Patents

Literature

197 results about "Lanthanum carbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lanthanum carbonate, La₂(CO₃)₃, is the salt formed by lanthanum(III) cations and carbonate anions. It is an ore of lanthanum metal, (Bastnäsite) along with monazite.

Treatment of swimming pool water

InactiveUS6146539AEasy to controlReduction of unpleasant chloraminesSeparation devicesSedimentation separationAlgal growthPhosphate

Methods and compositions are disclosed for treating swimming pool waters in order to remove one or more nutrients necessary for algal growth and to accelerate the breakdown of objectionable chloramines within chlorinated pool waters. The target nutrients of preference are those containing phosphorus or nitrogen. Phosphorus nutrients are preferably removed by ion-exchange with finely divided lanthanum carbonate, or by direct precipitation in the pool with liquid lanthanum chloride. Nitrogen nutrients (including, in particular, chloramines) may be removed (possibly with the aid of catalysts and in separate reactors). The same reagents used to scavenge phosphates are useful in this regard, the nitrogen being released from the pool water as a nitrogenous gas. To allow the fine lanthanum carbonates to be conveniently handled in the pool environment, they may be linked to larger carrier particles, such as those of diatomaceous earth, or they may be embedded within porous beads formed from polymers or gels. In this form the reagent can be either added to, retained within and backwashed from pool filters, or added directly to pools (with or without a flocculating agent) and sucked to waste after settling. A variety of formulations for these purposes is disclosed.

Owner:NATURAL CHEM

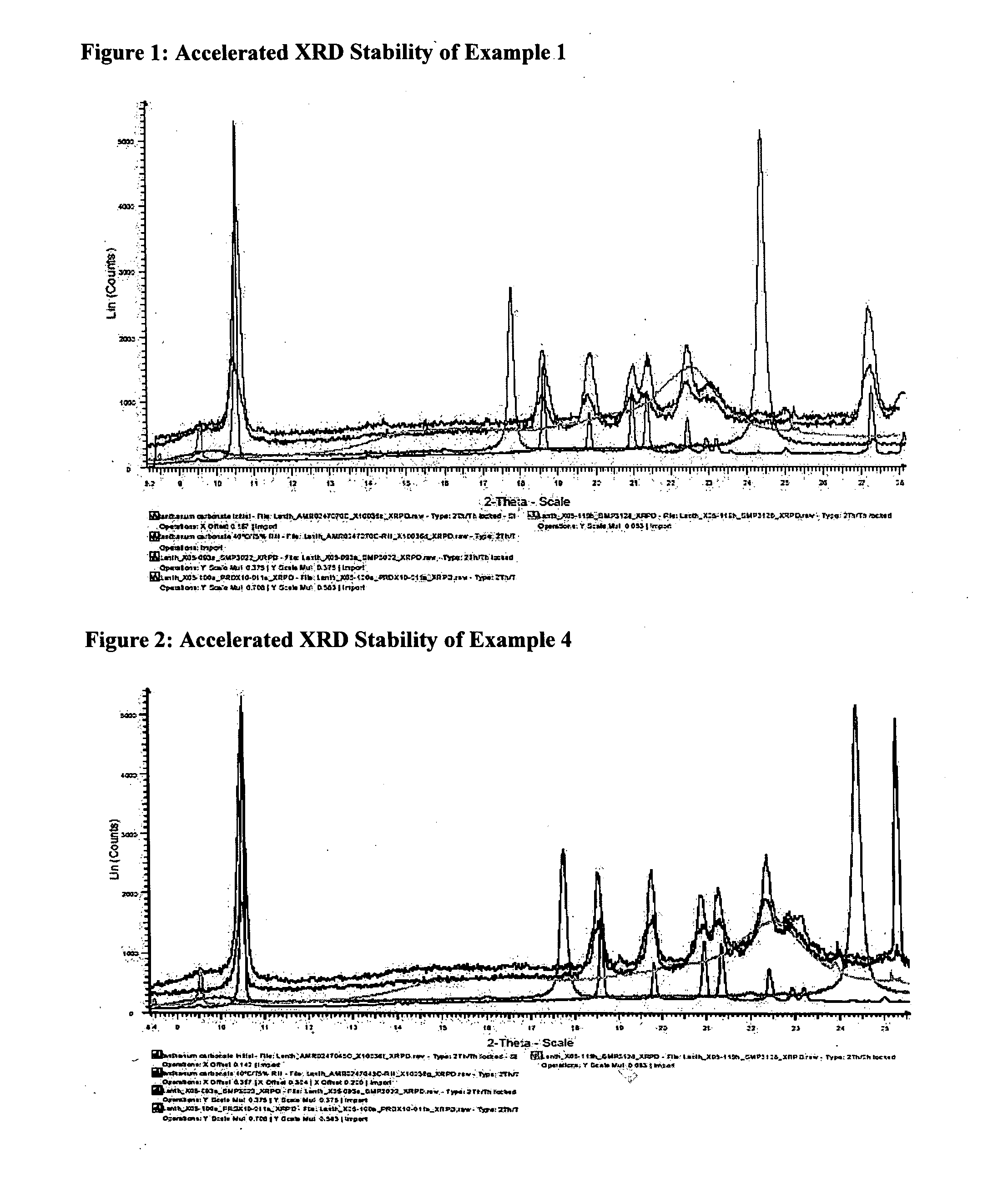

Stabilized lanthanum carbonate compositions

Owner:TAKEDA PHARMA CO LTD

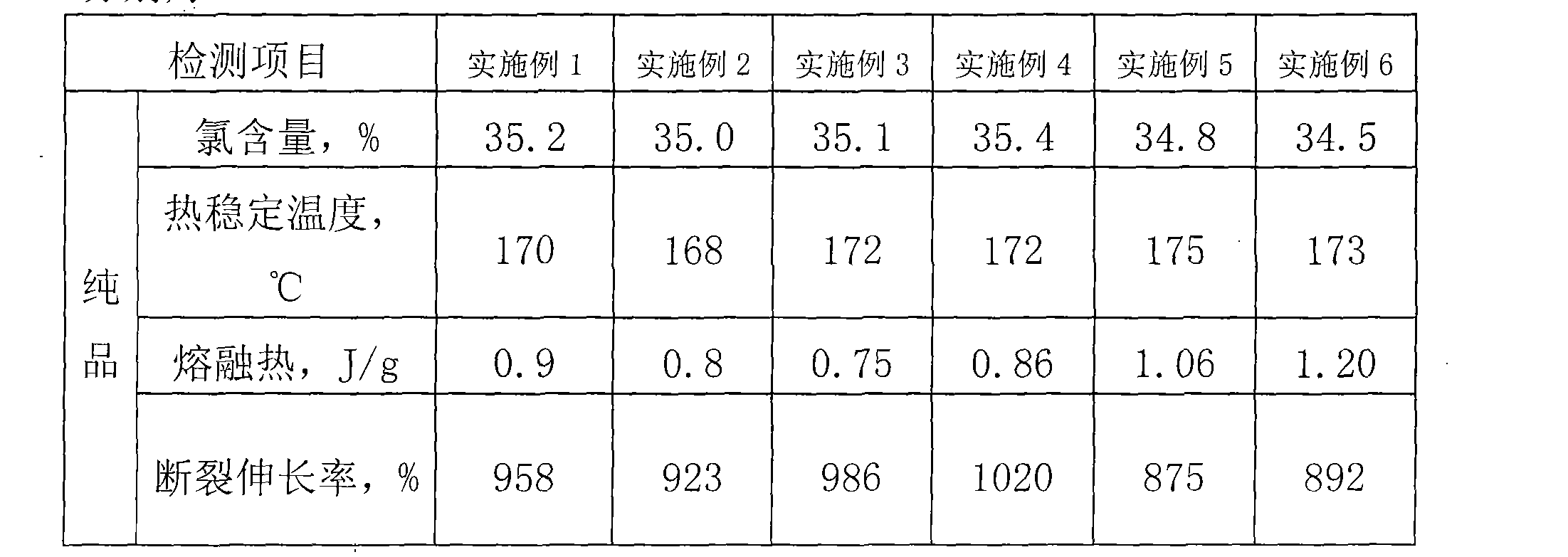

Preparation of chlorinated polythylene

InactiveCN101280030AReduce chlorination timeThe degree of chlorination in depthPolymer scienceChlorinated polyethylene

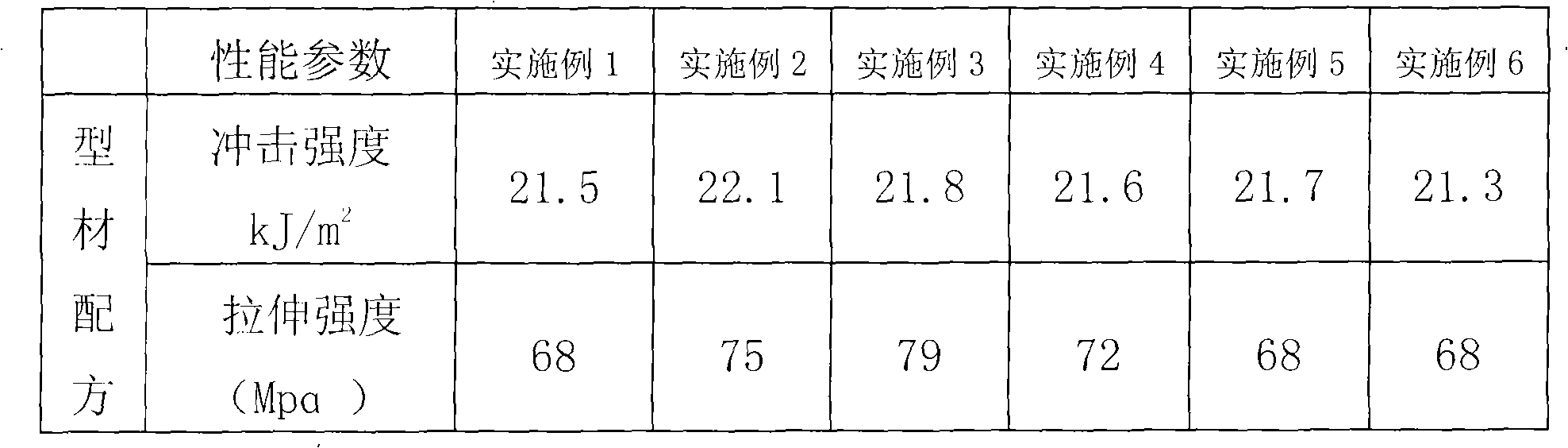

The invention belongs to plastic profile product modifier technical field and discloses a preparation method for a PVC anti-impact modifier chlorinated polyethylene. The invention is mainly technically characterized in that after dispersant, emulsifier, initiator and powdery high-density polyethylene resin are added into a chlorinating reactor with water inside in a stirring state, then the mixture is heated and processed through three chlorine reactions at different temperature ranges; after the reaction, the enwrapped HCl formed in the reactor is discharged; after repeated hot water washing, centrifugal dehydration and drying, calcium stearate, calcium carbonate and lanthanum carbonate are added to obtain the finished product through stirring, mixing and screening. As the high-density polyethylene resin in the preparation technology is high-mesh powdery material and three chlorine reactions are needed in the process, the chlorinated polyethylene prepared by the technology has higher thermal stable temperature and lower melting heat; if the chlorinated polyethylene serves as the anti-impact modifier of PVC products, the PVC product produced thereby has strong impact strength and tensile strength.

