Design method of plasma laser device

A design method, plasma technology, applied to the structure of optical waveguide semiconductors, etc., can solve problems such as the complexity of plasma laser methods, and achieve the effect of more complex solutions and simple design methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

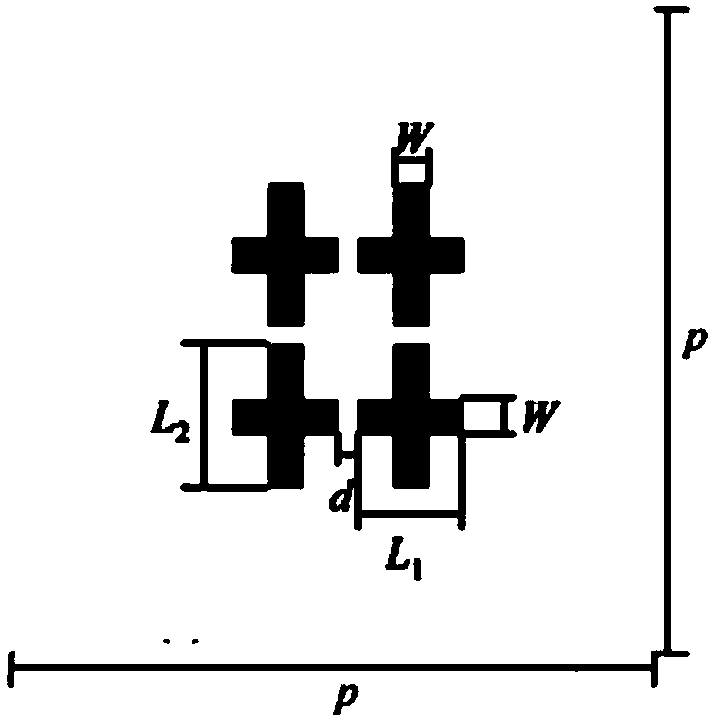

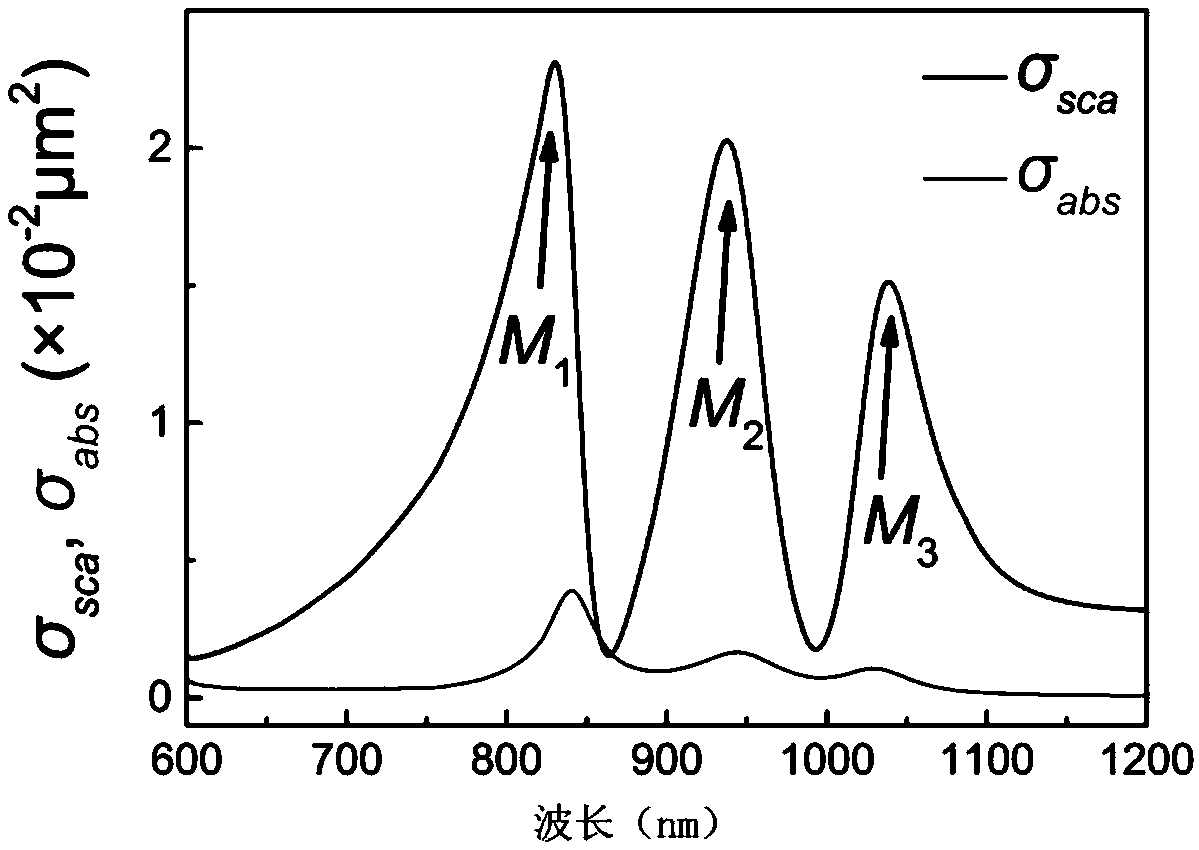

[0042] This embodiment provides a design method of a plasma laser, which obtains the required size of the cross-shaped metal structure on the substrate of the laser according to the corresponding relationship between the laser wavelength and the size of the cross-shaped metal structure on the substrate, and solves the problem of wavelength-based design in the prior art. The plasmonic laser approach complicates matters.

[0043] The design method of the plasma laser provided in this embodiment includes the following steps:

[0044] Obtain the desired laser wavelength;

[0045] According to the corresponding relationship between the laser wavelength and the substrate gain and the size of the cross-shaped metal structure on the substrate, the size of the cross-shaped metal structure on the substrate of the laser and the substrate gain are obtained.

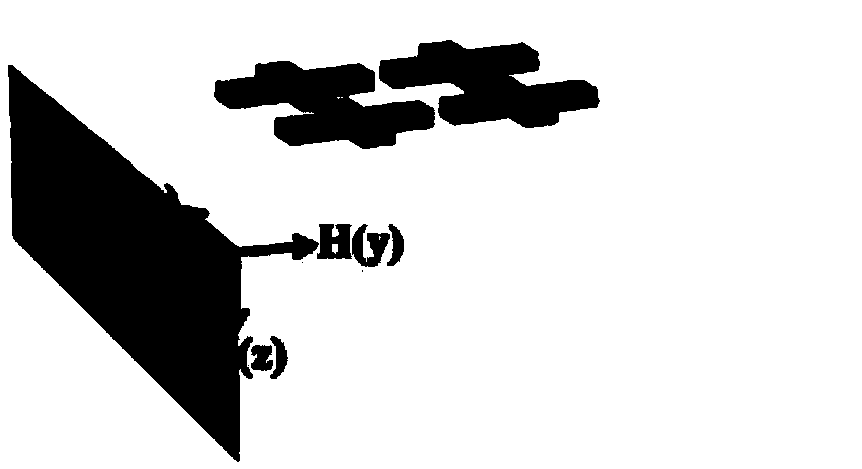

[0046] The structure of the plasma laser is as Figure 1a with Figure 1b As shown, including a substrate, a tetramer composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com