Bacteriostatic glyoxalated polyacrylamide-lanthanum carbonate modified graphene phosphorus chloride adsorbent

A technology for glyoxalating polyacrylamide and polyacrylamide, which is applied in adsorption water/sewage treatment, other chemical processes, chemical instruments and methods, etc. Contaminants and other problems, to achieve the effect of increasing volume and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] In order to achieve the above object, the present invention provides the following technical solutions: a bacteriostatic glyoxalated polyacrylamide-lanthanum carbonate modified graphene phosphorus chloride adsorbent, comprising the following raw materials in parts by weight, 75-87 parts Aminated graphene, 10-15 parts of polyacrylamide, 0.5-3 parts of lanthanum carbonate hydrate, 2-5 parts of glyoxal, 0.5-2 parts of titanate coupling agent, aminated graphene, the size is 2- 6μm, thickness: 1-3nm, ammoniation rate: about 3.7-4.2%, structural formula is Polyacrylamide is a non-ionic polyacrylamide with a molecular weight of 2.6 million-3.3 million, a degree of polymerization of 36600-46400, an aqueous solution viscosity (0.1% SOL): 330-470 (CPS), and a structural formula of The molecular formula of lanthanum carbonate hydrate is La 2 (CO 3 ) 3 ·8H 2 O, where La 2 o 3 The mass fraction is 71.5-74.6%, positive trivalent La 3+ With a high affinity for phosphate ions,...

Embodiment 1

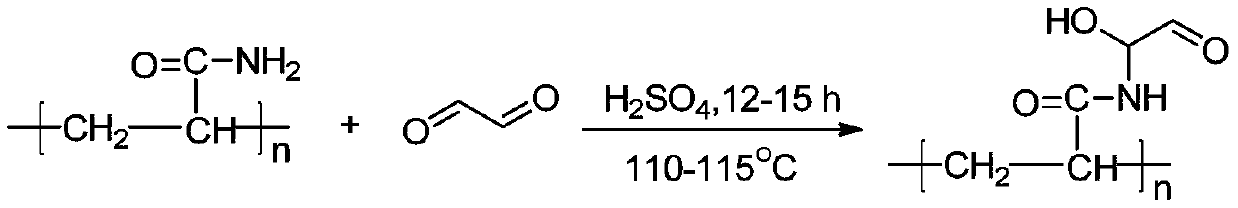

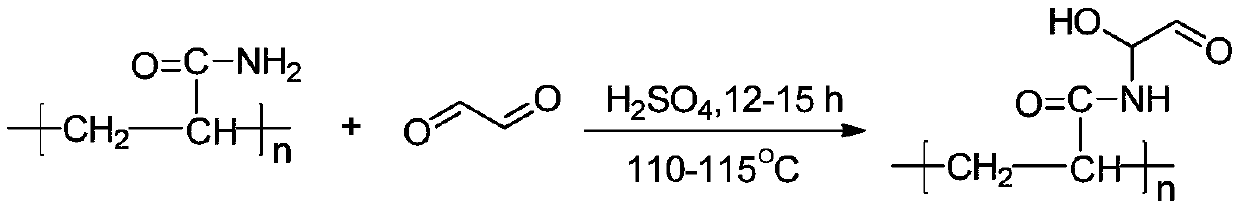

[0029] (1) Preparation of glyoxalated polyacrylamide: add 100mL of distilled water and 200mL of ethanol to a 500mL three-necked bottle, weigh 8 parts of polyacrylamide and 2 parts of glyoxal in turn, add them to the three-necked bottle, and then configure 0.4mol / L of dilute sulfuric acid, slowly add dropwise into the three-necked flask until the pH is 3-4, place the three-necked flask in an oil bath and heat to 110-115°C, stir at a constant speed for 12-15h to make the glyoxal and Polyacrylamide fully reacted, after the reaction is complete, add sodium carbonate to the three-neck flask to quench the reaction until the pH is 7-8, filter the material to obtain white floc, wash with 2500-3500mL distilled water to completely remove sulfuric acid , sodium sulfate, sodium carbonate and impurities to obtain pure glyoxalated polyacrylamide component 1, the reaction equation is:

[0030]

[0031] (2) Preparation of glyoxalated polyacrylamide-lanthanum carbonate hybrid polymer: Weig...

Embodiment 2

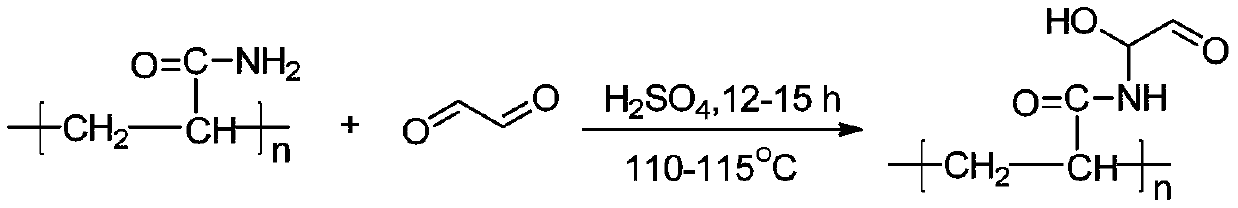

[0034] (1) Preparation of glyoxalated polyacrylamide: Add 100mL distilled water and 200mL ethanol to a 500mL three-necked bottle, weigh 10 parts of polyacrylamide and 3 parts of glyoxal into the three-necked bottle, and then configure 0.4mol / L of dilute sulfuric acid, slowly add dropwise into the three-necked flask until the pH is 3-4, place the three-necked flask in an oil bath and heat to 110-115°C, stir at a constant speed for 12-15h to make the glyoxal and Polyacrylamide fully reacted, after the reaction is complete, add sodium carbonate to the three-neck flask to quench the reaction until the pH is 7-8, filter the material to obtain white floc, wash with 2500-3500mL distilled water to completely remove sulfuric acid , sodium sulfate, sodium carbonate and impurities to obtain pure glyoxalated polyacrylamide component 2, the reaction equation is:

[0035]

[0036] (2) Preparation of glyoxalated polyacrylamide-lanthanum carbonate hybrid polymer: Weigh 1 part of lanthanum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com