Owner:HEBEI JINGXIN CHEM GRP CO LTD

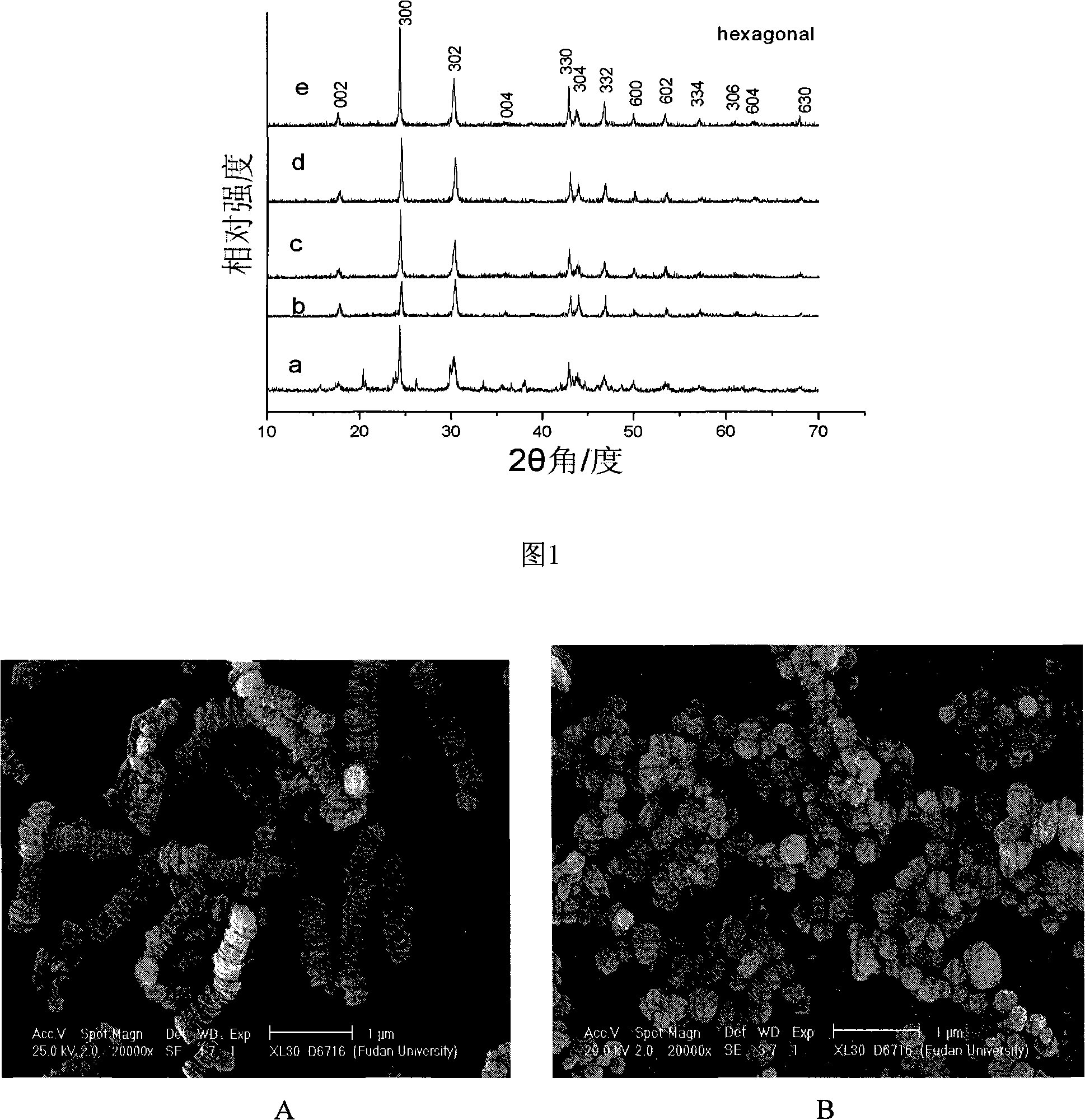

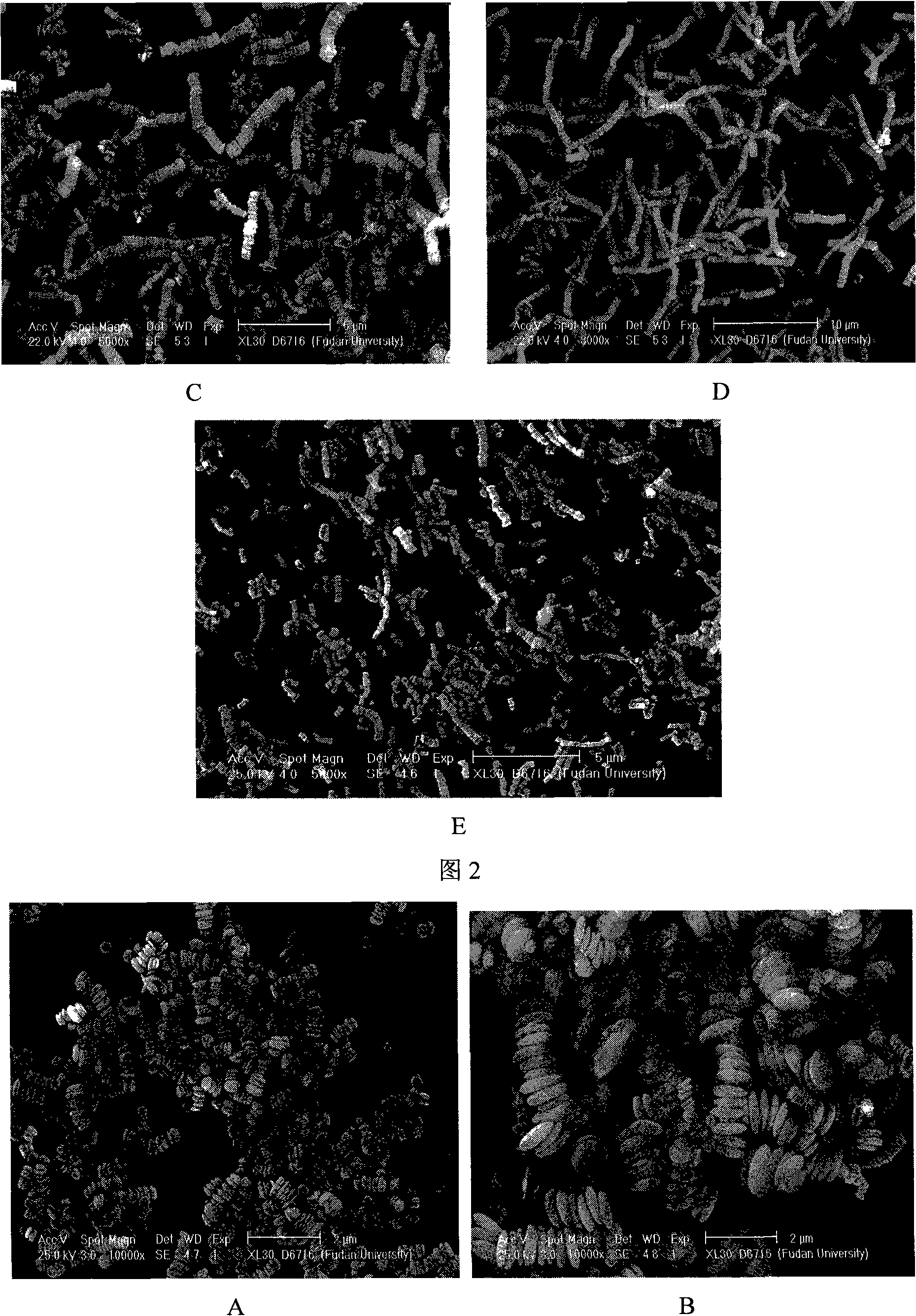

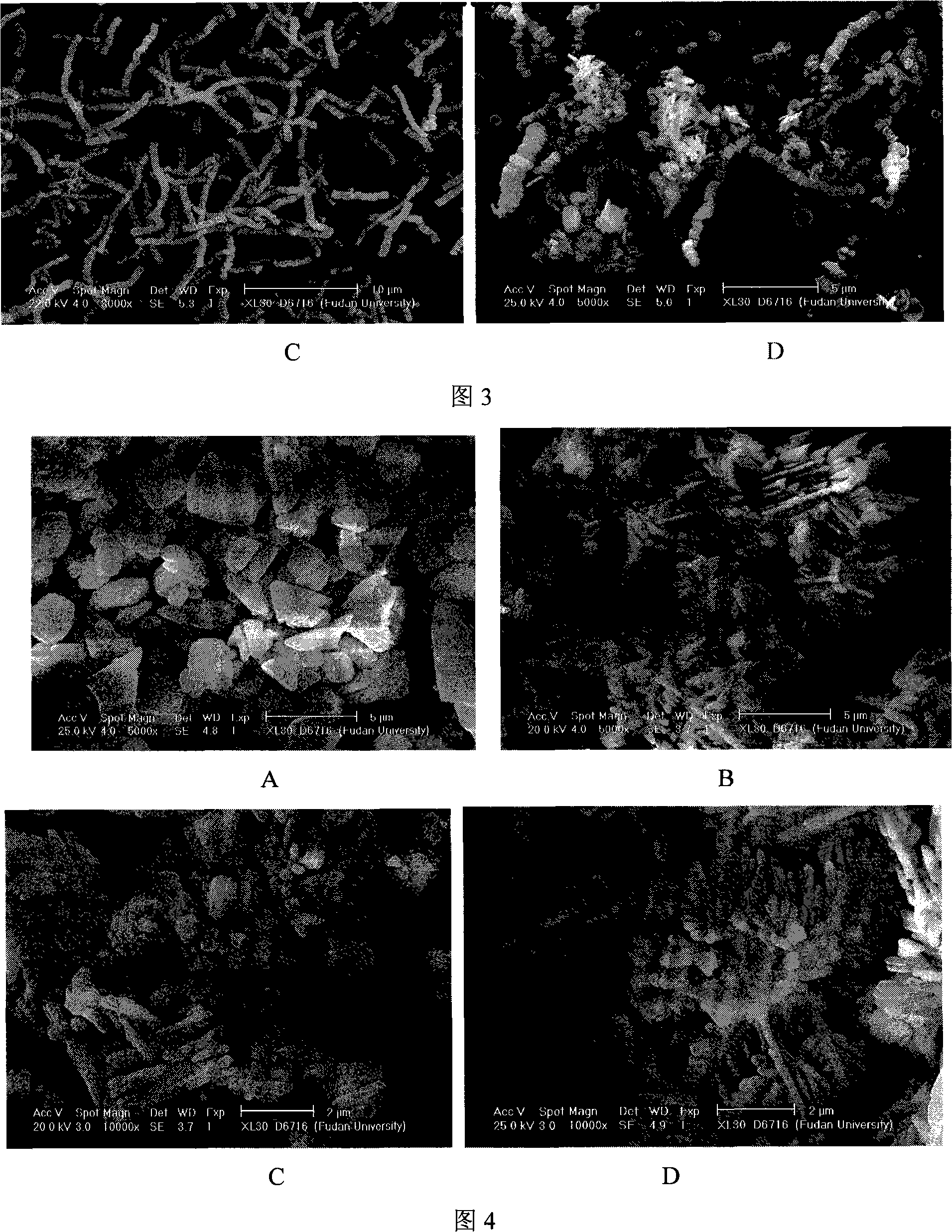

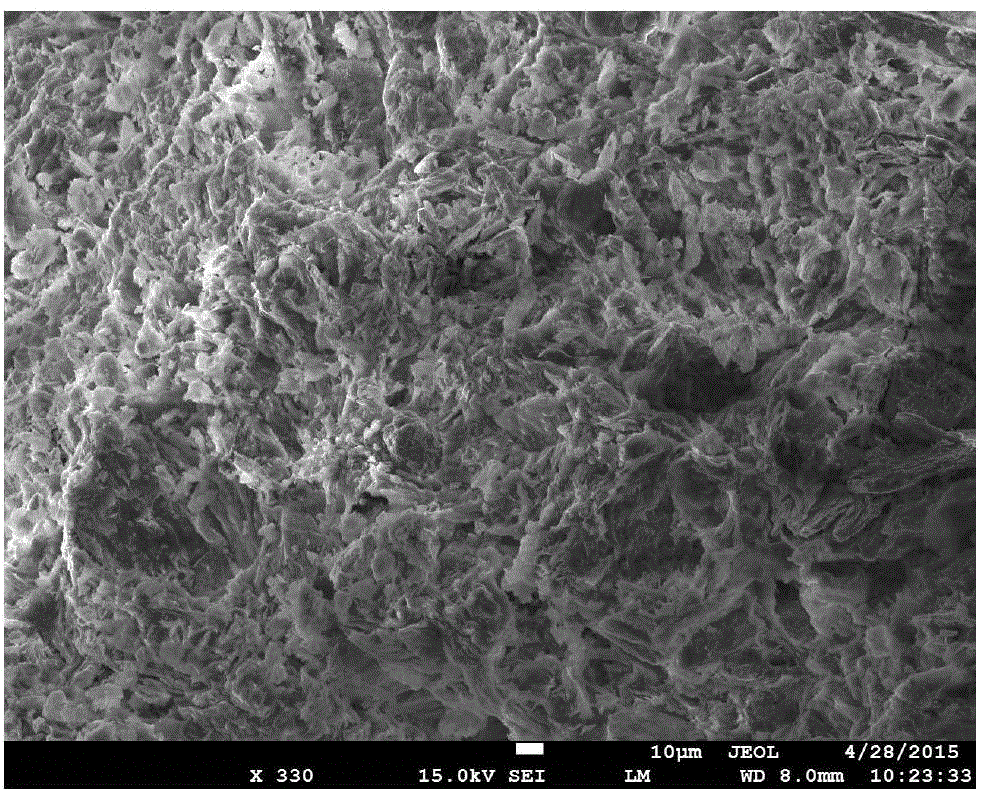

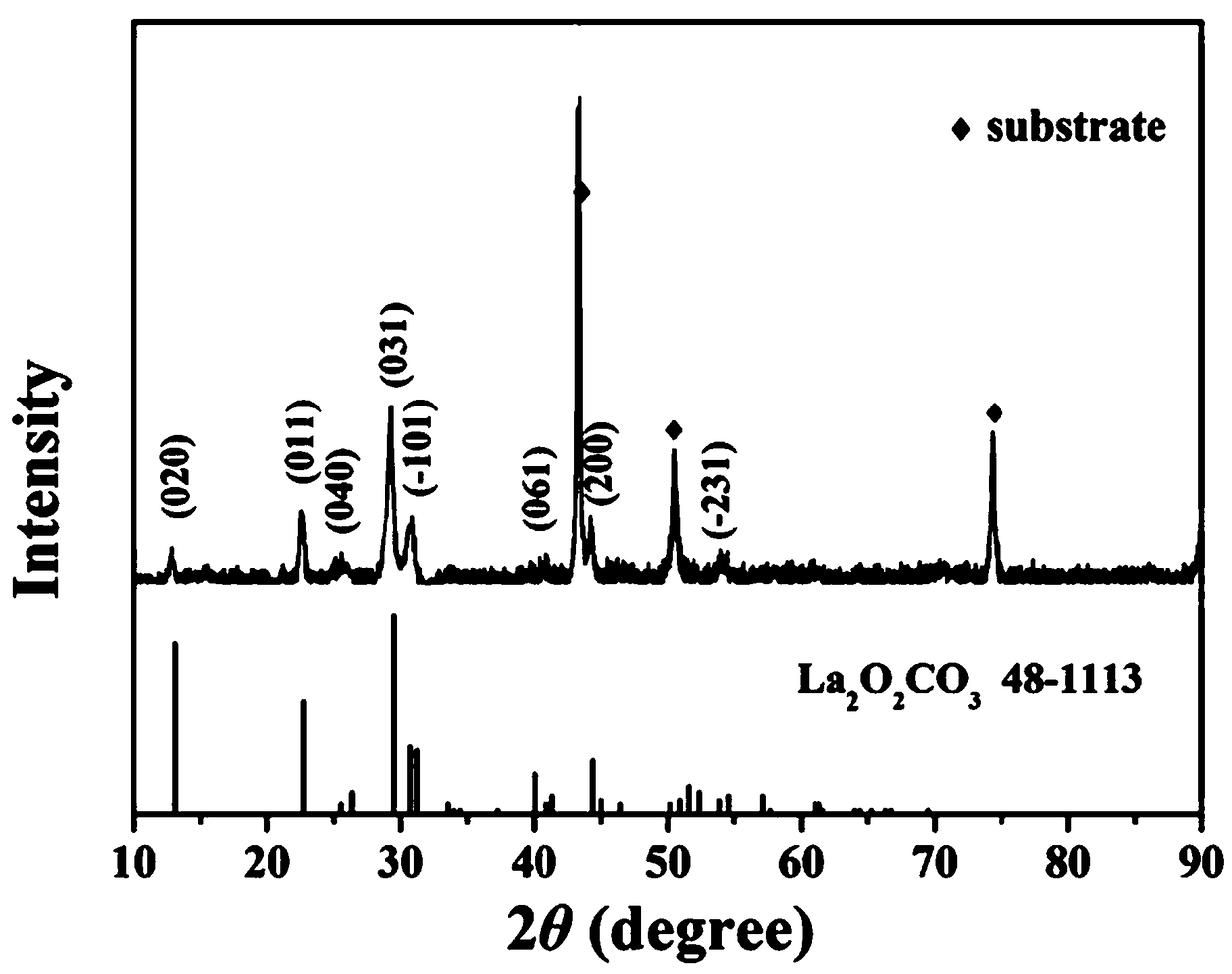

Preparation of pure monoclinic phase thorny-sphere-like lanthanum carbonate oxide (La2O2CO3) three-dimensional multi-stage structure

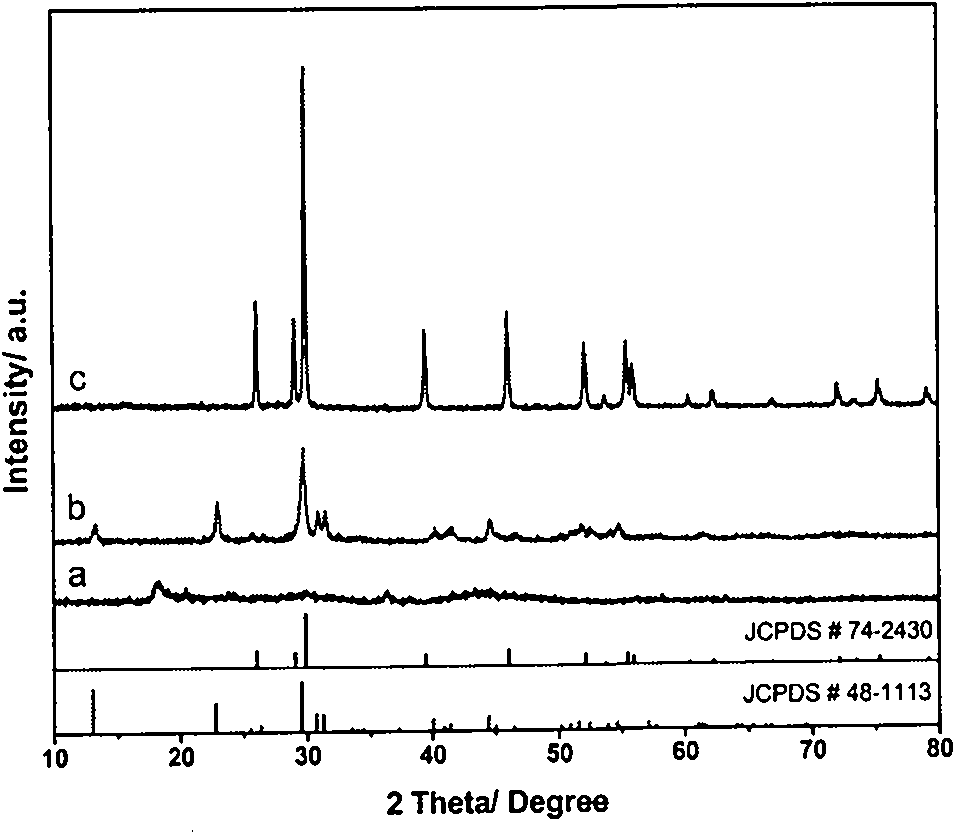

The invention provides a preparation method of a pure monoclinic phase thorny-sphere-like lanthanum carbonate oxide (La2O2CO3) three-dimensional multi-stage structure. A LaCO3OH three-dimensional structure, referred from references, is employed as a raw material and is subjected to high-temperature calcination to prepare the thorny-sphere-like lanthanum carbonate oxide (La2O2CO3) three-dimensional multi-stage structure. The compound can be used as a substrate material of a luminescent material.

