Improved four-ditch type oxidation ditch and sewage treatment method thereof

An oxidation ditch, an improved technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of large installed capacity, large maintenance, and high sludge concentration in sedimentation tanks. problems, to achieve the effect of reducing lifting lift, saving power consumption and saving civil construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

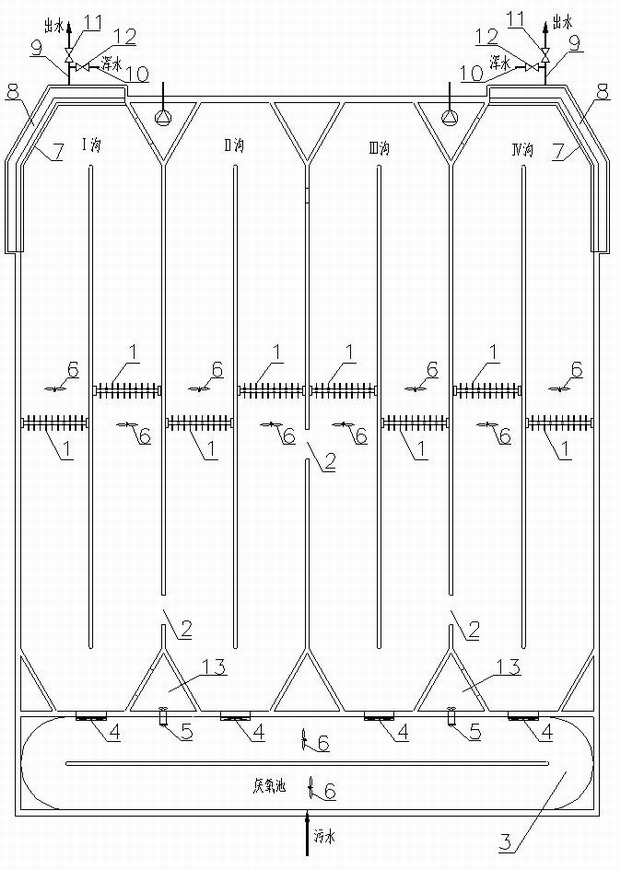

[0044] refer to figure 1 , an improved four-ditch oxidation ditch, including a four-ditch oxidation ditch, the four-ditch oxidation ditch is composed of four oxidation ditch, each oxidation ditch is provided with an aeration device 1, the four oxidation ditch A communication hole 2 connecting adjacent two oxidation ditches is provided at the common pool wall between them. It is characterized in that: an anaerobic pool 3 is arranged before the four-ditch type oxidation ditch, and the anaerobic pool 3 is controlled by four The valves 4 are respectively connected to the corresponding four oxidation ditches, and the sludge in the side ditch used for precipitation of the four-ditch type oxidation ditch is returned to the anaerobic tank 3 through the sludge return pump 5 .

[0045] The aeration equipment 1 is a rotating brush or a rotating disc, the sludge return pump 5 is a through-wall pump, the sludge return pump 5 is located in the sludge return pump room, and the sludge return ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com