Recycling technology for organophosphorus pesticide wastewater

An organophosphorus pesticide and wastewater technology, which is applied in aerobic process treatment, mechanical oscillation water/sewage treatment, water pollutants, etc. efficiency, saving water resources and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

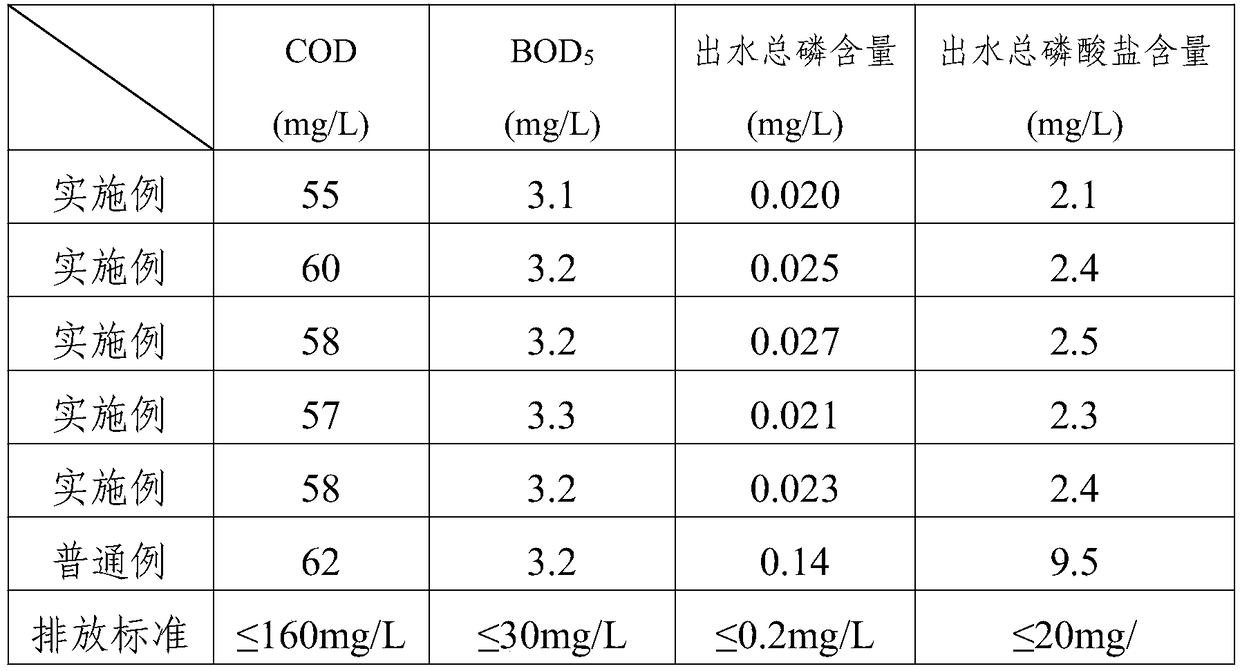

Examples

Embodiment 1

[0019] A kind of organophosphorus pesticide waste water reuse process, this process mainly comprises the following steps:

[0020] (1) Concentrate the untreated organophosphorus pesticide wastewater into the sump, pump it into the alkali solution sedimentation tank, and add 200mg / L of calcium oxide for precipitation;

[0021] (2) Put 2000mg / L ferric chloride into the above-mentioned unprecipitated waste liquid, enter the No. 1 pool of ultrasonic air flotation, discharge after air flotation, add 2300mg / L calcium hydroxide and 1500mg / L basic aluminum chloride The mixture enters the No. 2 pool of ultrasonic air flotation, and the waste water is discharged after air flotation;

[0022] (3) Pump the above-mentioned waste liquid into the adjustment tank and mix it with domestic sewage at a ratio of 1:2, pump it into the biological contact oxidation tank for 8 hours for biochemical treatment, and pump the treated waste liquid to the secondary sedimentation Larger particles of sludge...

Embodiment 2

[0024] A kind of organophosphorus pesticide waste water reuse process, this process mainly comprises the following steps:

[0025] (1) Concentrate the untreated organophosphorus pesticide wastewater into the sump, pump it into the alkali solution sedimentation tank, and add 220mg / L of calcium oxide for precipitation;

[0026] (2) Put 2400mg / L ferric chloride into the above-mentioned unprecipitated waste liquid, enter the No. 1 pool of ultrasonic air flotation, discharge after air flotation, add 2200mg / L calcium hydroxide and 1400mg / L basic aluminum chloride The mixture enters the No. 2 pool of ultrasonic air flotation, and the waste water is discharged after air flotation;

[0027] (3) Pump the above-mentioned waste liquid into the adjustment tank and mix it with domestic sewage at a ratio of 1:1.9, pump it into the biological contact oxidation tank for 5 hours for biochemical treatment, and pump the treated waste liquid to the secondary sedimentation Larger particles of slud...

Embodiment 3

[0029] A kind of organophosphorus pesticide waste water reuse process, this process mainly comprises the following steps:

[0030] (1) Concentrate the untreated organophosphorus pesticide wastewater into the sump, pump it into the alkali solution sedimentation tank, and add 180mg / L of calcium oxide for precipitation;

[0031] (2) Put 2800mg / L ferric chloride into the above-mentioned unprecipitated waste liquid, enter the No. 1 pool of ultrasonic air flotation, discharge after air flotation, add 2200mg / L calcium hydroxide and 1600mg / L basic aluminum chloride The mixture enters the No. 2 pool of ultrasonic air flotation, and the waste water is discharged after air flotation;

[0032] (3) Pump the above-mentioned waste liquid into the adjustment tank and mix it with domestic sewage at a ratio of 1:1.8, pump it into the biological contact oxidation tank for 6 hours for biochemical treatment, and pump the treated waste liquid to the secondary sedimentation Larger particles of slud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com