Non-air-exhaust drying device of feeding bottle sterilizing pot

A technology of drying device and sterilizing pot, which is applied in drying, disinfection, drying machine, etc., can solve the problems of secondary pollution of feeding bottles, strict air environment requirements, etc., and achieve the effect of scientific drying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

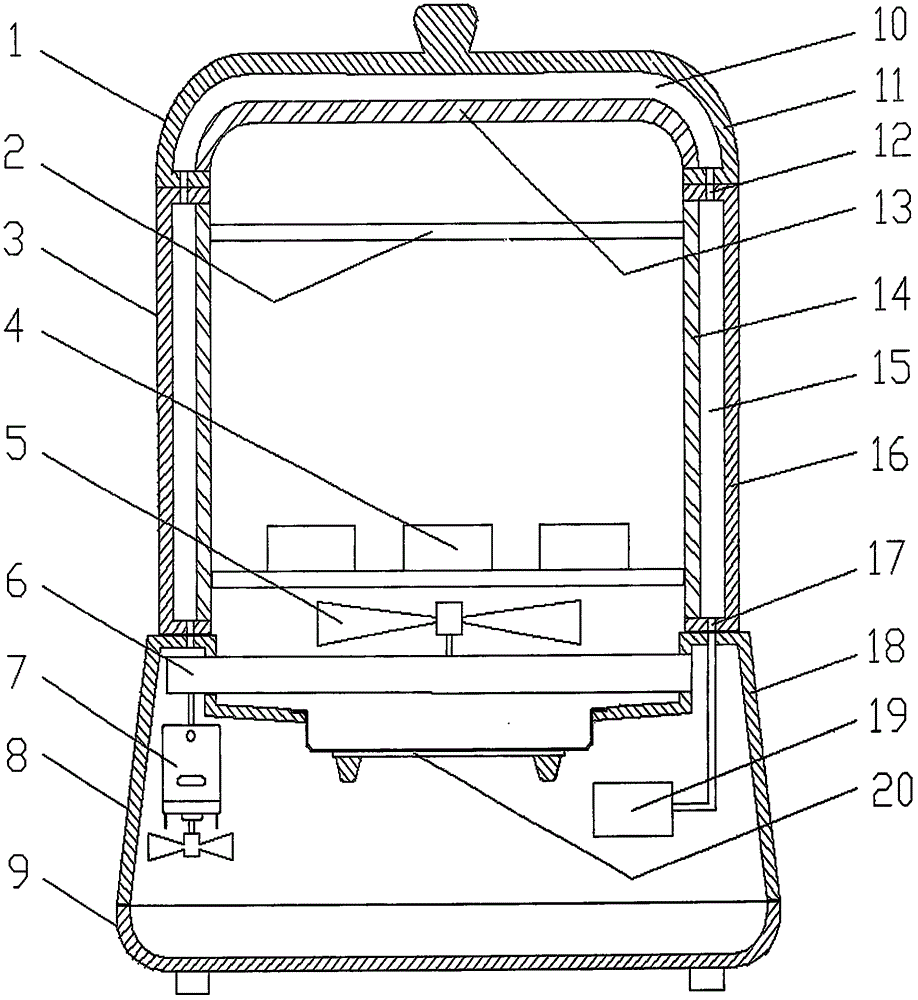

[0016] Below in conjunction with accompanying drawing, illustrate the present invention.

[0017] The invention is mainly composed of a pot cover 1, a pot body 3, a base 8, a guide vane 5, and a power transmission assembly 6, wherein the pot cover 1, the pot body 3, the base 8, the guide vane 5, and the power transmission assembly 6 are mutually Independent, the user can separate without tools; the power of the motor 7 is not directly transmitted to the guide fan 5 through the rotating shaft, but also transmitted through the power transmission assembly 6; the pot cover 1 and the pot body 3 adopt a double-layer shell with a gap ( Hollow for short), wherein the materials of the outer layer 11 of the pot cover and the outer layer 16 of the pot body are plastics with good thermal insulation performance, and the materials of the inner layer 13 of the pot cover and the inner layer 14 of the pot body are metals with better heat transfer performance; The hot air generated by the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com