Cuprous oxide nano hollow spheres as well as synthetic method and application method thereof

A technology of cuprous oxide and synthesis method, applied in the direction of copper oxide/copper hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of cumbersome product processing, large material size, small specific surface area, etc., and achieve excellent lithium battery performance and dye The effect of adsorption capacity, simple preparation process and simple experimental equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for synthesizing nano cuprous oxide hollow spheres, comprising the following steps:

[0038] (1) Weigh 0.004 mol of copper nitrate (analytical pure) into a beaker, then add 80 ml of ethylene glycol (analytical pure), stir magnetically until the copper nitrate solid is completely dissolved, and a light blue transparent solution is obtained;

[0039] (2) Transfer the solution described in step (1) into the liner of a 100 ml polytetrafluoroethylene hydrothermal kettle, put on a steel sleeve, put it into an oven that has been heated to 140 ℃ in advance, keep it warm for 3 hours, and cool naturally ;

[0040] (3) The yellow turbid liquid obtained in step (2) was centrifuged (centrifugal speed 5000 r / m), the obtained yellow solid was washed with ethanol, and dried in an oven at 40 °C to obtain hollow cuprous oxide nanospheres.

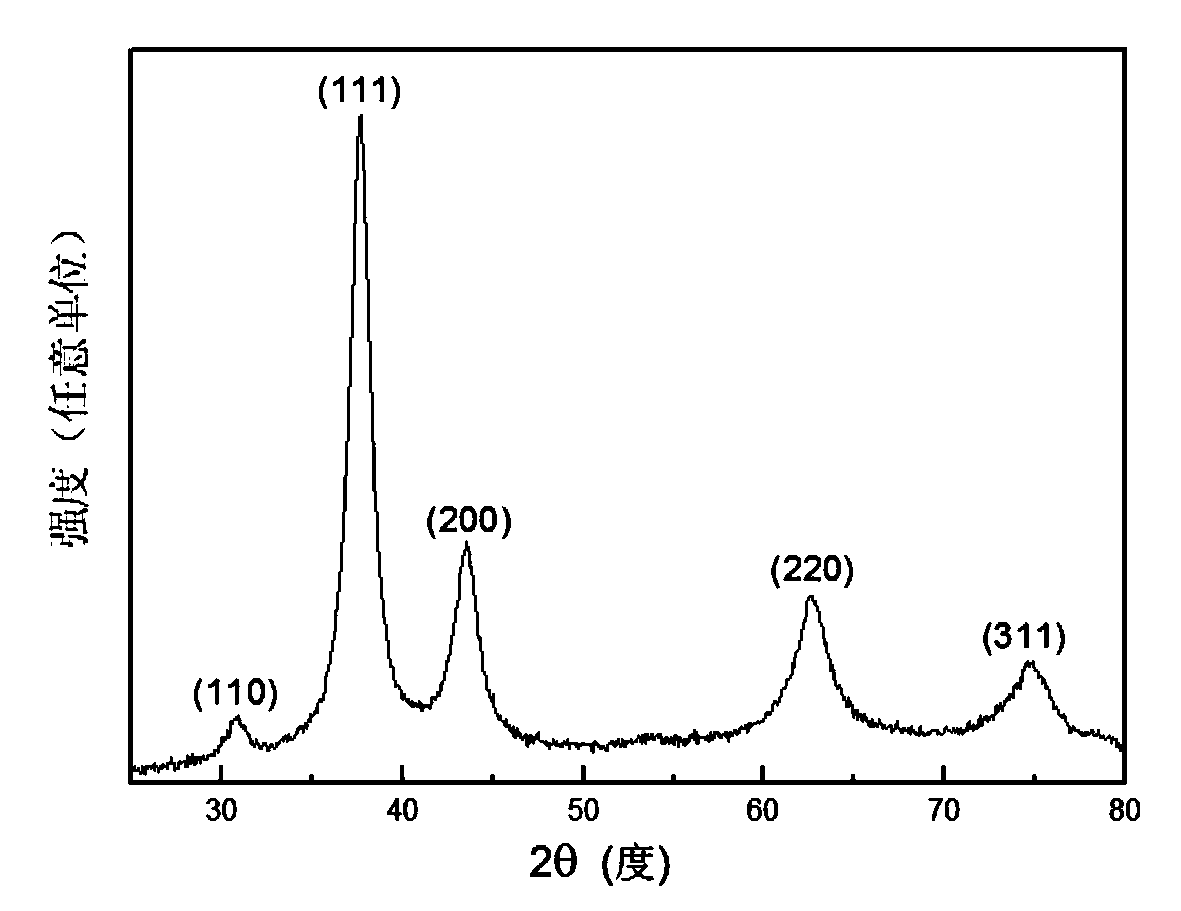

[0041] The product obtained in this embodiment is determined to be a cubic phase cuprous oxide crystal through X-ray diffraction, and the X...

Embodiment 2

[0045] A method for synthesizing nano cuprous oxide hollow spheres, comprising the following steps:

[0046] (1) Weigh 0.004 mol of copper nitrate (analytical pure) into a beaker, then add 80 ml of ethylene glycol (analytical pure), stir magnetically until the copper nitrate solid is completely dissolved, and a light blue transparent solution is obtained;

[0047] (2) Transfer the solution described in step (1) into the liner of a 100 ml polytetrafluoroethylene hydrothermal kettle, put on a steel jacket, put it into an oven that has been heated to 160 °C in advance, keep it warm for 2 hours, and cool naturally ;

[0048] (3) The yellow turbid liquid obtained in step (2) was centrifuged (centrifugal speed 5000 r / m), the obtained yellow solid was washed with ethanol, and dried in an oven at 40 °C to obtain hollow cuprous oxide nanospheres.

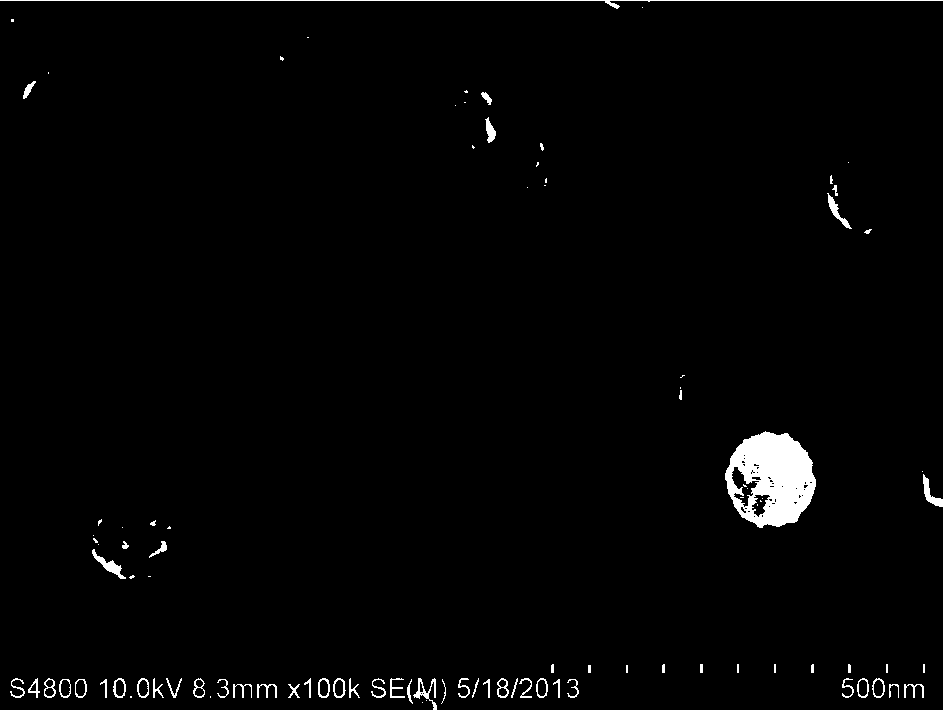

[0049] The product obtained in this example was determined to be a cubic cuprous oxide crystal through X-ray diffraction; scanning electron ...

