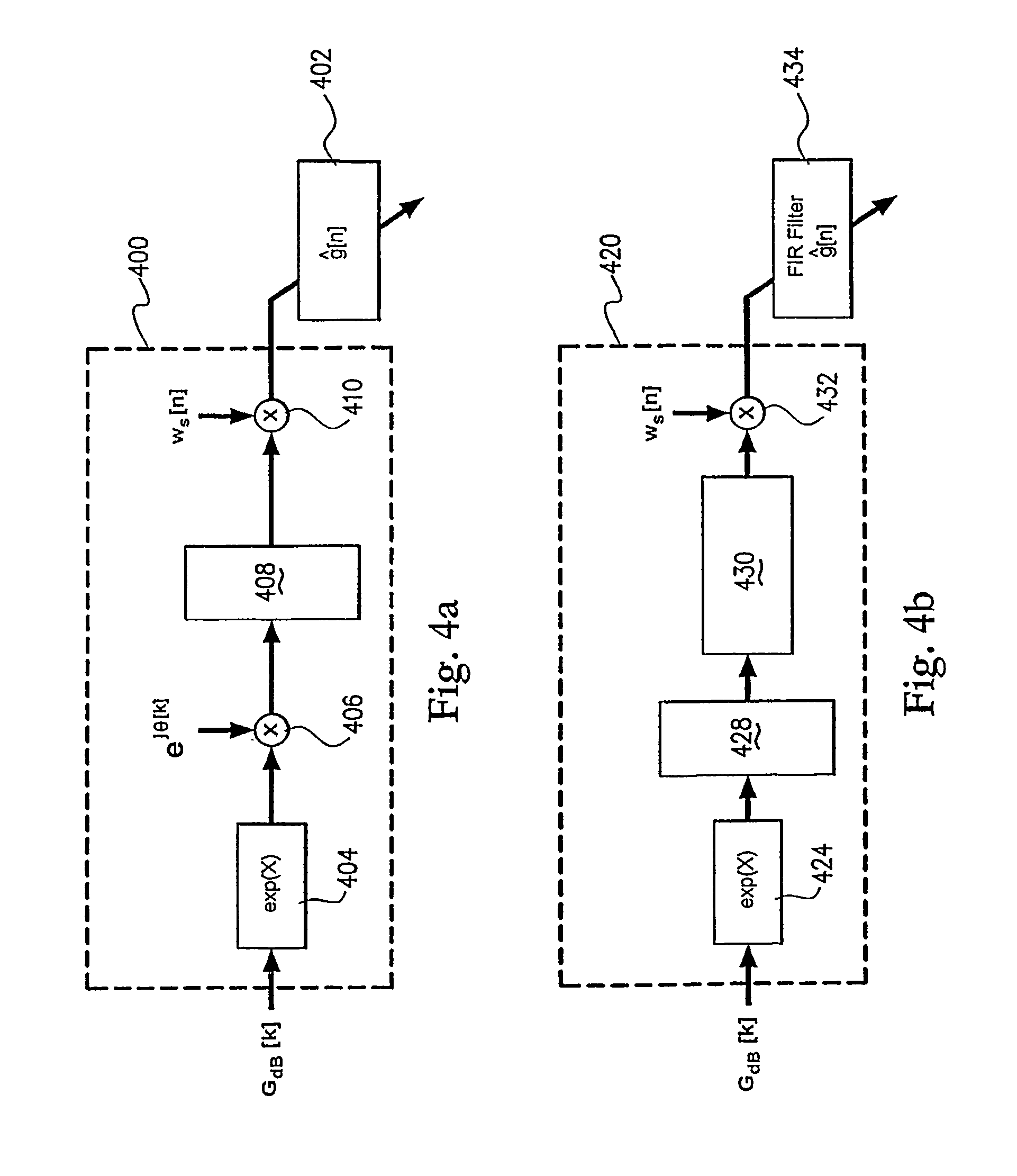

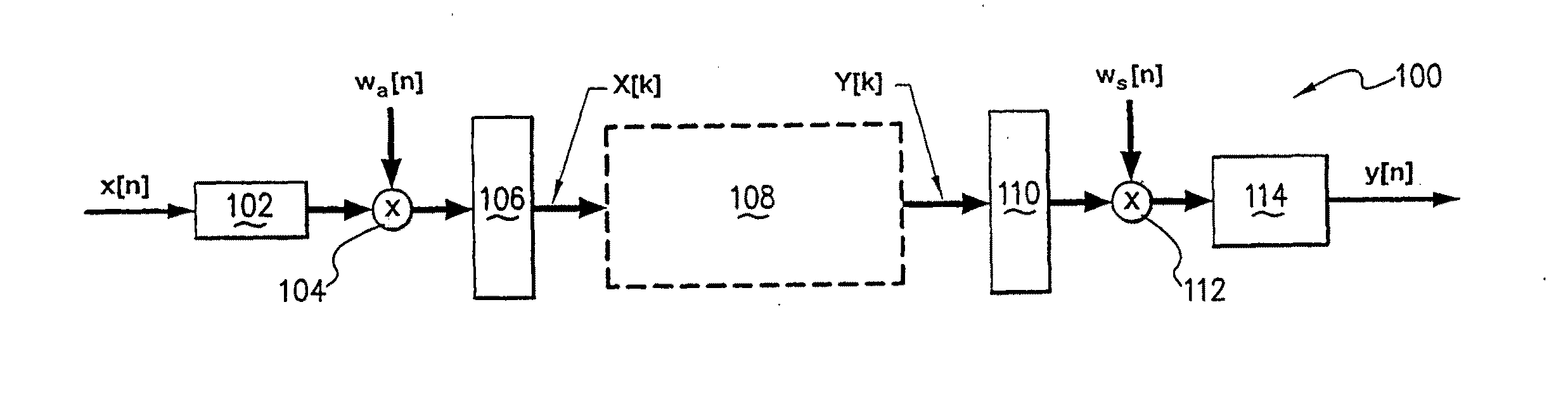

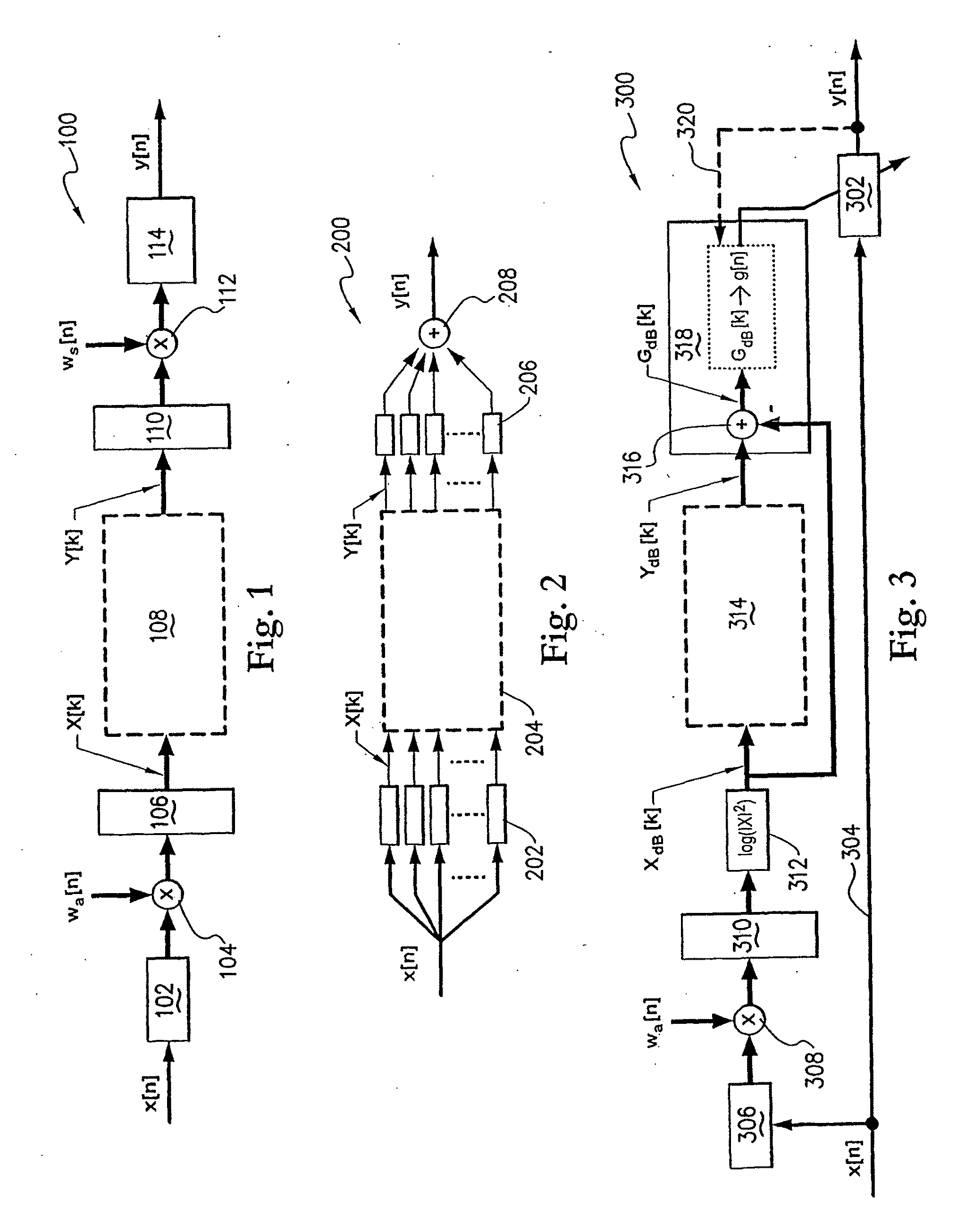

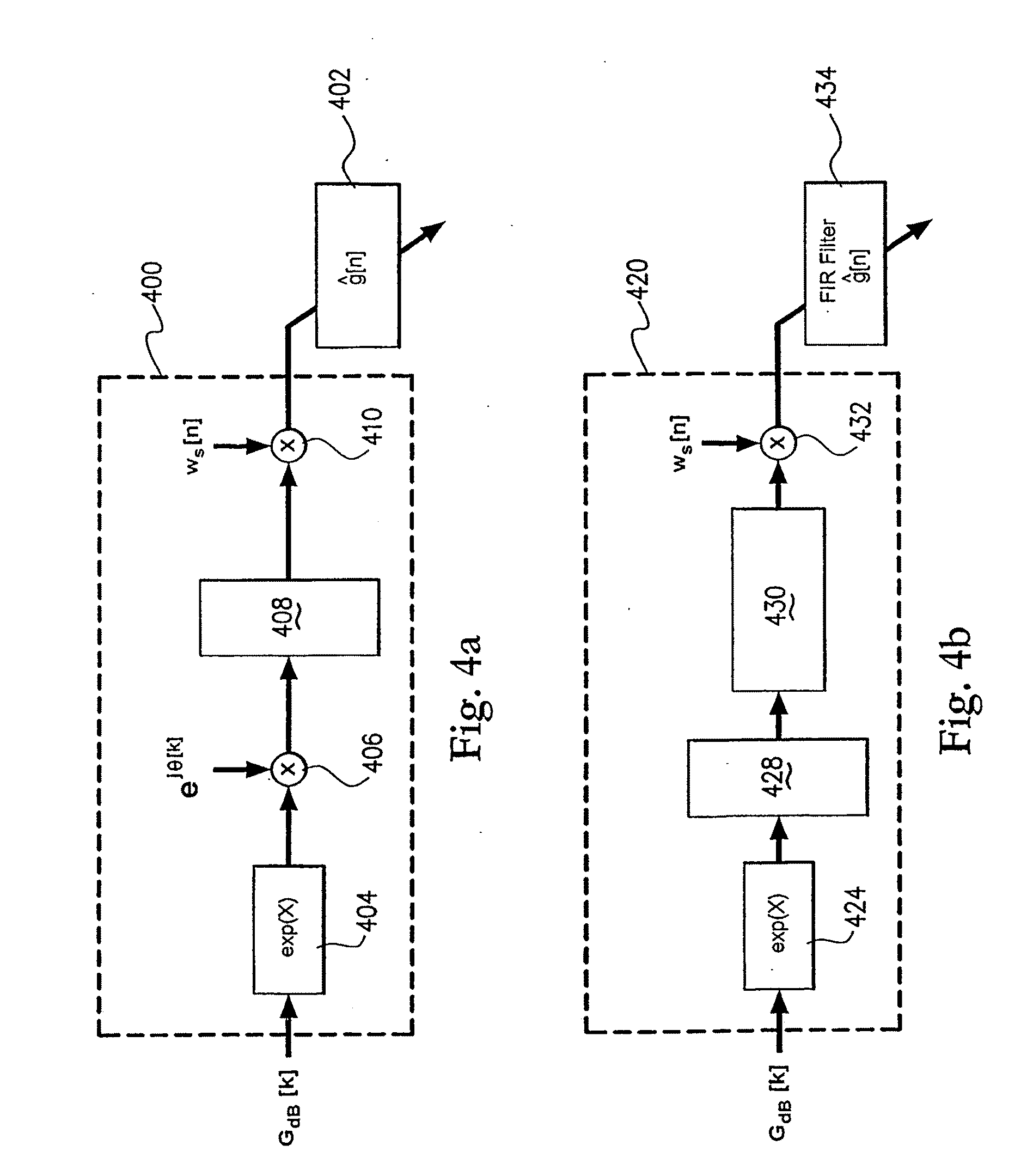

Method and device for low delay processing

ActiveUS8385864B2Reduce delaysImproved control of design compromises in signal analysisAdaptive networkDigital technique networkTime domainAdaptive filter

