Patents

Literature

210results about How to "Save civil investment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

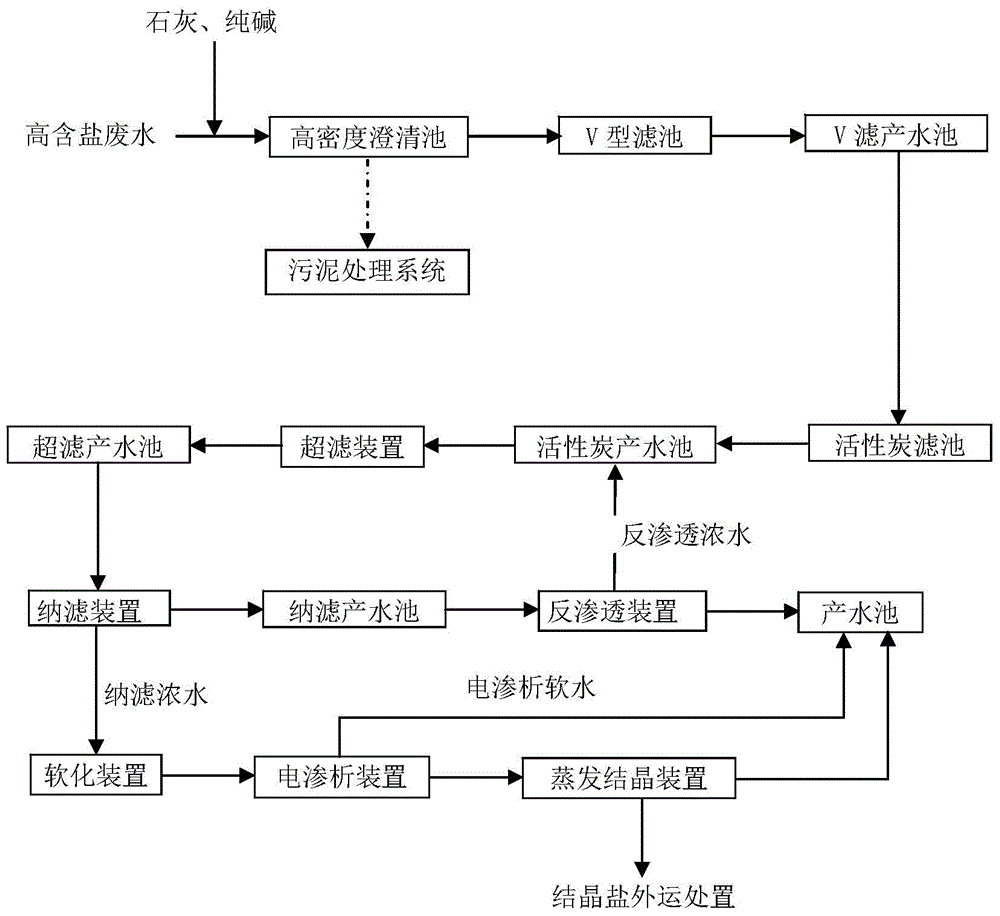

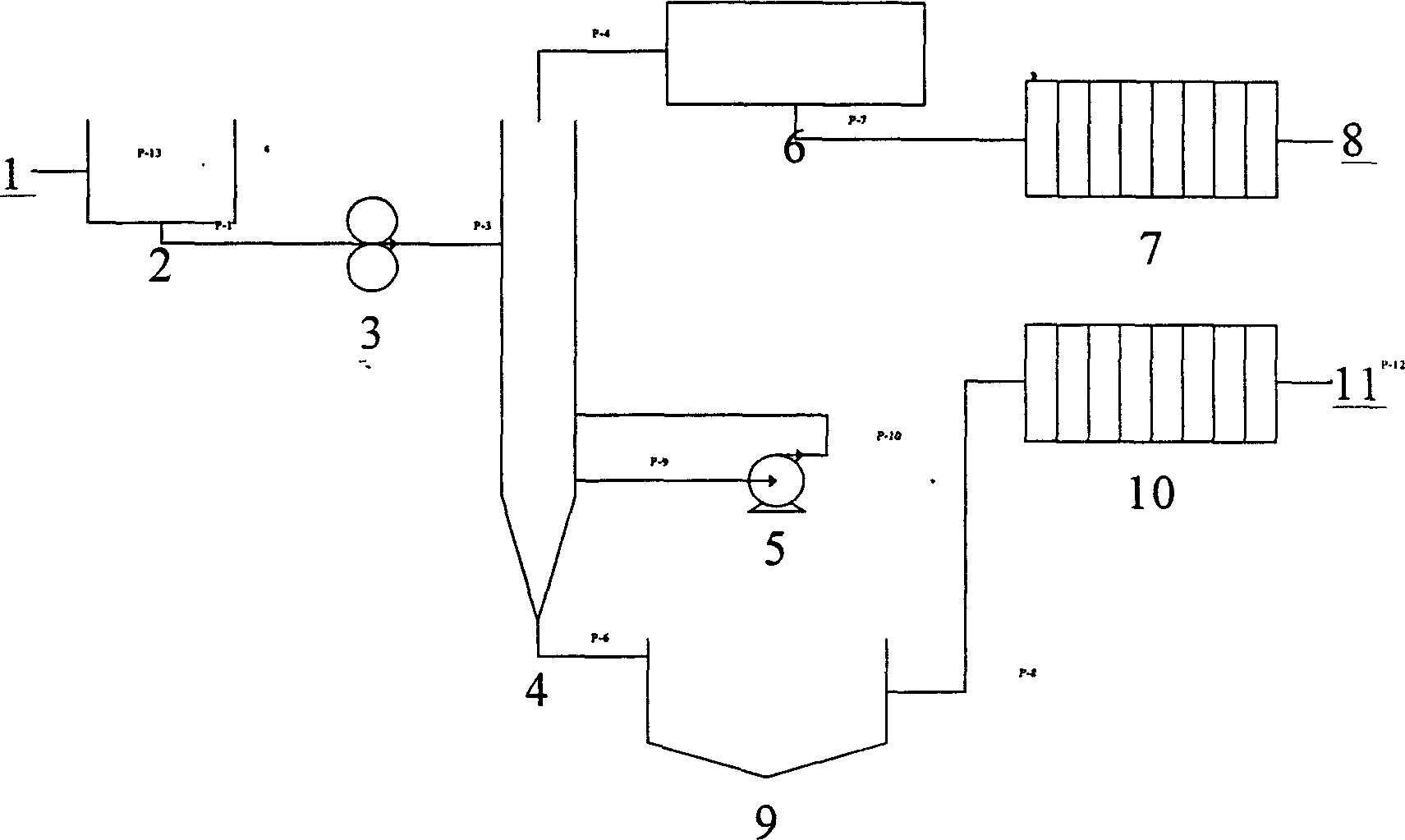

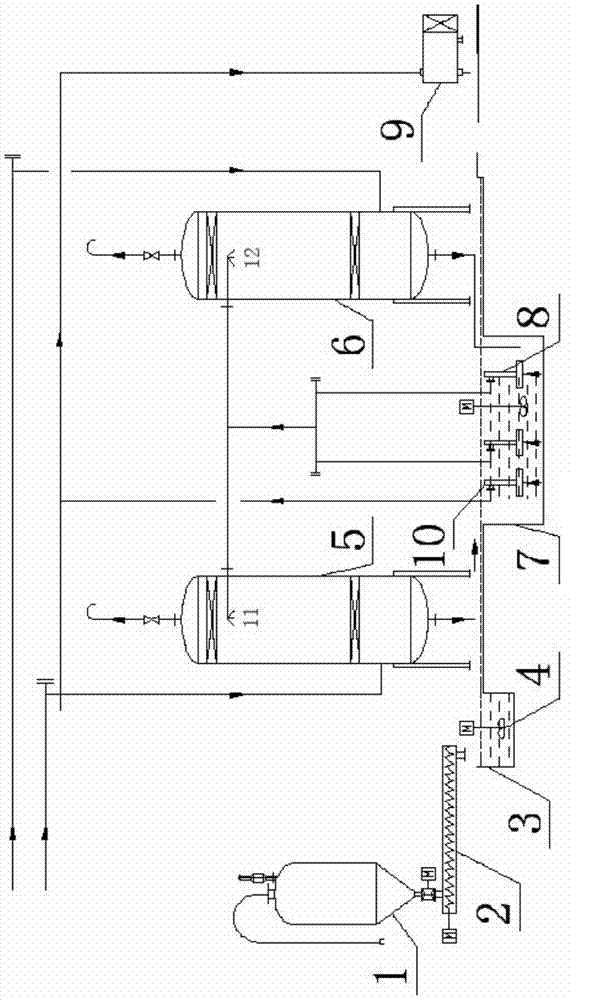

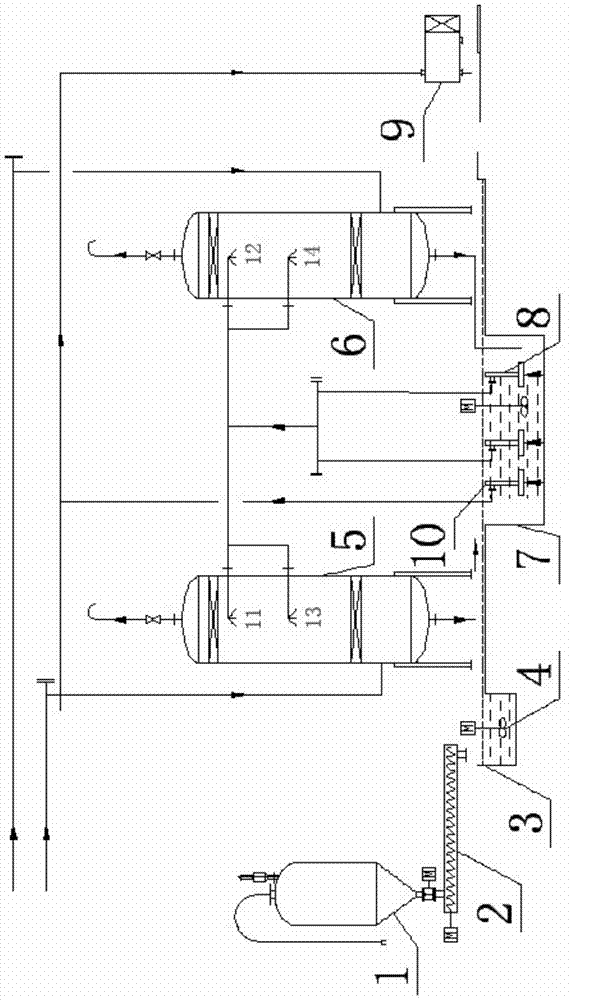

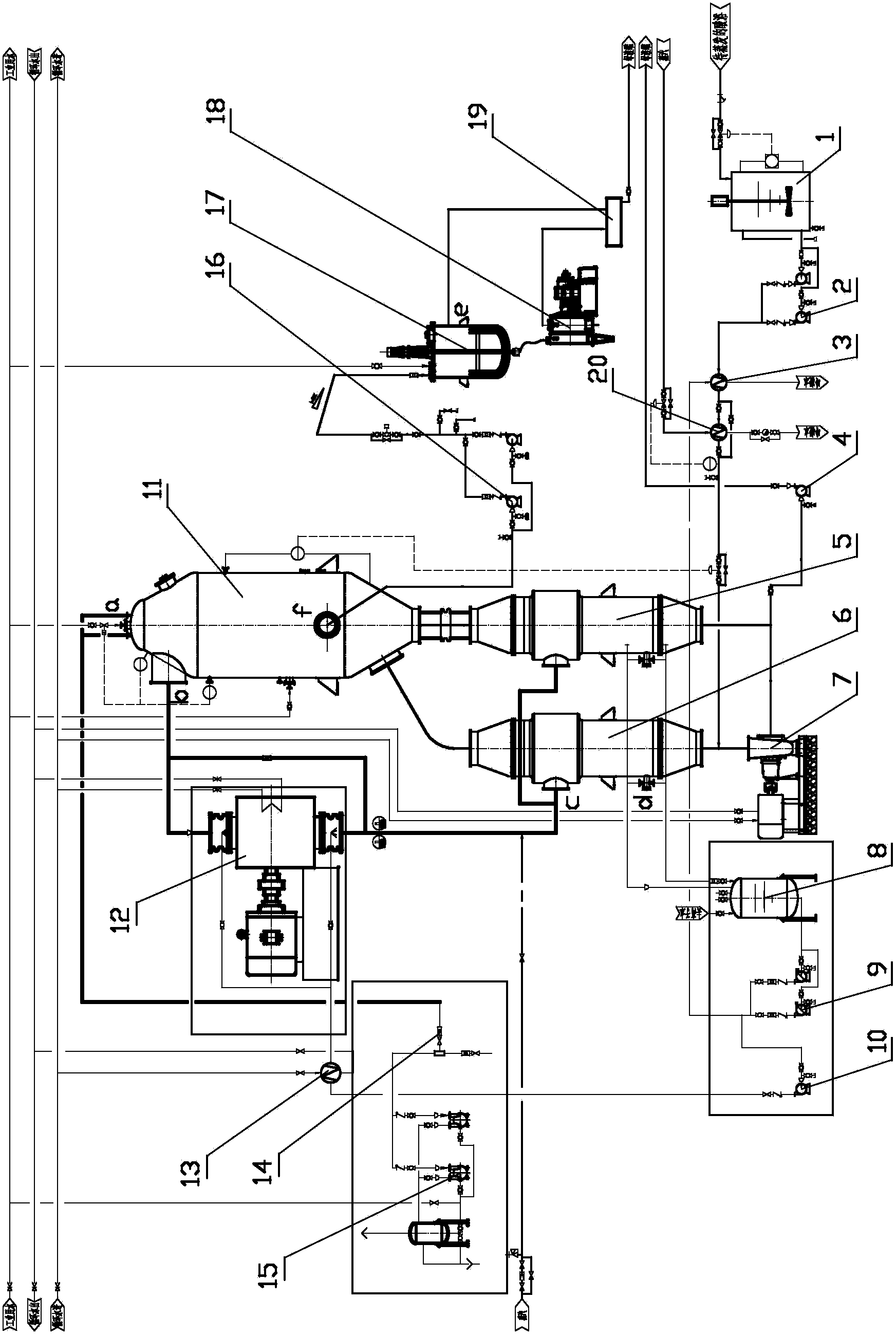

Zero-emission integrated process for treatment and reuse of high-salinity wastewater

ActiveCN104445788AHigh filtration precisionEasy to handleGeneral water supply conservationMultistage water/sewage treatmentSoftened waterEvaporation

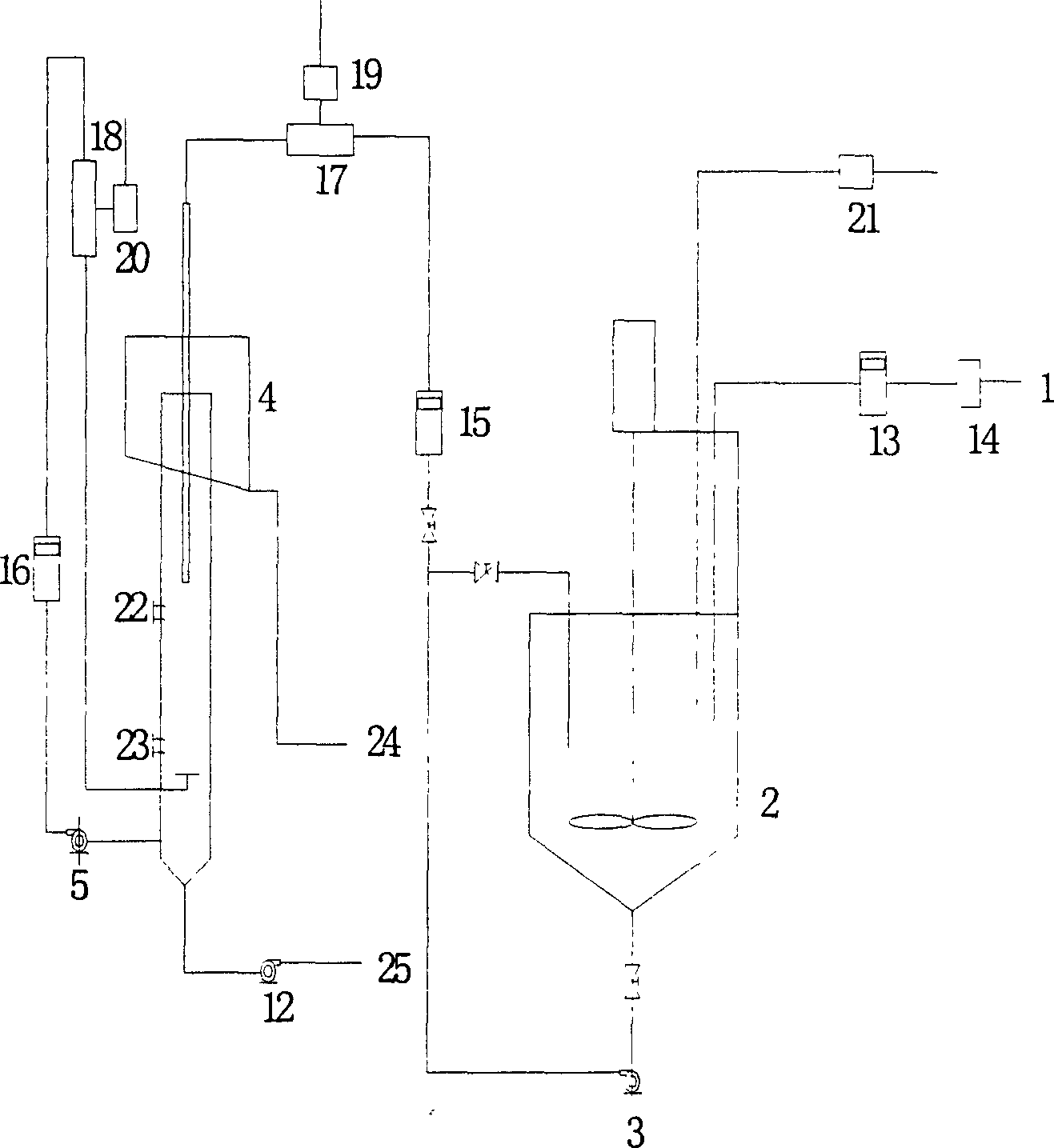

The invention discloses a zero-emission integrated process for treatment and reuse of high-salinity wastewater. The invention relates to a softening desalination treatment technology of water and particularly relates to a reuse treatment system for reverse osmosis concentrated water containing low-concentration organic matters which can achieve the requirement of 'zero emission'. The integrated process comprises the following steps: (1) firstly softening and pre-treating the high-salinity wastewater; (2) acquiring pre-treated water by virtue of activated carbon adsorption and an ultrafiltration device; (3) acquiring nanofiltration softened water and nanofiltration concentrated water by virtue of a nanofiltration device; (4) acquiring reverse osmosis softened water and reverse osmosis concentrated water by virtue of a reverse osmosis device; (5) acquiring electrodialysis softened water and electrodialysis concentrated water by virtue of an electrodialysis device; and (6) carrying out evaporation crystallization treatment on the electrodialysis concentrated water by virtue of an evaporation-crystallization device, regularly outwards transporting salts generated by the evaporation crystallization, feeding generated salt into a water-producing tank to enter a reuse system and finally completing the treatment and reuse of high-salinity wastewater. The integrated process is mainly used for the integrated treatment of the high-salinity wastewater.