Owner:NANJING UNIV

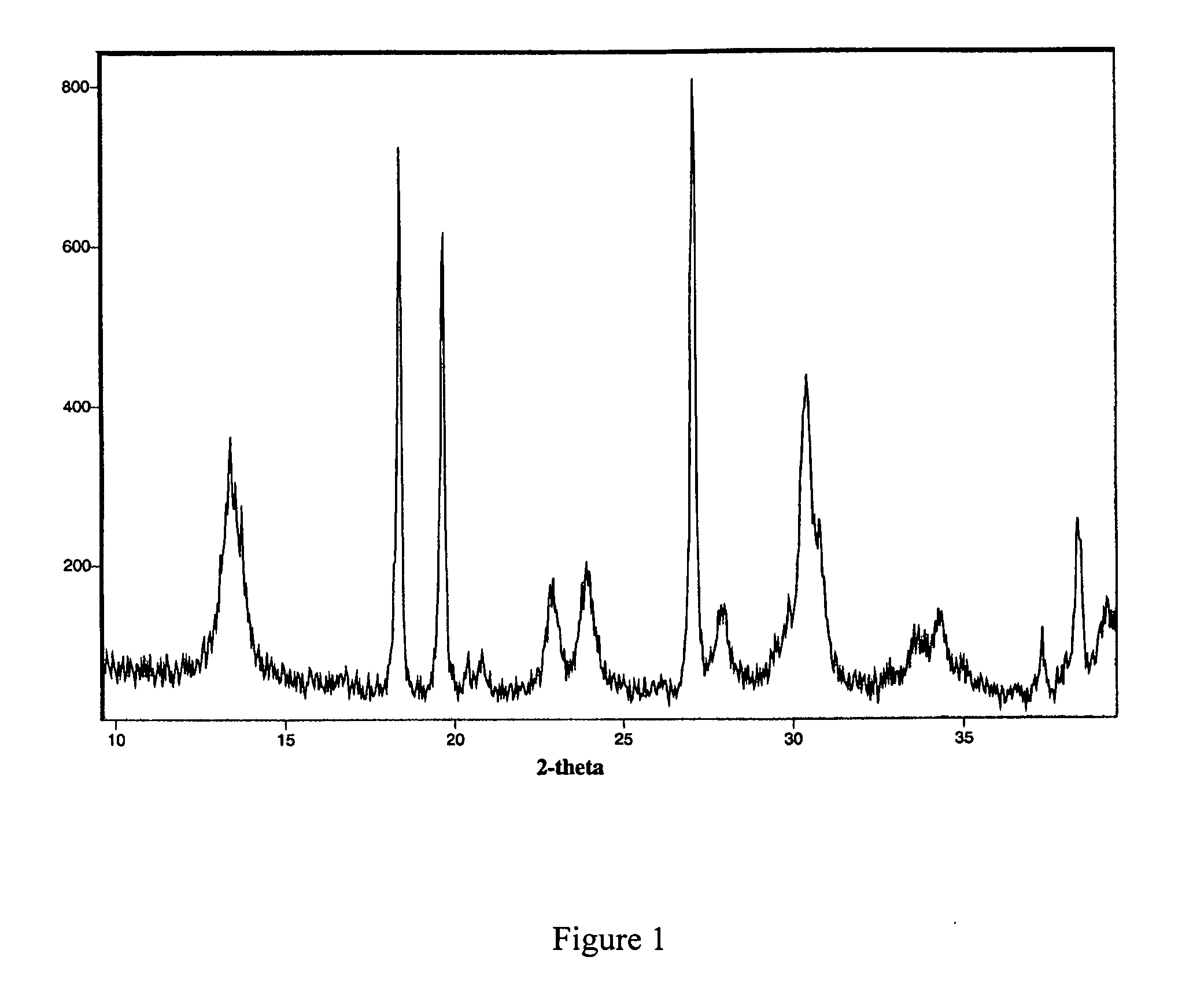

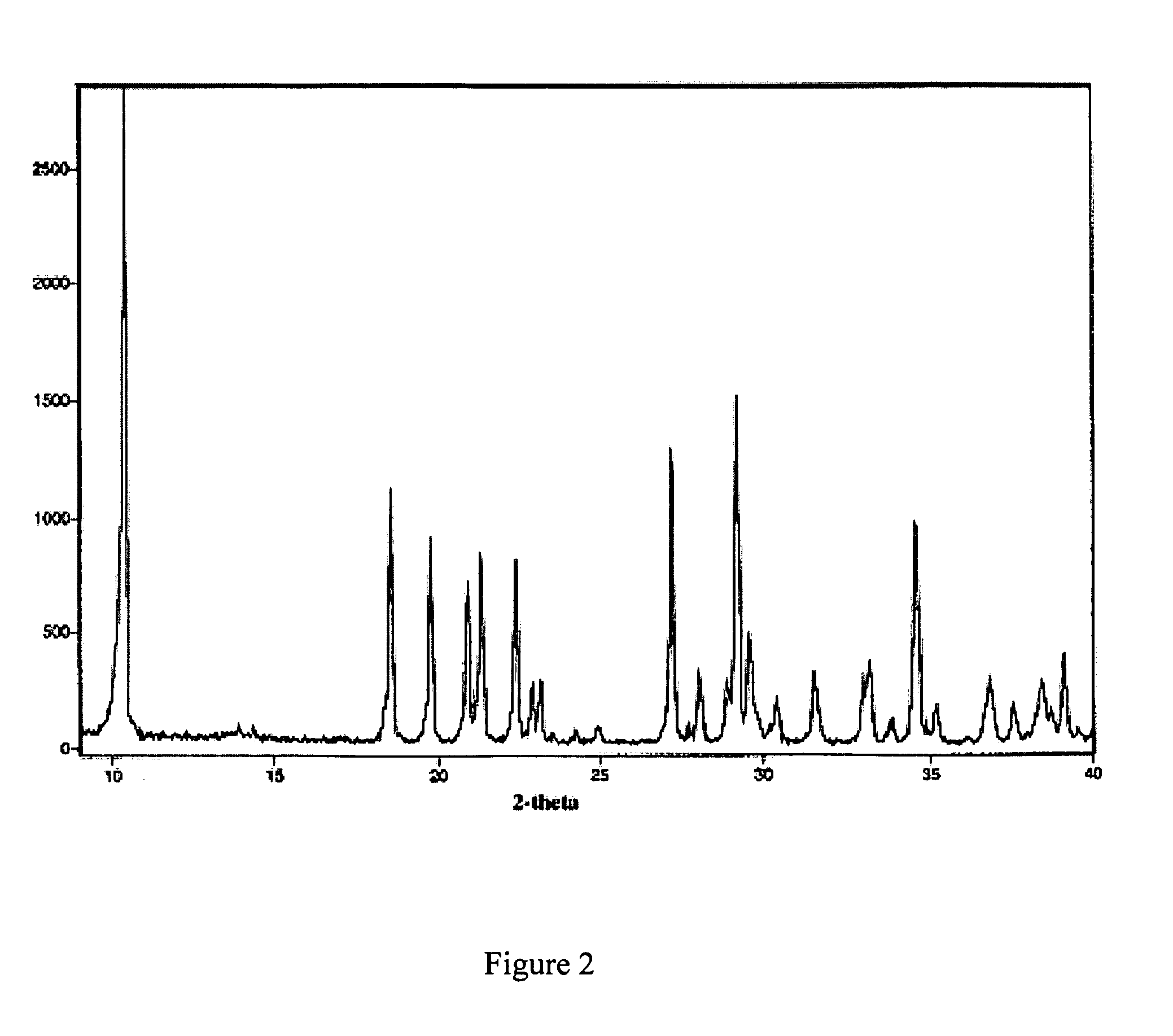

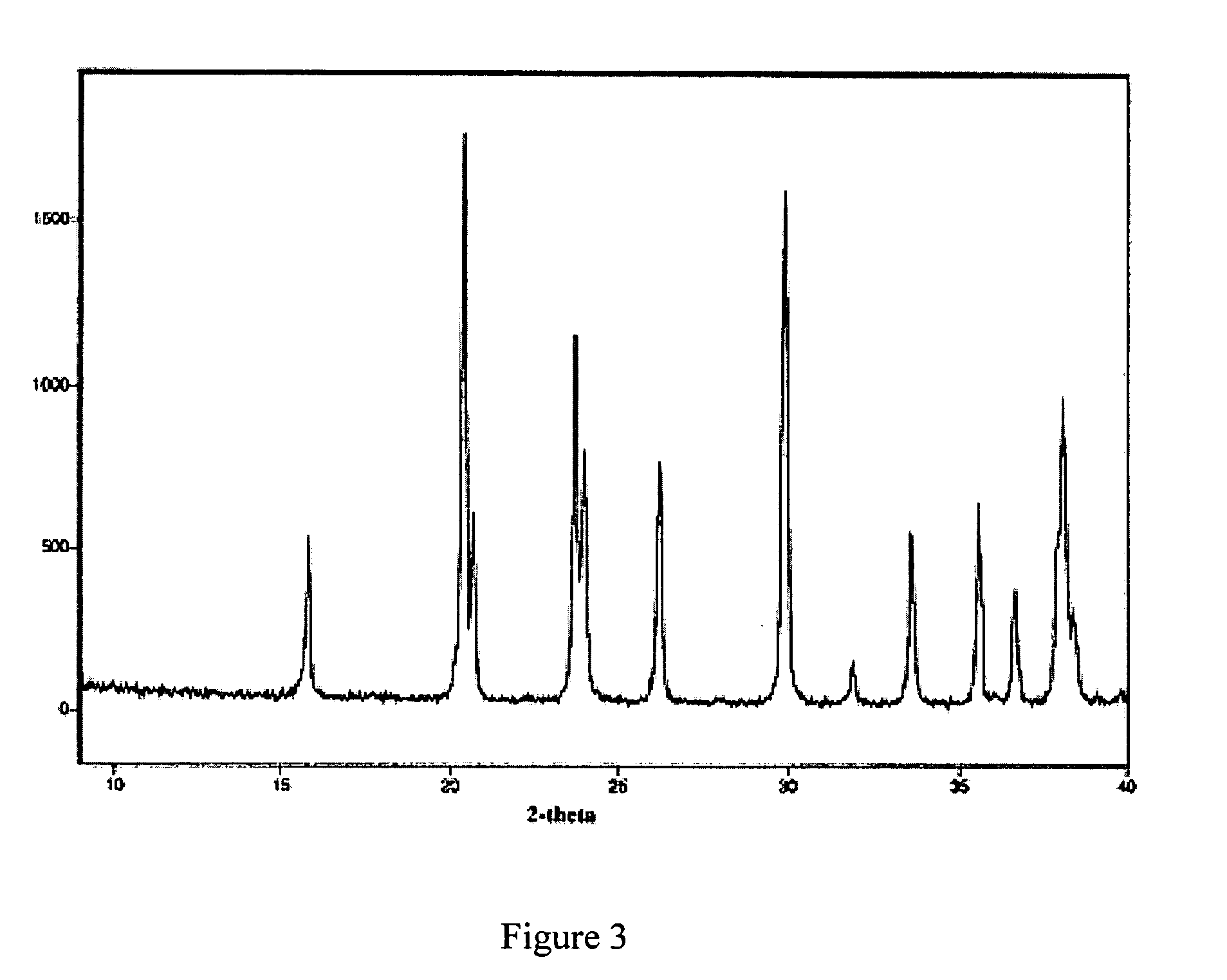

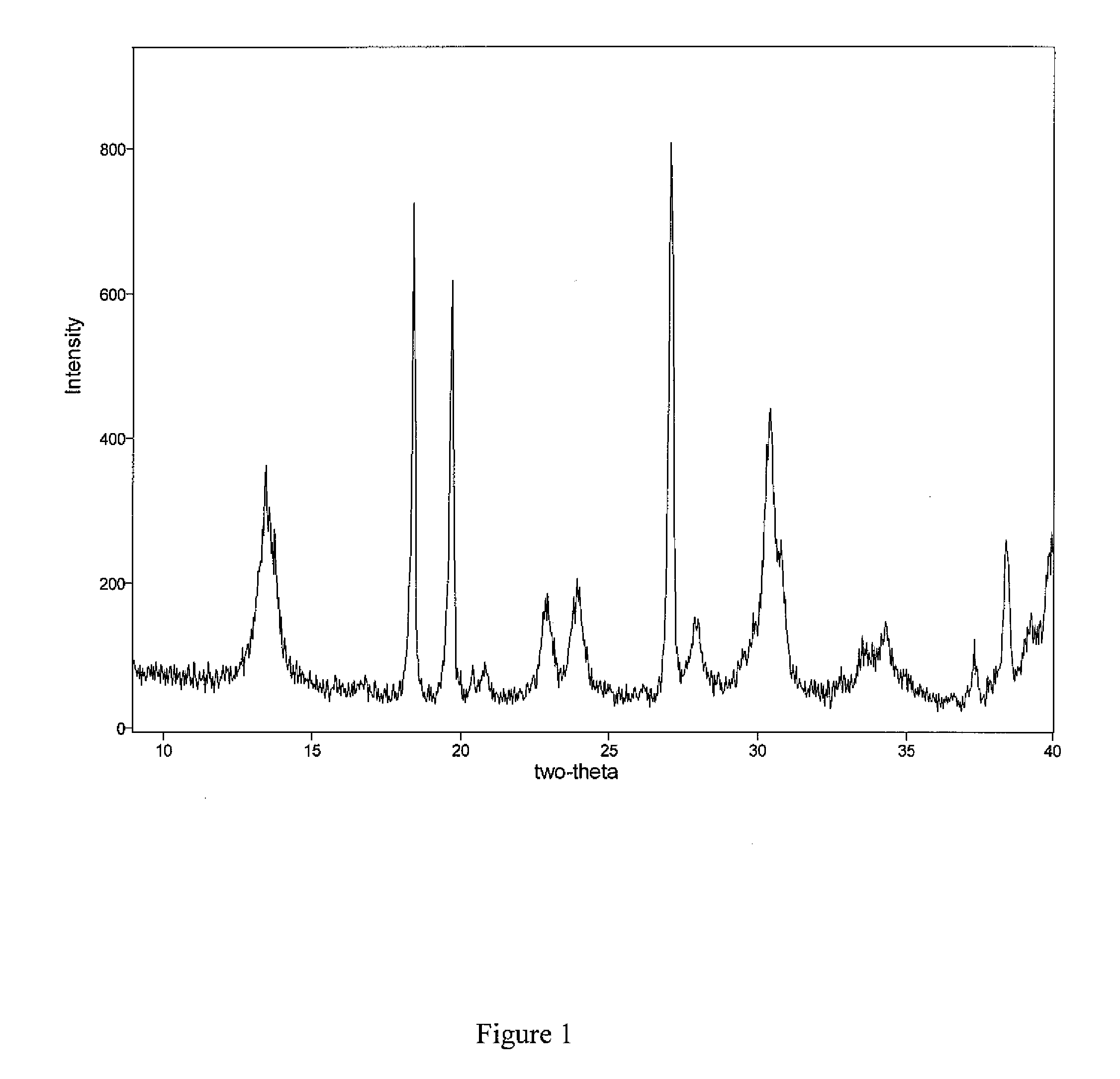

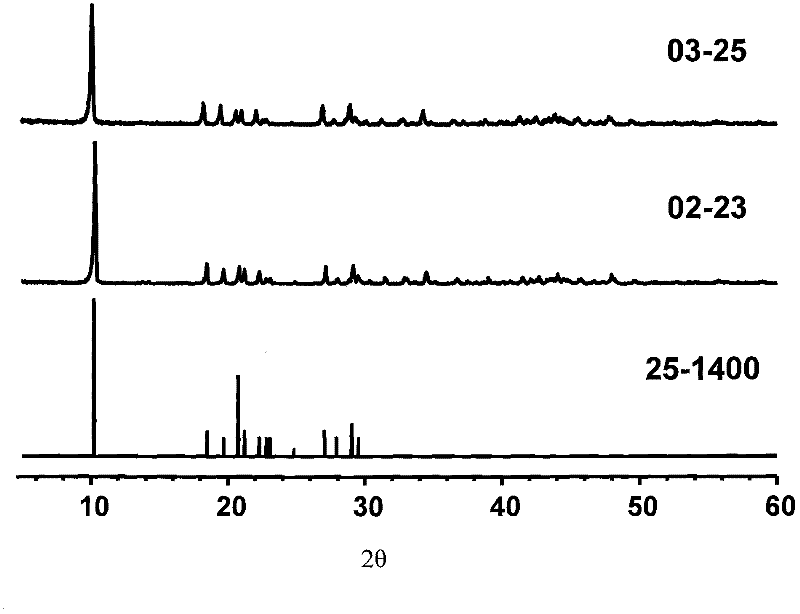

Assay for lanthanum hydroxycarbonate

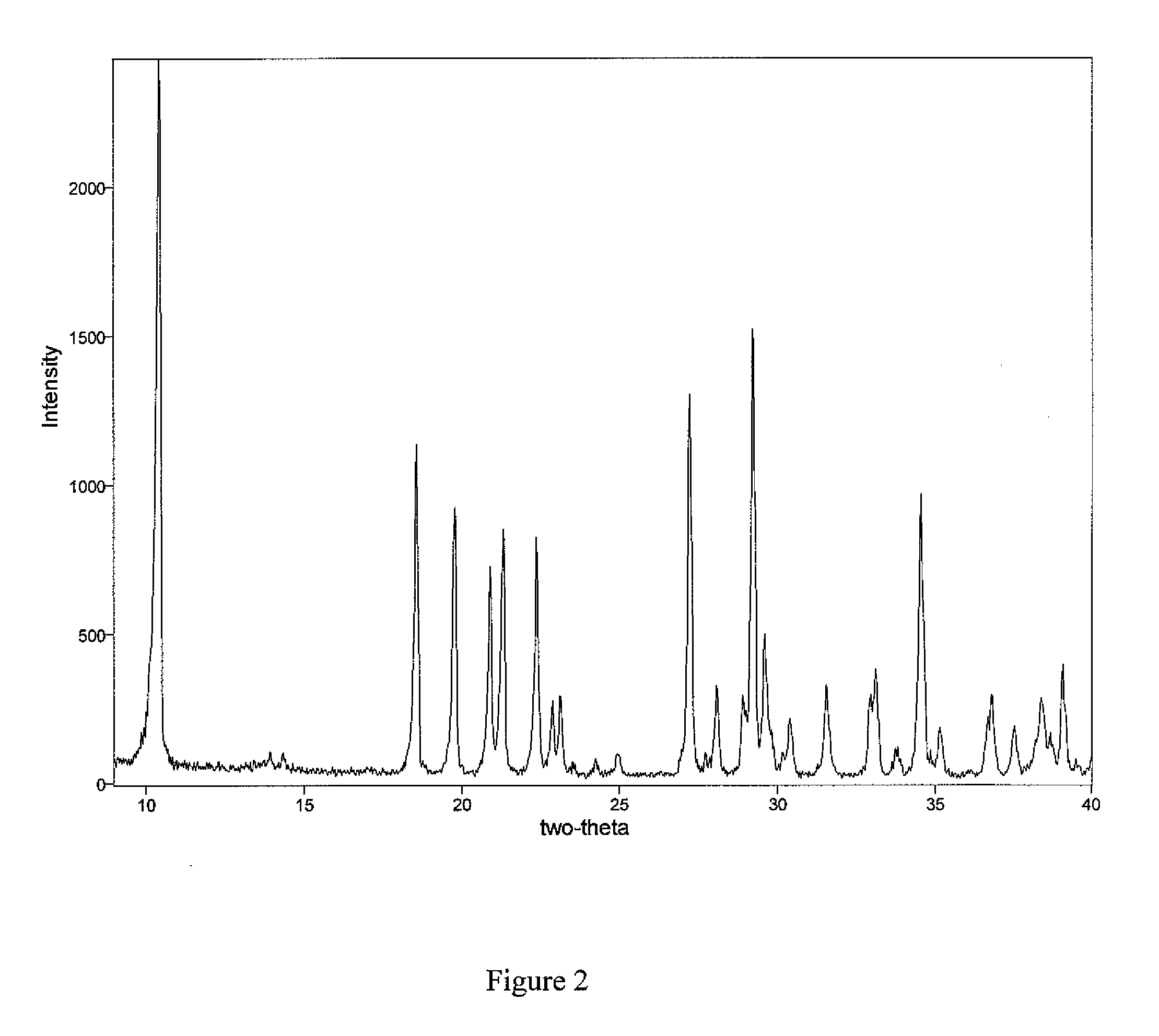

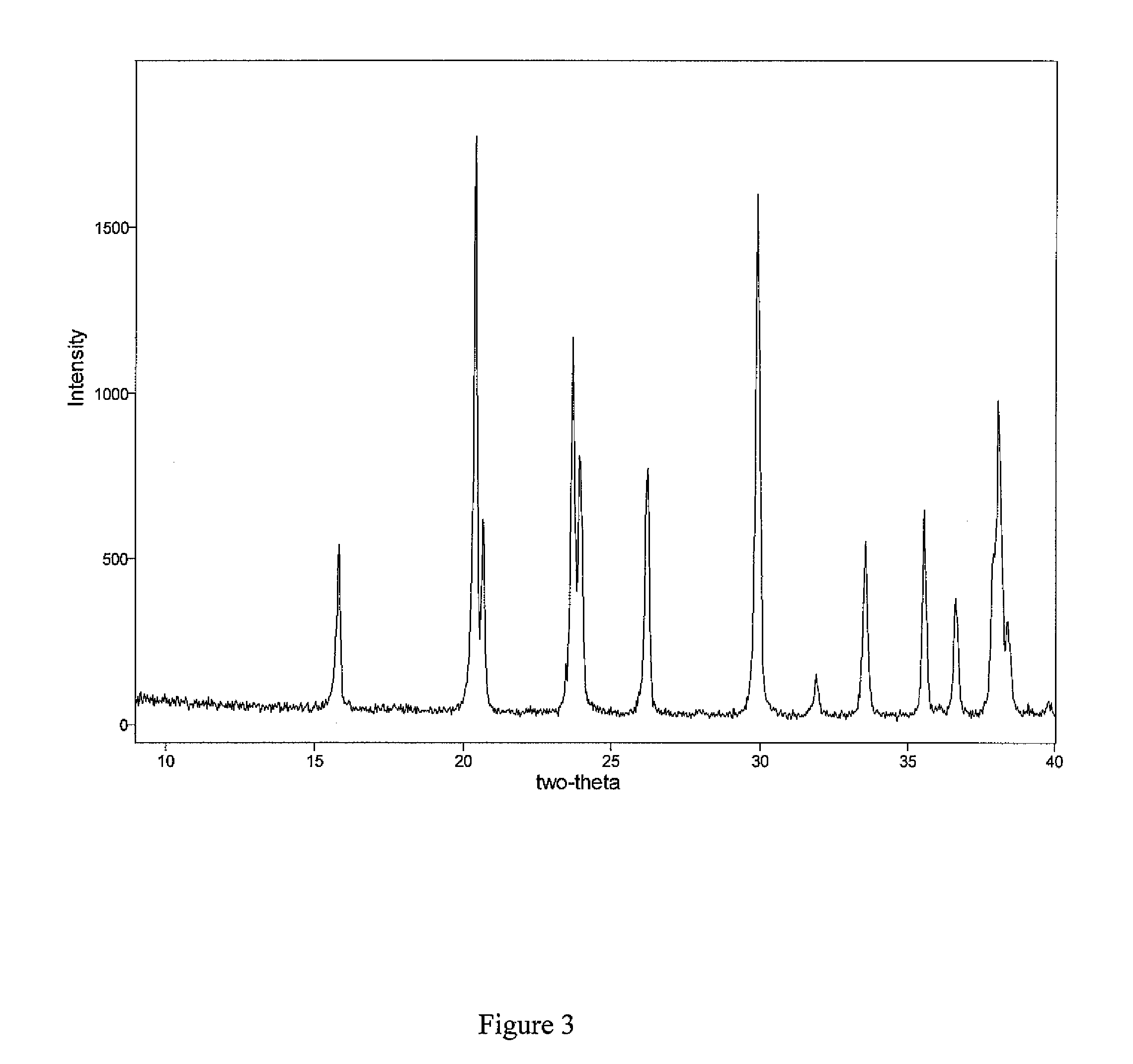

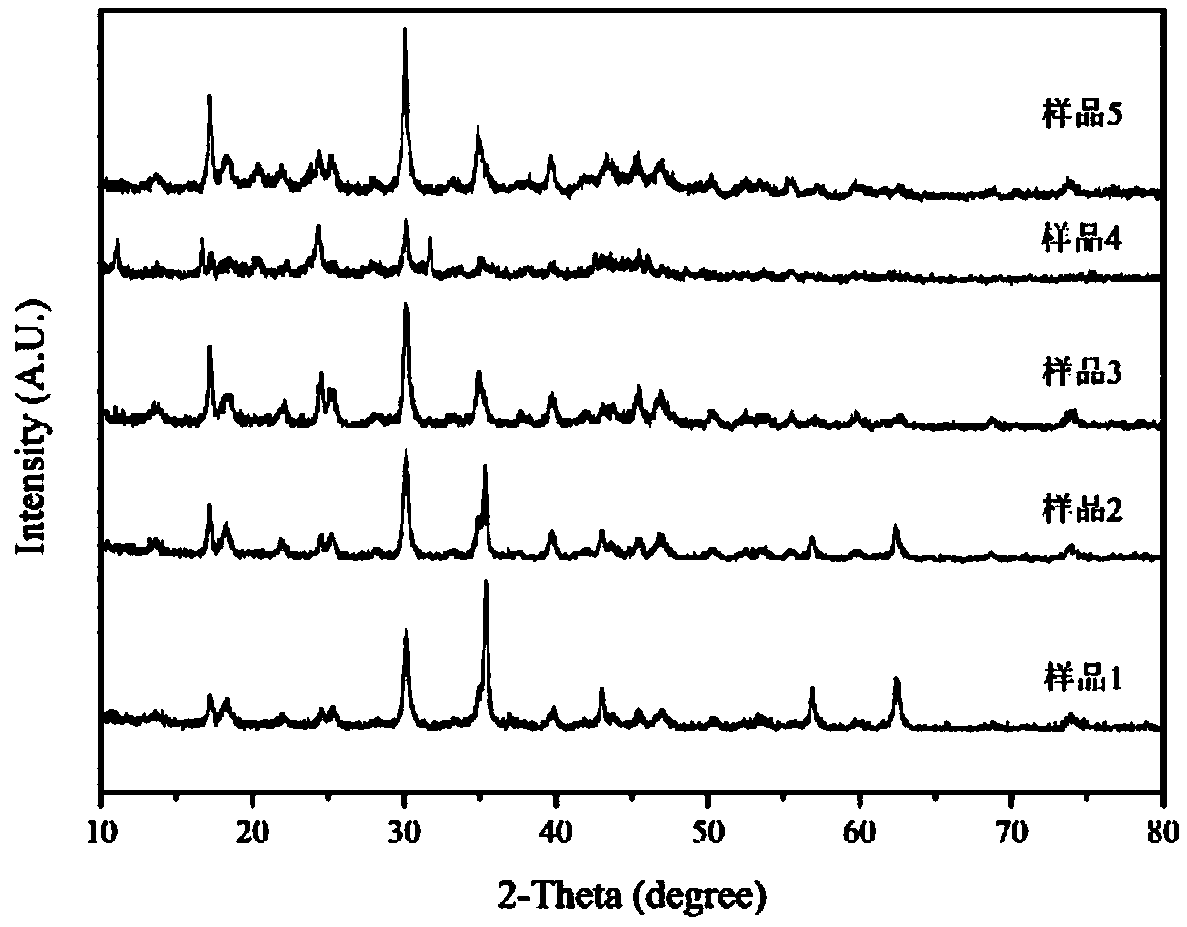

An assay for analytically determining the amount of an impurity in a solid sample is provided. This X-ray diffraction method preferably uses the Rietveld refinement.

