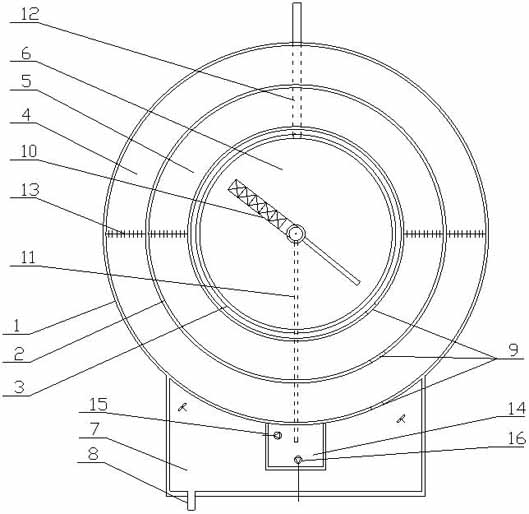

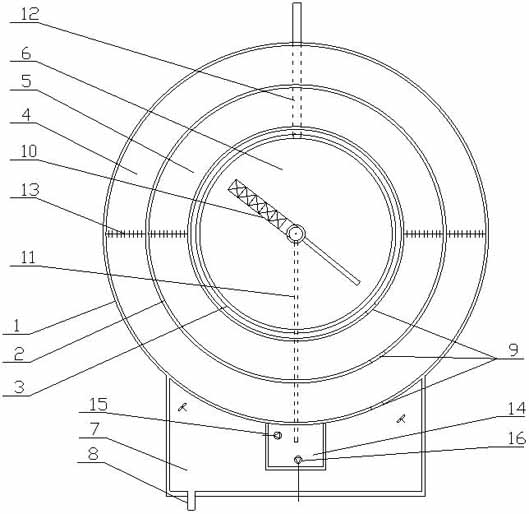

Integrated high-efficiency oxidation ditch and sewage treatment process thereof

An oxidation ditch, high-efficiency technology, applied in aerobic and anaerobic process treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of low system efficiency, poor stability, poor sedimentation effect, etc. , to achieve the effect of reducing process connection pipes, high overflow rate and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] A certain urban sewage plant adopts the present invention, and its water volume is 20,000 m 3 / d, anaerobic tank hydraulic retention time HRT = 1.0h, oxidation ditch hydraulic retention time HRT = 11.2h, total sludge age SRT = 14d, sludge load FWV = 0.072kgBOD 5 / kgMLSS.d, the effective water depth of the oxidation ditch H=4.0m, the maximum sludge return ratio of 100%, the sludge concentration in the oxidation ditch is uniform, the concentration of the mixed solution is 2500~3500mg / L, and the average COD, NH 4+ The removal rates of -N, SS and TP are as high as 92.6%, 86.6%, 91.2% and 83.3% respectively, and the effluent quality is better than the first-class B standard of "Pollutant Discharge Standards for Urban Sewage Treatment Plants" (GB18918-2002).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com