Owner:XINJIANG DELAND

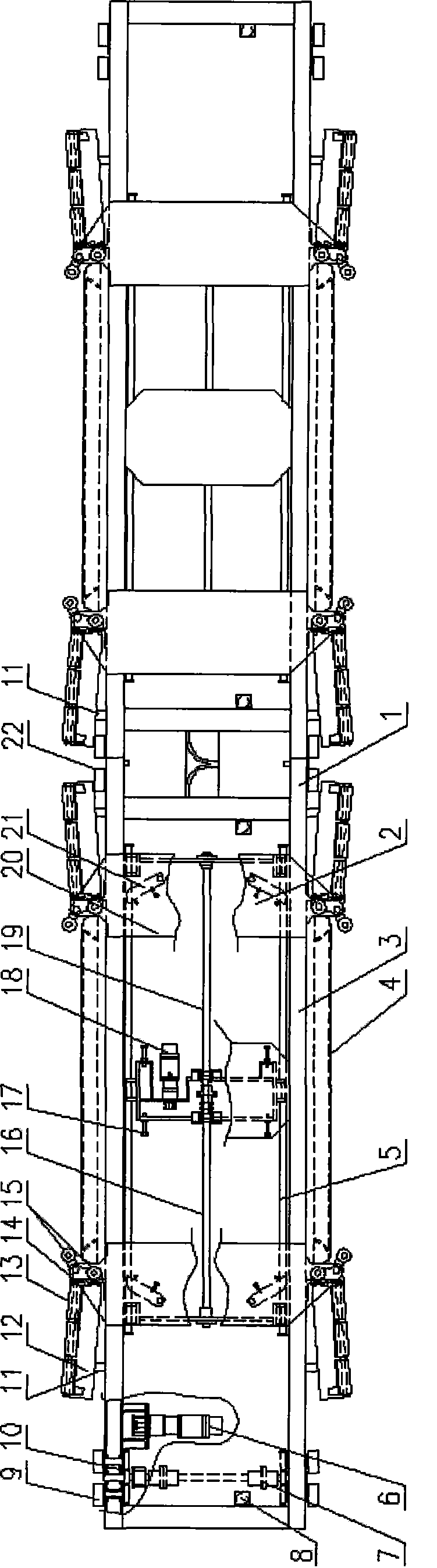

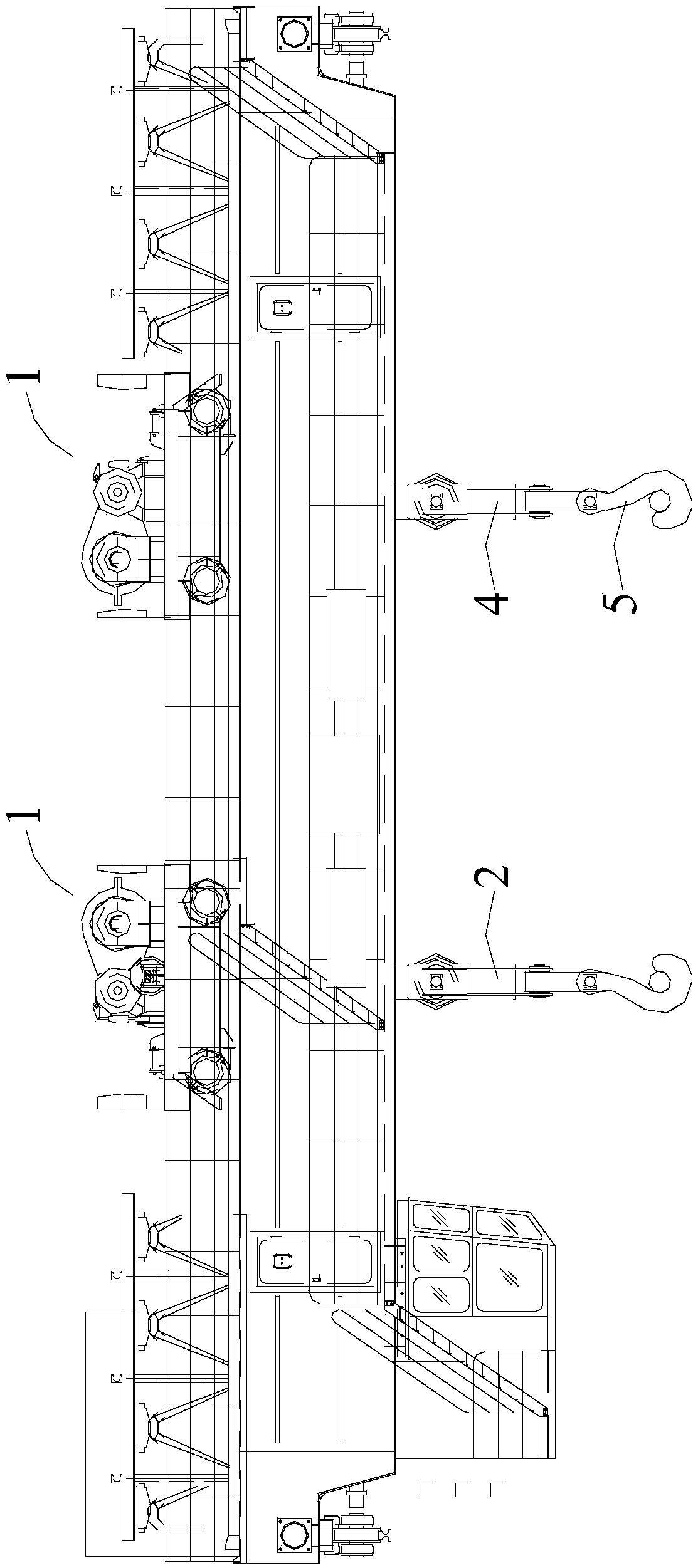

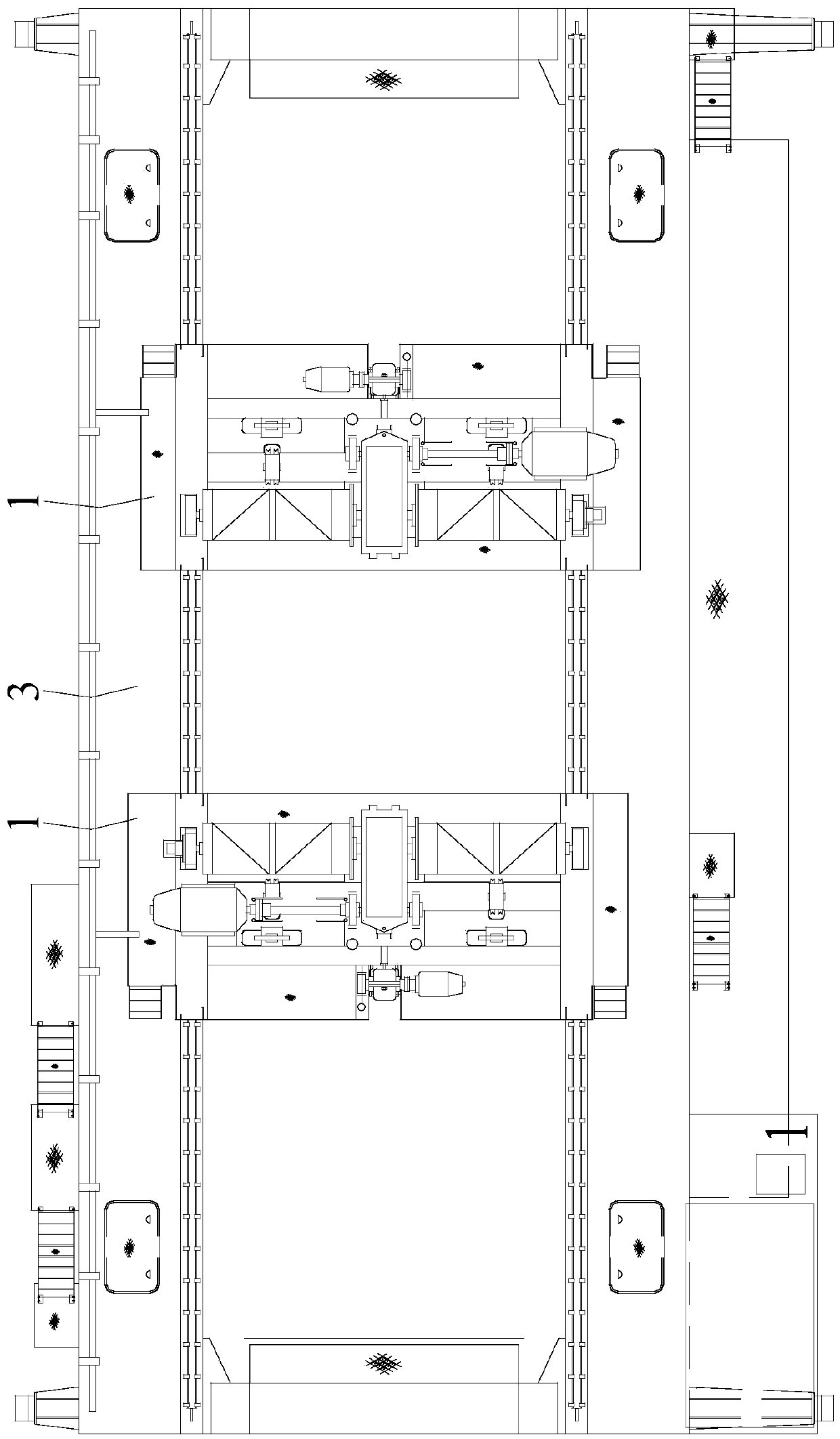

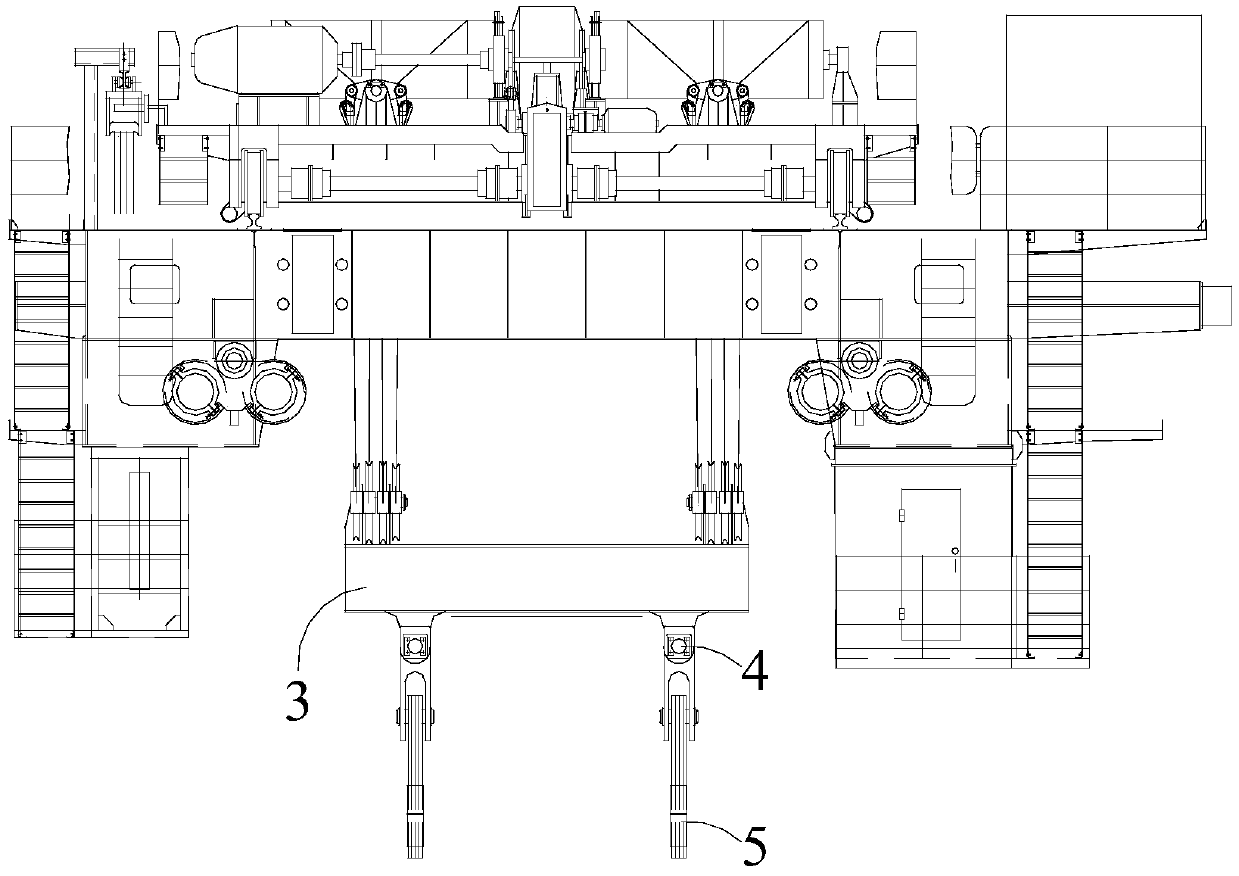

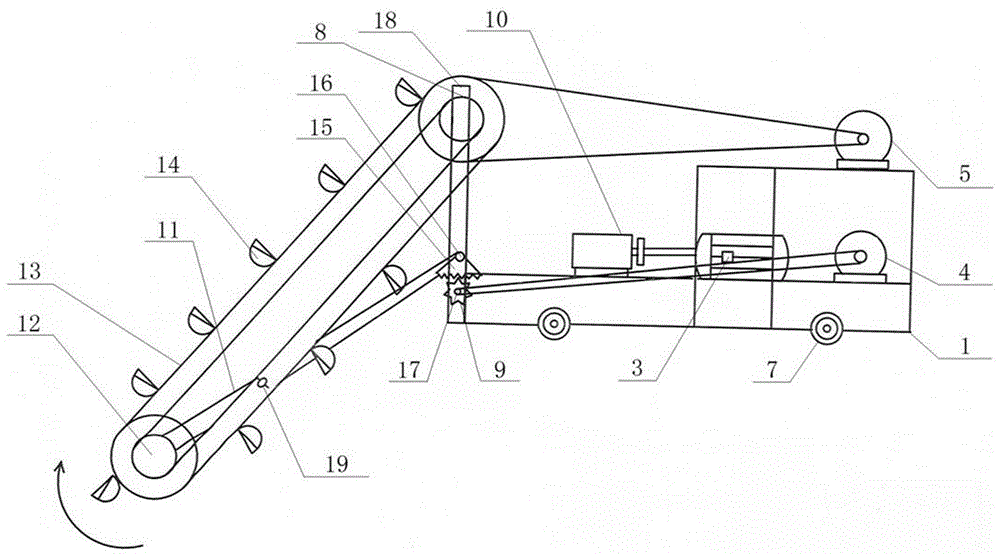

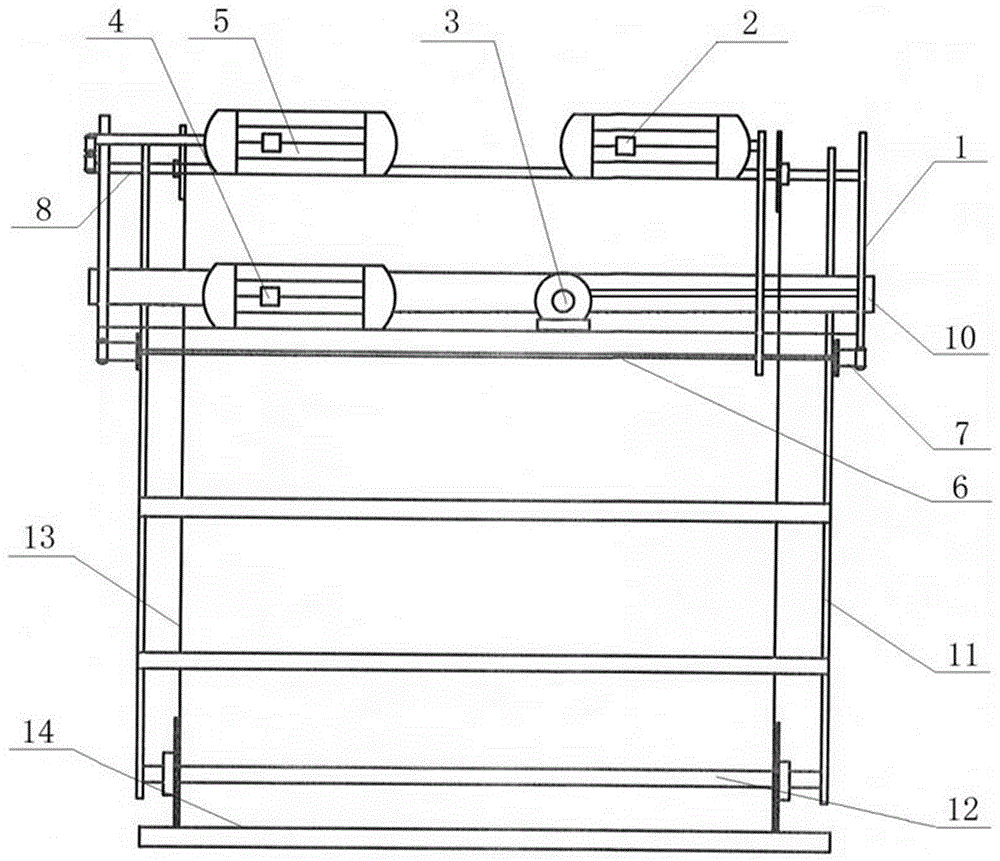

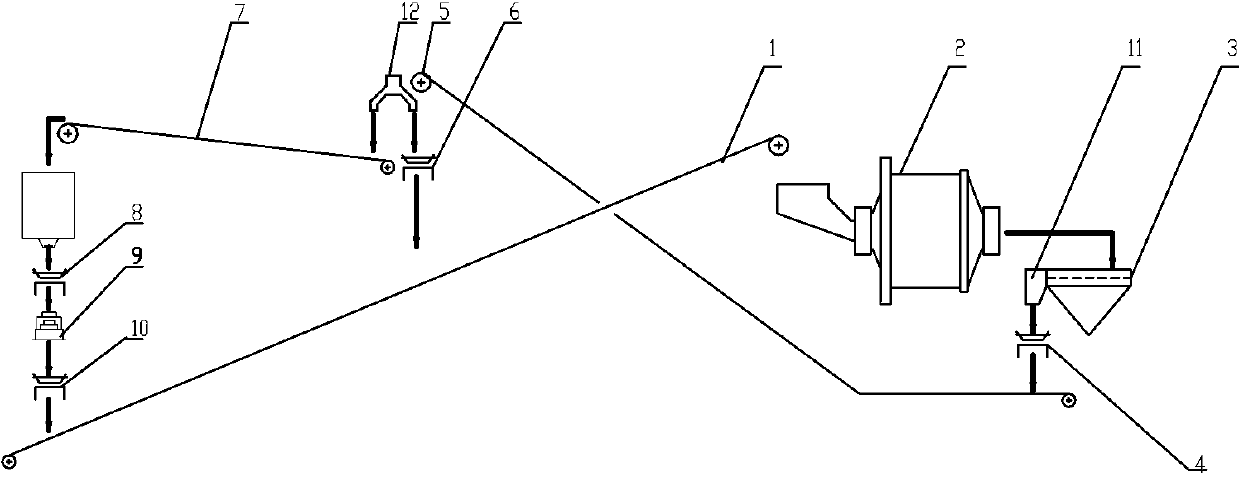

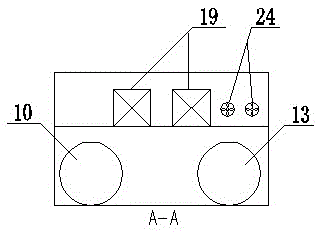

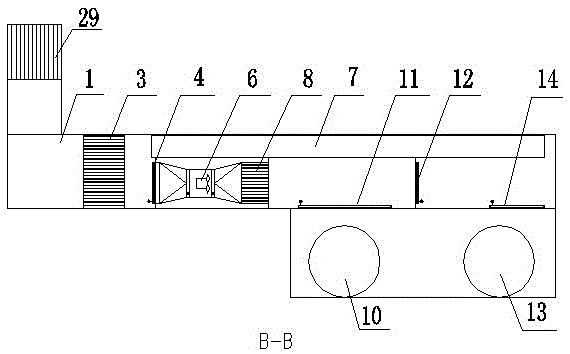

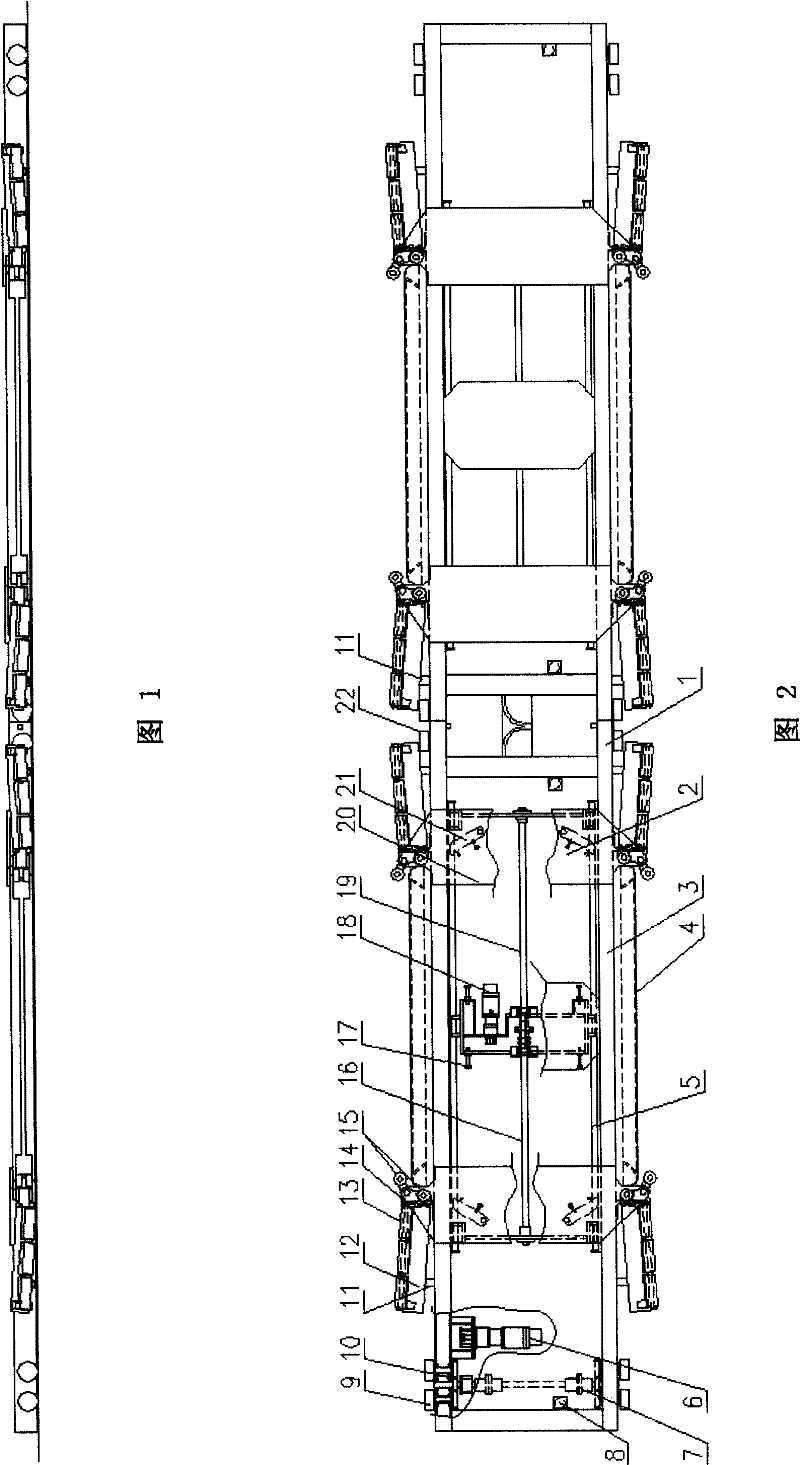

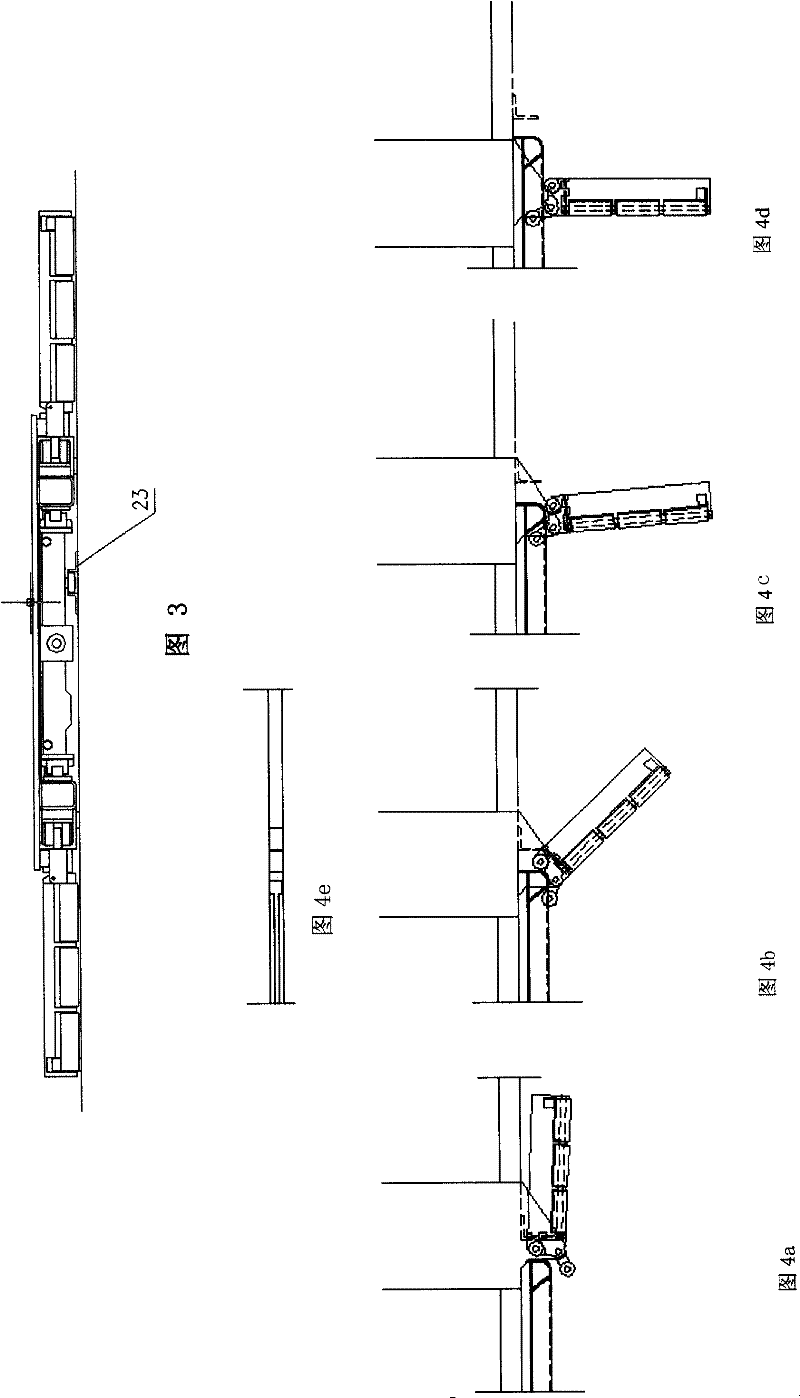

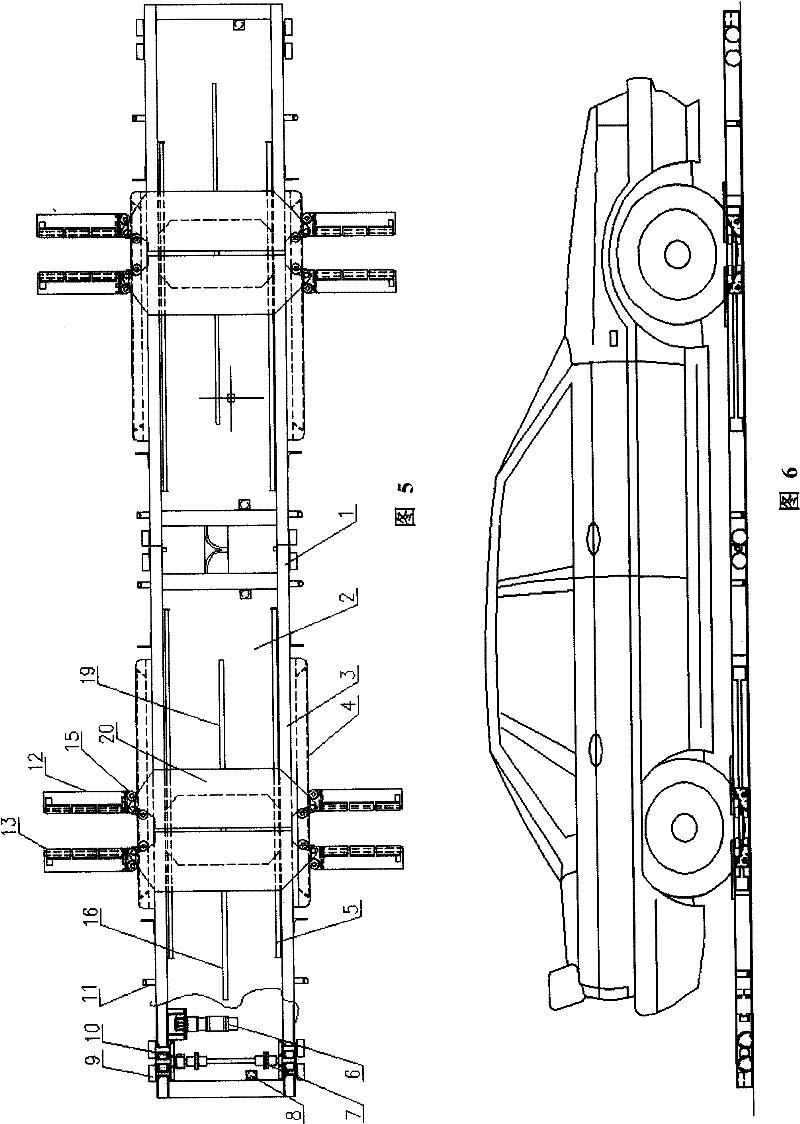

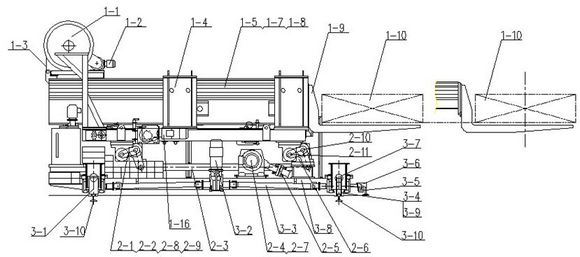

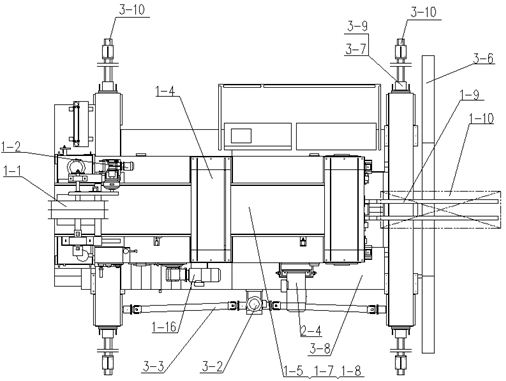

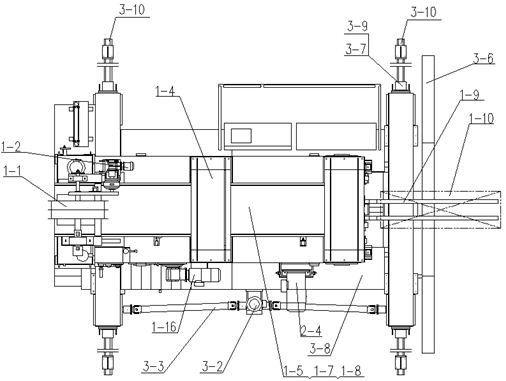

Ultra-thin full-floating vehicle-taking apparatus by manipulator

ActiveCN101476402ASolve parking problemImprove the speed of access to the carParkingsDrive wheelElectric machinery

The invention relates to an ultra-thin device for parking and taking cars through full floating mechanical hands. Two sides of a longitudinal movement trolley are symmetrically provided with full floating mechanical hands, and the ultra-thin device consists of the longitudinal movement trolley and the full floating mechanical hands symmetrically arranged on the two sides, wherein the longitudinal movement trolley comprises an underframe, a running mechanism driving motor, a driving wheel, a driving wheel driving shaft, and a driving wheel driving gear; the full floating mechanical hand comprises a mechanical arm driving mechanism, a mechanical hand transition sliding plate, a mechanical arm, linear guide rails arranged on the inner and outer sides of a long beam on the underframe of the trolley respectively, and a swinging arm guide groove, wherein the mechanical hand transition sliding plate drives the mechanical arm to move. The device is ultra-thin, and two sets of independent full floating mechanical hands float freely in a set range, can be placed on a conveying trolley to form a horizontal movement type mechanical parking device, and can be placed on a stacker to form a