Patents

Literature

101 results about "Chrome green" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

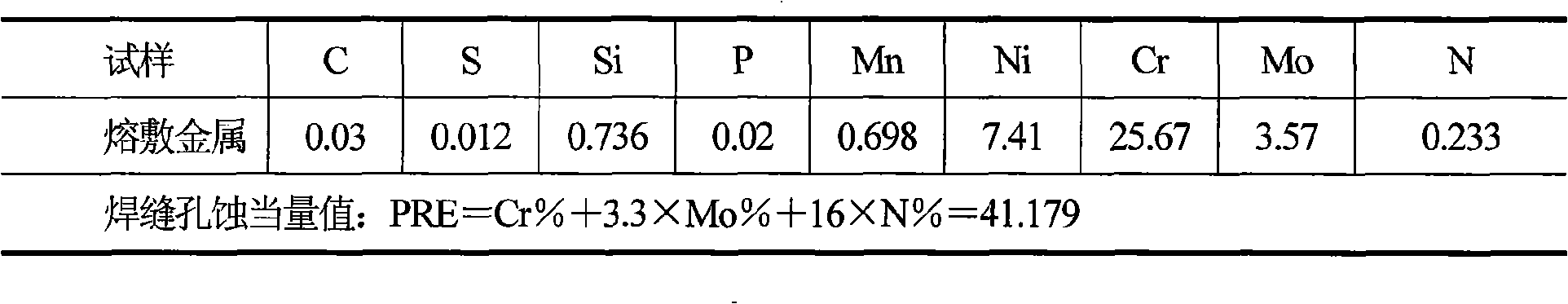

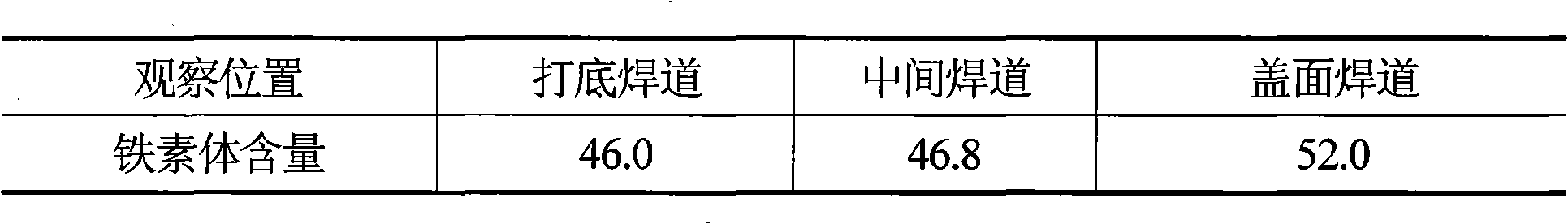

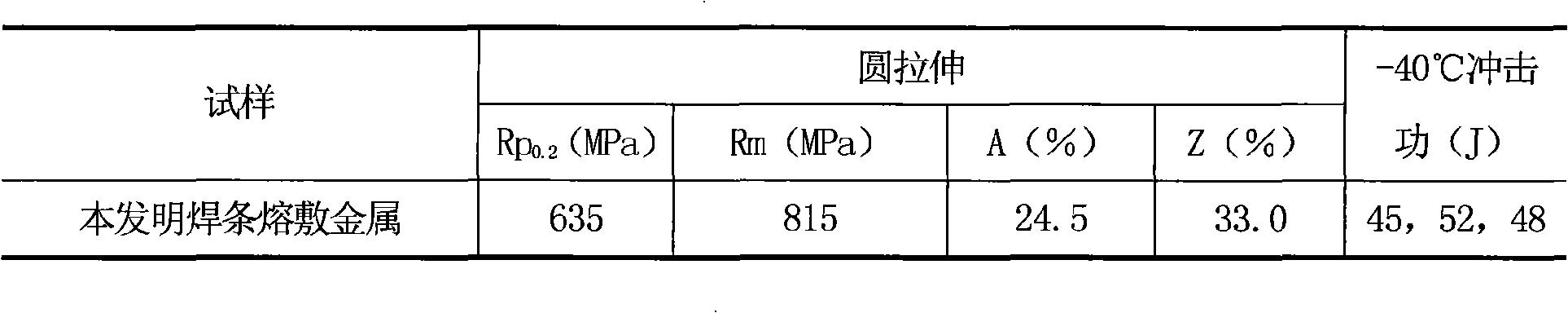

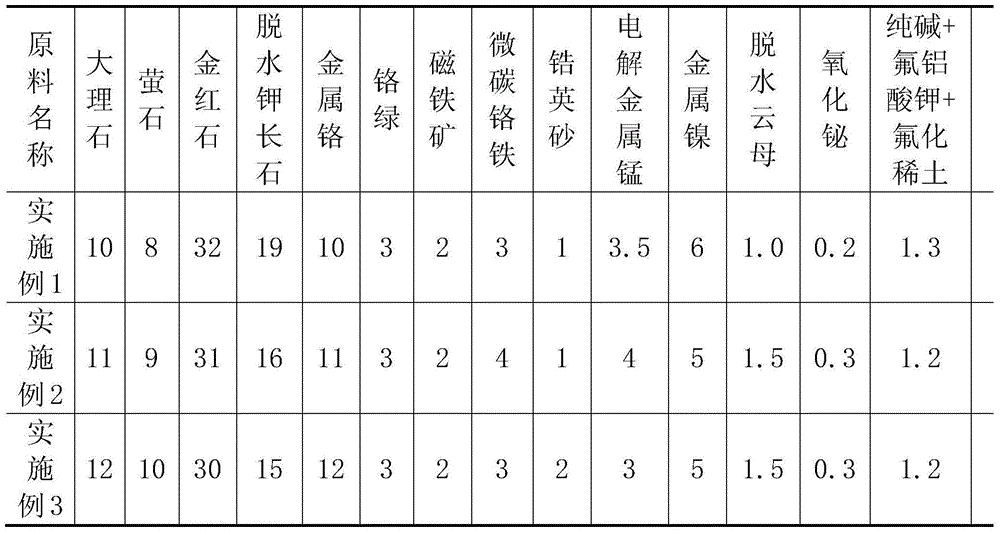

Acidic coating super two-phase stainless steel electrode

InactiveCN101323058ASimple welding processArc stabilizationWelding/cutting media/materialsSoldering mediaPhase ratioRare earth

The invention relates to an acidic coating super duplex stainless steel welding rod and belongs to welding material technology. The invention adopts 2507 duplex stainless steel wires as the welding core; the components and the weight percentages of the components of the welding rod coating are as follows: 30-40 of rutile, 3-7 of titanium dioxide, 15-20 of potash feldspar, 1-3 of phlogopite, 5-10 of marble, 16-20 of metal powder, 0.5-1.5 of rare earth fluoride, 2-3 of cryolite, 5-8 of chrome green, 0.5-1.0 of soda, and 1.5-3.5 of ferroalloy. The welding rod of the invention has the advantages, showed by the test results of manufacturability, metallographic observation, mechanical property and corrosion resistance, that the welding rod has extremely good welding technical property; electric arc is stable during welding, and spattering does not basically exist; the formation of weld joints is good; slag detachability is good; the manipulability of the welding rod is excellent; through metallographic observation, the content of ferrite in the structure of welding joints ranges from 40 percent to 60 percent, and the phase ratio can meet engineering application requirement; the welded welding joint has excellent mechanical property, and tensile strength can be more than 800 MPa; low temperature toughness is good; the stress corrosion resistance and pitting corrosion resistance of the welding joint are excellent.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

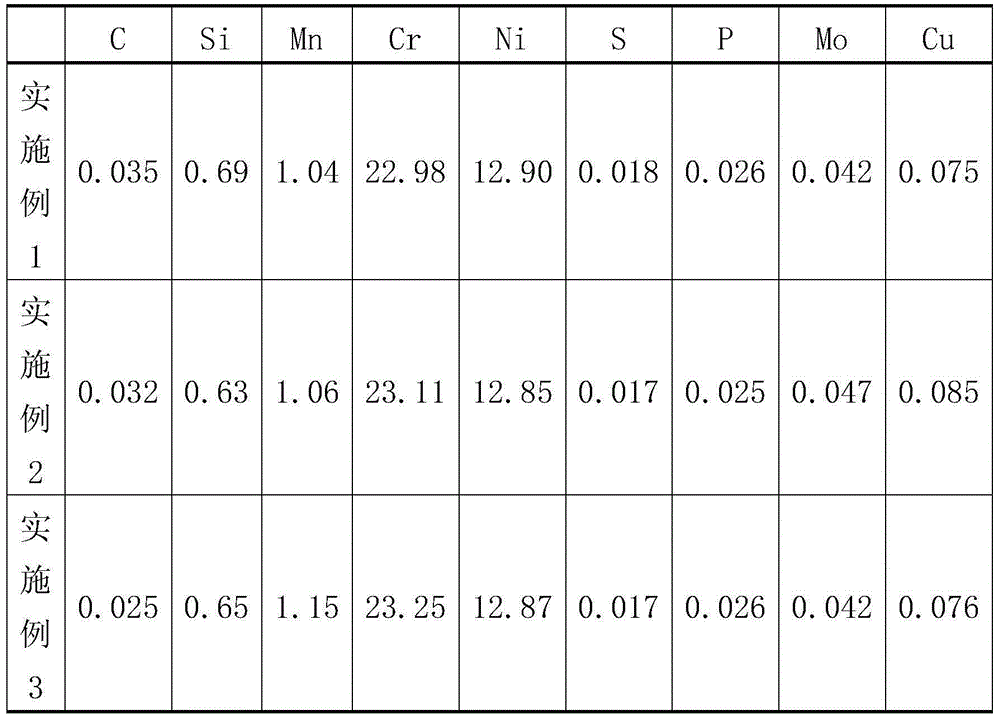

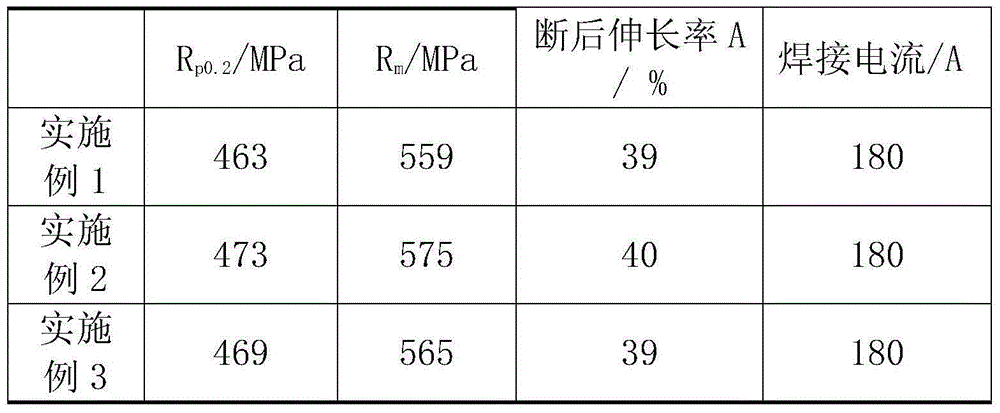

E309L stainless steel lengthened welding electrode capable of being used for large-current welding

