Patents

Literature

413 results about "Dye adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

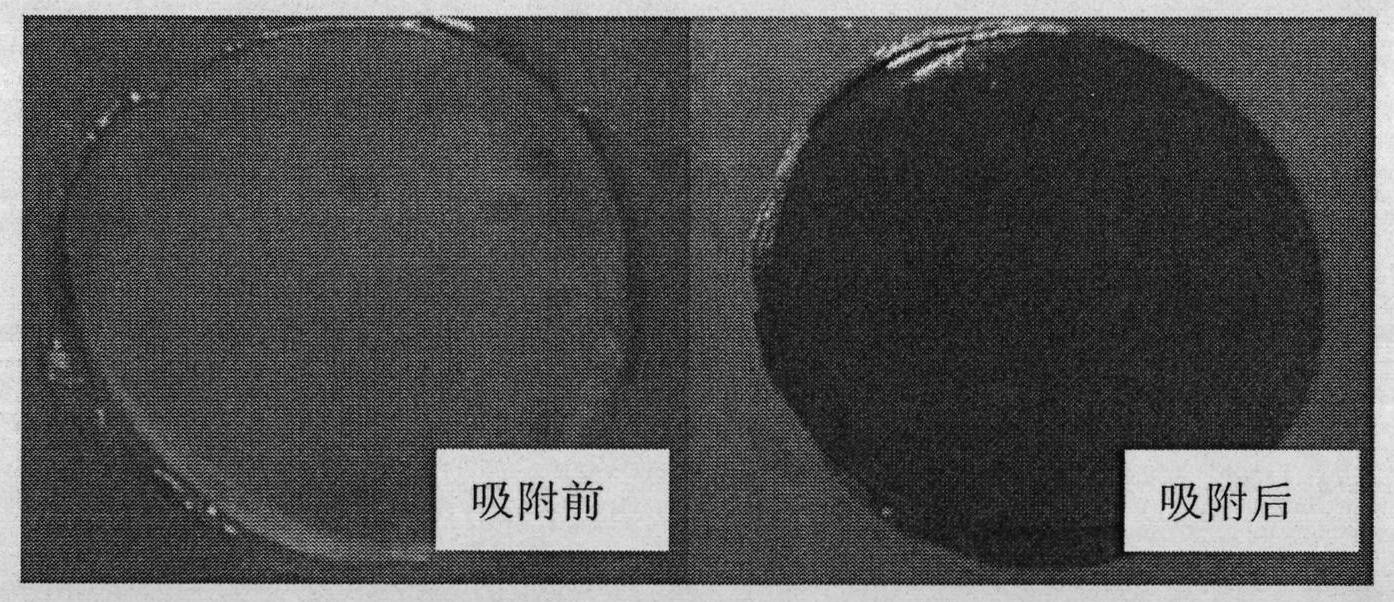

Nanometer clay-containing high absorptive hydrogel as well as preparation method and application thereof

InactiveCN101942167AImprove adsorption capacityImprove mechanical propertiesOther chemical processesWaste water treatment from textile industryBiopolymerWater soluble

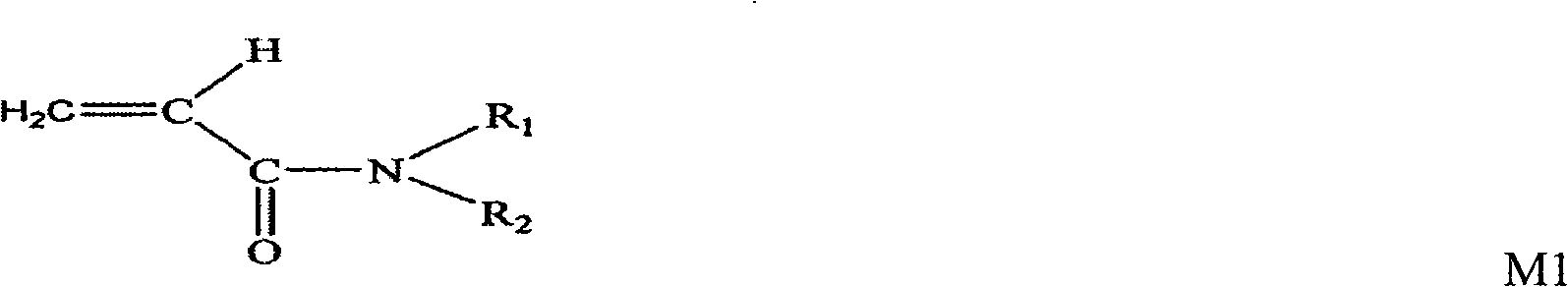

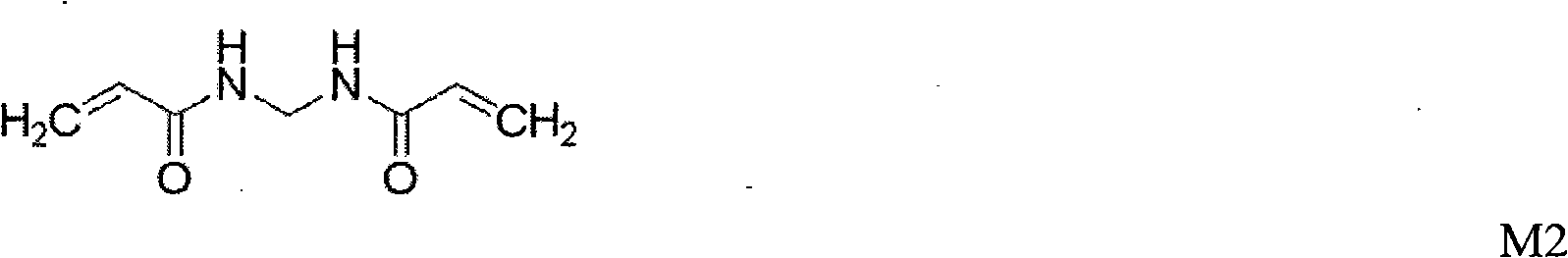

The invention relates to a nanometer clay-containing high absorptive hydrogel as well as a preparation method and application thereof. The hydrogel contains an acrylamide monomer M1, a chemical crosslinking agent M2, inorganic nanometer clay M3 and a water soluble biopolymer M4 with use level of 98-50:0-10:2-25:015 in mass percent. The preparation method comprises the following step of: taking M3 as a filler or a reinforcing agent or a physical crosslinking agent and taking M4 as a second component in a water solution to prepare the environmentally-friendly hydrogel with high water soluble dye adsorption property and excellent mechanical property. The method has the advantages of simple and reliable preparation process, no environmental pollution, very strong dye adsorption removal effects and practicability; and the dye adsorption quantity can be adjusted by temperature, pH value, crosslinking degree, dye concentration, nanometer clay or biopolymer variety and use level and a reactant charge ratio. The hydrogel can be used for the fields of weaving and dyeing wastewater treatment, dye adsorption, and the like.

Owner:TIANJIN POLYTECHNIC UNIV

Chemical/ionic/physical compounding cross linking hydrogel and preparation method thereof

The invention relates to chemical / ionic / physical compounding cross linking hydrogel and a preparation method thereof. The hydrogel is polymerized in a way that olefin monomer M1, a chemical cross-linking agent M2, multivalent ion biomacromolecule M3, an ionic cross-linking agent M4 and a physical cross-linking agent M5 are dissolved in water. The method comprises the following steps: preparing chemical / physical cross linked gel prepolymerization liquid, preparing chemical / ionic / physical cross linked gel prepolymerization liquid and preparing and purifying chemical / ionic / physical compounding cross linked gel. According to the invention, the characteristics and properties of the chemical cross-linking agent, the physical cross-linking agent and the ionic cross-linking agents are taken into consideration comprehensively, the compounding cross linking of molecular chains is realized; the prepared hydrogel is optically transparent and has higher mechanical ductility and rebound elasticity; the mechanic, optical and thermal performances and other performances can be regulated conveniently by controlling technology parameters and conditions; and the prepared hydrogel can be used in the fields such as tissue engineering, food industry, agricultural irrigation, daily chemical engineering, oil production, dye adsorption and biological medicine.

Owner:TIANJIN POLYTECHNIC UNIV

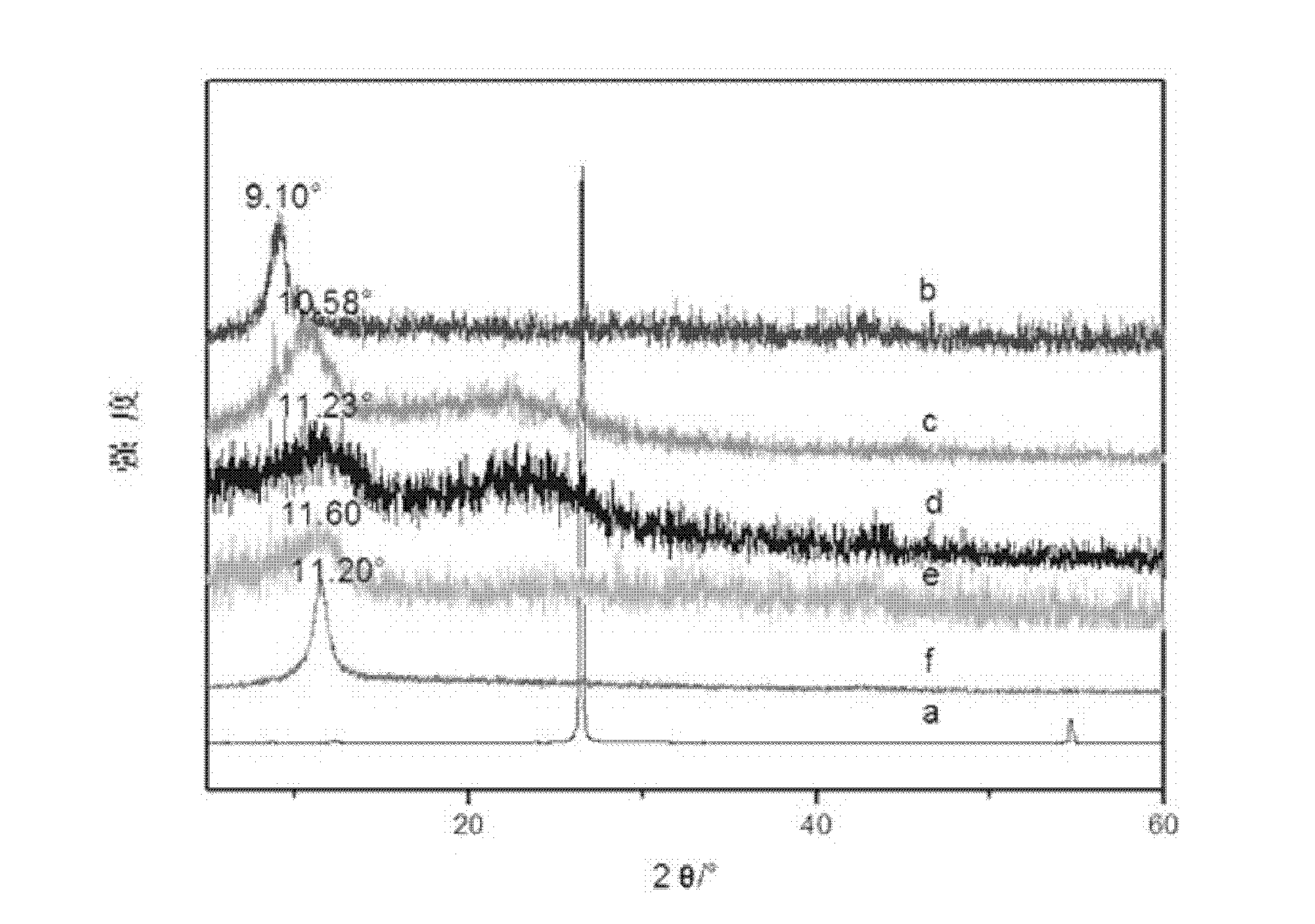

Method for preparing graphene oxide

InactiveCN102491318ACheap and easy to getAvoid it happening againCarbon compoundsToxic gasFiltration

The invention discloses a method for preparing a graphene oxide. The method comprises the following steps of: a) adding concentrated inorganic acid into a sealed reactor, adding graphite powder with stirring, reducing the temperature to the temperature of between 0 and 4 DEG C, and adding potassium permanganate to react for 0.5 to 2 hours; b) heating the obtained reaction system to the temperature of between 60 and 70 DEG C, and standing for 12 to 24 hours; c) adding hydrogen peroxide into distilled water in a volume ratio of 1:10, freezing to obtain ice, transferring the graphite oxide to the distilled water containing the hydrogen peroxide until the ice is completely dissolved, uniformly stirring, performing suction filtration, washing and drying to obtain the graphene oxide. The graphite powder, the concentrated acid and the potassium permanganate serve as raw materials, and the raw materials are low in cost and readily available; NO, NO2 and other toxic gases are prevented from being produced; the reaction temperature is as low as 60-70 DEG C; and the product has high dye adsorption capacity and high industrial application value.

Owner:HEBEI UNIV OF TECH

Printing medium

InactiveUS6576324B2Coatings with pigmentsDecorative surface effectsAlumina hydratePhysical chemistry

Disclosed herein is a printing medium provided on a base material with a porous ink-receiving layer which comprises, as principal components, an alumina hydrate having a boehmite structure and a binder, wherein when measuring with an ink containing 0.1% by weight of a surfactant, the time required to absorb 30 ng of an ink is 400 milliseconds or shorter, the dye-adsorbing capacity falls within a range of from 900 to 2,000 mg / m2, and the index of dye-adsorbing rate falls within a range of from 0.0 to 5.0.

Owner:CANON KK

Method for preparing activated carbon material with humic acid as raw material and application of activated carbon material

InactiveCN103641117ALarge reservesLarge specific surface areaCarbon compoundsOther chemical processesCapacitancePotassium hydroxide

The invention relates to a method for preparing activated carbon with humic acid as a raw material and an application of the activated carbon. The method comprises the steps of mixing industrial humic acid with an activating agent which is potassium hydroxide, sodium hydroxide, zinc chloride, potassium carbonate or phosphoric acid uniformly to react under inert atmosphere protection for 1-5 hours; then cooling the product, washing the product in an acid solution until the pH value is 6-7 and drying the product, thus obtaining the activated carbon. The method is convenient to operate, is relatively low in energy consumption and is suitable for large-scale industrial production. The humic acid porous activated carbon material obtained by the method has a rich porous structure and a relatively big specific surface area, is used for preparing water purifiers or electrode materials of supercapacitors, and has methylene blue dye adsorption value of 600mg / g. Besides, the humic acid porous activated carbon material is used as the electrode material of a supercapacitor to assemble a high-performance supercapacitor. The specific capacitance of the activated carbon single electrode is 351Fg<-1>. Various test results show that the activated carbon is microporous-mesoporous composite carbon and has specific surface area of about 3200m<2> / g, the pore size distribution of the activated carbon is 1-5nm, and the pore volume of the activated carbon is about 2cm<3> / g.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

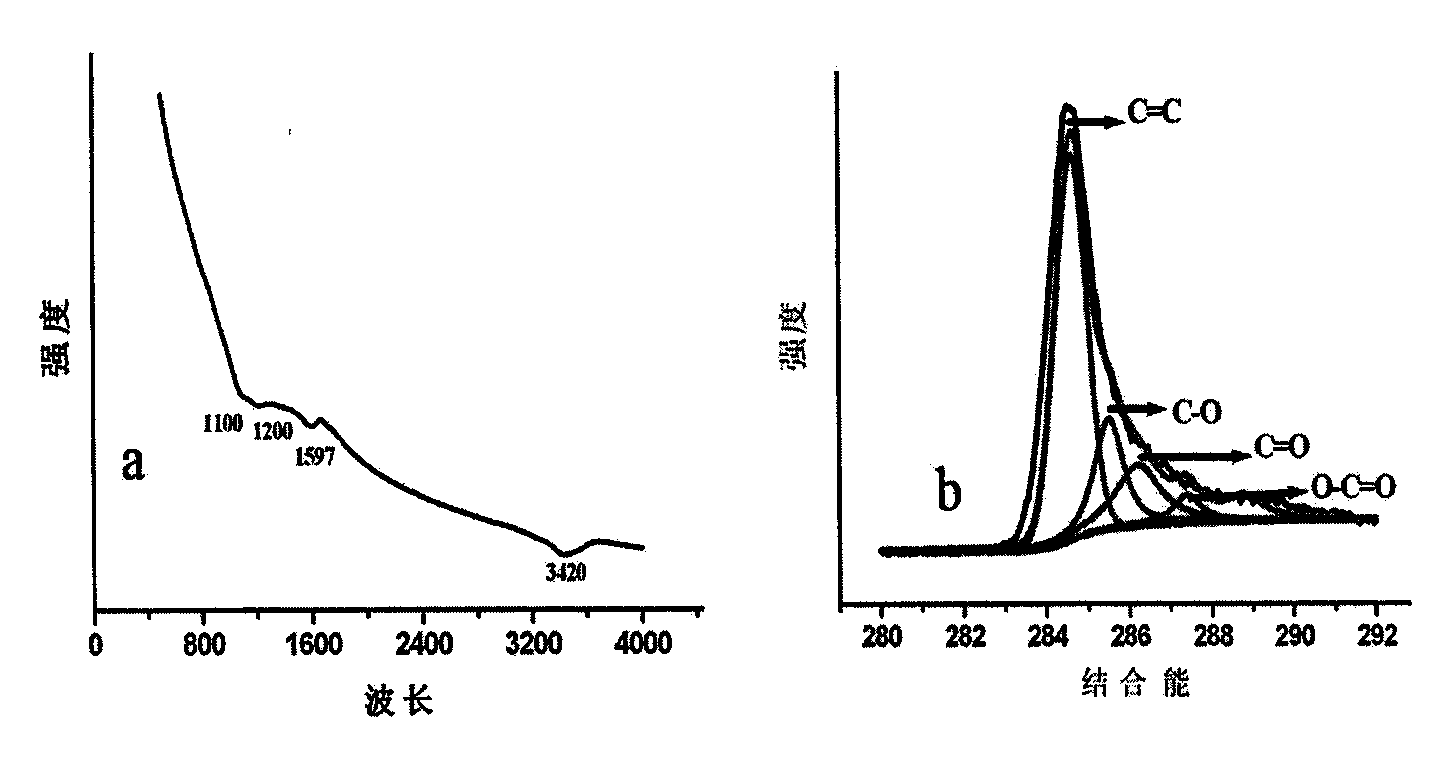

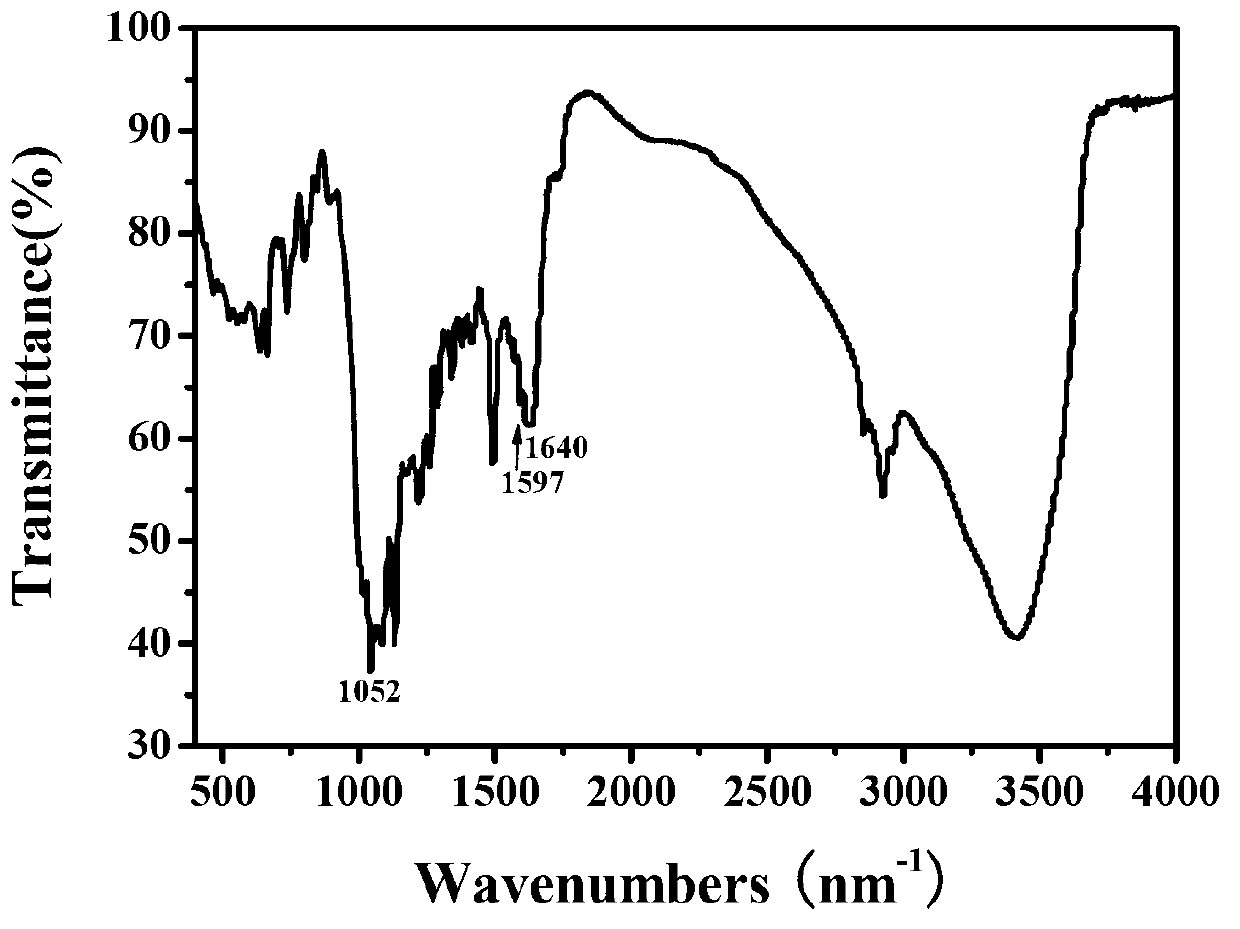

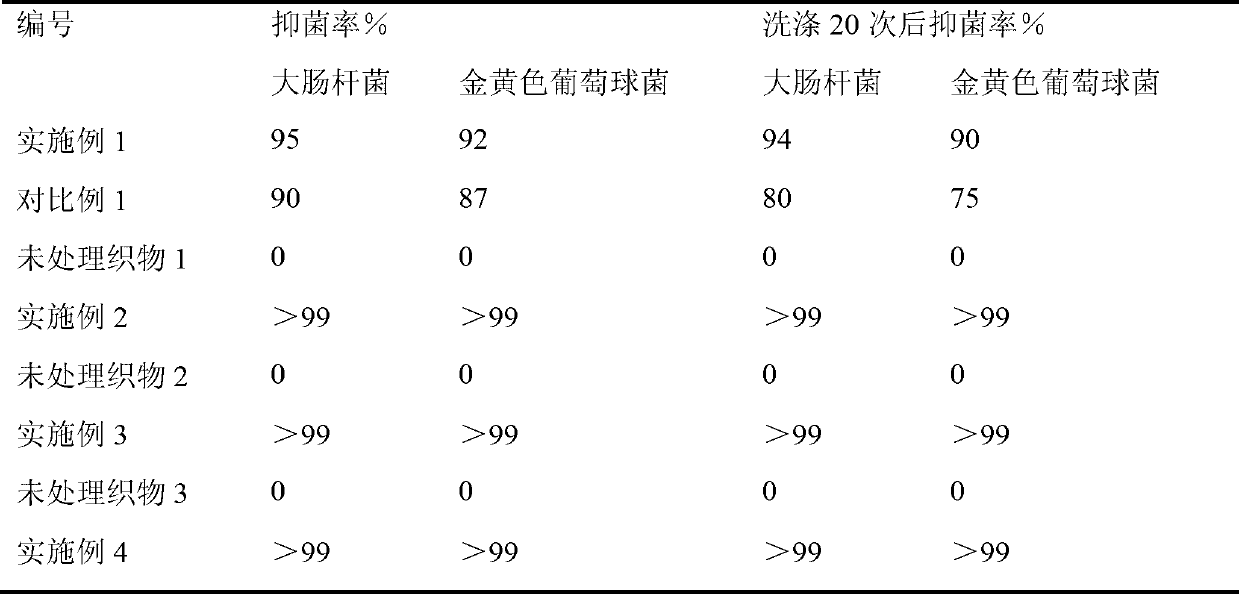

Graphene oxide-based anti-bacterial finishing agent for dyeing, and preparation method and application thereof

ActiveCN102995394AImprove dispersion stabilityIncrease the amount of bindingFibre treatmentDyeing processWater solubleGraphene

The invention overcomes the defects of cytotoxicity of the existing inorganic antibacterial agent and organic antibacterial agent, and complicated compounding process of graphene oxide and fabric, and provides a graphene oxide-based anti-bacterial finishing agent for dyeing, wherein the graphene oxide-based anti-bacterial finishing agent is a composite material of chitosan / graphene oxide / dye. A preparation method of the graphene oxide-based anti-bacterial finishing agent for dyeing comprises the steps of firstly, carrying out acylating chlorination on graphene oxide based on the reaction activity of carboxyl at the surface of graphene oxide, then covalently grafting a natural antibacterial material chitosan to graphene oxide based on the reactivity between acyl chloride and active amino or hydroxyl, and adsorbing the dye on the plane of graphene oxide by phi-phi interaction between graphene oxide and a water-soluble dye. The graphene oxide-based anti-bacterial finishing agent for dyeing can be applied to textiles. Graphene oxide which has no toxic or side effect on a human body, and natural cationic polymer chitosan are selected as antibacterial components, so that the cytotoxicity is low.

