Energy-saving plate-type micro filter device

A technology of filtration equipment and energy-saving boards, which is applied in the field of water treatment, can solve the problems of affecting the normal use of equipment, difficulty in equipment maintenance, and damage to filter cloth, etc., and achieves the effects of reduced consumption, simple shape, and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

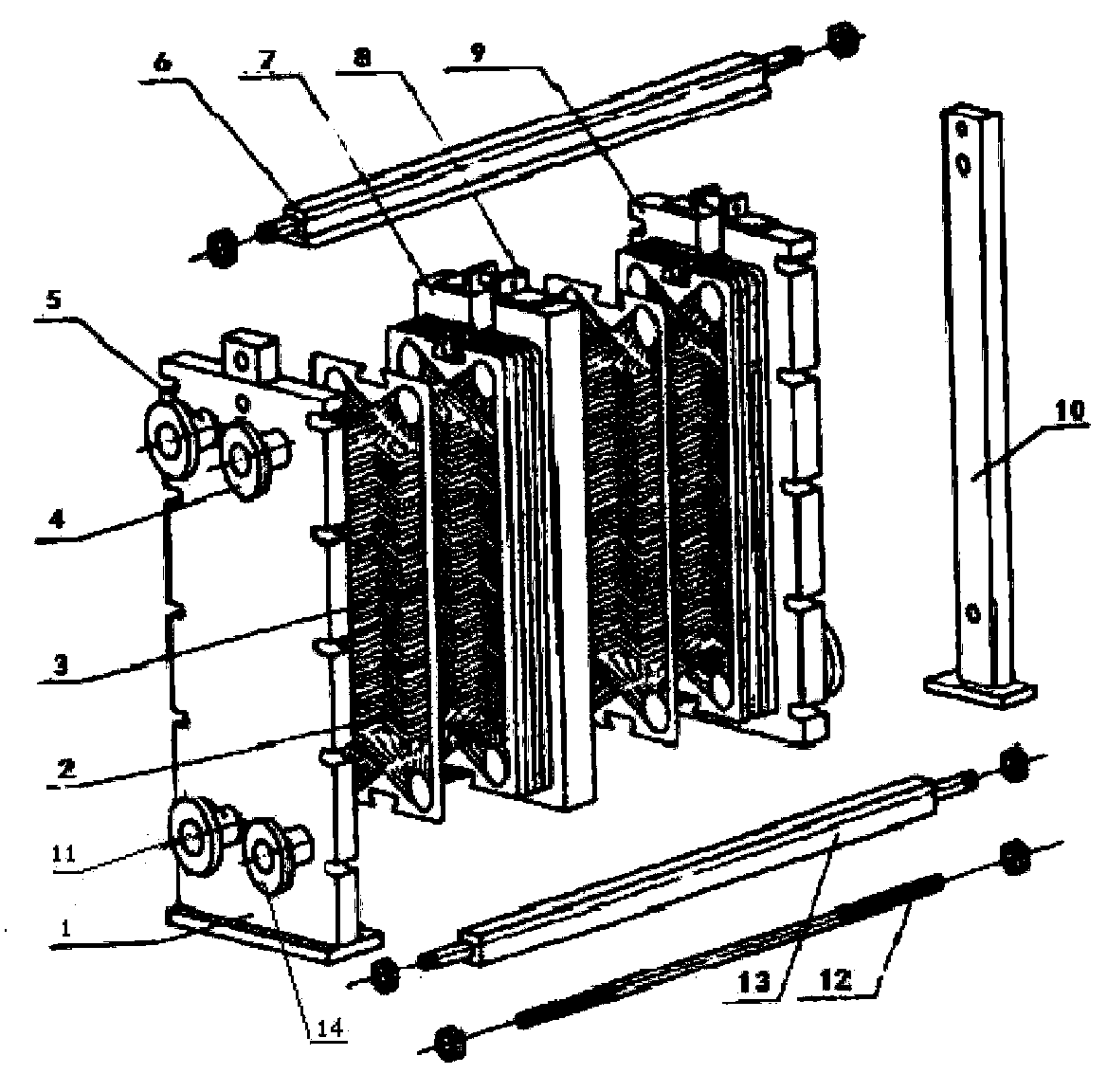

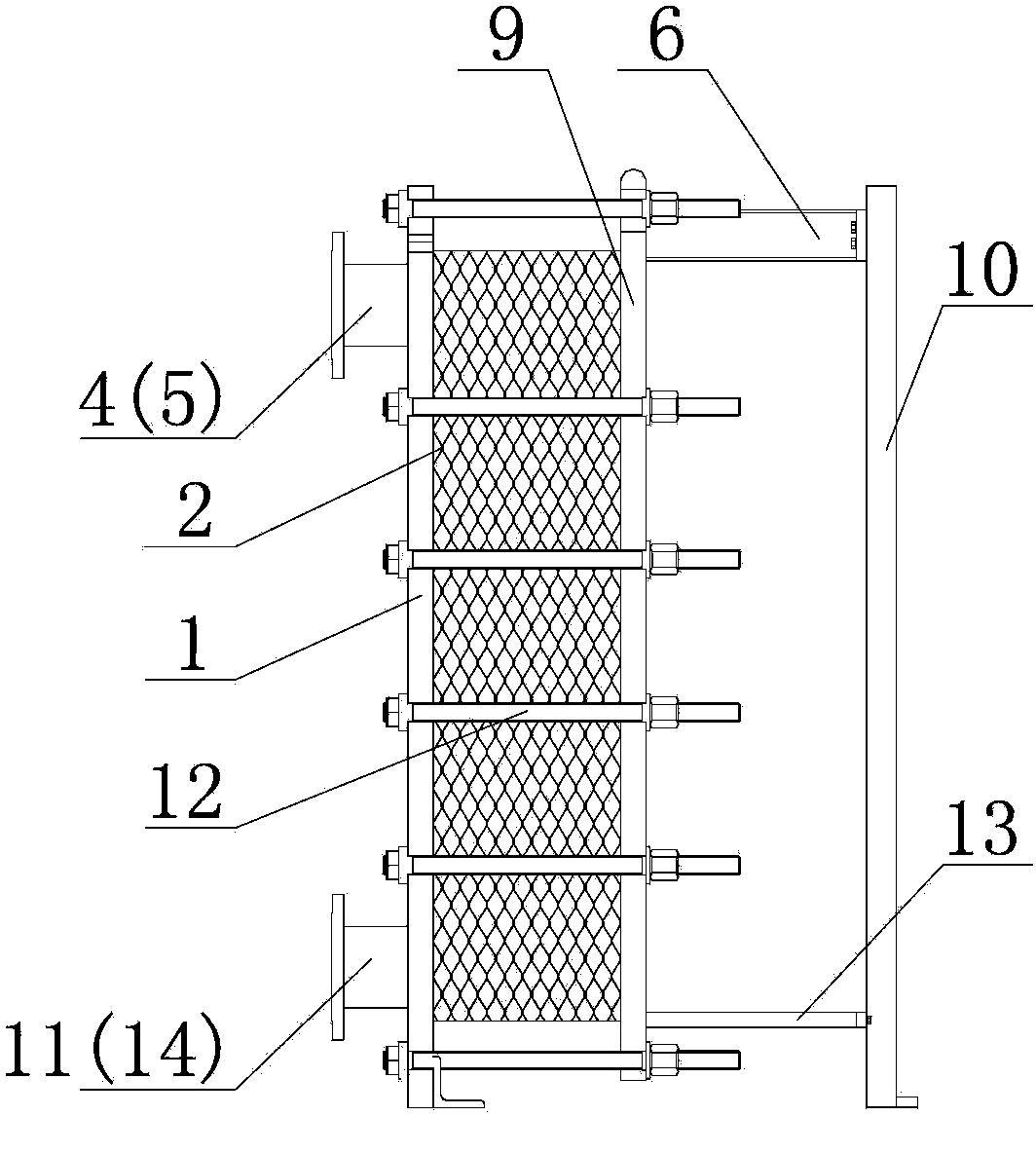

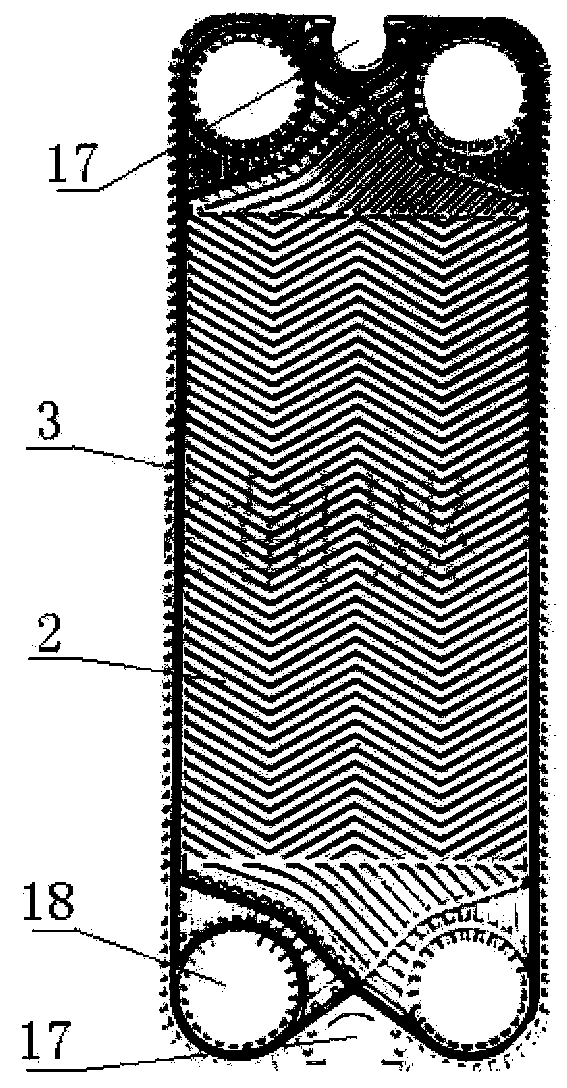

[0033] Embodiment 1 of the present invention: as figure 1 and figure 2 As shown, an energy-saving plate-type micro-filtration equipment includes a fixed compression plate 1, a filter plate 2, a movable compression plate 9 and a pillar 10, and the fixed compression plate 1 is connected to the pillar 10 through the upper guide rod 6 and the lower guide rod 13. connection, the movable compression plate 9 is set between the fixed compression plate 1 and the pillar 10, and no less than 2 filter plates 2 are arranged between the fixed compression plate 1 and the movable compression plate 9, and the adjacent 2 pieces Gaskets 3 are provided between the filter