Embodiment 3

[0052] A method for synthesizing nano cuprous oxide hollow spheres, comprising the following steps:

[0053] (1) Weigh 0.004 mol of copper nitrate (analytical pure) into a beaker, then add 80 ml of ethylene glycol (analytical pure), stir magnetically until the copper nitrate solid is completely dissolved, and a light blue transparent solution is obtained;

[0054] (2) Transfer the solution described in step (1) into the liner of a 100 ml polytetrafluoroethylene hydrothermal kettle, put on a steel jacket, put it into an oven that has been heated to 180 ℃ in advance, keep it warm for 1.5 hours, and cool naturally ;

[0055] (3) Centrifuge the yellow turbid liquid obtained in step (2) (centrifugal speed 5000 r / m), wash the obtained yellow solid with ethanol, put it in an oven to dry, and obtain hollow cuprous oxide nanospheres.

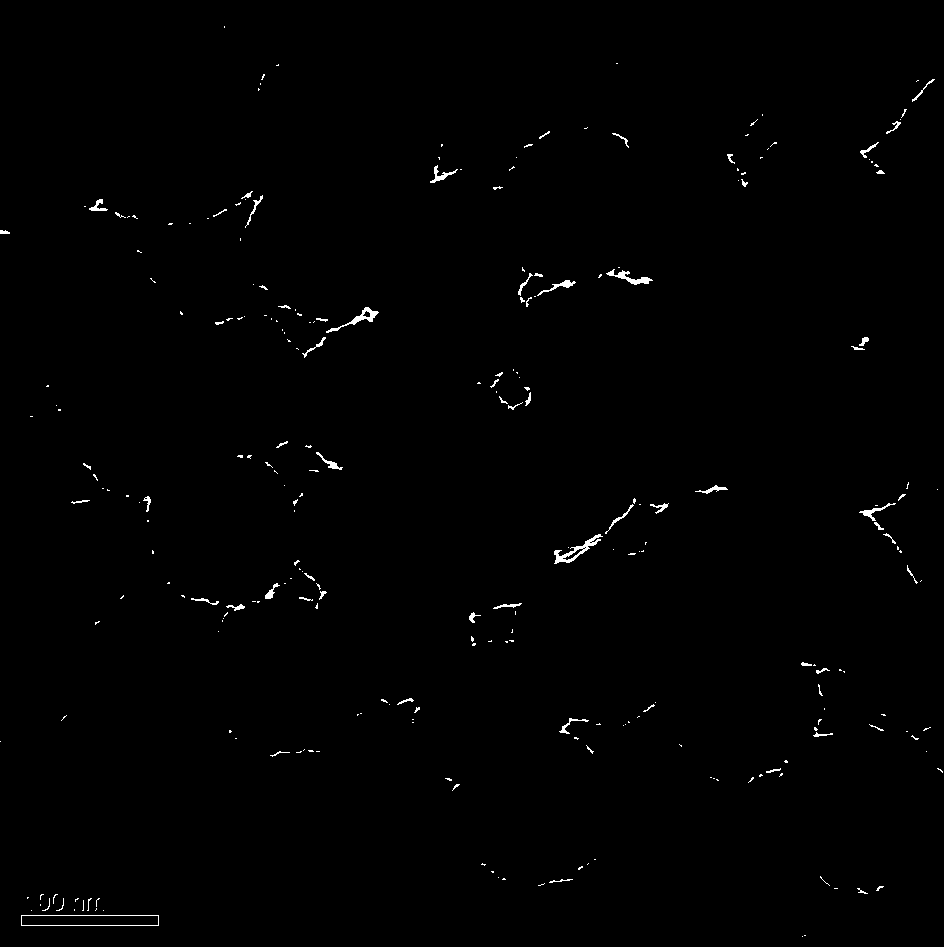

[0056] The product obtained in this example was determined to be cubic cuprous oxide crystals through X-ray diffraction; scanning electron microscope (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com