Owner:常熟市亿盛织造有限公司

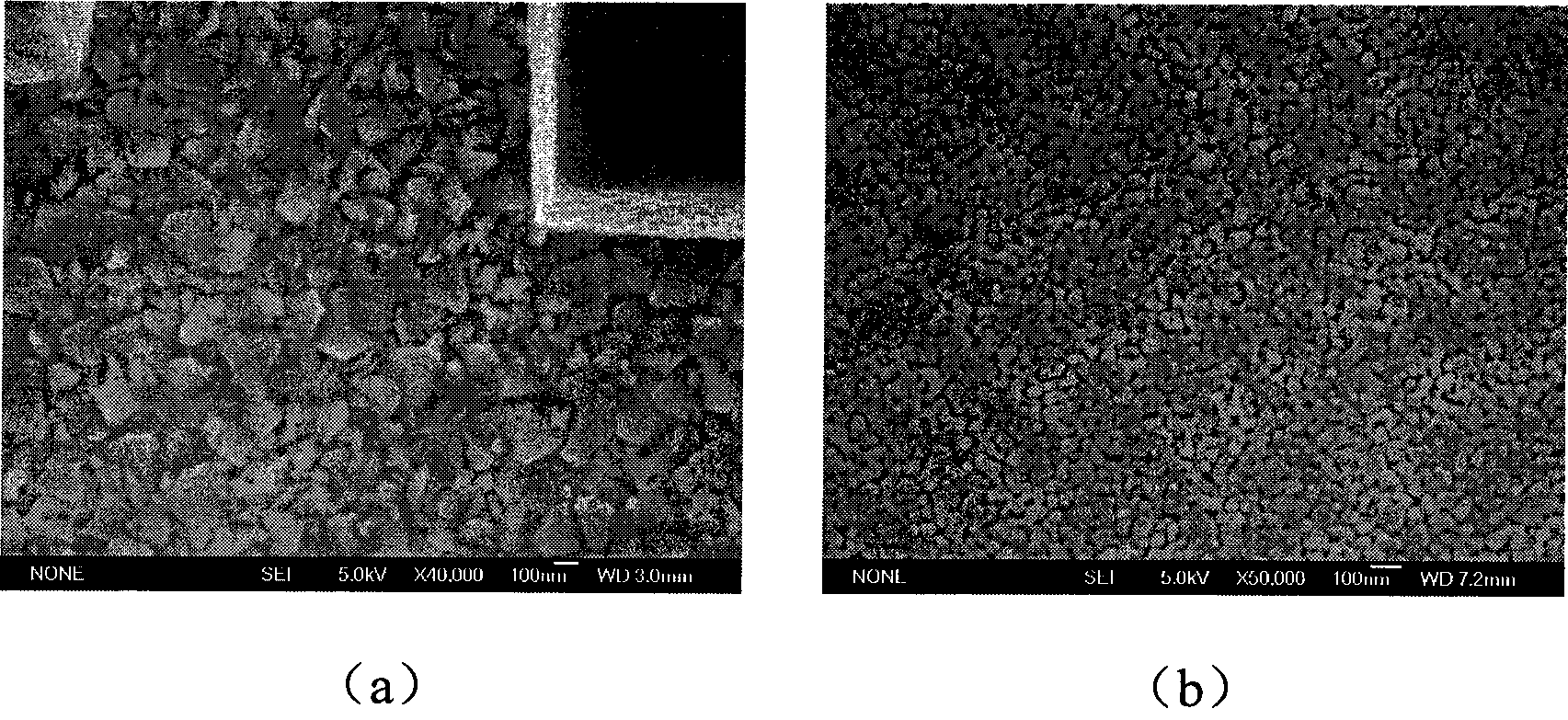

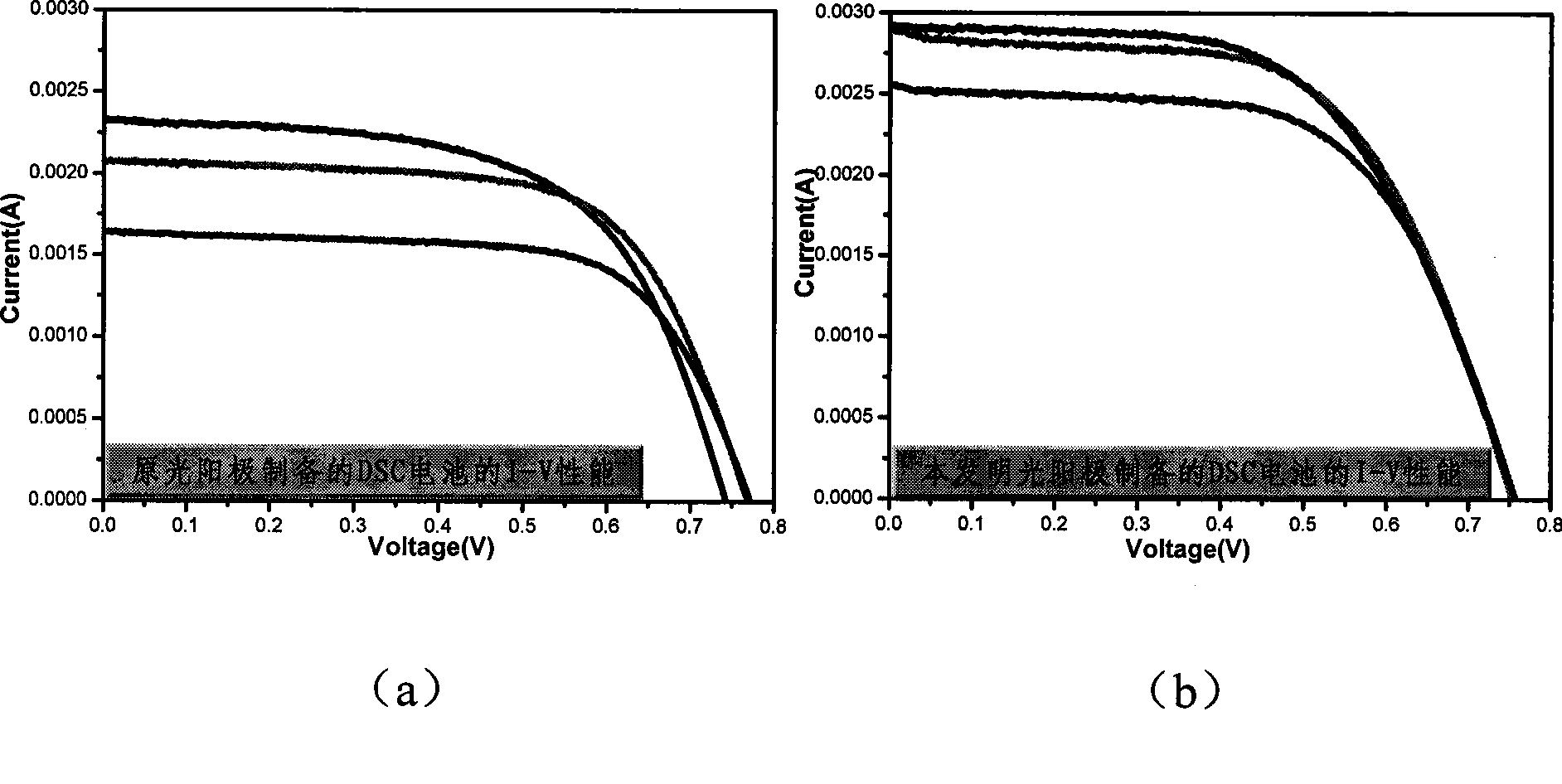

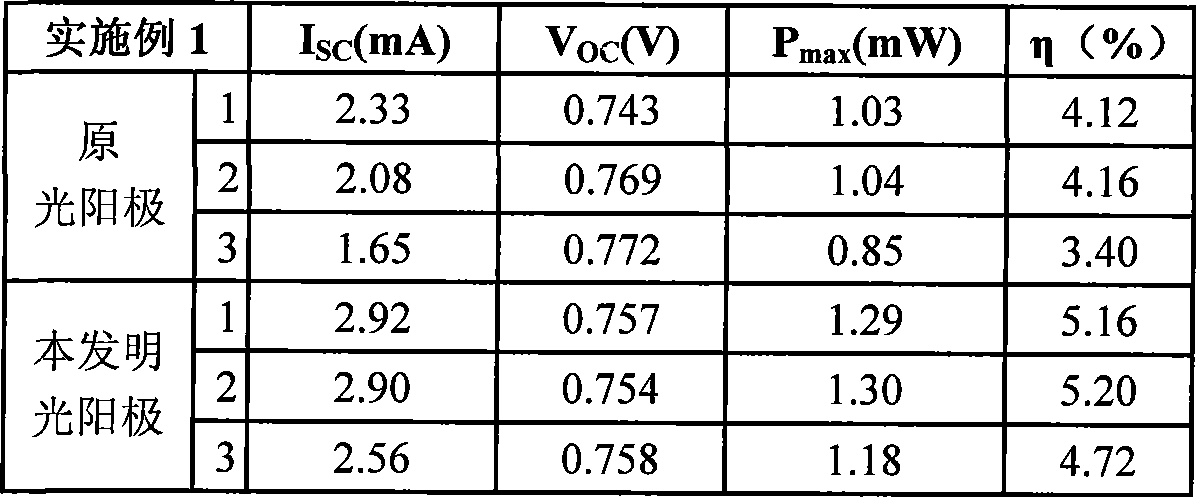

Preparation method for laminated photo-anode film of dye-sensitized solar cell

InactiveCN101521114AReverse RecombinationReduce porosityLight-sensitive devicesFinal product manufactureColloidBattery cell

The invention discloses a preparation method for laminated photo-anode film of dye-sensitized solar cell. A dense film can be prepared by adopting a magnetron sputtering method and a sol-gel spin-coating method, and the quality of the dense film is controlled by controlling magnetron sputtering parameters or the preparation of TiO2 colloid and the rotating speed of spin coating; nano TiO2 grain of small grain diameter (less than 8nm) is formed on the surface of porous nano TiO2 layer film by means of a liquid-phase chemical deposition method; and dye adsorption of the photo-anode film is increased by means of unsaturated bond on the surface of the nano TiO2 of small grain diameter. When the TiO2 photo anode prepared by the method is applied in a dye-sensitized solar cell, the cell has higher photoelectric conversion efficiency and the device has longer service life.

Owner:IRICO

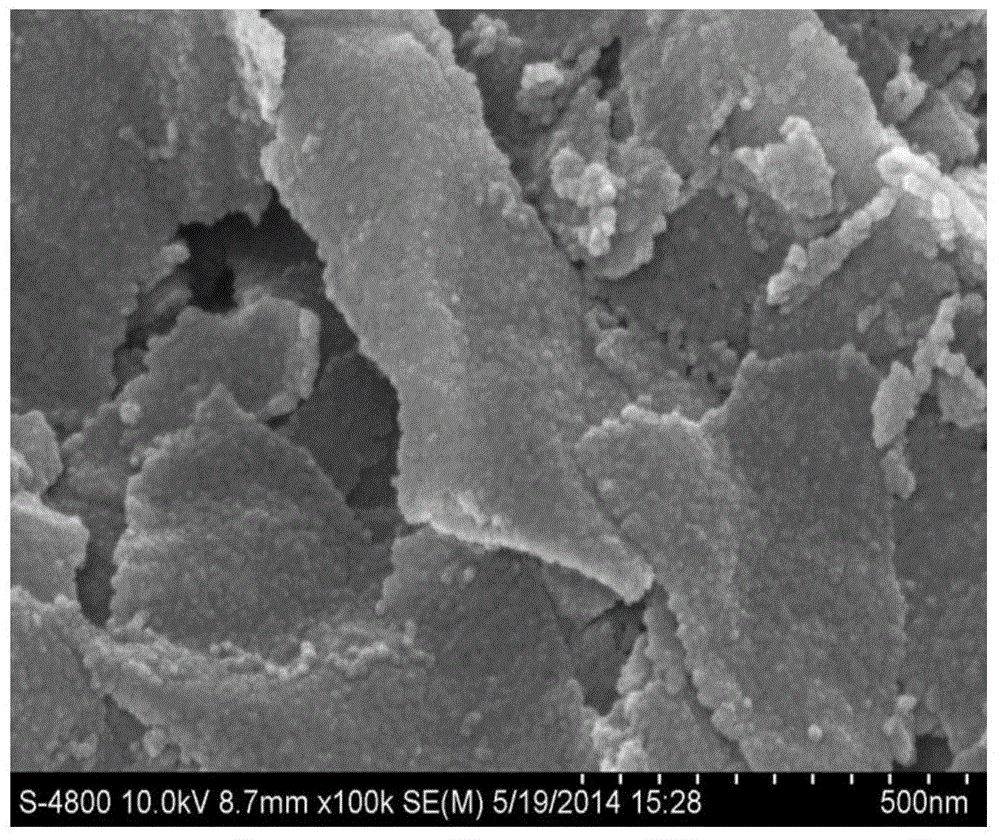

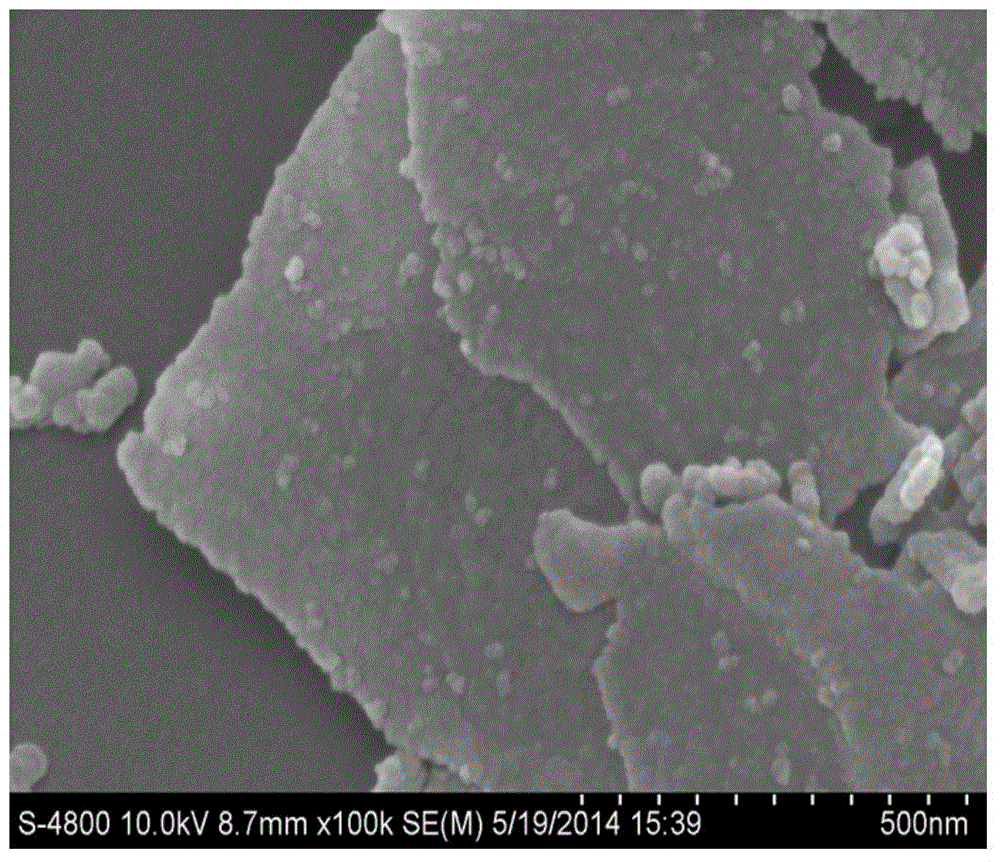

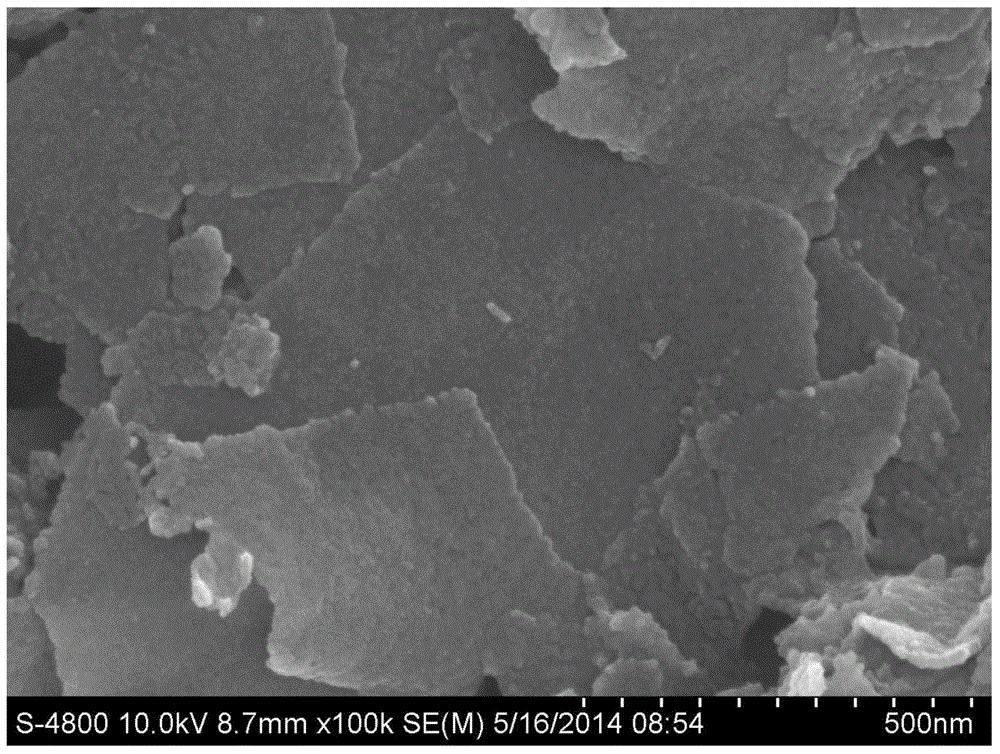

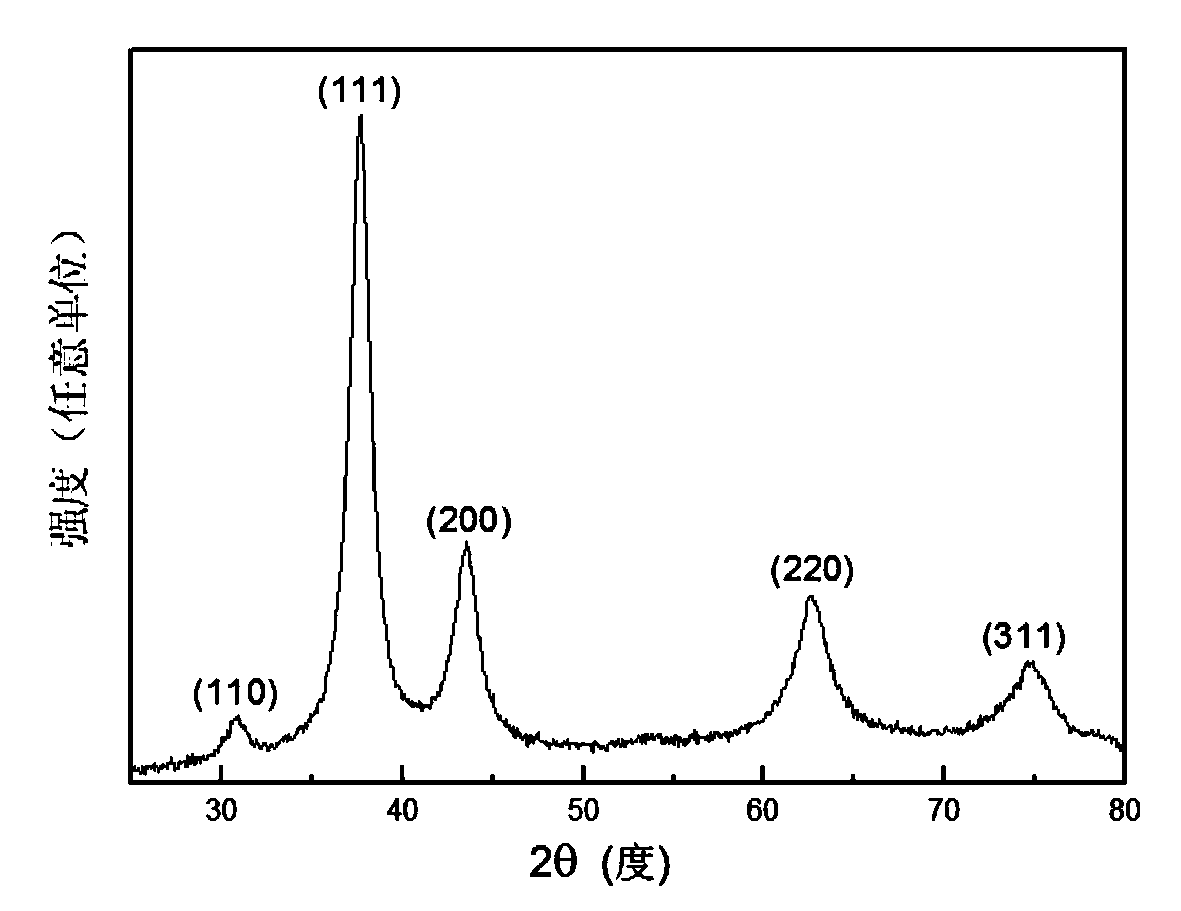

Silica-graphene composite and preparation method thereof, and treatment method for removing dye pollutants in water

InactiveCN106268630ALarge specific surface areaGood dispersionOther chemical processesWater/sewage treatment by sorptionDispersityGraphene flake

The invention provides a silica-graphene composite and a preparation method thereof, and a treatment method for removing dye pollutants in water. The silica-graphene composite has laminated graphene flake structures, and silica is loaded on the laminated graphene flake structures. The silica-graphene composite has advantages of a high specific surface area, good dispersity and good hydrophilicity. Since the silica-graphene composite is a porous laminated structure, and the pi conjugate structure of graphene strongly interacts with pi functional groups in dye molecules, the dye adsorption efficiency of the silica-graphene composite is improved, and thus, the composite exerts good adsorption effect on dye pollutants in water. The composite also has the characteristics of a fast dye pollutant removal rate, great adsorption capability and stable adsorption.

