A cuprous oxide micron hollow sphere and its synthesis method and application method

A technology of cuprous oxide and synthesis method, applied in copper oxide/copper hydroxide and other directions, can solve the problems of high energy consumption and time cost, difficulty in large-scale application, cumbersome product processing, etc., and achieves reduced energy consumption, good light Catalytic ability and gas-sensing performance, effect of short synthesis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for synthesizing cuprous oxide micron hollow spheres, comprising the following steps:

[0039] (1) Weigh 0.002mol of copper nitrate (analytical grade) and add it into the mixed solution of water and organic solvent (40 ml of ethylene glycol, 1 ml of deionized water), stir until completely dissolved, and obtain a light blue transparent liquid;

[0040] (2) Transfer the solution described in step (1) into the liner of a 50 ml polytetrafluoroethylene hydrothermal kettle, put on a steel sleeve, put it into an oven that has been heated to 60 °C in advance, and set the reaction temperature to 180 °C ℃, keep warm for 60 minutes after reaching the reaction temperature, and then cool naturally;

[0041] (3) The brick-red turbid liquid obtained in step (2) was centrifuged (5000 r / m), and the obtained brick-red solid was washed with ethanol and dried in an oven at 40°C to obtain cuprous oxide micron hollow spheres.

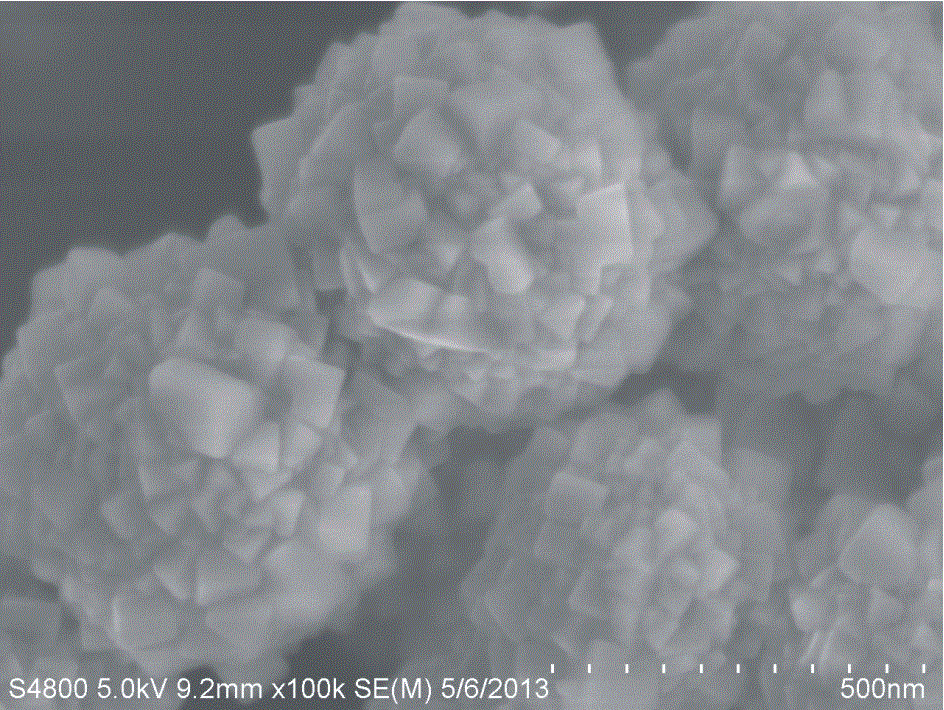

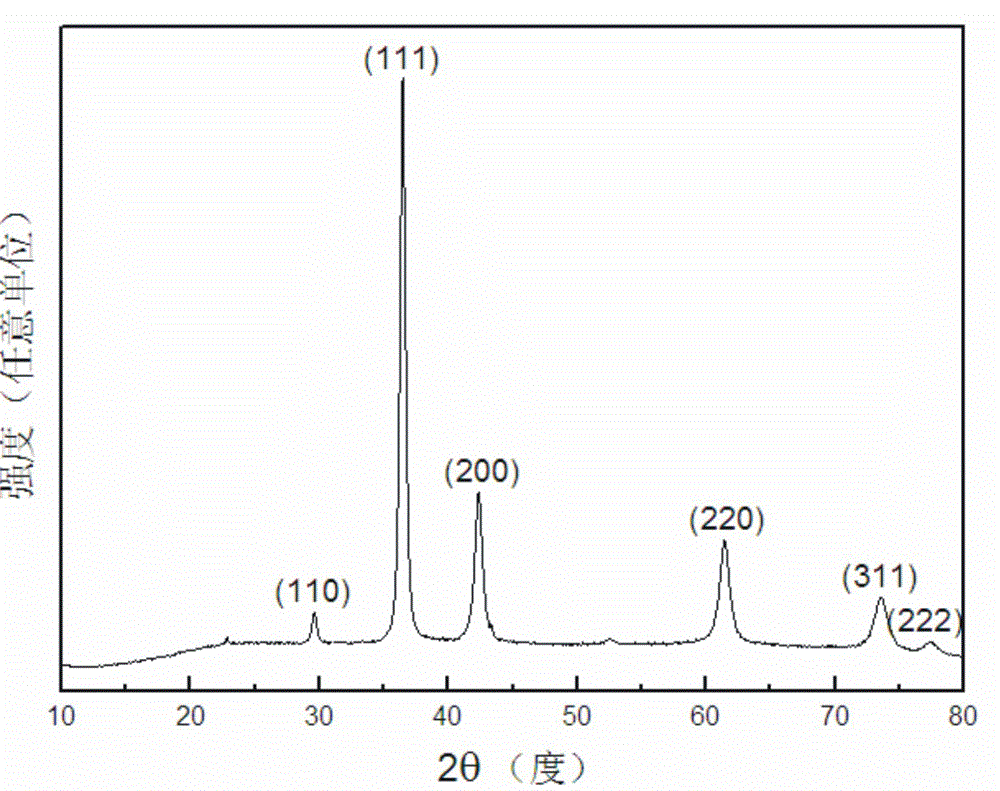

[0042] The product obtained in this example was determ...

Embodiment 2

[0044] A method for synthesizing cuprous oxide micron hollow spheres, comprising the following steps:

[0045] (1) Weigh 0.002mol of copper nitrate (analytical grade) and add it into the mixed solution of water and organic solvent (40 ml of ethylene glycol, 2 ml of deionized water), stir until completely dissolved, and obtain a light blue transparent liquid;