Adaptively processing an input signal, such as an input signal of a hearing aid. The input signal is passed through an adaptive time domain filter to produce an output signal. At least one of the input signal and the output signal is used as an analysis signal. The analysis signal is transformed into a transform domain to produce a transformed analysis signal, which is analyzed to produce a desired gain for each respective transform domain sub-band. A minimum phase time domain filter characteristic is synthesized which approaches the desired gains. The adaptive filter is updated with the synthesized filter characteristic.

Owner:CIRRUS LOGIC INT SEMICON

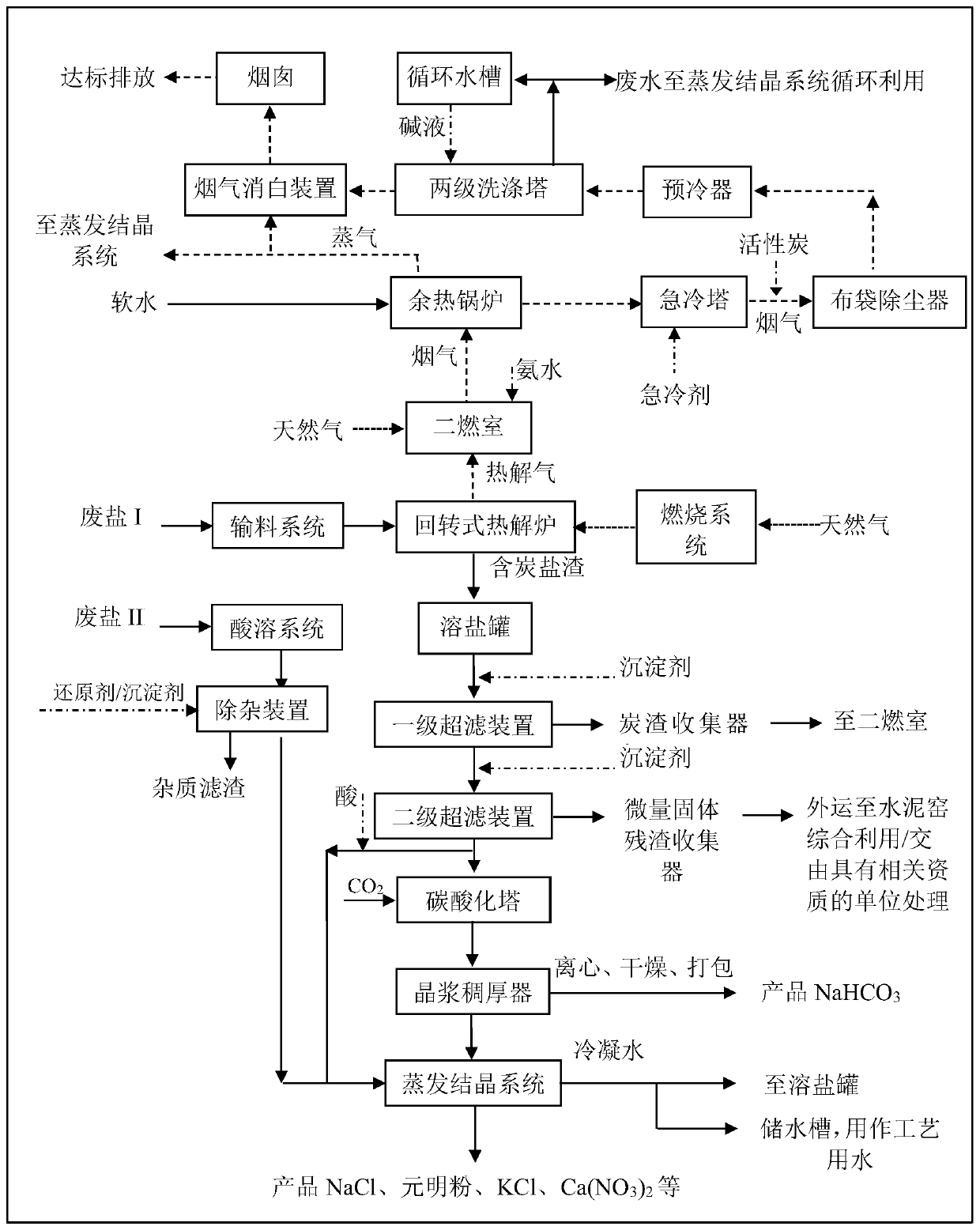

Waste salt resourceful treatment system and application

PendingCN110201975ARealize resourcesAchieve emission standardsSolid waste disposalTransportation and packagingSlagEvaporation

The invention relates to a waste salt resourceful treatment system which comprises a waste salt carbonization and pyrolysis system, a carbon-containing salt slag dissolving and filtering system and anevaporating and salt separating system in sequential connection, wherein the waste salt carbonization and pyrolysis system can carry out carbonization and pyrolysis treatment on waste salt I composedof sodium chloride, and sodium sulfate monomer salt or mixed waste salt and also can treat tail gas; the carbon-containing salt slag dissolving and filtering system can dissolve and filter the carbon-containing salt slag treated by the waste salt carbonization and pyrolysis system; and the evaporating and salt separating system can carry out evaporation and concentration, fractional crystallization and drying treatment on the strong brine treated by the carbon-containing salt slag dissolving and filtering system to obtain product salt. The waste salt resourceful treatment system takes industrial waste salt as the raw material, removes organic pollutant from waste salt and separates mixed inorganic salt to finally obtain an industrial second-grade salt product, so that recycling of waste salt is realized, and the flue gas generated during the production process is discharged after reaching the standard.

Owner:北京航天环境工程有限公司

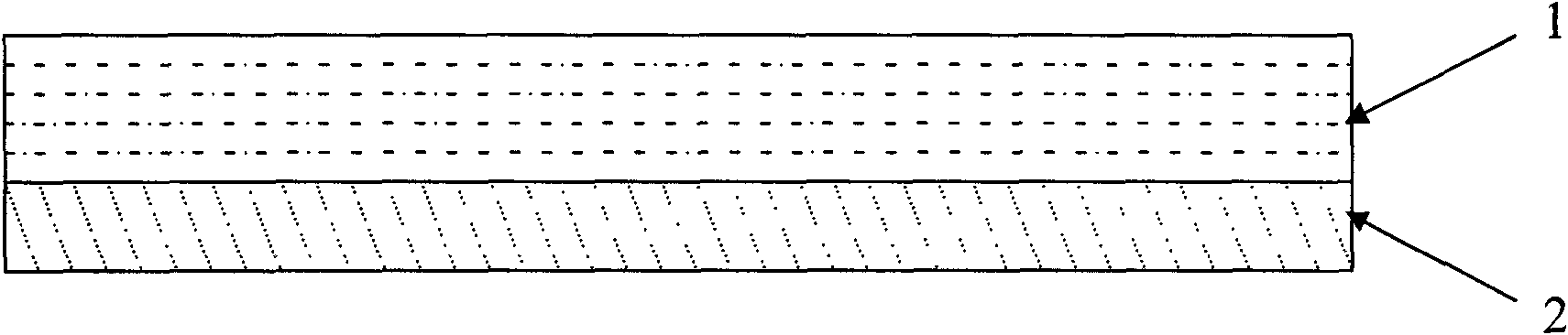

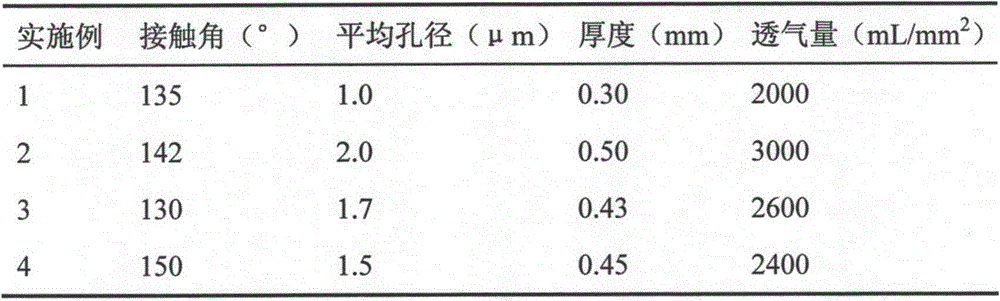

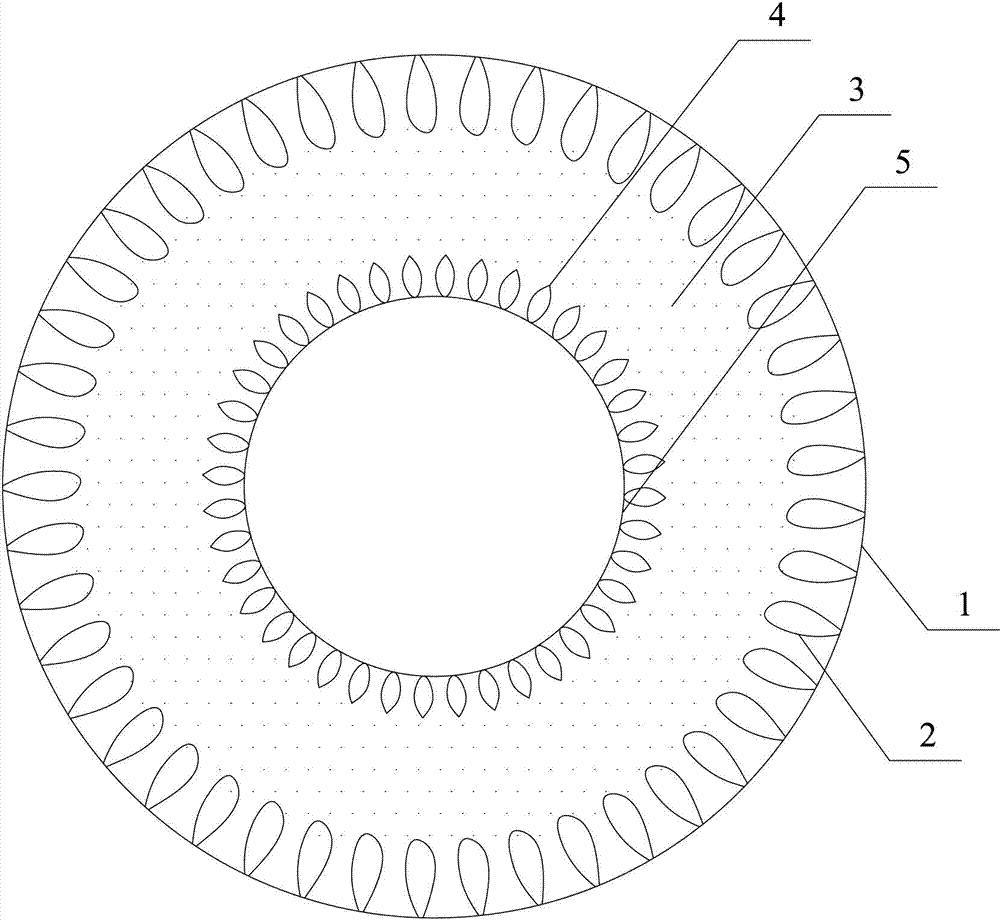

High temperature resistance basalt fiber composite filter material and preparation method thereof