Owner:PETROCHINA CO LTD

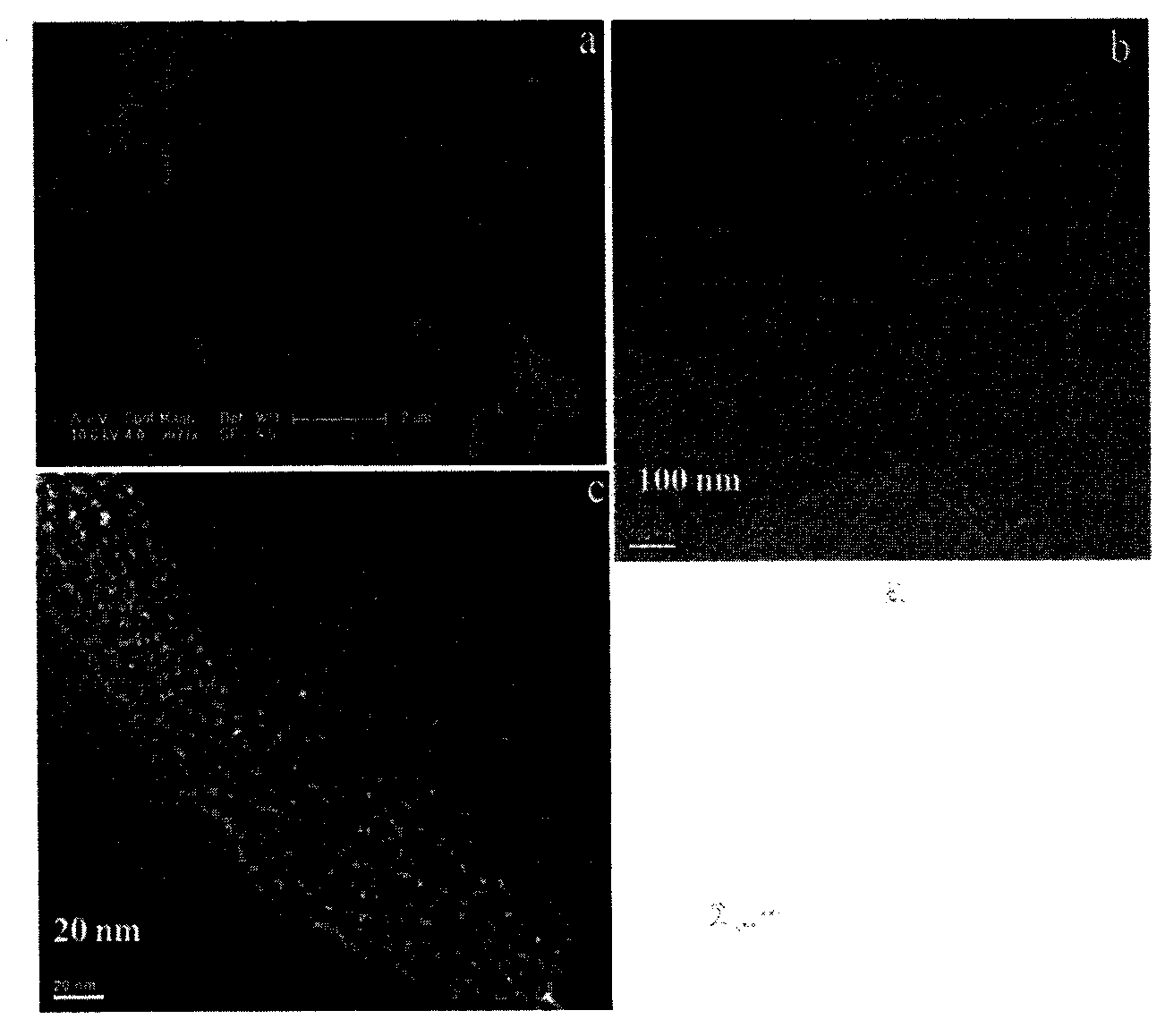

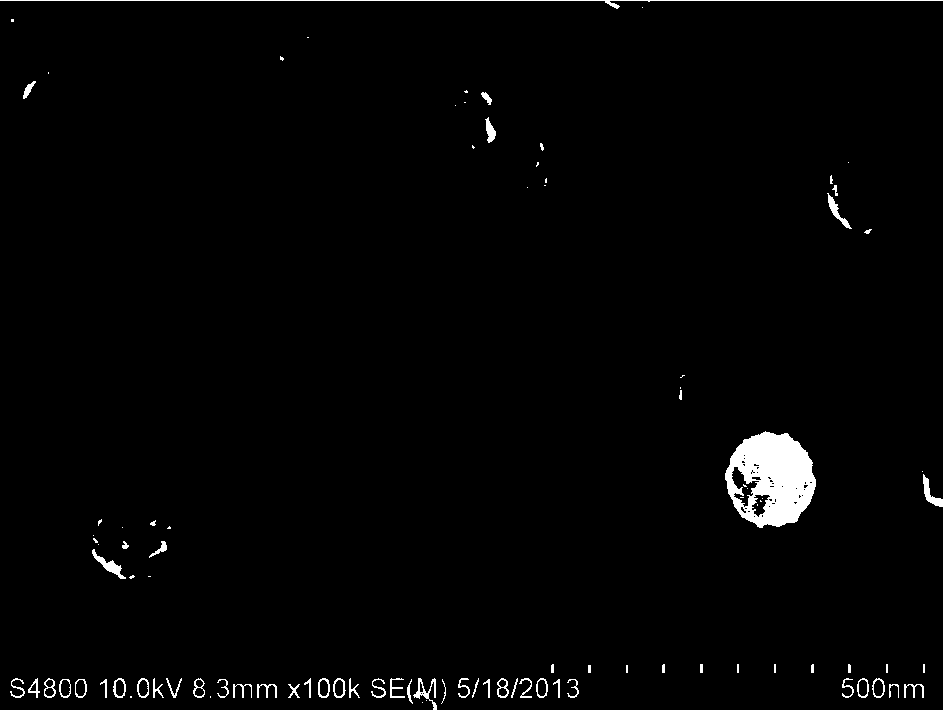

Cuprous oxide nano hollow spheres as well as synthetic method and application method thereof

InactiveCN103387258ASolve the complex problem of preparing nano-cuprous oxideThe solution is more complicatedMaterial nanotechnologyCopper oxides/halidesActive agentOrganosolv

The invention relates to cuprous oxide nano hollow spheres and a synthetic method thereof. The synthetic method comprises the following steps of: (1) dissolving a cupric salt in an organic solvent, and controlling the copper ion concentration at 0.01-0.6mol / L; (2) transferring the solution obtained in the step (1) into a reaction vessel, sealing the reaction vessel, putting the reaction vessel into a reaction environment in which the temperature is 120-200 DEG C, performing thermal reaction for 0.5-8 hours, and cooling the reaction vessel naturally; (3) separating the solid obtained in the step (2), washing and drying to obtain the cuprous oxide nano hollow spheres. According to the synthetic method, the cuprous oxide nano hollow spheres are prepared through a one-pot hydrothermal synthesis under the condition that any surfactant is not added; the prepared nano spheres with unique hollow structures have excellent dye adsorption capacity and lithium ion battery performance.

Owner:WUHAN UNIV OF TECH

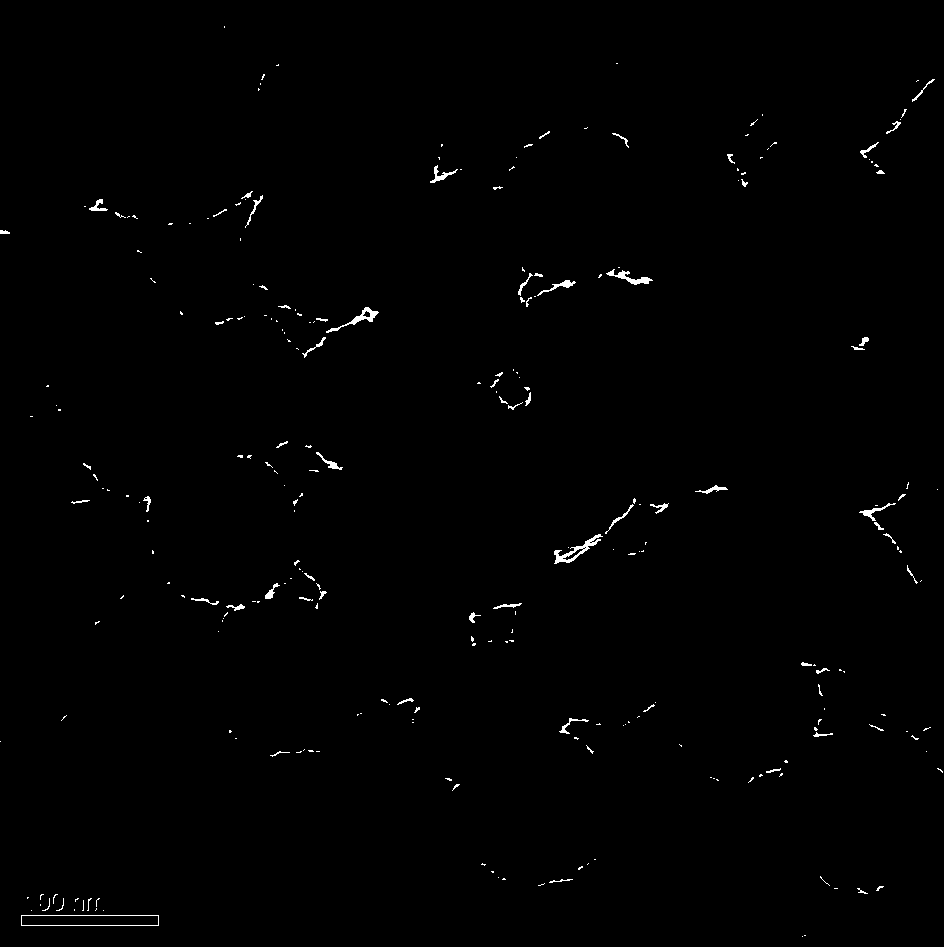

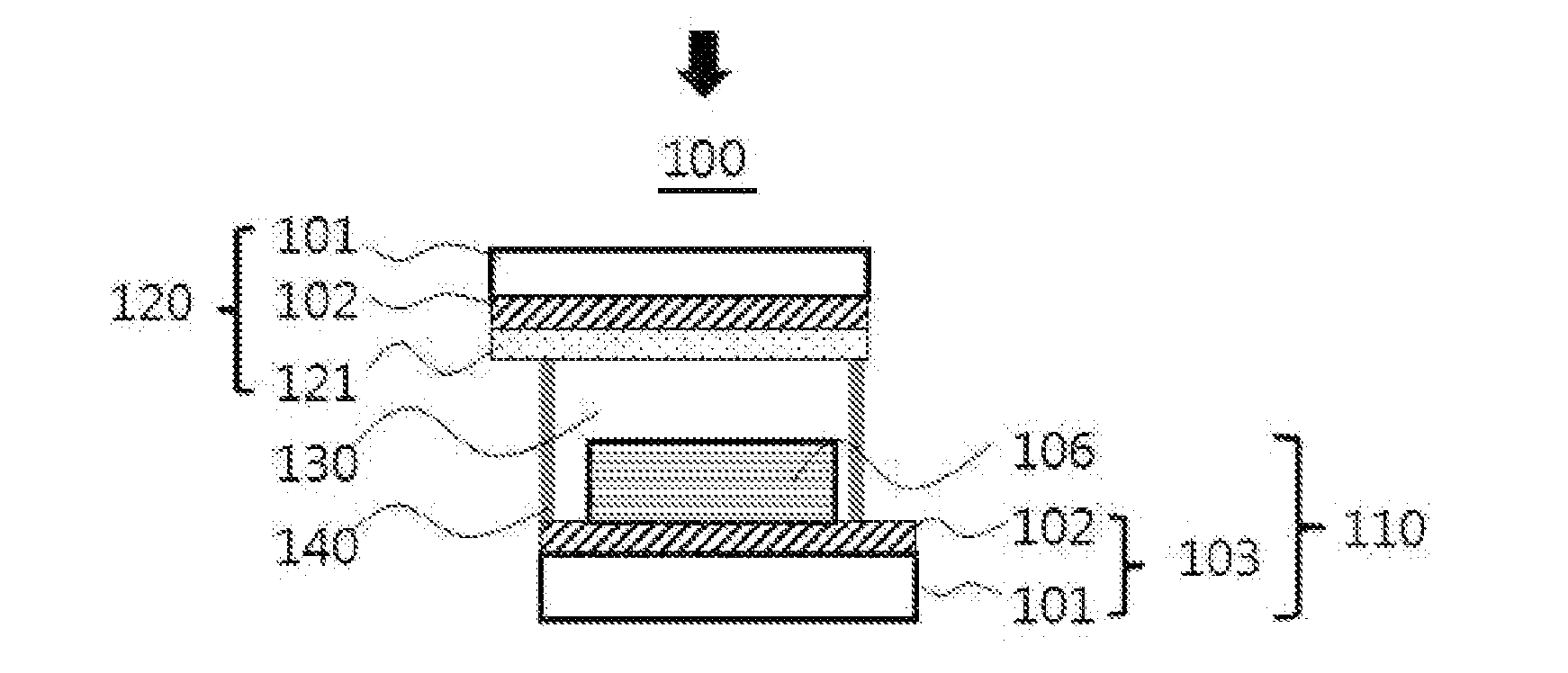

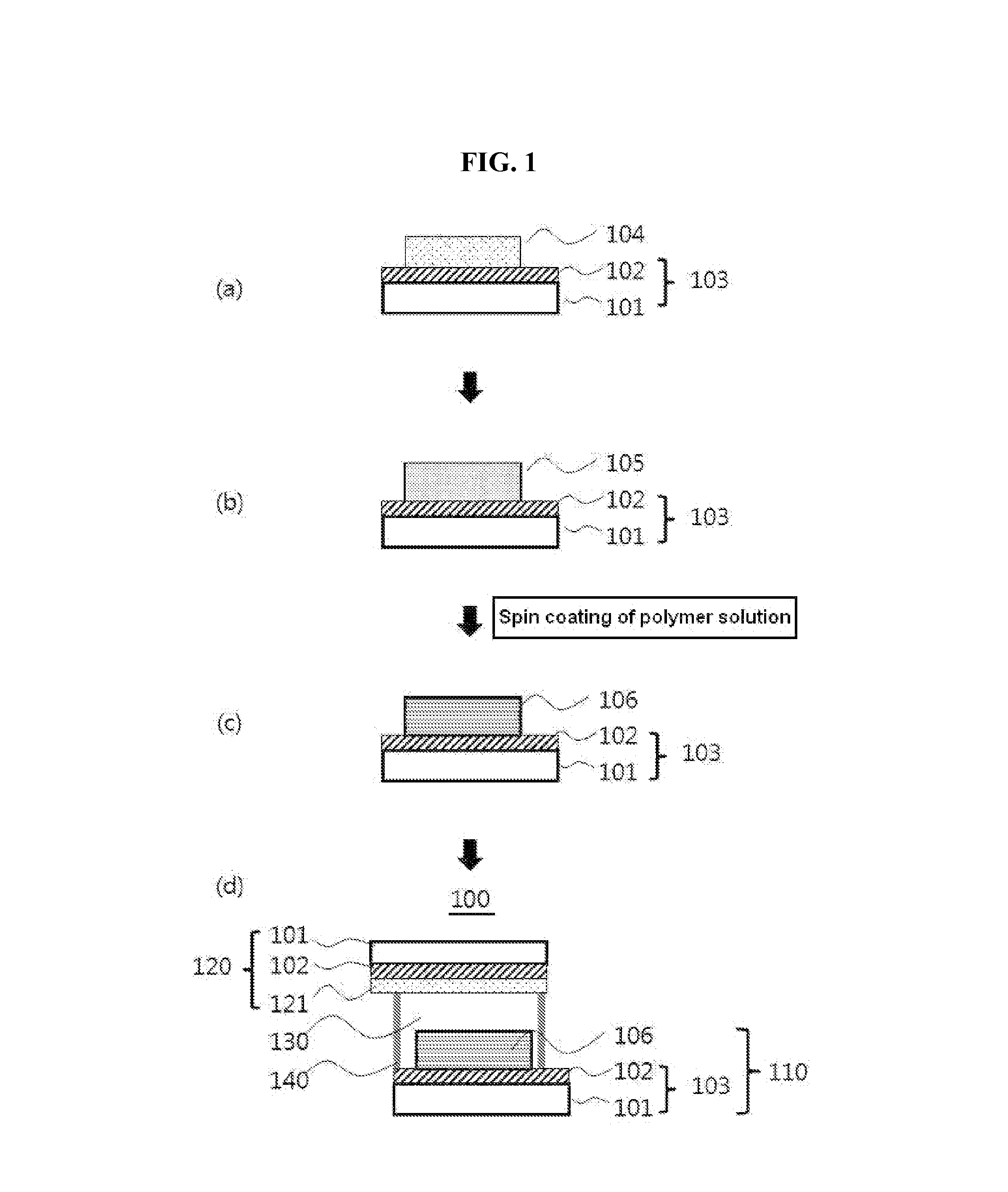

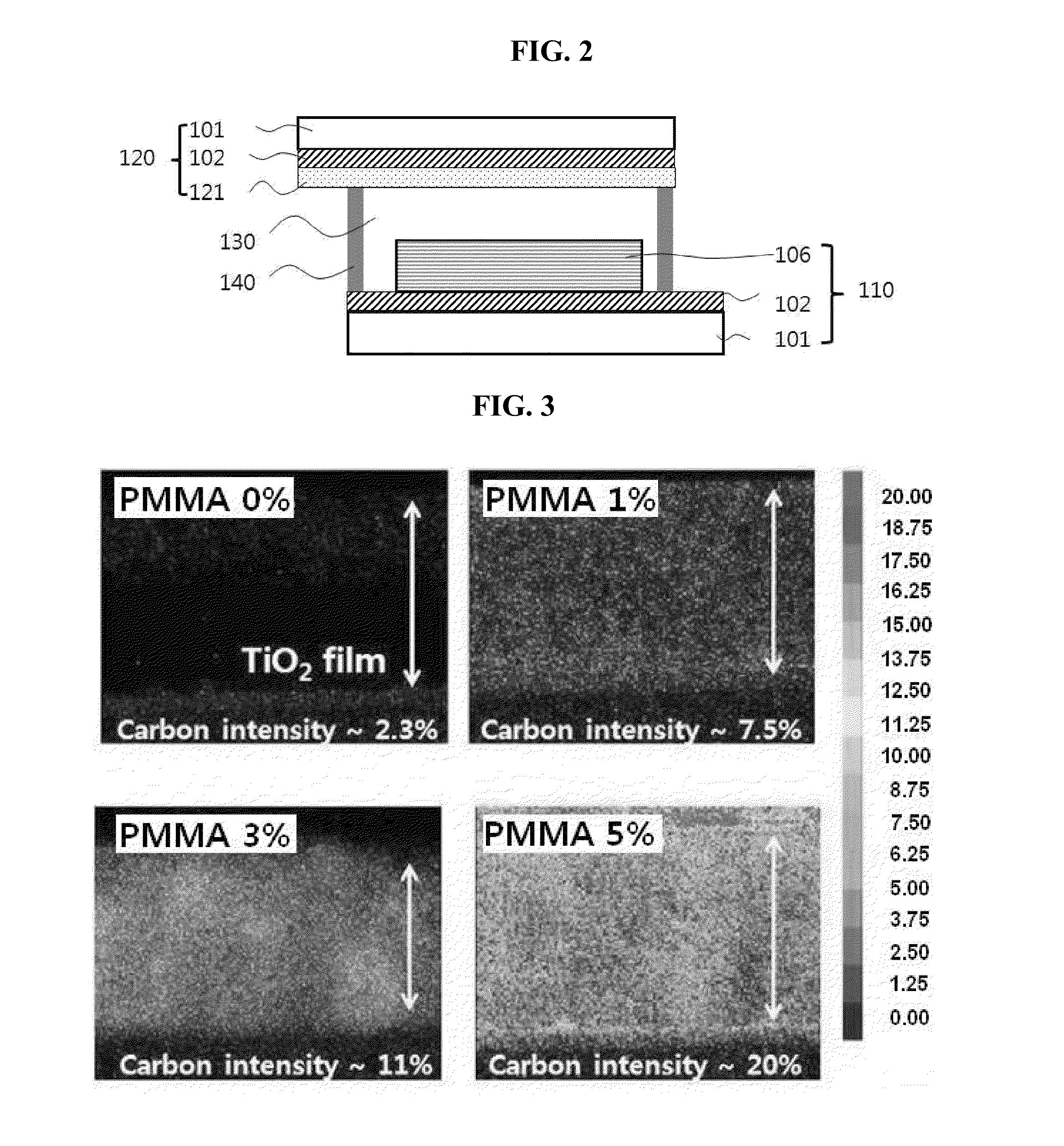

Preparation method of flexible electrodes and flexible dye-sensitized solar cells using the same

InactiveUS20130056068A1Improve photoelectric conversion efficiencySecuring durabilityMaterial nanotechnologyElectrolytic capacitorsNanoparticleSolar cell

The present invention relates to a method for manufacturing a flexible photoelectrode and a dye-sensitized solar cell using the same. More specifically, the method for manufacturingg a photoelectrode comprises forming a nanoparticle metal oxide layer on a flexible substrate, adsorbing dyes, and then, coating polymer, thereby forming a nanoparticle metal oxide layer consisting of nanoparticle metal oxide-dye-polymer.According to the present invention, the polymer penetrated between the nanoparticle metal oxide after dye adsorption may increase adhesion to the substrate and improve mechanical properties. Particularly, when applied for a flexible substrate such as a plastic substrate, bending property is excellent, and it may be useful for a flexible dye-sensitized solar cell having durability.