ActiveCN105215580ASimple welding processArc stabilizationWelding/cutting media/materialsSoldering mediaPotassiumRare earth

Provided is an E309L stainless steel lengthened welding electrode capable of being used for large-current welding. A coating contains marble, fluorite, rutile, dehydrated potassium feldspar, dehydrated mica, bismuth oxide, chrome green, magnetite, sodium carbonate, micro-carbon ferro chrome, electrolytic manganese metal, zircon sand, potassium fluoroaluminate, rare earth fluoride, chromium metal and metallic nickel, blending and even stirring are conducted according to the ratio of the coating, 15-20% of sodapotash water glass is added and evenly stirred according to the total weight of the coating, the coating and an ER308L welding wire are put in an oil pressure type welding electrode extrusion press to produce and prepare the lengthened welding electrode, and no coating cracks or flushing can happen when the large current is 170-180 A and the welding core length is 450 mm; though an ER308L welding core is adopted, the cladding metal chemical components meet the requirement of E309L chemical components through the coating transition alloy method, and therefore the welding electrode has good welding process performance and is stable in electric arc, convenient to operate, good in weld appearance during welding, and sediments are easily separated.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Refractory material for steel tapping hole of converter and preparation method for refractory material

The invention relates to a refractory material for a steel tapping hole of a converter and a preparation method for the refractory material. The technical scheme of the invention is as follows: the preparation method comprises the steps of spraying the surface of a magnesia-carbon brick body with a glaze slip coating with the thickness of 1mm to 2mm, carrying out drying, and carrying out heat preservation, thereby preparing the refractory material for the steel tapping hole of the converter. A preparation method for the magnesia-carbon brick body comprises the steps: mulling magnesia fines, flake graphite fines, expandable graphite, aluminum powder and silicon powder in a high-speed mulling machine, so as to prepare mixed fine powder; and then, mulling fused magnesia granules and artificial graphite granules, adding phenol-formaldehyde resin into the mixture, carrying out mulling, then, adding granulated graphite and the mixed fine powder into the mulled mixture, carrying out mulling, carrying out aging, carrying out shaping, and carrying out standing, thereby preparing the magnesia-carbon brick body. A preparation method for glaze slip comprises the steps of adding water into glass powder, spodumene, potassium feldspar, silicon micropowder, potassium carbonate, SiC fines, chrome green and aluminum dihydrogen phosphate, which serve as raw materials of the glaze slip, and carrying out grinding, thereby preparing the glaze slip. The refractory material for the steel tapping hole of the converter, prepared by the preparation method, has the characteristics that the thermal shock stability is good, the integrity is good, the oxidation resistance is good, the erosion resistance is good, and the life is long.

Owner:WUHAN UNIV OF SCI & TECH

Composite spinel-zirconium refractory material for smelting colored heavy metal

The invention discloses a composite spinel-zirconium refractory material for smelting colored heavy metal. The technical scheme is as follows: the material comprises 30-45 parts of 5mm-0mm emery, 10-30 parts of 5mm-0mm magnesia chromite clinker,15-25 parts of 3mm-1mm magnalium spinel clinker, 7-20 parts of 3mm-0mm magnesite clinker, 1-5 parts of chrome green less than or equal to 0.045mm and 2-8 parts of zirconium dioxide less than or equal to 0.045mm by weight part and a bonding agent is aluminium dihydrogen phosphate liquid the adding amount of which is 3-15% of the total weight of the emery, the magnesia chromite clinker, the magnalium spinel clinker, the magnesite clinker, the chrome green and the zirconium dioxide. A hydraulic press is adopted for molding and the composite spinel-zirconium refractory material is sintered by a hyperthermia tunnel kiln. The content of Cr2O3 of the composite spinel-zirconium refractory material is less than 10%, so that the composite spinel-zirconium refractory material not only is environment-friendly, but also has better slag erosion resistance, high-temperature melt washing resistance, metal melt permeation resistance and thermal shock stability performance.

Owner:辽宁青花耐火材料股份有限公司

Strong acid resistant and inner corrosion-resistant paint and its manufacturing method

InactiveCN1621464AGood acid corrosion resistanceGood flexibilityAnti-corrosive paintsEpoxy resin coatingsEpoxyCyclohexanone

The present invention relates to one kind of strong acid resistant inner anticorrosive paint and its production process. The paint is produced through adding epoxy resin into mixed solvent one xylene, diacetone alcohol and cyclohexanone; adding phenolic resin, chrome green, precipitated barium sulfate, graphite, PTFE, polyacrylate copolymer solution, polymethyl alkyl siloxane solution and polyamdie wax via mixing; and grinding. The paint may be coated to inner wall of acid gas pipeline and high sulfur matter conveying pipeline for preventing corrosion.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Water-soluble, high-temperature-resistant and anti-corrosive inorganic silicate paint and preparation method thereof

InactiveCN105017822AImprove high temperature resistanceImprove thermal shock resistanceAlkali metal silicate coatingsAnti-corrosive paintsMicrosphereThermal shock

The invention discloses water-soluble, high-temperature-resistant and anti-corrosive inorganic silicate paint and a preparation method thereof. The paint comprises a liquid-phase component, a solid-phase component and an auxiliary, wherein the solid-phase component comprises quartz powder, hollow microsphere powder, titanium dioxide, mica powder, silicon carbide and chrome green. The liquid-phase component comprises sodium water glass. Compared with the prior art, the paint has the advantages as follows: the paint has very good high-temperature-resistant performance, excellent thermal shock property, excellent bonding strength with a base material and extremely excellent water resistance and salt water resistance.

Owner:芜湖中电环保发电有限公司

High-temperature infrared radiant coating used for industrial furnace and preparation method thereof

The invention discloses a high-temperature infrared radiant coating used for an industrial furnace and a preparation method thereof. The high-temperature infrared radiant coating is mainly prepared from an infrared radiant base material, a high-temperature thermal expansivity regulator and a binder by direct ball-milling and mixing, wherein the infrared radiant base material has a stable spinel structure; the high-temperature thermal expansivity regulator is selected from micro silicon dioxide powder; the binder is one or two selected from the group consisting of high-temperature sol and micro oxide powder; and the infrared radiant base material is prepared by high-temperature sintering of transition metal oxides prepared by proportioning and mixing of MnO2, industrial grade chrome green, Co2O3, Ni2O3, CuO, Fe2O3, TiO2 and ZrO2. According to the invention, infrared radiance of the coating can be improved; stability of the infrared radiance of the coating can be guaranteed; meanwhile, the service life is enhanced; the process is simple and has no pollution to products in a furnace; and strong bonding strength and thermal shock resistance are achieved.

Owner:ZHEJIANG UNIV

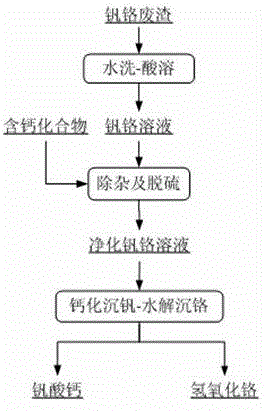

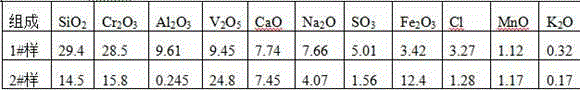

Method for synchronously recovering vanadium and chromium from vanadium-chromium slag by acid process

ActiveCN104805303AClean and efficient useReduce usageProcess efficiency improvementSlagCalcification

The invention relates to a method for synchronously recovering vanadium and chromium from vanadium-chromium slag by an acid process. The method comprises the steps: (1) carrying out water-washing desalting: washing water-soluble salts in the vanadium-chromium slag with water, filtrating so as to obtain a filter cake and a washing solution, cyclically washing the washing solution with water, and finally precipitating salts through cooling crystallization; (2) carrying out oxidizing acid-dissolving: adding the filter cake obtained in the step (1) into a sulfuric acid solution for acid dissolving, and adding an oxygen enrichment agent for closed oxygen-enriched leaching during acid dissolving, so as to obtain a vanadium-chromium solution and tailings; (3) carrying out purifying impurity removal: adding a calcium containing compound into the vanadium-chromium solution obtained in the step (2) for impurity removal-desulfurization, so as to obtain a purified vanadium-chromium solution; (4) carrying out calcification vanadium precipitating: adding a calcification agent into the vanadium-chromium solution obtained in the step (3) for calcification vanadium precipitating, so as to obtain calcium vanadate and a vanadium precipitated solution; (5) carrying out hydrolyzing chromium precipitating: reducing the vanadium precipitated solution obtained in the step (4) through a reducing agent, adding alkali to adjust the pH value of the solution to 7-9, precipitating to obtain chromic hydroxide, and calcining to obtain a chrome green product. According to the method provided by the invention, the consumption of additives is reduced, the production process is simplified, the production cost is reduced, and the clean and efficient utilization of the vanadium-chromium slag is realized.

Owner:孟立新

Corundum ladle seat brick casting material

The invention relates to corundum ladle brick cup casting material which can effectively deal with the problems of poor product consistency and environmental pollution. The invention has the technical proposal to take compact electro-melting corundum as the main skeletal material; corundum powder, Alpha-alumina powder, electrofusion spinel powder, oxidized chrome green powder and silicon fine powder as the substrate material; and alumina cement as the wedding agent. All materials are mixed evenly and then added with the additives. The ingredients have the proportions by weight: the compact electro-melting corundum of 60-70 percent, the corundum powder of 5-10 percent, the Alpha-alumina powder of 5-10 percent, the electrofusion spinel powder of 5-15 percent, the oxidized chrome green powder of 0.01-3percent, the silicon fine powder of 0.01-5 percent and the alumina cement of 0.01-5 percent. The above ingredients with a sum of 100 percent are mixed into the admixture and then added with 0.1-1.0 percent by weight of the metal powder and the organic fiber, and the added amount equals to 0.01-0.5 percent by weight of the admixture. The water capacity in the construction agitation is 4-7 percent of the total weight of the materials. The construction can be done on spot, thereby being flexile, swift and environment-friendly, and the service life is quite long.