Owner:SHIRE INT LICENSING

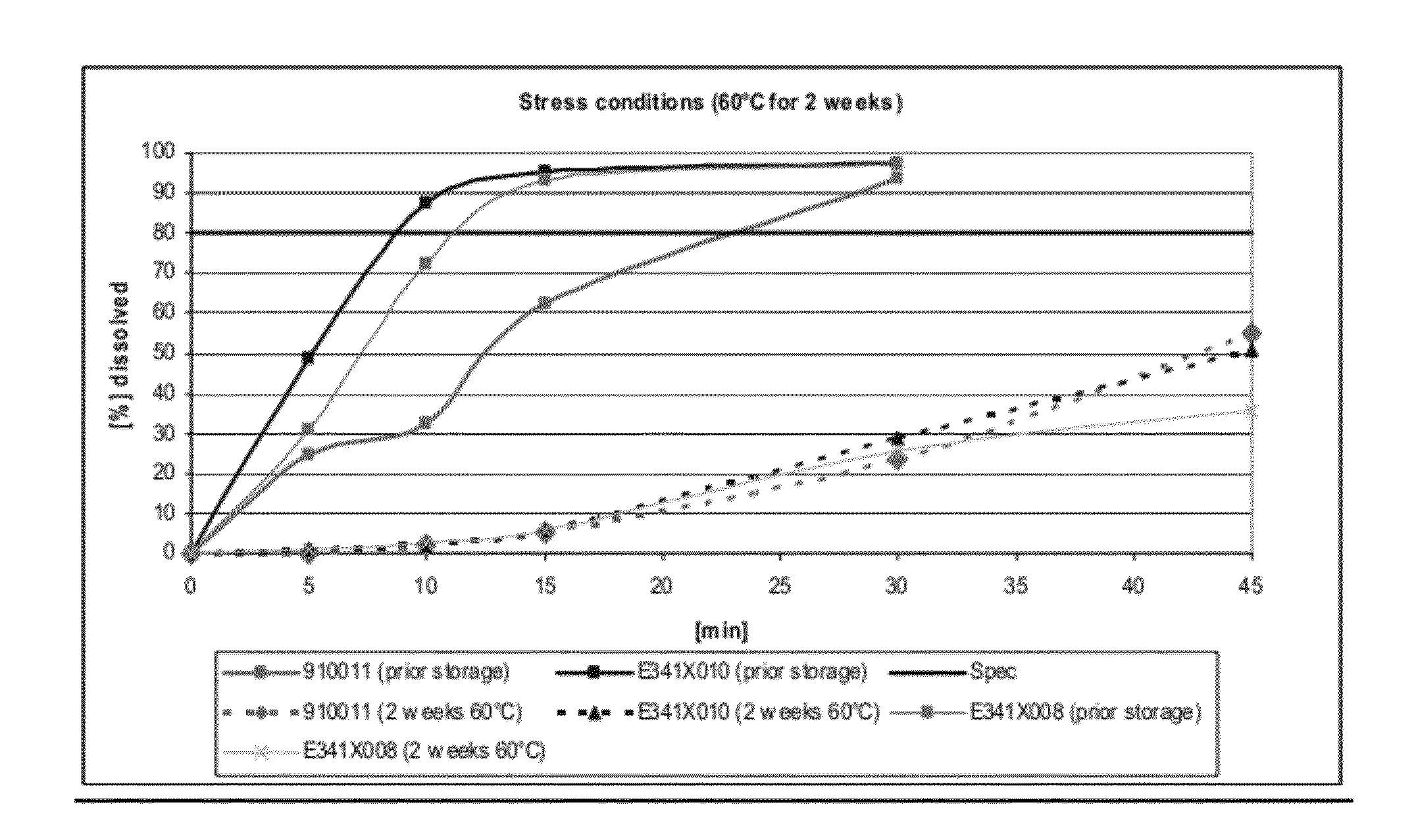

Capsule formulations containing lanthanum compounds

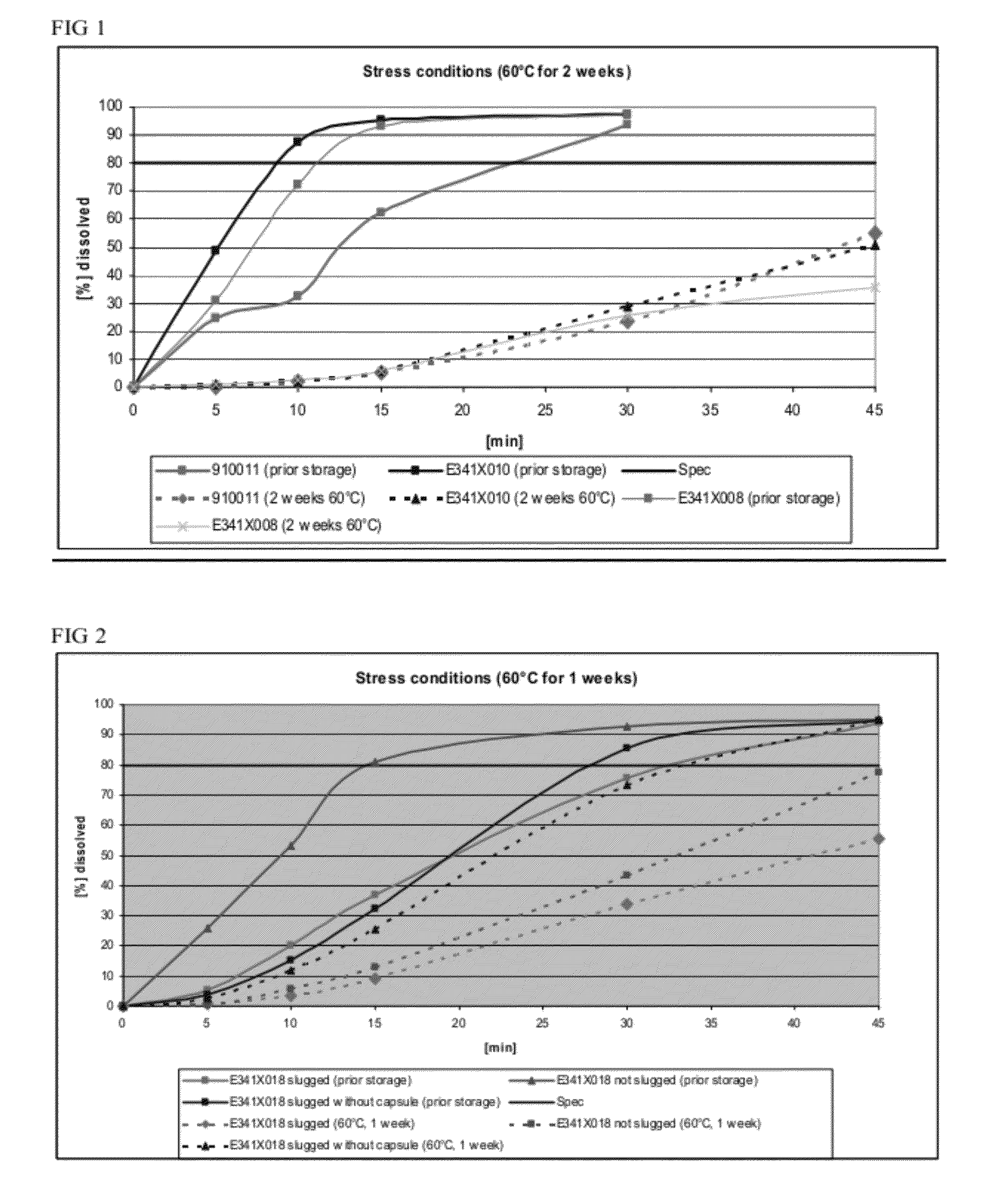

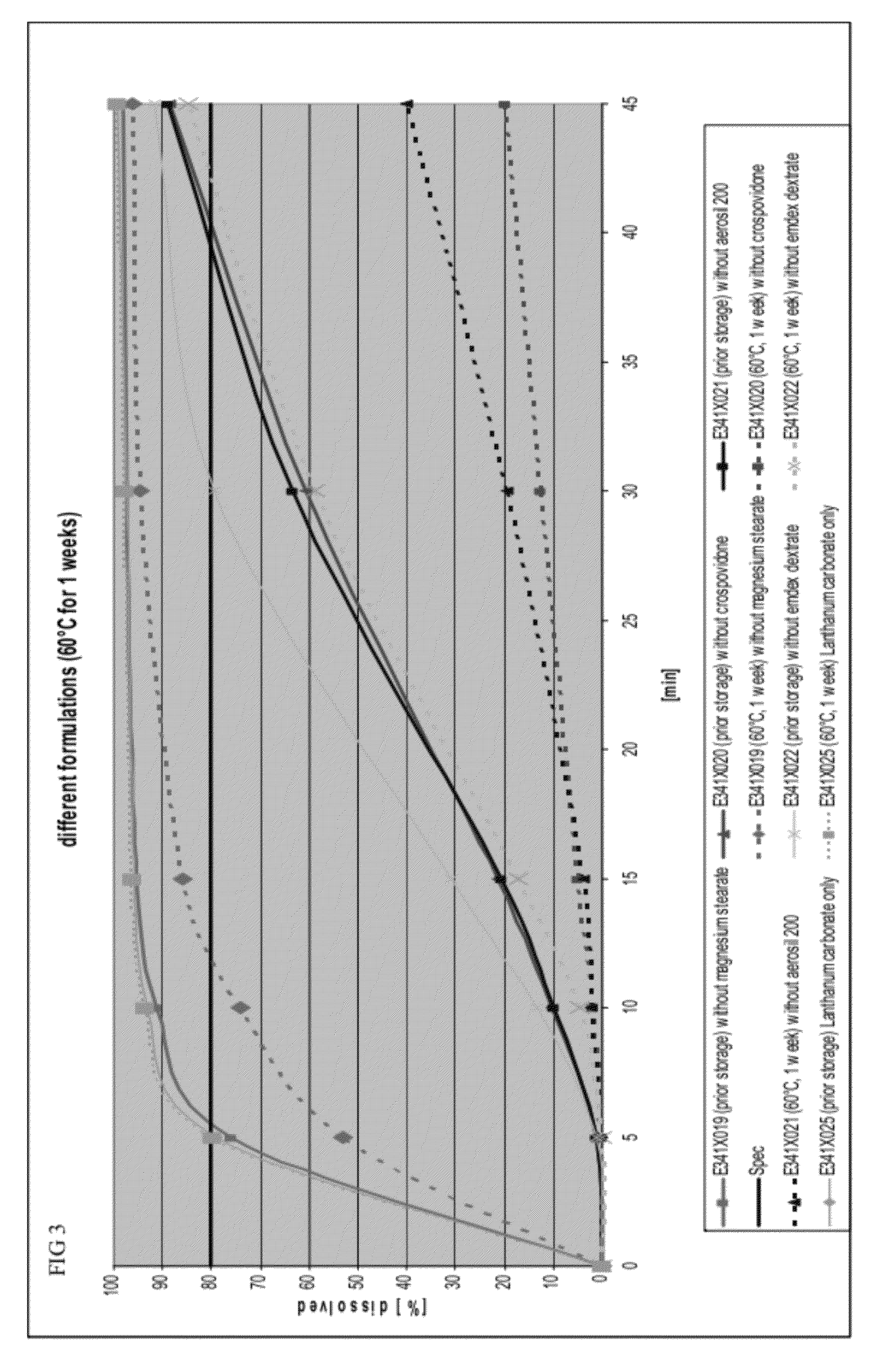

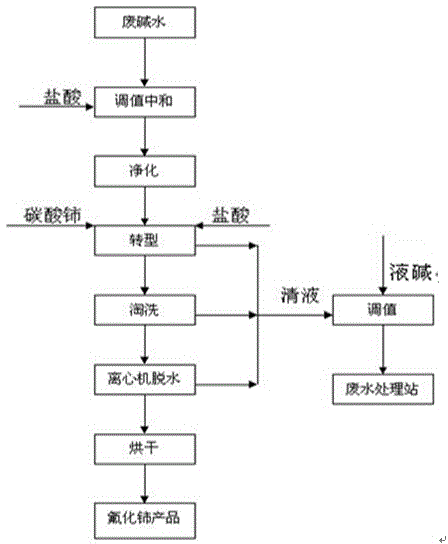

The present invention includes an oral pharmaceutical capsule comprising a shell, lanthanum carbonate or lanthanum carbonate hydrate, and a lubricant such as talc, wherein the shell encapsulates the lanthanum carbonate or lanthanum hydrate and the lubricant. Capsule shells comprise, for example, gelatin. The capsules of the present invention dissolve at a similar rate before and after storage. The oral pharmaceutical capsules of the present invention can be administered to treat a patient at risk for or suffering from hyperphosphatemia, at risk for or suffering from chronic kidney disease (CKD), at risk for or suffering from soft tissue calcification associated with CKD, or at risk for or suffering from secondary hyperparathyroidism.

Owner:SHIRE PLC

Method for fluorine removal of wastewater in bastnaesite hydrometallurgy

ActiveCN103979658AThe process is simple and flexibleEasy to operateWater contaminantsWaste water treatment from metallurgical processWastewaterHydrometallurgy

The invention relates to the field of bastnaesite hydrometallurgy, and in particular relates to a method for fluorine removal of wastewater in bastnaesite hydrometallurgy. A specific scheme comprises the following steps: A. regulating pH value of a fluorine-containing waste liquid to be acid through hydrochloric acid; B. adding cerium carbonate or lanthanum carbonate as well as hydrochloric acid to the waste liquid; C. adding a flocculant to the liquid obtained from reaction of the step B; and D. collecting a flocculating product. Through the method disclosed by the invention, chlorine in the wastewater is nearly completely turned into cerium fluoride; and therefore, the method not only reduces pollution but also facilitates operation.

Owner:SICHUAN PROVINCE LESHAN CITY RUIFENG METALLURGY CO LTD

Method for preparing lanthanum subcarbonate nana-/micro-crystal by double hydrolysis regulation

InactiveCN101279757ANovel and uniformReduce generationRare earth metal compoundsCrystallinitySolvent

The invention belongs to the micron-nanometer material preparation technique and the hydro-thermal synthesis technique field, in particular relates to a process for preparing a basic sodium lanthanum carbonate / micron crystal by means of double-hydrolytic regulation. The process has the specific steps that: a lanthanum oxide and an ammonium bicarbonate or a glycin being taken as precursors and a deionized water as a solvent are positioned in a hydrothermal reaction kettle in proportion, the mole ratio of the lanthanum oxide and the glycin or the ammonium bicarbonate is 1:20 to 1:45, and the added quantity of the deionized water is between 50 and 80 percent of the volume of a container; the hydrothermal reaction kettle provided with mixtures is put into a box-type resistance furnace for being heated to the temperature of between 150 and 220 DEG C, and the container is taken out after the 8 to 48h heating at such a temperature and is cooled naturally to the room temperature; and the needed product is obtained after washing and centrifugal separation. The preparing process has advantages of simple process, easy building of the whole preparing system, simple and convenient operation, easy control of conditions, low cost, easy control of the appearance and size of the product, high purity, good crystallinity and convenient and brief product treatment, and is applied to the mass industrial production.

Owner:TONGJI UNIV

Daily ceramic glaze with high refractive rate and preparation technique thereof

The invention relates to daily ceramic glaze with a high refractive rate and a preparation technique thereof, which belongs to the field of the preparation of ceramics. The daily ceramic glaze with high refractive rate comprises the following raw materials by weight percent: 36-38% of potash feldspar, 10-12% of kaolin, 4.5-5.5% of barium carbonate, 2.6-2.8% of strontium carbonate, 1.2-1.4% of lanthanum carbonate, 1.6-1.8% of lithium carbonate, 5.5-6.5% of zinc oxide and 34-36% of quartz. The daily ceramic glaze with high refractive rate is prepared by the steps of proportioning, ball milling,iron removing, sieving, aging and the like according to the mixture ratio of the raw materials. By adopting the daily ceramic glaze with high refractive rate and the preparation technique thereof, thefiring range of the glaze is wide, the glaze is free from the influence of a firing atmosphere, a fired porcelain has gorgeous and delicate colour, the glossiness of a glaze layer is as high as 108,and the quality and the grade of a daily ceramic product are greatly enhanced.

Owner:GUANGDONG SHUNXIANG PORCELAIN

Method of use for lanthanum carbonate and lanthanum hydroxycarbonate

A method for treating hyperphosphatemia using lanthanum carbonate, including analytically determining the amount of an impurity in the lanthanum carbonate sample is provided. This X-ray diffraction method preferably uses the Rietveld refinement.