Owner:KOREA INST OF SCI & TECH

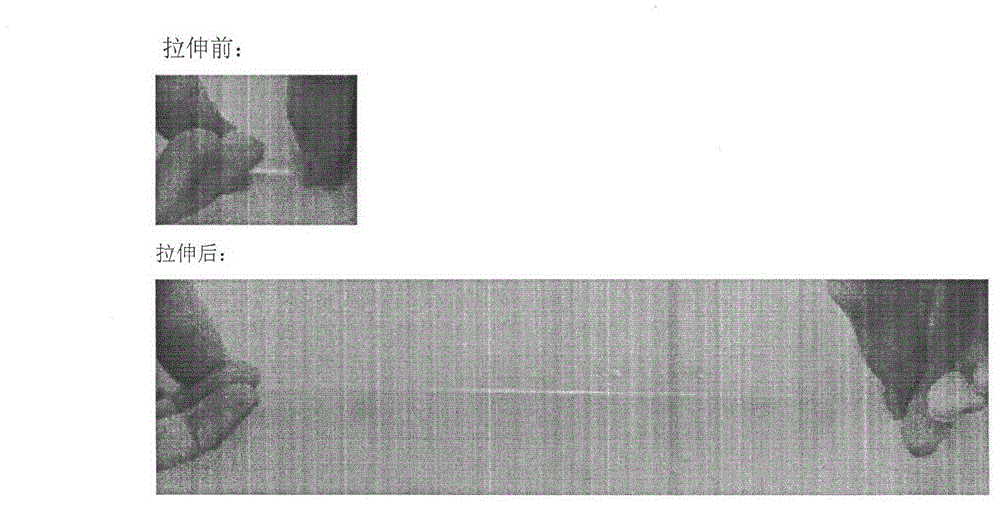

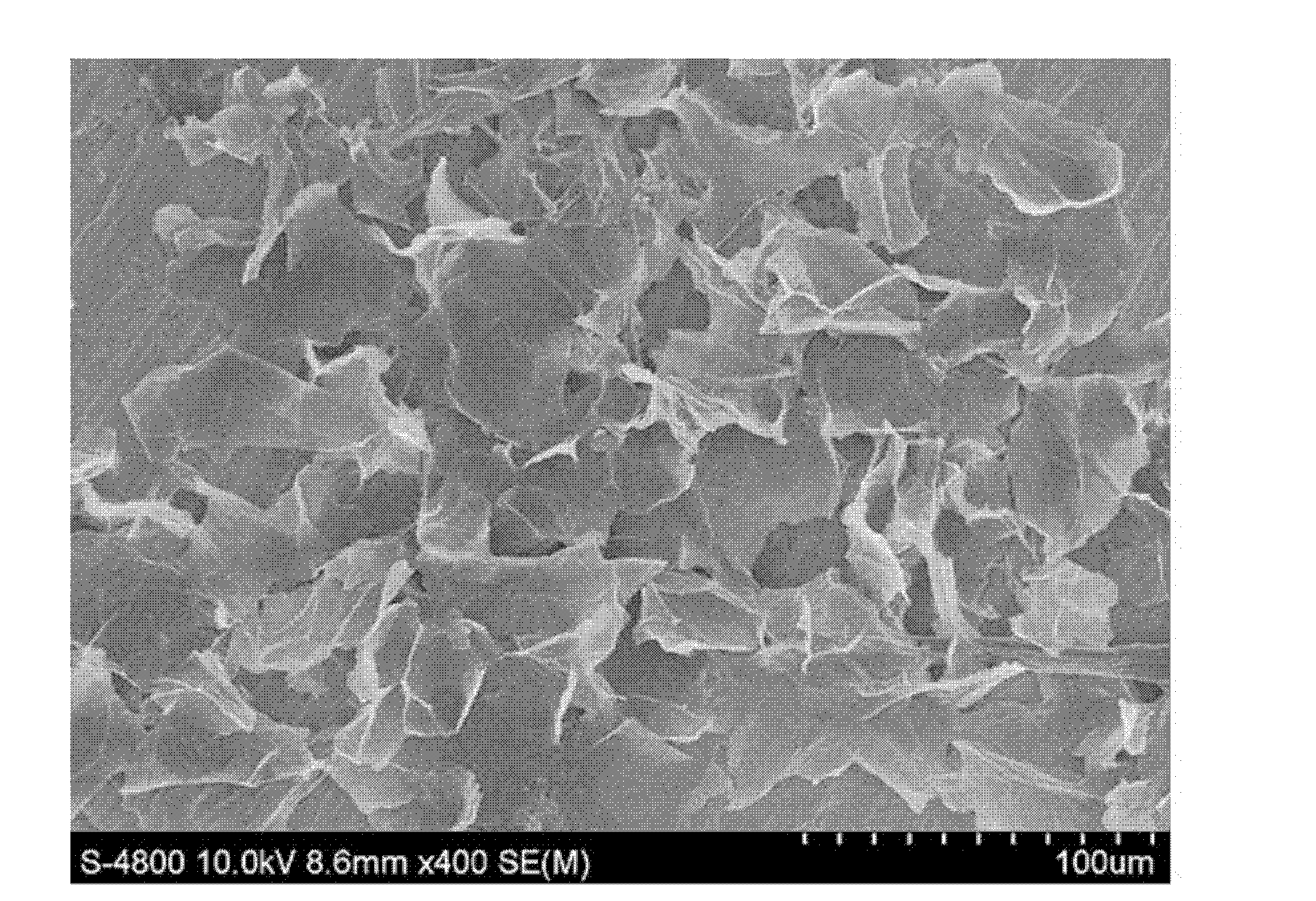

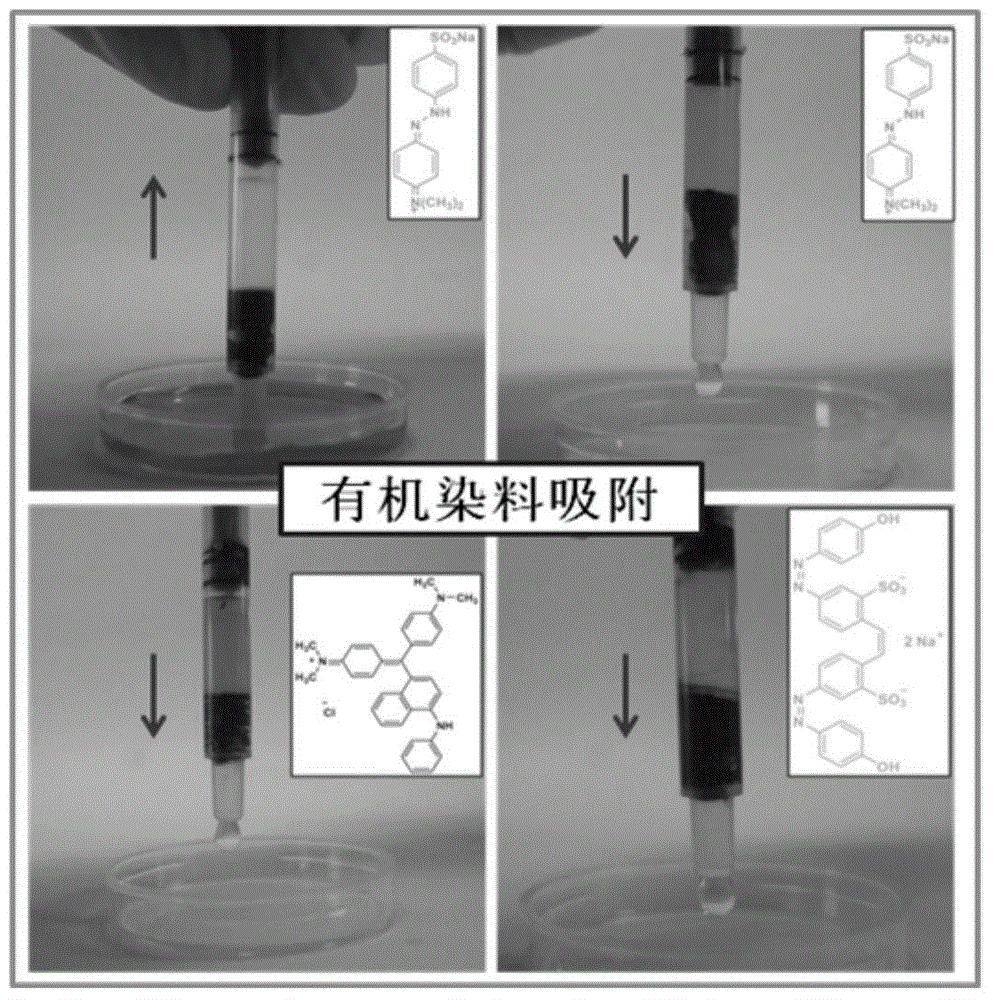

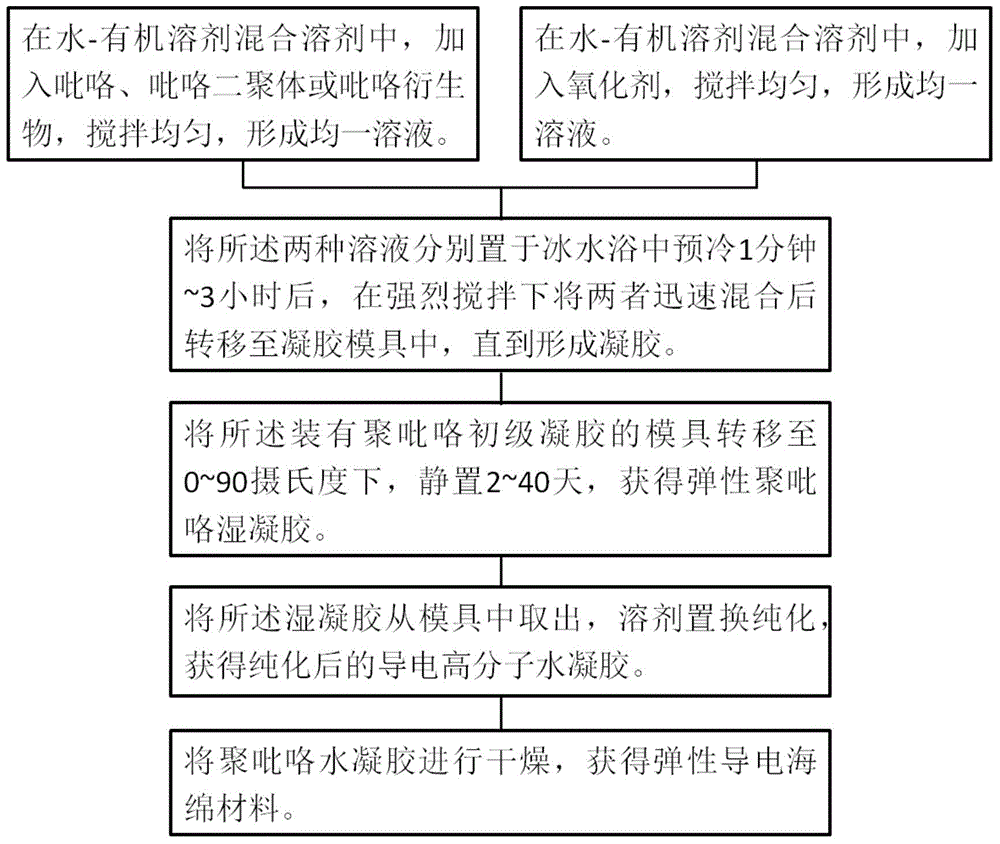

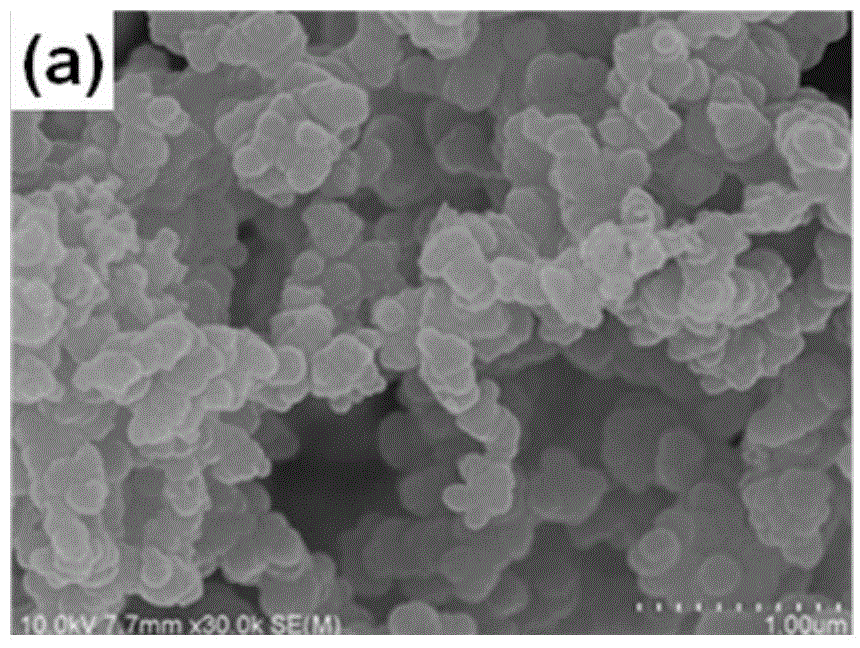

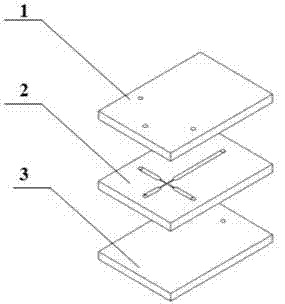

Elastic conducting polymeric hydrogel, sponge, preparation method and application thereof

ActiveCN105273187AHigh strengthIncrease elasticityOther chemical processesPolymer sciencePerylene derivatives

The invention discloses conducting polymeric hydrogel, sponge, a preparation method and an application thereof. Eigenstate conducting high-molecular polymer is used as a three-dimensional framework of the hydrogel, and the hydrogel is an organic conducting material having good mechanical strength and compression elasticity. The hydrogel can be obtained through step-by-step oxidative coupling polymerization on pyrroles and pyrrole derivatives by using an oxidizing agent and long-term secondary growth. Content of the conducting high-molecular polymer in the hydrogel is 1.5-21.5 wt%; maximum compression ratio can reach 90%; the hydrogel recovers to normal within 10 s to 5 min after compression; conductivity is 0.001-10 S / m; and the hydrogel has shape memory characteristics, and compression deformation recovery quantity is directly related to solvent volume. The sponge is obtained by drying the hydrogel. Mechanical strength, elasticity and conductivity of gel can be greatly maintained. With increasing of compression ratio, resistance value of the sponge is gradually reduced by 0-10%. The hydrogel and sponge of the invention can be widely applied in fields of dye adsorption, stress sensing, electrical switch and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

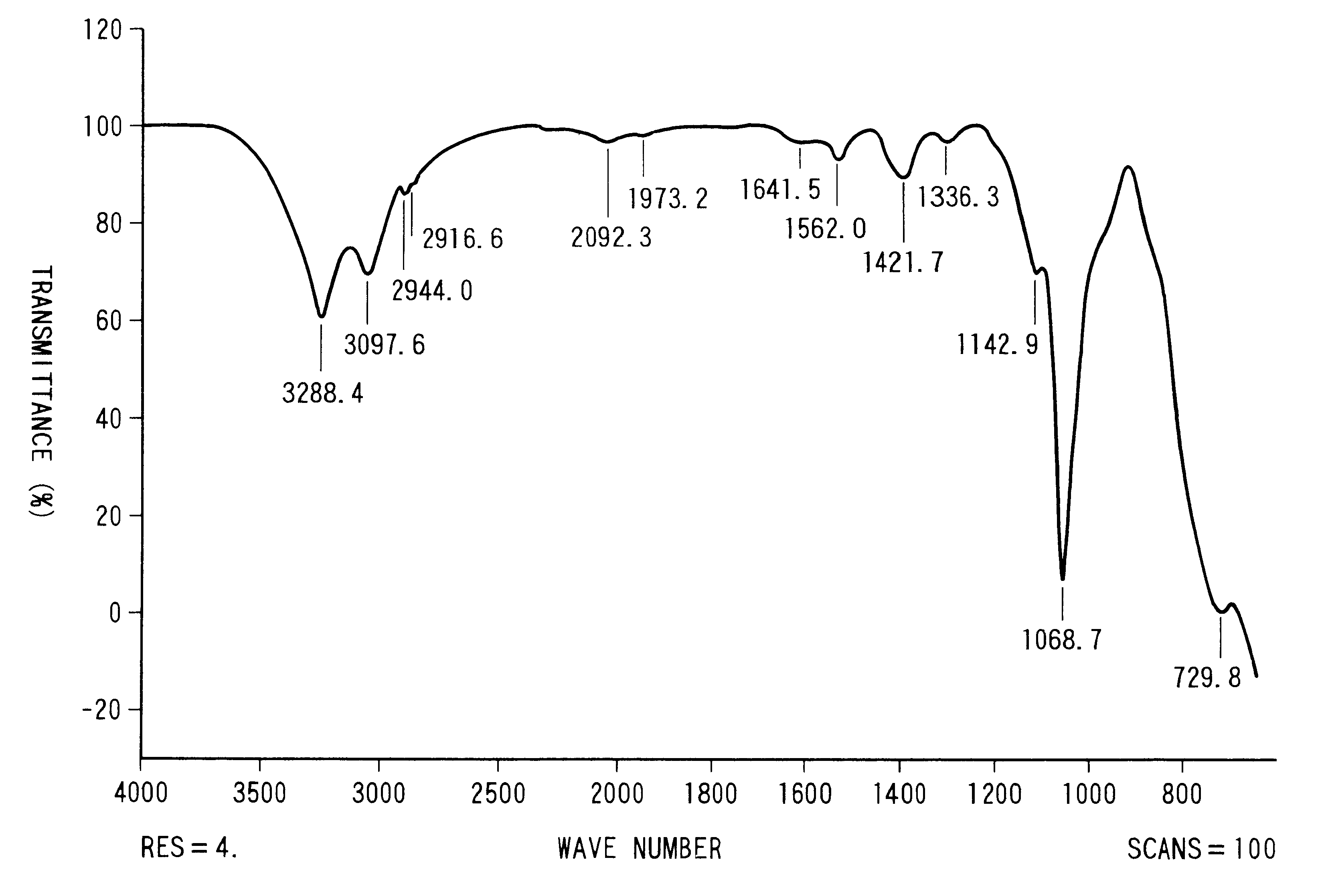

Preparation of hyperbranched polyetheramine-grafted GO adsorbent used for heavy metal and dye adsorption as well as application thereof

ActiveCN104707579AOther chemical processesWater/sewage treatment by sorptionPolymer scienceGlycidyl ethers

The invention relates to a preparation method of a hyperbranched polyetheramine-grafted GO adsorbent used for heavy metal and dye adsorption as well as an application thereof. The hyperbranched polyetheramine-grafted GO adsorbent is characterized in that polyether diglycidyl ether and a polyamine monomer are employed to prepare the hyperbranched polyetheramine HPEA, an alkalescence catalyst grafting oxidation graphene GO is used, so that the hyperbranched polyetheramine-grafted oxidized graphene GO-HPEA. The adsorbent preparation method is simple and easy, the adsorption quantity for the heavy metal ion or cation dye can be more than 500mg / g, and the hyperbranched polyetheramine-grafted GO adsorbent has the advantages of easy solid-liquid separation and repeatable utilization, and can be used for high efficiency treatment of heavy metal and dye in waste water.

Owner:UNIV OF JINAN

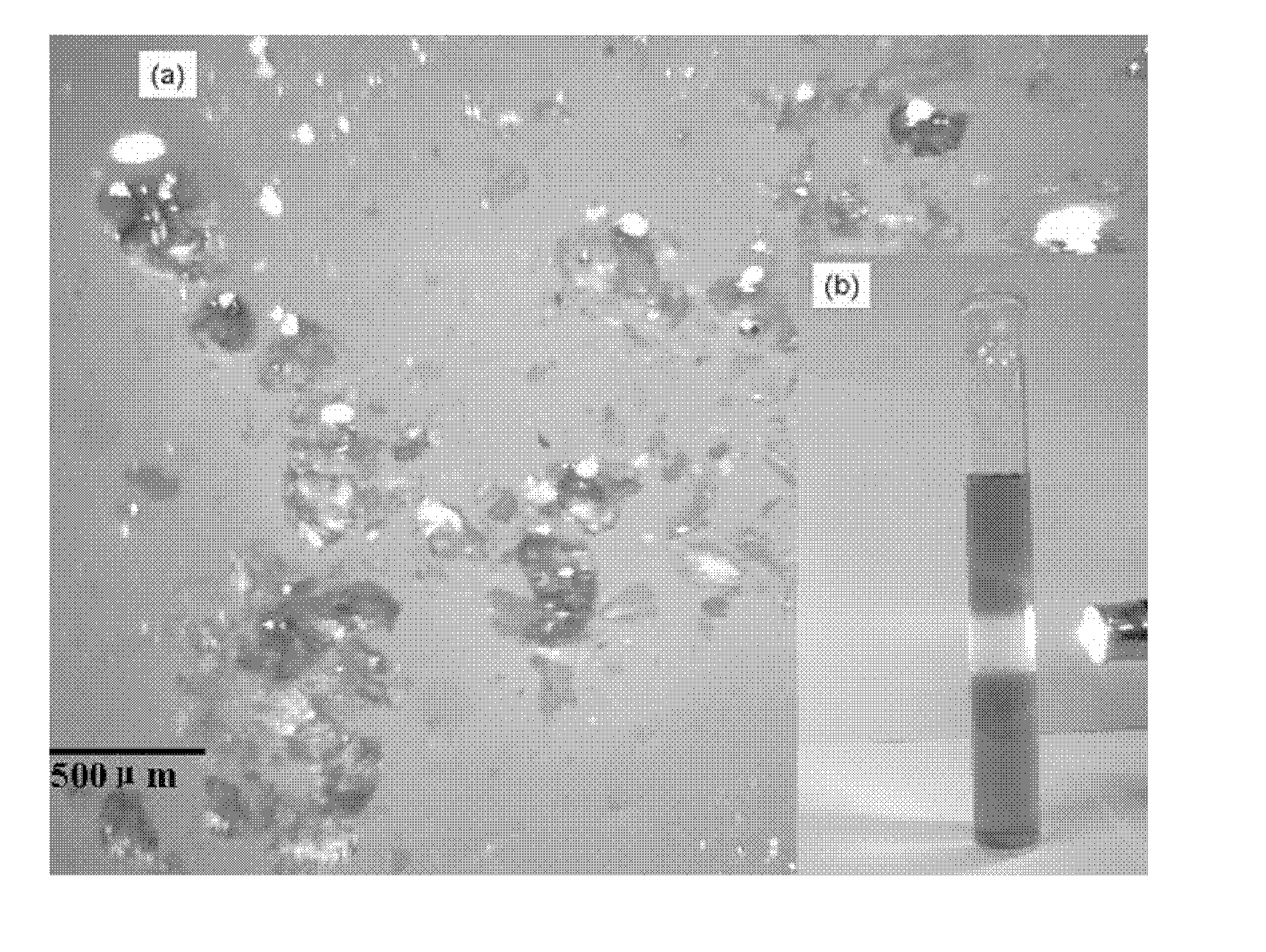

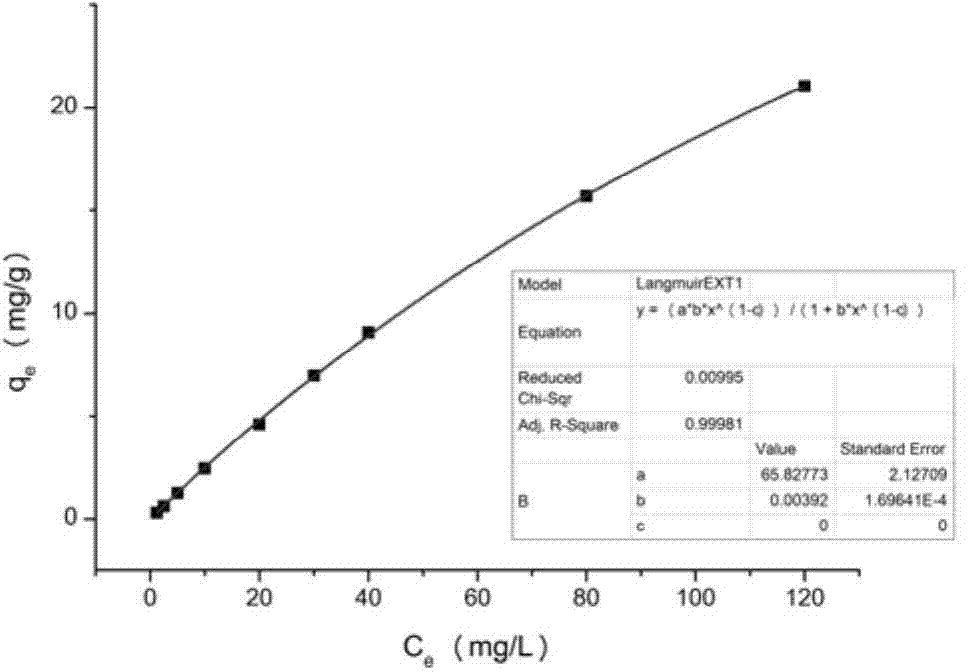

Method for preparing crosslinked-chitosan-system azo dye wastewater adsorbent

InactiveCN104741089ASimple structureHigh shapeOther chemical processesMicroballoon preparationCrosslinked chitosanMicron scale

The invention relates to a method for preparing a crosslinked-chitosan-system azo dye wastewater adsorbent. According to the method, the chitosan microsphere adsorbent aiming at azo dye wastewater treatment is prepared by carrying out reversed phase emulsification process and a cross-linking reaction on a microfluidic focusing type chip made from a laboratory-made polymethyl methacrylate (PMMA) material; the chitosan adsorbent prepared by virtue of the method belongs to a micron scale; compared with adsorbents at present, the chitosan adsorbent has the advantages that the specific surface area is larger, the degree of sphericity and the monodispersity are higher, the biocompatibility and the reproducibility of the chitosan adsorbent are guaranteed by virtue of a chitosan matrix, and the dissolving resistance and the swelling resistance of the chitosan adsorbent are improved under acid conditions when relatively high template dye adsorption capacity is guaranteed in a crosslinking process; by testing template dye wastewater methyl orange, the maximal adsorption capacity can reach 65.83mg / g.

