Silica-graphene composite and preparation method thereof, and treatment method for removing dye pollutants in water

A composite material and silicon dioxide technology, applied in the field of material science, can solve the problems of poor hydrophilicity and dispersion of graphene, achieve high specific surface area, improve adsorption efficiency, and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] In order to solve the above problems, the present invention provides a method for preparing a silica-graphene composite material, which includes the following steps: S1, using a pH regulator to adjust the pH value of water to 8-10 to obtain A solvent system, adding graphene oxide to the above solvent system to obtain a graphene oxide dispersion; S2, performing a sol-gel reaction with ethyl orthosilicate, a hydrolysis solvent and the above graphene oxide dispersion to form a silica-oxidized a graphene composite material; and S3, reducing the silica-graphene oxide composite material to obtain the above-mentioned silica-graphene composite material.

[0043] In the process of preparing the graphene oxide dispersion, the present invention unexpectedly finds that after first adjusting the pH value of water to 8-10 with a pH regulator, and then adding graphene oxide powder into the system, a higher stable graphene oxide dispersion. Through in-depth research on the reasons for...

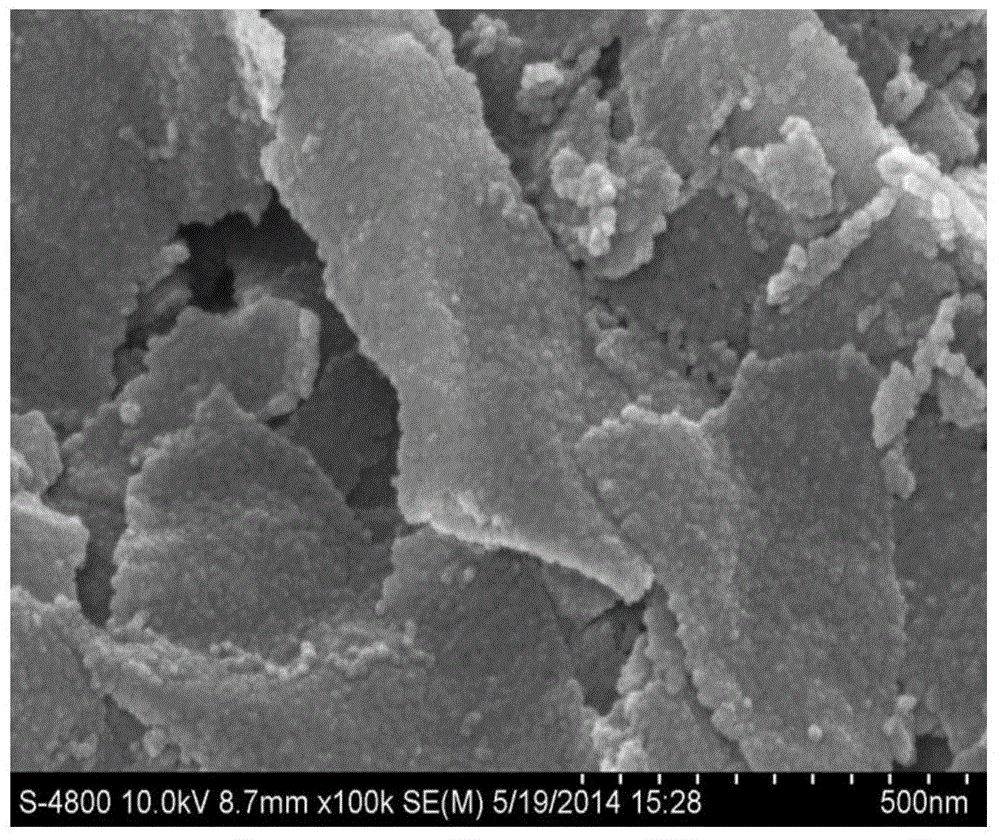

Embodiment 1

[0059] With 0.5mL 25% NH 3 ·H 2 O adjust the pH of 20mL of water to 9, add 50mg of graphene oxide to the system, and ultrasonicate for 60min to obtain the dispersion liquid mother liquor.

[0060] Mix 8mL of water, 100mg of polyvinylpyrrolidone (PVP) and 2mL of the above dispersion liquid, and stir evenly to obtain a graphene oxide dispersion liquid, wherein the weight ratio of PVP to graphene oxide is 20:1.

