Preparation method for preparing polymer skeleton with surface coated with HKUST-1 through 3D printing, and application of polymer skeleton

A HKUST-1, 3D printing technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., to achieve the effect of simple preparation process, good adsorption effect, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 23

[0037] Example 2 Preparation of PLA polymer skeleton coated with HKUST-1 by 3D printing and its adsorption to gentian violet.

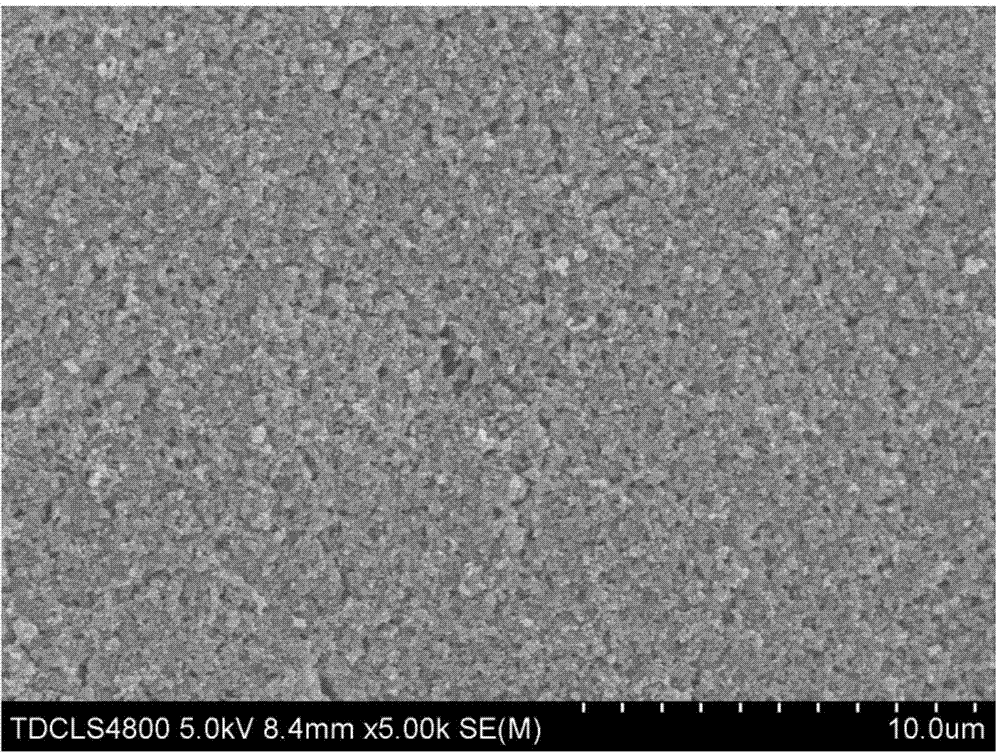

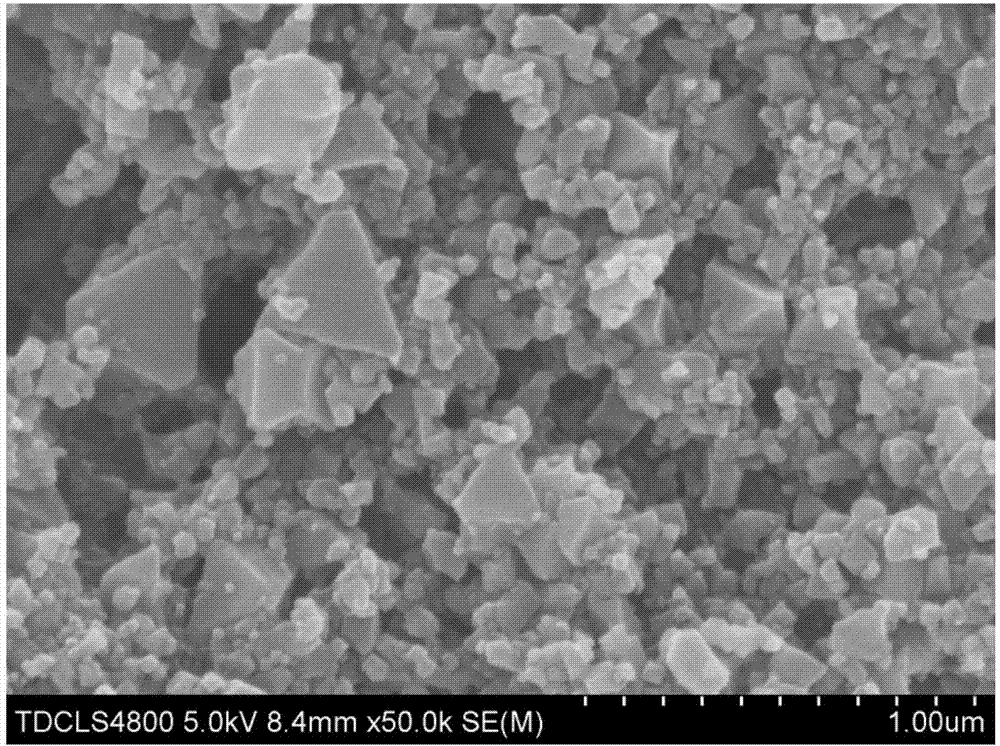

[0038] The computer makes the model file of the PLA polymer skeleton to be printed, and uses a 3D printer to print the polymer skeleton according to the structure determined by the model file. Add the printed polymer backbone to an aqueous ethanol solution (50 mL, ethanol and water v:v = 1:1) containing copper acetate (5 mmol) and trimesic acid (3 mmol). The temperature was raised to 45° C. under constant stirring, and triethylamine (4.5 mmol) was added dropwise to the solution. After stirring for 4 hours, the mixture was dried at room temperature for 12 hours. The resulting product was soaked in methanol for 2 days, during which the methanol solvent was changed every 8 hours. The obtained product was dried at 60 °C for 12 h. The resulting grain size for this example was 20nm–5μm. A gentian violet aqueous solution with a concentration of 1 mg / L was...

Embodiment 33

[0039] Example 3 Preparation of PMMA polymer skeleton coated with HKUST-1 by 3D printing and its adsorption on rhodamine 6G.

[0040]The computer makes the model file of the PMMA polymer skeleton to be printed, and uses a 3D printer to print the polymer skeleton according to the structure specified in the model file. The printed polymer backbone was added to an aqueous ethanol solution (120 mL, ethanol and water v:v = 1:1) containing copper chloride (4 mmol) and trimesic acid (3 mmol). The temperature was raised to 85° C. under constant stirring, and triethylamine (1.5 mmol) was added dropwise to the solution. After stirring for 2 hours, the mixture was dried at 80° C. for 12 hours. The resulting product was immersed in methanol for 3 days, during which the methanol solvent was changed every 8 hours. The obtained product was dried at 60 °C for 12 h. The resulting grain size for this example was 20nm–5μm. Configuration concentration is the rhodamine 6G aqueous solution of 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com