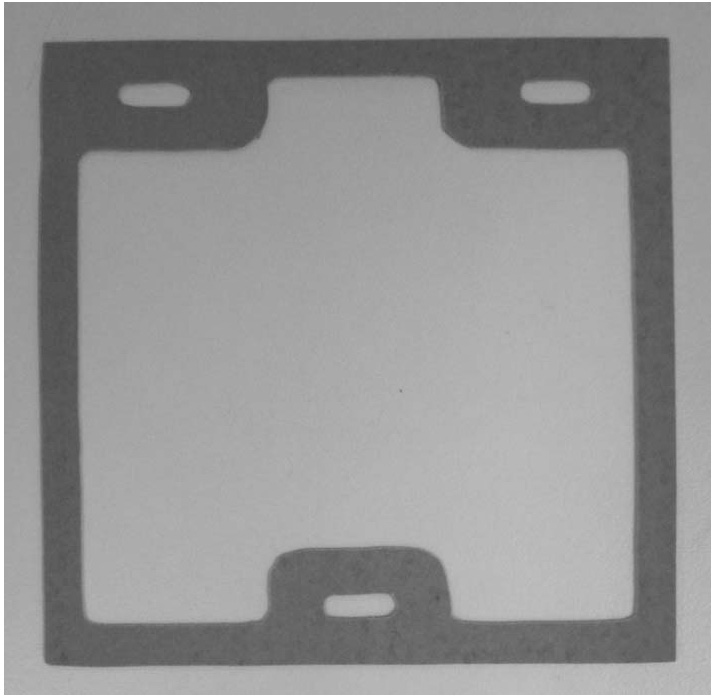

Sealing gasket for medium-and-low temperature solid oxide fuel cell, and manufacturing method and application of sealing gasket

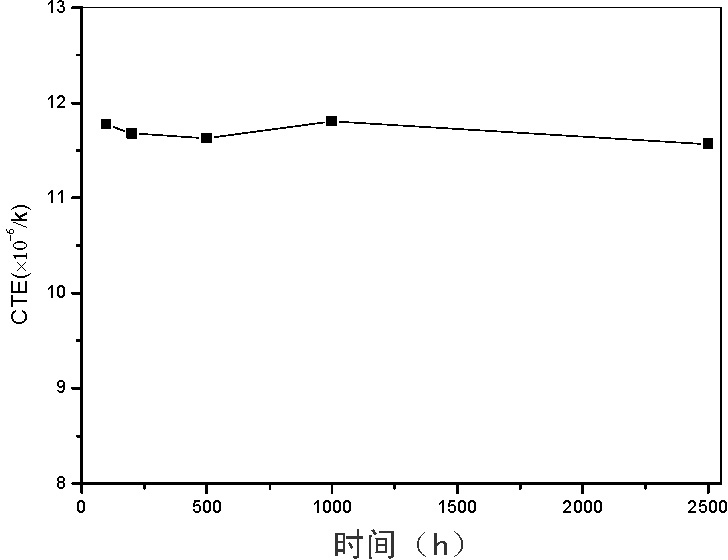

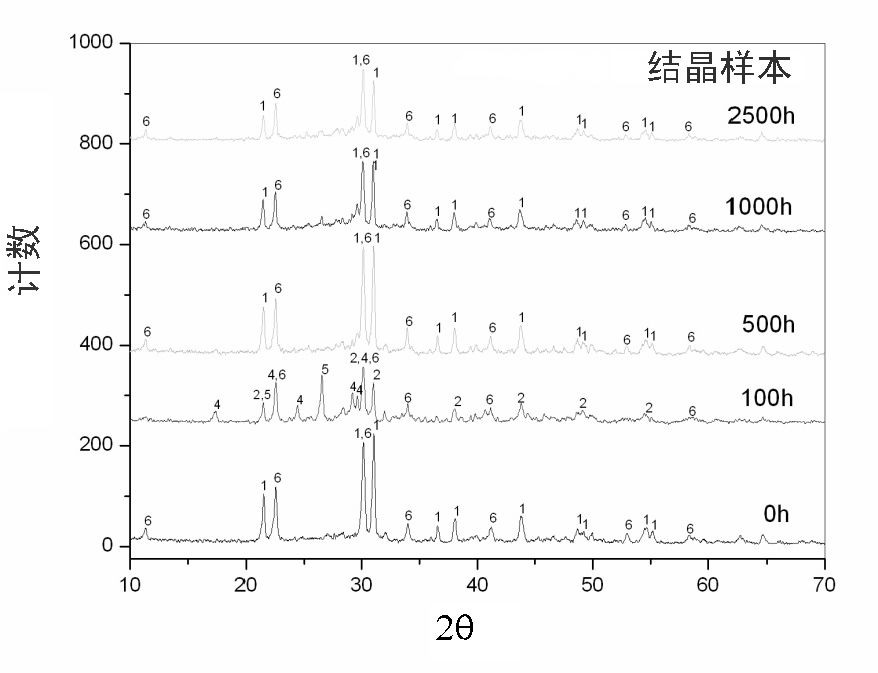

A solid oxide and fuel cell technology, which is applied to battery components, circuits, electrical components, etc., can solve problems such as sealing failure, affecting battery stack current collection, and difficult quality control, achieving small changes in thermal expansion coefficient and easy industrialization Good application and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described with reference to the accompanying drawings and the following embodiments. It should be understood that the accompanying drawings and the following embodiments are only used to illustrate the present invention rather than limit the present invention.

[0035] The sealing material provided by the present invention is based on BaO, B 2 o 3 , SiO 2 As the core component, a material with a thermal expansion coefficient close to the target and a suitable viscosity can be obtained, which is suitable for sealing with a thermal expansion coefficient of 10 to 12.5×10 -6 Materials between / k, such as cubic zirconia (YSZ) electrolyte and connector materials in SOFC.

[0036] Of which SiO 2 It is the main glass-forming agent in glass, and its molar percentage can be 28-38 mol%. In addition to enhancing the thermal stability and chemical stability of glass, it can also enhance the bonding strength between glass and metal and improve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com