Owner:郑州荣达工矿集团有限公司

Low-porosity magnesium aluminate spinel-zirconia corundum zirconia composite sintered refractory material and production technology thereof

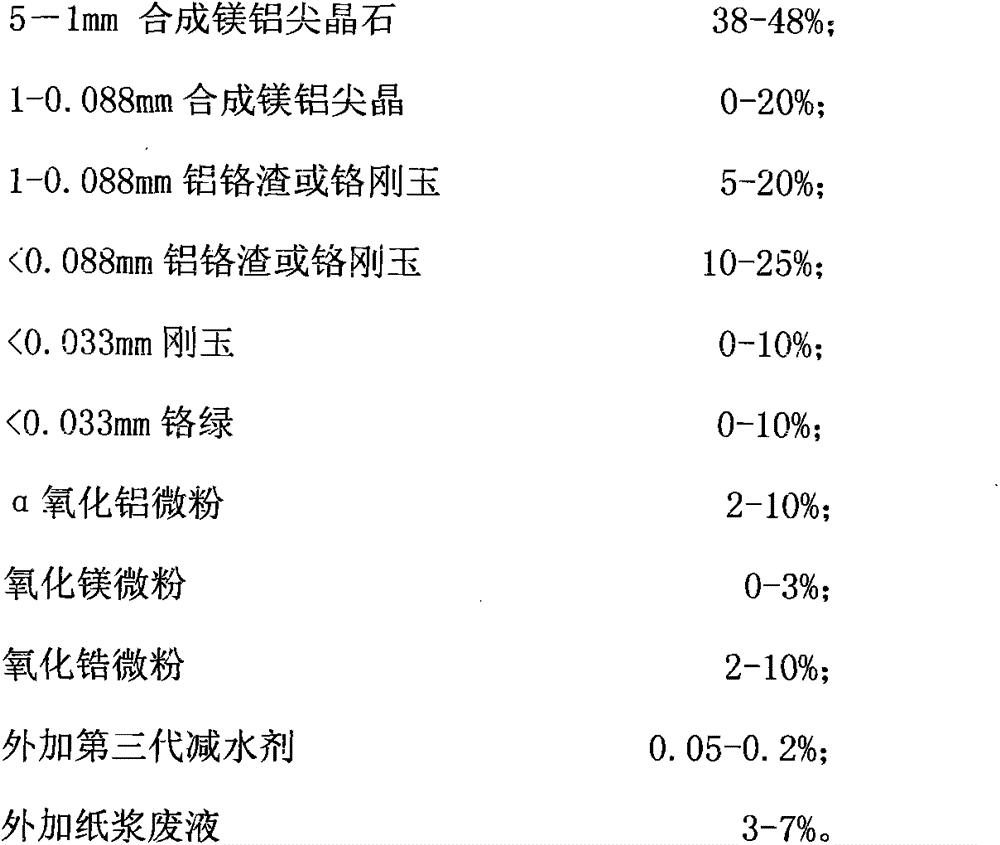

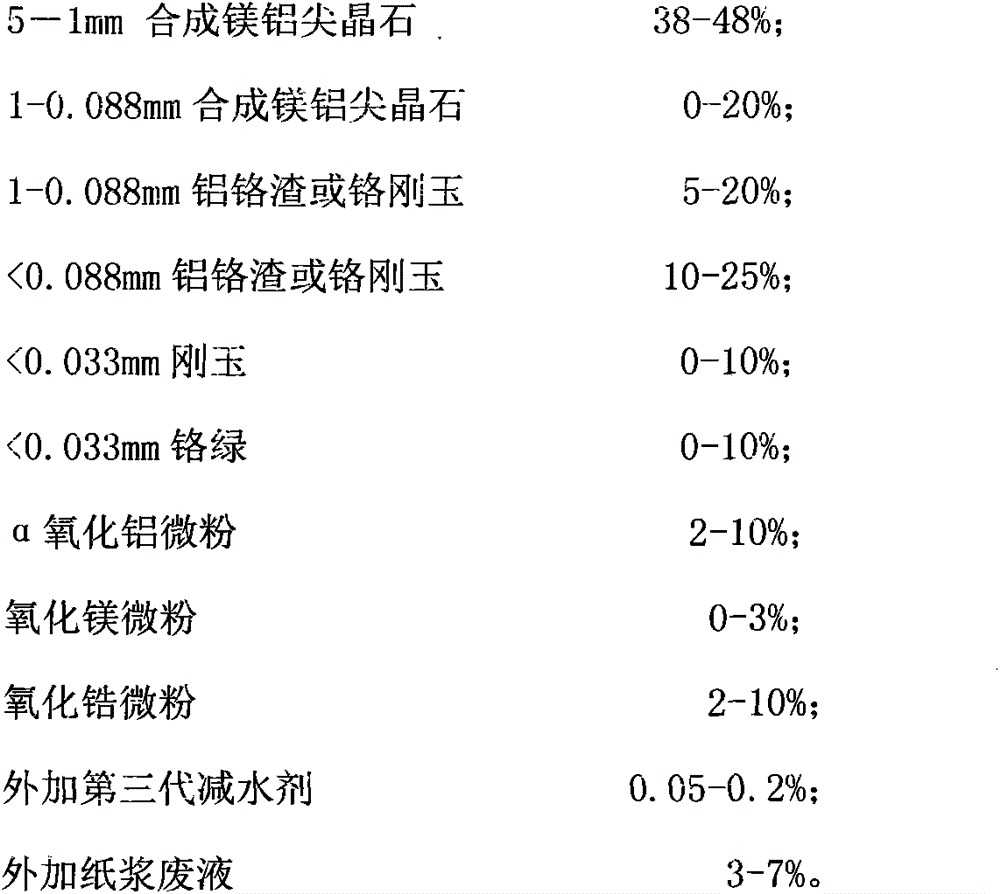

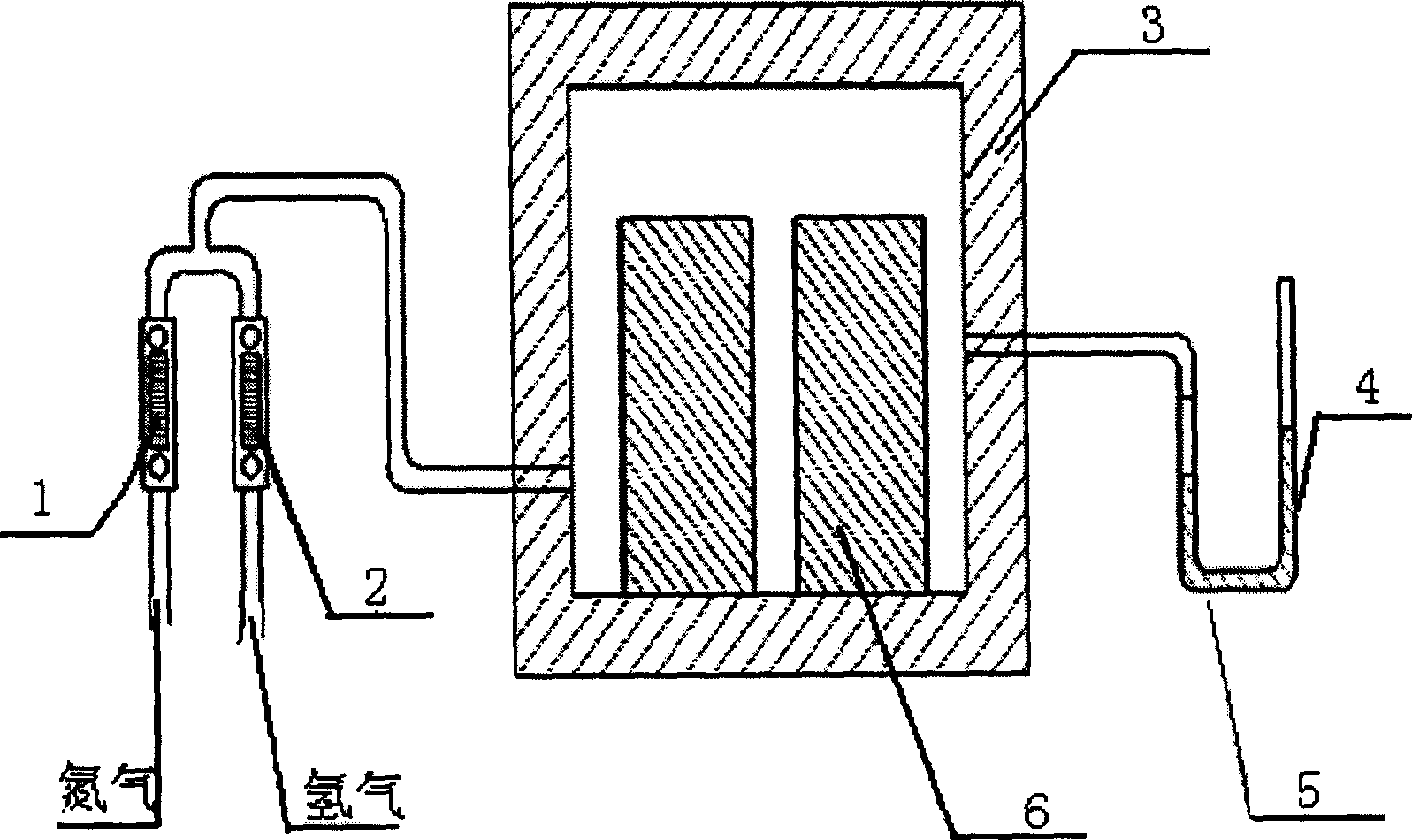

The invention discloses a low-porosity magnesium aluminate spinel-zirconia corundum zirconia composite sintered refractory material and a production technology thereof. The composite sintered refractory material comprises, in percent by weight, 38-48% of synthetic magnesium aluminate spinel with a size of 5-1 mm, 0-20% of synthetic magnesium aluminate spinel with a size of 1-0.088 mm, 5-20% of an aluminium chromium slag or zirconia corundum with a size of 1-0.088 mm, 10-25% of an aluminium chromium slag or zirconia corundum with a size less than 0.088 mm, 0-10% of corundum with a size less than 0.033 mm, 0-10% of chrome green with a size less than 0.033 mm, 2-10% of alpha alumina micro powder, 0-3% of magnesium oxide micro powder, 2-10% of zirconia micro powder, 0.05-0.2% of additional third generation water reducer and 3-7% of additional paper pulp waste liquid. The production technology comprises: weighing, burdening, mixing, molding, drying, and sintering at 1660-1800 DEG C for 5-10 h. The low-porosity magnesium aluminate spinel-zirconia corundum zirconia composite sintered refractory material has lowapparent porosityand the performances of resisting high temperature, resisting corrosion and resisting thermal shock, and is applicable to kiln lining at severe positions of a kiln.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

