Graphene oxide-based anti-bacterial finishing agent for dyeing, and preparation method and application thereof

An antibacterial finishing agent, graphene technology, applied in the field of antibacterial finishing agent, one-step dyeing of textiles, antibacterial finishing, and graphene oxide-based dyeing fields, can solve the problems of complex composite process of cytotoxic graphene oxide and fabrics, and improve the combination Fastness, simple handling, low cytotoxicity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

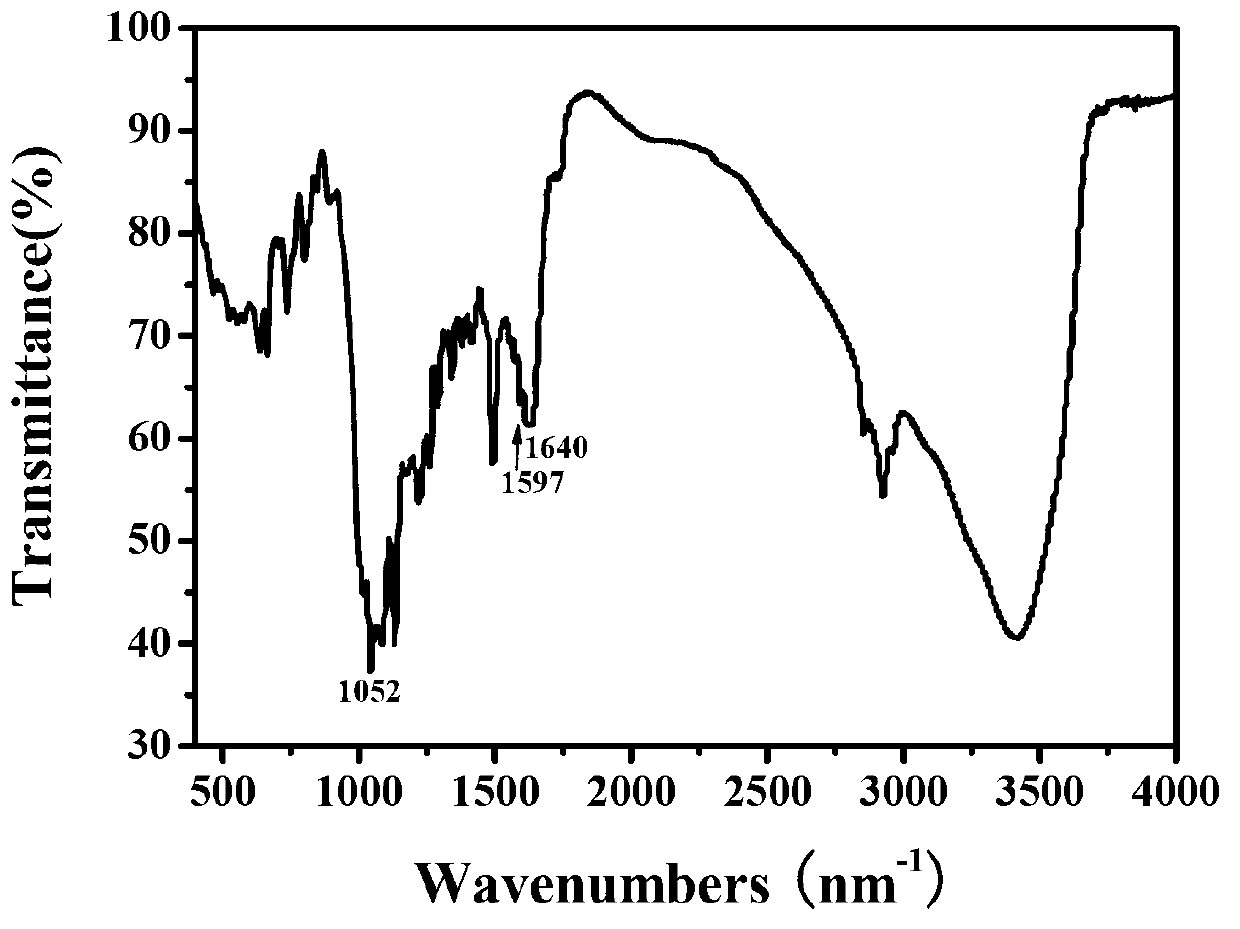

Image

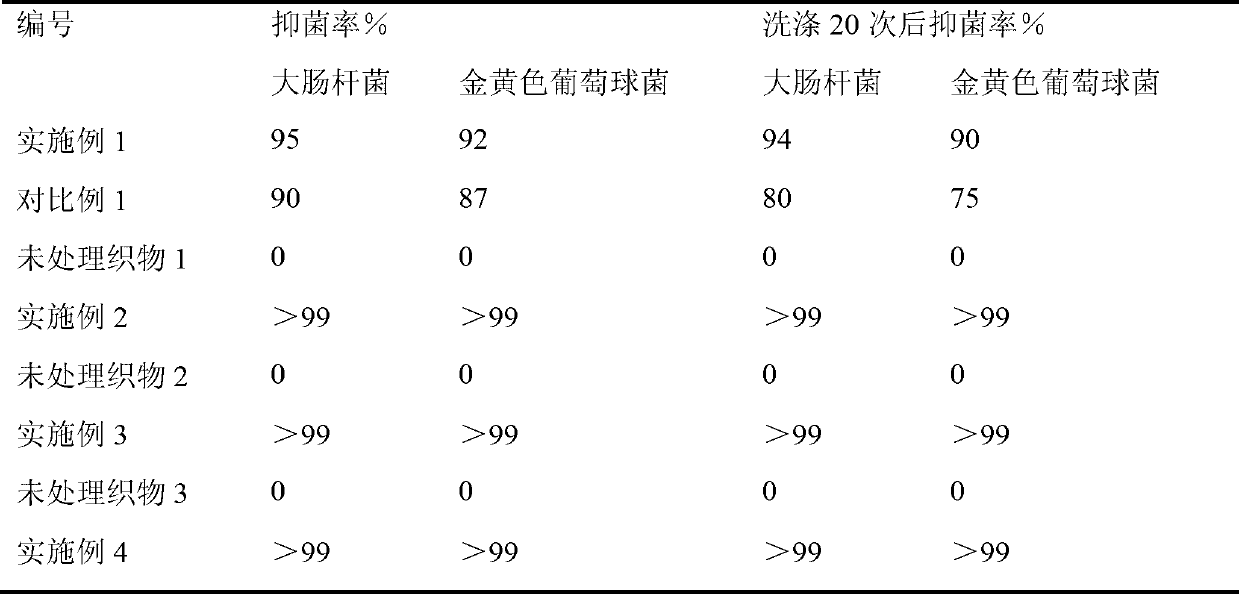

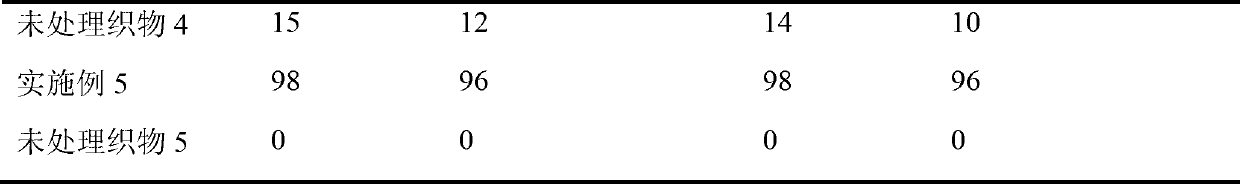

Examples

Embodiment 1

[0030] (1) Disperse 1g of graphite oxide into 10ml of N,N-dimethylformamide (DMF) solution, and ultrasonically treat it for 1h to obtain a graphene oxide (GO-COOH) dispersion;

[0031] (2) Mix the above graphene oxide dispersion with 100ml thionyl chloride (SOCl 2 ) solutions were mixed, then heated to 70°C, and reacted for 72h under stirring. After the reaction, centrifuged, the solid was washed 3 times with anhydrous tetrahydrofuran (THF), and then vacuum-dried at 60°C for 24h to obtain acyl chloride graphite oxide Alkenes (GO-COCl);

[0032] (3) Disperse 6g chitosan (relative molecular weight 5000, deacetylation degree 85%) in 360ml N,N-methylformamide, heat to 140°C under stirring, keep warm for 1h, after chitosan is completely dissolved, add 1g GO-COCl was reacted at 140°C for 48h. After the reaction, the solvent was removed by suction filtration, and the solid was washed 3 times with 2% acetic acid solution to remove unreacted chitosan, then washed 5 times with distille...

Embodiment 2

[0044] (1) Disperse 1g of graphite oxide into 40ml of N,N-methylacetamide (DMAC) solution, and ultrasonically treat it for 2 hours to obtain a graphene oxide (GO-COOH) dispersion;

