Humic acid microsphere as well as preparation method and application thereof

A humic acid and microsphere technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of high cost and refractory degradation, and achieve high recycling rate, good practicality The effect of high stability and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

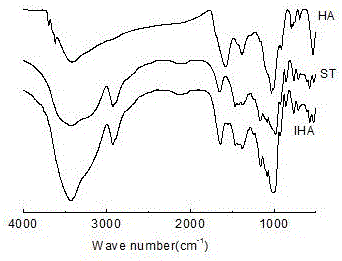

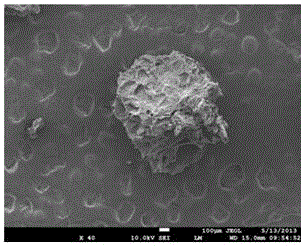

[0029] The suspension polymerization granulation method is used to immobilize the humic acid in the starch by wrapping the water phase with the organic phase to prepare the humic acid microsphere material. The specific process is as follows:

[0030] Add 1mL of Span-80 and 2g of epichlorohydrin to 300mL of liquid paraffin, stir and mix; this is the organic phase. Add 3g of starch and 2g of humic acid to 50mL of water in the water phase, stir and heat the paste solution to 80°C, add 1.5g of sodium hydroxide at 30°C for alkalization, then add 3g of epichlorohydrin into a water bath at 20°C. Add the organic phase and the water phase successively to the 25°C oil bath reaction device for high-speed mechanical stirring, so that the water phase is dispersed into small liquid droplets in the organic phase, react for 24 hours, filter out the black humic acid microspheres, first use cyclohexane Wash 3 times with alkane to remove liquid paraffin, then wash 3 times with 100% ethanol to re...

Embodiment 2

[0035] The adsorption performance of embodiment 2 humic acid microspheres to crystal violet dye

[0036] The concentration of crystal violet was measured by absorbance at 590 nm with a UV-visible spectrophotometer.

[0037] The formula for calculating the adsorption capacity q is:

[0038] q = ( C 0 - C e ) V m

[0039] In the formula, C 0 and C e are the concentration of crystal violet solution before adsorption and adsorption equilibrium; V is the solution volume, and m is the mass of humic acid microsphere adsorbent.

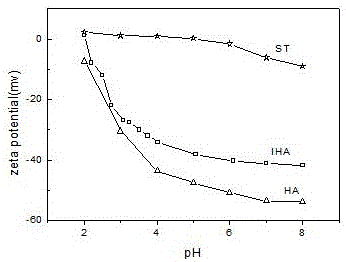

[0040] The experiment of the effect of pH value on adsorption was carried out at room temperature 25°C. The initial concentration of the crystal violet solution is set at 400 mg / L, the pH value of the crystal violet dye solution is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com