Regenerative magnesium-aluminium-chromium brick and preparation method

The invention relates to a regenerative magnesium-aluminium-chromium brick and a preparation method. The regenerative magnesium-aluminium-chromium brick comprises the following components in parts by weight: 65 to 80 parts of waste magnesite brick particles and powder; 15 to 25 parts of alumina-chrome slag powder; 5 to 15 parts of chrome ore powder; 0 to 5 parts of chrome green powder and 0 to 5 parts of zirconium oxide powder. The preparation method comprises the following steps of: removing etching layers of waste magnesite bricks, crushing and sieving into particles with particle sizes of below 1mm, 1 to 3mm and 3 to 5mm; respectively crushing alumina-chrome slags, chrome ores, chrome green, zirconium oxide and part of waste magnesite brick particles with the particle size of below 1mm into powder with the particle size of less than or equal to 0.088mm; adding the powder into a mixing rolling mill and adding calcium lignosulphonate solution to carry out mixing rolling; after mixing rolling, carrying out compression moulding in a press; and drying and firing to obtain the regenerative agnesium-aluminium-chromium brick. According to the invention, the alumina-chrome slags and the waste magnesite bricks are used as raw materials, the price is low, waste slags and waste bricks are timely processed and the problems of space occupation and environmental pollution are solved; the prepared regenerative magnesium-aluminium-chromium brick has good bonding strength, strong wear resistance, good anti-erosion ability and high thermal shock resistance.

Owner:JINZHOU YINGMING REFRACTORY MATERIALS

High-quality chromium drainage sand for steel ladle

ActiveCN105541358AModerate intensityHigh temperature resistanceMelt-holding vesselsGraphiteMolten steel

The invention provides high-quality chromium drainage sand for a steel ladle, which is composed of 68-94wt% of chromium ore sand, 5-30wt% of sea sand, 0-15wt% of quartz sand, 1-12wt% of high-aluminum ball, 0-2.5wt% of graphite, 0.1-1wt% of carbon black and 0-1wt% of chrome green. The high-quality chromium drainage sand has the characteristics of strong molten steel erosion resistance, good molten steel penetration resistance, good high-temperature sintering performance, uniform particle size distribution and good fluidity, and can effectively improve the automatic pouring rate of a multiple-refining steel ladle. By using the product provided by the invention, the automatic pouring rate of the steel ladle can reach more than or equal to 99%, so as to guarantee the quality of multiple refined molten steel and safe and continuous production of a continuous casting process.

Owner:RONGYUAN METALLURGICAL MATERIALS CO LTD

Method for manufacturing high-grade chromite-based stuffing sand for ladle

The invention discloses a method for manufacturing high-grade chromite-based stuffing sand for a ladle. The method comprises a pre-mixing step, in which graphite is poured into a sodium carboxymethylcellulose solution and is subjected to pre-mixing for 10-20 min, and carbon black is added and is subjected to mixing for 10-20 min to obtain a pre-mixed material. The method further comprises a step-by-step mixing step, in which sea sand, quartz sand, and high-alumina balls are added into an agitator and are subjected to mixing for 5-10 min; then chrome ore is added and is subjected to mixing for 8-15 min; then chrome green is added and is subjected to mixing for 5-10 min; and the pre-mixed material is added and is subjected to stirring for 10-20 min to obtain a mixed material. The method further comprises a rotary drying step, in which the mixed stuffing sand obtained through the above steps is sent into a rotary drying cylinder and is subjected to baking at 200-230 DEG C for 15-30 min in order to obtain the dried high-grade chromite-based stuffing sand for a ladle. The stuffing sand obtained through the method has characteristics of uniform mixing and mobility and a low water content. An automatic free-opening rate can be effectively increased.

Owner:RONGYUAN METALLURGICAL MATERIALS CO LTD

Phosphate-based high-temperature-resistant anti-corrosion paint and preparation method thereof

The invention discloses a phosphate-based high-temperature-resistant anti-corrosion paint and a preparation method thereof. The paint is composed of phosphate, ultra-fine chrome green, boric acid, water, a passivator, a surfactant, and chromic salt. The phosphate is obtained through a reaction of phosphoric acid and a metal oxide containing magnesium, aluminum and zinc, or a reaction of phosphoric acid and a metal hydroxide. The paint provided by the invention is especially suitable to be applied in corrosion protection of metal or alloy under high temperatures and severe environments. The paint is used for protecting engines, exhaust pipes, incinerators, and the like. With the paint, the service lives of equipments can be prolonged.

Owner:中昊北方涂料工业研究设计院有限公司

Chrome oxide product sintering method

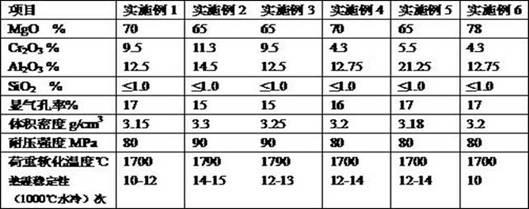

The invention provides a method for burning chrome green product which comprises: venting the N2 / H2 mixing gas to the electric stove with chrome green product, controlling the rate and the gauge of N2 and H2 by flow gauge to ascertain it is positive pressure condition inside the stove, burning the chrome green product at the tempter of 1400-1550 deg. for 1-8 hours. Wherein in the N2 / H2 mixing gas (by volume rate), N2 95-99.5%, H2 0.5-5%; The positive pressure rage is 10-30 mille water columns.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

One-time sintered chrome green frit dry particles and preparation method thereof

The invention discloses one-time sintered chrome green frit dry particles and a preparation method thereof. The frit dry particle preparation raw materials comprise boric acid, borax, feldspar, quartz, dolomite, barium carbonate, non-calcined alumina, zirconium silicate, fluorspar, and chromium oxide. The frit dry particles have an intrinsic chrome green color and good gloss, and are semitransparent. The particles are shiny under light. Because the frit dry particles have the intrinsic chrome green color, a ceramic factory glaze line printing process can be eliminated, glaze line length can be reduced, related staffs can be reduced, modularization collection degree is improved, production efficiency is improved, cost of ceramic enterprises is reduced, and quality controllability is improved. The frit dry particles can be used in a one-time sintering method for preparing microcrystalline tiles. The sintered microcrystalline tile surface glaze has a glistening gentle chrome green color and no pore which is visible to naked eyes. With the one-time sintering process, energy can be saved, emission can be reduced, and consumption can be reduced by approximately 15% than that of twice sintering.