Owner:SHIRE INT LICENSING

Porous phosphorus removal ceramisites and preparation method thereof

InactiveCN104876639ARealize resource utilizationLarge specific surface areaCeramicwareClaywaresPhysical chemistryStrong acids

The invention provides porous phosphorus removal ceramisites and a preparation method thereof. The ceramisites are prepared from the following raw materials in parts by weight: 55-85 parts of attapulgite, 10-30 parts of crop straws and 10-20 parts of lanthanum carbonate. The raw materials are subjected to the steps of blending, preparing a blank, sintering and cooling to prepare the porous phosphorus removal ceramisites. The ceramisites provided by the invention are simple in preparation process and high in adsorption rate, the cylinder pressure strength meets cylinder requirements on high-strength lightweight aggregates in national standards, the phosphorus adsorption capacity of the ceramisites in a wide pH value range of 1-12 is high, and the maximum phosphorus removal rate can reach 98.6%. Because the ceramisites have strong acid and alkali resistance, after adsorbing phosphorus and being eluted by a sodium hydroxide solution, the porous phosphorus removal ceramisites not only can realize recovery of adsorbed phosphorus but also can be obtained again, and are convenient to recycle, so that resources can be effectively saved. The ceramisites can be widely applied to the field of practical engineering to achieve an aim of treatment of wastes with processes of wastes against one another.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

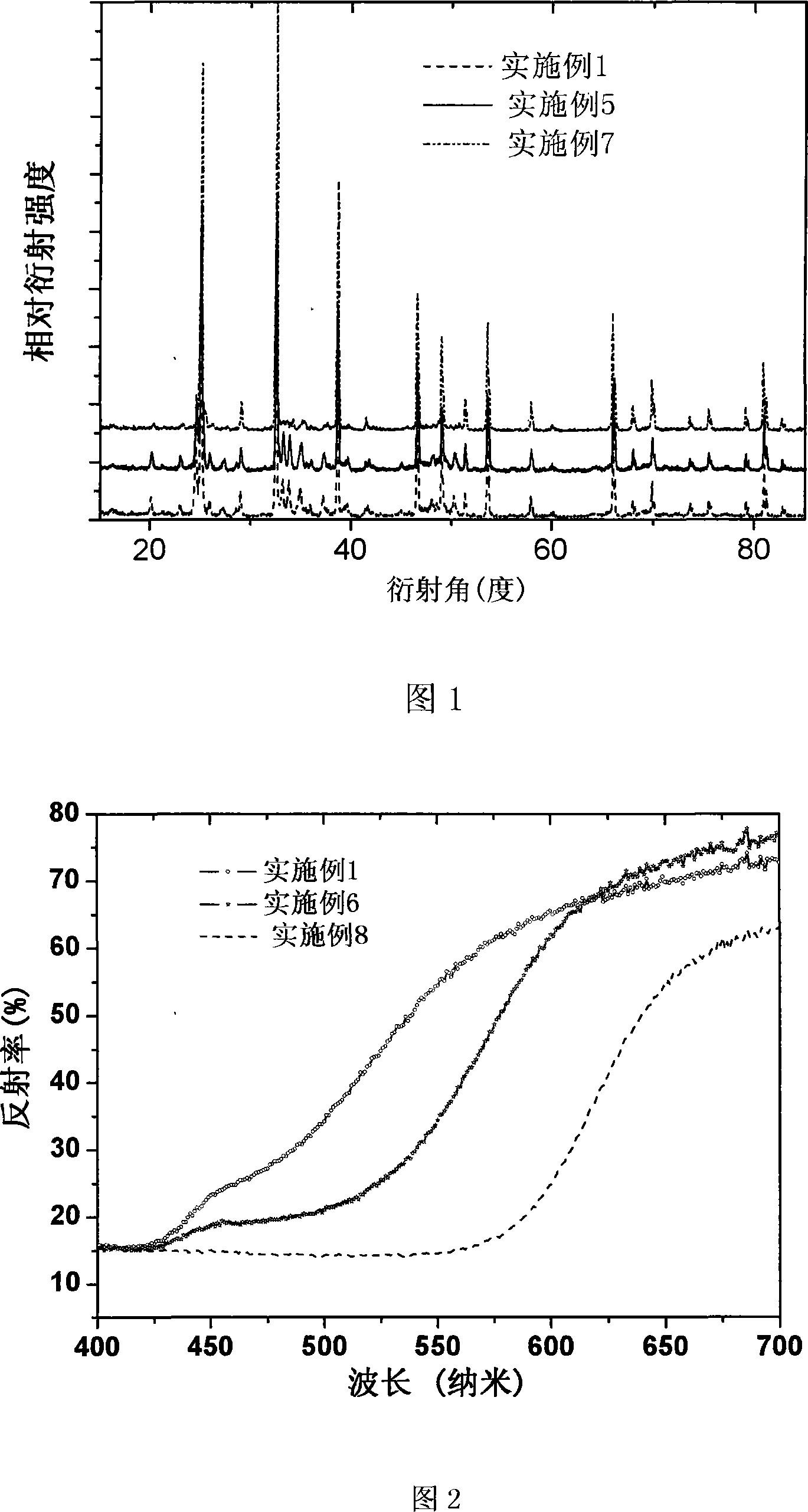

Tin-doped (IV) sulfide lanthanum pigment and preparation method thereof

InactiveCN101200604AIncrease contentAbundant and relatively cheapInorganic pigment treatmentTin dioxideRare earth

The invention relates to sn-doped (IV) lanthanum sulfide pigment and a preparation method thereof. The pigment chemical formula is SnxLa<2-x>S<3+x / 2>, wherein, x is less than or equal to 0.5 and more than or equal to 0, and the color can gradually transit from yellow to orange and red. The raw materials of tin dioxide and rare earth lanthanum oxide (or lanthanum carbonate) are uniformly mixed and are put in a reaction furnace then. The inert gas of nitrogen or argon and sulfur source gas are input. Through a certain period of high temperature reaction, the sn-doped rare earth lanthanum sulfide pigment is obtained after being cooled. Through regulating the doping amount of tin, a series of nontoxic pigments continuously changing from yellow to red can be obtained. The invention can be widely applied to coloring the building materials of plastics, paints, coatings, rubbers, leather, ceramics, inks, paper, cosmetics, cement, etc.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Preparation method of low-impurity-entrainment lanthanum carbonate or cerium lanthanum carbonate

ActiveCN105502470AReduce concentrationConcentration is not dilutedRare earth metal carbonatesCeriumManganese

The invention relates to a preparation method of low-impurity-entrainment lanthanum carbonate or cerium lanthanum carbonate. The preparation method is characterized in that a lanthanum carbonate or cerium lanthanum carbonate solution is taken as a feed solution, an ammonium bicarbonate solution is taken as an ammonium bicarbonate, and new water or carbon precipitation supernatant is left at the bottom of a precipitation reaction kettle to serve as a base solution. The preparation method comprises the following steps: adding lanthanum carbonate or cerium lanthanum carbonate seed crystal in which seed crystal REO (Rare Earth Oxide) to feed solution REO is 1 percent by weight to 10 percent by weight; adding rare earth chloride and the ammonium bicarbonate solution into a reaction kettle at the same time at 20-50 DEG C to carry out a precipitation reaction, wherein the adding rate ratio is 1:1-3:1; at the end of the reaction, performing solid-liquid separation and water washing to obtain a carbonate lanthanum or cerium lanthanum carbonate product. The preparation method has the advantages that the process parameters of feeding way, relative feeding rate, precipitation pH value and final pH value of a ammonium bicarbonate precipitation lanthanum carbonate or cerium lanthanum carbonate solution are adjusted, so that manganese, copper and the like do not undergo the precipitation reaction, and the formed carbonate lanthanum or cerium lanthanum carbonate product has the characteristics of less soft agglomeration, small crystalline grain size and less entrainment of manganese and copper impurities.

Owner:NAT ENG RES CENT OF RARE EARTH METALLURGY & FUNCTION MATERIALS +2

Nano lanthanum carbonate and orally disintegrating tablet and preparation method

InactiveCN101077338AEvenly dispersedAvoid reunionHeavy metal active ingredientsPill deliveryAdditive ingredientMedicine

The present invention is orally disintegrated nanometer lanthanum carbonate tablet and its preparation process. The orally disintegrated nanometer lanthanum carbonate tablet is prepared through one dry tabletting process, which includes the steps of drying the main medicine ingredient and supplementary material, including disintegrant, stuffing, effervescent, etc, sieving and tabletting; or one wet tabletting process, which includes the steps of mixing the main medicine ingredient and partial supplementary material, including disintegrant, stuffing, corrective, etc, sieving, drying, mixing with the other supplementary material and tabletting. The tabletting pressure is 2-15 MPa, and prepared orally disintegrated tablet has hardness of 2-5kg and extracorporeal disintegrating period of 20-80 sec. The orally disintegrated nanometer lanthanum carbonate tablet has high bioavailability, small dosage and high patient' s compliance.

Owner:TIANJIN UNIV

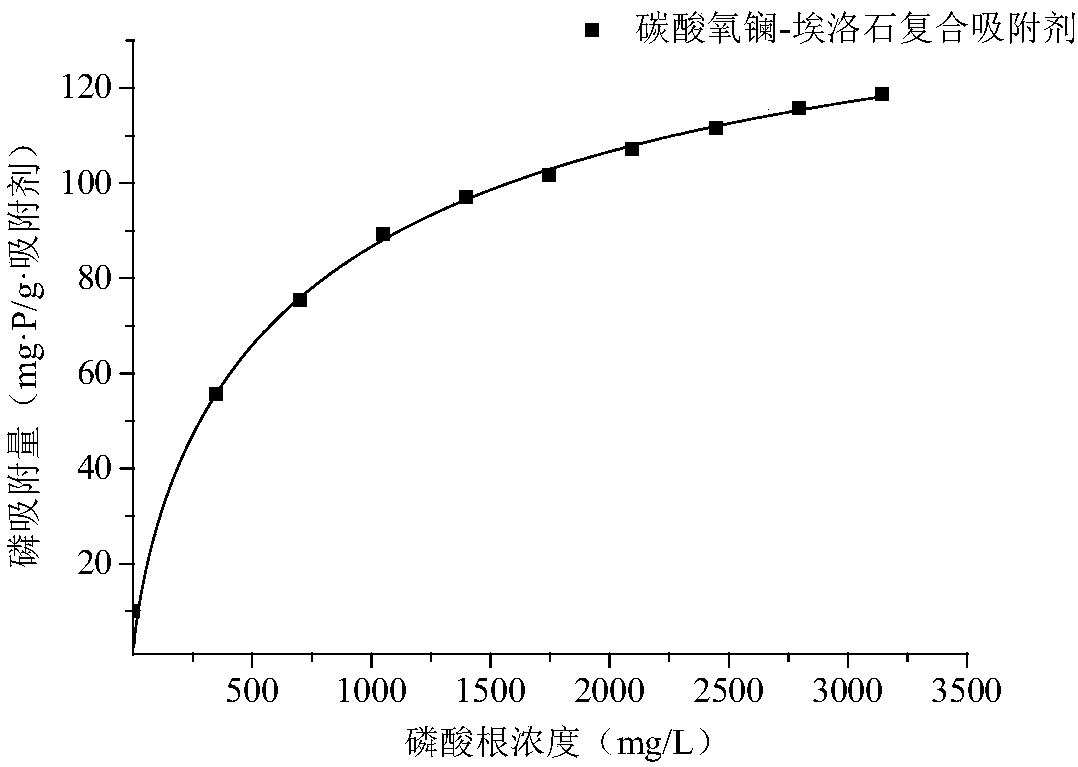

Lanthanum carbonate-nerchinskite composite material as well as preparation method and application thereof

ActiveCN108380175AFacilitated DiffusionEnhanced mass transferOther chemical processesWater contaminantsVacuum pumpingPhosphate ion

The invention discloses a lanthanum carbonate-nerchinskite composite material as well as a preparation method and application thereof. Natural nanometer tubular nerchinskite mineral and a lanthanum carbonate precursor solution are uniformly mixed; the composite material of uniformly loading the lanthanum carbonate at the inner and outer parts of a nerchinskite nanometer tube is prepared by methodsof vacuum pumping, low-temperature sintering and the like; the mesoporous structure of nerchinskite is reserved; the inner cavity cannot be blocked; the saturation adsorption capacity on phosphate anions reaches up to 100mg.P / g; the composite material can be used for adsorbing the phosphate anions or preparing a phosphorus removal adsorbent. The preparation method of the composite material also has the advantages that the energy consumption is low; the operation is simple; the preparation period is short, and the like. The preparation method has good application prospects.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Preparation of low iron and high specific surface area cerium lanthanum oxide

InactiveCN101481130AQuality improvementEase of industrial productionRare earth metal compoundsCeriumRare earth

The invention relates to a method for preparing lanthana (cerium oxide) with a low content of iron and high specific surface, which is characterized by comprising method of removing Fe from lanthanum and cerous rare earth carbonate and the method of controlling the specific surface of the lanthana (cerium oxide); the method for removing Fe adopts single-stage extraction or serial extraction with a complexation settling method, namely firstly, removing Fe in LaCeCL6 to be less than 0.005wt% by using an extracting agent with an extraction method and reducing the content of Fe in LaCeCL6to be less than 0.002wt% by using a complexing agent, wherein the extracting agent is C8-C10 tertiary amine and the complexing agent is sulpho-amino niobate; lanthanum carbonate or cerous carbonate is precipitated from the ammonium hydrogen carbonate or the sodium carbonate from which Fe is removed; the specific surface of the lanthanum carbonate or the cerous carbonate is controlled by the method of increasing the temperature in a gradient elevation way, the temperature is increased to be below 800 DEG C from 320 DEG C in a gradient elevation way and is reduced to the room temperature. The method has the advantages that the lanthana (cerium oxide) with a low content of iron and high specific surface, which is produced by the technique method fully satisfying the requirement on the raw material required by the accurate and high-speed rare earth polishing material, has stable quality, is easy to implement the industrial production, and can reach the following specific technical indexes with TREO being more than or equal to 90 percent, La2O3 / TREO being 25 percent to 30 percent, CeO2 / TREO being between 70 percent and 75 percent, Pr6O11 / TREO being less than 0.002 percent, Fe2O3 being less than 0.002 percent, and the aged specific surface being more than 30m / g.