laneway stacker type mechanical parking device without a carrying plate and a comb teeth rack; and the interbedded clear height is only 1.65 meters so that the construction investment is reduced, the structure is simple, the maintenance is convenient, and particularly the device is applicable to large mechanical garage.

Owner:HANGZHOU XIZI IUK PARKING SYST CO LTD

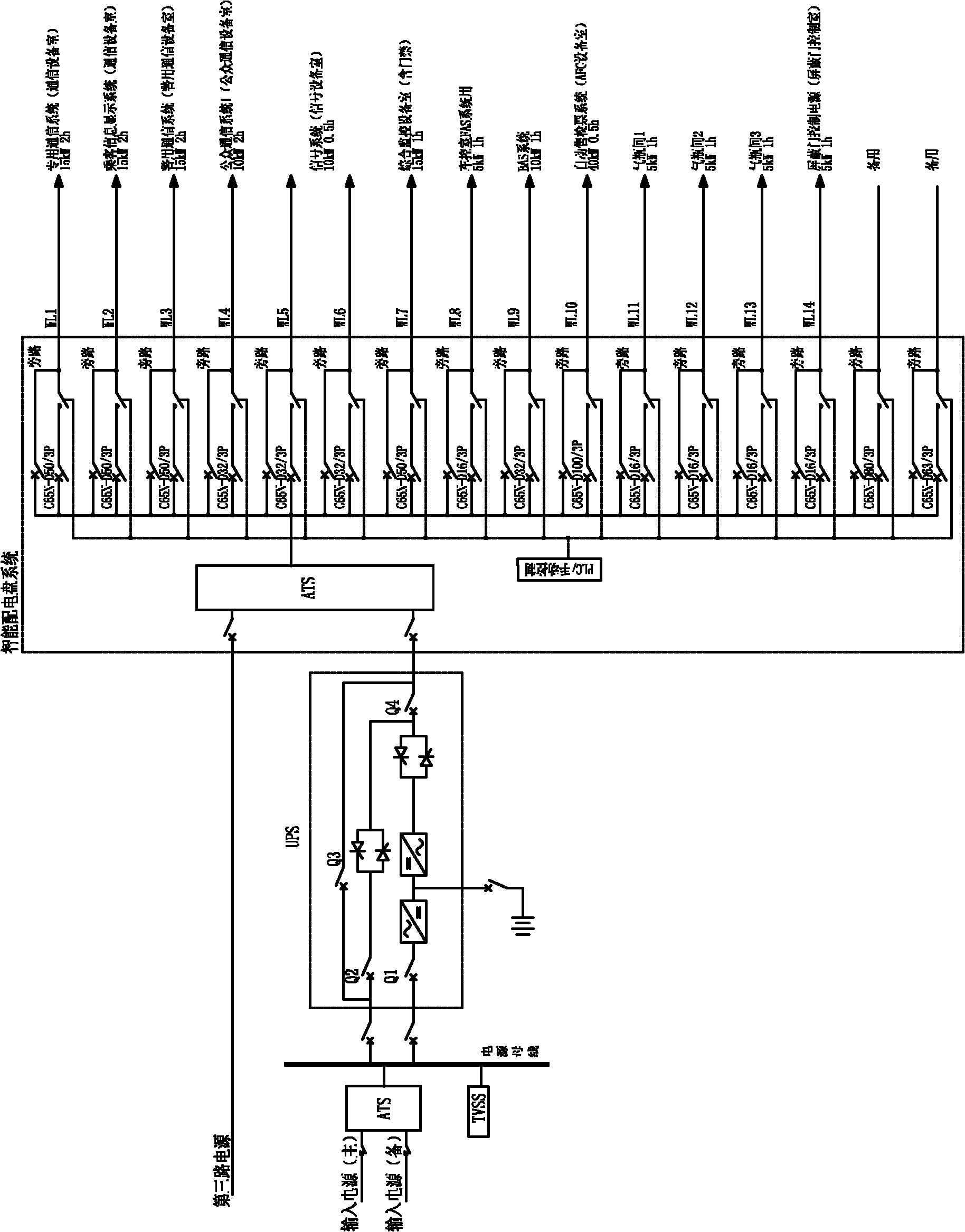

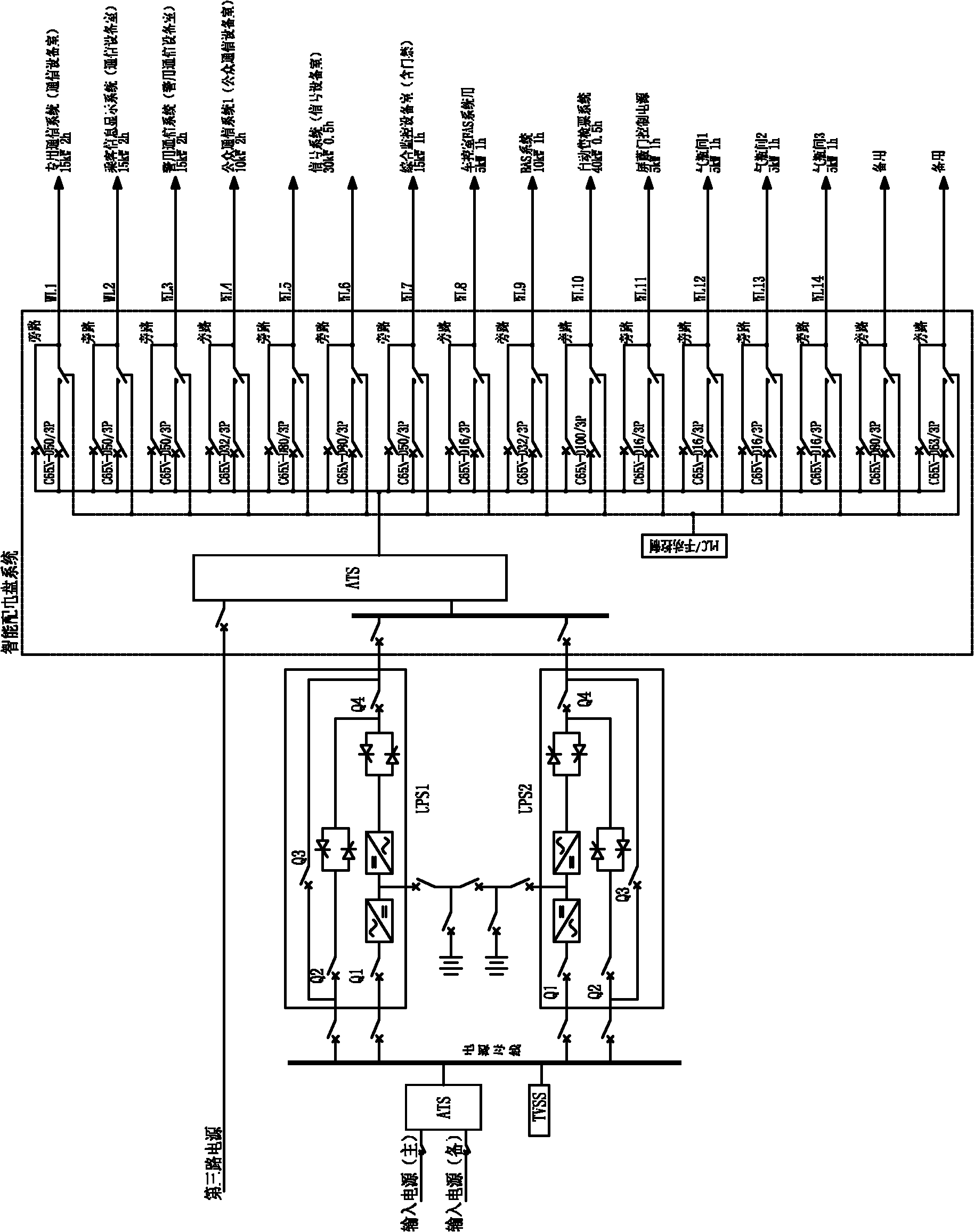

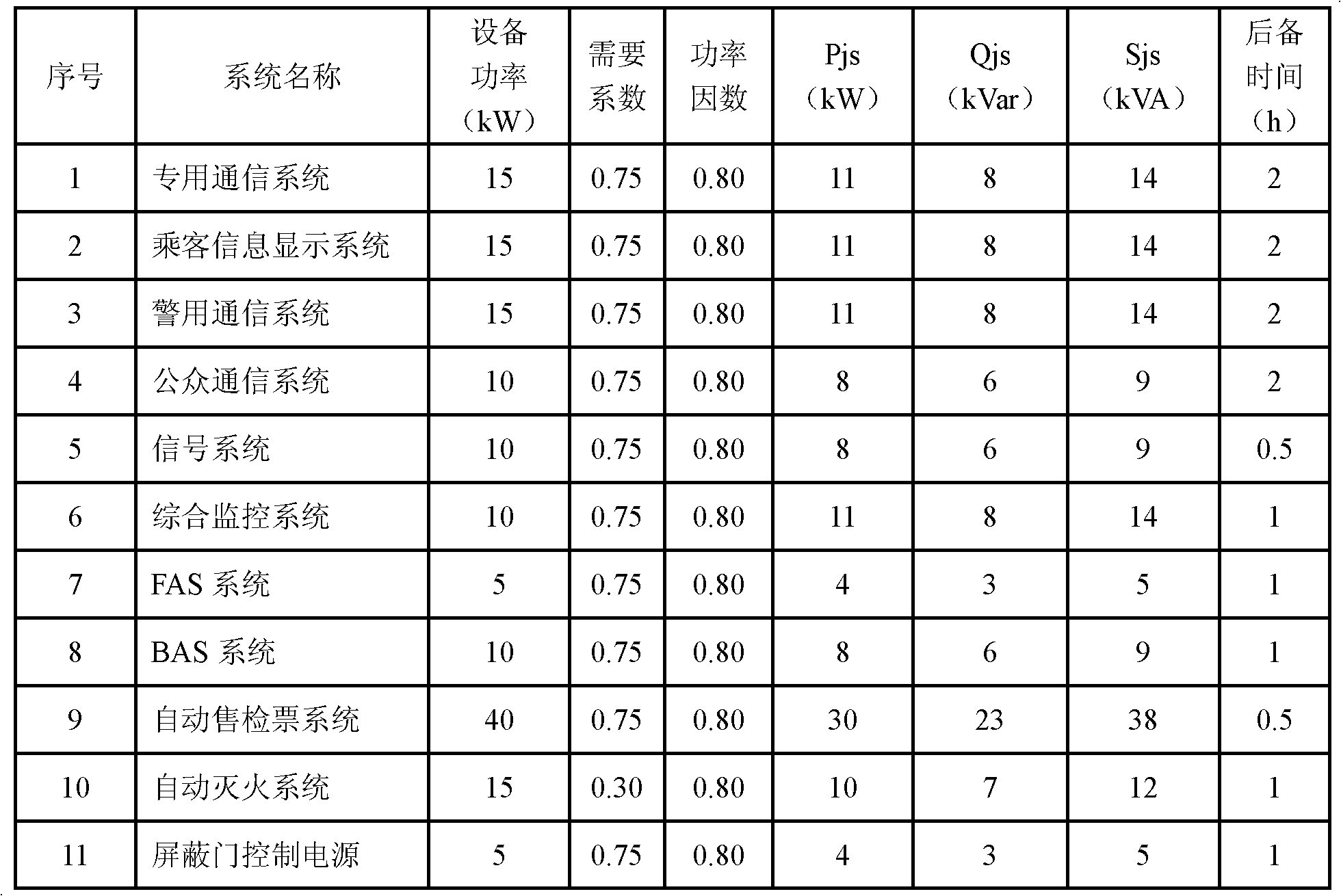

Weak current integrated UPS power system applied to urban mass transit and power supply method

ActiveCN102118058AImprove reliabilityEasy to integratePower network operation systems integrationInformation technology support systemMaintainabilityElectric power distribution

The invention discloses a weak current integrated UPS (uninterrupted power supply) power system applied to urban mass transit and a power supply method. The weak current integrated UPS power system comprises a power source input distribution system, a UPS and storage battery system, an intelligent distributor system and a UPS monitoring system, wherein the UPS and storage battery system is connected with the power source input distribution system and the intelligent distributor system in sequence; and UPSs distributed in weak current systems of urban mass transit are integrated under the premise of meeting certain conditions and requirement, so that an integrated UPS power system meeting the requirements of relevant weak current systems can be formed, and UPS can be provided for weak current systems in the positions such as stations, car depots, parking sites and control centers. The weak current integrated power system can improve the reliability, availability and maintainability of the UPS system, reduce the investment in the UPS, reduce the configuration for the total capacity of the storage battery and increase the spare total capacity of each system, thereby facilitating centralized monitoring and management and maintenance of the UPS.