plates 2, the fixed compression plate 1, the movable compression plate 9 and the filter plate 2 are fixedly connected together by clamping studs 12; the fixed compression plate 1 is provided with a filter Water inlet 4, filter water outlet 11, backwash water inlet 5 and backwash water outlet 14. The distance between two adjac...

Embodiment 2

[0038] Embodiment 2 of the present invention: as figure 1 and figure 2 As shown, an energy-saving plate-type micro-filtration equipment includes a fixed compression plate 1, a filter plate 2, a movable compression plate 9 and a pillar 10, and the fixed compression plate 1 is connected to the pillar 10 through the upper guide rod 6 and the lower guide rod 13. connection, the movable compression plate 9 is set between the fixed compression plate 1 and the pillar 10, and no less than 2 filter plates 2 are arranged between the fixed compression plate 1 and the movable compression plate 9, and the adjacent 2 pieces Gaskets 3 are provided between the filter plates 2, the fixed compression plate 1, the movable compression plate 9 and the filter plate 2 are fixedly connected together by clamping studs 12; the fixed compression plate 1 is provided with a filter Water inlet 4, filter water outlet 11, backwash water inlet 5 and backwash water outlet 14. The distance between two adjac...

Embodiment 3

[0042] Embodiment 3 of the present invention: as figure 1 and figure 2 As shown, an energy-saving plate-type micro-filtration equipment includes a fixed compression plate 1, a filter plate 2, a movable compression plate 9 and a pillar 10, and the fixed compression plate 1 is connected to the pillar 10 through the upper guide rod 6 and the lower guide rod 13. connection, the movable compression plate 9 is set between the fixed compression plate 1 and the pillar 10, and no less than 2 filter plates 2 are arranged between the fixed compression plate 1 and the movable compression plate 9, and the adjacent 2 pieces Gaskets 3 are provided between the filter plates 2, the fixed compression plate 1, the movable compression plate 9 and the filter plate 2 are fixedly connected together by clamping studs 12; the fixed compression plate 1 is provided with a filter Water inlet 4, filter water outlet 11, backwash water inlet 5 and backwash water outlet 14. The distance between two adjac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com