Owner:BAOTOU JINMENG RARE EARTH

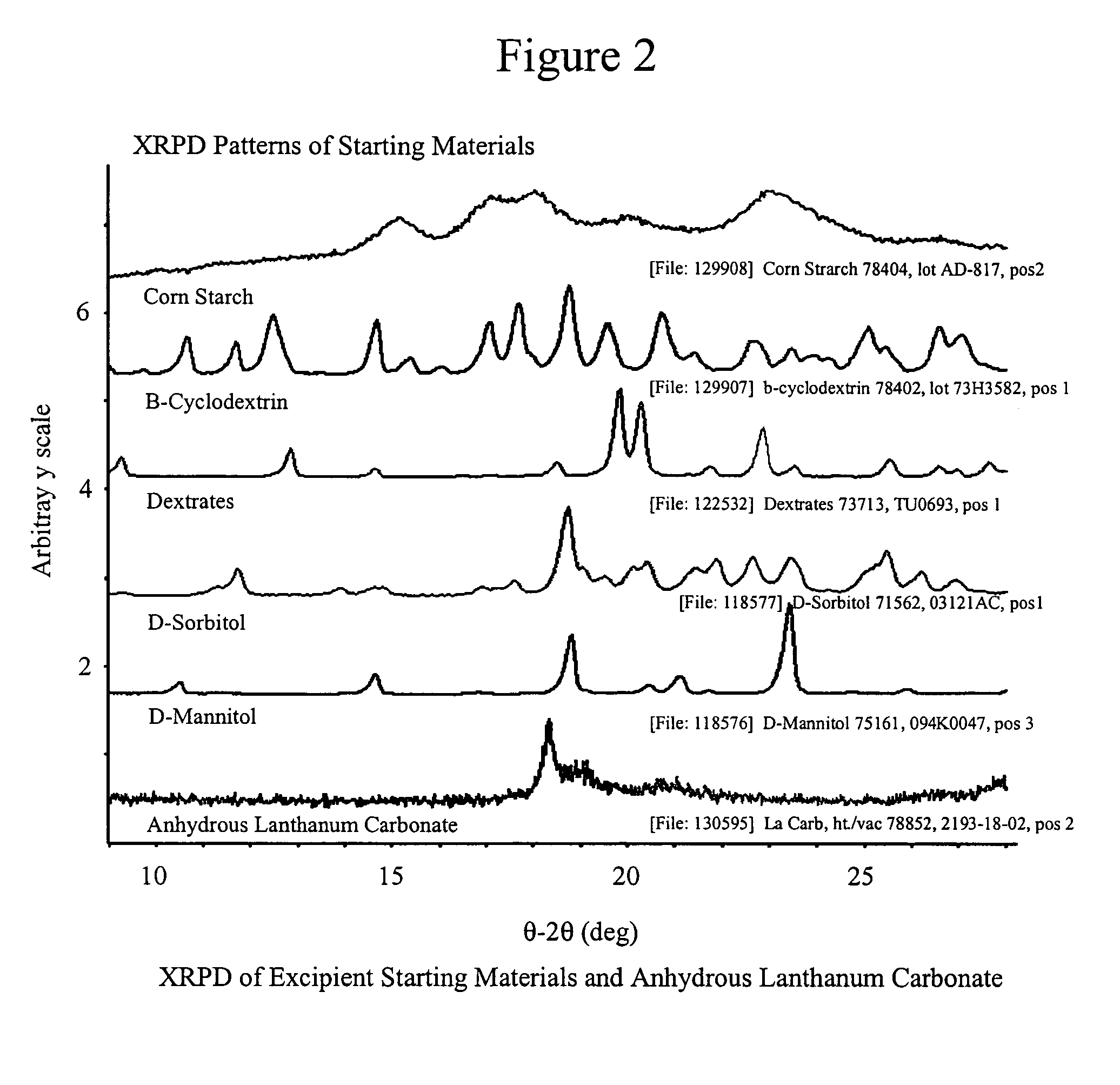

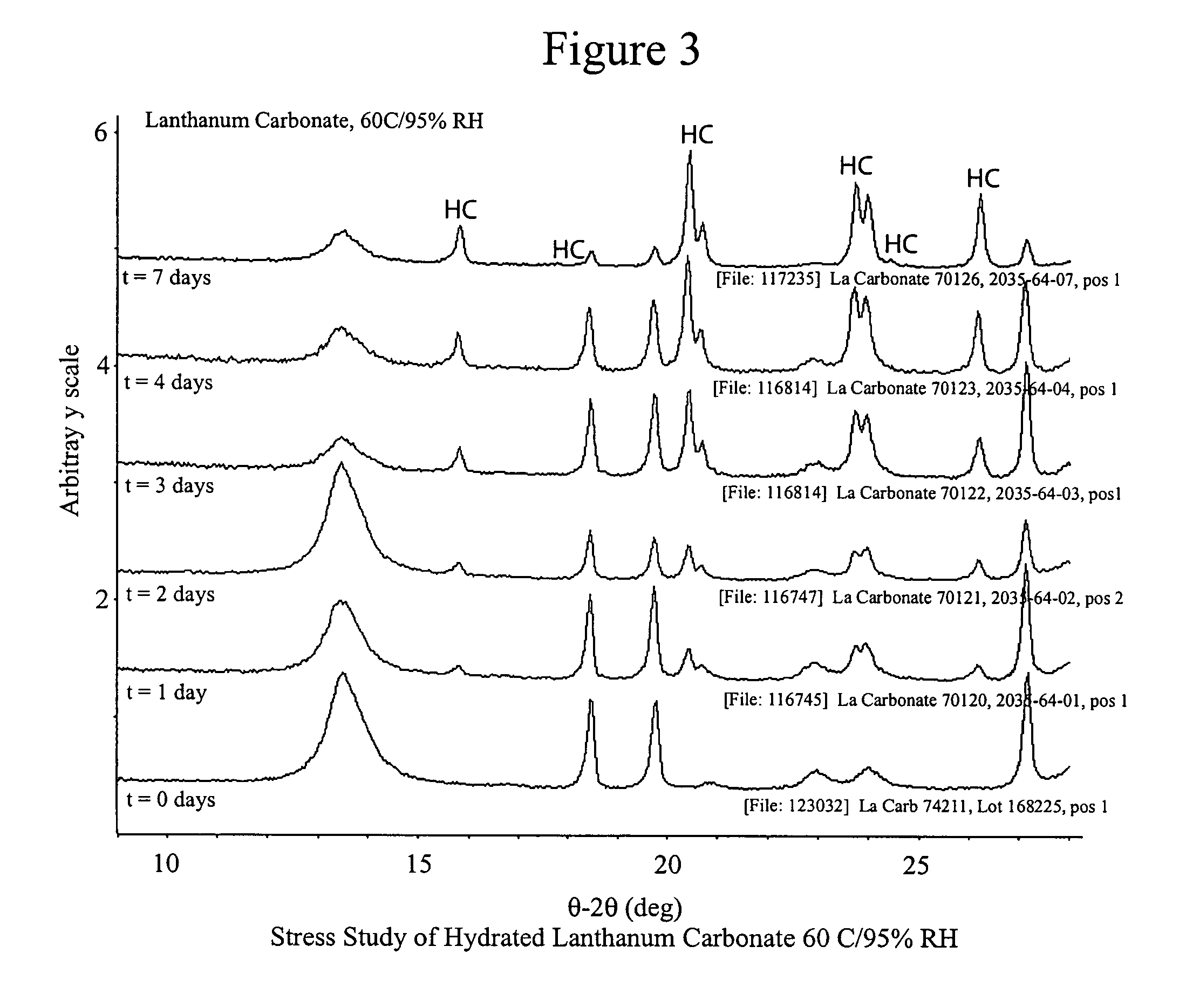

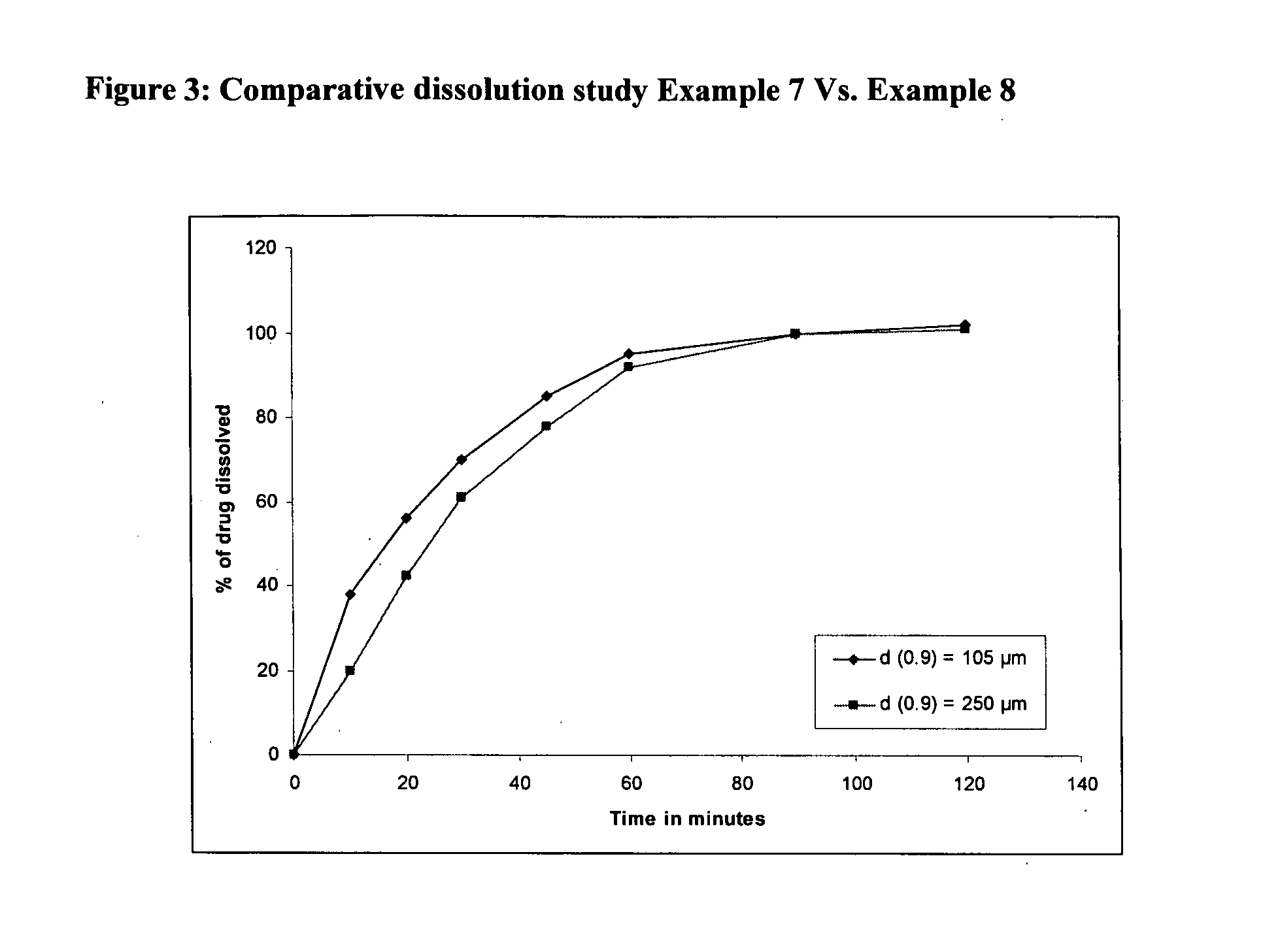

Lanthanum composition

ActiveUS20110020456A1High hydration stateImprove abilitiesHeavy metal active ingredientsBiocideLanthanumNuclear chemistry

The present invention discloses stable, solid oral pharmaceutical composition comprising Lanthanum carbonate having more than 6 molecules of water per molecule of lanthanum carbonate and pharmaceutically acceptable carriers or diluents, wherein said carrier or diluent excludes monosaccharide / s or disaccharide / s, such that the composition has comparable in-vitro dissolution profile similar to that of FOSRENOL®.Also disclosed is a wet granulation process for making the same.

Owner:MYLAN LAB

Novel lanthanum cyanurate composite PVC (polyvinyl chloride) heat stabilizer

The invention discloses a novel lanthanum cyanurate composite PVC (polyvinyl chloride) heat stabilizer. A preparation method of lanthanum cyanurate comprises the following steps of: mixing lanthanum carbonate with nitric acid; stirring the mixture so that lanthanum carbonate is completely dissolved; boiling; filtering; and adjusting pH value to obtain lanthanum nitrate; adding lanthanum nitrate to cyanuric acid, heating and stirring to be uniform; then adding sodium hydroxide with appropriate solubility and continuing stirring for a certain time; and filtering, washing, dehydrating and drying to finally obtain lanthanum cyanurate. Lanthanum cyanurate serving as a heat stabilizer has good synergic effect with calcium stearate, zinc stearate and pentaerythritol and the heat stability of PVC can be improved by combined use of lanthanum cyanurate, calcium stearate, zinc stearate and pentaerythritol.

Owner:TIANJIN DAOJUN PACKAGING PROD SALES

Method for manufacturing oil-water separation net with super-hydrophilic underwater super-oleophobic property

ActiveCN108970418ASpecial wettabilityEfficient separationSemi-permeable membranesMembranesUnderwaterOil water

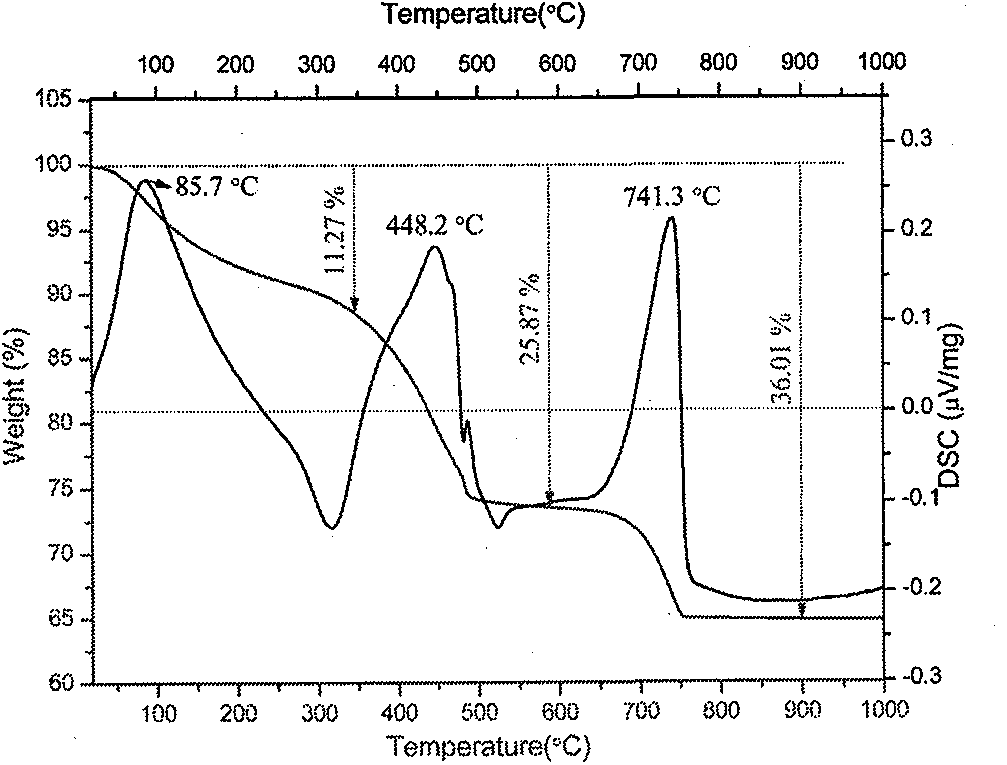

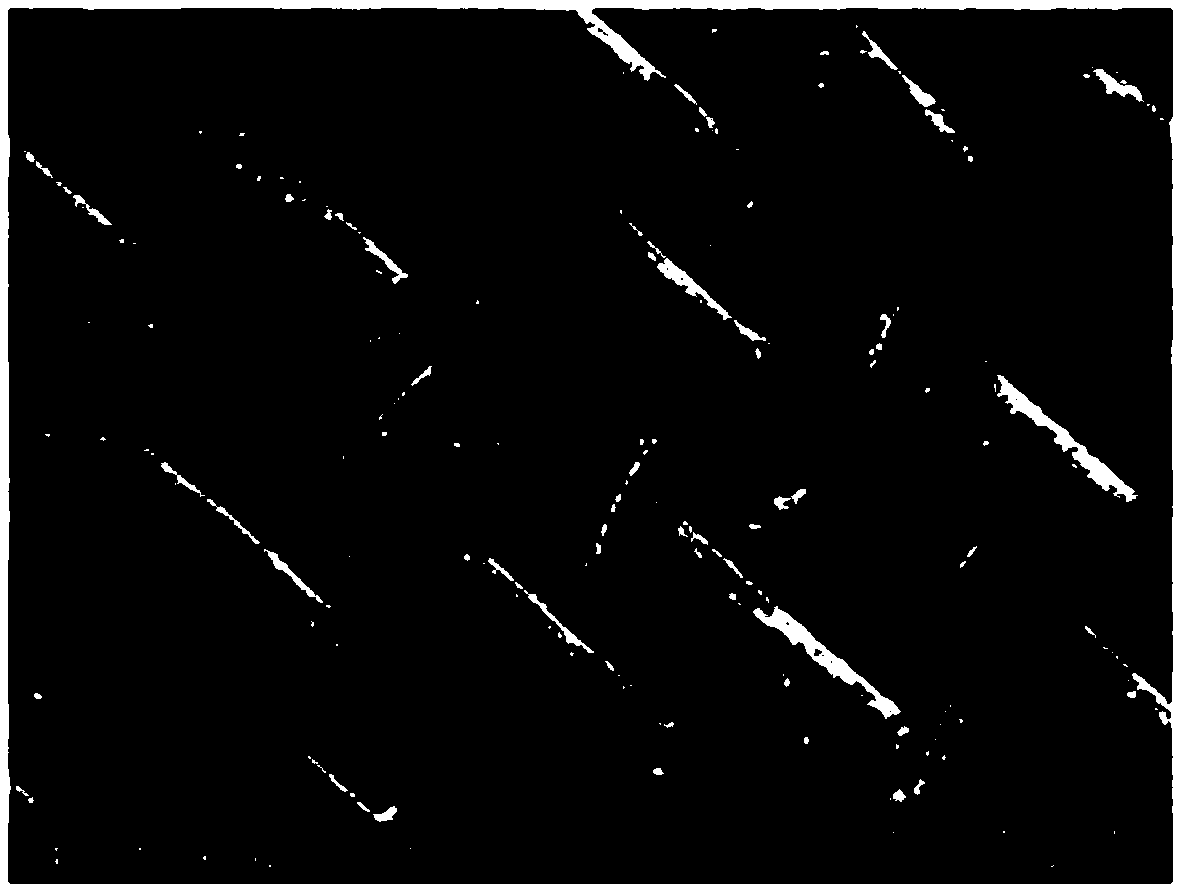

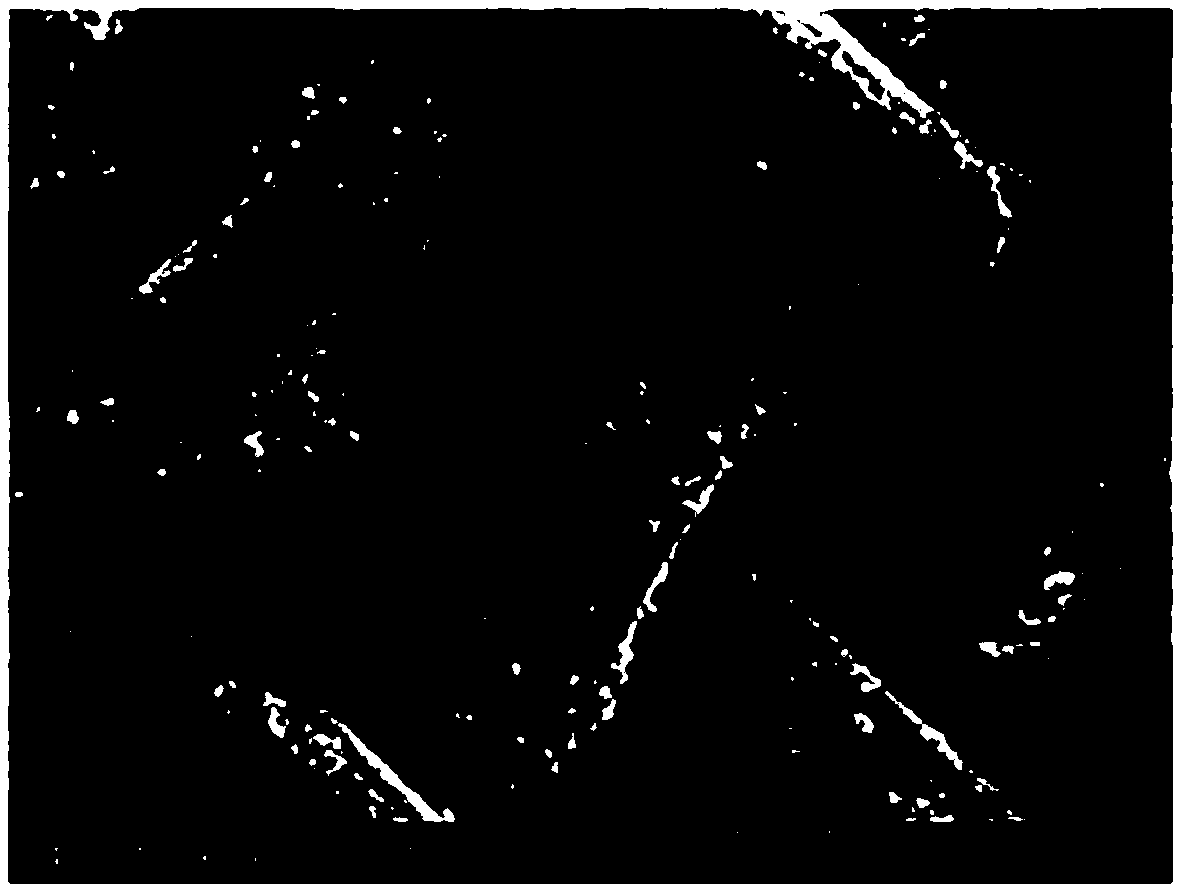

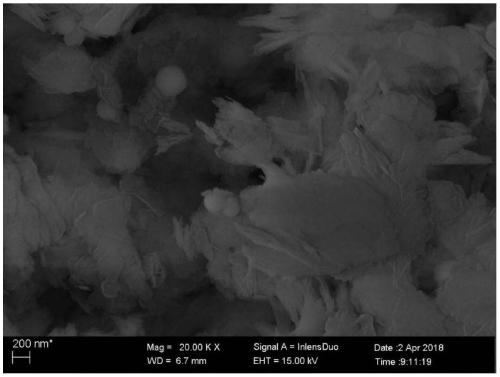

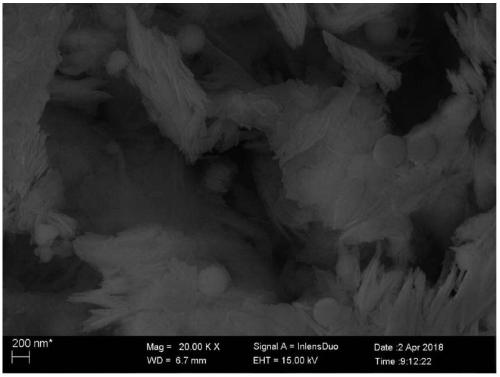

The invention belongs to the technical field of surface functionalization modification of materials, and particularly relates to a method for manufacturing an oil-water separation net membrane with super-hydrophilic underwater super-oleophobic property. According to the method, a (400-1800)-mesh stainless steel wire mesh serves as a base, a micro-nanostructure lanthanum carbonate (La2O2CO3) whichhas hydrophilic property is formed on the stainless steel wire mesh using a hydrothermal method, and finally annealing treatment is carried out at 550 DEG C to obtain the stainless steel wire mesh with the super-hydrophilic underwater super-oleophobic property. The method is simple to operate, has readily available materials, can be used for separation of oil-water mixtures, can be reused, and does not cause secondary pollution.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

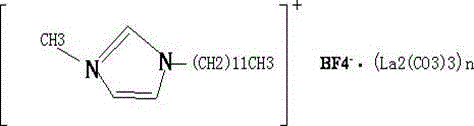

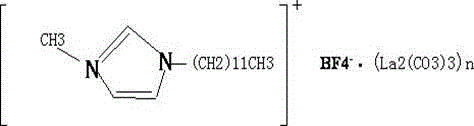

Extreme-pressure anti-wear agent, preparation method of extreme-pressure anti-wear agent and application of extreme-pressure anti-wear agent to water-based metal working fluid

ActiveCN104673433AImprove wear resistanceExcellent anti-rustOrganic chemistryAdditivesWater basedMetal working fluid

The invention discloses an extreme-pressure anti-wear agent, a preparation method of the extreme-pressure anti-wear agent and application of the extreme-pressure anti-wear agent to a water-based metal working fluid and belongs to the field of metal working. The extreme-pressure anti-wear agent is a 1-methyl-3-dodecylimidazole borate modified lanthanum carbonate compound. The water-based metal working fluid comprises the following components in parts by weight: 70-90 parts of a basic fluid, 10-19 parts of an oiliness agent and 2.3-12 parts of the extreme-pressure anti-wear agent. The invention further discloses a preparation method of the extreme-pressure anti-wear agent. The water-based metal working fluid with the extreme-pressure anti-wear agent has favorable wear resistance, rust resistance, corrosion resistance and other properties, is environment-friendly, has a huge application prospect, and can be used for promoting the metal working fluid industry to develop toward environmental compatibility, biological degradability and renewability.