Owner:EAST CHINA UNIV OF SCI & TECH

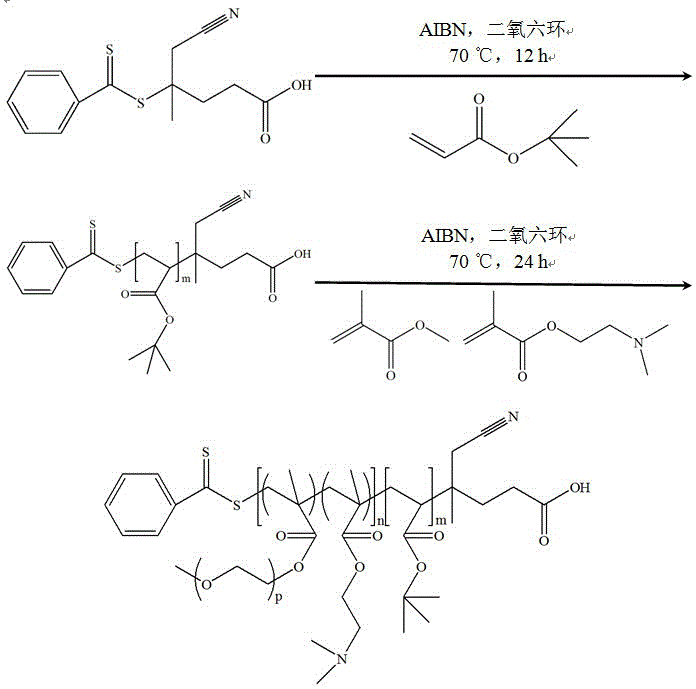

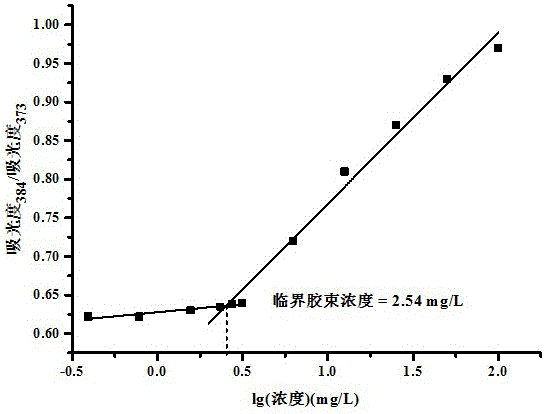

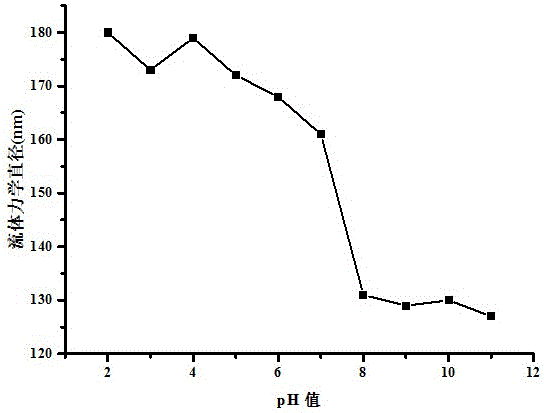

Preparation method for amphiphilic segmented copolymer with pH value and temperature sensitivities

The invention relates to a preparation method for an amphiphilic segmented copolymer with pH value and temperature sensitivities. The preparation method comprises the following steps: by adopting a reversible addition-fragmentation chain transfer polymerization process, synthesizing a macromolecular chain transfer agent namely tert-butyl polyacrylate, and subjecting the tert-butyl polyacrylate with dimethylaminoethyl methacrylate and ethylene glycol monomethyl ether methacrylate to the reversible addition-fragmentation chain transfer (RAFT) polymerization process again so as to synthesize the amphiphilic segmented copolymer P(tBA)-b-P(DMAEMA-co-PEGMA. The segmented copolymer provided by the invention can self-assemble to form micelles in an aqueous solution, and has pH value and temperature sensitivities, wherein the micelles have a critical pH value of 7 and a critical temperature of 37.5 DEG C. The preparation method provided by the invention has the advantages of high yield, relatively wide applicable monomer range, low requirements on reaction conditions, simple and convenient operation, greenness and environmental friendliness; and the amphiphilic segmented copolymer prepared by using the method provided by the invention has double pH value and temperature sensitivities and broad application prospects, and can be applied to the chemical production fields like dye adsorption, the environment protection fields like heavy metal pollution treatment, and the biomedical fields like controllable release of insoluble drugs.

Owner:TONGJI UNIV

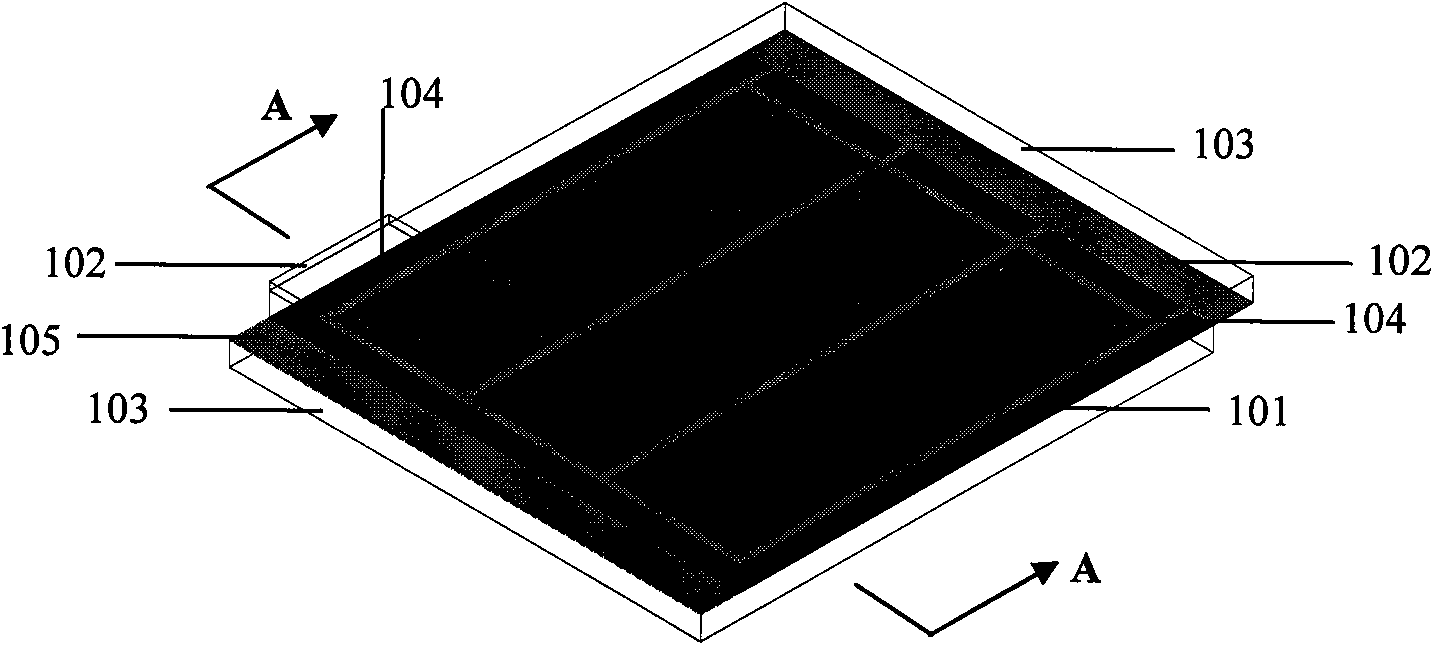

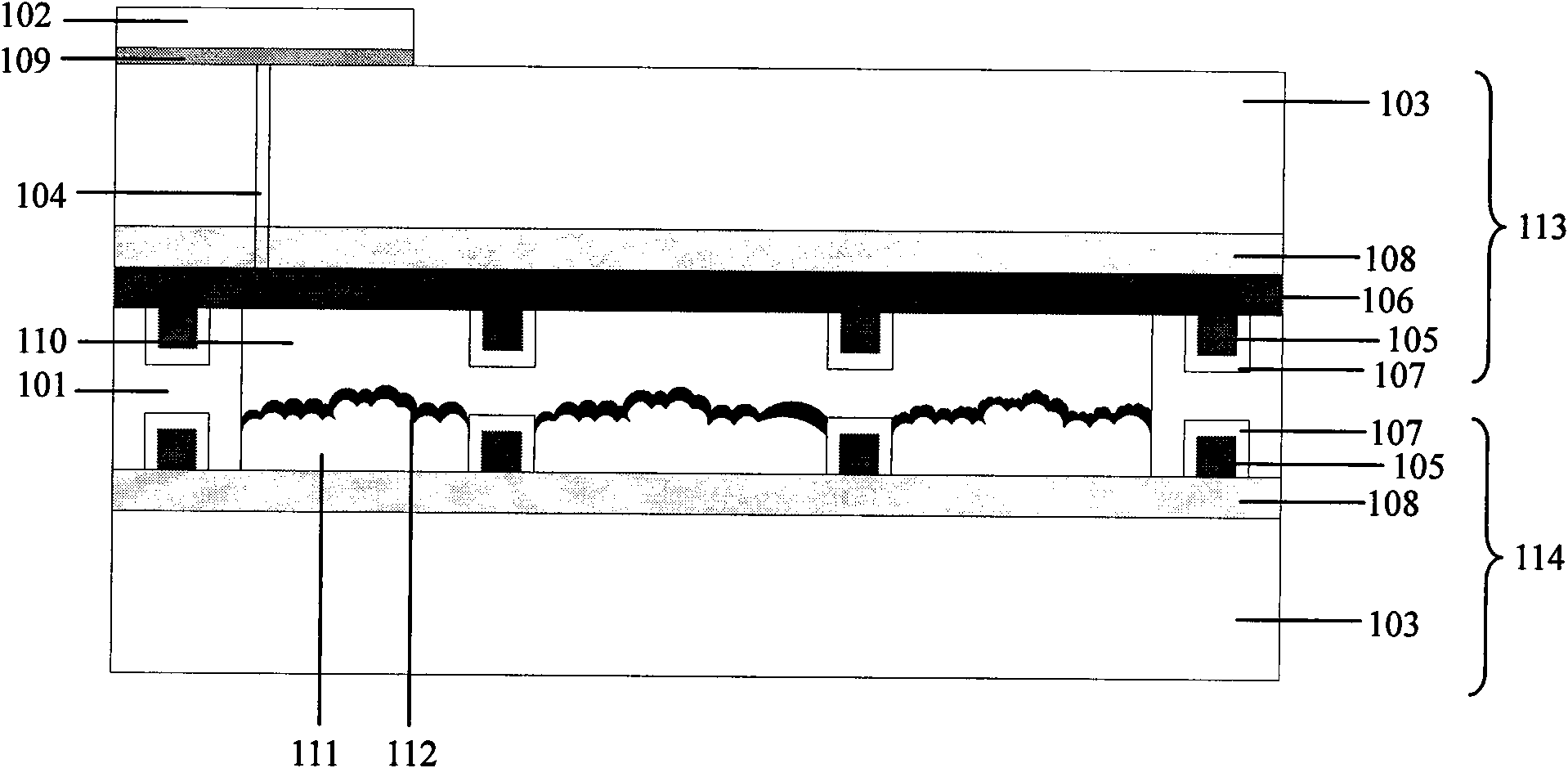

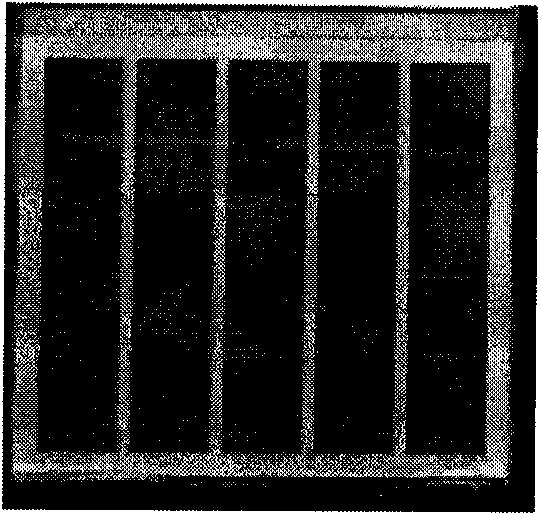

Method for preparing dye-sensitized solar cell module

InactiveCN101593631AMature technologyLow costLight-sensitive devicesSolid-state devicesScreen printingMature technology

The invention belongs to the technical field of solar cells, and relates to a method for preparing a dye-sensitized solar cell module. The invention utilizes flat screen printing and thermal sintering technology to prepare various structural layers of the dye-sensitized solar cell module, and then encapsulates the structural layers; the various structural layers are as follows: a photo-anode consists of a transparent glass substrate, a transparent conductive film, a nanometer porous semiconductor film, a dye adsorption layer, a conductive silver grate layer, an insulating medium protective layer and an insulating medium encapsulation layer; and a cathode consists of a transparent glass substrate, a transparent conductive layer, a platinum catalysis layer, a conductive silver grate layer, an insulating medium protective layer, an insulating medium encapsulation layer, an ultraviolet curing layer and a sealing substrate; and electrolyte is poured between the photo-anode and the cathode through a cathode hole. The method has mature technology, low cost, simplicity, controllability, and easy operation, and can realize mass-production preparation of dye-sensitized solar cell modules with large areas and various internal structures.

Owner:IRICO

Preparation method of crop straw dye adsorption material

InactiveCN103881033ANo pollution in the processSimple methodOther chemical processesWaste water treatment from textile industryItaconic acidPyrrolidinones

The invention relates to a preparation method of a crop straw dye adsorption material. The preparation method is characterized by comprising the process steps of adding straw powder into N, N-dimethylformamide, putting into an ultrasonic cleaning tank to perform ultrasonic treatment for 20-60 minutes at 30-50 DEG C, then adding phytic acid and urea into the system, heating to 50-90 DEG C, reacting for 2-6 hours, then cooling a product to the room temperature, precipitating, washing, drying and crushing to obtain phytic acid modified straw; neutralizing itaconic acid by using NaOH, then adding the phytic acid modified straw, acrylamide, vinyl pyrrolidone and a crosslinking agent, fully stirring for 30 minutes, then gradually heating to 50-60 DEG C, and finally slowly dropwise adding a redox initiator into a polymerization system to initiate a polymerization reaction for 3-5 hours; and after polymerization, precipitating, washing and drying to obtain the crop straw dye adsorption material. The adsorption capacity of the crop straw dye adsorption material to a cationic dye aqueous solution with the initial concentration of 200-2000mg / L is 195-1400mg / g, the decolorization rate of the crop straw dye adsorption material is 55-90%, and the crop straw dye adsorption material can reach adsorption equilibrium after 100-200 minutes of room temperature adsorption, and can be widely applied to the adsorption, separation and purification of cationic dyes, the environmental pollution control of cationic dye wastewater, and the like.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

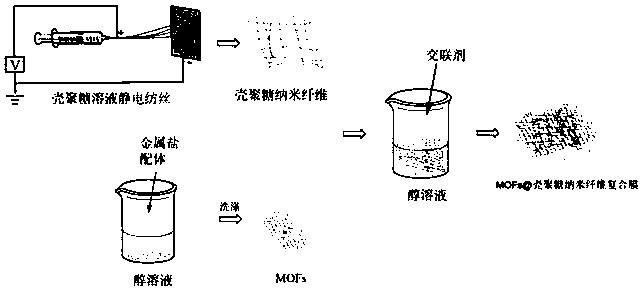

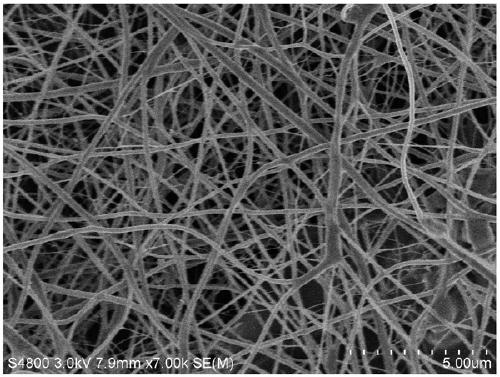

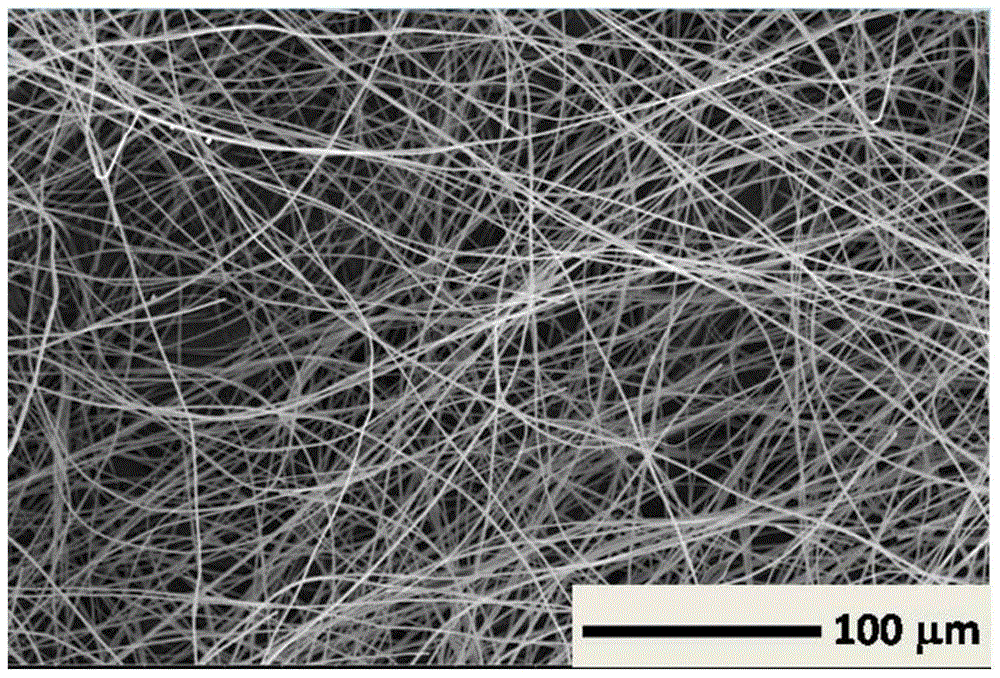

Preparation method of MOFs-chitosan nanofiber composite membrane

The invention belongs to the technical field of preparation of polymer materials and particularly relates to a preparation method of a MOFs-chitosan nanofiber composite membrane. The preparation method comprises: preparing chitosan nanofibers through an electrospinning method, and blending a synthesized MOFs material and the chitosan nanofibers so that the MOFs material and chitosan nanofibers arecompounded under the action of a cross-linking agent to form the MOFs-chitosan nanofiber composite membrane. The MOFs-chitosan nanofiber composite membrane effectively solves the problem of low strength, poor stability and poor dispersibility of the MOFs material in the chitosan fibers. The MOFs-chitosan nanofiber composite membrane has the advantages of high MOFs retention rate, high strength, excellent water resistance and excellent solvent resistance. The preparation method is simple and easy, the preparation conditions are mild, the preparation method is suitable for large-scale production, and the MOFs-chitosan nanofiber composite membrane can be used in the fields of dye adsorption, metal ion adsorption, gas adsorption and storage.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