[0046] (2) Transfer the solution described in step (1) into the liner of a 50 ml polytetrafluoroethylene hydrothermal kettle, put on a steel sleeve, put it into an oven that has been heated to 60 °C in advance, and set the reaction temperature to 180 °C ℃, keep warm for 60 minutes after reaching the reaction temperature, and then cool naturally;

[0047](3) The brick-red turbid liquid obtained in step (2) was centrifuged (5000 r / m), and the obtained brick-red solid was washed with ethanol and dried in a 40°C oven to obtain cuprous oxide micron hollow spheres.

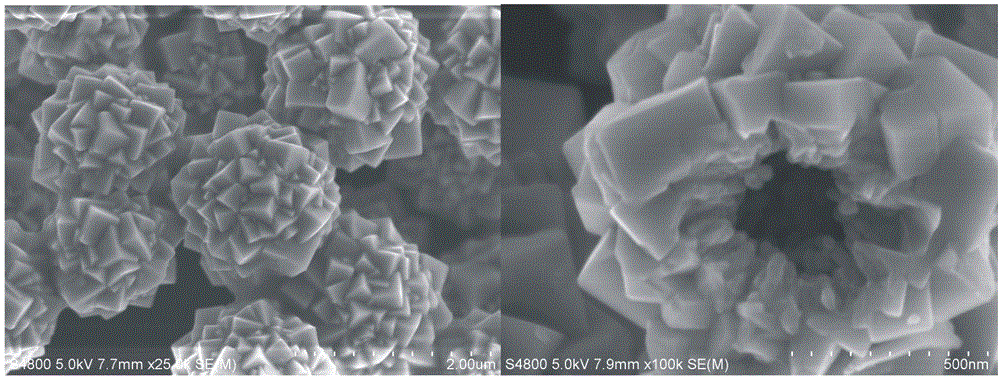

[0048] The product obtained in this embodiment is determine...

Embodiment 3

[0052] A method for synthesizing cuprous oxide micron hollow spheres, comprising the following steps:

[0053] (1) Weigh 0.002mol of copper nitrate (analytical grade) and add it to the mixed solution of water and organic solvent (40 ml of ethylene glycol, 3 ml of deionized water), stir until completely dissolved, and obtain a light blue transparent liquid;

[0054] (2) Transfer the solution described in step (1) into the liner of a 50 ml polytetrafluoroethylene hydrothermal kettle, put on a steel sleeve, put it into an oven that has been heated to 60 °C in advance, and set the reaction temperature to 180 °C ℃, keep warm for 60 minutes after reaching the reaction temperature, and then cool naturally;

[0055] (3) The brick-red turbid liquid obtained in step (2) was centrifuged (5000 r / m), and the obtained brick-red solid was washed with ethanol and dried in an oven at 40°C to obtain cuprous oxide micron hollow spheres.

[0056] The product obtained in this example was determin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com