Owner:GUANGZHOU METRO DESIGN & RES INST

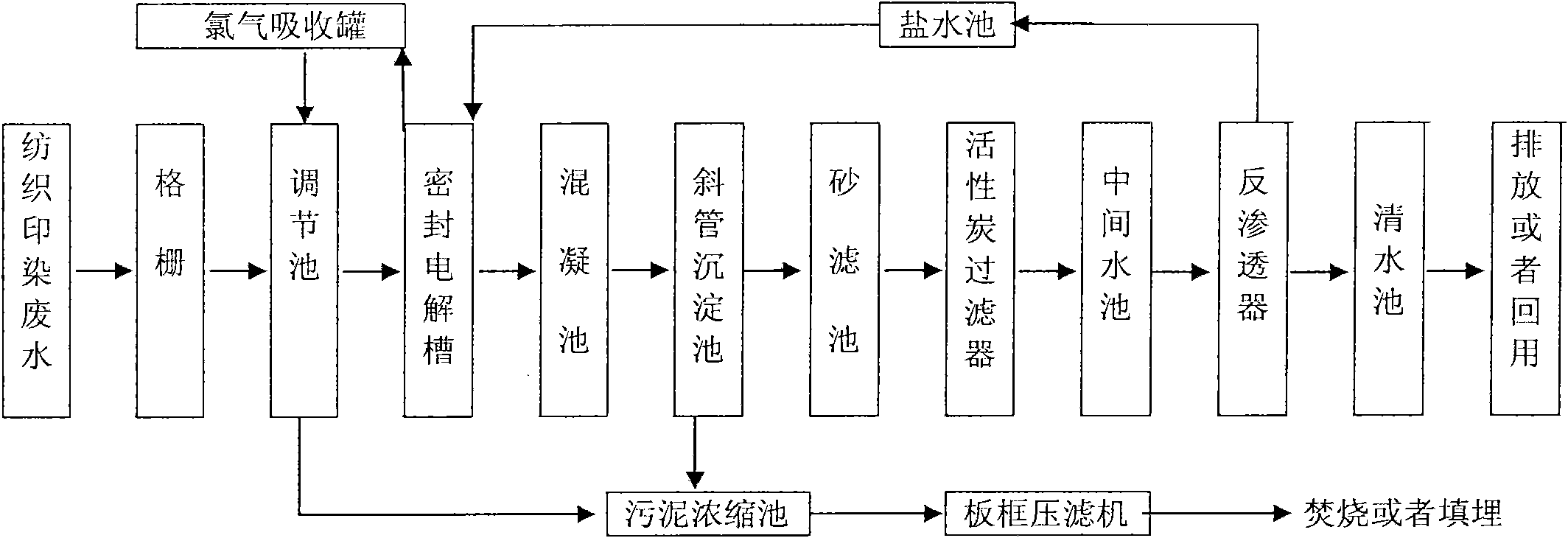

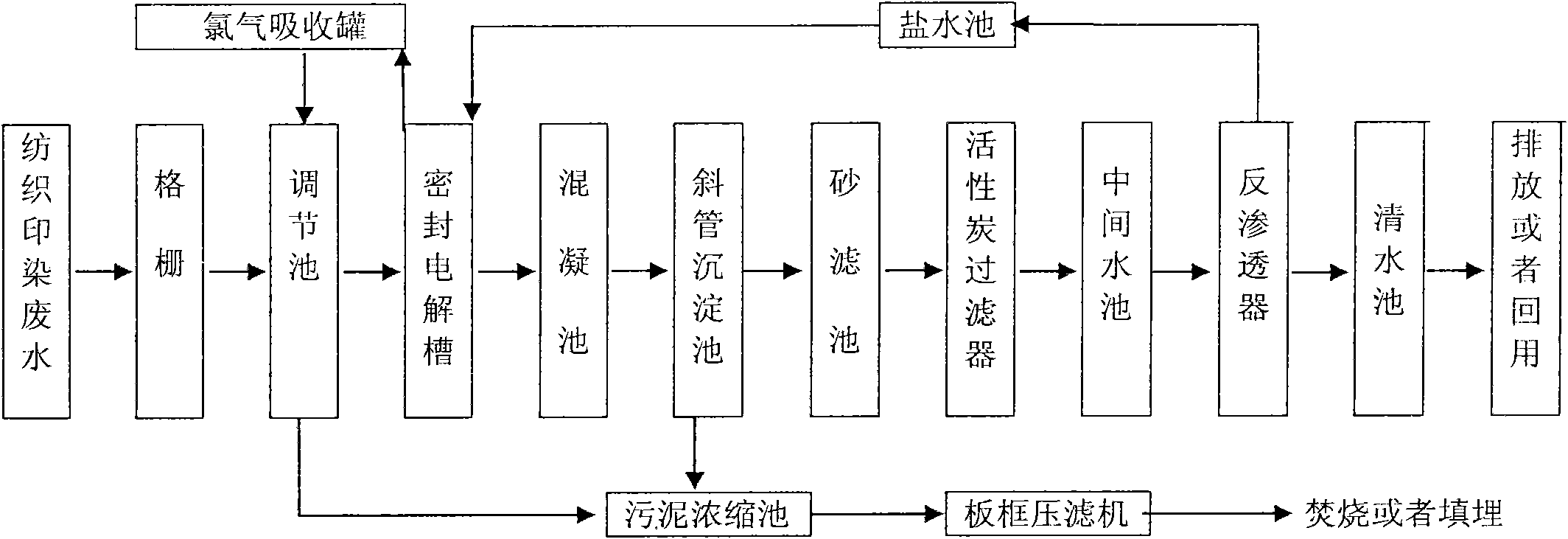

Spinning printing and dyeing waste water reclamation method, device and application thereof

InactiveCN101857328AEfficient removalReduce work stressWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentAluminium chlorideActivated carbon filtration

The invention discloses a spinning printing and dyeing waste water reclamation method, a device and the application thereof. The method comprises the steps of: filtering spinning printing and dyeing waste water; sequentially carrying out homogenizing, equalizing quantity and primary sedimentation on filtrate; adding sodium chloride into waste water supernate, and evenly mixing for indirect electro-catalysis oxidation; sequentially evenly mixing the waste water treated by indirect electro-catalysis oxidation with basic aluminium chloride and polyacrylamide; removing the precipitated supernate, and sequentially treating by activated carbon adsorption and reverse osmosis; removing trace organic chloride generated in the electrolytic process and the rest COD and color; and obtaining recyclable water resource. The device for realizing the method comprises a grate, a regulating reservoir, a sealed electrolytic cell, a flocculation tank, an inclined tube sedimentation tank, a sand filter tank, an active carbon filter, an intermediate water tank, a reverse osmosis unit, a clear water reservoir, a brine tank, a chlorine absorbing tank, a sludge concentration tank and a plate-and-frame filter press. The invention can effectively treat spinning printing and dyeing waste water, and has the advantages of high treatment efficiency, stable effluent quality, simple technological process and the like.

Owner:DONGGUAN HONGJIE ENVIRONMENTAL PROTECTION TECH +1

Method for treating odors produced by drying sewage sludge

InactiveCN102068878AReduce usageAvoid temperature riseDispersed particle separationSecondary emissionChemical reaction

The invention discloses a method for treating odors produced by drying sewage sludge. The method comprises the following steps: (1) delivering odors exhausted by a sewage sludge drying system to a pretreatment tower through a fan to be rinsed with clean water, wherein the components soluble in water in the odors are absorbed by the clean water, and the odors are cooled at the same time; (2) rinsing the pretreated odors in a primary spraying tower, wherein the acid gases and volatile organic compound gases in the odors are subjected to chemical reaction with the spraying solution with strong oxidability and alkalinity in the primary spraying tower and are absorbed; (3) rinsing the remaining gases after treatment in the step (2) in a secondary spraying tower, wherein alkaline gases in the gases are subjected to neutralization reaction with the acid spraying solution in the secondary spraying tower and are absorbed; and (4) exhausting the tail gases after treatment in the step (3) through an exhaust pipe. After the odors produced by drying the sewage sludge are treated by the method disclosed by the invention, the obtained tail gases can reach the secondary emission standard in the Emission Standards for Odor Pollutants (GB14554-93).

Owner:广州中洲环保科技有限公司

Flotation column process for separating carbon residue in fly ash

The invention offers a kind of craft for separating pillars in the coal powder. It includes three parts of mineral liquid preparation, pillar separate choosing, and product off water. It uses double liquid pillar and material and water-off equipment, and then makes the pillar-box press filter craft, taking off the carbon grains not fired in the coal powder. Put the high carbon coal and water into the mixing bucket, through mixing the mineral liquid is made, transfer it to the entrance of pillar, by the separating choosing, we get pure mineral and the mineral coal powder, through box press filter machine, we get the carbon product and coal powder product. The advantages of the invention are: simple craft, little cost, little energy, and repair little, operating cost little.

Owner:UNIV OF SCI & TECH BEIJING

Lifting tool having four rotary lifting points and crane provided with lifting tool

Owner:TAIYUAN HEAVY IND

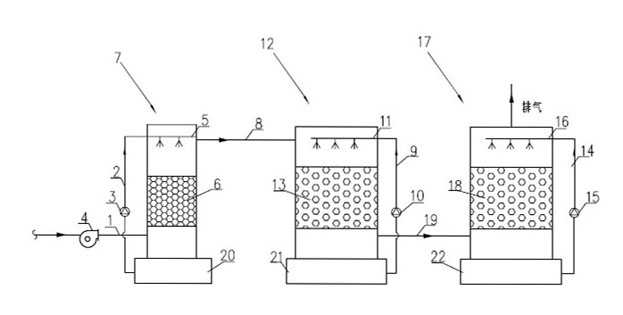

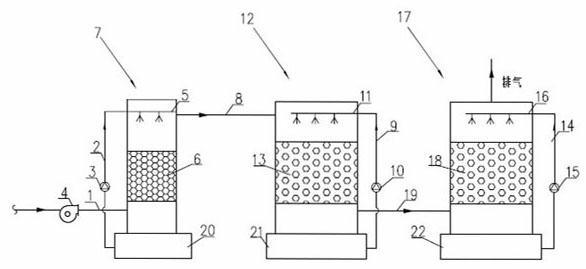

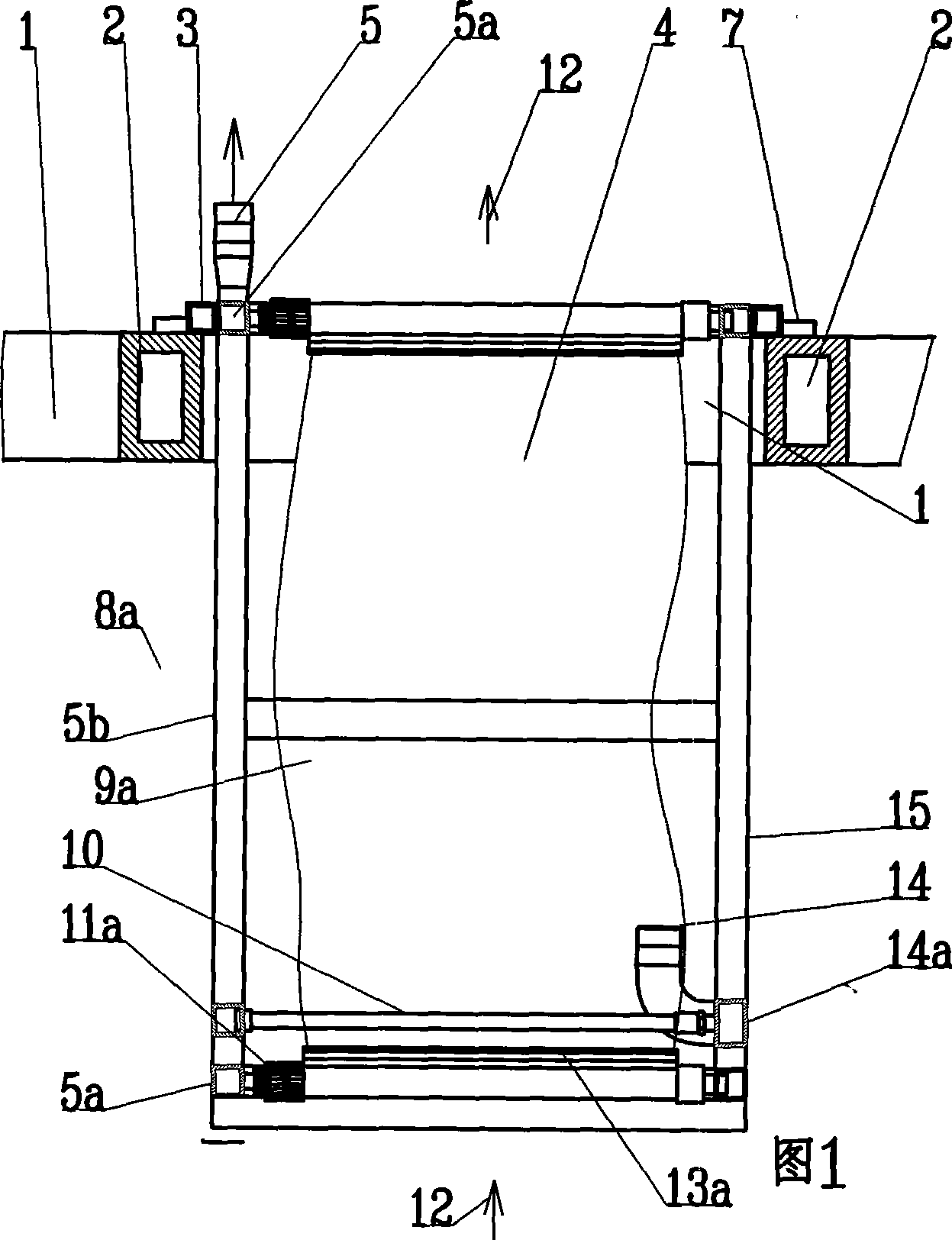

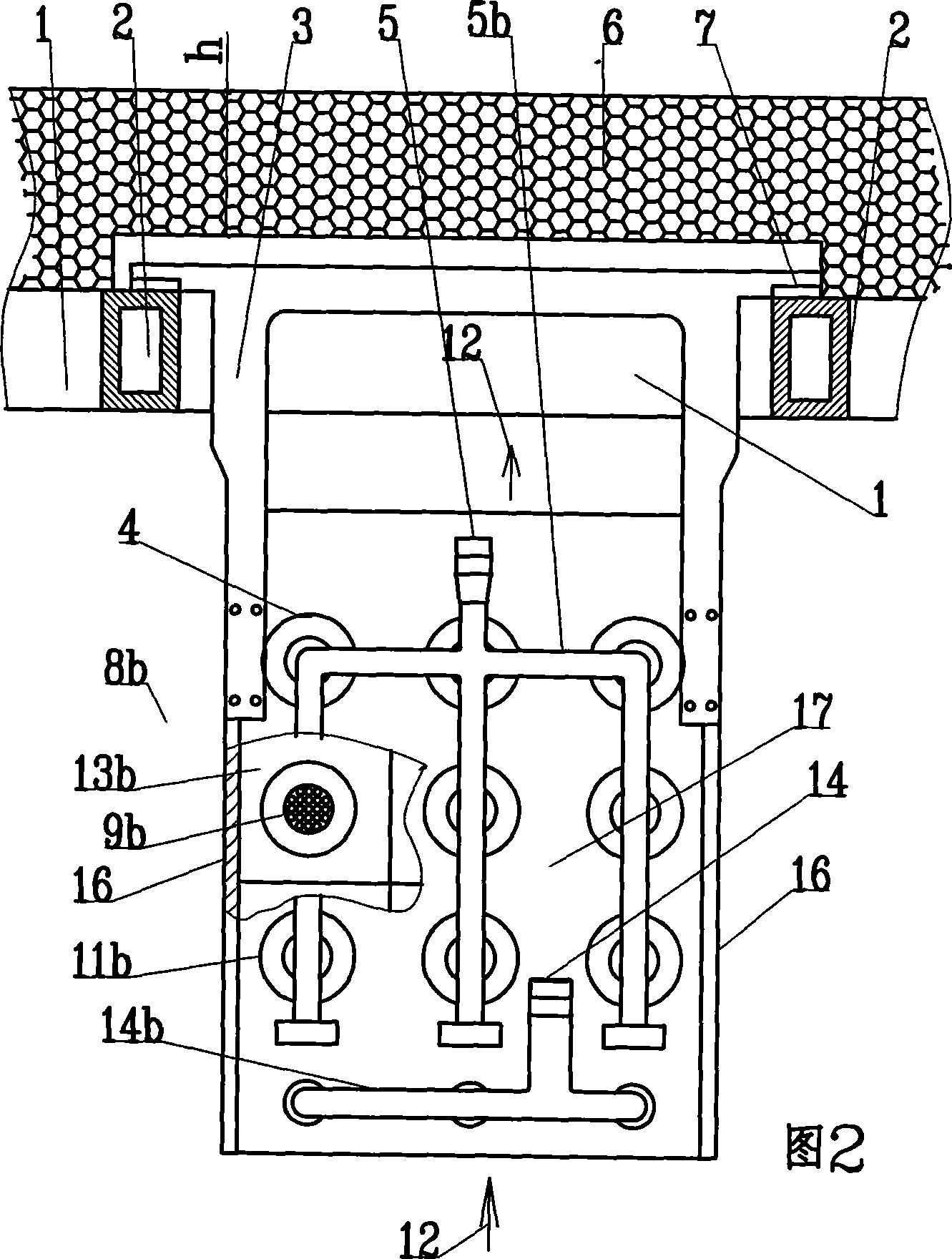

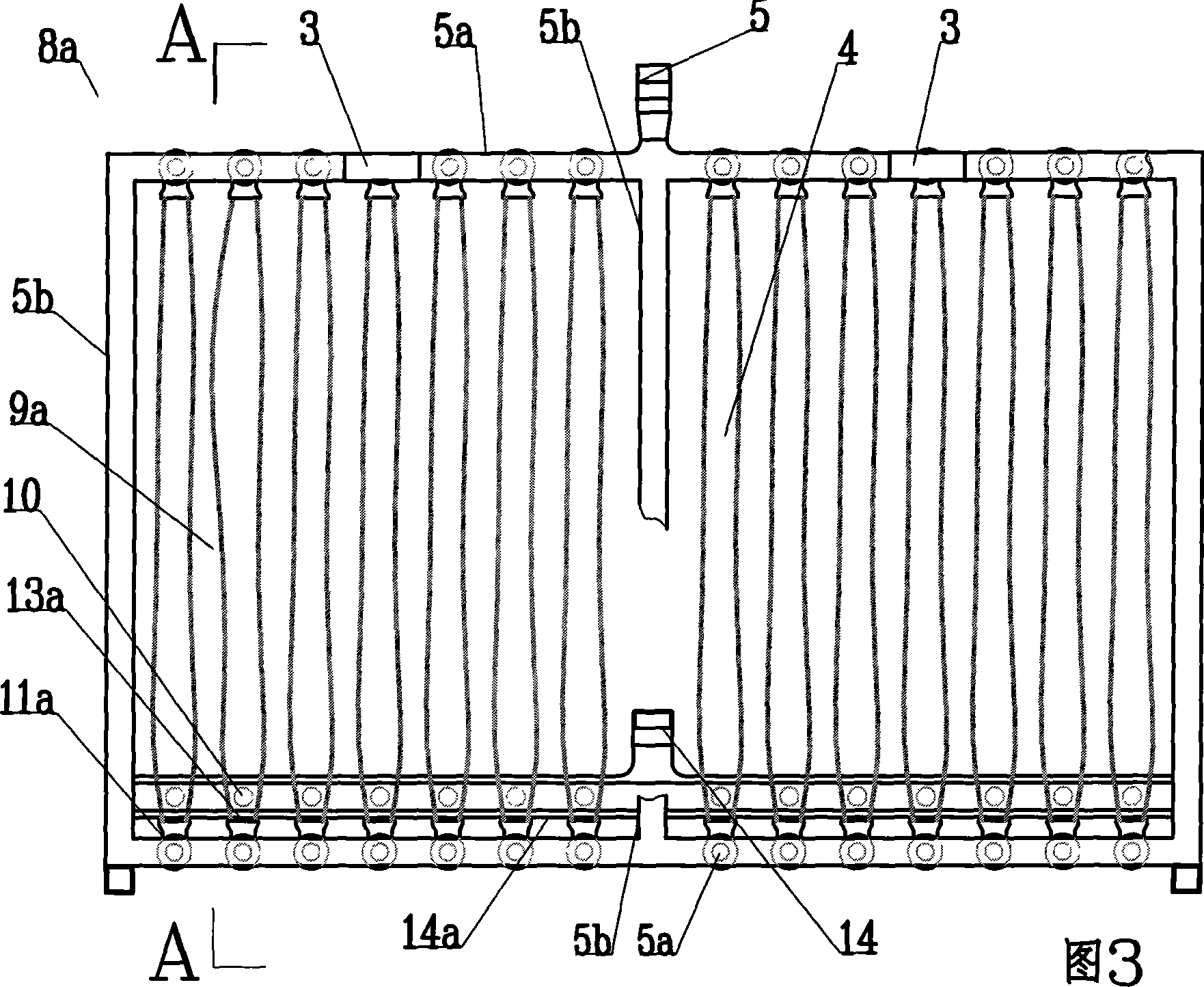

Water purifying device and system for hanging swinging type biochemical reactor

InactiveCN101058458ASimple processSmall footprintTreatment using aerobic processesSustainable biological treatmentAeration systemMembrane reactor

The invention discloses a water purifying device and system of suspension sway-typed biochemical reactor, which comprises the following parts: water body, purifying device, water body fender system, technique flow path, pipe system, aerating system and program control system, wherein at least one purifying element is set in the water purifying device, which adopts MBR membrane reactor; the suspension system of the purifying element is set in the water purifying device, which contains rigid frame, rotary mechanism and locking piece; the water barrier wall divides the water body fender system into water body S1, S2 and S3...; the water body S2 and S3... is seal loop-shaped water body; the device assembles the purifying element in the water body S1 through the suspension unit of the purifying element, which combines the MBR membrane reactor with solid-liquid separator and oxidation ditch technique together; a pusher is set in the loop-shaped water body, which flows the water body and sways the purifying element.

Owner:天津市石化通用机械研究所有限公司 +1

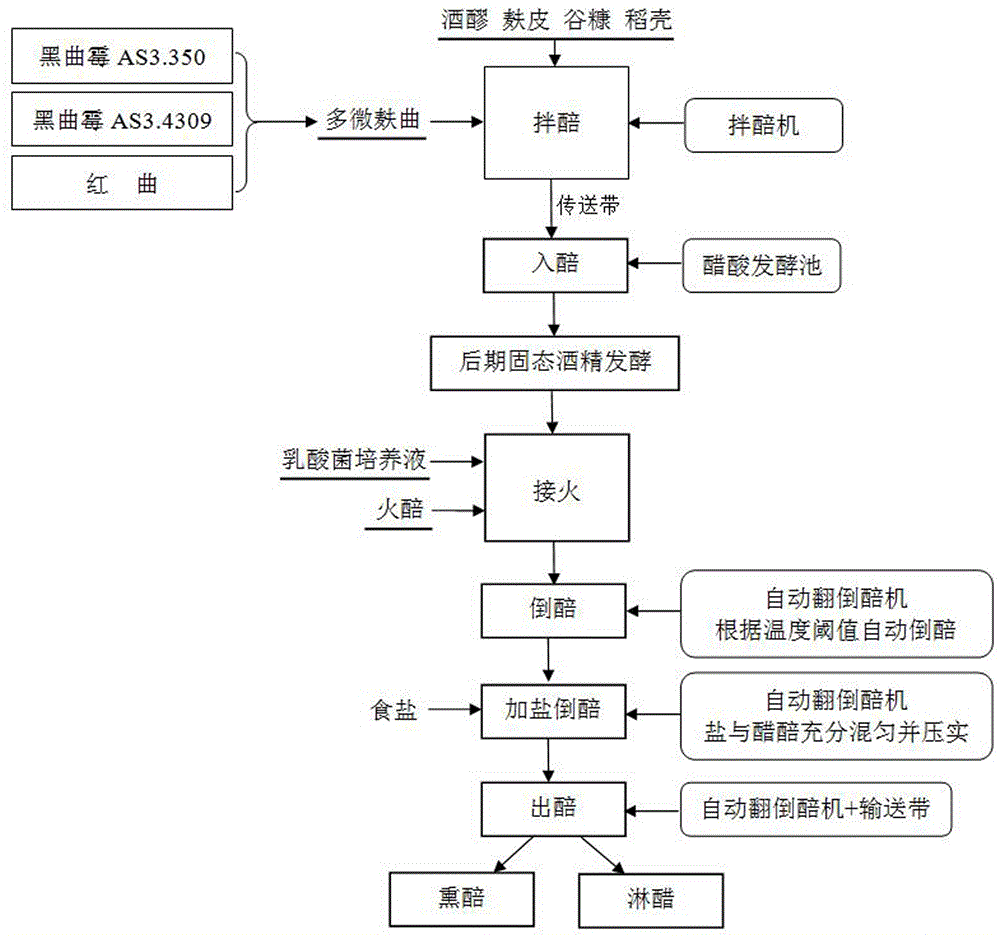

Mechanized production technique for mature vinegar by solid-state acetic acid fermentation

ActiveCN106635735AIncrease enzyme activityLess irritatingMicroorganism based processesVinegar preparationFlavorAcetic acid

The invention provides a mechanized production technique for mature vinegar by solid-state acetic acid fermentation. A machine for stirring fermented grains is used to mix wine mash obtained after an thick mash alcoholic fermentation is ended, accessories and multi-microbe mouldy bran; a conveyor belt conveys materials into a stainless steel long-strip-shaped acetic acid fermentation vat for performing later solid-state alcoholic fermentation; then fire-fermented grains mixed with lactic acid bacteria is added for performing multi-microbe acetic acid fermentation; a temperature control type machine for automatically stirring and pouring the fermented grains is used to replace manpower for stirring and tank pouring of the fermented grains. The prepared multi-microbe mouldy bran and the lactic acid bacteria are added in a preparation process, so the physical appearance and flavor of a product are improved.