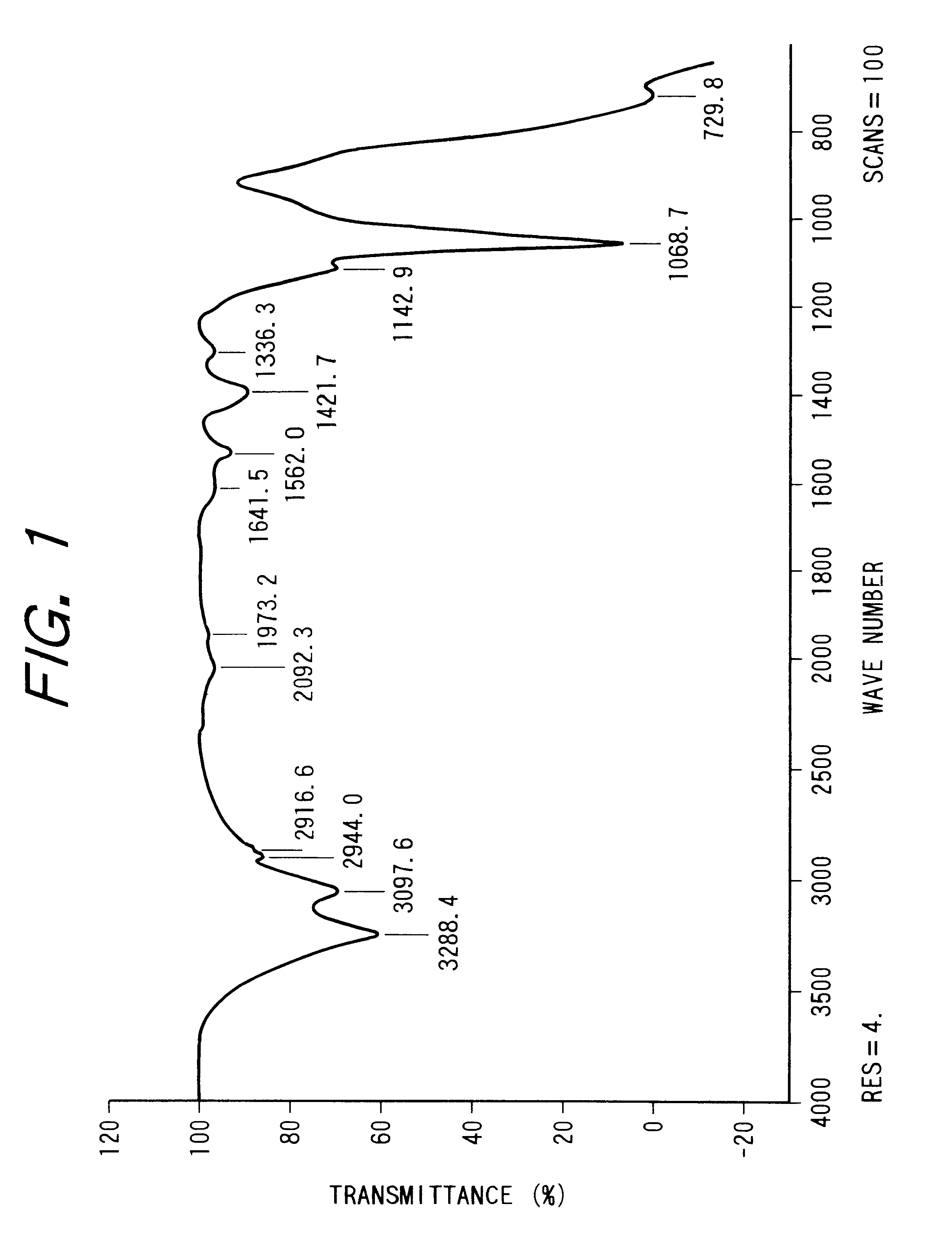

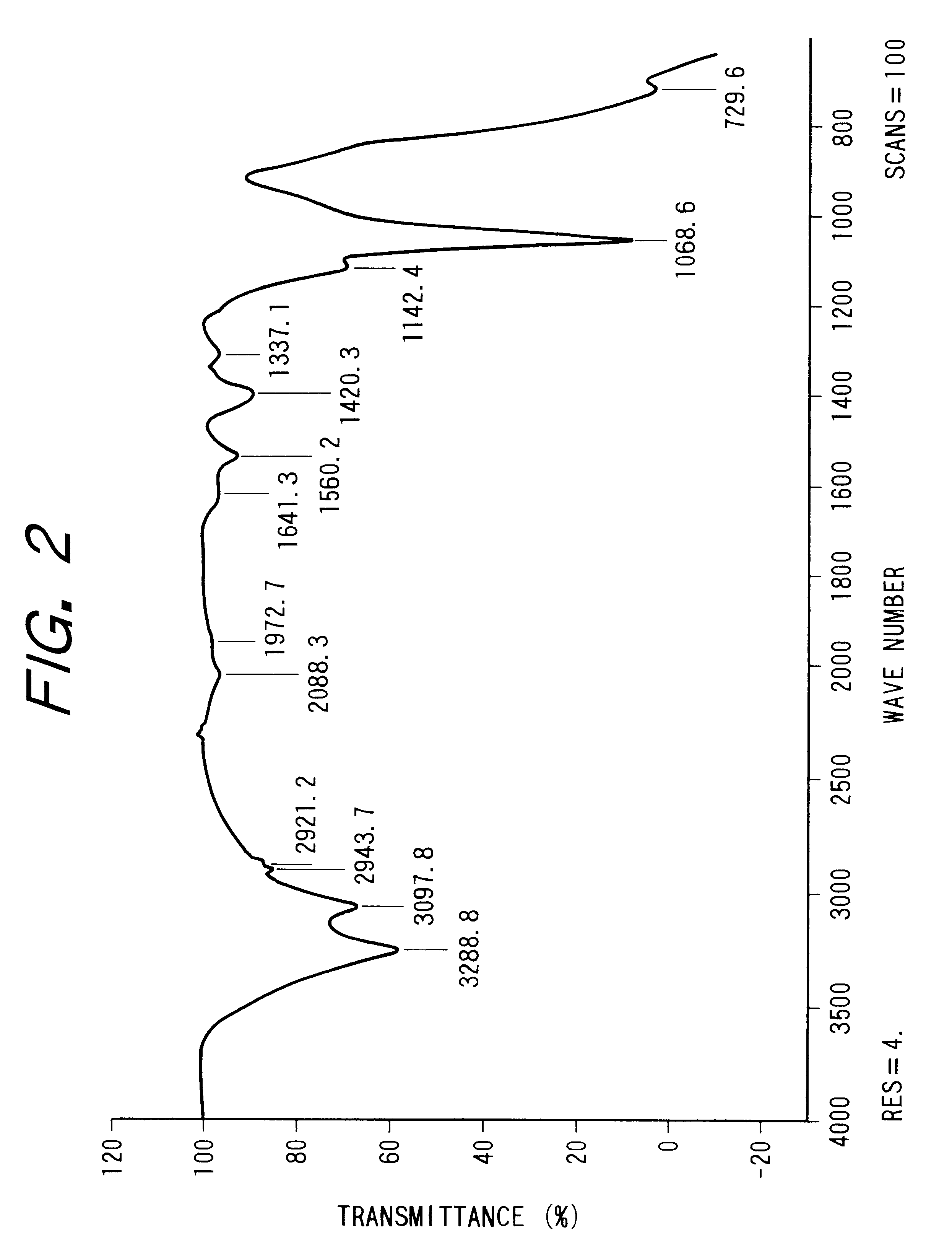

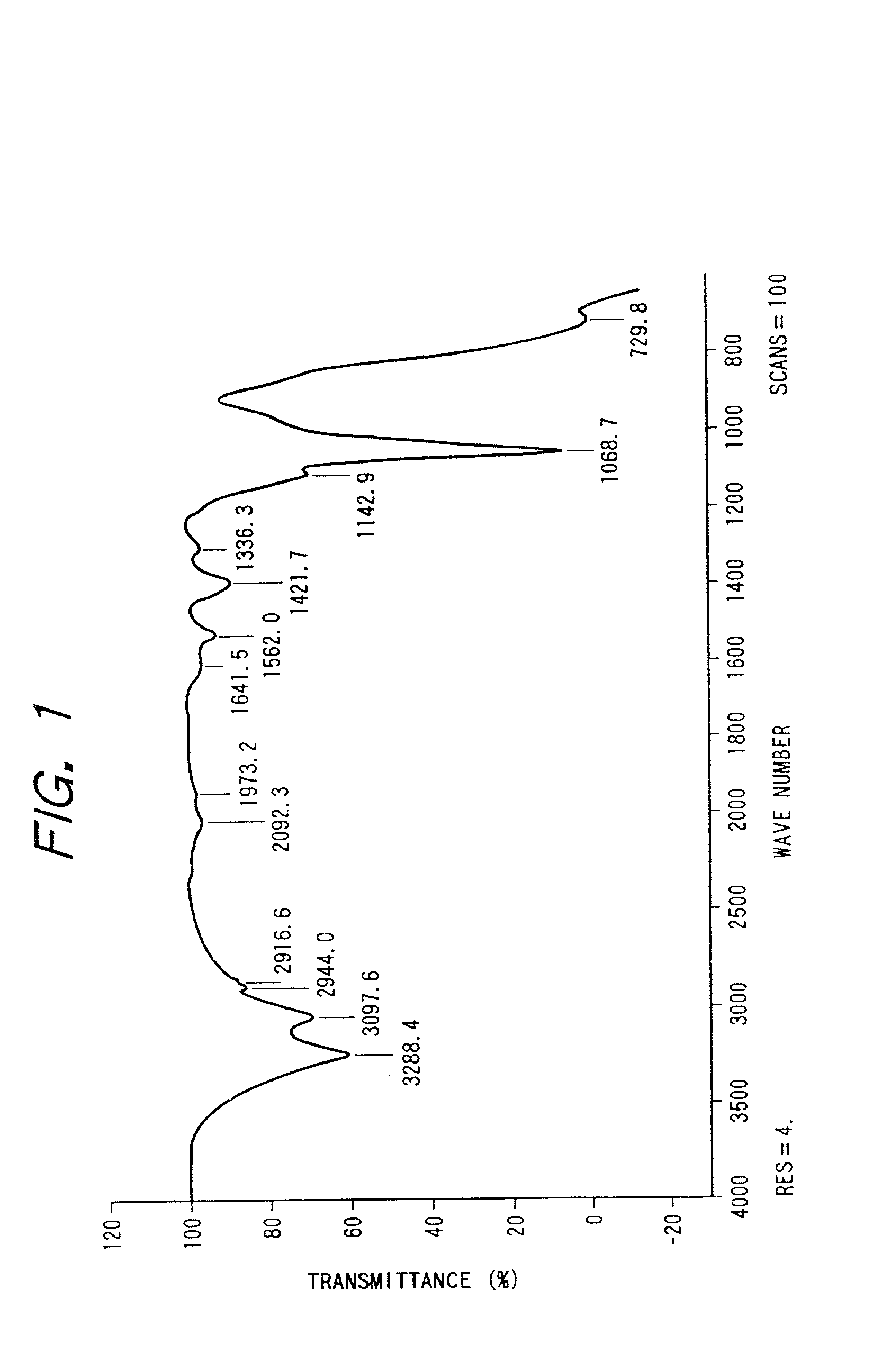

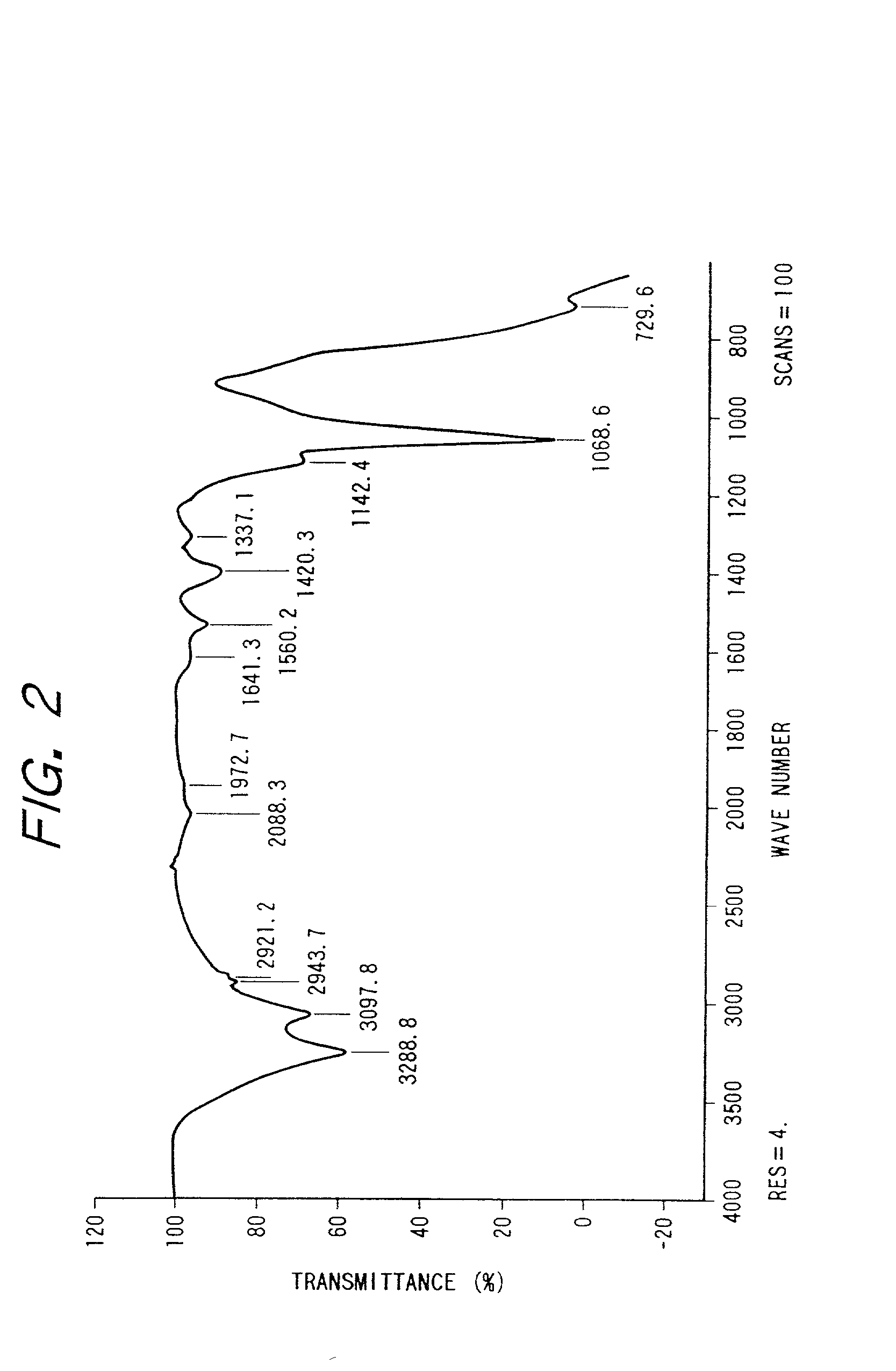

Printing medium, production process thereof and image-forming process

Disclosed herein is a printing medium provided on a base material with a porous ink-receiving layer which comprises, as principal components, an alumina hydrate having a boehmite structure and a binder, wherein when measuring with an ink containing 0.1% by weight of a surfactant, the time required to absorb 30 ng of an ink is 400 milliseconds or shorter, the dye-adsorbing capacity falls within a range of from 900 to 2,000 mg / m2, and the index of dye-adsorbing rate falls within a range of from 0.0 to 5.0.

Owner:CANON KK

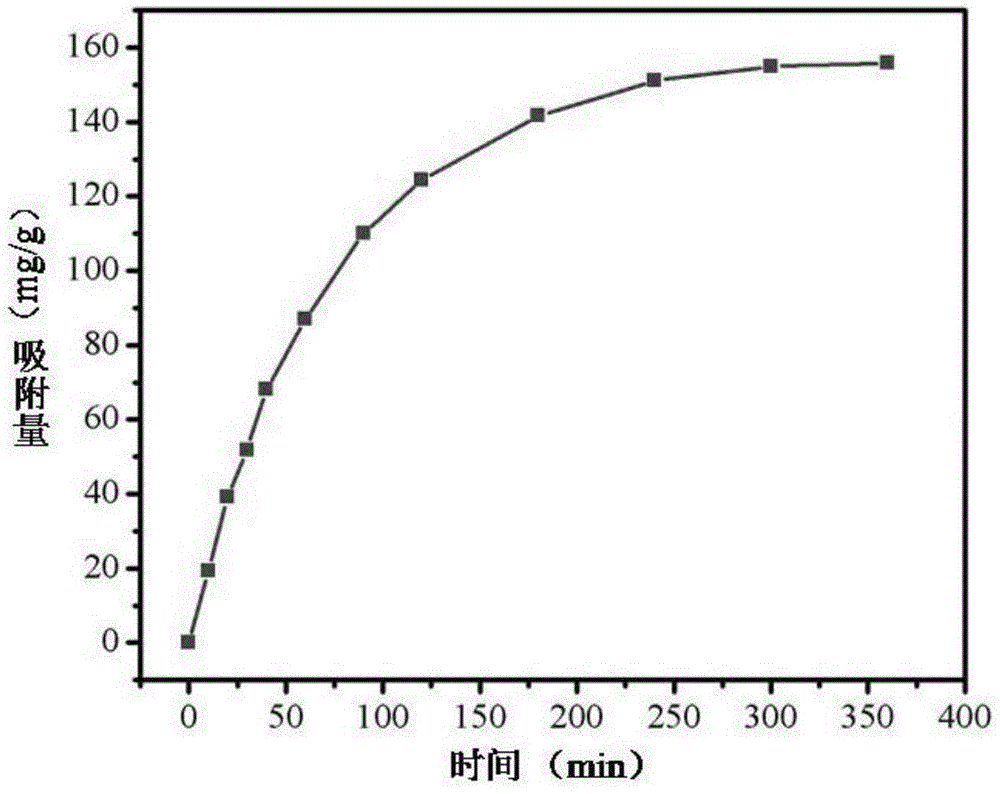

Preparation method of magnetic polymer dye adsorbent

ActiveCN107376870ANo pollution in the processSimple methodOther chemical processesWater contaminantsFunctional monomerSorbent

The invention relates to a preparation method of a magnetic polymer dye adsorbent. An improved chemical co-precipitation method is adopted to prepare magnetic nano particles. Then the surface of nano particles is modified by using gamma-chloropropyl trimethoxysilane and polyethyleneimine to obtain polyethyleneimine modified magnetic nano particles. Finally, polyethyleneimine modified magnetic nano particles and functional monomers carry out copolymerization to prepare the magnetic polymer dye adsorbent with a multilayer crosslinking structure and multiple adsorption groups. The saturation magnetization intensity is 3.5 to 15.5 emu / g. The residual magnetism and coercive force are close to zero. The dye adsorbent has para-magnetism and magnetic responsiveness. For a dye water solution with a primary concentration of 100 to 1000 mg / L, the dye adsorption capacity can reach 50 to 600 mg / g; and the adsorption balance is reached within 60 to 150 minutes. After the dye adsorbent is repeatedly used for five times, the dye adsorption capacity exceeds 90% of first adsorption capacity. The dye adsorbent can be applied to dye adsorption separation and dye wastewater pollution treatment.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

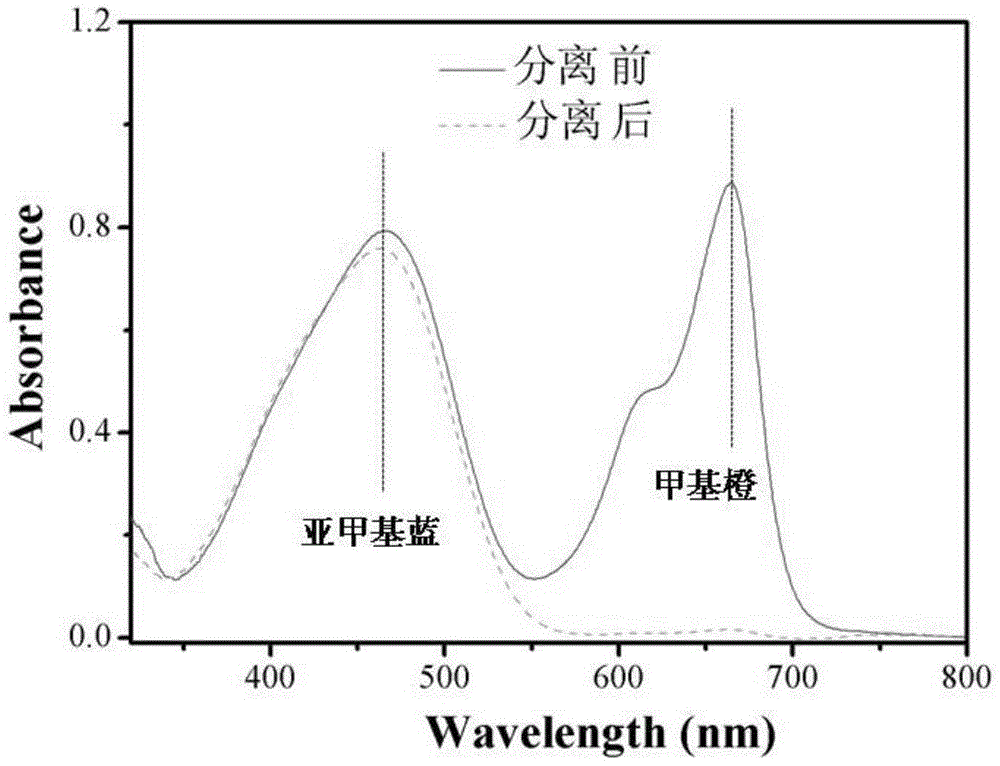

Beta-cyclodextrin-based nanometer fiber film, preparation method thereof, and application of beta-cyclodextrin-based nanometer fiber film to dye adsorption and separation

ActiveCN105220362AIncrease contentImprove adsorption capacityNon-woven fabricsArtifical filament manufactureFiberCell separation

The invention relates to a beta-cyclodextrin-based nanometer fiber film, a preparation method thereof, and application of the beta-cyclodextrin-based nanometer fiber film to dye adsorption and separation. The nanometer fiber dye adsorption and separation film is prepared by combining the electrospinning technology with the in-situ thermo-crosslinking method. The beta-cyclodextrin-based nanometer fiber film is prepared from body beta-cyclodextrin, crosslinking agent citric acid and polyacrylic acid which plays a role of crosslinking agents while assisting in spinning macromolecules. A crosslinking reaction happens between hydroxide radicals of beta-cyclodextrin and carboxyl of citric acid and polyacrylic acid to form ester bonds, and therefore the ester bonds are connected to form a three-dimensional crosslinked structure. The beta-cyclodextrin-based electrospinning nanometer fiber film obtained through the method can effectively separate positive ion and negative ion mixed solutions; the obtained beta-cyclodextrin-based electrospinning nanometer fiber film is high in recycling capacity. The preparation process is simple and easy to implement, raw materials can be easily obtained, friendliness to the environment is achieved, cost is low, and good application prospects are achieved.

Owner:吉林省贞靓科技有限公司

Dye adsorbent and its application in treating dye effluent

InactiveCN1348926AImprove adsorption capacityGood dispersionSedimentation separationEnergy based wastewater treatmentEmission standardWastewater

This invention dislcoses a dye adsorbent and its application as flocculant in the process of dye waste water treatment. This invented dye adsorbent is the compound of dicyandiamide, formaldehyde and alum according to a certain proportion, and after mixing, the product is produced by reaction under a certain temp., and its advantages include very good effect in decoloring the dye waste water up tothe standard of direct discharge, and cheap price and low dosage of dye adsorbent.