Owner:广东陶瓷共赢商科技有限公司

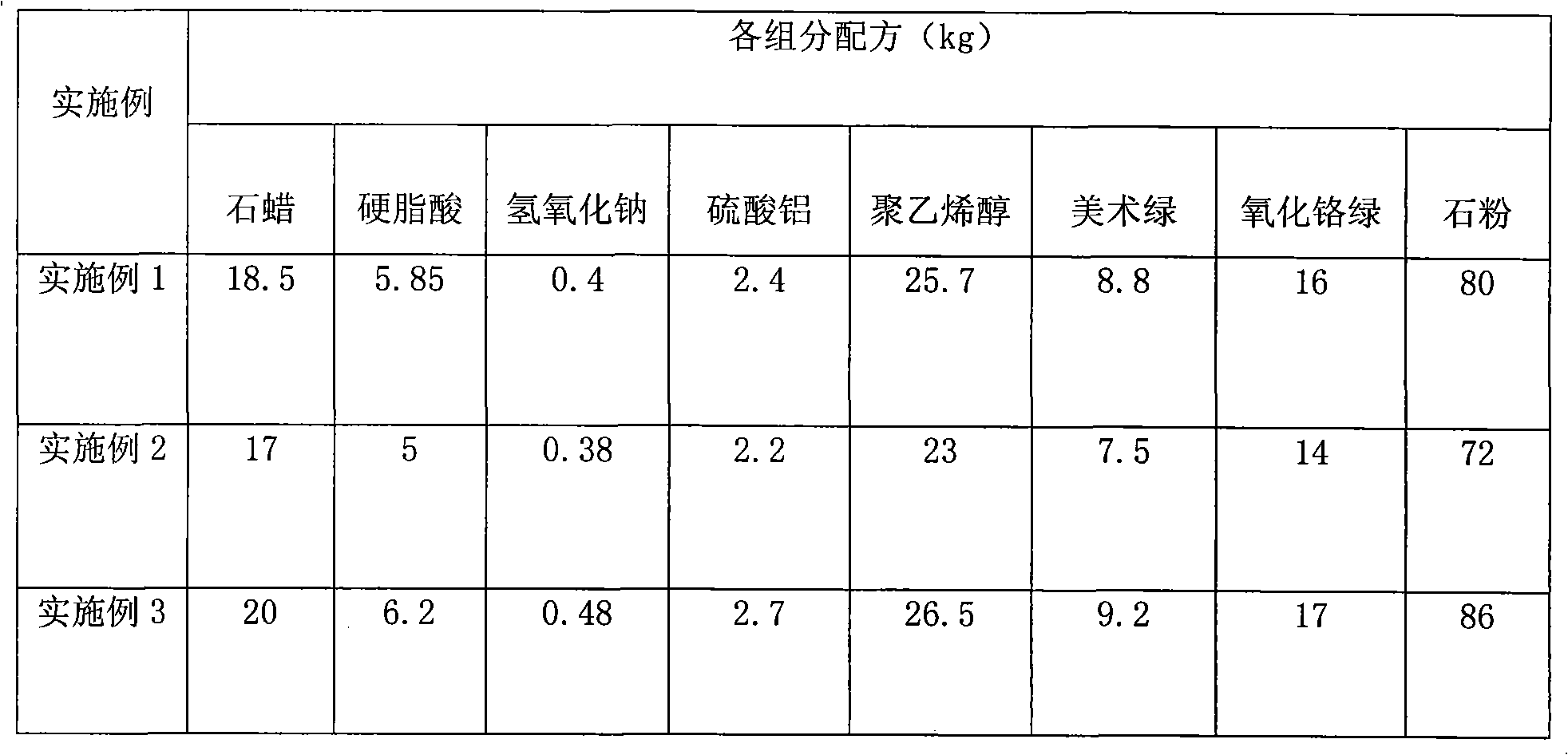

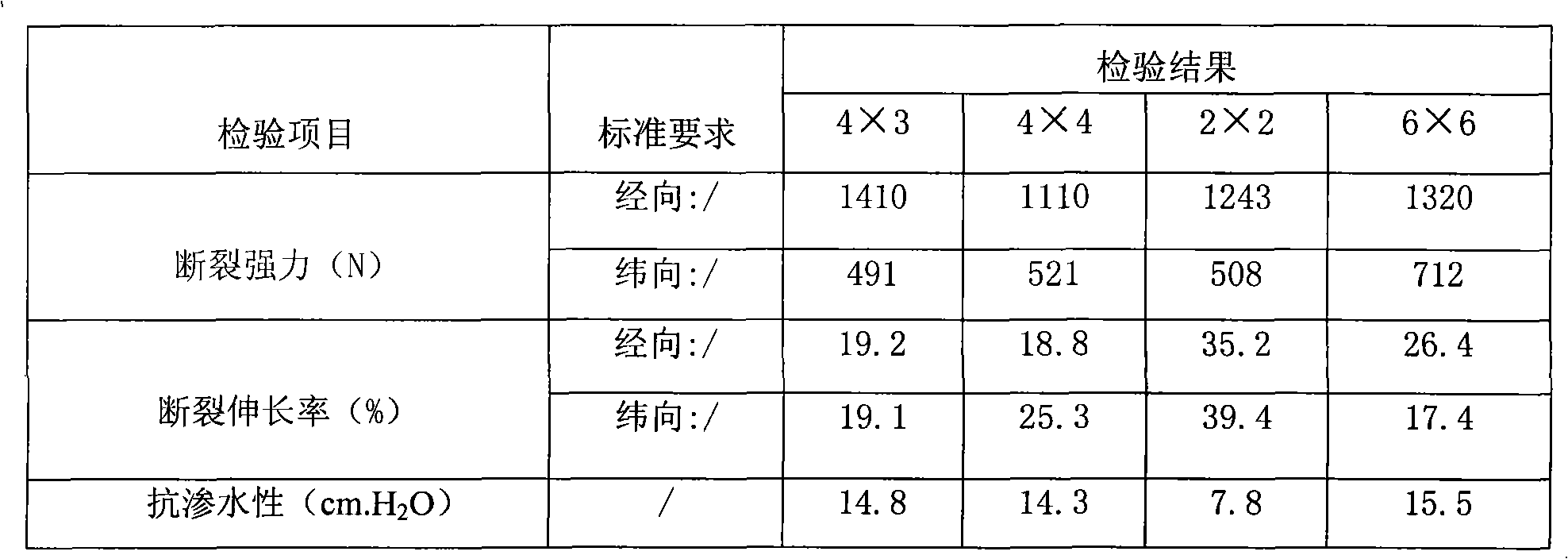

Waterproof agent used for waterproof oil wax cloth

InactiveCN101525839AReduce pollutionEnvironmental productivityFibre treatmentPolyvinyl alcoholStone dust

The invention discloses a waterproof agent used for waterproof oil wax cloth. The waterproof agent consists of the following components by weight: 9%-14% of paraffin, 3%-5% of stearic acid, 0.2%-0.4% of sodium hydroxide, 0.5%-3.5% of aluminium sulphate, 12%-20% of polyvinyl alcohol, 4%-7% of chrome green, 6%-13% of chrome oxide green and 40%-60% of stone dust. The oil wax cloth produced by using the waterproof agent has wide application range and can be used in the environment with the temperature ranging from minus 40 DEG C to plus 80 DEG C, is not crisp in cold climate, and does not soften in high temperature climate, feels always the same and is kept in the stable state; and the production of the waterproof agent is environment-friendly, nontoxic and harmless. Therefore, the product has good economic and social benefits.

Owner:NINGBO TIANDUN WATERPROOF MATERIAL CO LTD

High-performance mild cleanser for cleansing wall face brick

InactiveCN102080024AWon't hurtCompatibility is reasonableOrganic detergent compounding agentsSurface-active detergent compositionsSide effectBrick

The invention relates to the technical field of a building cleanser, in particular to a high-performance mild cleanser for cleansing a wall face brick, which solves the technical problems that the proportioning is unreasonable in the prior art, the gelation system of the cement and the glaze of the face brick can be easily damaged and the like. The cleanser comprises the following components in parts by weight: 1-8 parts of oxalic acid, 0.1-5 parts of polyethylene glycol and 50-90 parts of water. Compared with the prior art, the high-performance mild cleanser for cleansing a wall face brick has the following advantages: 1, the proportioning is reasonable; and the high-performance mild cleanser has high dirt-removing power and small side effect, and is safe and convenient to use; and 2, the high-performance mild cleanser does not react with bodies of iron oxide black, iron oxide red, iron oxide yellow, chrome green and other pigments, and can not cause damage to the gelation system of the cement and the glaze of the face brick.

Owner:杭州正博新型建筑材料有限公司

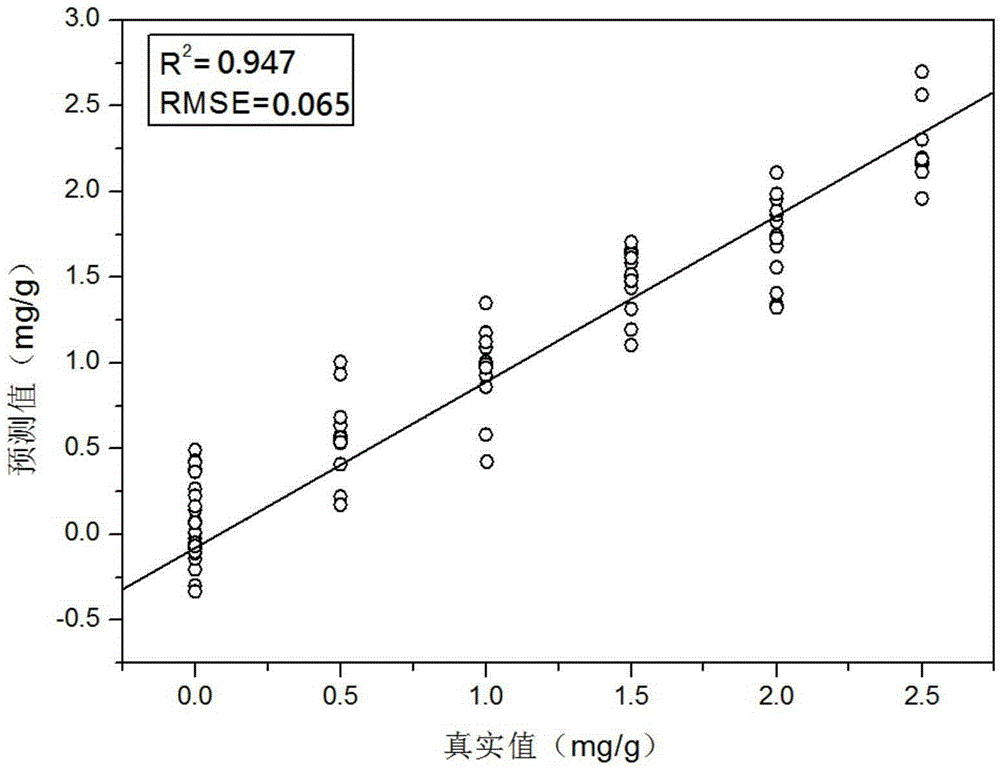

Method for detecting lead chrome green addition content of tea leaves

InactiveCN105424640AGuaranteed sourceGuaranteed accuracyMaterial analysis by optical meansTest sampleTransmittance

The invention discloses a method for detecting the lead chrome green addition content of tea leaves. The method includes the steps of firstly, using tea leaves with different lead chrome green addition contents as test samples, and obtaining infrared absorption spectrums, within the set wave number range, of all the test samples; secondly, extracting transmittance of characteristic absorption peaks of lead chrome green and obtaining absorbance of all the characteristic absorption peaks according to the infrared absorption spectrums of the test samples; thirdly, establishing linear regression models between lead chrome green contents and all the absorbance; fourthly, obtaining the absorbance, at the characteristic absorption peaks of lead chrome green, of the test samples, and obtaining the contents of lead chrome green in the test samples according to the linear regression models. The method has the advantages of being simple, rapid and high in accuracy.

