Cerium modified lanthanum oxide catalyst and preparation method and application thereof

A lanthanum oxide and catalyst technology, applied in the field of preparation of cerium additive modified lanthanum oxide catalyst, can solve problems such as slow speed, achieve long service life, improve oxygen transport/migration ability, excellent catalytic performance and thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

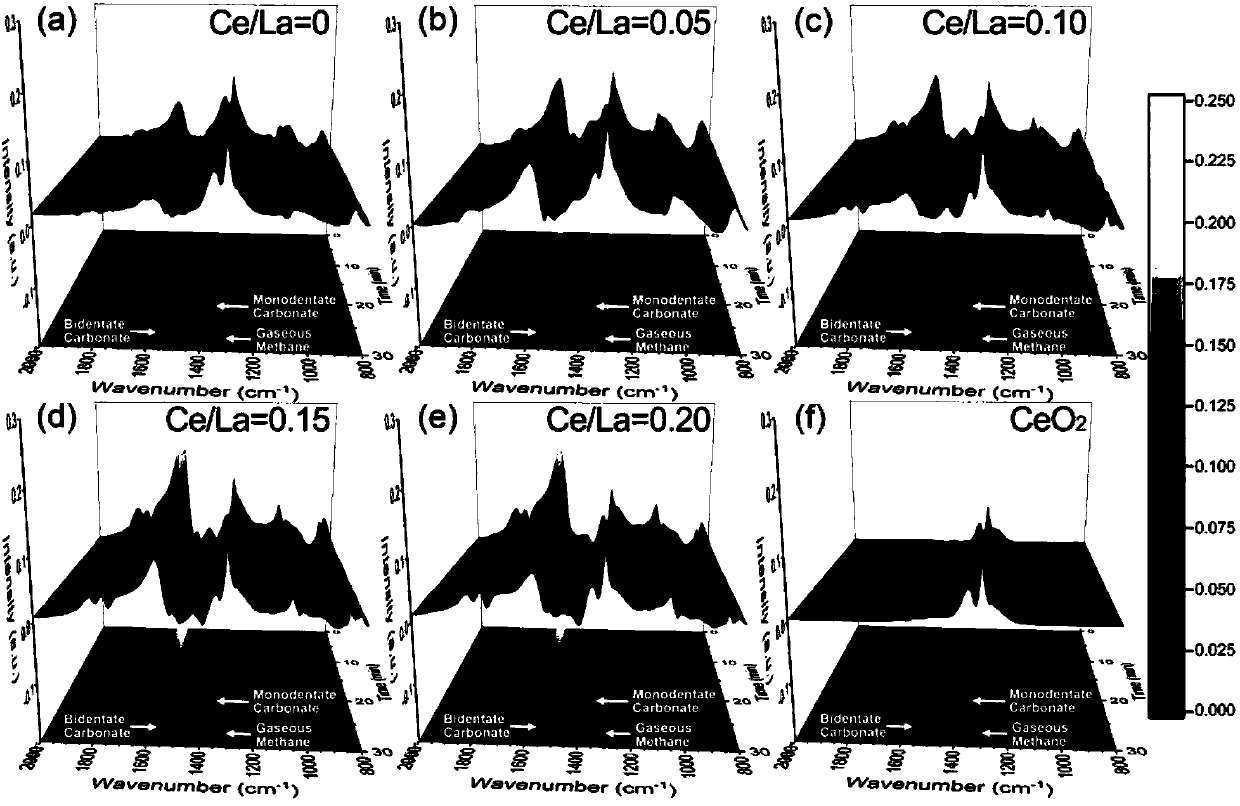

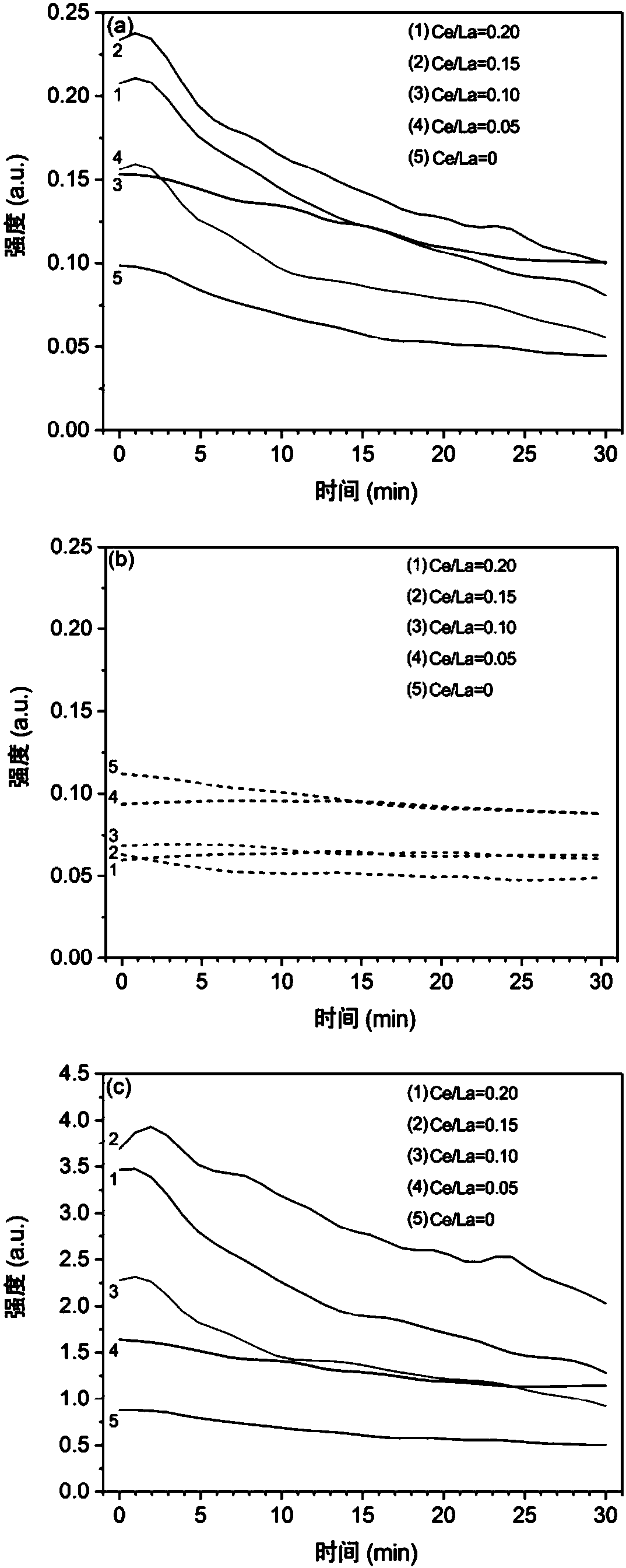

Image

Examples

Embodiment 1

[0031] (1) Take lanthanum nitrate hexahydrate (La(NO 3 ) 3 ·6H 2 O) and urea (CO(NH 2 ) 2 ) were completely dissolved in deionized water respectively, and after complete dissolution, the above two solutions were mixed and continuously stirred; in the resulting mixed solution, La 3+ The molar concentration of the substance is 0.015mol / L, and the molar concentration of the urea substance is 0.30mol / L; add ammonia water to the resulting mixed solution to adjust the pH to 8.5, stir in a water bath at 90°C for 3 hours, and the obtained white suspension Naturally cool to room temperature; centrifuge the suspension, wash the obtained precipitate twice with absolute ethanol and centrifuge; dry the white precipitate at 80°C until it is completely dry, and then roast it at 500°C 2 hours, obtain hexagonal lanthanum oxycarbonate (La 2 o 2 CO 3 ) carrier.

[0032] (2) Take cerium nitrate hexahydrate (Ce(NO 3 ) 2 ·6H 2 O) be completely dissolved in deionized water, and the hexago...

Embodiment 2

[0035] Adopt embodiment 1 method to carry out catalyst preparation cerium modified lanthanum oxide catalyst, its difference is only in (one) in mixed solution La 3+ The concentration of the substance is 0.010mol / L.

Embodiment 3

[0037] Adopt embodiment 1 method to carry out catalyst preparation cerium modified lanthanum oxide catalyst, its difference is only in (one) in mixed solution La 3+ The concentration of the substance is 0.020mol / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com