Owner:张明

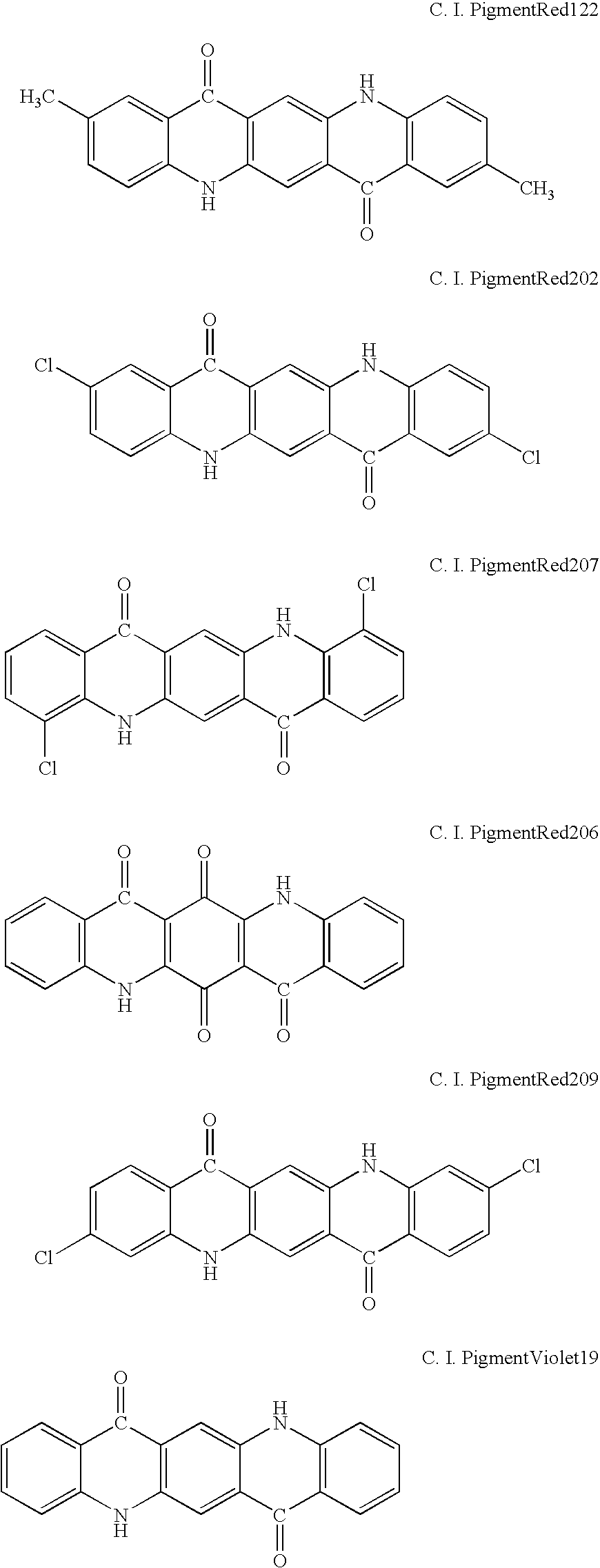

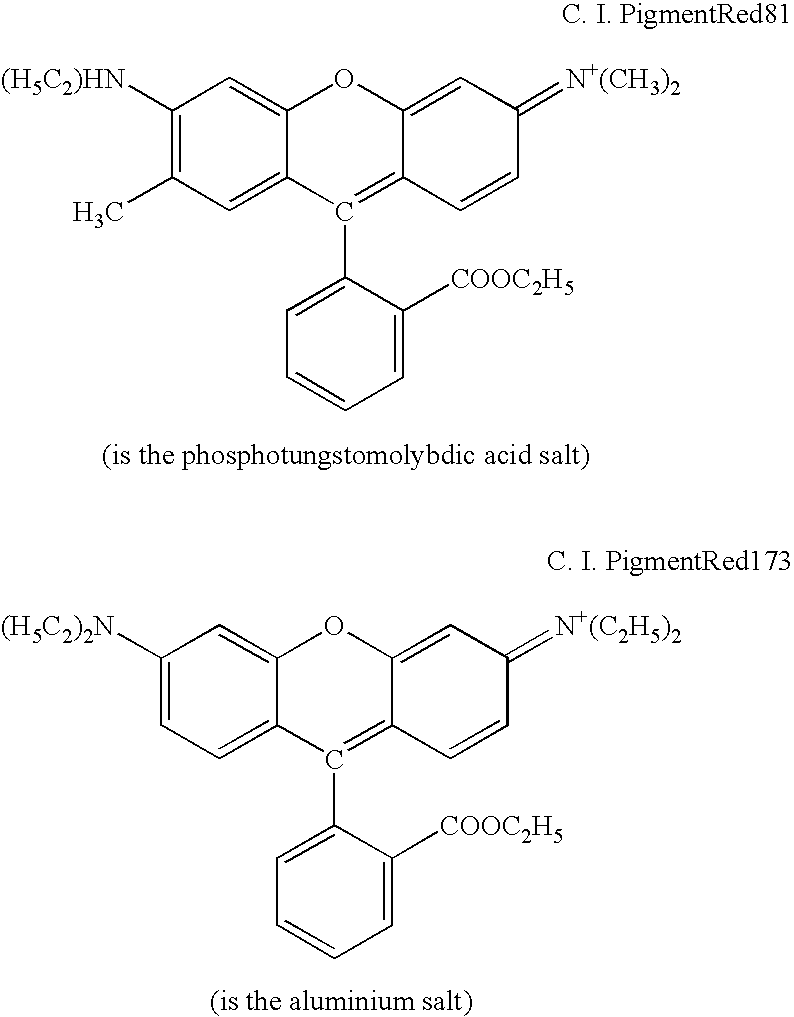

Ink-jet recording liquid and process for producing the same

InactiveUS20050022695A1Good dispersionImprove dispersion stabilityInksChemical reactionAqueous medium

An ink-jet recording liquid using a dye and a pigment, which is excellent in dispersibility and has good printing performance and storage stability, and a process for producing the same are provided. There are provided an ink-jet recording liquid containing a pigment, a dye and a surfactant which are incorporated in an aqueous medium, characterized in that (1) the pigment and the dye at least partly comprise a pigment and a dye reversibly adsorbed thereon without involving a chemical reaction, (2) the dye reversibly adsorbed on the pigment without involving a chemical reaction contains a dye having a dye adsorption shown by the following formula (1) of 0.02 g / g or more, and (3) as the surfactant, a nonionic surfactant and an anionic surfactant coexist; and a process for producing the same.

Owner:MITSUBISHI CHEM CORP

Three-component cationic dye adsorbent and preparation method thereof

InactiveCN103447008AHigh adsorption rateFast adsorptionOther chemical processesWaste water treatment from textile industryMicrosphereEthylic acid

The invention discloses a three-component cationic dye adsorbent and a preparation method thereof. The adsorbent comprises carbon nano tubes, sodium alginate and chitosan. The preparation method comprises the following steps: (1) utilizing a mixed acid solution to carry out ultrasonic treatment on the carbon nano tubes, thus obtaining water-soluble carbon tubes; (2) dissolving chitosan in a dilute acetic acid solution, then adding sodium alginate, and stirring the materials to dissolve the materials, thus obtaining sodium alginate / chitosan blending sol A; (3) dispersing the water-soluble carbon tubes in the sol A, thus obtaining carbon tube / sodium alginate / chitosan blending sol B; (4) utilizing a No.5 injection syringe to drop the blending sol B into a calcium chloride solution one by one, carrying out crosslinking to form carbon tube / sodium alginate / chitosan composite microspheres, and then drying the carbon tube / sodium alginate / chitosan composite microspheres, thus obtaining the cationic dye adsorbent. The adsorbent gives play to the triple adsorbing effects of the carbon nano tubes, sodium alginate and chitosan on dyes, so that the cationic dye adsorption rate of the adsorbent is improved, and the adsorbent can be widely used for treating wastewater containing cationic dyes. Meanwhile, the preparation method is low in equipment requirements, simple in operation process and mild in conditions, is environment-friendly and is suitable for industrial production.

Owner:SHANDONG UNIV OF TECH

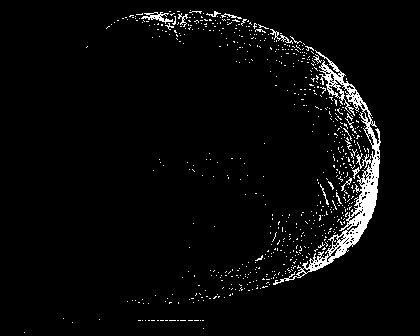

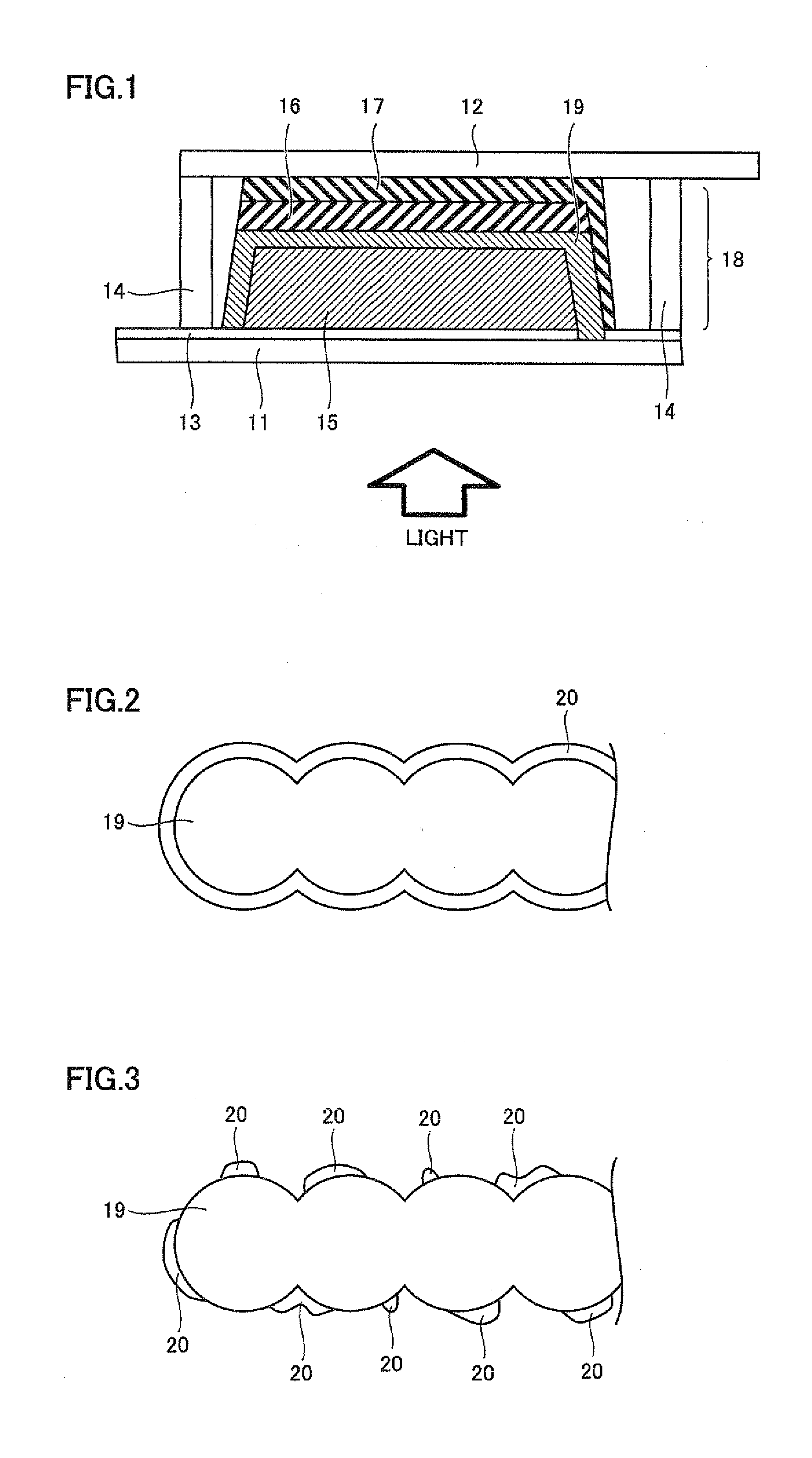

Dye-sensitized solar cell and dye-sensitized solar cell module

Disclosed are a dye-sensitized solar cell and a dye-sensitized solar cell module that suppress a decrease in photoelectric conversion efficiency caused by dye adsorption to an insulation layer. The dye-sensitized solar cell is characterized by having a stacked structure wherein an electroconductive layer, a photoelectric conversion layer formed of a porous semiconductor layer into which a dye is absorbed, a porous insulation layer, a catalyst layer, and a counter-electrode electroconductive layer are stacked in this order on a light-transmissive support body, with an insulation cover part that is comprised of a material which differs from that of the porous insulation layer formed on at least a part of or on all of the surface of the porous insulation layer.

Owner:SHARP KK

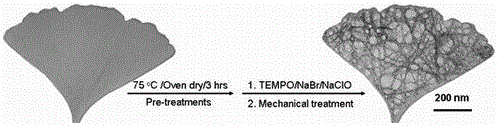

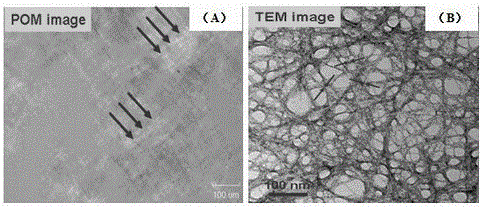

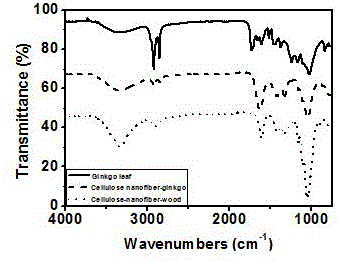

Method for preparing nanocellulose for efficiently adsorbing heavy metal ions from natural fallen leaves

ActiveCN106345426AEfficient use ofReduce pollutionOther chemical processesWater contaminantsFiberWater source

The invention relates to a method for preparing nanocellulose for efficiently adsorbing heavy metal ions from natural fallen leaves and a simple method for efficiently adsorbing heavy metal ions or dyes in the polluted water, wherein the nanocellulose fiber with a diameter of 1-100nm and a length-diameter ratio of 10-1,000 is prepared. With rich functional groups on the surface, the nanocellulose can interact with the heavy metal ions or dyes in the polluted water source through complexing or static electricity so as to achieve an aim of adsorbing heavy metal ions or dyes.

Owner:BEIJING UNIV OF CHEM TECH

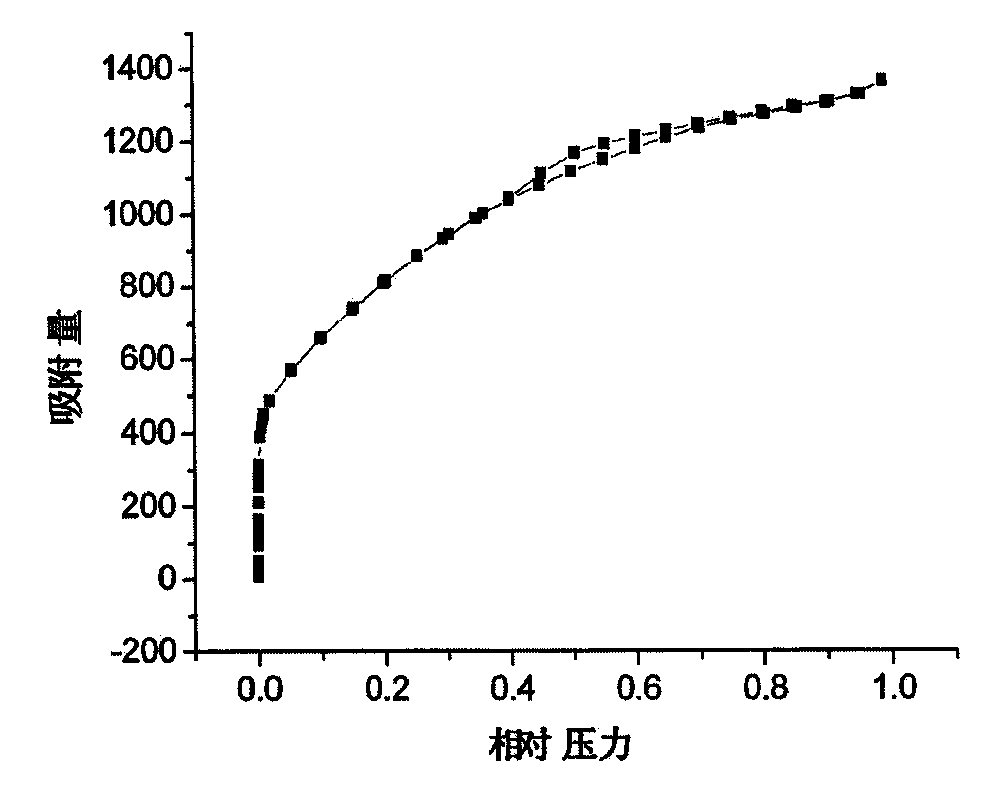

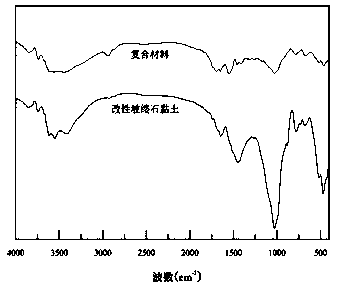

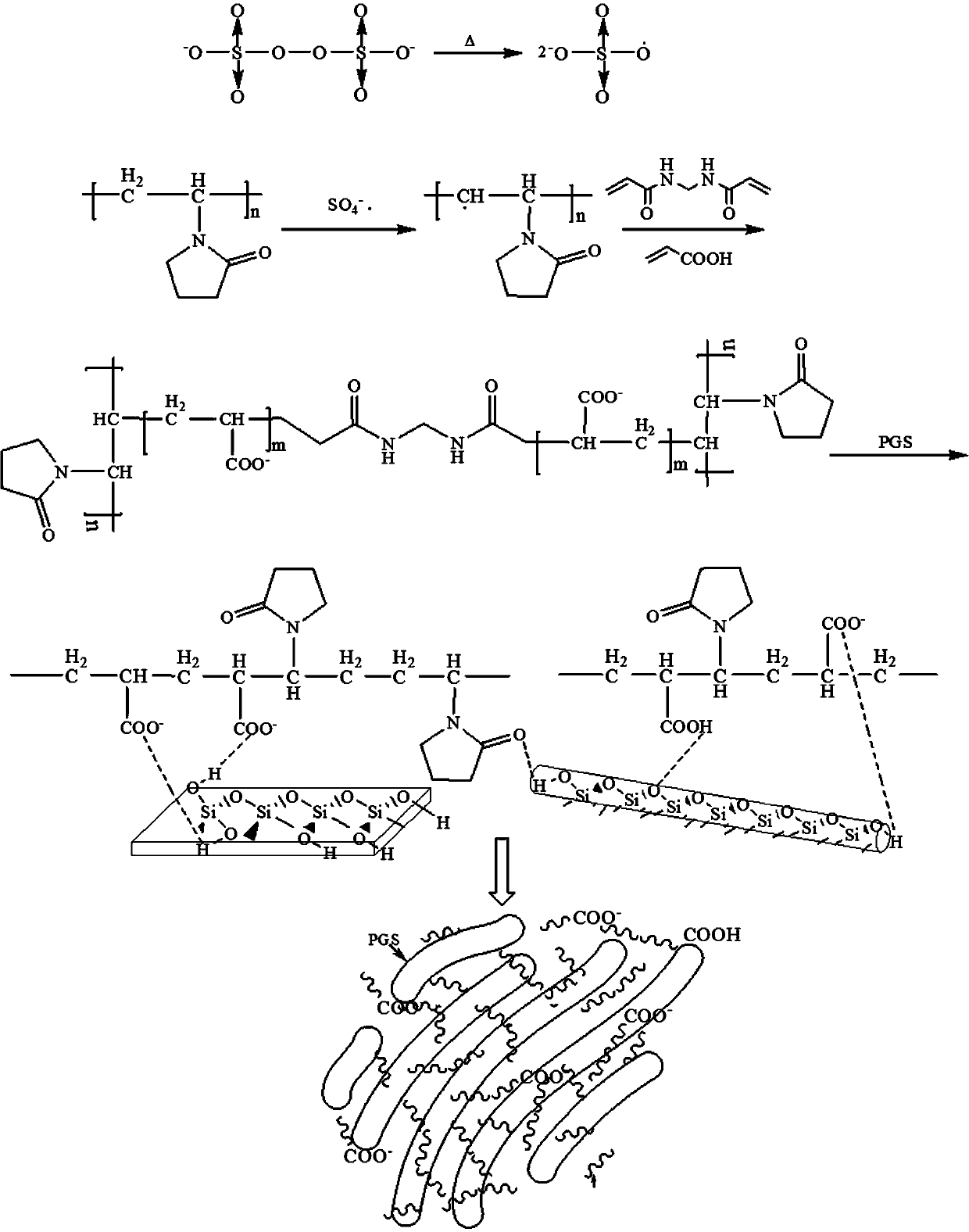

Preparation method of acrylic acid/polyvinylpyrrolidone/palygorskite composite adsorbing material

InactiveCN103623787AIncrease molecular spaceIncrease adsorption sitesOther chemical processesAlkali metal oxides/hydroxidesSpatial structurePalygorskite

The invention provides a preparation method of an acrylic acid / polyvinylpyrrolidone / palygorskite clay composite adsorbing material. The preparation method is characterized in that acrylic acid, polyvinylpyrrolidone and palygorskite clay are used as raw materials, N, N'-methylene-bisacrylamide is used as a crosslinking agent, potassium peroxodisulfate is used as an initiating agent, and the composite material with a network interpenetration structure is obtained through free radical polymerization. As the polyvinylpyrrolidone and the palygorskite clay are introduced, the network spatial structure of the polymer is adjusted through the special structure on the surface of the palygorskite clay, adsorption sites of the spatial three-dimensional network structure of the composite material are increased, and the molecular clearance gathering of the polymer is increased, so that the cationic dye adsorption property of the polymer is improved. Experiments prove that the cationic dye methylene blue adsorption capacity of the composite adsorbing material prepared by the method is 1700mg / g-1980mg / g, and the removal rate of cationic dye methylene blue is 85%-99%.