Owner:SHANXI ZILIN VINEGAR

Fluorine-containing exhaust gas treatment device and method

InactiveCN104740985AStable concentrationRealize automatic continuous preparationDispersed particle separationTreatment effectFiltration

The invention discloses a fluorine-containing exhaust gas treatment device and method. The method comprises A, continuously preparing alkaline liquor from quicklime or calcium oxide by conveying quicklime in a quicklime storage tank into an alkaline liquor tank by a quicklime continuous feeding device and carrying out continuous adjustable preparation of alkaline liquor, B, carrying out exhaust gas absorption by distributing the prepared alkaline liquor down by an alkaline liquor distribution device above the interior of an exhaust gas absorption tower so that the alkaline liquor countercurrent contacts with fluorine-containing exhaust gas fed from the bottom of the exhaust gas absorption tower, discharging the gas without HF from the top of the exhaust gas absorption tower after contacting, and returning the waste liquid flowing out of a discharge outlet at the bottom of the exhaust gas absorption tower to the alkaline liquor tank, and C, treating the waste liquid by feeding precipitates on the bottom of the alkaline liquor tank into a precipitate treatment device such as a filtration device and carrying out treatment. The fluorine-containing exhaust gas treatment device and method have the advantages of environmental friendliness, safety and good exhaust-gas treatment effects.

Owner:XINDI ENERGY ENG TECH

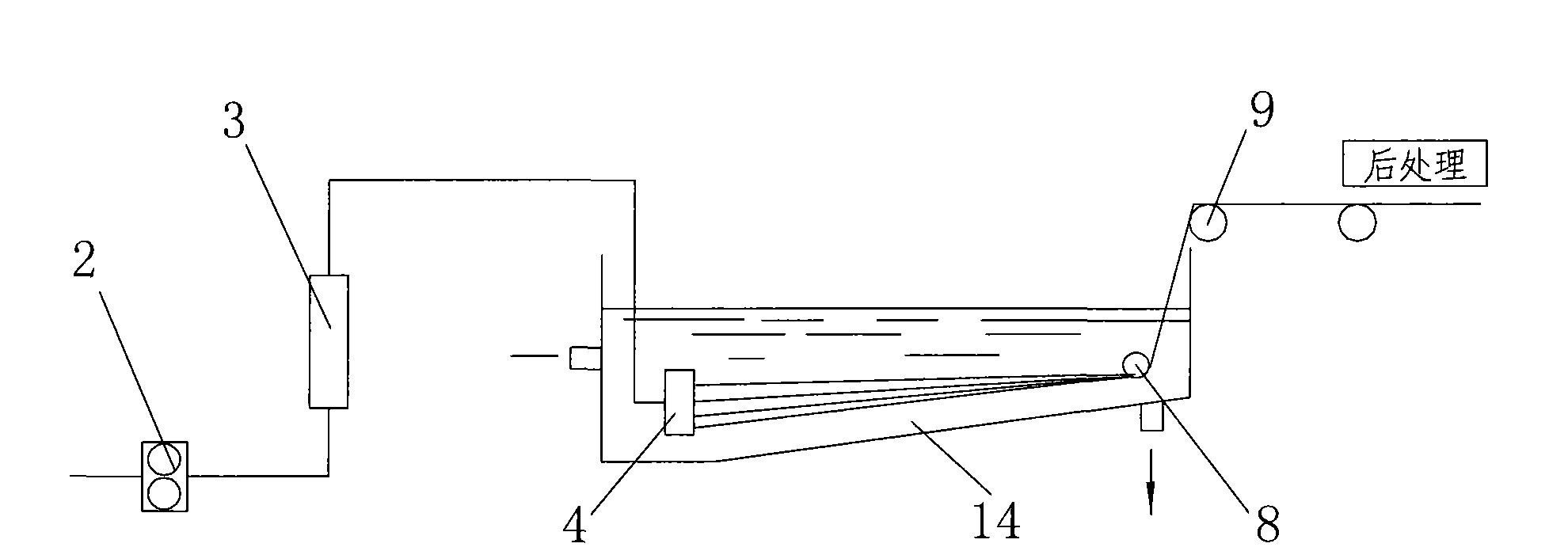

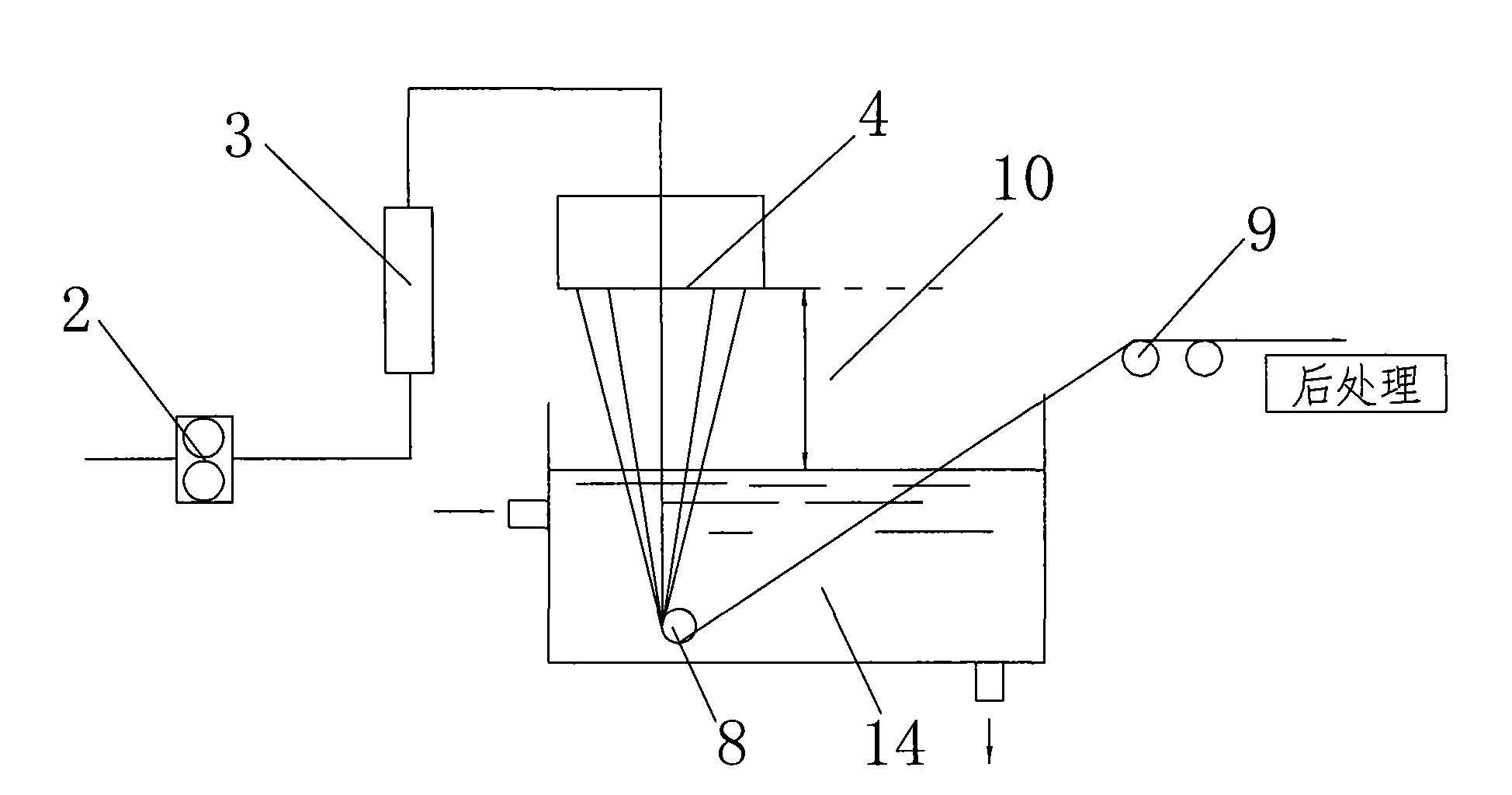

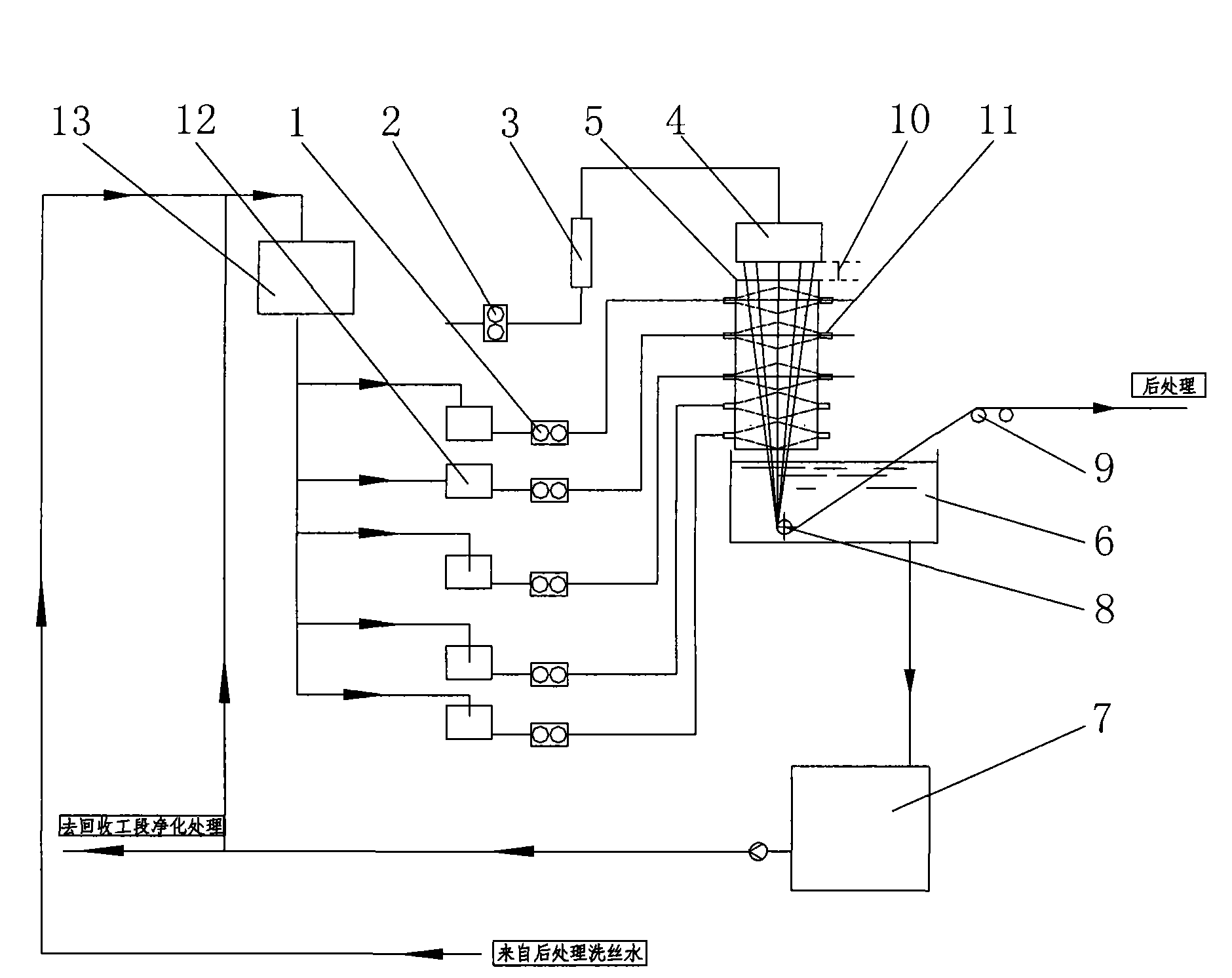

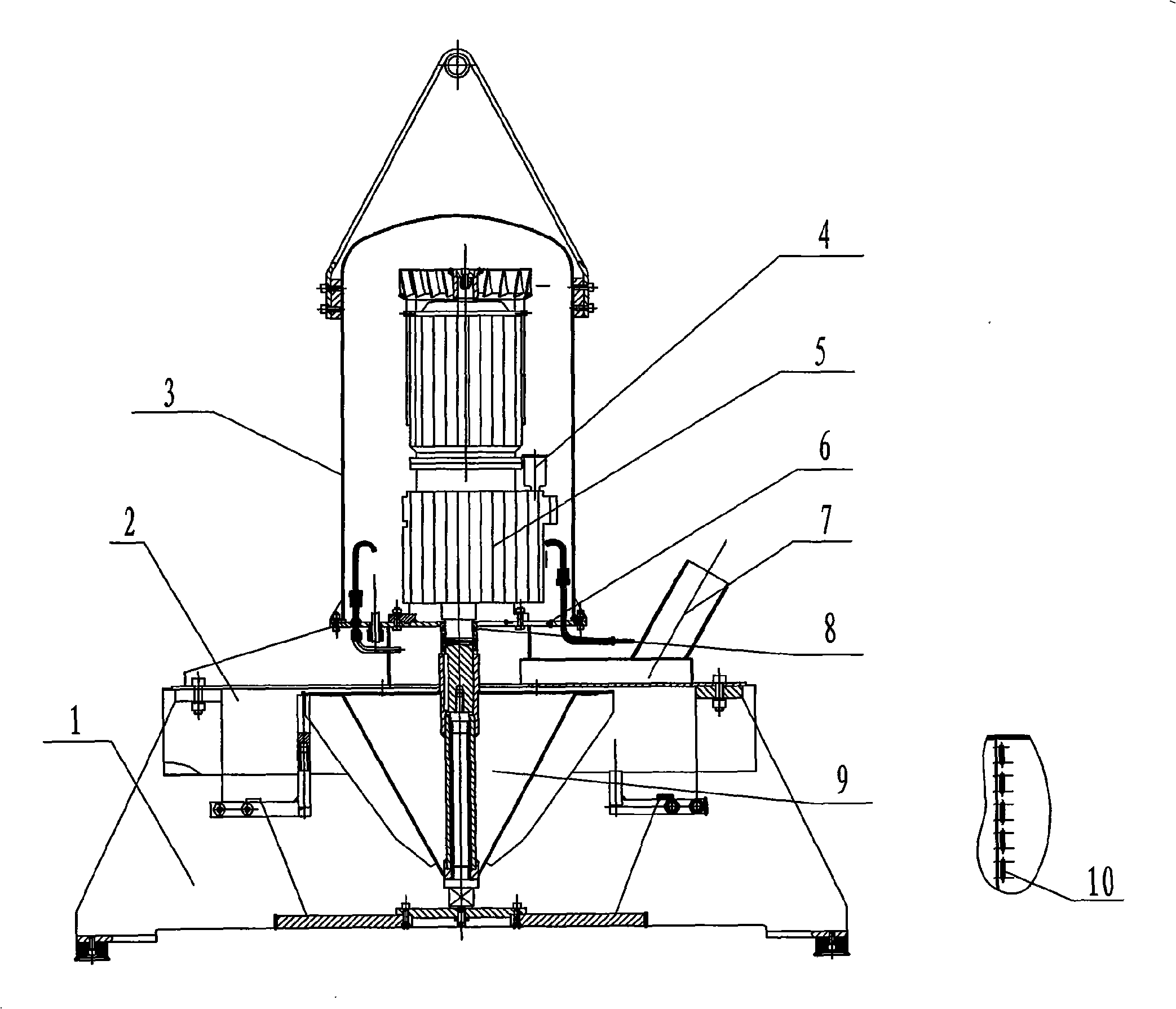

Vertical atomized chemical fiber molding method

InactiveCN101988217AEasy to operateIncrease spinning speedArtificial filament physical treatmentArtificial thread manufacturing machinesFiberMetering pump

The invention belongs to the field of manufacturing of chemical fibers and particularly relates to a vertical atomized chemical fiber molding method. The vertical atomized chemical fiber molding method comprises the following steps that: 1, spinning raw materials enter a spinneret plate of a spinning assembly after passing through a distributing pipe, a metering pump and a filter; 2, an air gap is used for cooling; 3, cooling and solidification is carried out in a solidification chamber; 4, bunching bath is carried out; and 5, post processing is carried out. In the invention, the cooling and solidification are uniform so as to avoid causing fibrillation. The mechanical property of the obtained strand silk is special. A distance from the surface of the spinneret plate to the surface of bunching solution is more than 500mm and the making-up operation is convenient. The spinning speed can reach 200 to 350m per minute so as to greatly improve the productivity, save equipment investment and civil engineering investment and reduce operation cost. The vertical atomized chemical fiber molding method can be popularized and applied to the cooling and molding of heavy denier melt spun fibers (more than 20 deniers per piece) which cannot be spun by the conventional air serving as a cooling medium.

Owner:SHANGHAI PACIFIC TEXTILE COMPLETE EQUIP

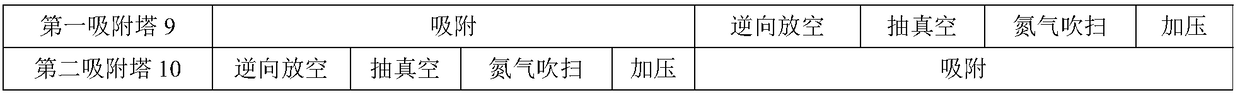

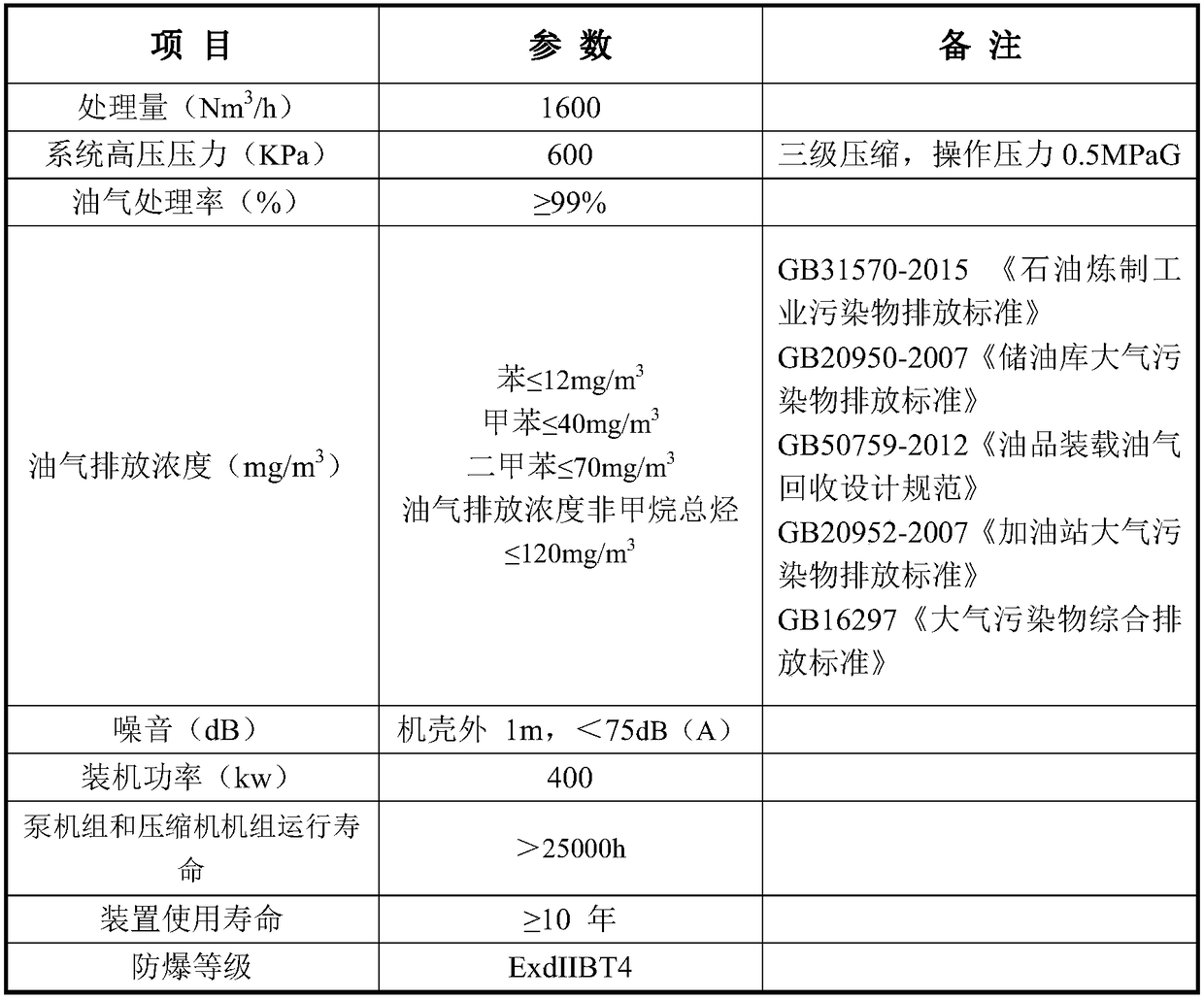

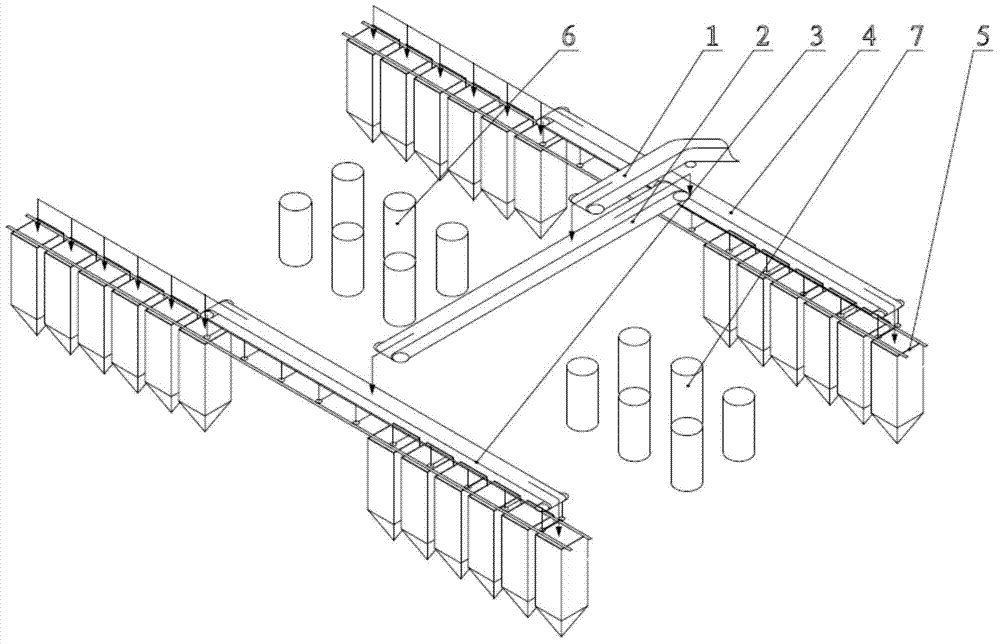

Integrated oil and gas recovery system and recovery process

InactiveCN109045739ALow quality scoreEliminate multi-stage preprocessingGas treatmentDispersed particle separationRecovery methodAtmospheric air

The invention belongs to the technical field of oil and gas recovery, and discloses an integrated oil and gas recovery system and a recovery process. The integrated oil and gas recovery system comprises a pressure buffer tank, a tail gas compression and preliminary condensation device, a lean oil cooling and absorbing device, an absorption device and a recovery device, wherein the original oil andgas are conveyed into the pressure buffer tank, and then sent to the tail gas compression and preliminary condensation device; after being subjected to compression and condensation, the oil and gas enter an absorption tower of the lean oil cooling and absorbing device; gasoline No.93 enters the absorption tower after being precooled by means of an absorbent oil precooler and subjected to deep cooling of an absorbent oil deep freezer; after being subjected to low-temperature spraying of the absorption tower, the oil and gas is conveyed to an oil collecting tank, and the remaining tail gas enters the absorption device for absorbing; the absorbed tail gas is discharged to the atmosphere, and the absorbed hydrocarbon components are recovered to the pressure buffer tank by means of vacuum thermal analysis. The system and the process integrate compression, condensing absorption and absorbing, can enable emissions to reach the standards, have multiple safeguards, can remarkably improve the oil and gas recovery effect, and greatly reduce equipment size and equipment investment.