Owner:ZHEJIANG UNIV

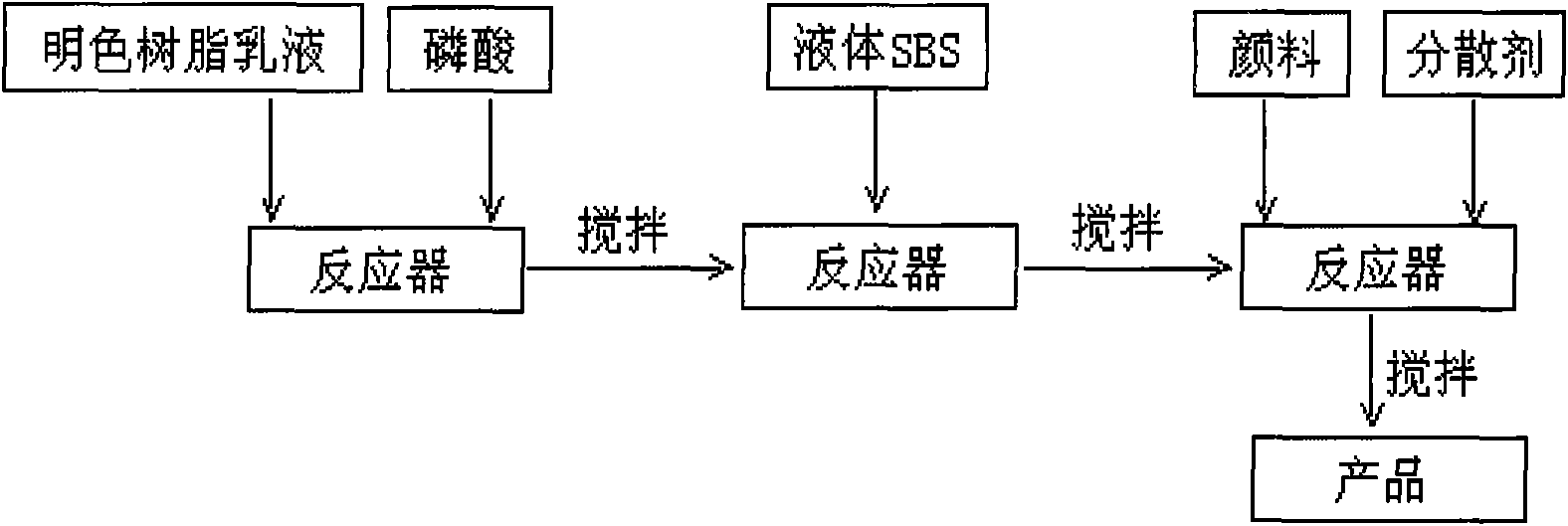

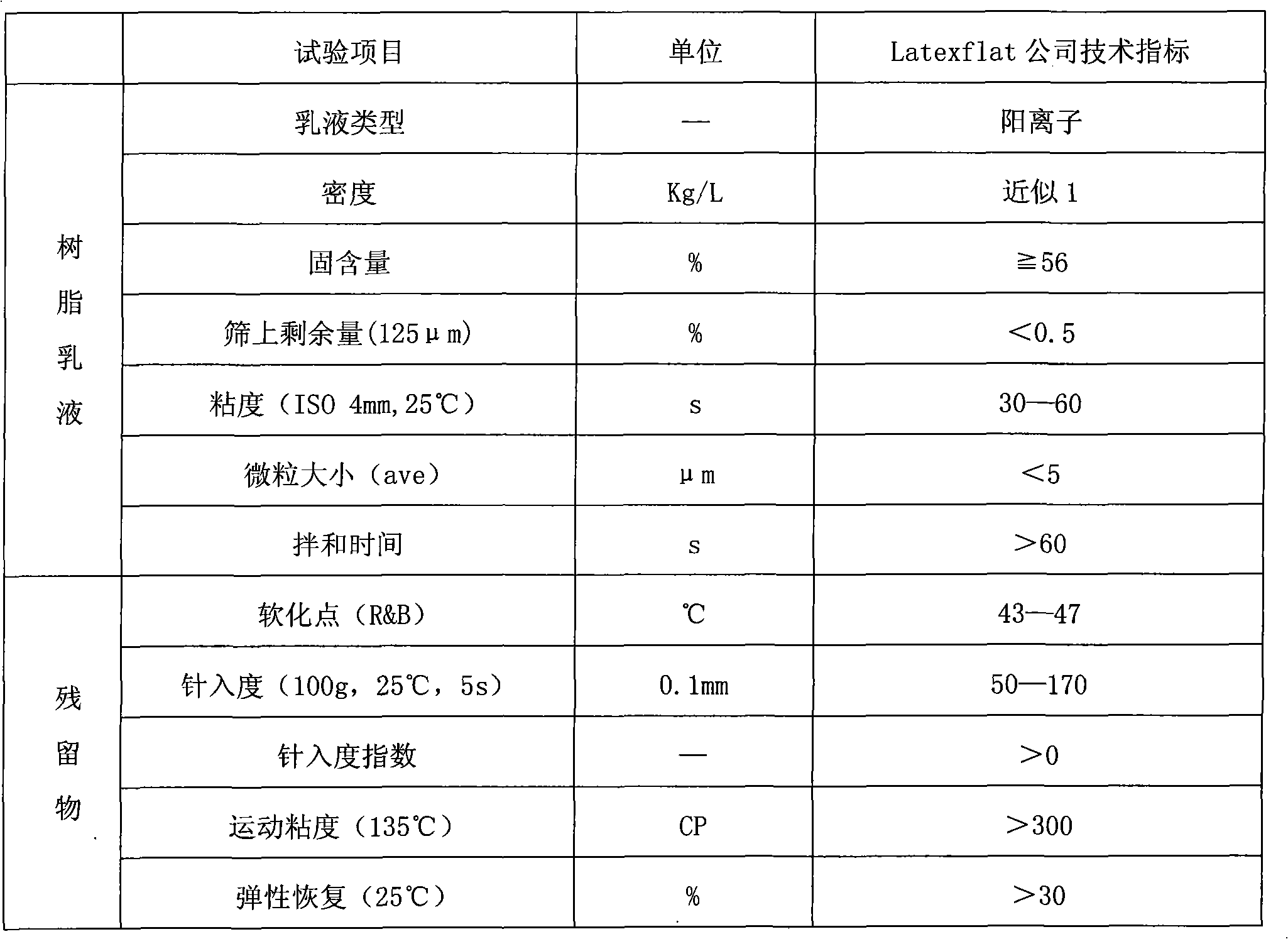

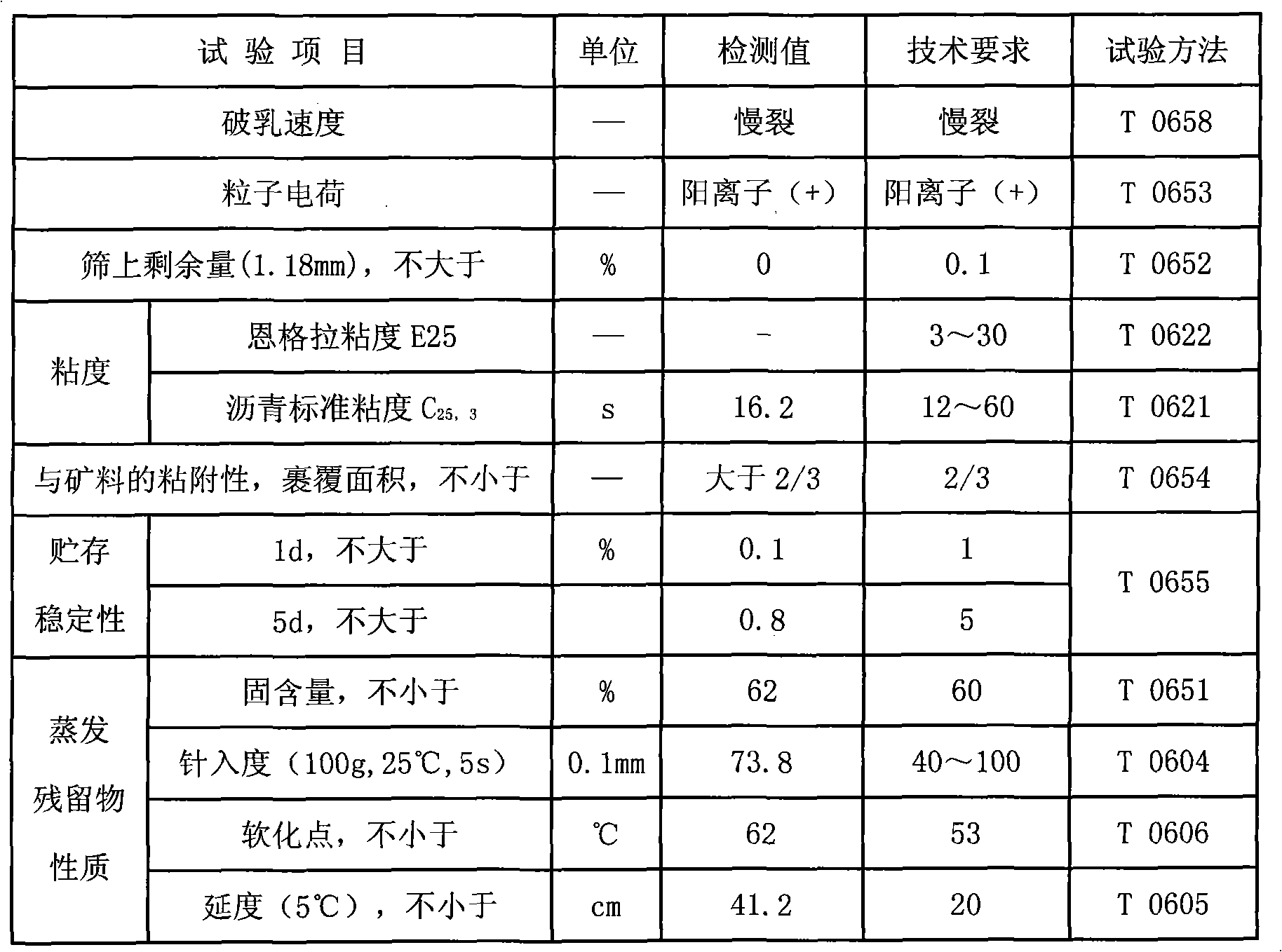

Method for preparing color liquid SBS modified emulsion resin

ActiveCN101565533AImprove road performanceNothing producedBuilding insulationsPhosphoric acidRoad surface

The invention aims at solving the technical problems that the environment is polluted, the production cost is high and the product can not be used as the color micro-surface cementing material due to poor performance in the process for preparing the existing color modified emulsion discolored asphalt, and provides a method for preparing color liquid SBS modified emulsion resin which consists of the following raw materials: light color resin emulsion, liquid SBS modifier, inorganic pigment 307 chrome molybdenum red pigment or SGC-M chrome green pigment, pigment dispersant polycarboxylic acid sodium salt or polyacrylic acid ammonium salt. The method comprises the steps of: when in preparation, adding the raw materials into a reactor, maintaining the temperature of the reactor within 20 DEG C to 30 DEG C, adding phosphoric acid to adjust the pH value of the system to be 2.5-4.5, uniformly stirring the system and then obtaining the high-performance color liquid SBS modified emulsion resin. The method has the advantages of simple preparation process, low production cost and non-toxic harmless performance, can be constructed at room temperature, and can prepare the high-performance color micro-surface cementing material to be used for heavy traffic roads by choosing appropriate modifier.