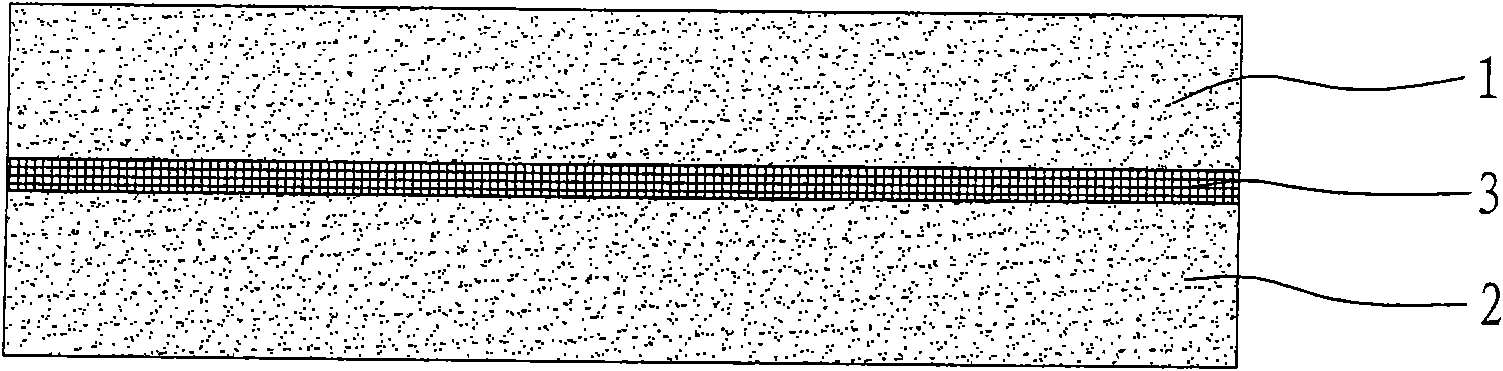

InactiveCN101612496AStable structureHigh filtration precisionLayered productsFiltration separationFiltrationPore diameter

The invention relates to a high temperature resistance basalt fiber composite filter material and a preparation method thereof; the composite filter material comprises basalt fiber base fabric and high-performance fiber mesh in a weight ratio of 7:1-2:1; the preparation method comprises the following steps: forming high-performance fiber mesh on the basalt fiber base fabric, combining and strengthening the material more by spunlaced process, hot rolling the material, then soaking the material in water repellent oil-proofing agent, sizing and obtaining the finished product. The filter material of the invention has the advantages of stable structure, high filtration accuracy, small bore diameter, concentrated pore diameter distribution and high temperature resistance, can bear 450 DEG C of instantaneous high temperature and can be used stablely for long time below 280 DEG C.

Owner:DONGHUA UNIV

A kind of polytetrafluoroethylene hollow fiber membrane and preparation method thereof

InactiveCN102266725AReduce filter pore sizeHigh filtration precisionSemi-permeable membranesHollow fibre membranePore diameter

The invention discloses a polytetrafluoroethylene hollow fiber membrane, which comprises a polytetrafluoroethylene hollow fiber with a pore diameter range of 0.5-2 μm and at least one layer of polytetrafluoroethylene hollow fiber with a pore diameter range of 0.02-0.5 μm. Microporous polytetrafluoroethylene film layer with a thickness of 5-100 μm and a thickness of 5 μm. The present invention also provides a preparation method of the polytetrafluoroethylene hollow fiber membrane. The polytetrafluoroethylene hollow fiber membrane of the invention has the advantages of small filter aperture, high filter precision, high porosity, high filter flux and high strength.

Owner:ZHEJIANG DONGDA ENVIRONMENTAL ENG

Preparation method of pinhole-free dedusting filter bag

ActiveCN104436866AHigh filtration precisionImprove dust removal efficiencyDispersed particle filtrationFiltration separationEngineeringNonwoven fabric

The invention discloses a preparation method of a pinhole-free dedusting filter bag. A filter bag is adopted, wherein the filter bag is sewn by a punched felt or nonwoven cloth the dustward surface of which is compounded with a polytetrafluoroethylene micro-pore film; a bag body is sewn by three stitches, and the bag opening is sewn by four stitches. The preparation method of the pinhole-free dedusting filter bag is characterized in that the sewing needle and thread of the filter bag is compounded with a micro-pore band which is sintered and shaped in a single surface in a hot pressing mode, and the micro-pore band covers stitch clearances of the bag body and the bag opening, so that the filtering precision at the stitch clearances of the sewn filter bag is improved; the hot pressing temperature is 400-1000 DEG C, and the compounding pressure is 0.2-1MPa. Compared with the prior art, the pinhole-free dedusting filter bag is high in filtering precision, good in dedusting efficiency, and the technical scheme is especially suitable for filter bags used for filtering PM2.5 dust; the effective filtering rate of PM2.5 dust can reach 99.99%; the pinhole-free dedusting filter bag is convenient to manufacture, is low in production cost, has a good use effect, and the preparation method is a PM2.5 filter bag manufacturing method with good application prospect and practical value.

Owner:SHANGHAI JINYOU FLUORINE MATERIALS

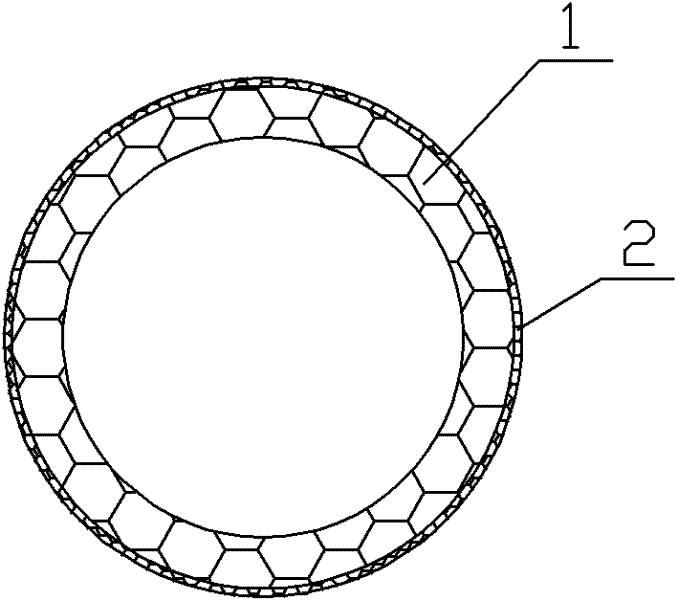

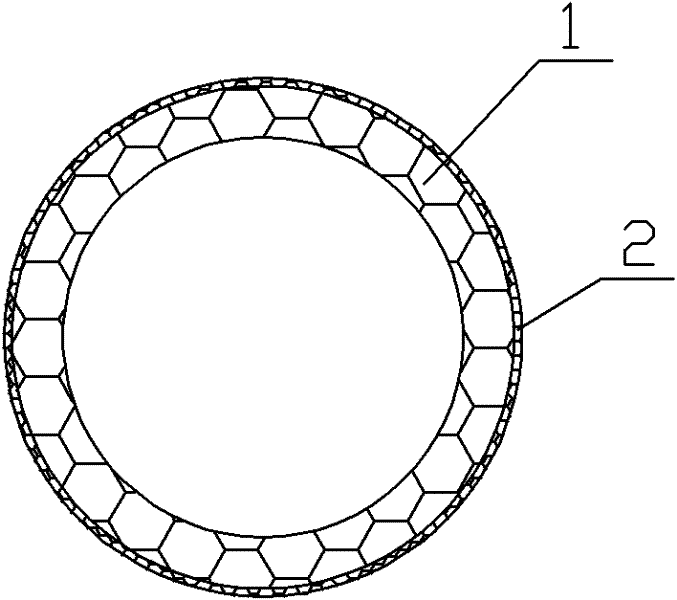

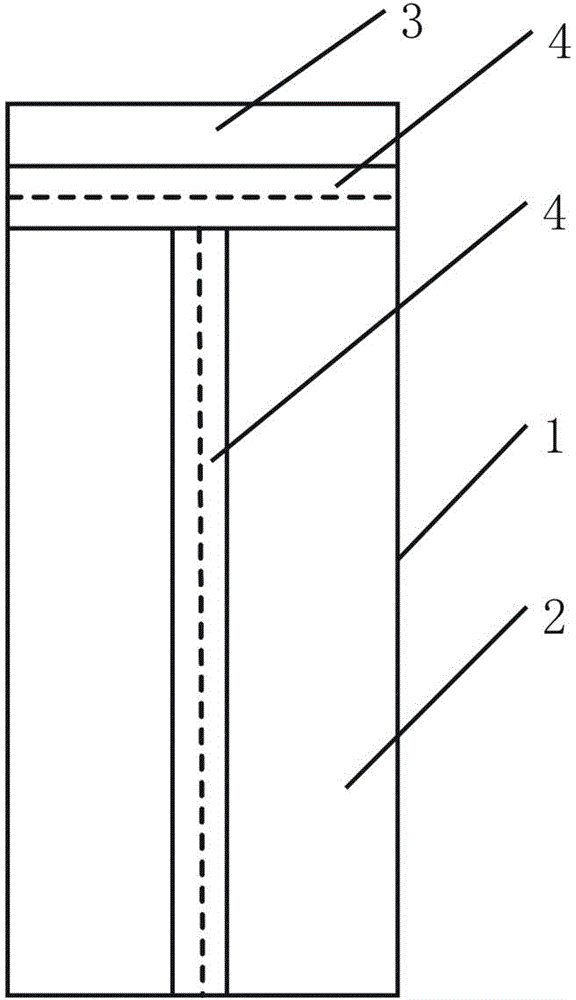

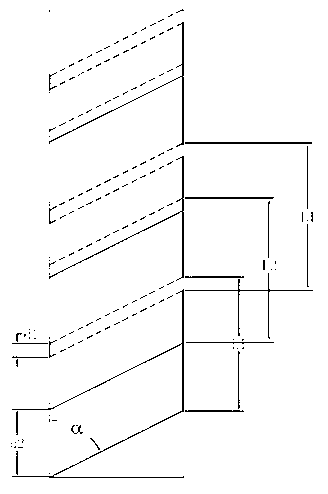

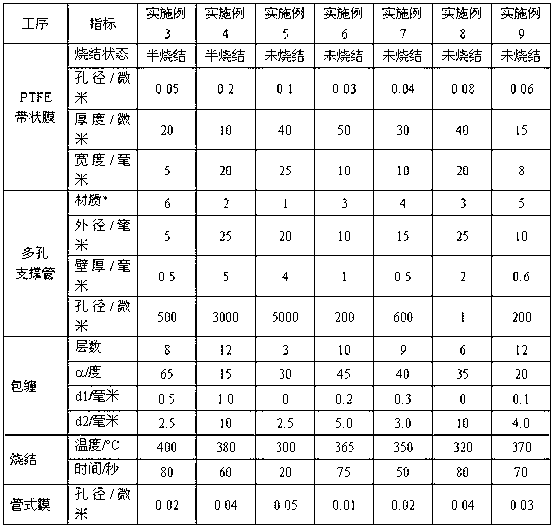

Preparation method of wrapped polytetrafluoroethylene ultra-micro filter tube membrane

ActiveCN103007788AAvoid layeringUniform filtering effectSemi-permeable membranesPorosityOrganic solvent

The invention discloses a preparation method of a wrapped polytetrafluoroethylene ultra-micro filter tube membrane. A sintered or unsintered drown polytetrafluoroethylene membrane of which the aperture is 0.03-0.3micon and the thickness is 10-50micon is cut into polytetrafluoroethylene strip-shaped membranes which are 5-25mm in width; the membranes are wrapped on a porous support tube which resists a temperature of 300-500 DEG C and is corrosion resistant and organic solvent resistant; and the support tube wrapped with the prepared polytetrafluoroethylene membranes is sintered for 20-80s at the temperature of 300-400 DEG C so as to prepare the wrapped polytetrafluoroethylene ultra-micro filter tube membrane of which the aperture of a filtering layer is 0.01-0.05micon. The wrapped polytetrafluoroethylene ultra-micro filter tube membrane has the advantages of high porosity, small aperture, uniformity in filtering layer, blocking resistance, internal and external pressure resistance, capability of back washing and the like, and can be used in solid-liquid and gas-liquid separation with high viscosity, high solid content and high pollution in food concentration, waste penetration liquid treatment, oil-water separation, membrane biologic reactor and the like.