Owner:SHANDONG YUANGEN PETROLEUM CHEM

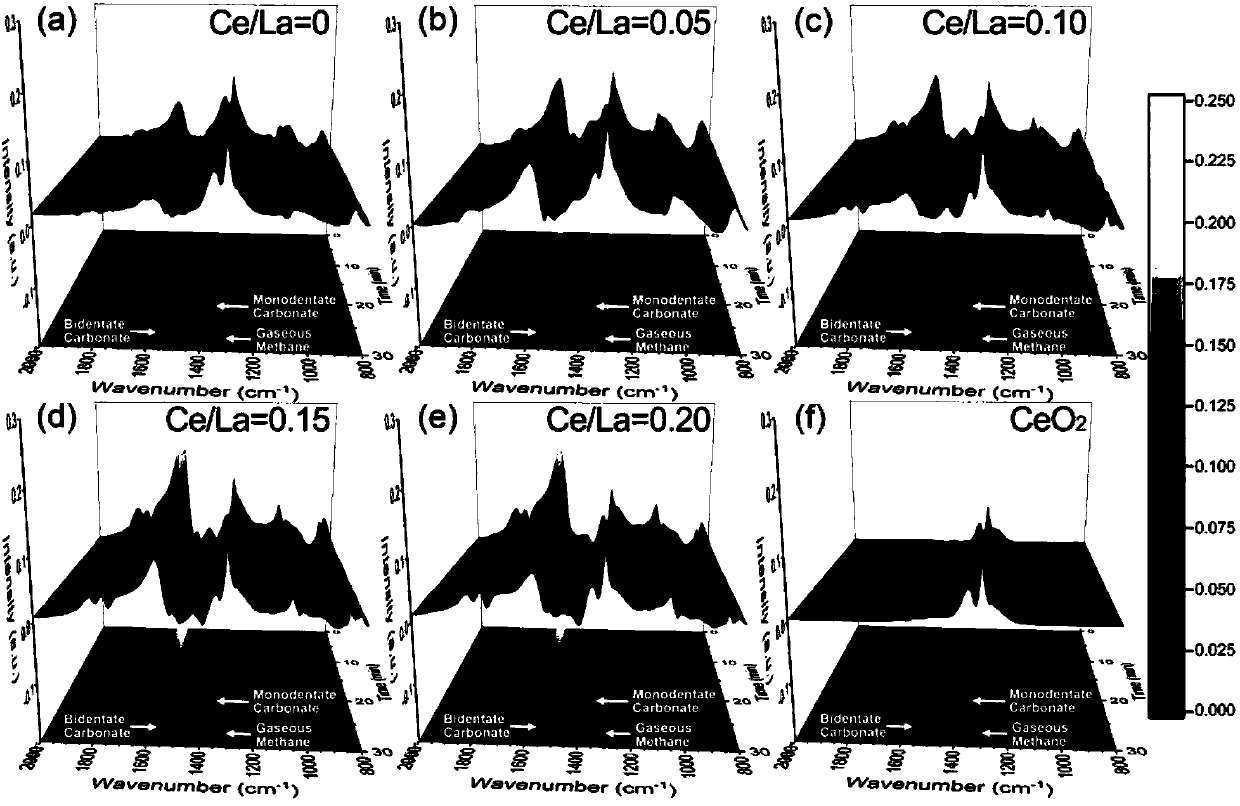

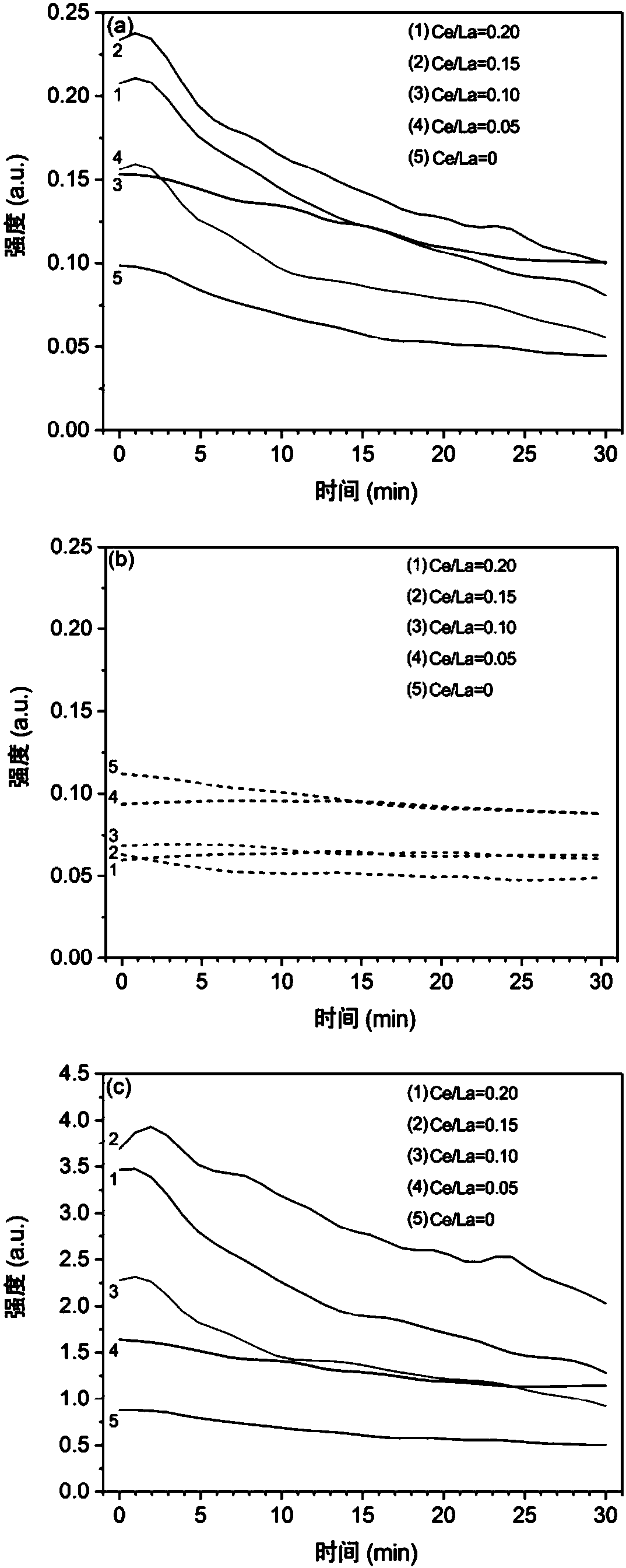

Cerium modified lanthanum oxide catalyst and preparation method and application thereof

ActiveCN107790120AImprove adsorption capacityHigh activityHydrogenCatalyst activation/preparationRare-earth elementReaction rate

The invention belongs to rare earth element auxiliary modified lanthanum oxide catalysts and discloses a cerium modified lanthanum oxide catalyst and a preparation method and application thereof. Thecatalyst is obtained by uniformly dispersing cerium oxide nanoparticles on the surface of a lanthanum oxide carrier, and a chemical metering proportion of Ce / La is 0.10-0.20. The preparation method includes: taking and completely dissolving hexahydrate cerous nitrate in deionized water, and using an obtained solution to soak a hexagonal oxygen lanthanum carbonate carrier through a wet process; performing rotary evaporation on an obtained sample, and performing depressurizing distillation until a solvent is completely evaporated, drying to be dry, grinding, and calcining. The catalyst can be applied to preparing cerium modified nickel loaded lanthanum oxide catalysts. The invention demonstrates effect of a cerium auxiliary on the surface of lanthanum oxide; by regulating and controlling adsorption and activation of CO2 on the surface of lanthanum oxide, the catalyst can be used for participating in eliminating accumulated carbon in the process of methane dry gas reforming to prepare synthetic gas, so that reaction rate of this speed control step of eliminating accumulated carbon reaction is increased, and activity and stability of the catalyst are improved.

Owner:TIANJIN UNIV

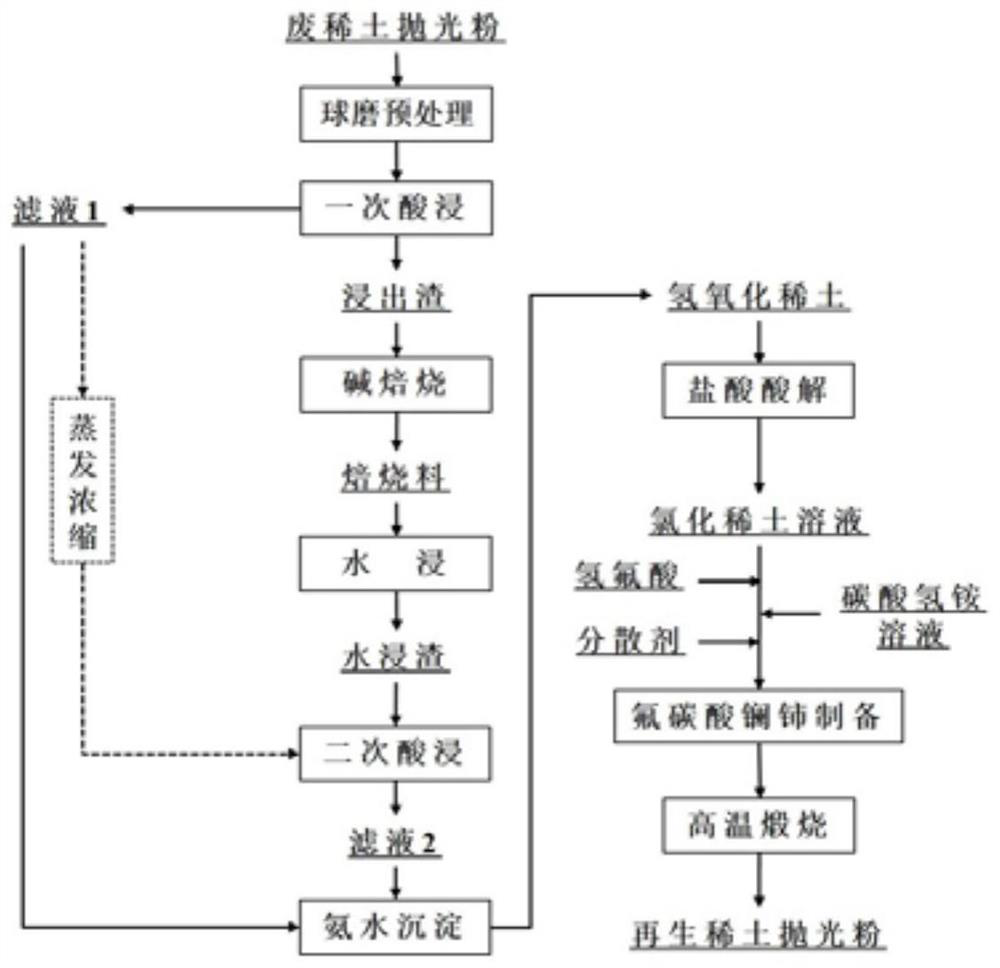

Method for separating and extracting rare earth and regenerated rare earth polishing powder from waste rare earth polishing powder

ActiveCN112725623AImprove leaching rateEasy to polishRare earth metal compounds preparation/treatmentProcess efficiency improvementCeriumLanthanum

The invention relates to a method for separating and extracting rare earth and regenerated rare earth polishing powder from waste rare earth polishing powder. The method is characterized by comprising the following steps that a primary acid leaching, alkali fusion and secondary acid leaching combined treatment process is firstly used for separating and extracting the rare earth in the waste rare earth polishing powder to obtain rare earth chloride leachate; then ammonia water is used for precipitation and impurity removing, and hydrochloric acid is used for acidolysis to obtain a purified rare earth chloride solution; then, hydrofluoric acid, an ammonium bicarbonate solution and a dispersing agent are used for coprecipitation to obtain a rare earth chloride solution so as to obtain cerium lanthanum fluorocarbonate powder; and finally, the regenerated rare earth polishing powder with good polishing performance is obtained through drying, two-stage high-temperature calcination and ball milling. According to the method, the total leaching rate of the rare earth in the waste rare earth polishing powder reaches 95% or above, the total recycle rate of the rare earth reaches 93% or above, and efficient separation, extraction and recycling of the rare earth in the waste rare earth polishing powder are achieved.

Owner:BEIJING UNIV OF TECH

Pharmaceutical compositions of lanthanum carbonate and process for the preparation thereof

Owner:ALKEM LAB LTD

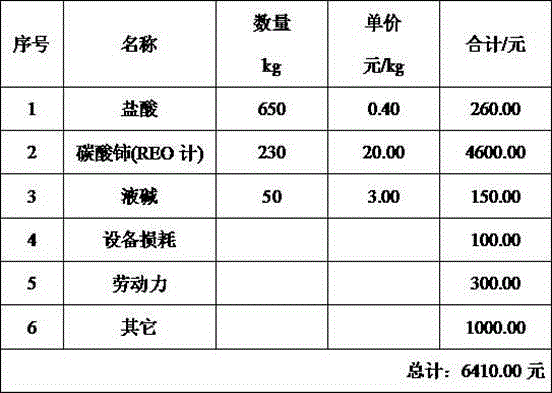

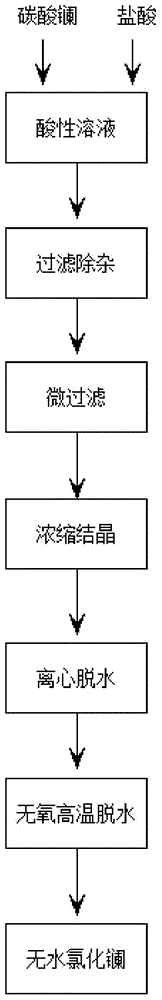

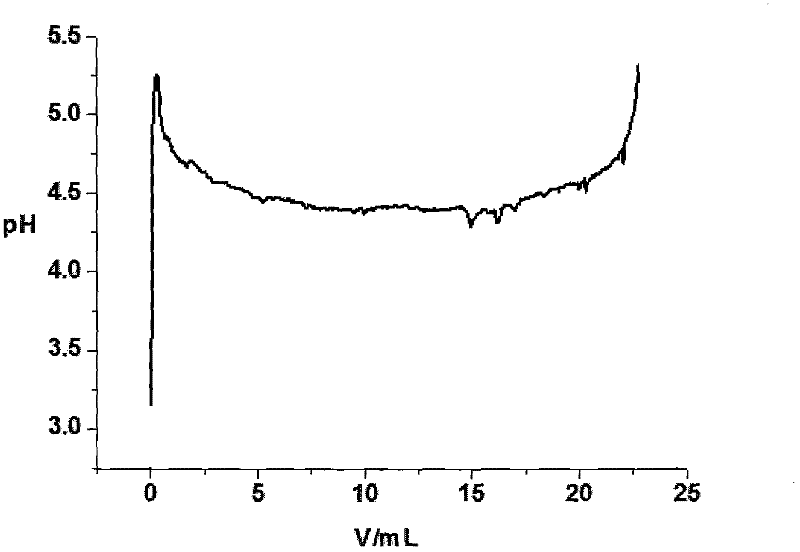

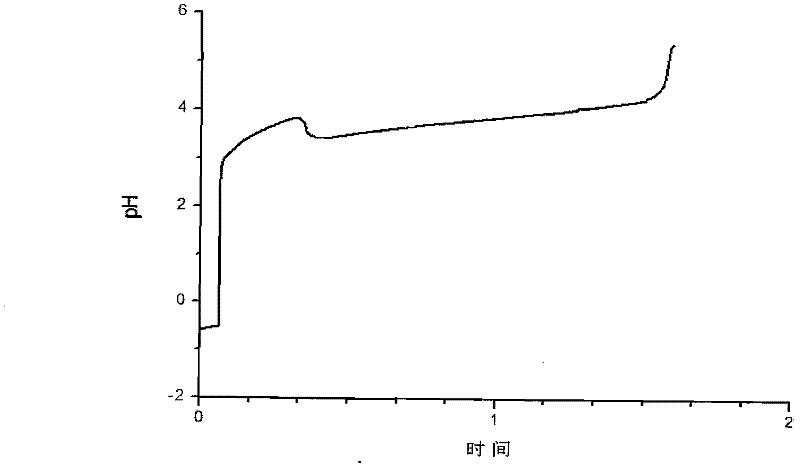

Preparation method of anhydrous lanthanum chloride

InactiveCN104973617AImprove responseThe reaction process is easy to controlRare earth metal compoundsThermal insulationFiltration

The invention relates to a preparation method of anhydrous lanthanum chloride. The preparation method comprises following steps: 1, lanthanum carbonate powder is dissolved in dilute hydrochloric acid until pH value is detected to be 2-3, and stirring reaction is carried out for 1 to 5h; 2, an obtained solution is filtered so as to remove impurities; 3, an obtained mixed solution is subjected to millipore filtration so as to obtain a filtrate; 4, the filtrate is subjected to evaporative concentration; 5, an obtained product is cooled on a crystallizing pan to 20 DEG C, and is subjected to 12 to 24h of nature crystallization; 6, an obtained filter liquor is filtered so as to obtain a crystal, and the crystal is delivered into a centrifugal hydroextractor for 20 to 60min of dehydration so as to obtain an intermediate product; 7, the intermediate product is delivered into a non-oxidation drying oven, is heated to 70 DEG C, and is subjected to thermal insulation for 2h so as to obtain LaCl3*3H2O crystal, is heated to 160 DEG C, and is subjected to thermal insulation for 2h so as to obtain LaCl3*H2O crystal, and then is heated to 250 DEG C, and is subjected to thermal insulation for 4h so as to obtain anhydrous lanthanum chloride. Beneficial effects of the preparation method are that: reaction processes are simple, and are convenient to control; production period is short; a clear transparent solution can be obtained via dissolving of the obtained finished product, and impurity content is low.