Owner:SHANXI PROVINCIAL RES INST OF COMM

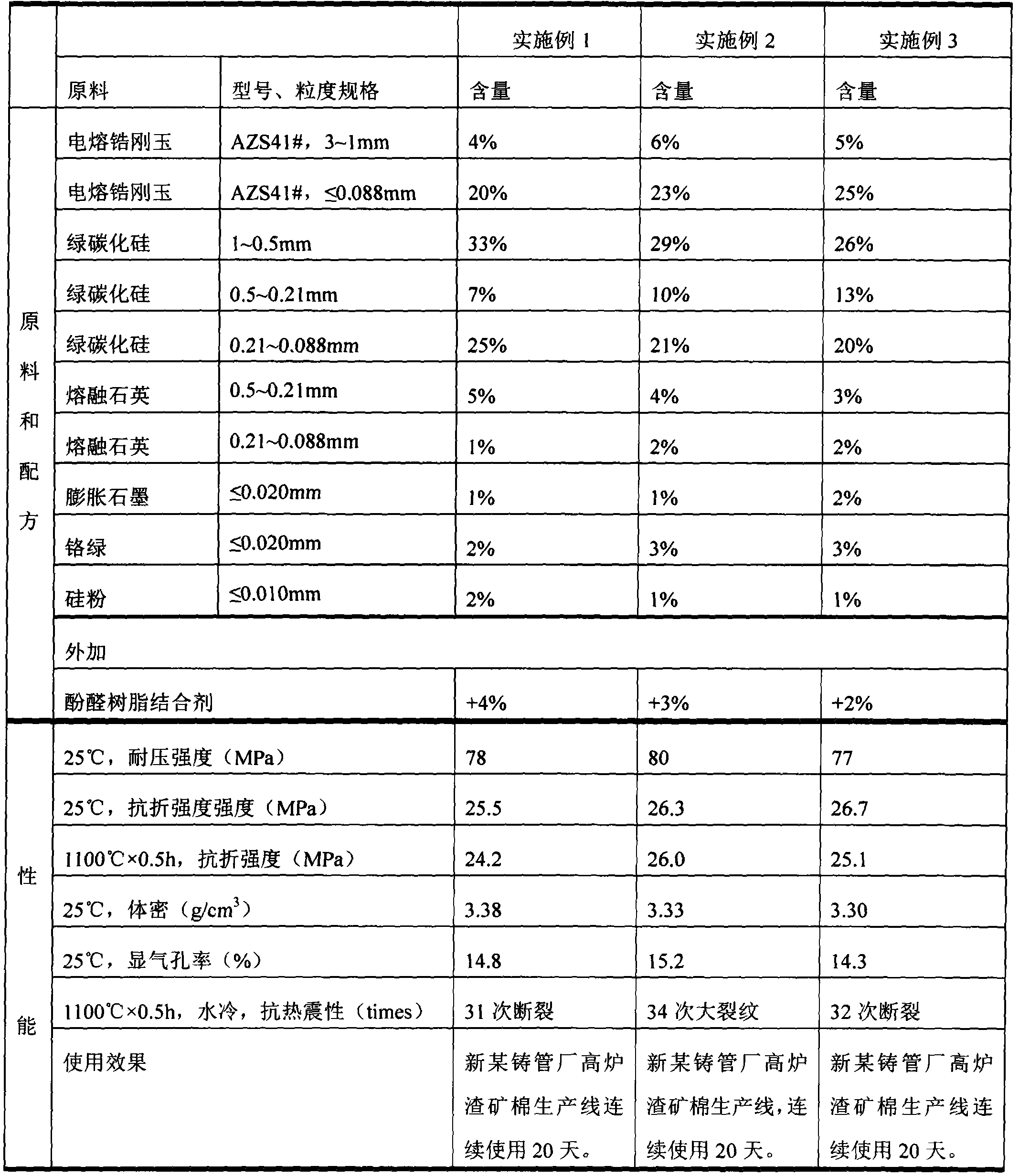

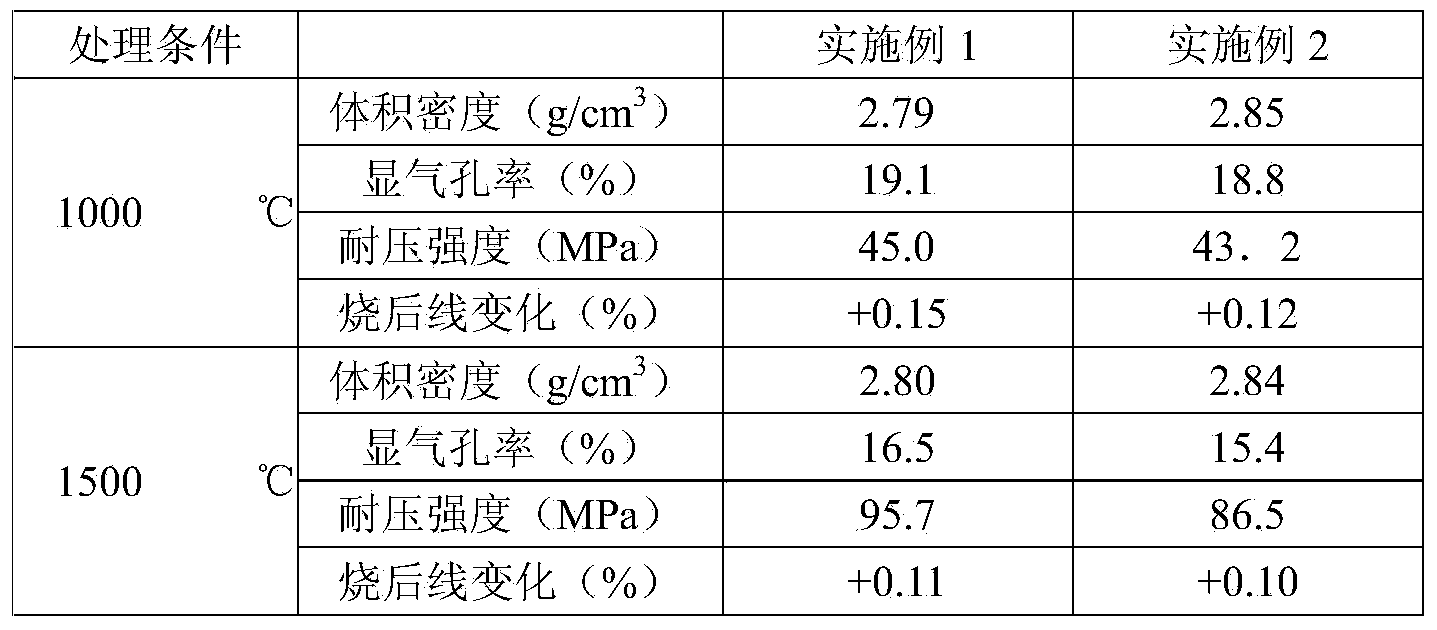

Flow controlling water gap for production of mineral wool from blast furnace slag and production process thereof

The invention relates to a flow controlling water gap for production of mineral wool from blast furnace slag and a production process thereof, and belongs to the field of refractory materials. The flow controlling water gap is prepared from the following components: 3-6% of electrically-fused zirconia corundum with the granularity of 3-1mm, 20-25% of electrically-fused zirconia corundum with the granularity smaller than or equal to 0.088mm, 25-35% of green silicon carbide with the granularity of 1-0.5mm, 5-15% of green silicon carbide with the granularity of 0.5-0.21mm, 20-25% of green silicon carbide with the granularity of 0.21-0.088mm, 3-5% of fused quartz with the granularity of 0.5-0.21mm, 1-2% of fused quartz with the granularity of 0.21-0.088mm, 1-2% of expanded graphite with the granularity of smaller than or equal to 0.020mm, 2-3% of chrome green with the granularity of smaller than or equal to 0.020mm, 1-2% of silicon powder with the granularity of smaller than or equal to 0.010mm and 2-4% of plaenolic resin binder. The production process comprises the following steps: mixing, ageing a mixture, performing isostatic pressing forming, drying, sintering, performing flaw detection, performing glaze spraying and the like. The flow controlling water gap has excellent erosion resistance, heat shock resistance and oxidation resistance, and has the service life of more than 20 days, which is far longer than the service life of graphite water gap (about 4 days).

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD +1

Coating material with catalytic function of color light

InactiveCN101709159AImprove photocatalytic efficiencyRich in colorMulticolor effect coatingsCatalytic functionAnatase

The invention provides a coating material with the catalytic function of color light, belonging to the technical field of building coating. The coating material comprises the following raw materials: titanium dioxide photocatalysis powder or modified titanium dioxide photocatalysis powder, deionized water or distilled water, accessory ingredient and inorganic pigment, wherein proportion thereof is as follows: 2-50%:35-90%:0.1-5%:0.1-10%. The titanium dioxide photocatalysis powder or the modified titanium dioxide photocatalysis powder is anatase phase titanium dioxide, nonmetal-doped titanium dioxide, transition metal-doped titanium dioxide, rare earth metal-doped titanium dioxide, noble metal-doped titanium dioxide or oxide semiconductor-doped titanium dioxide; the accessory ingredient is dispersing agent and defoaming agent; the inorganic pigment is one kind of several kinds of iron blue, cobalt blue, iron red, chrome red, molybdenum red, titanium chromium yellow, iron yellow, titanium nickel yellow, chrome green, iron green, zinc green, titanium green, ultramarine violet, cobalt violet, manganese violet, titanium manganese brown, iron manganese brown, copper chromium black, titanium white black, zinc white and wollastonite powder. The coating material has the advantages of high photocatalysis efficiency, stable performance, abundant colors, low cost, stable combination, and convenient preparation and use.

Owner:KUNMING ZHONGYOU FENGYU TECH

Magnesite-dolomite ramming refractory taking castor oil as binding agent

The invention discloses magnesite-dolomite ramming refractory taking industrial castor oil as a binding agent. The magnesite-dolomite ramming refractory is characterized by comprising the following raw constituents in weight percentage: 65 percent of dead burned high-calcium magnesite MgO, 29 percent of CaO, smaller than or equal to 3 percent of Al2O, Fe2O3 and SiO2, 6 to 7 percent of castor oil, 25.5 percent of 98 fused magnesite with 240 meshes, 1 to 2 percent of chrome green, 0.5 percent of 92 silica fume, 2 percent of fluorite powder with 325 meshes, and 1 percent of resin powder 4012 (thermoset). Before being mixed, dead burned high-calcium magnesite particles are preheated, the temperature is 100 to 110 DEG C, and the time is 10 to 12 hours; then the rest of raw fine powder is preheated, and the fine powder is uniformly mixed to be reserved, so that the fine powder is more perfectly combined with the particles. Compared with the prior art, the magnesite-dolomite ramming refractory has the benefits that firstly, magnesium calcium refractory can be effectively prevented from being hydrated; secondly, the magnesite-dolomite ramming refractory is convenient to use and innocuous; thirdly, the magnesite-dolomite ramming refractory does not contain impurities capable of polluting molten steel; fourthly, the magnesite-dolomite ramming refractory is easy to sinter, has good thermal shock resistance, and can have high strength at the baking stage of stainless steel refining equipment.