Owner:ZHEJIANG SCI-TECH UNIV

Filter paper of air filter for saving fuel and method for manufacturing same

ActiveCN101392703AReduce resistanceEasy to useWater-repelling agents additionMachines/enginesWater basedFuel conservation

The invention provides filter paper of an air filter of fuel conservation and a manufacture method thereof. The filter paper consists of base paper and a sizing agent which is coated on a single side or double sides of the base paper gram weight of between 110 and 160 gram / meter<2>, and water-base resin (butt) is 5 to 30 percent of mass of the base paper. The sizing agent comprises the following components in weight percentage: 2 to 20 percent of the water-base resin (butt), 1 to 20 percent of powder functional material, and 60 to 80 percent of water. The powder functional material is more than one of tourmaline ore powder with far infrared emitting property and releasing anion property, molten mass powder of rare-earth zirconium oxide and alumina, molten mass powder of rare-earth zirconium oxide, titanium oxide or rare-earth zirconium oxide, zinc oxide and the like. With the filter paper, fuel can be saved by 3 to 10 percent, but power of the engine is increased by 5 to 20 percent; noise of the engine is reduced by over 10 decibels, and exhaust emission pollutants are reduced by over 10 to 30 percent.

Owner:湖北国鼎华明纳米新材料有限公司

Method and Device for Low Delay Processing

ActiveUS20090017784A1Reduce probabilityReduce errorsAdaptive networkDigital technique networkTime domainAdaptive filter

Owner:CIRRUS LOGIC INT SEMICON

Polyvinylidene fluoride based micro-pore film and preparation method thereof

InactiveCN105879710ASolve the disadvantage of insufficient hydrophobicityHas super hydrophobic effectSemi-permeable membranesMembranesPolymer sciencePolyvinylidene difluoride

The invention discloses a polyvinylidene fluoride (PVDF) based micro-pore film and a preparation method thereof. The polyvinylidene fluoride based micro-pore film comprises a polyvinylidene fluoride micro-pore film provided with a supporting layer in the middle and a low-surface-energy substance coating on the surface of the polyvinylidene fluoride micro-pore film. The preparation method comprises the following steps: selecting two types of polymers, wherein one is polyvinylidene fluoride; dissolving the two polymers into a solvent system to prepare a polymer solution; adding a pore-forming agent into the polymer solution; after uniformly stirring, standing and de-foaming to obtain a film-forming solution; immersing the supporting layer into the film-forming solution to obtain a primary micro-pore film; dissolving and etching the other polymer from the primary micro-pore film to obtain a primary PVDF based micro-pore film; immersing the primary PVDF based micro-pore film into a finishing solution containing the low-surface-energy substance and drawing out from a roller to obtain the PVDF based micro-pore. The film-forming solution is prepared by selecting two types of the incompatible polymers and the surface of the porous film is coated with the low-surface-energy substance, so that a microcosmic rough structure is formed on the surface of the micro-pore film and the super-hydrophobic effect is achieved.

Owner:DONGHUA UNIV

High temperature resistant flame retardant filter paper used for diesel filter and preparation method thereof

ActiveCN102877368AHigh temperature resistant and flame retardantBursting strengthPaper/cardboardFiltration separationBursting strengthCellulose

The invention discloses a high temperature resistant flame retardant filter paper used for a diesel filter and a preparation method thereof. The high temperature resistant flame retardant filter paper comprises the following raw materials in parts by weight: 60-70 parts of wood pulp celluloses, 30-40 parts of vinylon fibers, 10-15 parts of glass fibers, 2-5 parts of dolomite dust, 1-3 parts of nanometer titanium dioxide, 2-4 parts of light calcium carbonate, 1-2 parts of modified nano-carbon, 1-2 parts of nanometer titanium oxide, 0.5-0.8 part of ammonium dihydrogen phosphate, 3-4 parts of modified water-soluble phenolic resin emulsion, 2-5 parts of styrene-acrylic emulsion, 0.5-1 part of diethanolamide, 0.5-1 part of silane coupling agent KH550, 0.4-0.8 part of sodium laurylsulfate and 4-6 parts of a wet strength agent. The filter paper, prepared by the invention, has the advantages of good water permeability, large filtering area, small maximum aperture, high filtering precision, strong bursting strength, high temperature resistance and flame resistance, the filtering efficiency is 99.999%, the filter paper has stable performance index at normal temperature and high temperature, and better temperature resistance and filtering effect.

Owner:ANHUI PHOENIX INT CO LTD

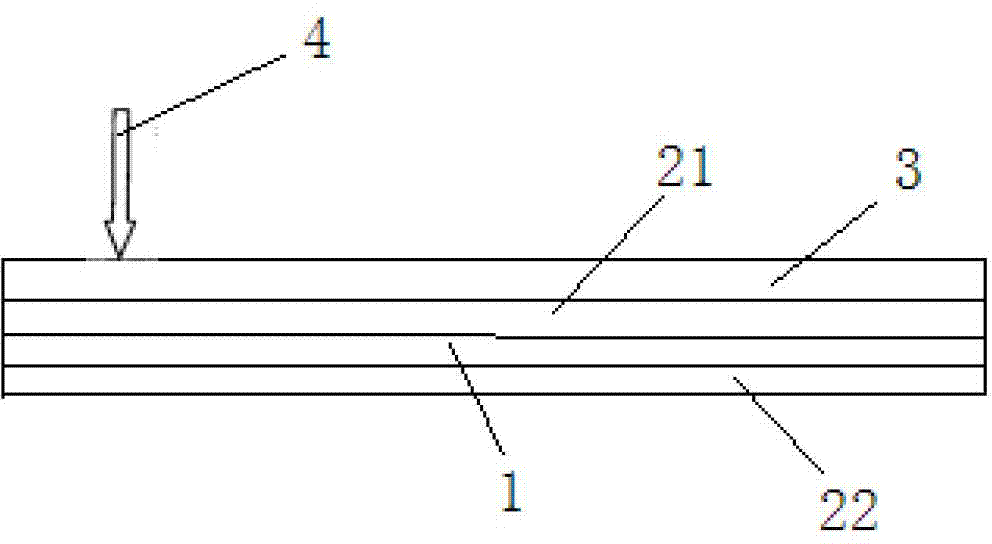

High-intensity low-stretchability polysulfonamide high-temperature-resisting membrane filter material and preparation method thereof

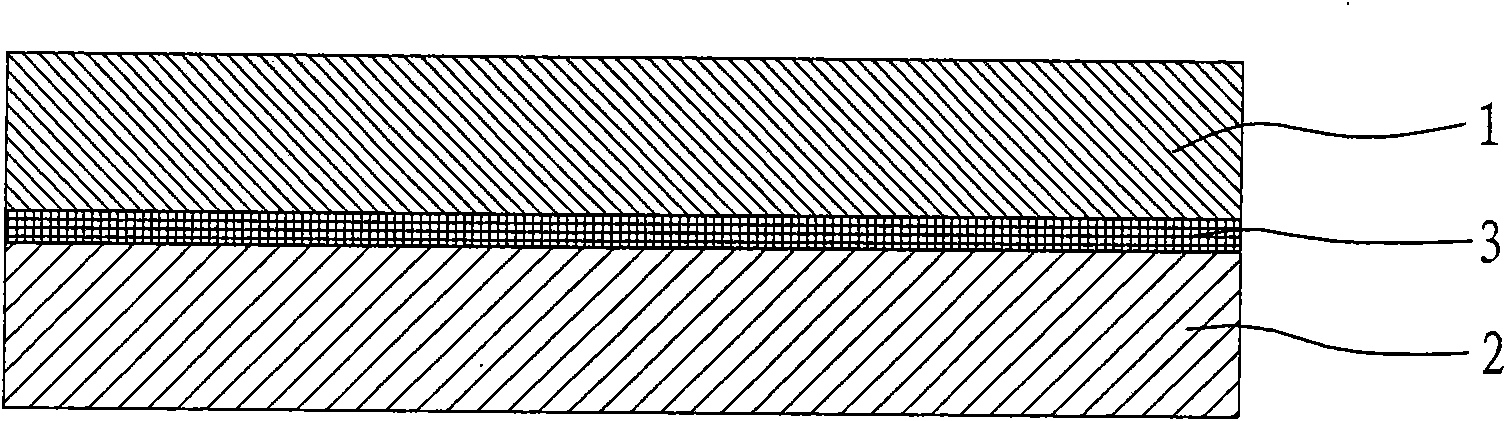

ActiveCN103170183AHigh filtration precisionHigh operabilityFibre typesSynthetic resin layered productsFiberEngineering

The invention provides a high-intensity low-stretchability polysulfonamide high-temperature-resisting membrane filter material and a preparation method thereof. The filter material disclosed by the invention is formed by compounding a PTFE (Polytetrafluoroethylene) high-compactness microporous membrane layer and a punched felt in sequence from top to bottom. The punched felt is formed by compounding a first polysulfonamide fiber surface layer, a high-intensity low-stretchability base cloth layer and a second polysulfonamide fiber surface layer in sequence from top to bottom. The preparation method comprises steps of: preparation of the punched felt, high-temperature thermoforming, singeing and pressing treatment, full-saturation immersion treatment, predrying, baking curing, and high-temperature high-pressure coating with the PTFE high-compactness microporous membrane. The high-intensity low-stretchability polysulfonamide high-temperature-resisting membrane filter material has high intensity and low stretchability, longitude and latitude strengths are both larger than 3000N / 50mm; the longitude and latitude elongations at break are both smaller than 10%; and the filter material can resist a high temperature grade of 250 DEG C and has high corrosion resistance, good oxidization resistance, smooth surface, high deashing efficiency and wide application range.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Composite acupuncture filter bag used for smoke treatment of ceramic kiln

ActiveCN101695615AShort production processHigh porosityDispersed particle filtrationFiltration separationYarnAlkali free

The invention discloses a composite acupuncture filter bag used for smoke treatment of a ceramic kiln. Short fibers and base fabrics are acupunctured by adopting non-woven acupuncture technology to form a composite acupuncture plain felt, the plain felt is soaked and coated by adopting a surface chemical treatment agent, and then the plain felt is dried and cured at a high temperature and is tailored and sewn to form the filter bag, wherein the base fabrics adopt 30-count alkali-free glass fiber woven fabrics; the short fibers for acupuncture comprise polypropylene fibers, polyphenylene sulfide fibers and 80-count short glass fiber yarns; and the surface chemical treatment agent comprises polytetrafluoroethylene emulsion, polyacrylic ester emulsion, coupling agent, antistatic agent and water. The invention provides the composite acupuncture filter bag used for the smoke treatment of the ceramic kiln, which has the advantages of moisture resistance, good acid corrosion resistance, long service life, high strength of the base fabrics and lower production cost. The problems of poor moisture resistance, poor corrosion resistance, low strength, short service life and high production cost of the filter bag in the prior art are solved. The filter bag is suitable for dust removal and purification treatment for the smoke of the ceramic kiln.

