Chrome oxide product sintering method

A sintering method and chromium oxide technology are applied in the field of sintering chromium oxide products by controlling the atmosphere, which can solve problems such as failure to realize industrialization, and achieve the effects of easy industrial application, low labor intensity, and easy process control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

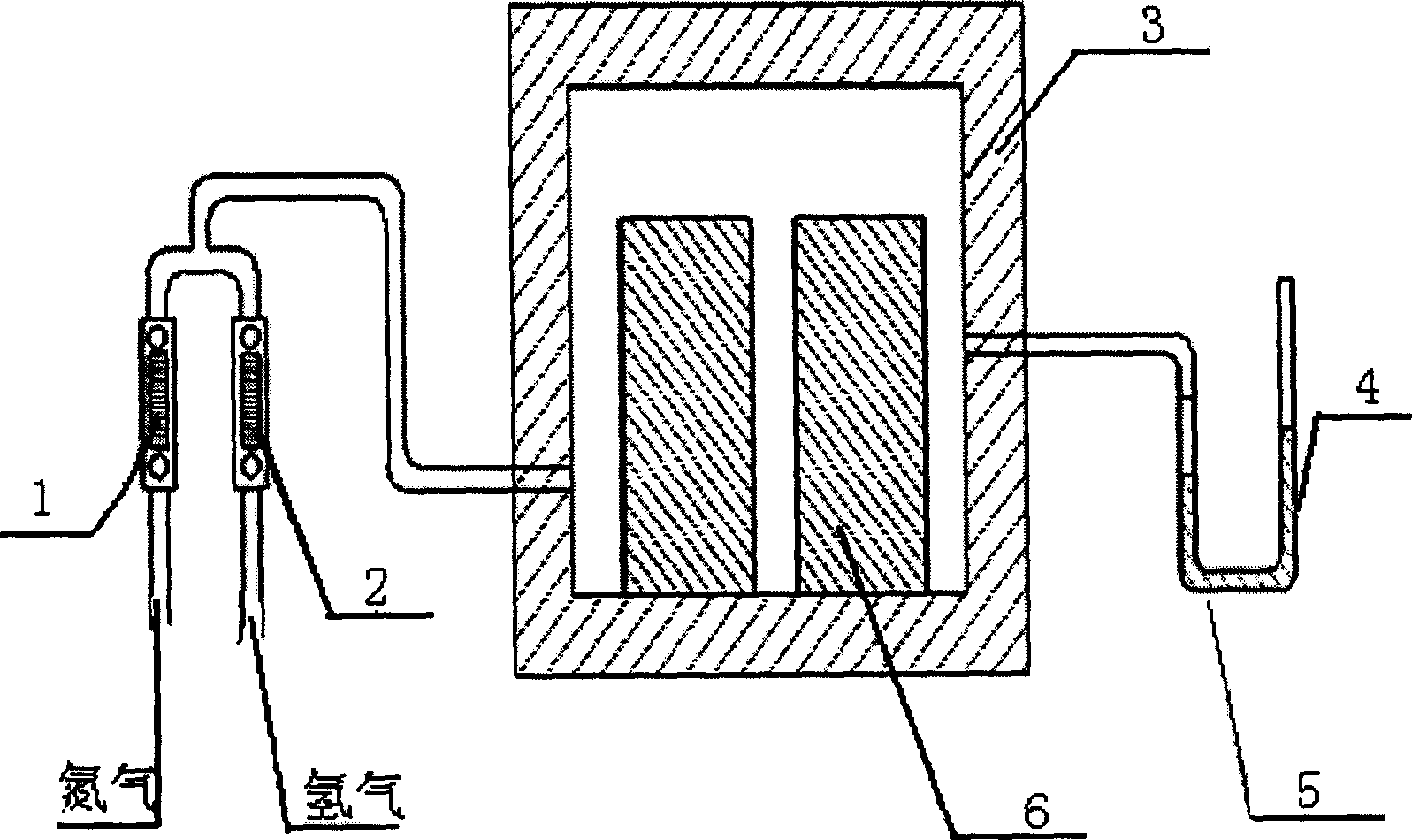

Embodiment 1

[0012] Chromium oxide products use pure Cr 2 o 3 The fine powder is put into the electric furnace kiln after being pressed and formed, and 98% N is fed into the kiln through the control of the flow meter. 2 and 2%H 2 Observe the height difference of the water column in the U-shaped tube so that the pressure in the kiln is 20 mm of water column to ensure that the kiln is in a state of slight positive pressure and a reducing atmosphere to prevent outside air from entering the electric furnace kiln, and then keep warm at 1450 ° C for 1 hour sintering. In Comparative Example 1, the same sample was sintered at 1700°C for 1 hour in an air atmosphere. Under the same atmosphere, the higher the firing temperature, the higher the bulk density of the chromium oxide product and the lower the apparent porosity. Their bulk density and apparent porosity are compared in Table 1.

[0013] Bulk density (g / cm 3 )

Embodiment 2

[0015] Chromium oxide products use pure Cr 2 o 3 Composite fine powder, its raw material composition is (by percentage weight): Cr 2 o 3 97%, TiO 2 3%, put it into the electric furnace kiln after being pressed and formed, and pass 95% N into the kiln through the control of the flow meter 2 and 5%H 2 Observe the height difference of the water column in the U-shaped tube so that the pressure in the kiln is 10 mm of water column, and keep the temperature at 1400 °C for 4 hours for sintering. In Comparative Example 2, the same sample was sintered at 1680° C. for 1 hour in an air atmosphere. Their bulk density and apparent porosity are compared in Table 2.

[0016] Bulk density (g / cm 3 )

Embodiment 3

[0018] Chromium oxide products use pure Cr 2 o 3 Composite fine powder, its raw material composition is (by percentage weight): Cr 2 o 3 88%, TiO 2 4%, ZrO 2 8%, put it into the electric furnace kiln after being pressed and formed, and pass 99.5% N into the kiln through the control of the flow meter 2 and 0.5% H 2 Observe the height difference of the water column in the U-shaped tube so that the pressure in the kiln is 30 mm of water column, and keep the temperature at 1500 ° C for 2 hours for sintering. In comparative example 3, the same sample was sintered at 1700° C. for 2 hours in an air atmosphere. Their bulk density and apparent porosity are compared in Table 3.

[0019] Bulk density (g / cm 3 )

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com