[0061] Mix 100 μL tetraethyl orthosilicate, 20 mL ethanol, the above graphene oxide dispersion and 0.1 mL 25% NH 3 ·H 2 O (catalyst) is mixed, carry out sol-gel reaction, after reacting for 24h, form silica-graphene oxide composite material, wherein, the volume ratio of ethanol and water is 2:1, the ratio of graphene oxide and ethyl orthosilicate The dosage ratio is 0.05g / 1mL, and the volume ratio of catalyst to ethyl orthosilicate is 1:1.

[0062] Add 2 mL of 80% hydrazine hydrate to the above-mentioned sol-gel reaction system for reduction reaction, heat and reflux...

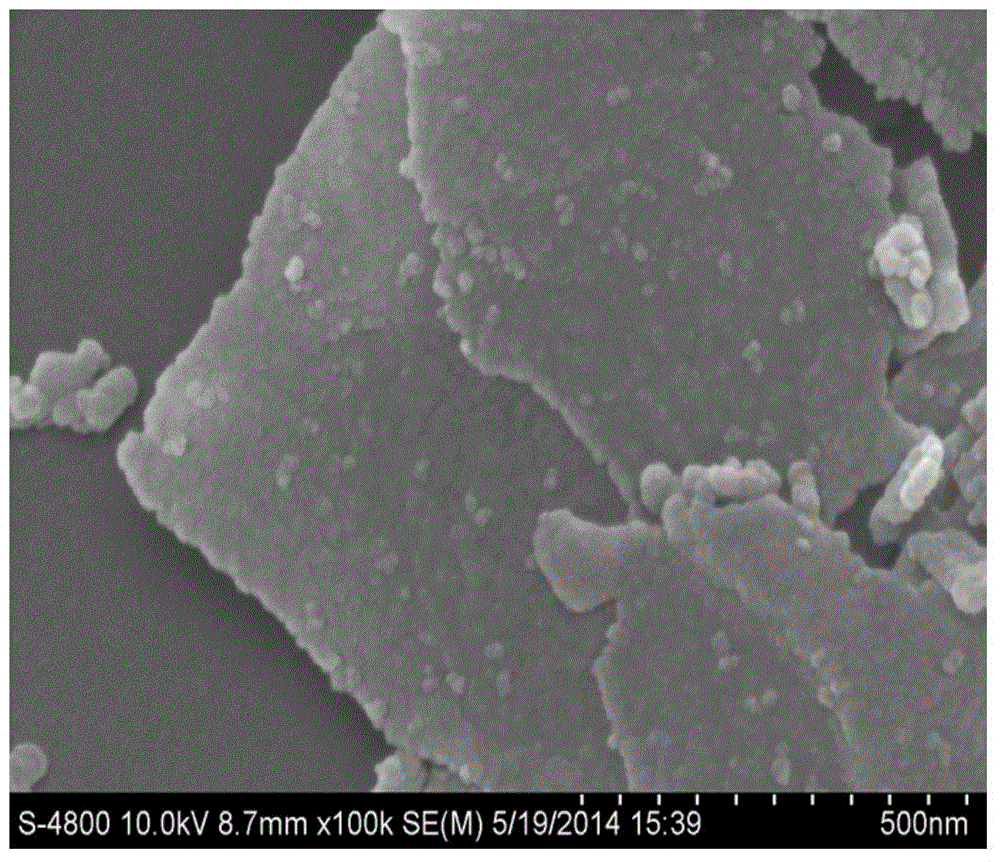

Embodiment 2

[0064] With 0.5mL 25% NH 3 ·H 2 O adjust the pH of 20mL of water to 9, add 50mg of graphene oxide to the system, and ultrasonicate for 60min to obtain the dispersion liquid mother liquor.

[0065] 8mL of water, 100mg of PVP and 2mL of the above dispersion were mixed to obtain a graphene oxide dispersion, wherein the weight ratio of PVP to graphene oxide was 20:1.

[0066] Mix 100 μL tetraethyl orthosilicate, 20 mL ethanol, the above graphene oxide dispersion and 0.5 mL 25% NH 3· h 2 O (catalyst) is mixed, carry out sol-gel reaction, after reacting for 24h, form silica-graphene oxide composite material, wherein, the volume ratio of ethanol and water is 2:1, the ratio of graphene oxide and ethyl orthosilicate The dosage ratio is 0.05g / mL, and the volume ratio of catalyst to ethyl orthosilicate is 5:1.

[0067] Add 2 mL of 80% hydrazine hydrate to the above-mentioned sol-gel reaction system for reduction reaction, heat and reflux at 80°C for 2h, centrifuge and wash with water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com