Owner:山东兴国新力环保科技股份有限公司

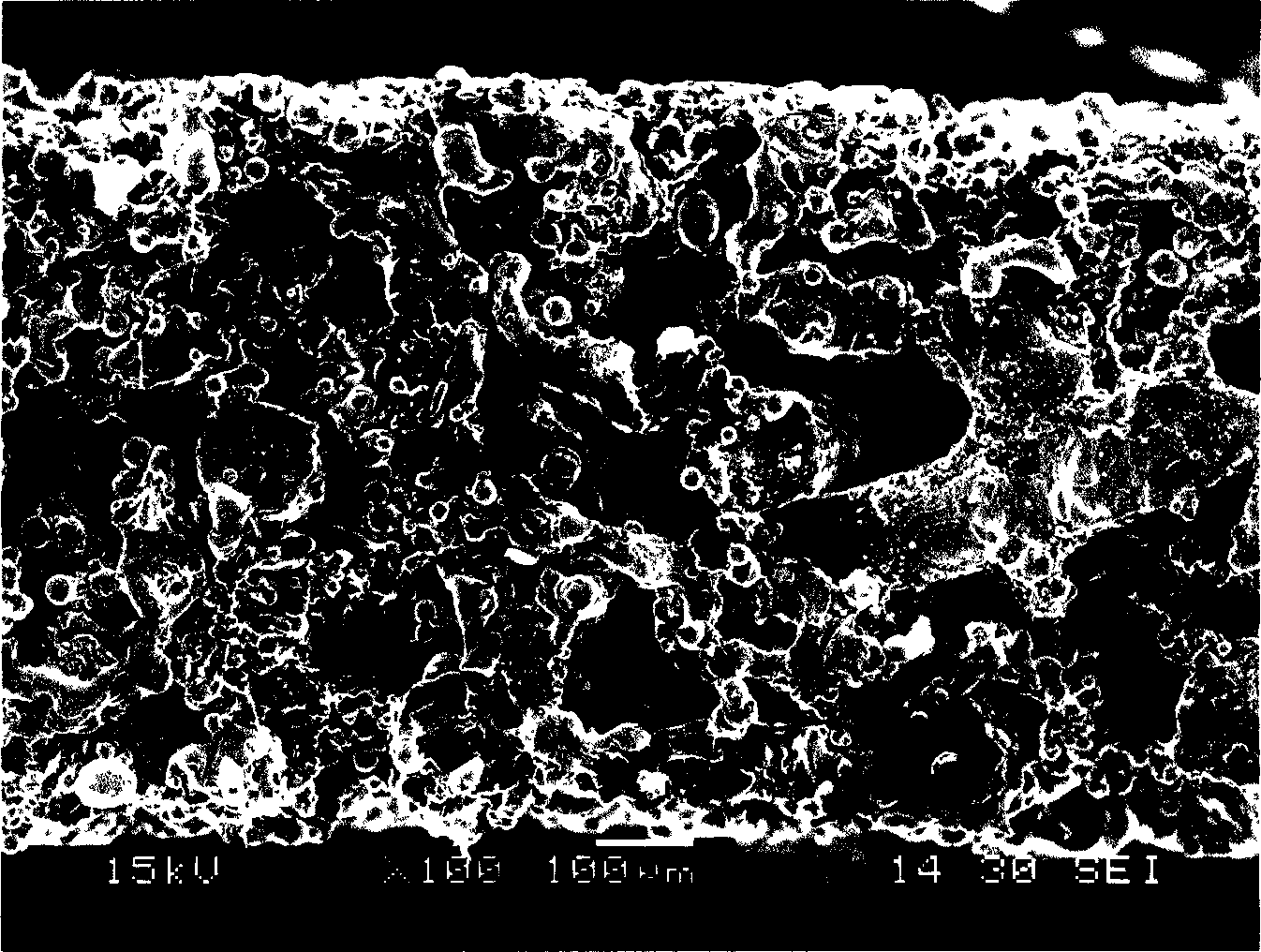

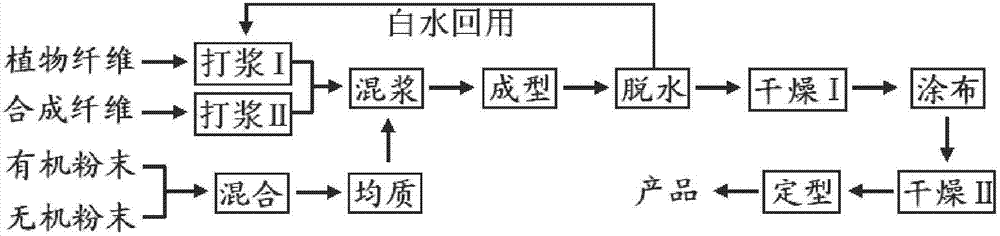

Battery capacitor membrane filtration material prepared by using wet papermaking forming process, and preparation method thereof

InactiveCN102728144AImprove uniformityImprove physical propertiesSpecial paperPaper/cardboardEconomic benefitsPolymer science

The present invention discloses a battery capacitor membrane filtration material prepared by using a wet papermaking forming process, and a preparation method thereof. Raw materials for preparing the material comprise, fibers, inorganic powder, organic powder and a reinforced material, wherein the fibers comprise, by weight, 3-10% of plant fibers and 90-97% of synthetic fibers, the weight of the inorganic powder is 1-40% of the weight of the fibers, the weight of the organic powder is 0.1-20% of the weight of the fibers, and the weight of the reinforced material is 10-30% of the weight of the fibers. The preparation method is characterized by: respectively carrying out pulping on the plant fibers and the synthetic fibers, and respectively carrying out high pressure homogenization mixing on the inorganic powder and the organic powder. The preparation method of the present invention has the following advantages that: the process is simple, the hole size can be effectively controlled, and the hole uniformity can be improved, wherein the holes are the labyrinth type curved holes. The material of the present invention has the following advantages that: filtration accuracy and filtration efficiency are high, internal resistance of the membrane prepared by the material is lowered, the membrane prepared by the material has characteristics of high liquid retention rate, good high temperature resistance, small deformation size, avoidance of dendrite generation and long service life. The raw material and the preparation cost of the material of the present invention are the same as the raw material and the preparation cost of full chemical fiber filtration material, and the performance price ratio of the material of the present invention is more excellent than the performance price ratio of the traditional materials, such that good economic benefits and social benefits are provided.