Owner:乐山沃耐稀电子材料有限公司

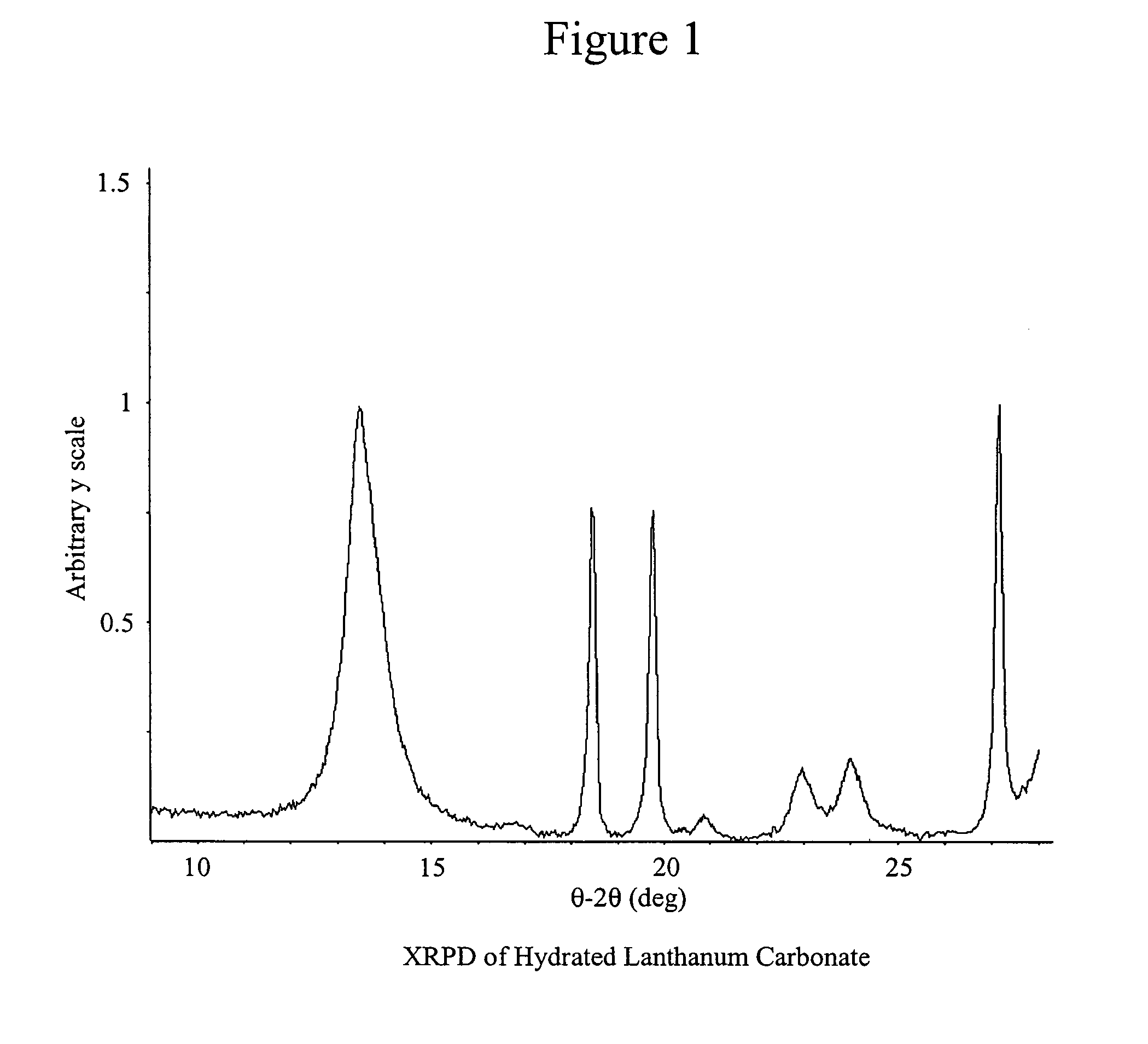

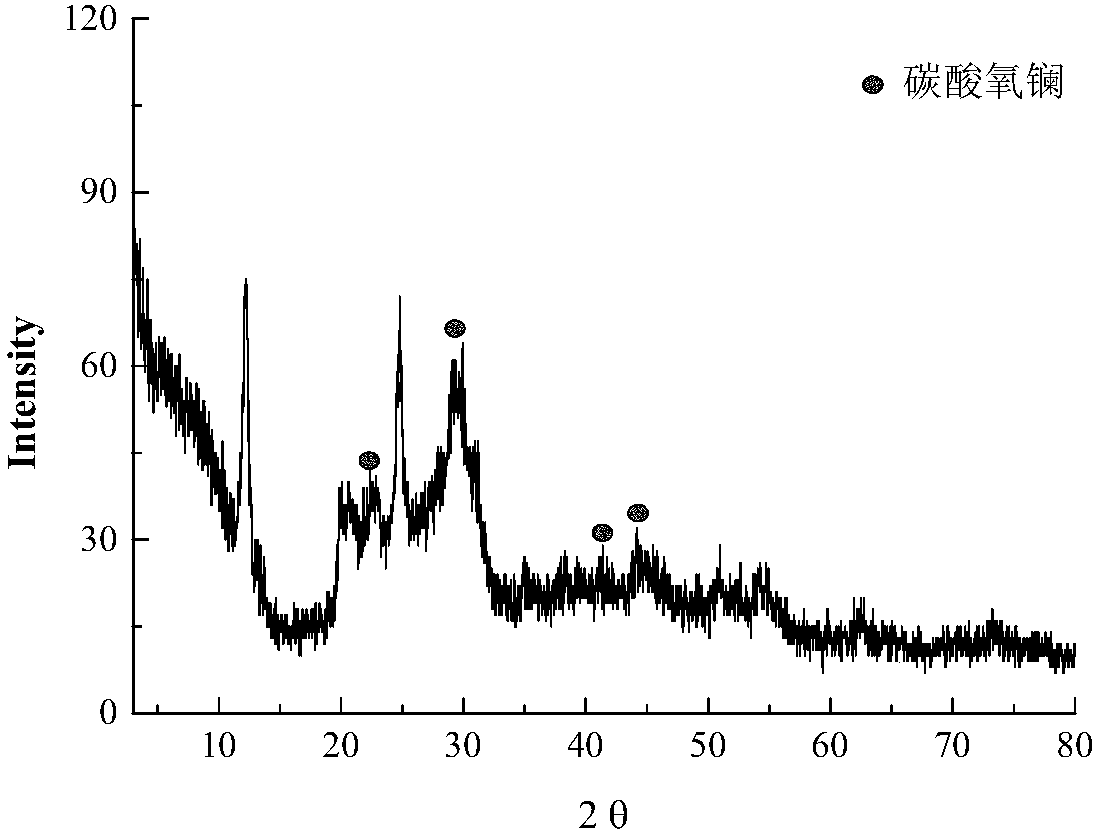

Lanthanum carbonate hydrate, preparation method thereof and method for judging whether alkali lanthanum carbonate is doped in lanthanum carbonate

InactiveCN102442692ASimple and fast operationThe result is accurate and reliableMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsSodium bicarbonateChloride

The invention relates to a preparation method of a lanthanum carbonate hydrate, which comprises the steps of: 1) adding a sodium bicarbonate solution into a lanthanum chloride solution to prepare a lanthanum carbonate octahydrate; and 2) dehydrating at a normal pressure and a temperature of 40-120 DEG C to prepare steady lanthanum carbonate containing 1-4 water. The invention also relates to the lanthanum carbonate octahydrate La2(CO3)3.8H2O and lanthanum carbonate containing 1-4 water La2(CO3)3.xH2O obtained by the preparation method (wherein x is in a range from 1 to 4) and an application of the lanthanum carbonate hydrate in preparation of drugs which are used for treating hyperphosphatemia. The invention also relates to a method for judging whether alkali lanthanum carbonate is doped in the lanthanum carbonate by calculatinga molar ratio of carbon to lanthanum in a lanthanum carbonate sample.

Owner:PEKING UNIV +3

Composite clarifying flux of La-containing aluminium alloy and its production process

The present invention provides composite clarifying flux of La-containing aluminum alloy and its production process. The composite clarifying flux consists of magnesium chloride 30-50 wt%, sodium chloride 15-25 wt%, potassium chloride 15-25 wt%, calcium chloride 2-7 wt%, barium chloride 3-7 wt%, lanthanum carbonate 5-15 wt% and potassium teraborate 5-15 wt%. The composite clarifying flux has three effects, including inhibiting the loss of RE lanthanum of La-containing aluminum alloy during flux purification, effectively reducing the content of harmful Fe element in the alloy, and powerful adsorption and elimination of non-metal inclusion from the alloy. The composite clarifying flux has high chemical stability, low harmful gas content, easy adding, simple operation and low cost.

Owner:鄂尔多斯市天旭轻合金有限责任公司

Magnetic/non-magnetic lanthanum carbonate sodium dephosphorization adsorbent and synthetic method thereof

ActiveCN109569552AComplete structureSmall sizeOther chemical processesWater contaminantsSorbentDissolution

The invention discloses a magnetic / non-magnetic lanthanum carbonate sodium dephosphorization adsorbent and a synthetic method thereof. The synthetic method comprises the following steps: adding lanthanum salt and ferric salt to a solvent according to a certain proportion, after ultrasonic dissolution, adding a certain amount of a chelating agent, a dispersing agent and a precipitant, after acutelyand uniformly stirring, enabling mixed solution to be sealed in a stainless steel reaction kettle lined with tetrafluoroethylene; placing the reaction kettle in an oven for reacting, after ending a reaction, cooling to a room temperature; and after performing solid-liquid separation on a product, washing for several times by pure water and ethyl alcohol, after drying in vacuum, to obtain the adsorbent. The prepared magnetic / non-magnetic lanthanum carbonate sodium dephosphorization adsorbent is complete in crystal structure, smaller in size, and uniform in particle size distribution. In addition, experiment conditions are simple, operation is easy without a special equipment requirement, and repeatability is good.

Owner:BEIJING FORESTRY UNIVERSITY

High-strength rock plate and preparation method thereof

ActiveCN113248242AImprove flexural strengthHigh rate of straight crystal whiskersPolycrystalline material growthAfter-treatment detailsApatiteAluminium hydroxide

The invention discloses a high-strength rock plate and a preparation method thereof, and belongs to the technical field of rock plates. The high-strength rock plate is prepared from the following raw materials in parts by weight: 22 to 30 parts of albite, 15 to 20 parts of kaolin, 10 to 16 parts of nepheline powder, 6 to 12 parts of wollastonite, 5 to 9 parts of clay, 4 to 8 parts of hydroxyapatite, 3 to 6 parts of modified hollow glass beads, 2 to 6 parts of modified silicon carbide whiskers, 2 to 6 parts of aluminum oxide, 1 to 3 parts of strontium carbonate, 0.8 to 2 parts of calcium hydrophosphate, 0.8 to 2 parts of aluminum hydroxide, 1 to 2 parts of corundum powder, 0.6 to 1.5 parts of zinc oxide and 0.5 to 1 part of lanthanum carbonate. The rock plate disclosed by the invention has good breaking strength, and the modified silicon carbide whisker capable of remarkably improving the breaking strength is obtained by synthesizing and sintering in a solution by taking silicon dioxide and fly ash as silicon sources and crushed lignite as a carbon source.

Owner:GUANGDONG OVERLAND CERAMICS CO LTD

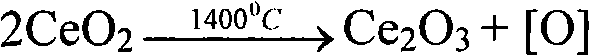

Method for clarifying and decoloring float glass

InactiveCN102079616AHigh visible light transmittanceReduce whitenessGlass furnace apparatusBreaking strengthCerium

The invention provides a method for clarifying and decoloring float glass. On the basis of the common float glass, a lanthanum carbonate [La2(CO3)3], cerium carbonate [Ce2(CO3)3], praseodymium carbonate [Pr2(CO3)3] and sodium sulfate (NaSO4) composite clarifying and decoloring agent is added, or rare earth richment (lanthanum cerium carbonate richment or lanthanum cerium praseodymium carbonate richment) which is initially separated from rare-earth mineral in Baotou and sodium sulfate are added, so that the thickness of the melted glass is 4 millimeters, visible light transmissivity in wavelength range of 380 to 780 nm is over 94 percent, whiteness is less than 0.085, breaking strength is more than 310 MPa, and microhardness is more than 8,100 MPa. The glass has high visible light transmissivity, small whiteness value, high breaking strength and high microhardness. The quality of the white float glass is obviously improved. The method can be widely applied in the fields of building glass, photovoltaic electric technology, experimental apparatuses and the like.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

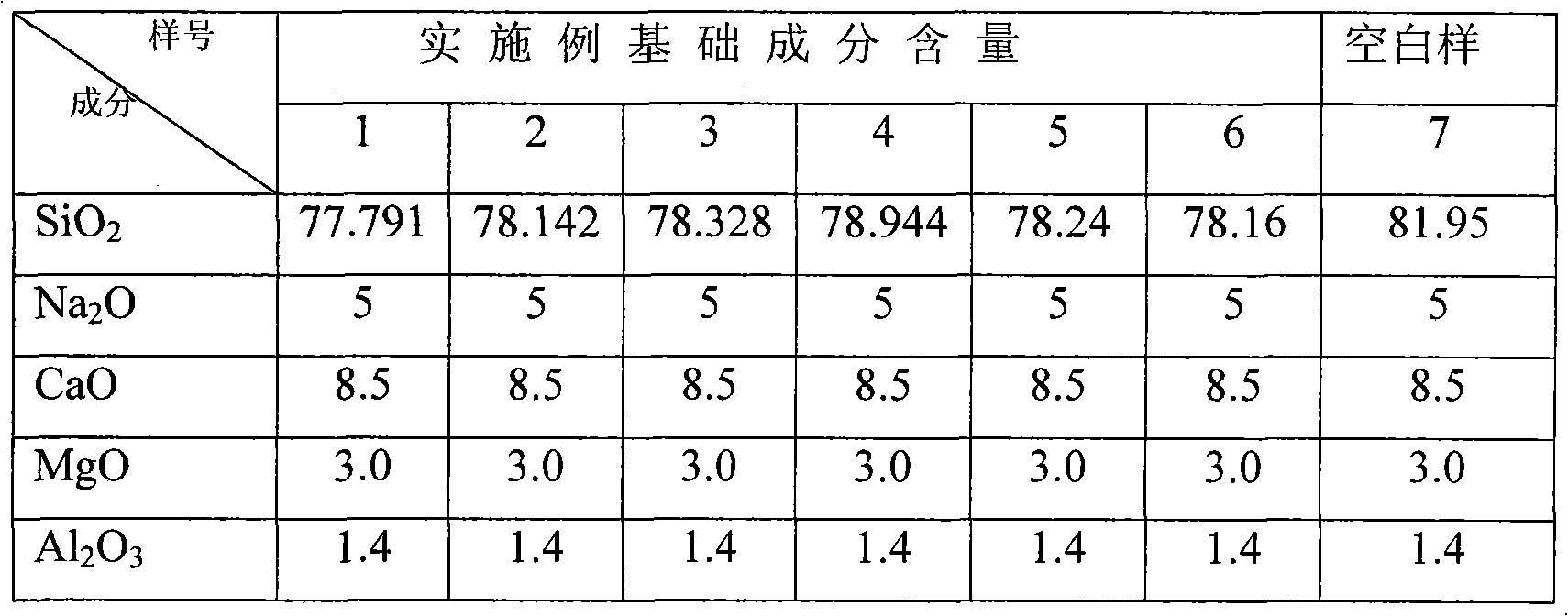

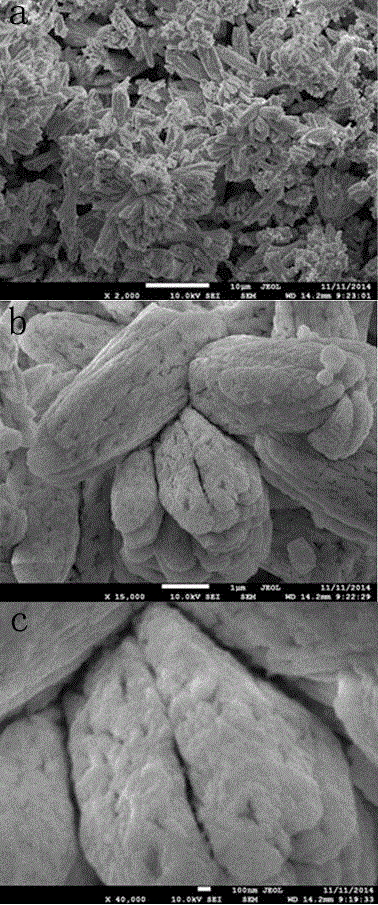

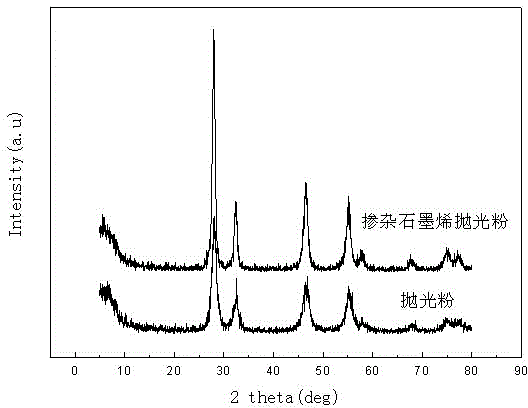

Corn-shaped nano lanthanum cerium oxide/graphene composite rare earth polishing powder and preparation method thereof

The invention discloses corn-shaped nano lanthanum cerium oxide / graphene composite rare earth polishing powder and a preparation method thereof. The preparation method comprises the following steps: dissolving industrial lanthanum cerium carbonate into diluted acid, then adding proper amounts of graphene oxide, urea and a cationic surfactant namely hexadecyl trimethyl ammonium bromide, and performing in-situ composition to prepare a nano lanthanum cerium oxide / graphene composite material by adopting a microwave stirring hydrothermal chemical method, wherein the content of graphene in the lanthanum cerium oxide / graphene composite material is 0.3-1.5%. According to the invention, a main body of the nano lanthanum cerium oxide / graphene composite material is corn-shaped in appearance, and corn kernels on the surface of the main body are nano-sized particles; and the preparation method disclosed by the invention adopts microwave heating and stirring, is advanced in process, short in reaction time and low in cost, has a high polishing corrosion quantity on glass, ensures that the glass surface has no scratch, and is especially suitable for precision polishing of products such as intelligent mobile phone display screens and optical glass.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com