Owner:海城市金福锋科技有限公司

Seed crystal introduced chromium tin pink ceramic pigment and preparation method thereof

The invention discloses seed crystal introduced chromium tin pink ceramic pigment and a preparation method of the seed crystal introduced chromium tin pink ceramic pigment. The preparation method comprises the following steps of: (1) preparing seed crystals, evenly mixing calcium carbonate, stannic oxide, quartz and chrome green according to a molar ratio of (0.9-1.1):(0.9-1.1):(0.9-1.1):(0.115-0.135) to obtain a mixture, mixing and grinding the mixture, agate ball stones and water according to proportion by weight of 100:(450-550):(54-66) until the grain size achieves D90<=5mu m, drying and sieving grinded mixture, then adding boric acid which is 3%-5% of total weight, evenly mixing, burning, grinding and drying to obtain the seed crystals; and (2) preparing the pigment, evenly mixing calcium carbonate, stannic oxide, quartz and chrome green according to a molar ratio of (0.9-1.1):(0.9-1.1):(0.9-1.1):(0.005-0.05), adding the seed crystals which are 1%-3% of the total weight and boric acid which is 3%-5% of total weight, evenly mixing, calcinating, grinding and drying to obtain end products. The seed crystal introduced chromium tin pink ceramic pigment has the advantages the thermostability is high, the color development is strengthened, and the stability and the red degree value are improved.

Owner:佛山市南海万兴材料科技有限公司

Glass melting furnace regenerator top special-use compound spinel zirconium brick and producing method thereof

The present invention discloses a glass melting furnace regenerator top special-use compound spinel zirconium brick comprising 35 to 62 parts of dense corundum, 12 to 18 parts of tabular corundum, 8 to 14 parts of electrically-fused zirconia mullite, 5 to 11 parts of chrome ore, 10 to 13 parts of chrome green, 1 to 4 parts of electrically-fused fused zirconia, 2 to 5 parts of beta-Al2O3 and the proper amount of a binding agent; the above ingredients are put into a powerful sand mixing machine for mixing and ageing mixture for 48h, and then pressed into green bricks on a hydraulic machine, the green bricks are sent into a drying kiln for drying for more than 60 hours, and then fed into a high-temperature tunnel kiln for firing at the temperature of 1600-1650 DEG C to obtain a compound spinel zirconium brick finished product, wherein the cart time is 120 to 150 minutes. The compound spinel zirconium brick finished product can replace other refractory bricks applied to a glass melting furnace regenerator top in the prior art, and greatly improves the life of a glass melting furnace. At the same time a producing method of the compound spinel zirconium brick is simple and has the characteristics of short production cycle and high efficiency.

Owner:郑州汇特耐火材料有限公司

Seed crystal introduced agate red ceramic pigment and preparation method thereof

The invention discloses a seed crystal introduced agate red ceramic pigment and a preparation method of the seed crystal introduced agate red ceramic pigment. The preparation method comprises the following steps of: (1) preparing seed crystals: evenly mixing calcium carbonate, stannic oxide, quartz and chrome green according to a molar ratio of (0.9-1.1):(0.9-1.1):(0.9-1.1):(0.115-0.135), mixing and grinding the obtained mixture, agate ball stone and water according to proportion by weight of 100:(450-550):(54-66) until the grain size achieves D90<=5mu m, drying and sieving the ground mixture, then adding boron-contained compounds which are 3%-5% of total weight, evenly mixing, burning, grinding and drying to obtain the seed crystals; and (2) preparing the pigment: evenly mixing calcium carbonate, stannic oxide, quartz and chrome green according to a molar ratio of (0.9-1.1):(0.9-1.1):(0.9-1.1):(0.115-0.135), adding the seed crystals which are 1%-3% of the total weight and the boron-contained compounds which are 3%-5% of the total weight, evenly mixing, burning, grinding and drying to obtain end products. The seed crystal introduced agate red ceramic pigment and the preparation method can reduce synthetic difficulties of the pigment and are strong in color development, bright in color and luster and good in thermostability.

Owner:佛山市南海万兴材料科技有限公司

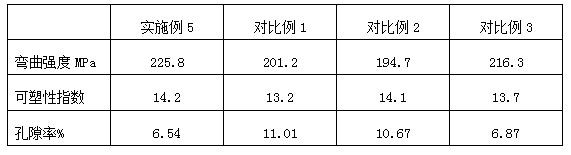

High-strength siliceous brown glaze electric porcelain and preparation method thereof

ActiveCN112898003ALow softening temperatureImprove liquidityCeramic materials productionClaywaresSesquioxideManganese

The invention discloses high-strength siliceous brown glaze electric porcelain and a preparation method thereof, and relates to the technical field of siliceous electric porcelain. The invention discloses a high-strength siliceous brown glaze electric porcelain, the raw materials comprise a blank material and a brown glaze material; the blank material comprises the following raw materials: kaolin, wollastonite, Jiepai mud, siliceous porcelain waste powder, low-melting-point glass powder, spodumene, yttrium oxide, ceramic-grade talcum powder and a nucleating agent; the brown glaze material is composed of the following raw materials: potassium feldspar powder, quartz powder, blank mud, calcite powder, cooked talcum powder, iron oxide, chrome green, manganese sesquioxide and Jiepai mud. The invention also discloses the preparation method of the brown glaze electric porcelain. The siliceous brown glaze electric porcelain has the advantages of simple and easily available raw materials, low cost, high bending strength, good plasticity and good stability; and the brown glaze is low in cost, short in glaze dipping time, good in glazing effect, ruddy and full in glaze surface, bright in luster, stable in color generation and free of color difference, and the strength of the brown glaze electric porcelain is improved by 10% or above compared with the strength of the brown glaze electric porcelain before glazing.

Owner:湖南省醴陵市华电电瓷制造有限公司

Corundum durable moisturizing plastic material

The invention discloses a corundum durable moisturizing plastic material which is low in cost, has long storage period and is prepared through a simple production process, and a preparation method thereof. The plastic material is prepared from the following raw materials in percentage by weight: 10-14 percent of 5-3 mm super alum, 20-30 percent of 3-1 mm super alum, 10-12 percent of white corundum particles, 7-9 percent of kyanite, 24-30 percent of white corundum powder, 7-9 percent of Guangxi mud, 2.5-3.5 percent of chrome green, 4.5-5.5 percent of binding agent and 3-4 percent of aluminum sulfate solution. The preparation method of the plastic material comprises the following steps: (1) pre-preparing the aluminum sulfate solution; (2) adding the kyanite, the white corundum powder, the Guangxi mud and the chrome green into a stirrer to mix according to the proportions; (3) adding the two super alums and the white corundum particles into the stirrer and stirring for 3-5 minutes, then adding fine powder to stir for 10 minutes, then adding the binding agent with the weight being 2 / 3 of the weight of the binding agent and discharging; (4) adding the remaining binding agent and stirring for 10-15 minutes after the mixture is aged for 48 hours, discharging and packaging.

Owner:无锡市宜宏耐火材料有限公司

Low hygroscopicity submerged-arc welding sintered flux and preparation method thereof

InactiveCN109454361ALow S contentImprove the ability to resist H2S corrosionArc welding apparatusWelding/cutting media/materialsSlagPolyvinyl alcohol

The invention relates to low hygroscopicity submerged-arc welding sintered flux and a preparation method thereof. The low hygroscopicity submerged-arc welding sintered flux is prepared from the following components in percent by weight: 13-28% of fluorite, 16-20% of bauxite, 20-28% of magnesite, 28-45% of marbles, 17-20% of wollastonite, 3-6% of rutile, 0.1-1.2% of zircon sand, 3-6% of polyvinyl alcohol, 1.2-3.6% of chrome green, 2-8% of sodium carbonate, 3-6% of metal nickel, 2-5% of manganese metal and 1-3% of rare earth oxides. By adjusting a flux slag system and improving the manufacturingprocess by means of a weld joint alloy transitional mode, the invention provides the low hygroscopicity submerged-arc welding sintered flux which is excellent in low temperature impact toughness.

Owner:DONGGUAN UNIV OF TECH

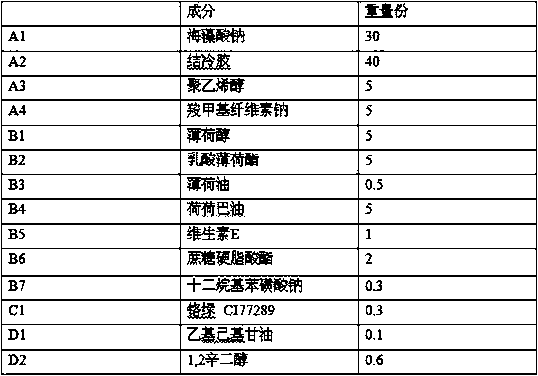

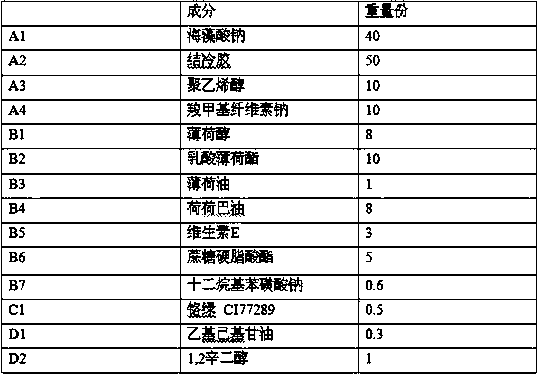

A kind of flake microcapsule containing cooling formula

ActiveCN105395378BReduce surface tensionGood natureCosmetic preparationsToilet preparationsPolyvinyl alcoholJojoba oil

The invention discloses a flake-like microcapsule containing a cool formula and belongs to the technical field of microcapsules. The flake-like microcapsule containing the cool formula comprises, by weight parts, 30-40 parts of sodium alginate, 40-50 parts of gellan gum, 5-10 parts of polyvinyl alcohol, 5-10 parts of carboxymethyl cellulose sodium, 5-8 parts of menthol, 5-10 parts of menthyl lactate, 0.5-1 part of mint oil, 5-8 parts of jojoba oil, 1-3 parts of vitamin E, 2-5 parts of sucrose stearate, 0.3-0.6 part of sodium dodecyl benzene sulfonate, 0.3-0.5 part of chrome green CI77289, 0.1-0.3 part of ethylhexylglycerin and 0.6-1 part of 1,2 octanediol. The raw materials are selected through creative tests on the basis of no damage of natural cool raw materials, and through collaborative compatibility effect of the raw materials, the flake-like microcapsule has good quality and is good in stability.

Owner:CHONGQING PELLETS TECHN & TRADE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com