Owner:吕凯

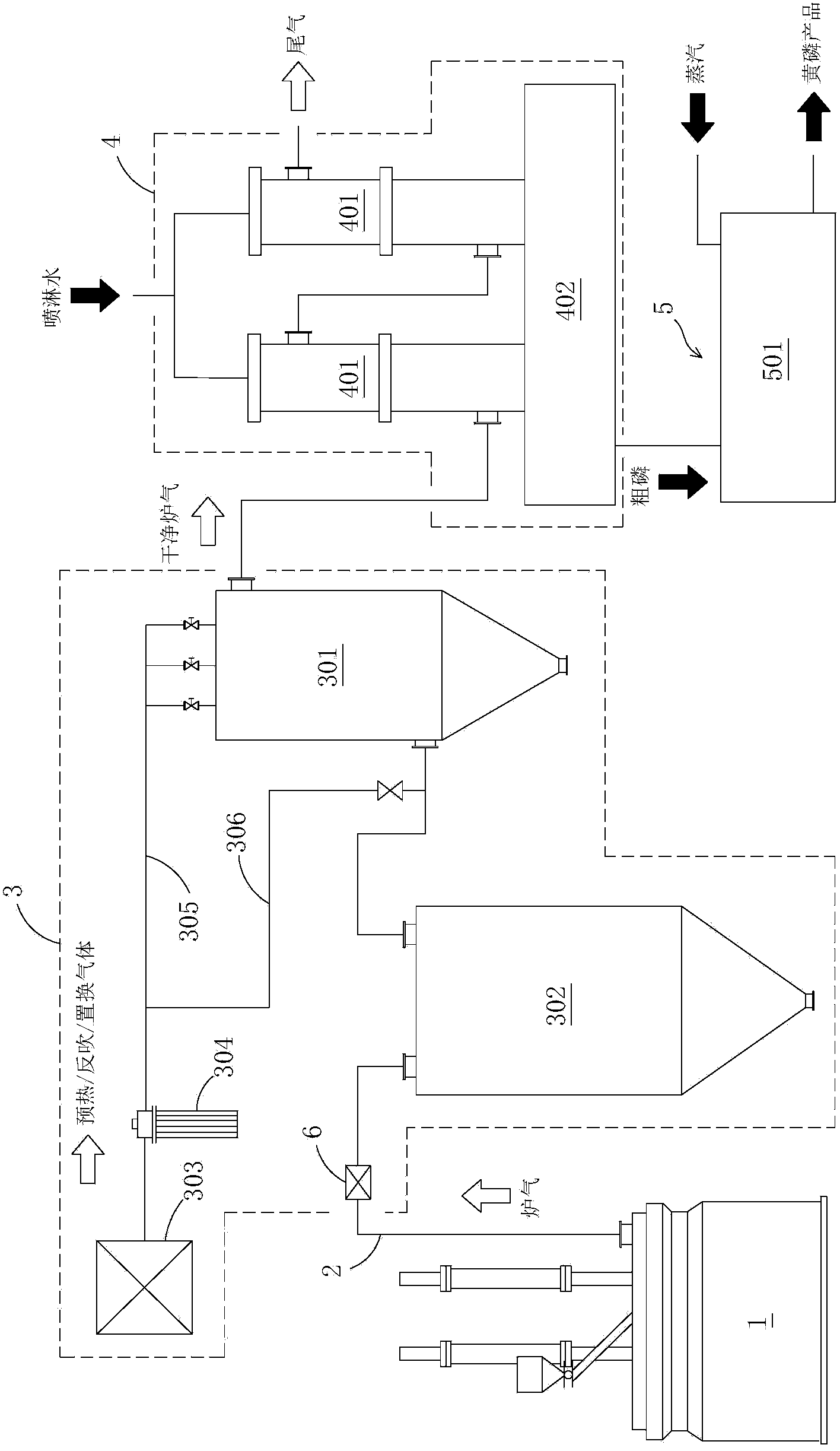

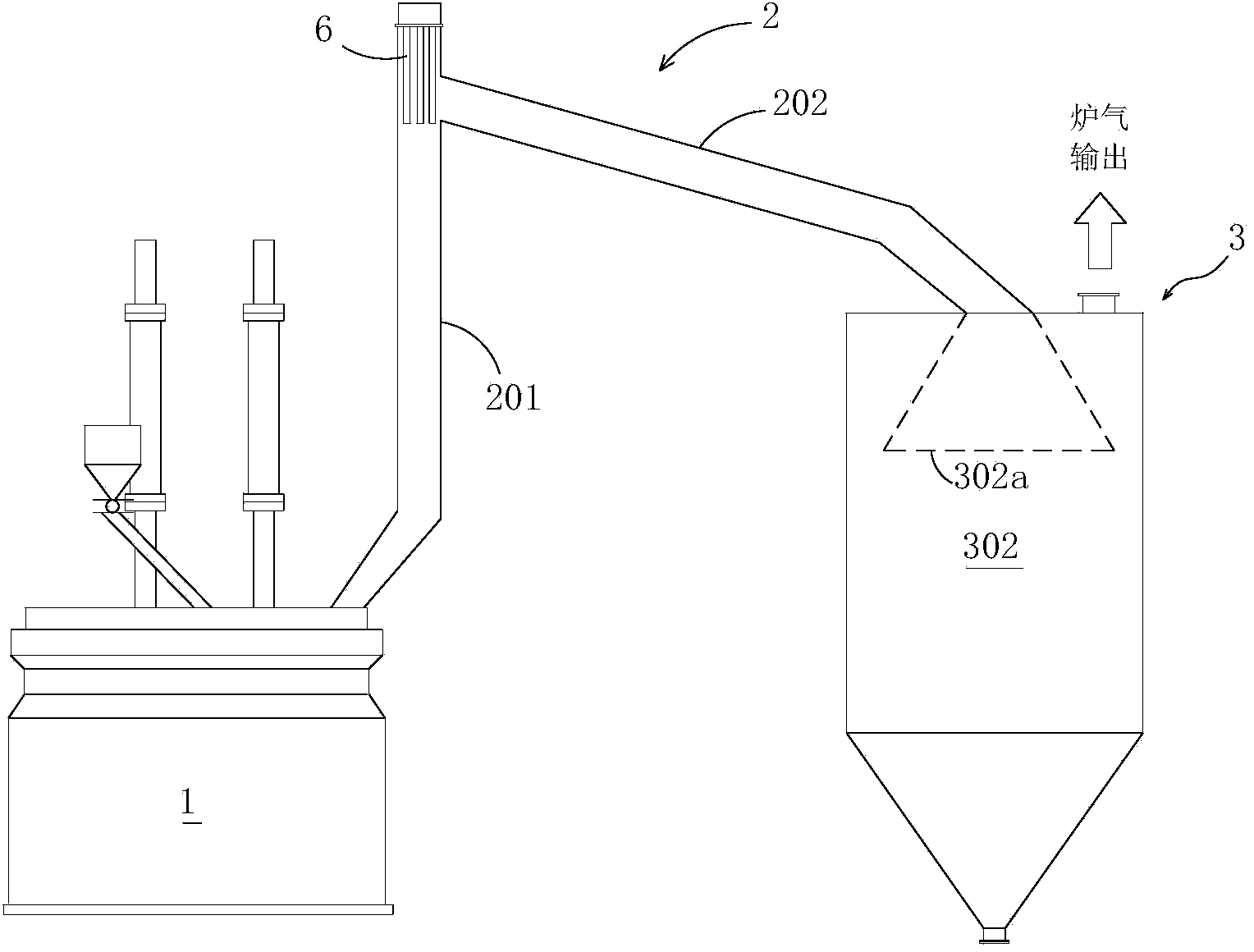

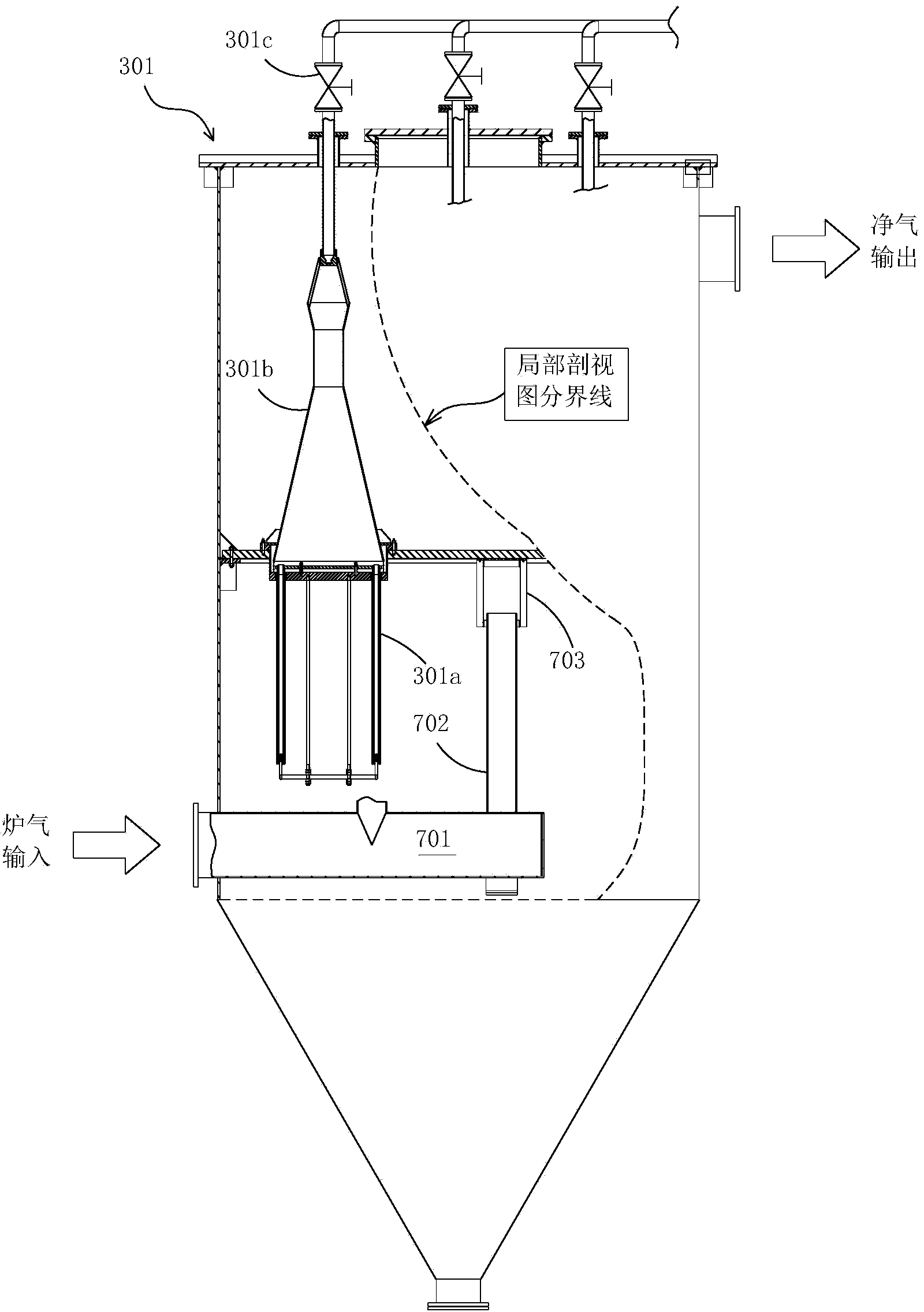

Yellow phosphorus preparation method and yellow phosphorus preparation equipment

ActiveCN103508429AHigh filtration precisionGood thermal shock resistancePhosphorus compoundsProcess engineeringSlurry

The invention discloses a yellow phosphorus preparation method and yellow phosphorus preparation equipment, which produce no phosphorous slurry and reduce the dust content of tail gas. The yellow phosphorus preparation method comprises the technological processes of electric furnace smelting, furnace gas purifying and phosphorus collecting and refining. In the process of furnace gas purifying, the furnace gas discharged out from an electric furnace is guided into a furnace gas dust-collection system through a smoke discharge pipeline, the furnace gas dust-collection system at least comprises a filter for filtering the furnace gas, the filter is provided with a sintering inorganic porous material filter element meeting the following working conditions, and the operations executed on the filter comprise the operation executed during starting a machine, the operation executed during normal operation, the operation executed during back flowing and the operation executed during stopping the machine; in the operation executed during starting the machine, pre-heated inertia gas is injected into the filter so as to preheat the sintering inorganic porous material filter element in the filter to the temperature of more than 187.5 DEG C, and in the operation executed during the normal operation, the to-be-filtered furnace gas of which the temperature is kept at 420-590 DEG C is input into the filter and the dust content of the filtered clean furnace gas is lower than 10-20 mg / m<3>.

Owner:CHENGDU INTERMENT TECH

High-flux polyvinylidene fluoride hollow fiber membrane

ActiveCN103111189AIncrease water productionReduce manufacturing costSemi-permeable membranesFiltrationHigh flux

The invention relates to a high-flux polyvinylidene fluoride hollow fiber membrane which is in an asymmetrical structure. From outside membrane fibers to the hollow inside, the high-flux polyvinylidene fluoride hollow fiber sequentially comprises a compact outer skin layer, a first structural layer with finger-like pores, a spongy layer with abundant pores, a second structural layer with finger-like pores and an inner skin layer, wherein the finger-like pores in the first structural layer are larger than those in the second structural layer. The high-flux polyvinylidene fluoride hollow fiber membrane is prepared through a dry-wet spinning process. According to the invention, the polyvinylidene fluoride hollow fiber membrane is in a five-layer structure; above all, the loose spongy layer structure ensures that the polyvinylidene fluoride hollow fiber membrane has high pure water flux and high filtration accuracy; and meanwhile, the polyvinylidene fluoride hollow fiber membrane also has the advantages of satisfactory flexibility and chemical resistance of a polyvinylidene fluoride material. Thus, the water yield in unit membrane area can be effectively increased, and the manufacturing and use cost of a membrane component can be lowered.

Owner:JIANGSU SUJING GROUP +1

Heat-resistant basalt fibre filter material and preparation method thereof

ActiveCN101856577AStable structureHigh filtration precisionFiltration separationNatural mineral layered productsFolding enduranceEmulsion

The invention provides a heat-resistant basalt fiber filter material and a preparation method thereof. The filter materials of the invention can be used in environment of ultra-high temperature, and has excellent folding endurance, corrosion resistance and abrasive resistance. The preparation method of the heat-resistant basalt fiber filter material has the technical scheme as follows: firstly, preparing a basalt fiber foundation and basalt fiber meshes; putting the basalt fiber foundation between the upper basalt fiber mesh and the lower basalt fiber mesh to be manufactured into the filter material; and preparing basalt fiber used for the basalt fiber foundation and then carrying out dipping treatment of teflon mix emulsion.

Owner:昆山万瑞达工业纺织品有限公司

Ceramic membrane for treating dusty, poisonous and high-temperature gases and preparation method thereof

ActiveCN103495346AHigh filtration precisionImprove permeabilitySemi-permeable membranesDispersed particle separationSilicon-controlled rectifierMetallic materials

The invention belongs to the field of inorganic nonmetal materials and particularly relates to a ceramic membrane for treating dusty, poisonous and high-temperature gases and a preparation method thereof. 90-99% by mass of ceramic membrane supporting body and 1-10% by mass of catalyst are prepared into a complex, and then, a ceramic membrane coating is spray coated on the outer surface of the complex to prepare the ceramic membrane. The catalyst is an SCR (Silicon Controlled Rectifier) denitration catalyst, and the ceramic membrane supporting body is prepared from aggregate, a high temperature binder, a pore forming agent, a forming assistant and a release agent. The preparation method is as follows: firstly, preparing the ceramic membrane supporting body, and then, compounding the catalyst in the pore of the supporting body, spray coating a layer of ceramic membrane coating material on the outer surface of the supporting body, and carrying out heat treatment to prepare a ceramic membrane material. The prepared ceramic membrane material has the advantages of high filtering precision, high permeability and erosion resistance and has dust removal and catalysis functions, thereby integrating denitration with dust removal and changing the traditional mode of gradual operation of independent operation units.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

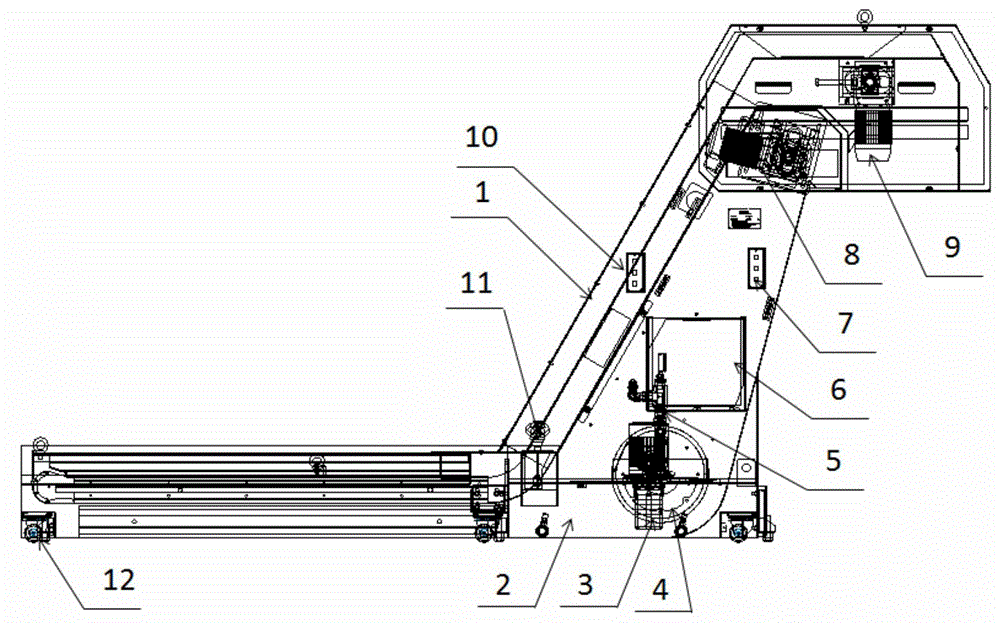

Chip removal and cutting fluid purification device for machine tool

InactiveCN103551909AReduce wasteReduce manufacturing costMaintainance and safety accessoriesMoving filtering element filtersEngineeringControl switch

The invention relates to a chip removal and cutting fluid purification device, in particular to a chip removal and cutting fluid purification device for a machine tool. The chip removal and cutting fluid purification device for the machine tool is characterized by being formed by movably connecting and assembling an upper layer chain board chip remover and a bottom layer recoil roller scraper chip remover by a middle part, wherein the upper layer chain board chip remover is controlled by an upper layer control switch and is driven by an upper layer chip remover speed reduction motor; the bottom layer recoil roller scraper chip remover is controlled by a bottom layer control switch and is driven by a bottom layer chip remover speed reduction motor. The invention provides the chip removal and cutting fluid purification device for the machine tool, which is suitable for turning and milling composite wet machining, can greatly reduce waste of cutting fluid and reduce production cost, can replace a plurality of machines to work, reduces an occupied space, reduces energy consumption, is clean in removing chips and has no pollution to a factory.

