Error measuring device and screw rod assembly with same

A technology of error measurement and measurement components, which is applied in feeding devices, measuring/indicating equipment, manufacturing tools, etc., can solve problems such as complicated ball screw methods, and achieve the effect of more complicated solutions, convenient installation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

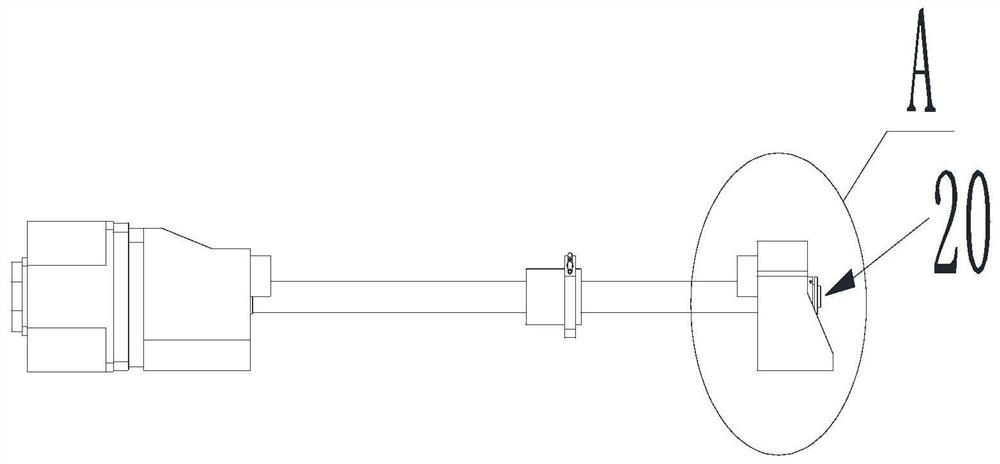

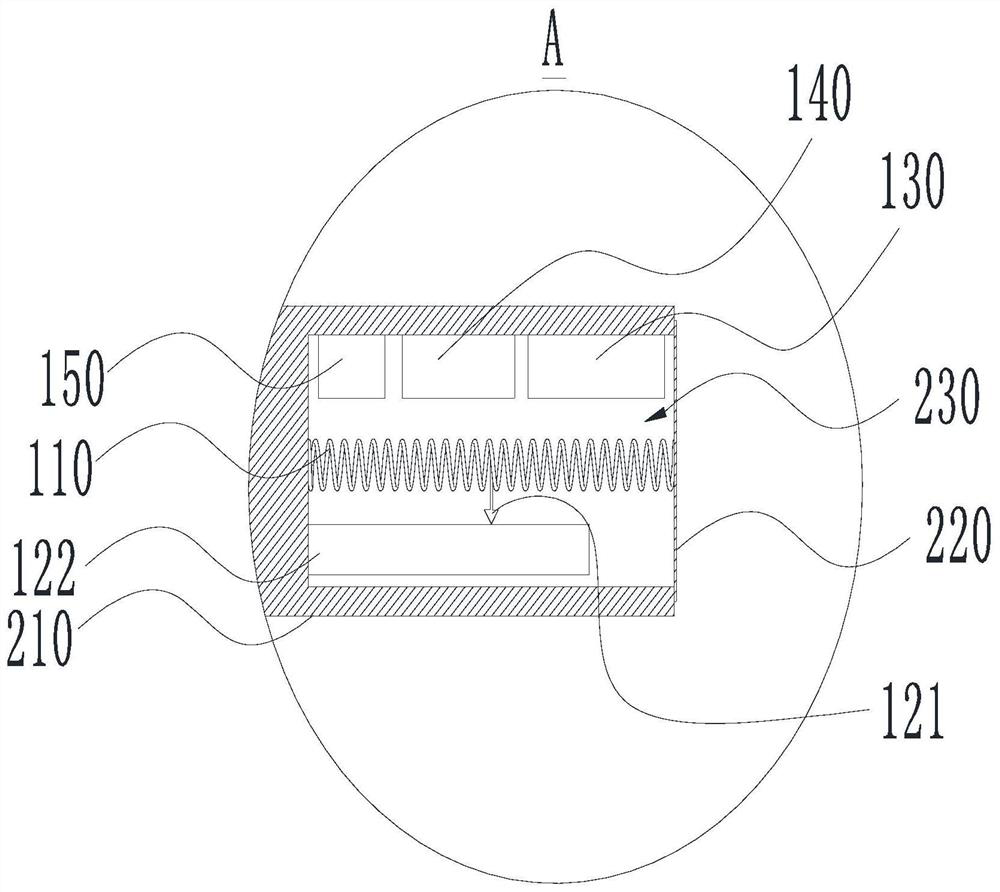

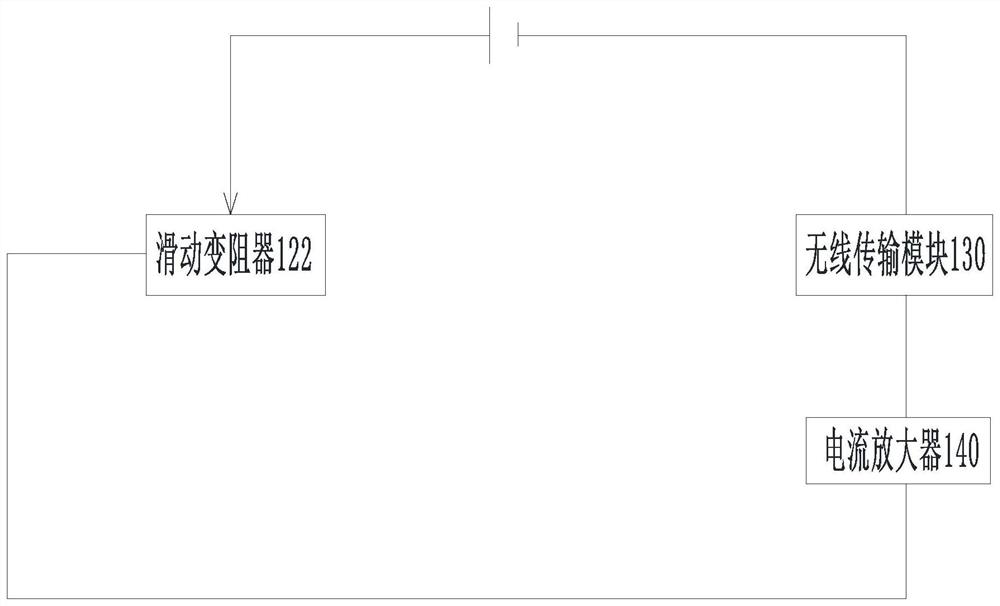

[0024] see Figure 1 to Figure 3 , the invention provides an error measuring device. The error measuring device is used for measuring the screw rod 210 , and the screw rod 210 is provided with an installation cavity 230 . The error measuring device includes an elastic member 110 and a measuring component. The elastic member 110 is arranged in the installation cavity 230 and extends along the axial direction of the screw rod 210 . The elastic member 110 is connected with the screw rod 210 to drive the elastic member 110 to deform when the screw rod 210 deforms. The measuring component is connected with the elastic member 110 to obtain the deformation of the screw rod 210 according to the defo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com