[0045] (2) Mix the above graphene oxide dispersion with 60ml of thionyl chloride (SOCl 2 ) solutions were mixed, heated to 80°C, and reacted for 24 hours under stirring. After the reaction, centrifuged, the solid was washed with N,N-dimethylacetamide (DMAC) for 5 times, and then vacuum-dried at 80°C for 12 hours. Obtain graphene oxide (GO-COCl) of acid chloride;

[0046] (3) Disperse 10g chitosan (relative molecular weight 30000, deacetylation degree 95%) in 1000ml N,N-methylacetamide, heat to 120°C under stirring, keep warm for 2h, after chitosan is completely dissolved, Add 1g of GO-COCl, and react at 120°C for 96h. After the reaction, remove the solvent by suction filtration, wash the solid with 5% citric acid solution for 5 times, remove unreacted chitosan, and wash with distilled water for 3 ...

Embodiment 3

[0051] (1) Disperse 1g of graphite oxide into 20ml of N,N-dimethylformamide (DMF) solution, and ultrasonically treat it for 1.5h to obtain a graphene oxide (GO-COOH) dispersion;

[0052] (2) Mix the above graphene oxide dispersion with 80ml of thionyl chloride (SOCl 2 ) solutions were mixed, heated to 75°C, and reacted for 36h under stirring. After the reaction, centrifuged, the solid was washed with N,N-dimethylformamide (DMF) for 4 times, and then vacuum-dried at 70°C for 12h. Obtain graphene oxide (GO-COCl) of acid chloride;

[0053] (3) Disperse 8g chitosan (relative molecular weight 10000, degree of deacetylation 90%) in 640ml mixed solution of N,N-methylacetamide and N,N-methylformamide (the volume ratio of the two is 1: 1), heat to 130°C under stirring, keep warm for 1.5h, after the chitosan is completely dissolved, add 1g GO-COCl, react at 130°C for 60h, after the reaction, remove the solvent by suction filtration, use a mass concentration of 3% Wash the solid matter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com