Owner:KOCEL GROUP +1

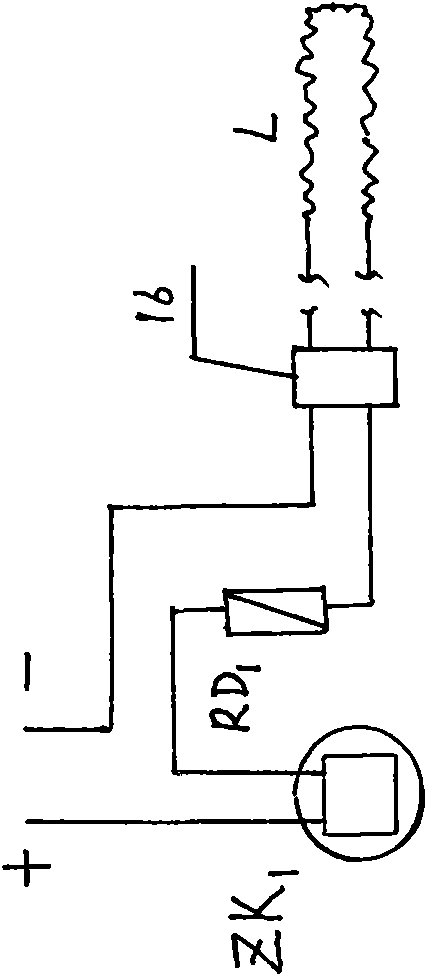

Automatic temperature control heating device of diesel vehicle fuel system

ActiveCN101592101AImprove combustion efficiencyEmission reductionMachines/enginesThermal treatment of fuelTemperature controlElectrical resistance and conductance

The invention discloses an automatic temperature control heating device of a diesel vehicle fuel system, belongs to the technical field of accessories of a motor vehicle fuel system, and solves automatic temperature control heating for fuel. Electric heaters which can independently and automatically control the temperature respectively and have automatic safety protection function are assembled at the corresponding parts of a fuel system; the heating device comprises a fuel pipe inner heater, a filter and an oil tank inner heater, wherein the fuel pipe inner heater consists of an electric heating wire L, a thermal fuse RD1 and a bimetallic temperature controller ZK1 which are connected in series together and form a whole through injection molding and packaging; and the filter and the oil tank inner heater form a whole through a heat-sensitive resistance heating sheet and the bimetallic temperature controller which are connected in series together. The heating device has the advantages that the heating device not only can solve the problems that a diesel vehicle is difficult to start and easy to shut down during running, but also can keep the temperature of the diesel supplied to an engine by the fuel system between 7 and 24 DEG C all the time, realizes year-round use of No.0 diesel oil, has high fuel heating speed, high efficiency and reliable safety protection function, can improve filter precision and reduce oil consumption and discharge, is convenient for a user to assemble and use the heaters for the fuel system parts as required in a single mode, a combined mode or a full system mode according to different vehicles and different seasons, and simultaneously is quite convenient to use.

