Heat machining and heat treatment process of aluminum-silicon alloy plate prepared by powder sintering

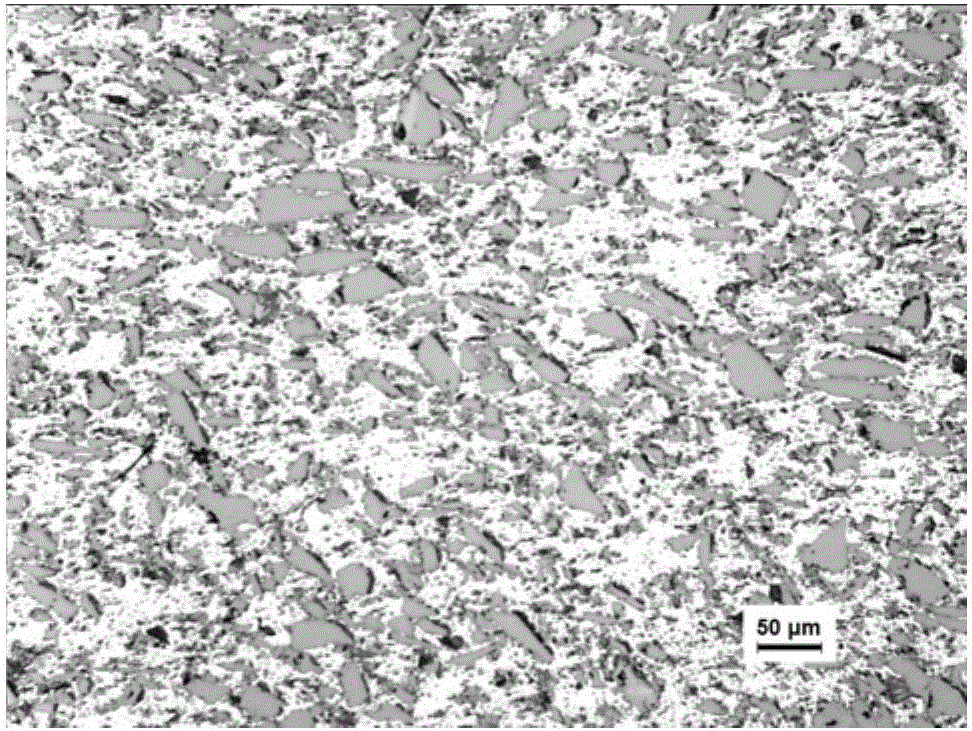

A technology of aluminum-silicon alloy and thermal processing, which is applied in the field of processing and heat treatment of powder metallurgy materials, to achieve the effects of excellent mechanical properties, fine grains of the matrix, and excellent air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

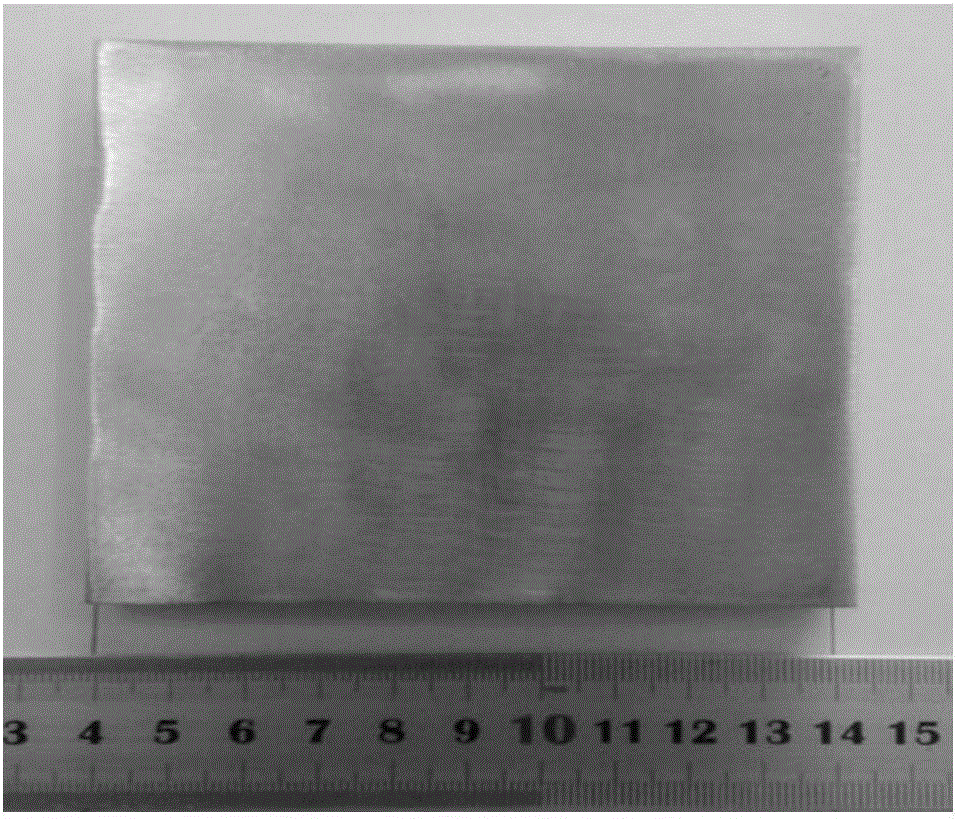

[0047] Use aluminum powder and silicon powder with a purity >99.9%, and mix them thoroughly according to the Al-40% Si composition ratio, put the Al and Si mixed powder into the mold, and apply a pressure of 20Mpa to the Al and Si mixed powder. The mold and the Al and Si mixed powder are heated together to 510°C and kept for 10 minutes; then, continue to heat up to the sintering temperature of 1000°C and sinter for 20 minutes. During the sintering process, a pressure of 50Mpa is applied to the Al and Si mixed powder. , depressurization, and natural cooling to obtain an Al-40% Si alloy sintered ingot;

