Tin-doped (IV) sulfide lanthanum pigment and preparation method thereof

A technology of lanthanum sulfide and pigments, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of monotonous color and limited pigment application, and achieve the effects of low price, considerable application prospects, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

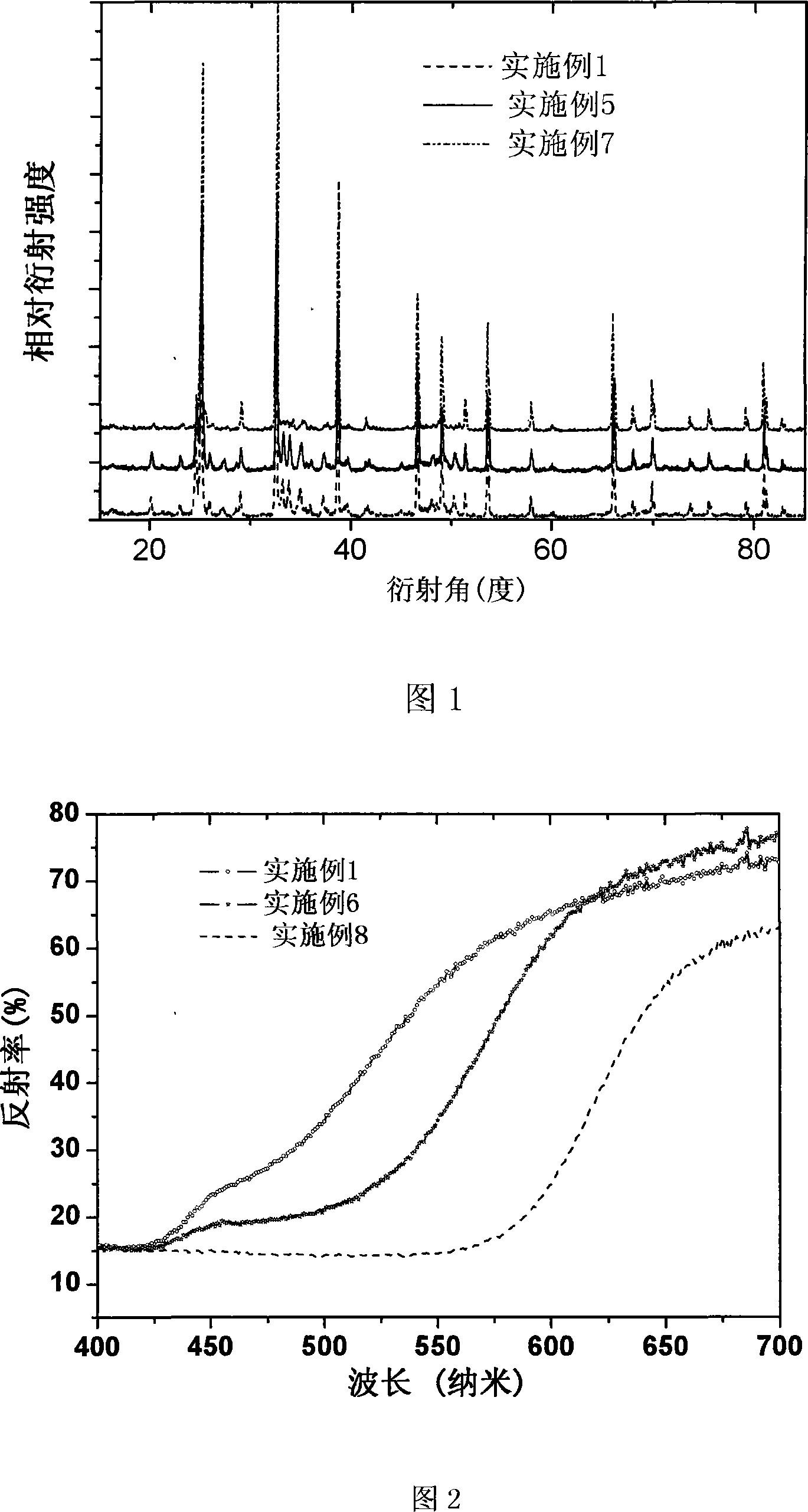

Embodiment 1

[0031] According to the chemical structural formula of the product is Sn 0.005 La 1.995 S 3.0025 The molar content of various metal raw materials and the total amount of raw materials are 500 grams to weigh the raw materials tin dioxide (purity ≥ 98%) and rare earth lanthanum oxide (purity ≥ 99%), mix them evenly, and then put them into the reaction boat in the tube furnace. Then, close the reaction furnace, feed high-purity argon gas (purity ≥ 99.99%), the gas flow rate is 0.1 liter / min, and feed ammonium thiocyanate to heat and melt after 10 minutes to generate sulfur source gas. Then, the temperature of the high-temperature tubular reactor was raised to 700°C at a heating rate of 10°C / min, and the temperature was kept at this temperature for 4 hours. Continue to pass sulfur source gas and inert gas, then continue to heat up to 900°C with a heating rate of 10°C / min, keep warm at this temperature for 1h, then stop heating and flow sulfur source gas, cool naturally, and con...

Embodiment 2

[0036] The rare earth raw material adopts lanthanum carbonate, and others are the same as in Example 1. Obtain yellow product, CIE color coordinate is: L * =77.270,a * =6.514,b * = 43.699.

Embodiment 3

[0038] Sulfur source using H 2 S, gas flow rate 0.05 liter / min, other with embodiment 1, obtains yellow product, and CIE color coordinate is: L * =77.270,a * =6.514,b * = 43.699.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com