Owner:BEIJING GAOXIN GREAT FILTER CO LTD

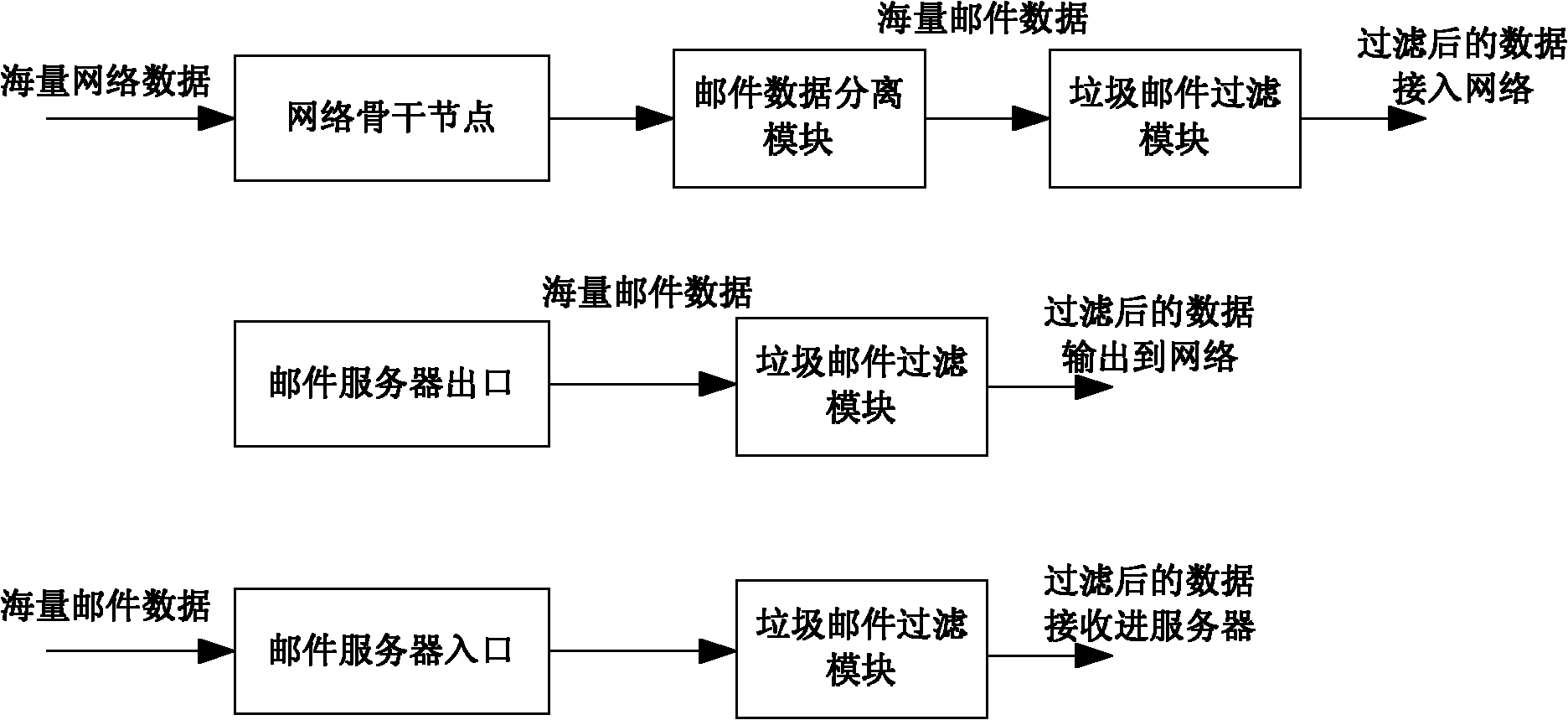

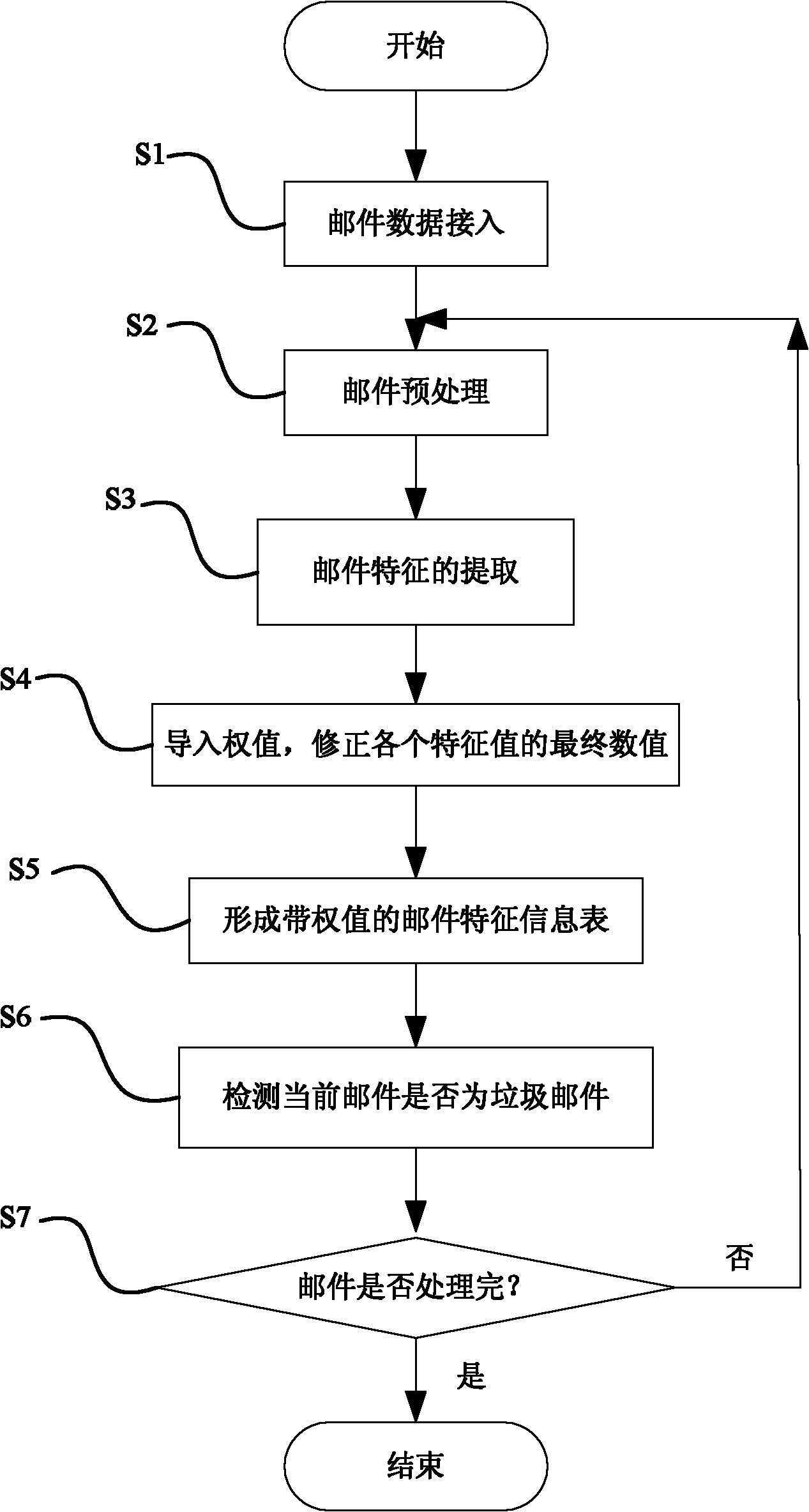

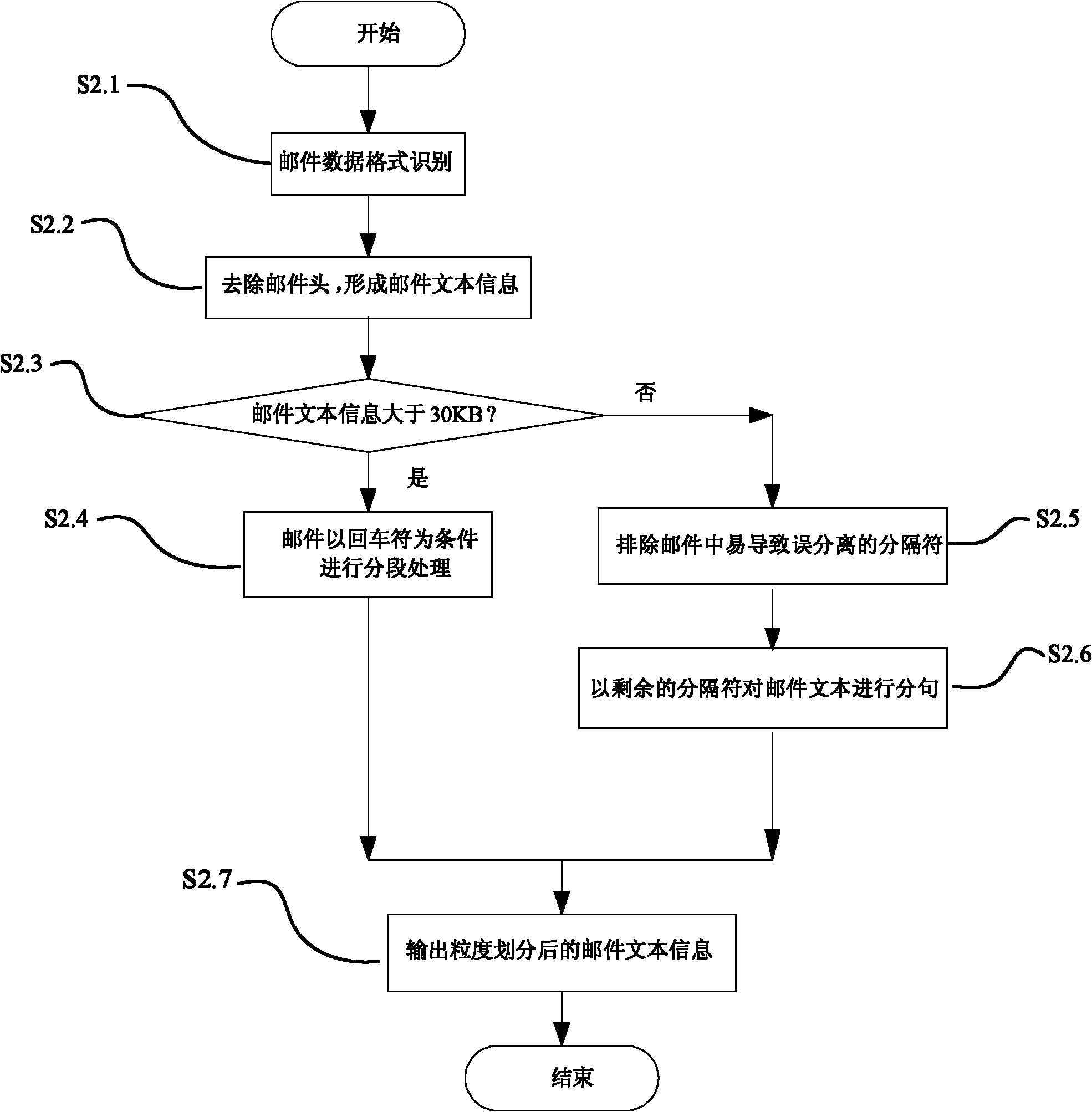

Rapid and high-accuracy junk mail filtering method

InactiveCN102158428AFast filteringImprove accuracyData switching networksSpecial data processing applicationsRepeat emergencyData mining

The invention discloses a rapid and high-accuracy junk mail filtering method, which relates to a processing method of electronic mails. The method comprises the steps of firstly preprocessing all received mails and extracting the feature information of the mails, then comparing the feature information of the mails with a junk mail filtering database to find out whether a mail the same to a mail in the database or smaller than a certain threshold exists, judging the mail to be a similar mail with a mail in the database if the mail exists, and marking the mail as a junk mail, and recording the repeated emergency of the feature of the mail, or judging the mail as a normal mail and adding the feature information of the mail to the junk mail filtering information database. The method also comprises the steps of accessing mail data, preprocessing mails, extracting mail features, importing weights, detecting whether a mail is a junk mail and the like. The method can improve the recognition speed and the filtering accuracy of junk mails, and has the characteristics of high filtering speed, high accuracy rate, wide application situations and the like.

Owner:LIUZHOU VOCATIONAL & TECHN COLLEGE

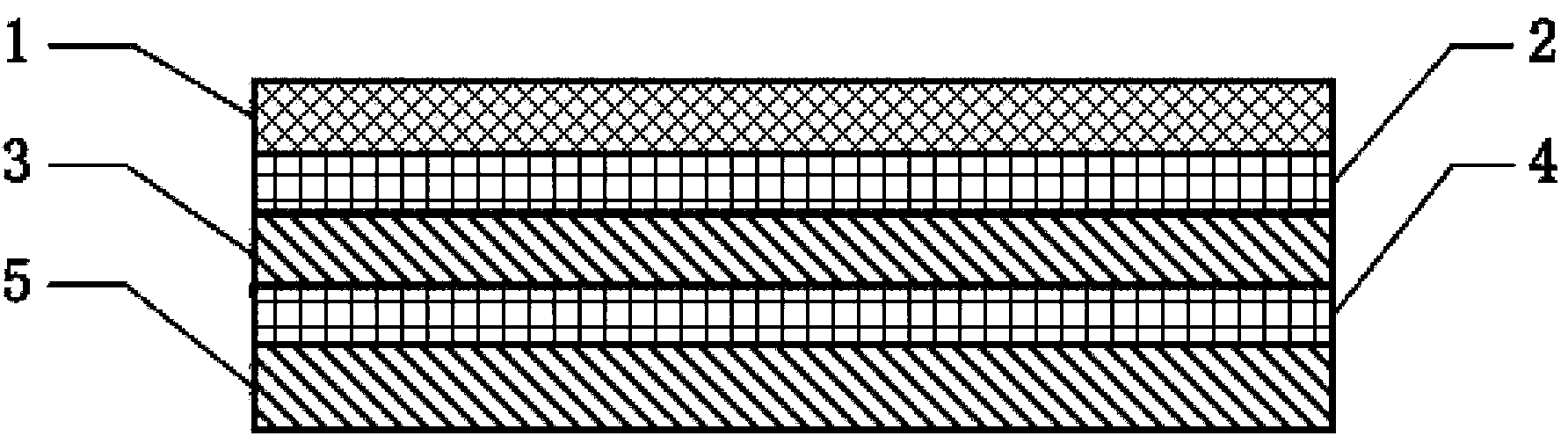

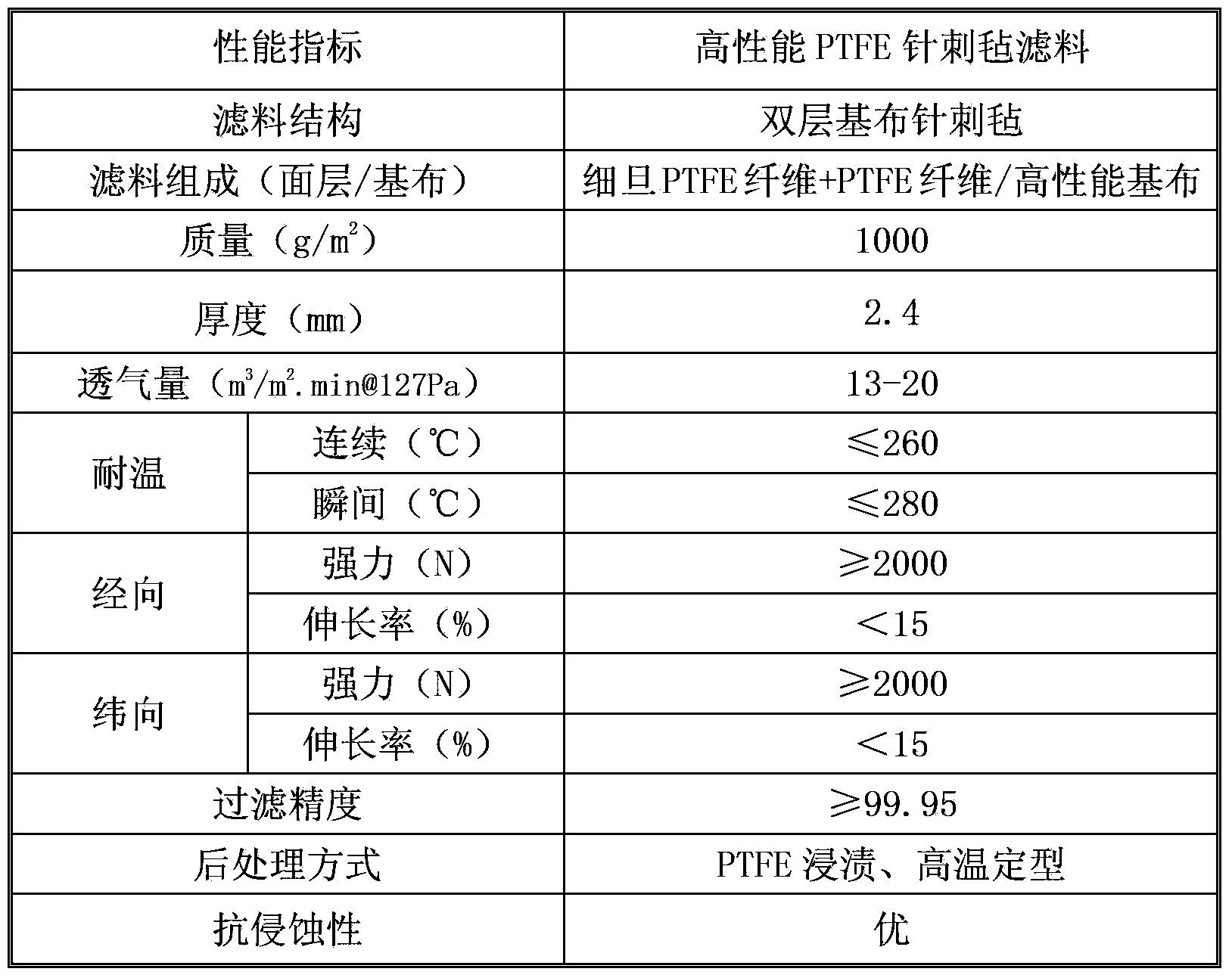

High-performance PTFE (Polytetrafluoroethylene) needled felt filter material and preparation process thereof

ActiveCN103432827ASmall apertureHigh porositySynthetic resin layered productsFiltration separationHeat resistanceFilter material

The invention provides a high-performance PTFE (Polytetrafluoroethylene) needled felt filter material and a preparation process thereof. The filter material sequentially comprises a fine denier PTFE fiber mesh layer, a first base fabric layer, an upper PTFE fiber mesh layer, a second base fabric layer and a lower PTFE fiber mesh layer; the fine denier PTFE fiber mesh layer is made by pre-treating, pre-opening and carding a fine denier PTFE fiber, the first base fabric layer and the second base fabric layer are made by pre-treating PTFE base fabrics, and the upper PTFE fiber mesh layer and the lower PTFE fiber mesh layer are made by pre-treating, pre-opening and carding common PTFE fibers. The filter material provided by the invention is stable in structure, high in filter precision and strength, and good in heat resistance and corrosion resistance, and is used for filtering smoke and collecting products under various complex working conditions.

Owner:辽宁新洪源环保材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com