Owner:伟林环保科技(大连)有限公司

Hydraulic control turning steel dam gate

InactiveCN102995611ASimple structureSave civil investmentBarrages/weirsHydraulic controlCivil engineering

The invention discloses a hydraulic control turning steel dam gate which comprises a bottom rotating shaft, a gate leaf, a connecting rod, a bottom rotating shaft support hinge, a hydraulic headstock gear and a locking device; the bottom rotating shaft is in rigid connection with the gate leaf, is arranged on the bottom rotating shaft support hinge, and is connected with the connecting rod; the connecting rod is connected with the hydraulic headstock gear; and the locking device is arranged on the hydraulic headstock gear. According to the hydraulic control turning steel dam gate, a gate pier with a plurality of holes can be saved, so that not only is the structure simple and can a lot of civil engineering investment be saved, but also a dam can be built to store water, the horizontal gate dredges the flood and drain the stagnant water, and a landscape effect of artificial waterfall is formed by causing the water to pass through the top of the dam.

Owner:YANGZHOU LANXIANG ELECTROMECHANICAL ENG CO LTD

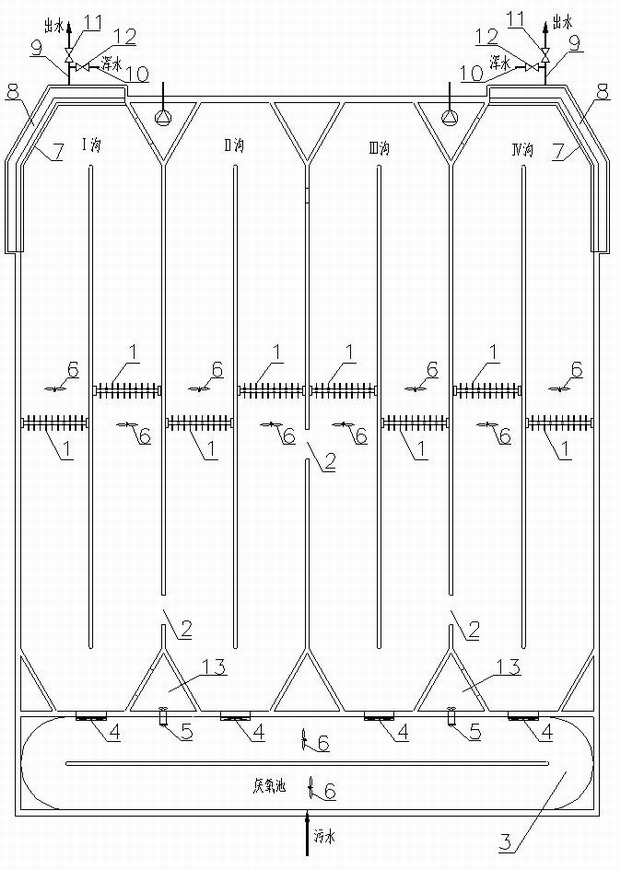

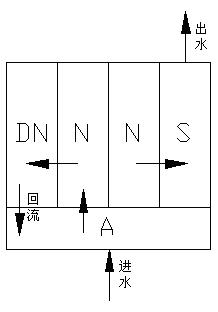

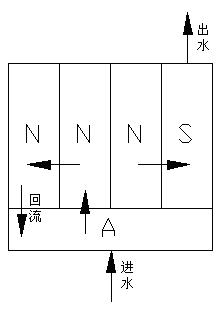

Improved four-ditch type oxidation ditch and sewage treatment method thereof

ActiveCN101985383AReduce lifting headReduce power consumptionTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentRefluxControl valves

The invention relates to an improved four-ditch type oxidation ditch comprising a four-ditch type oxidation ditch, wherein the four-ditch type oxidation ditch comprises four oxidation ditches; each oxidation ditch is provided with aeration equipment; communication holes for communicating the two adjacent oxidation ditches are reserved on the public pond walls among the four oxidation ditches. The invention is characterized in that anaerobic ponds are arranged in the front of the four-ditch type oxidation ditch; the anaerobic ponds are respectively connected with the corresponding four oxidation ditches through four control valves; and the sludge in the side ditches for precipitation of the four-ditch type oxidation ditch reflows to the anaerobic ponds through a sludge reflux pump. Based on the improved four-ditch type oxidation ditch, the invention provides a sewage treatment method of the improved four-ditch type oxidation ditch. The improved four-ditch type oxidation ditch and the sewage treatment method thereof can enhance the efficiency of biological dephosphorization and denitrification, enhance the utilization rate of the equipment, reduce energy consumption and save investment and operation cost.

Owner:FUZHOU URBAN CONSTR DESIGN RES INST CO LTD

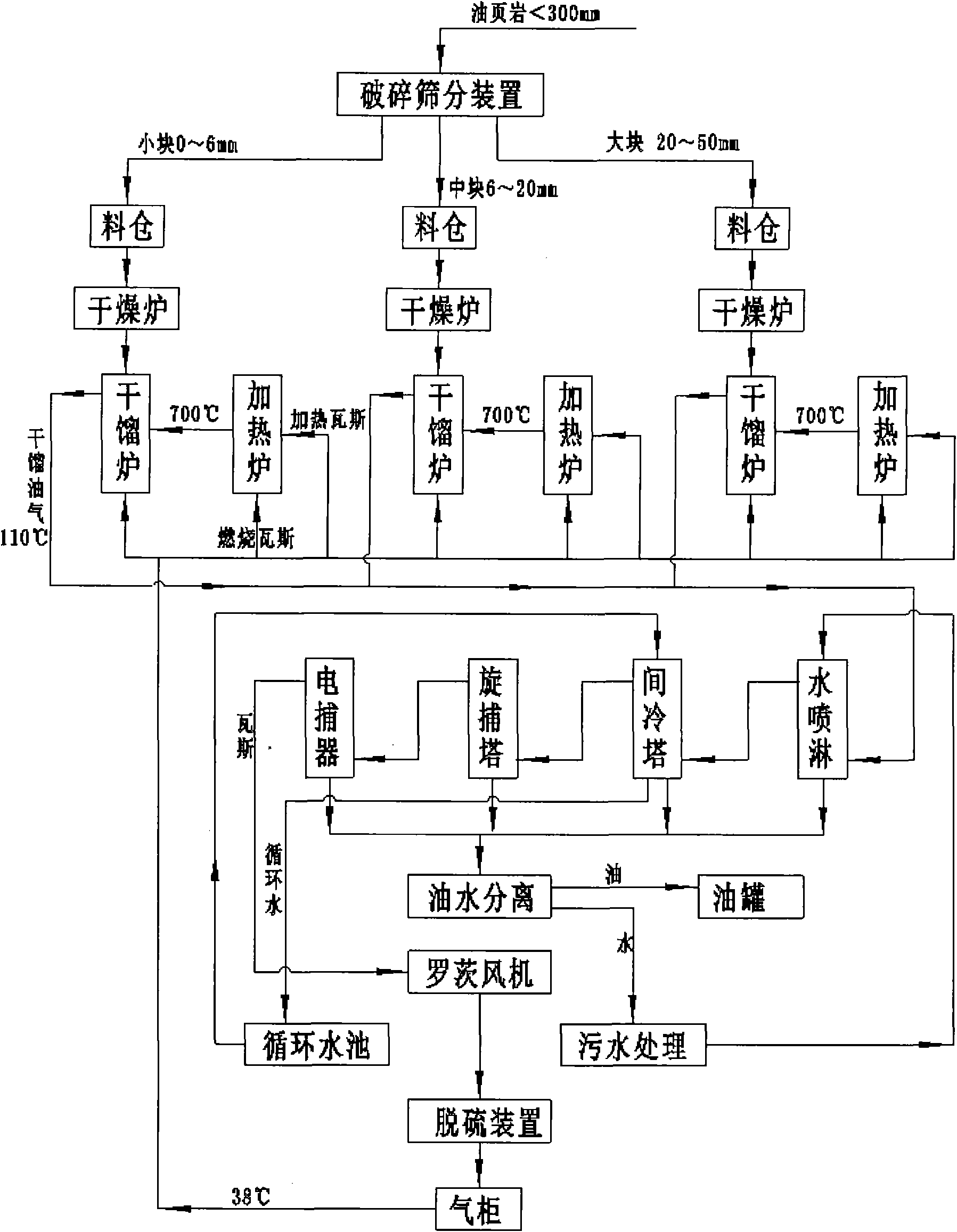

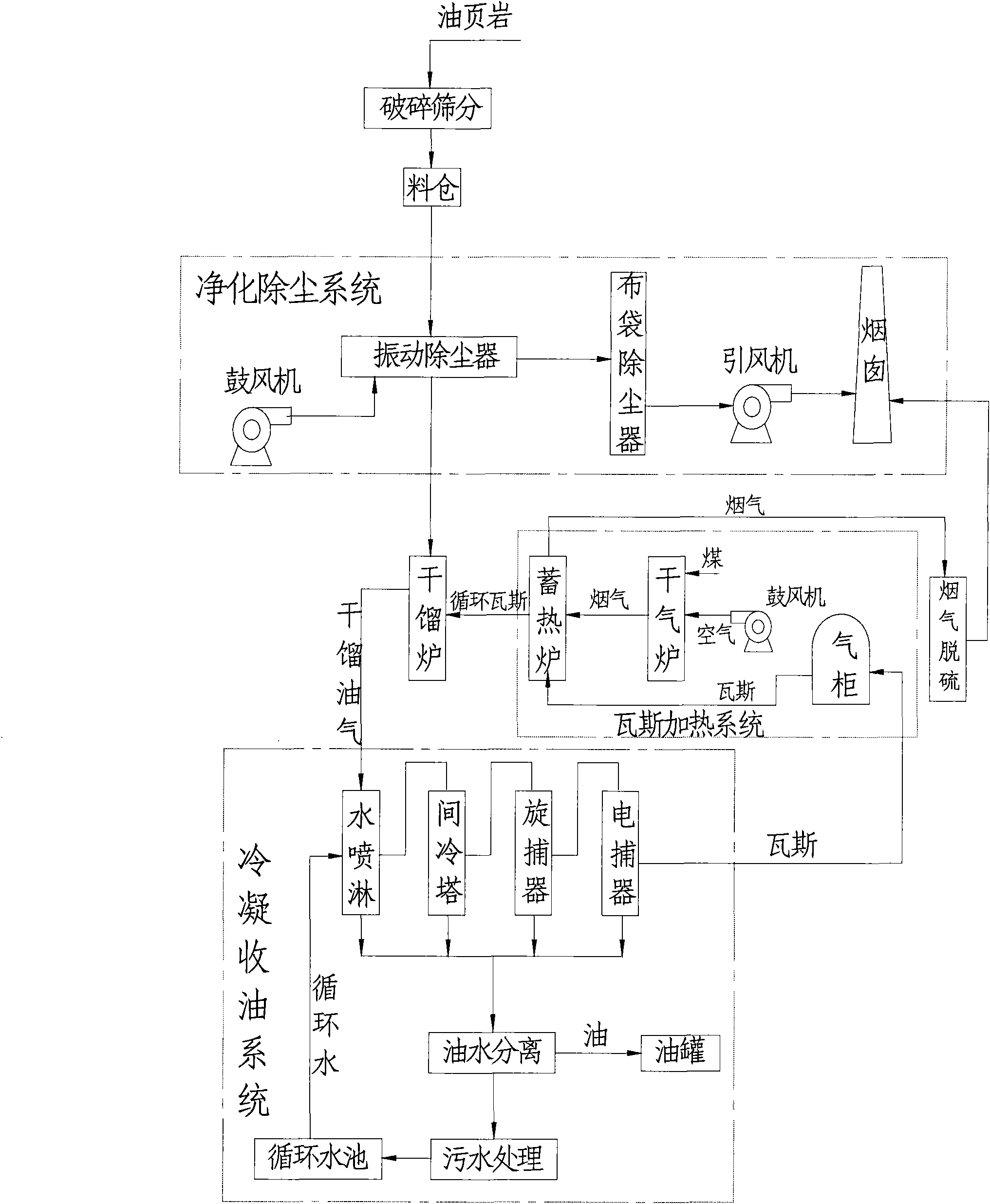

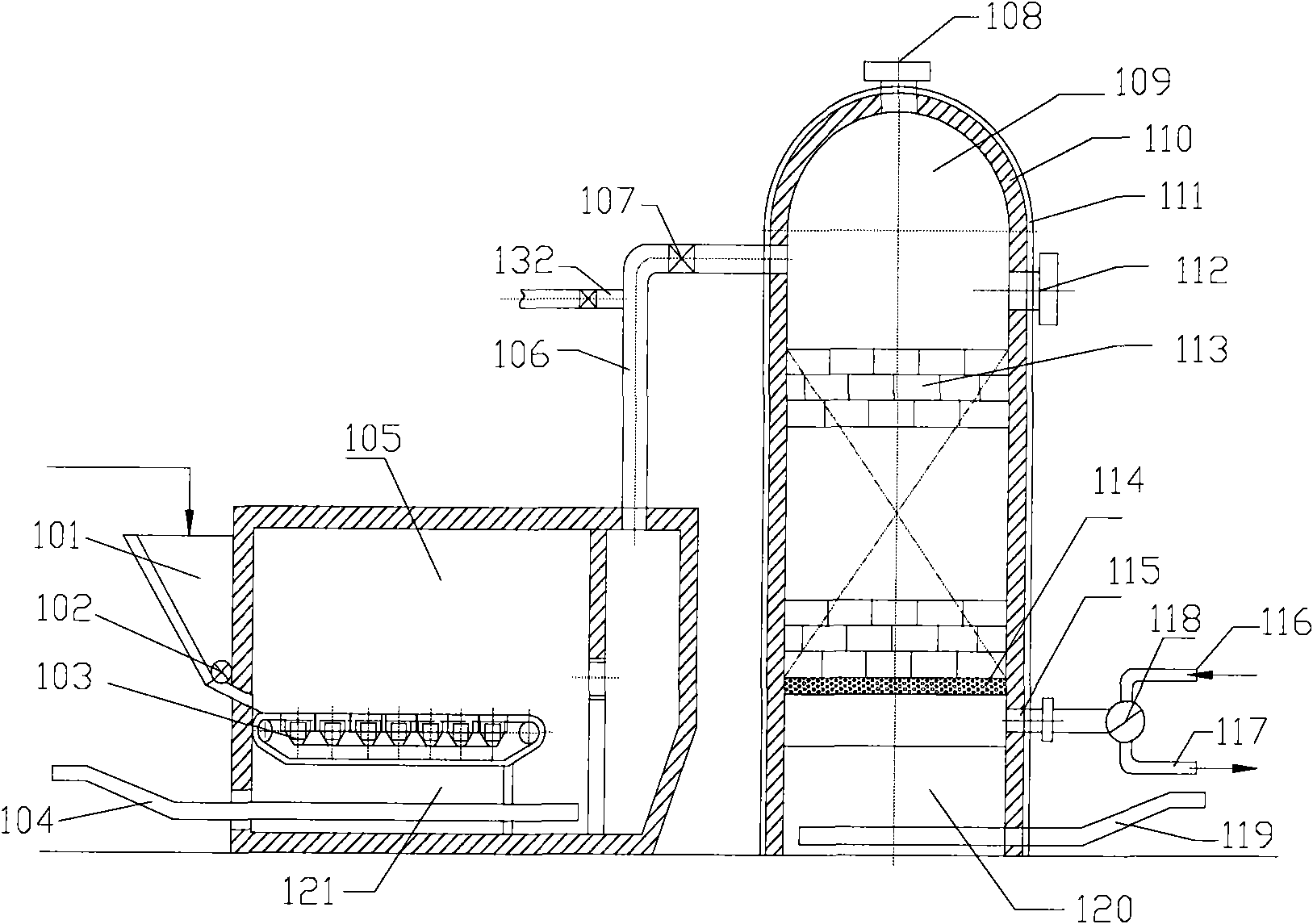

Process and device for dry distillation of oil shale with low gas content

InactiveCN102134498ALow recovery rateGuaranteed normal operationDirect heating destructive distillationSpecial form destructive distillationHeat carrierFlue gas

The invention discloses a process and a device for dry distillation refining of oil shale with low gas content, low fixed carbon content and low water content. The invention is characterized in that: tiny dust in the oil shale is removed by a vibration deduster; gas generated through dry distillation serves as a heat carrier for dry distillation refining of the oil shale; and the gas is heated and cycled by an external combustion regenerative heating furnace. The process flow comprises the following steps of: crushing and screening; grading and warehousing; purifying and dedusting; performing dry distillation refining; condensing and collecting oil; heating the gas; and desulfurizing flue gas. The device for dry distillation refining is an optimized combination of general equipment and proprietary equipment, and the oil recovery rate is over 85 percent.