[0048] The Al-40% Si alloy sintered billet was annealed for 72 hours at 500 ° C for homogenization heat treatment;

[0049] The Al-40%Si alloy ingot after homogenization heat treatment annealing is heated to 550°C, and then forged on a hydraulic press, the forging reduction rate is controlled at about 1m / min, and the forging deformation is 15%. Rolling, the reduction amount of ...

Embodiment 2

[0052] Use aluminum powder and silicon powder with purity >99.9%, according to the Al-10% Si composition ratio, after fully mixing evenly, put the Al and Si mixed powder into the mold, and apply a pressure of 5Mpa to the Al and Si mixed powder. Heat the mold together with the Al and Si mixed powder to 490°C and keep it warm for 5 minutes; then, continue to heat up to the sintering temperature of 800°C and sinter for 10 minutes. During the sintering process, a pressure of 10Mpa is applied to the Al and Si mixed powder. , depressurization, and natural cooling to obtain an Al-40% Si alloy sintered ingot;

[0053] The Al-10%Si alloy sintered billet was annealed for 24 hours at 300°C for homogenization heat treatment;

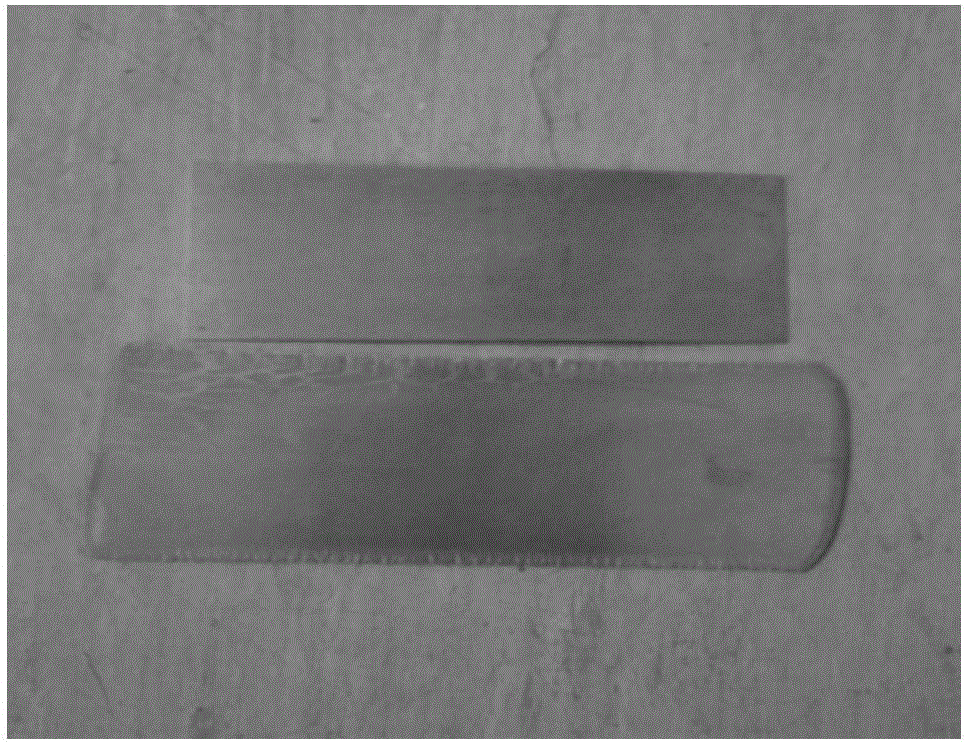

[0054] The Al-10%Si alloy sintered ingot after homogenization heat treatment and annealing is heated to 400°C, and hot rolled directly without forging. The reduction of each pass of hot rolling is controlled at about 3%, and the cumulative deformation reaches 30 %,...

Embodiment 3

[0057] Use aluminum powder and silicon powder with a purity >99.9%, according to the distribution ratio of Al-27% Si, after fully mixing evenly, put the Al and Si mixed powder into the mold, and apply a pressure of 15Mpa to the Al and Si mixed powder. Heat the mold together with the Al and Si mixed powder to 500°C and keep it warm for 7 minutes; then, continue to heat up to the sintering temperature of 900°C and sinter for 15 minutes. During the sintering process, a pressure of 25Mpa is applied to the Al and Si mixed powder. , depressurization, and natural cooling to obtain an Al-40% Si alloy sintered ingot;

[0058] The Al-27%Si alloy sintered billet was annealed for 48 hours at 400°C for homogenization heat treatment;

[0059] The Al-27% Si alloy ingot after homogenization heat treatment and annealing is heated to 450°C, and hot rolled directly without forging. The reduction of each pass of hot rolling is controlled at about 10%, and the cumulative deformation reaches 30%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com