Owner:江苏尚励环境工程有限公司

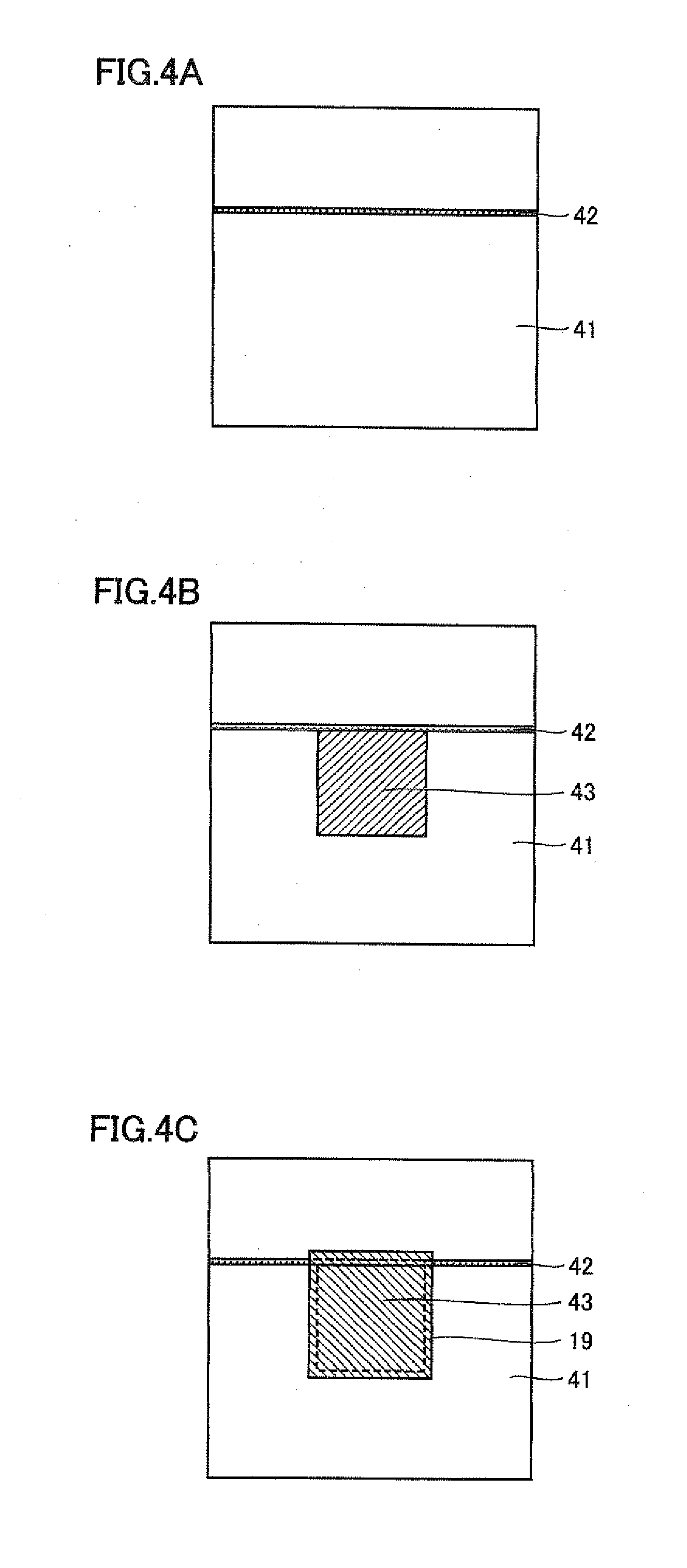

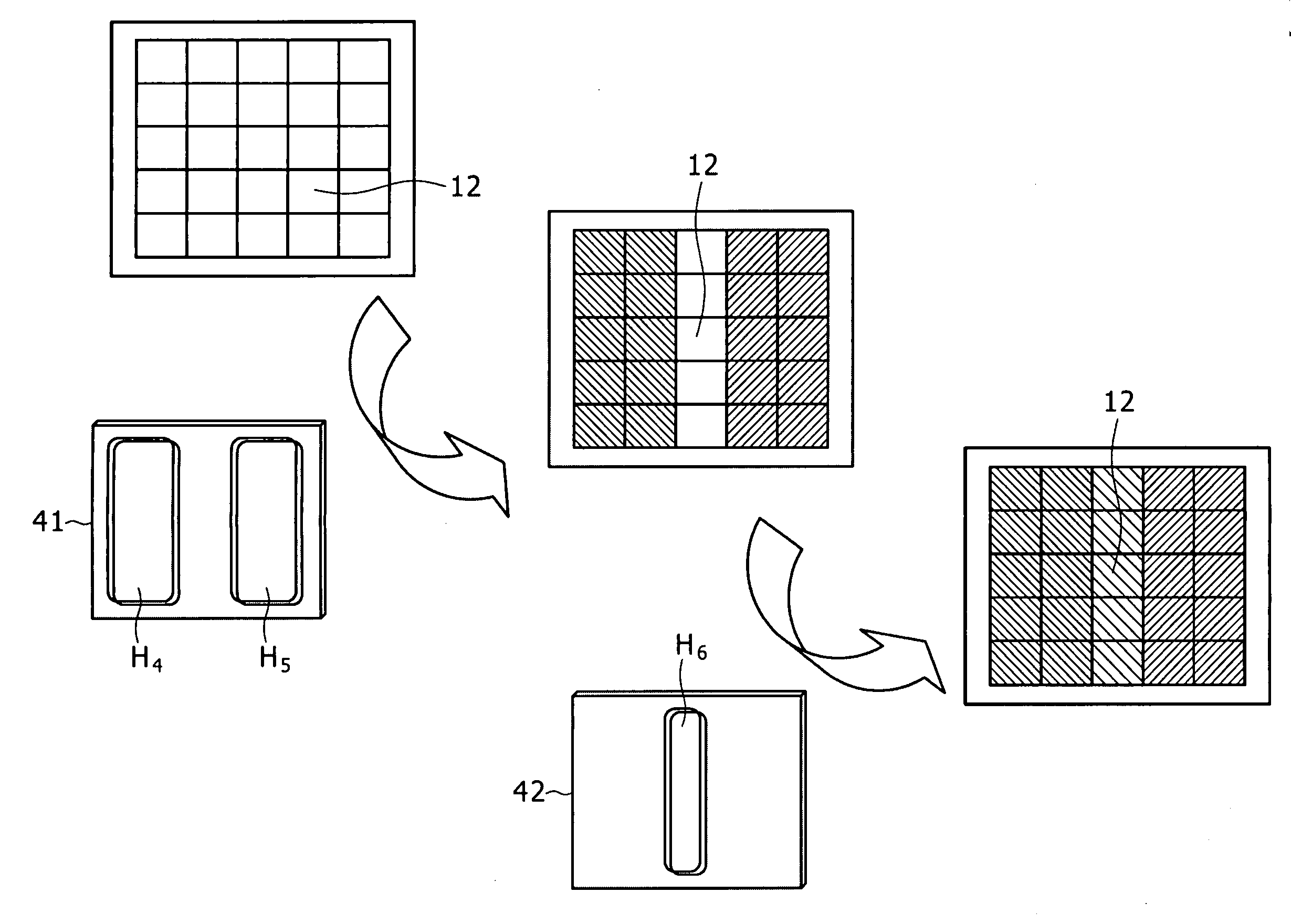

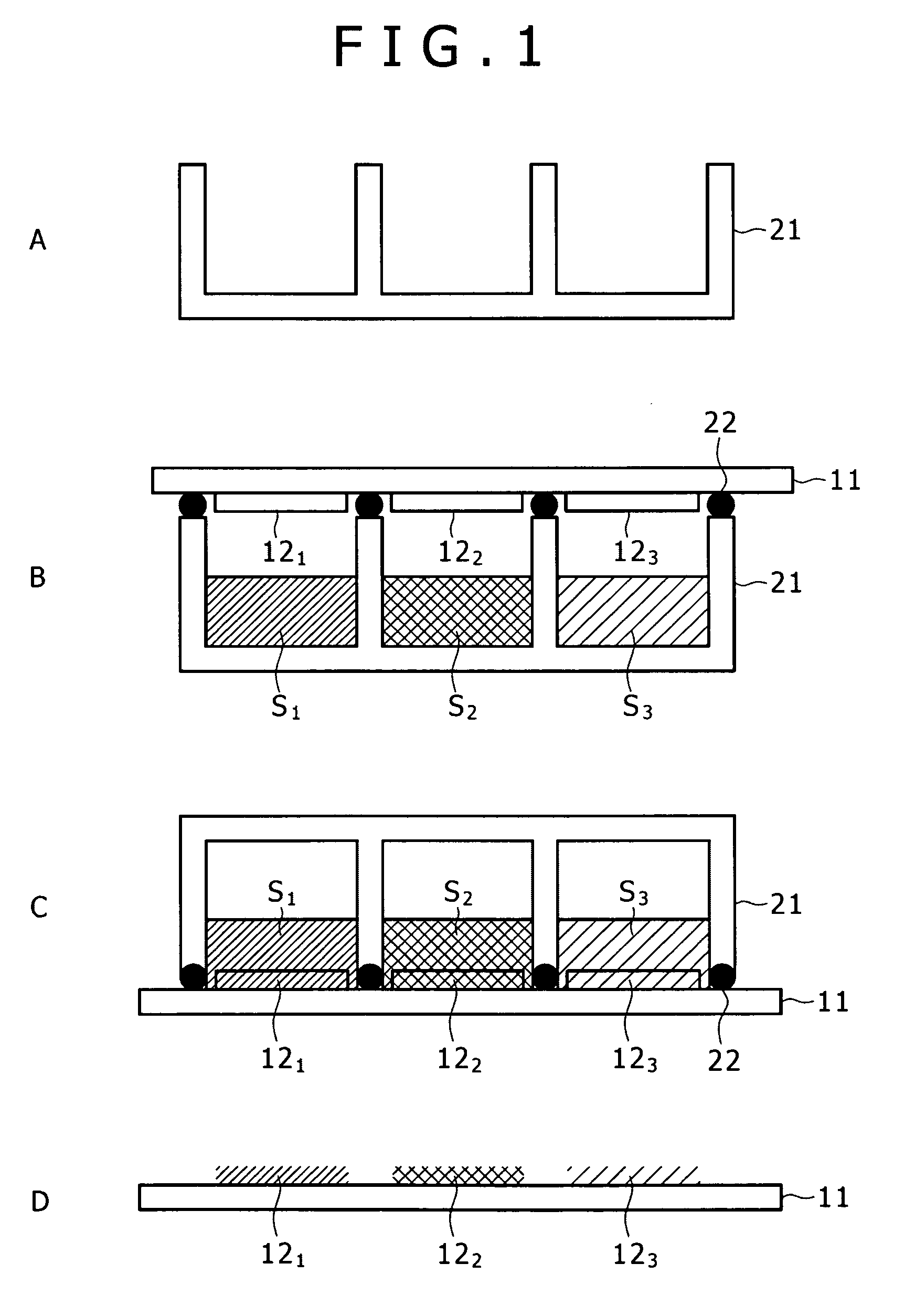

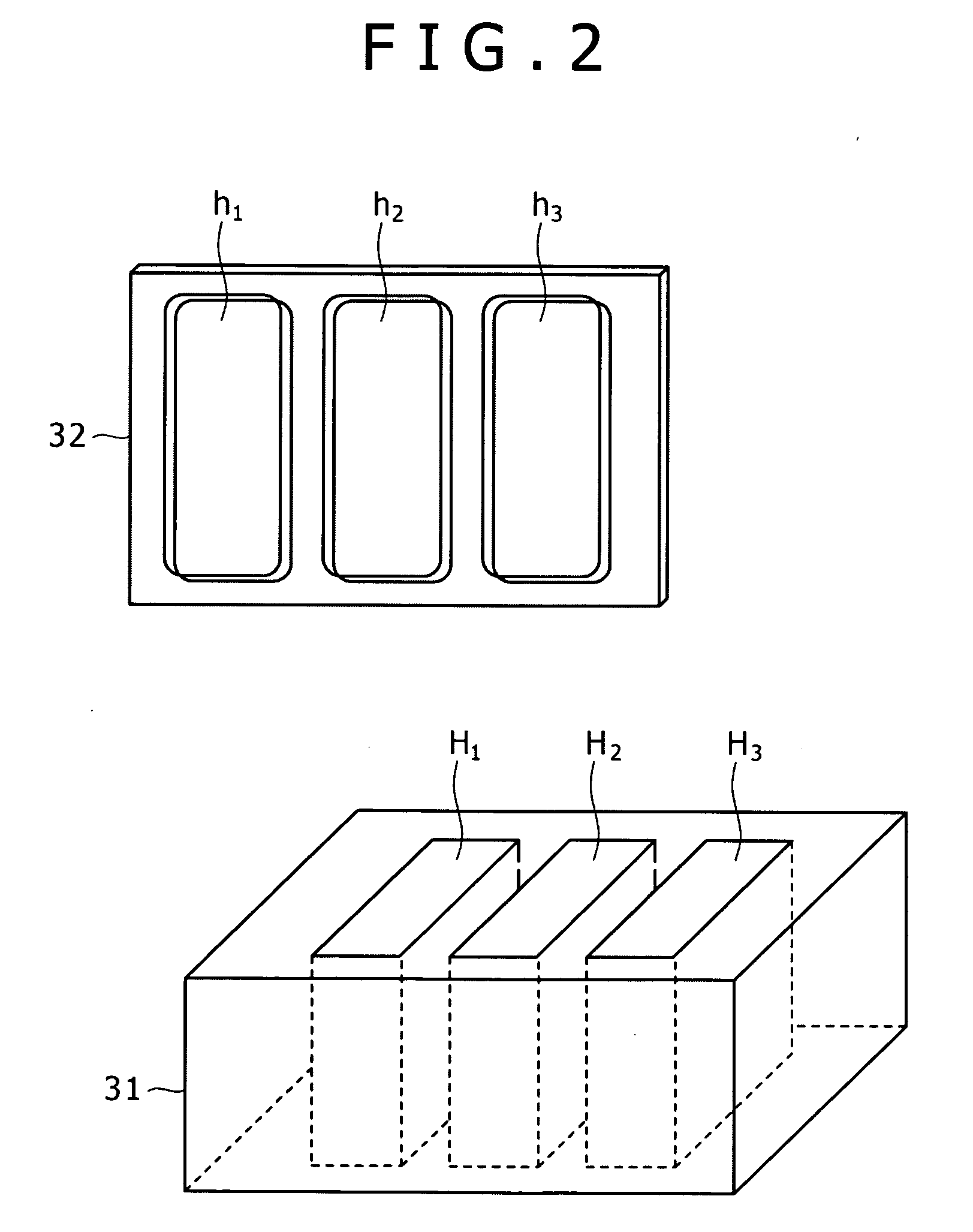

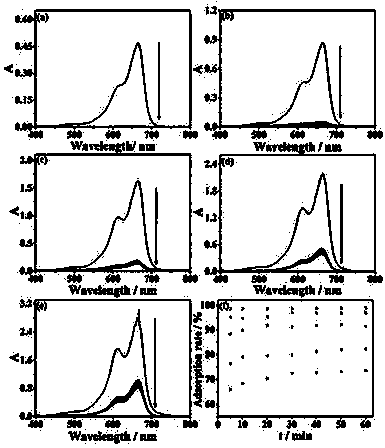

Method of manufacturing photoelectric conversion device

InactiveUS20100144083A1Easy to implementAvoid difficult choicesElectrolytic capacitorsFinal product manufactureSemiconductor electrodeAdhesive

The present invention relates to a method of manufacturing a photoelectric conversion device in which selective dye adsorption can be performed easily. In the step of a dye adsorbing process, a material unit 21 having partition walls of a predetermined shape is placed over semiconductor electrodes 121 to 123, which are a titanium oxide electrode. The material unit 21 is laminated by a UV cure adhesive. Dye solutions S1 to S3 obtained by dissolving each of three kinds of dyes of N719, Black dye, and D149, for example, into a CH3CN / t-BuOH mixed solution are put in each of sections divided by the partition walls. The material unit 21 is inverted in that state, and left standing still for 24 hours. Then, the adhesive is removed after passage of the 24 hours. Thus, the semiconductor electrodes 121 to 123 having regions corresponding to the sections which regions are colored with the three different kinds of dyes are obtained. The present invention is applicable to a method of manufacturing a dye sensitized solar cell.

Owner:SONY CORP

Preparation method for polyacid @ MIL-101 composite material and application of polyacid @ MIL-101 composite material

InactiveCN103769036AStable structureSimple methodOther chemical processesWater/sewage treatment by sorptionTetramethylammonium hydroxideDye absorption

The invention belongs to the technical field of inorganic composite materials and particularly relates to a preparation method for an MIL-101 composite material based on Keggin type poly-tungstate and a molecule-group porous material, and an application of dye absorption of the MIL-101 composite material. The material is prepared from the Keggin type poly-tungstate, tetramethylammonium hydroxide, terephthalic acid and chromic nitrate which are used as raw materials by adopting a hydrothermal method. The prepared material can be used for adsorbing a cation organic dye; the adsorption rate to methylene blue within short time can be up to 98% and the adsorption effect is obviously higher than that of a pure MIL-101 material and is higher than the adsorption capability of active carbon. The preparation method has the characteristics of being easy and convenient to prepare and rapid and efficient in adsorption; the prepared material has a wide acid-base applicable range, is easy to separate and can be repeatedly used.

Owner:NORTHEAST NORMAL UNIVERSITY

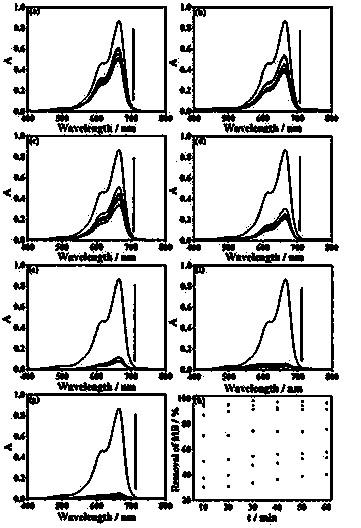

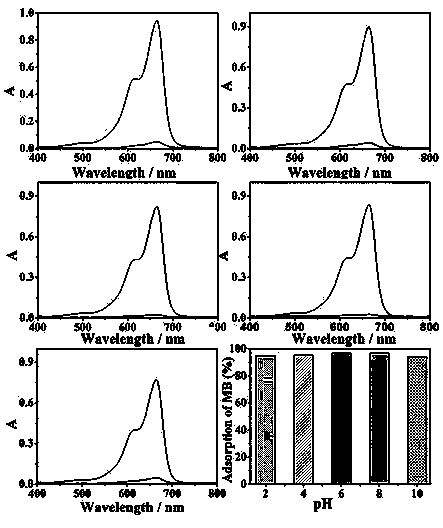

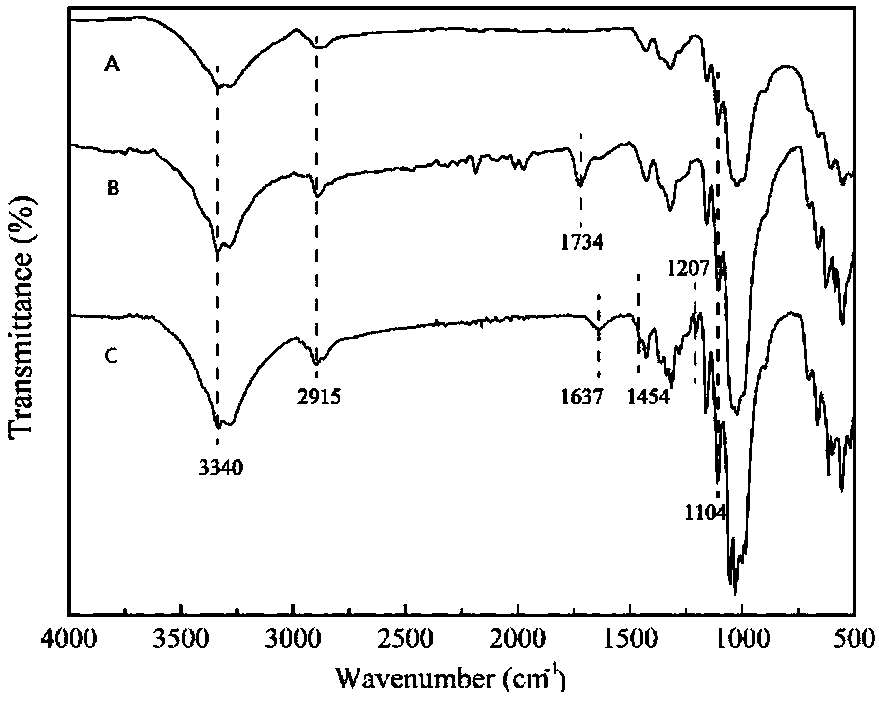

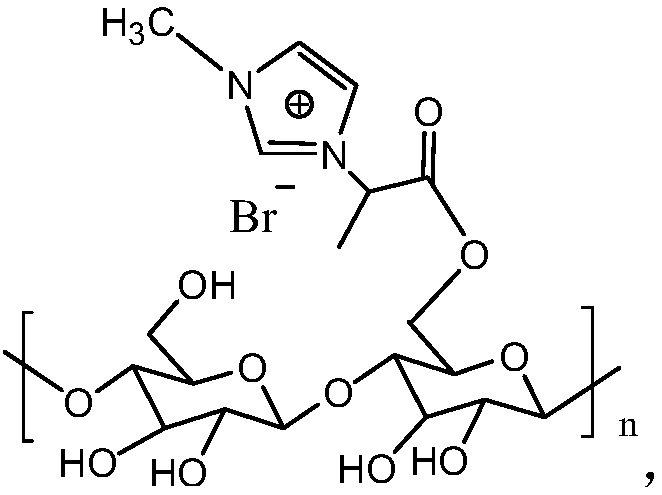

Ion liquid modified cellulose-based adsorbent as well as preparation method and application thereof

ActiveCN108393075AImprove adsorption capacitySolve the problem of low adsorption capacityOther chemical processesWater contaminantsWater bathsPropanoic acid

The invention discloses an ion liquid modified cellulose-based adsorbent as well as a preparation method and application thereof, and relates to the technical field of dye adsorption. The adsorbent can be degraded; the environment sustainable development is facilitated; the adsorbent can be widely applied to the printing and dying waste water treatment. The preparation method comprises the following steps of S1, adding cellulose, 2-bromo-propionic acid, p-toluenesulfonic acid and toluene into a container; connecting a water distributer on a container; S2, putting the container in an oil bath pot being 110 to 130 DEG C for constant temperature heating; performing condensing backflow for 7 to 10 hours; then, opening a side pipe piston of a water distributor to discharge out toluene-water mixed solution in the side pipe; evaporating out the toluene in the container to obtain a cellulose 2-bromopropionate coarse product; S3, performing post treatment on the cellulose and 2-bromopropionatecoarse product in the S2 to obtain dry cellulose 2-bromopropionate; S4, adding 1-methylimidazole and cellulose 2-bromopropionate dried in S3 into ethanol; performing water bath constant temperature stirring reaction for 24 to 48 hours at 40 to 70 DEG C; then, performing washing and drying to obtain the adsorbent. The method is simple; the used raw materials can be easily obtained.

Owner:SHAANXI UNIV OF SCI & TECH

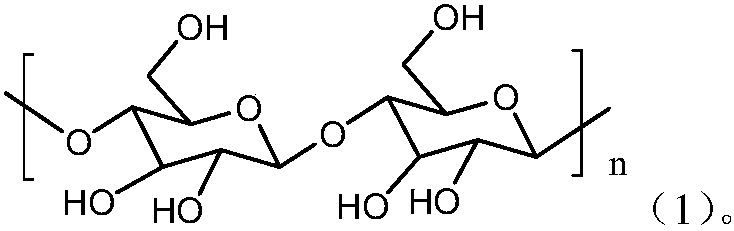

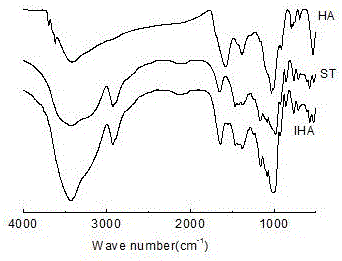

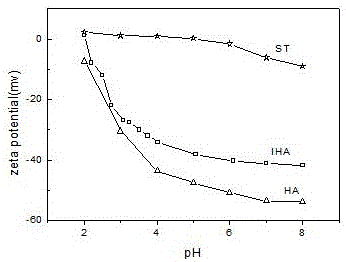

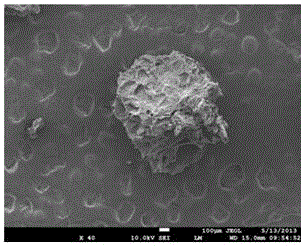

Humic acid microsphere as well as preparation method and application thereof

InactiveCN105854828AInexpensive, environmentally friendly and fully biodegradableImprove removal efficiencyOther chemical processesWater contaminantsMicrosphereSorbent

The invention discloses a humic acid microsphere as well as a preparation method and application thereof. An isoelectric point of the humic acid microsphere is pH 2, and is negatively charged when pH is more than 2, and the humic acid microsphere is of a quasi-spheral shape with a diameter of 1mm. According to the preparation method, humic acid is fixed on starch to form the fixed microsphere. The humic acid gel sphere is low in cost and environmentally friendly and can be completely biologically degraded; meanwhile, adsorptive property research of the humic acid gel sphere finds that the humic acid gel sphere has very high efficiency in the removal of cationic dyes in waste water as well as very high recovery utilization rate, so that the humic acid gel sphere has wide use in many fields of dye adsorption, water treatment, adsorbents and the like as well as very high practicability.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com