Owner:吴启成

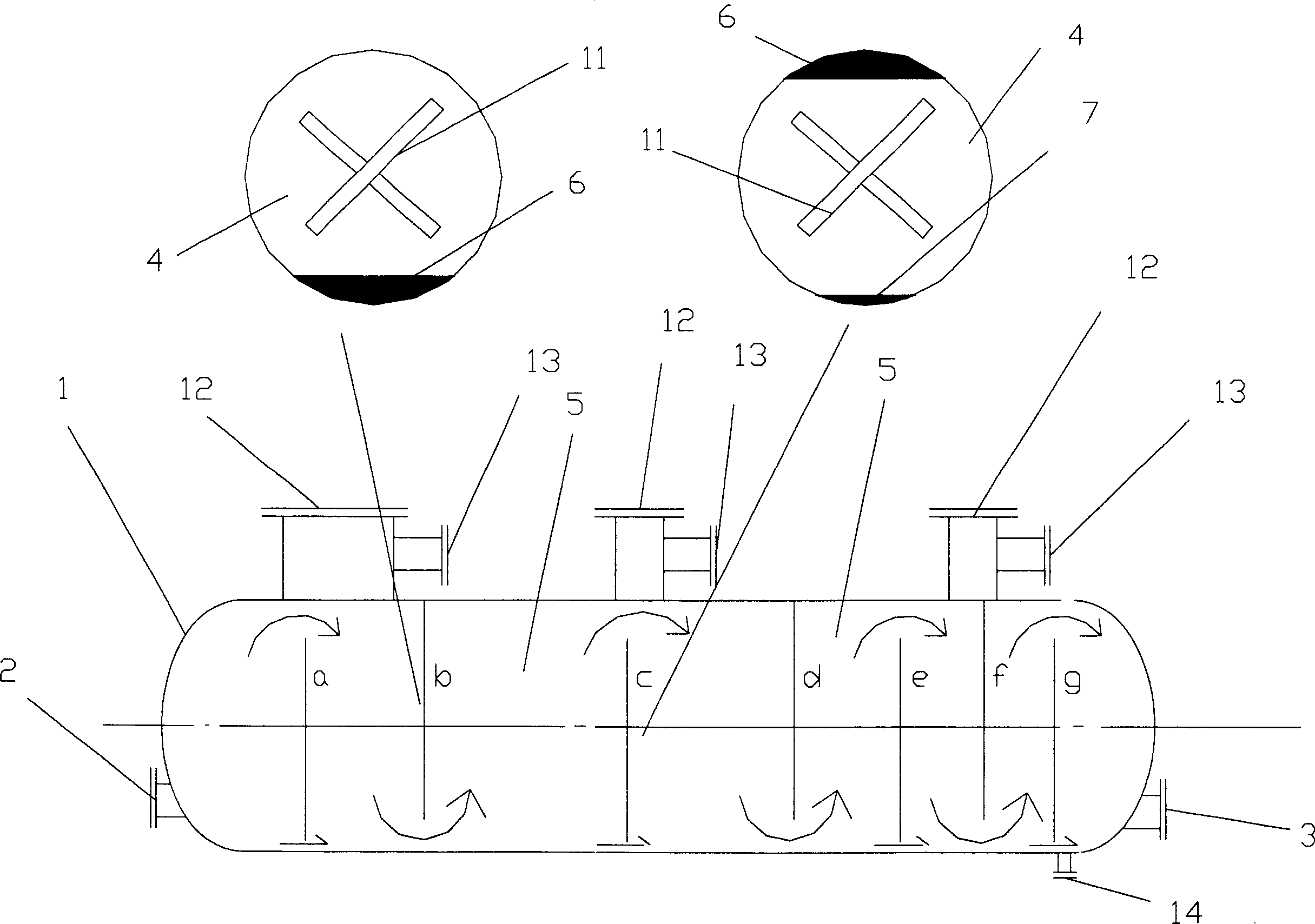

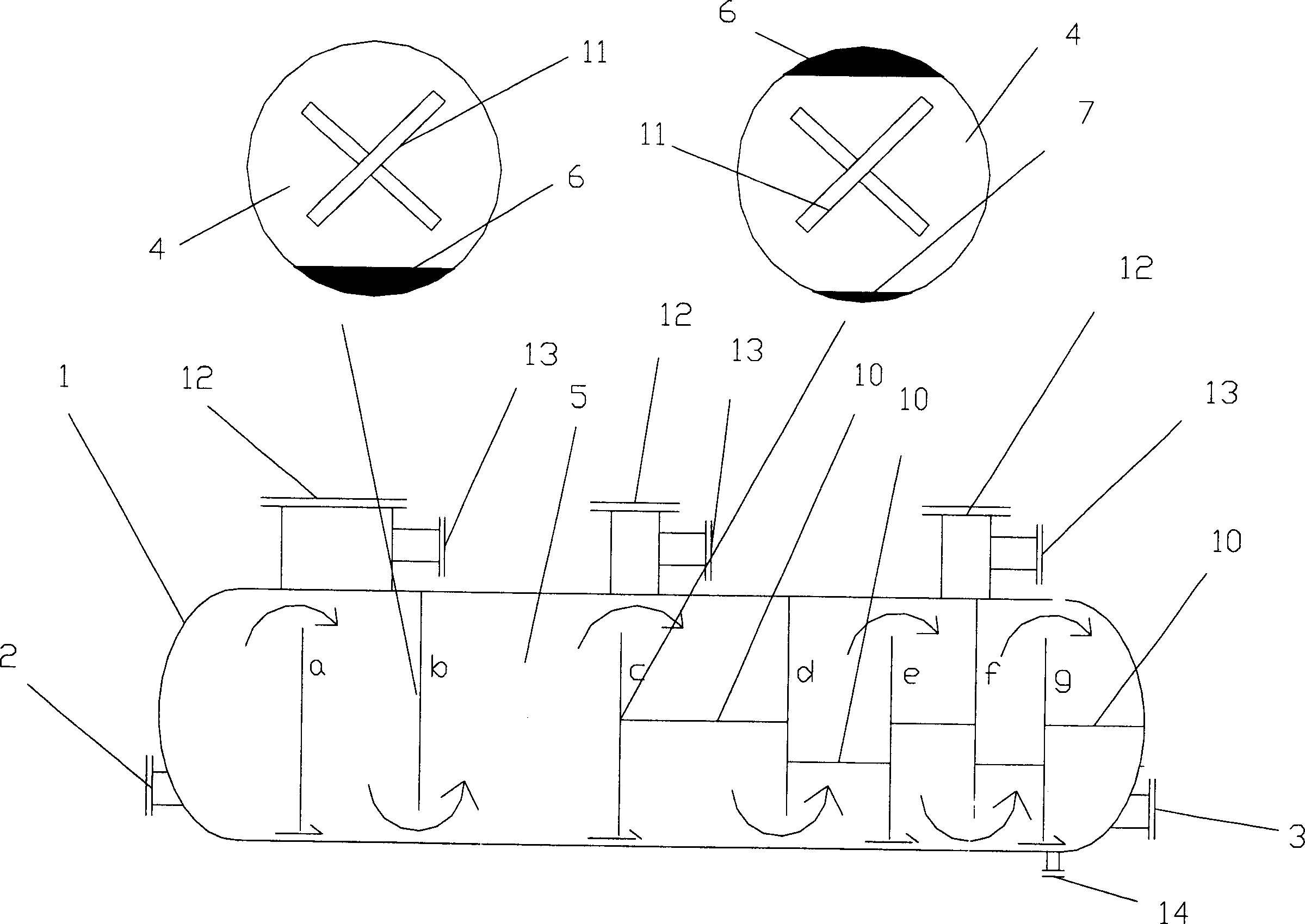

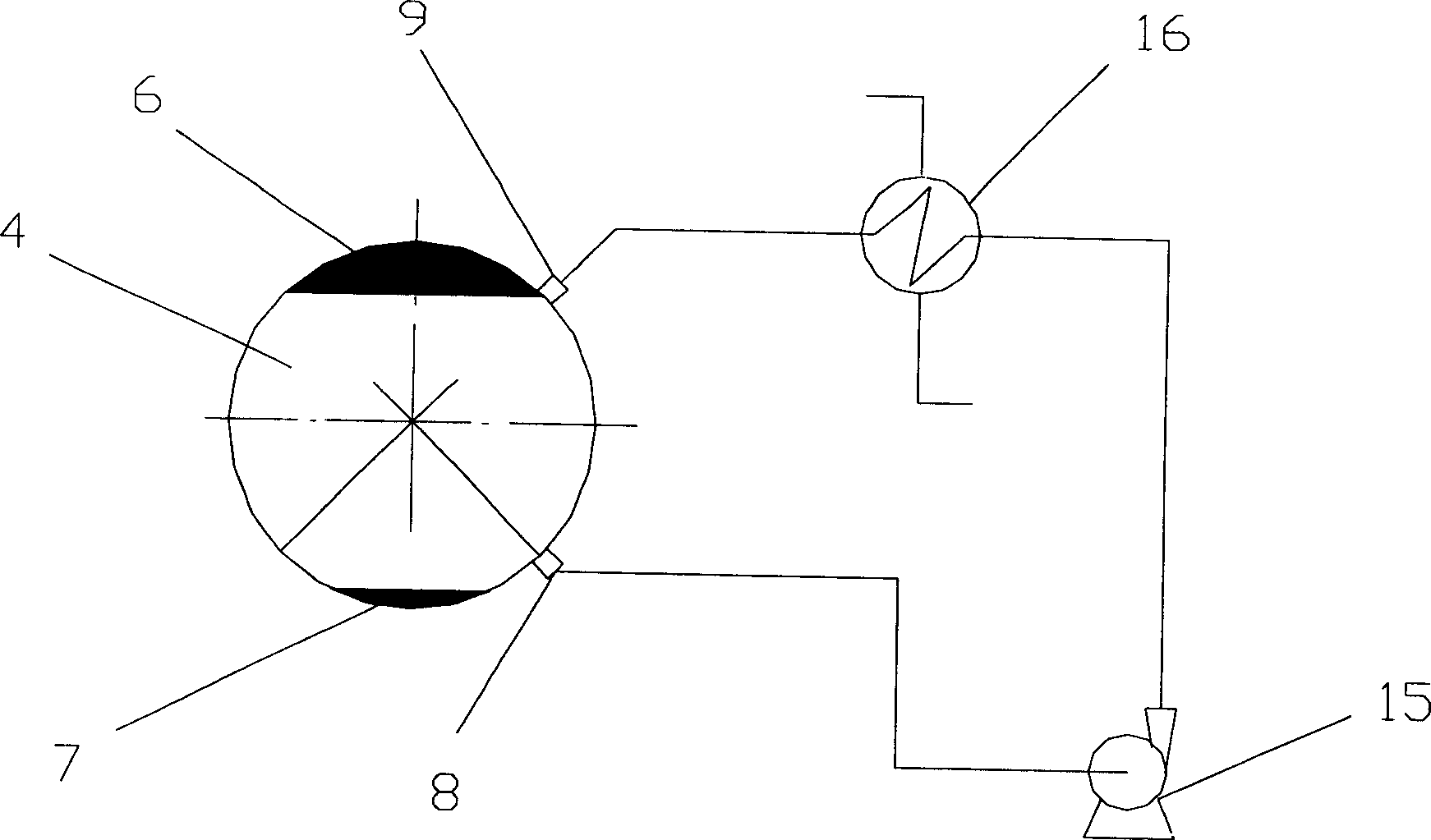

Horizontal baffled alcohol fermentation tank

ActiveCN1904030AImprove filtration efficiencyReduce dead angleBioreactor/fermenter combinationsBiological substance pretreatmentsContinuous fermentationAlcohol

The present invention discloses a horizontal partition alcoholic fermentation tank. It includes a tank body, and said tank body is characterized by that the vertical radial length of said tank body is less than its horizontal axial length, its axial two ends are respectively equipped with material inlet and material outlet, in the tank body interior at least one partition is radially vertically placed, said partition can be used for dividing tank body interior into two compartments, the upper portion or lower portion of said partition is equipped with a notch for making said two comportments be communicated each other.

Owner:GUANGDONG ZHONGKE TIANYUAN NEW ENERGY SCI & TECH

Hard rock bypass crushing system of autogenous mill

The invention relates to a hard rock bypass crushing system of an autogenous mill. The system comprises an autogenous mill feeding belt type conveyor and the autogenous mill. The system is characterized in that a double-layer vibrating sieve is arranged below an ore discharge hopper of the autogenous mill; a hard rock chute and a hard rock bypass crushing system body are arranged on the side surface of an upper-layer sieve of the double-layer vibrating sieve; the hard rock bypass crushing system body comprises an on-sieve hard rock discharging belt type conveyor, a hard rock transfer belt type conveyor, a hard rock bypass belt type conveyor, a hard rock crushing feeding bin feeding belt type conveyor, a hard rock crusher feeding belt type conveyor, a hard rock crusher and a crushed product belt type conveyor connected sequentially. The system is simple, convenient to maintain, high in operability, free from standby application of the crusher, low in investment and capable of conveying hard rocks to a hard rock crushing system and directly returning the hard rocks to the autogenous mill for autogenous grinding during maintenance of the crusher, so that the recovery rate of ore is increased, and the processing capacity of the autogenous mill is guaranteed.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

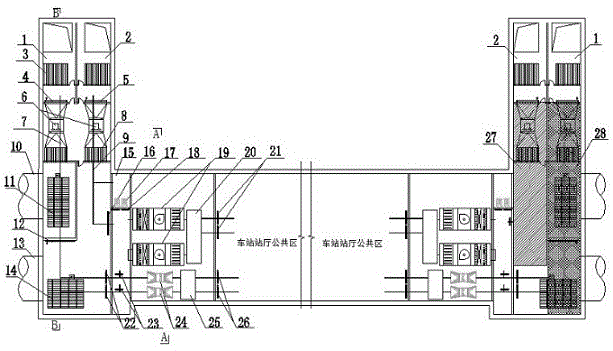

Combined and closed subway station ventilation and air conditioning system and application thereof

ActiveCN105525935ASave construction areaLow costTunnel/mines ventillationExhaust valveControl system

The invention provides a combined and closed subway station ventilation and air conditioning system. The system comprises exhaust ducts and fresh air ducts, wherein the exhaust ducts and the fresh air ducts are communicated with accident air ducts through accident fan valves I and accident fan valves II respectively; an accident fan is arranged in each accident air duct, each accident air duct is communicated with a tunnel I and a tunnel II through a tunnel valve I and a tunnel valve II, an exhaust header pipe and a fresh air header pipe are arranged above each accident air duct, two ends of each exhaust header pipe are communicated with the corresponding exhaust duct and an exhaust fan respectively, two ends of each fresh air header pipe are communicated with the corresponding fresh air duct and a combined air conditioner, an exhaust valve is arranged on each exhaust header pipe, a fresh air valve is arranged on each fresh air header pipe, and each combined air conditioner and the corresponding exhaust fan are communicated with the corresponding station hall public area through a valve I and a valve II. A traditional piston air duct is omitted, air ducts of an interval tunnel ventilation system and the station air conditioning system are combined together, the building area is reduced, the accident fans and the station air conditioning system are separately arranged, a control system is simplified, and the maintenance workload is reduced.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

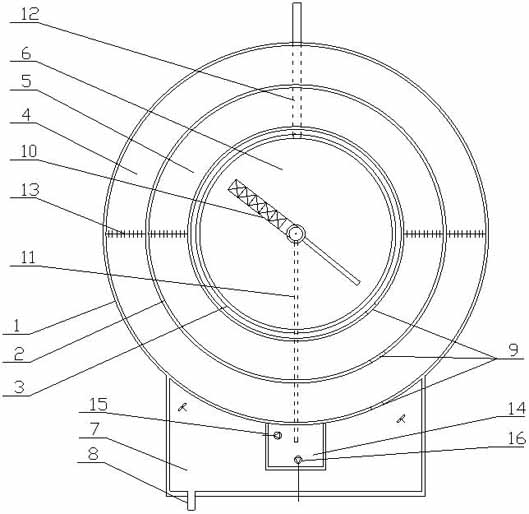

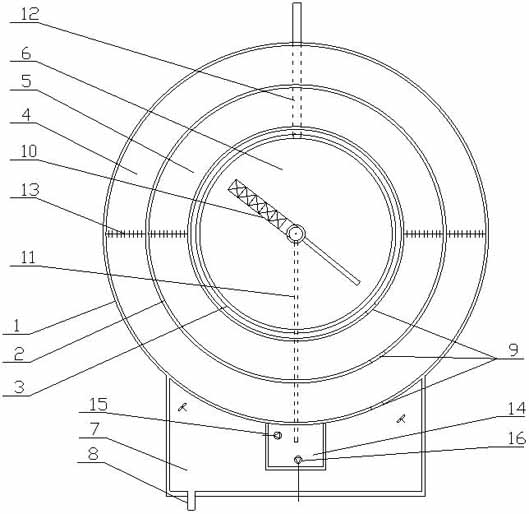

Integrated high-efficiency oxidation ditch and sewage treatment process thereof

InactiveCN102010106APhosphorus removalImprove stabilityTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentSewageDenitrification

The invention relates to an integrated high-efficiency oxidation ditch and a sewage treatment process thereof. The integrated high-efficiency oxidation ditch is characterized by comprising a first annular wall, a second annular wall and an annular sedimentation tank wall with sequentially reducing annular radiuses, wherein an oxidation ditch anoxic region and an oxidation ditch aerobic region are formed between every two annular walls respectively; a peripheral inlet and outlet radial flow type sedimentation tank is positioned in the annular sedimentation tank wall; one side edge of the outer side wall of the first annular wall is provided with an anaerobic tank with a sewage inlet; the first annular wall, the second annular wall and the annular sedimentation tank wall are provided with communicating holes for communicating the anaerobic tank with the oxidation ditch anoxic region, communicating the oxidation ditch anoxic region with the oxidation ditch aerobic region and communicating the oxidation ditch aerobic region with the peripheral inlet and outlet radial flow type sedimentation tank respectively; a suction dredger and a sludge reflux pipe are arranged in the peripheral inlet and outlet radial flow type sedimentation tank for discharging sludge to a sludge reflux pump room; and a water outlet pipe is also arranged in the peripheral inlet and outlet radial flow type sedimentation tank. The integrated high-efficiency oxidation ditch has a simple structure and is favorable for improving the efficiency and the stability of biological denitrification and dephosphorization.

Owner:FUZHOU URBAN CONSTR DESIGN RES INST CO LTD

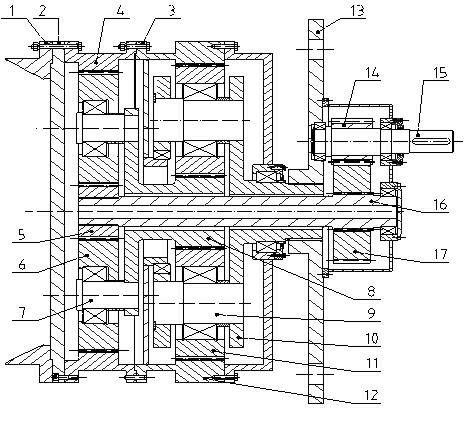

Transmission gear of tube mill

ActiveCN102562954ASimple on-site installationEasy to installToothed gearingsGrain treatmentsFlangeWheel and axle

The invention discloses a transmission gear of a tube mill. An input shaft (15) is arranged on a torsion frame (13); an input mating gear (17) is engaged with an input gear (14) on the input shaft (15); a flexible hollow shaft (16) is arranged at the centre of a join box body (3); the input mating gear (17) and a secondary sun wheel (5) are arranged on the flexible hollow shaft (16); a secondary planetary wheel (6) on a secondary planetary wheel shaft (7) is engaged with the secondary sun wheel (5); a secondary inner gear ring (4) is arranged on the join box body (3); the secondary planetary wheel shaft (7) is connected with a tertiary sun wheel (8); a tertiary planetary wheel shaft (9) is arranged on a tertiary planetary frame (10) on the torsion frame (13); a tertiary planetary wheel (11) on the tertiary planetary wheel shaft (9) is engaged with the tertiary sun wheel (8); and a tertiary inner gear ring (12) is connected on the join box body (3). The transmission gear is of fully enclosed structure and is connected by flanges, the installation is easy, and the installation period is short.

Owner:JIANGSU JINXIANG TRANSMISSION EQUIP

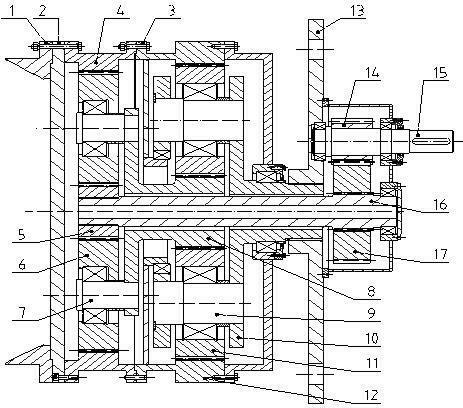

Submerged arc furnace top distribution system

ActiveCN103925799ALess investmentCompact structureCharge manipulationDistribution systemBelt conveyor

A submerged arc furnace top distribution system comprises a feed mechanism and a furnace top stock bin arranged linearly. The feed mechanism comprises a feed belt conveyor, a fixed reversible belt conveyor and a running reversible belt conveyor. The running reversible belt conveyor is installed above the furnace top stock bin. The fixed reversible belt conveyor and the running reversible belt conveyor are perpendicularly and fixedly installed. The end of the fixed reversible belt conveyor is arranged on the running reversible belt conveyor. The head of the feed belt conveyor is arranged on the fixed reversible belt conveyor. The submerged arc furnace top distribution system has the advantages that each system can achieve feeding for two submerged arc furnaces, equipment investment is low, the workshop structure is compact, smelting span is small, investment is small, construction is easy, the technology is mature, operation is stable, the fault rate is low, operation environment is good, automatic furnace top distribution can be achieved, the workshop structural design is simple, the manufacturing cost is low, and the workshop structure of the submerged arc furnaces can be optimized.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

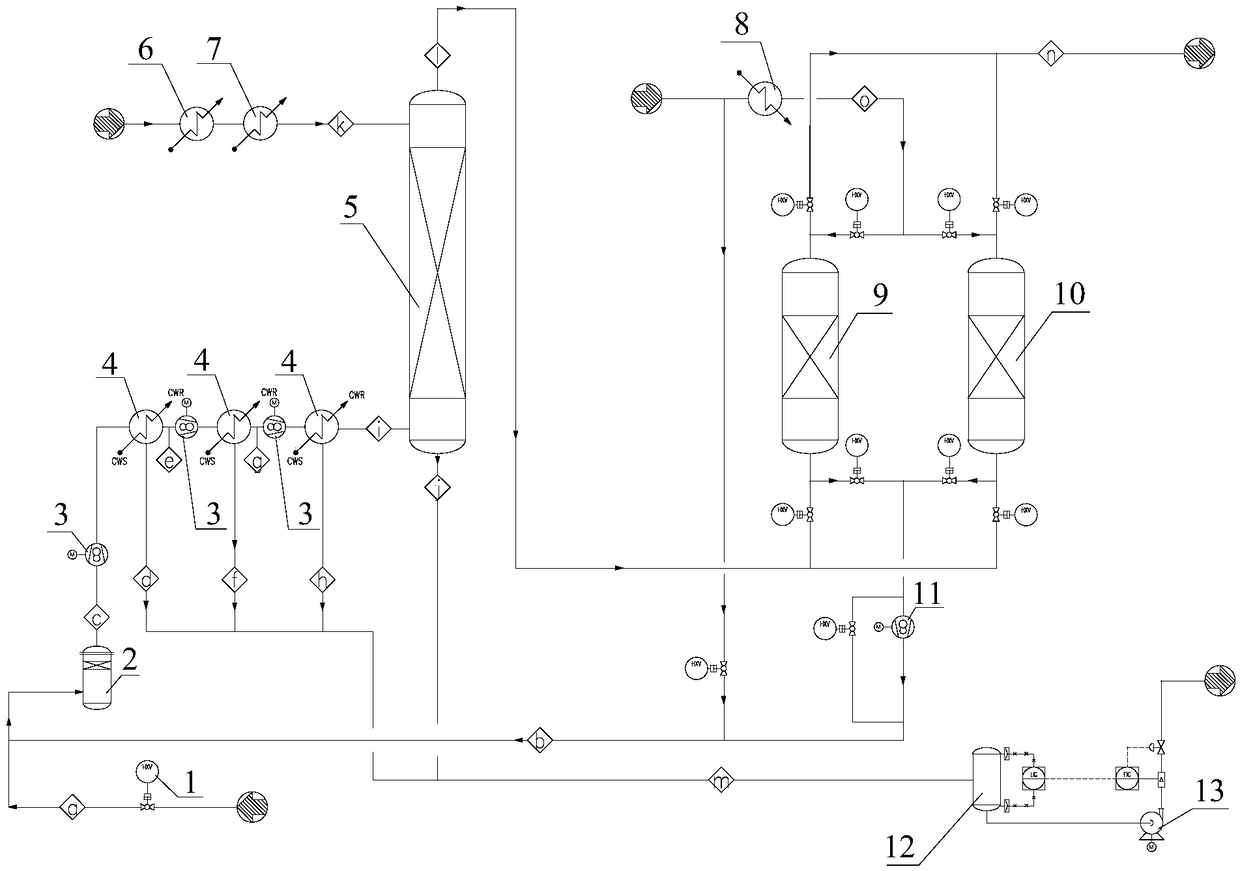

Glue fiber acid bath low temperature evaporation and continuous crystallization process and device thereof

ActiveCN103952798AFewer public works projectsReduce energy consumptionArtificial filament recoveryTextile/flexible product manufactureFiberEvaporation

The invention discloses a glue fiber acid bath low temperature evaporation and continuous crystallization process and a device of the process. The process comprises an acid bath to be evaporated, an acid bath middle bucket, a conveying pump, a preheater, a heat exchanger A, an evaporator, a steam compressor, a heat exchanger A, a heat exchanger B, a discharge pump, a crystal pulp tank and a centrifuge, wherein the output of the acid bath middle bucket to be evaporated and crystallized is connected with the steam preheater through the conveying pump the condensed water preheater; the output of the steam preheater is connected with an evaporation crystallizer and the heat exchanger B through the heat exchanger A; the evaporation crystallizer and the heat exchanger B are in serial connection; the output of the evaporation crystallizer is connected with the crystal pulp tank through the discharge pump; the output of the crystal pulp tank is connected with a separator; the output of the separator is connected with a mother liquid tank. The energy is greatly saved; moreover as the evaporation and the crystallization are integrated, stable evaporation and continuous crystallization are achieved; meanwhile the whole set of the equipment is compact and reliable, the civil engineering investment is saved, small space is occupied, the number of operators needed is small, the operation is stable and reliable, and the whole system can be under configuration control and is highly automatic.

Owner:JIUJIANG HENGSHENG CHEM FIBER

Three-shelling four-reduction two-sizing high-efficient low-consumption simplified mill diagram

The invention simplifies a prior milling process with 4-belt, 8-center, 2-slag and 2-tail to the milling process with 3-belt, 4-center and 2-slag by increasing 2 impact mills in a front section of a reduction system, using one impact mill to replace a four-belt roller mill and all the bran finishers and using 3 to 4 impact mills to replace a roller mill with 4-center and more and a tail roll grinding system. The invention can reduce the investment on devices of a milling plant of a flour production line and the civil construction by 20 percent to 30 percent, reduce the power consumption per ton flour by about 5 percent, reduce the operation cost of the production line by about 5 percent, greatly simplify the operation of the devices and the production management, simultaneously improve the good flour yield of the front section of the flour production line by about 10 percent and improve the total flour extraction rate of the flour production line by 1 percent to 5 percent, thus increasing daily economic benefits of a flour mill due to the consumption reduction.

Owner:王洪福

Ultra-thin full-floating vehicle-taking apparatus by manipulator

ActiveCN101476402BSolve parking problemImprove the speed of access to the carParkingsDrive wheelElectric machinery

The invention relates to an ultra-thin device for parking and taking cars through full floating mechanical hands. Two sides of a longitudinal movement trolley are symmetrically provided with full floating mechanical hands, and the ultra-thin device consists of the longitudinal movement trolley and the full floating mechanical hands symmetrically arranged on the two sides, wherein the longitudinalmovement trolley comprises an underframe, a running mechanism driving motor, a driving wheel, a driving wheel driving shaft, and a driving wheel driving gear; the full floating mechanical hand comprises a mechanical arm driving mechanism, a mechanical hand transition sliding plate, a mechanical arm, linear guide rails arranged on the inner and outer sides of a long beam on the underframe of the trolley respectively, and a swinging arm guide groove, wherein the mechanical hand transition sliding plate drives the mechanical arm to move. The device is ultra-thin, and two sets of independent fullfloating mechanical hands float freely in a set range, can be placed on a conveying trolley to form a horizontal movement type mechanical parking device, and can be placed on a stacker to form a laneway stacker type mechanical parking device without a carrying plate and a comb teeth rack; and the interbedded clear height is only 1.65 meters so that the construction investment is reduced, the structure is simple, the maintenance is convenient, and particularly the device is applicable to large mechanical garage.

Owner:HANGZHOU XIZI IUK PARKING SYST CO LTD

Submersible high-efficiency energy-saving mixing aeration device

InactiveCN101514048AWide adaptabilityImprove oxygen transfer efficiencySustainable biological treatmentBiological water/sewage treatmentImpellerEnergy conservation

The invention relates to a submersible high-efficiency energy-saving mixing aeration device combined with mixing self suction and blast aeration. The device comprises a base assembly, an air duct body and a disc seat, wherein the air duct body and the disc seat are arranged in the base assembly; a seal outer housing is fixed on the disc seat; a speed reducing motor is arranged in the seal outer housing, and is fixed on the disc seat; an output shaft of the speed reducing motor is connected with a rotating shaft of an impeller; a conical impeller is fixed on the rotating shaft of the impeller; a mechanical seal is arranged between the output shaft of the speed reducing motor and the disc seat; the base assembly is provided with an inlet pipe communicated with the air duct body; and the air duct body is provided with an air outlet. The submersible high-efficiency energy-saving mixing aeration device has the advantages of high oxygen transfer efficiency, energy conservation, consumption reduction, non blockage, stable operation, quick and convenient installation, empty omission of an aeration tank, free motion and lifting of equipment and easy maintenance.

Owner:XINXIANG LANHAI ENVIRONMENT ENG

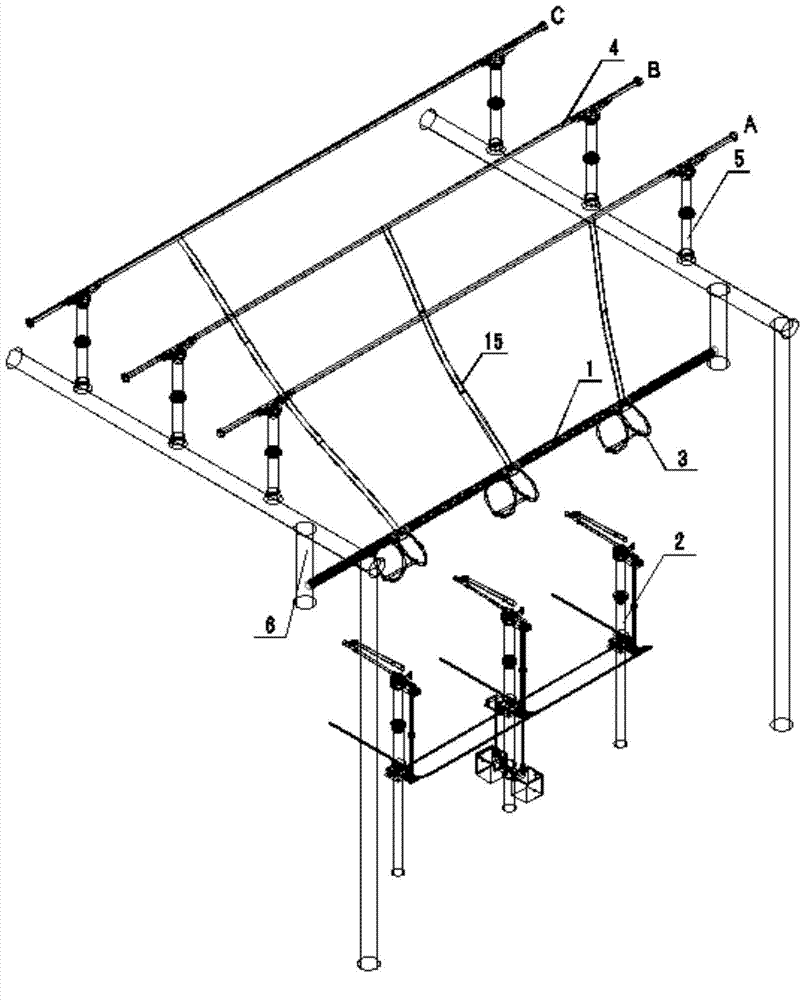

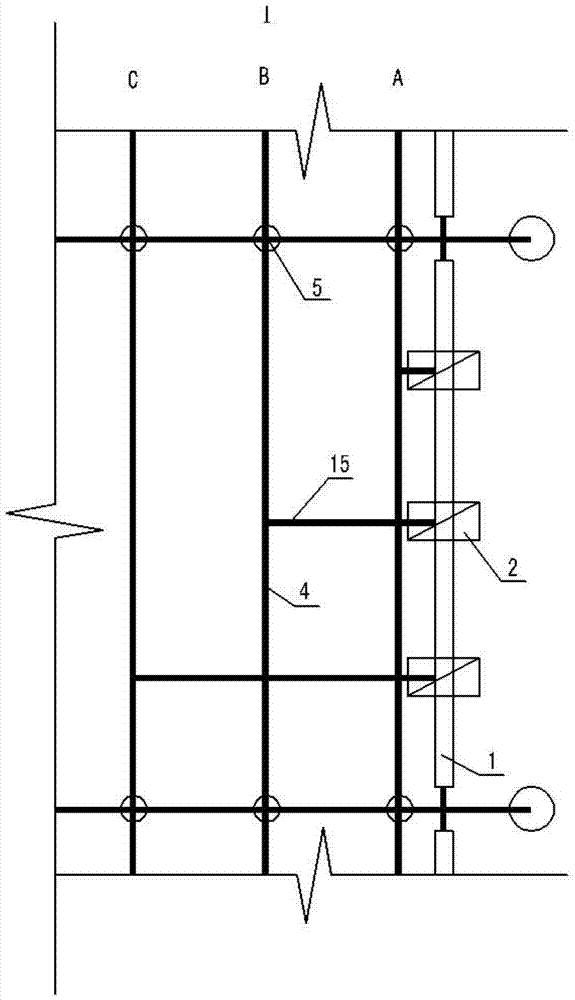

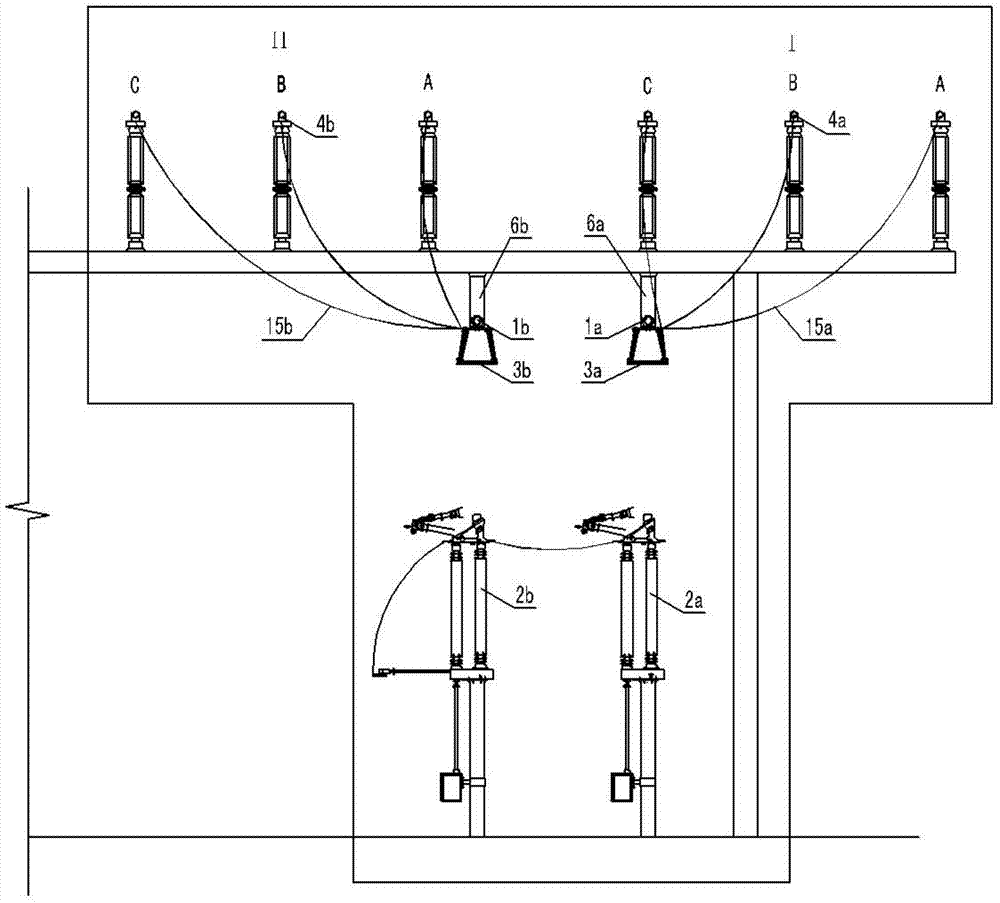

Disconnecting switch arrangement structure for transformer substation power distribution unit

The invention discloses a disconnecting switch arrangement structure for a transformer substation power distribution unit. The disconnecting switch arrangement structure is characterized in that a vertical telescopic 0-degree disconnecting switch is adopted, and each movable contact in the 0-degree disconnecting switch is arranged along a direction parallel to a tubular bus bar; an insulating bar is arranged above the movable contacts of the 0-degree disconnecting switch along the direction parallel to the tubular bus bar according to a set height; each static contact in the 0-degree disconnecting switch is distributed on the insulating bar at set intervals; each tubular bus bar fixedly arranged on a tubular bus bar framework is connected with each corresponding static contact in the 0-degree disconnecting switch through leads. By adopting the disconnecting switch arrangement structure, the longitudinal size of a power distribution unit area can be reduced effectively, the floor area of a transformer substation is reduced, and the application range of an AIS (Automatic Identification System) power distribution unit is enlarged.

Owner:ANHUI ELECTRIC POWER DESIGN INST CEEC

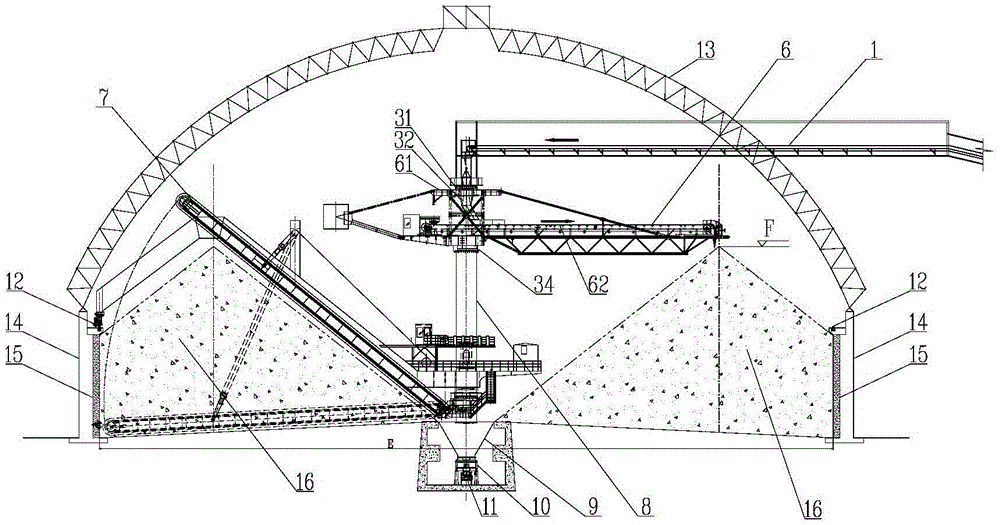

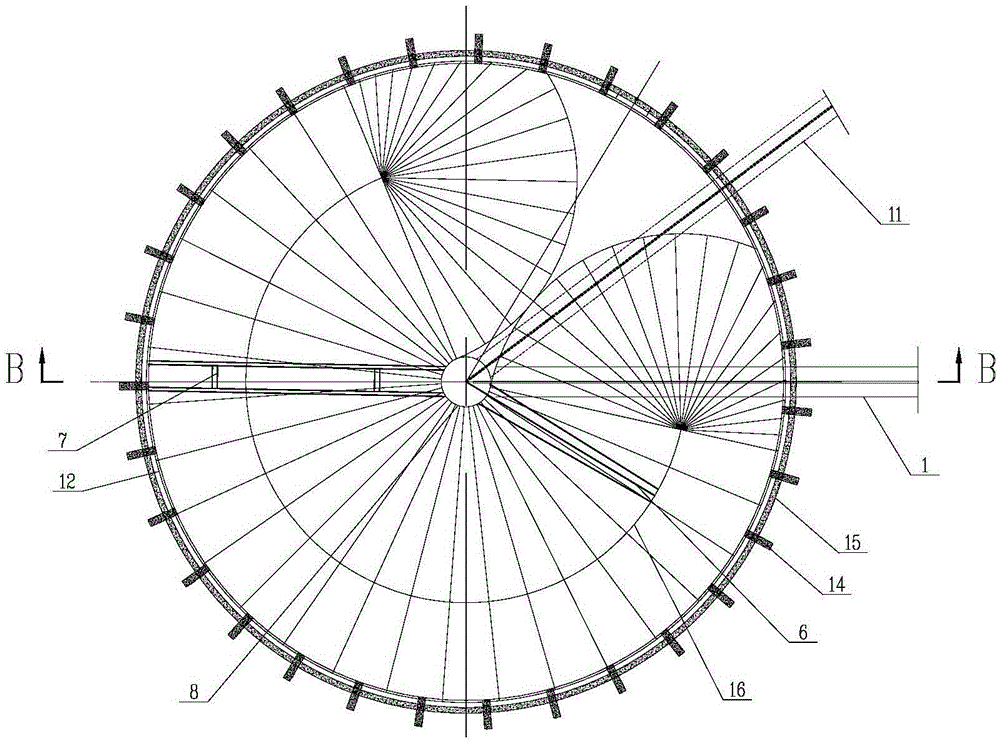

Environment-friendly pitching stacking circular material yard

ActiveCN105523389AImprove stabilityAvoid it happening againConveyorsLoading/unloadingStack machineWorking environment

The invention discloses an environment-friendly pitching stacking circular material yard, and is mainly designed for improving stability of a feeding belt conveyor of the material yard, improving a working environment of the material yard and saving investments. A central column of the environment-friendly pitching stacking circular material yard can penetrate through a stacking machine frame to be rigidly connected with the head of the feeding belt conveyor, so that the stability of a conveying gallery of the feeing belt conveyor is improved; up-down pitching of a discharging end of a cantilever type conveyor of a stacking machine surround the stacking machine frame is realized through an electric hydraulic pushing pole, pitching stacking of the stacking machine is realized, fall during stacking is reduced, and a large amount of raised dust is avoided; and meanwhile, the conveying gallery of the feeding belt type conveyor is arranged above a material shed by the environment-friendly pitching stacking circular material yard, mounting space of the feeding belt conveyor is not required to be reserved in the material shed, and civil engineering investments on the material shed and supporting equipment thereof are saved when the material yard with the same material storage amount is constructed.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

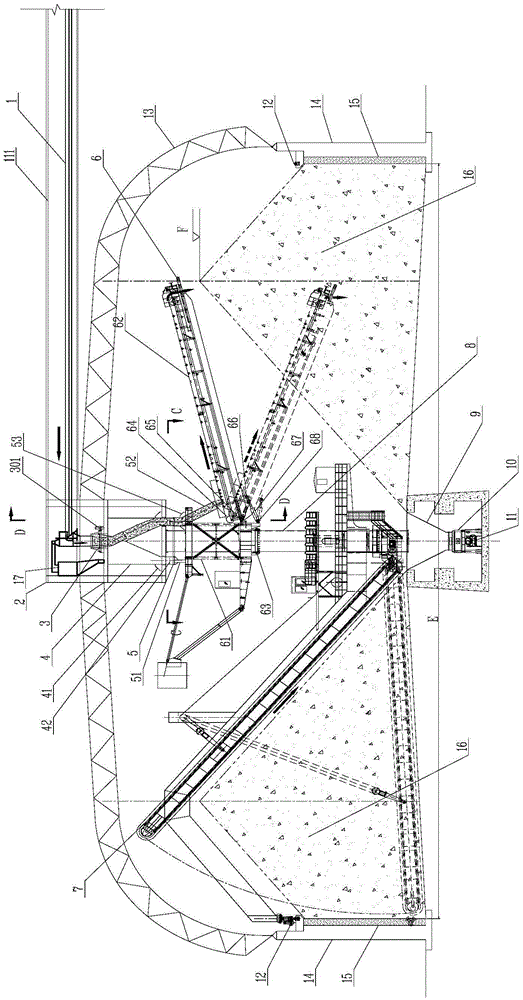

Loading and unloading machine of annular furnace

ActiveCN101943520AReduce the temperatureImprove rigidityFurnace typesEngineeringMechanical engineering

The invention relates to a loading and unloading machine of an annular furnace. The machine is formed by connecting a traveling device, a lifting device and an expansion device, wherein the traveling device comprises traveling wheels, a driving mechanism, a universal coupler, traveling guide wheels, a linear code reader, a bar code shield, a rubber buffer, a machine frame, a guide rail cleaning mechanism and a traveling track; the lifting device comprises a straight swing arm, an angular swing arm, a joint rod, a driving mechanism, a connecting rod, a swing rod, a crank, a fixing rotary shaft seat, a lifting rotary shaft seat, a fixing rotary shaft and a lifting rotary shaft; and the expansion device comprises a reel group, a reel driving mechanism, a cooling hose, a bracket, a third-level telescopic arm, a supporting guide wheel group, a second-level telescopic arm, a first-level telescopic arm, a material fork, a driving tension mechanism, a first-level driving mechanism, a second-level driving mechanism, a rubber buffer mechanism, a third-level driving mechanism, a main driving mechanism, a manual driving mechanism, and a machine frame. The machine can load and unload pieces with different sizes of a plurality of pieces of equipment at a plurality of working stations. The application effect of the machine is obvious.

Owner:天津新玛特科技发展有限公司

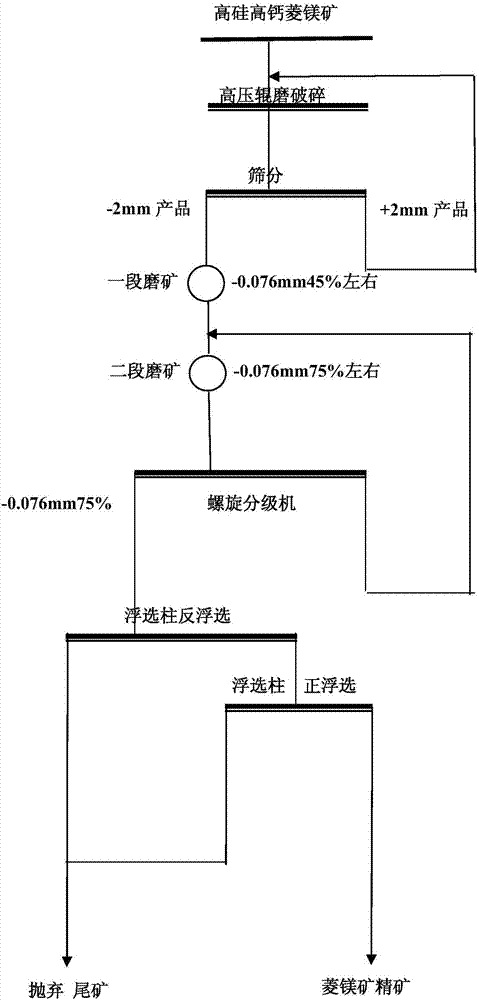

Low-cost mineral processing technology for high-silicon high-calcium magnesite

The invention relates to a low-cost mineral processing technology for high-silicon high-calcium magnesite. The low-cost mineral processing technology comprises the steps of raw material crushing operation, grinding operation and flotation operation. The low-cost mineral processing technology is characterized by comprising the following specific technological steps that raw magnesite is crushed through a medium crusher, grinding operation is conducted through a closed circuit grinding assembly composed of a primary grate ball mill, a secondary grate ball mill and a spiral grading machine, an overflow product with the particle size of 70-80% of the overflow product being -0.076 mm is obtained and subjected to flotation operation adopting primary reverse flotation and primary obverse floatation, the magnesite comprising 46.50-47.00% of magnesium oxide, 0.80-1.50% of silicon dioxide and 0.90-2.00% of calcium oxide is obtained, wherein the concentrate yield is 82.00-90.00%, and the recovery rate is 81.45-85.00%. The low-cost mineral processing technology has the advantages that flotation operation adopting only primary reverse flotation and primary obverse floatation, thus, the grade of the silicon dioxide in the high-silicon high-calcium magnesite can be lowered to 0.5-1.5% from 2%, the content of silicon is lowered by 50% or above, the grade of the calcium oxide is lowered to 1-2% from 3%, and the content of calcium is lowered by 50% or so.

Owner:中冶北方(大连)工程技术有限公司

Cyclone treatment technique of nickel-containing electroplating wastewater

InactiveCN104724864AIncrease current densityIncrease workloadPhotography auxillary processesWater contaminantsElectroplating wastewaterImpurity

The invention discloses a cyclone treatment technique of nickel-containing electroplating wastewater. By adopting a cyclone technique which is completely different from the traditional technique for electrodepositing nickel, the current efficiency can reach 90% above which is much higher than 75% in the traditional nickel electrodeposition. The current density is 600-800 A / m<2> which is more than twice higher than that of the traditional technique. Besides, the nickel product produced by the technique has the advantages of stable quality and low requirements for impurity content in the catholyte. The technique can decrease civil engineering investment, and has the advantages of low production cost, high degree of mechanization, low workshop labor requirement, low worker labor intensity and the like.

Owner:江苏地一环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com